Wat e r & Sanitation

Complete water resource and wastewater management

Complete water resource and wastewater management

Save on mine water treatment costs

Water boards

Investing in liveable cities

Industry 4.0 In-depth defence

skIlls & traInIng When the levy is dry

EWSETA believes that skills development and training is a collective responsibility. Together with our Board, our and most importantly, our strategic partners, we are contributing towards the skills drive in the energy and water sector.

This is your opportunity to work with us and put your mark on the skills landscape in the country.

Contact Details

Physical Address: Sunnyside Park Sentinel House, 2nd & 3rd 32 Princess of Wales Terrace Parktown, Johannesburg

Postal Address: PO Box 1273 Houghton 2041

Tel: (011) 274 4700

Fax: (011) 484 8953 / (011) 484 1078

info@eseta.org.za

www.ewseta.org.za

Publisher Elizabeth Shorten

Managing editor Alastair Currie

Editor Frances Ringwood

Head of design Beren Bauermeister

Designer Ramon Chinian

Chief sub-editor Tristan Snijders

Sub-editor Morgan Carter

Contributors Malcolm Hall, Nora Hanke-Louw, Valerie Naidoo, Danielle Petterson, Alex Visser

Client services & production manager

Antois-Leigh Botma

Production coordinator Zenobia Daniels

Distribution manager Nomsa Masina

Distribution coordinator Asha Pursotham

Financial manager Andrew Lobban

Printers United Litho Johannesburg

t +27 (0)11 402 0571

Advertising sales Hanlie Fintelman / Jenny Miller

t +27 (0)11 467 6223 h.fintelman@telkomsa.net / jennymiller@lantic.net

Publisher

Physical address:

No 9, 3rd Avenue, Rivonia, 2191

Postal address: PO Box 92026, Norwood, 2117, South Africa

t +27 (0)11 233 2600 • f +27 (0)11 234 7274/5 frances@3smedia.co.za

ISSN: 1990 - 8857

Annual subscription: R300 (SA rate) subs@3smedia.co.za

Copyright 2017. All rights reserved. All articles herein are copyright protected and may not be reproduced either in whole or in part without the prior written permission of the publishers. The views of contributors do not necessarily reflect those of the Water Institute of Southern Africa or the publishers.

WISA Contacts:

Head offiCe

Tel: 086 111 9472(WISA)

Fax: +27 (0)11 315 1258

Physical address: 1st Floor, Building 5, Constantia Park, 546 16th Road, Randjiespark Ext 7, Midrand

BRANCHES

eastern Cape

Chairperson: Selby Thabethe

Tel: +27 (0)41 506 2862 | email: ssthabethe@vodamail.co.za

Secretary: Christopher Maduma

Tel: +27 (0)41 506 7527 | email: cmaduma@mandelametro.gov.za

free State

Chairperson: Sabelo Mkhize

Tel: +27 (0)53 830 6681 | email: smkhize@solplaatje.org.za

Secretary: Noeline Basson

Cell: +27 (0)71 362 3622 | email: ndb@malachi3.co.za

KwaZulu-Natal

Chairperson: Vishnu Mabeer

Tel: +27 (0)31 311 8684 | email: vishnu.mabeer@durban.gov.za

Treasurer: Renelle Pillay

email: PillayR@dws.gov.za

Limpopo

Chairperson: Paradise Shilowa

Cell: +27 (0)79 905 9013 | email: paradises@polokwane.gov.za

Secretary: Salome Sathege

Tel: +27 (0)15 290 2535 | email: salomes@polokwane.gov.za

Mpumalanga

Chairperson: Susan van Heerden

Cell: +27 (0)82 800 3137 | email: susanvanhd@gmail.com

Secretary: Theo Dormehl

Cell: +27 (0)83 294 0745 | email: dormehl@soft.co.za

Namibia

Chairperson: Dr Vaino Shivute

Secretary: Kristina Afomso

Tel: +264 61 712080 | email: afomsok@namwater.com.na

Western Cape

Chairperson: Natasia van Binsbergen

Tel: +27 (0)21 448 6340 | email: natasia@alabbott.co.za

Secretary: Wilma Grebe

Tel: +27 (0)21 887 7161 | email: wgrebe@wamsys.co.za

This year has been a tough one for the South African water sector and it’s easy to dwell on local woes. However, now is not the time to lose faith in the country or its competitiveness. With comparatively low corruption levels and solid performance on key water and sanitation access metrics, South Africa still has a good story to tell investors.

Corruption indexed

The latest Transparency Index report rates different countries from around the world on a points system based on the rigour of their anti-corruption oversight mechanisms. South Africa may not compete with the likes of Denmark and New Zealand (who tied for the cleanest administrations) but, looking at the results in context, the country is not performing badly at all.

Coming in at 64 out of 176 index positions means South Africa is well out of range of the 100 most corrupt countries in the world. Of our fellow BRICs members, South Africa comes out tops, with Brazil, India and China sharing the 79th spot, and Russia ranked at 131. We are also one of the top-performing countries in Africa, outdone only by Botswana, Cape Verde, Rwanda, Namibia, São Tomé and Príncipe. For context, South Africa’s economy dwarfs the rest of those countries combined and a bigger economy does make policing transparency more complex.

Yes, we still need to fight corruption and there is a long way to go yet, but

our internal issues are not insurmountable.

In fact, we are a leader among developing nations: something to be proud of.

Water access

Looking at the water quality of strategically and economically key metros and towns in South Africa, it’s apparent that we are doing something right. Again, the figures need to be looked at in context. South Africa is a highly water-stressed country, yet we manage to provide water for 92.5% of households and households with access to a toilet facility within 200 m is 94%.

The goal is 100% access but South Africa stands proudly among countries like China, India, Chile, Mexico and Australia, all of which have been rated by the World Resources Institute as similarly water-stressed. These countries, including South Africa, all score over the 90% water-access mark.

When it comes to sanitation, the picture looks brighter still. South Africa ranks in the top three among countries in the similarly water-stressed band. Australia provides 100% and Chile 99%. India’s figures are lower, providing only 40% of the population with sanitation, China 77% and Mexico 85%.

The past year may have seen some setbacks but, overall, there is still a lot to build on and feel positive about.

Mine process water doesn’t always need to be treated to mint condition. Daniel Basson, process engineer, AquaPlan

Watertreatment Engineering, explains how treating recycled water to different qualities for different uses saves money, water, energy and the environment.

Basson says that treating mines’ wastewater so that it’s fit for purpose is more affordable than treating it to potable standards because the technology involved is more cost-effective and robust. With new mines being established north of the SADC region, he notes that the greatest savings can be achieved when fit-for-purpose treatment plants are built right from the start. “In cases where excess tailings water is created, some mines will opt to aerosolise it using evaporators. This is extremely wasteful of electricity and also water.”

Evaporation is sometimes used as an interim solution when excess wastewater is produced. The practice is largely frowned upon, given the region’s extreme water scarcity, combined with power-supply uncertainties. Building a permanent treatment plant is a far better option, providing a long-term solution that uses far less electricity, cuts down on water utility bills and has a far smaller

environmental footprint. “Capital costs are always an issue, especially in the current market where a number of mines have unfortunately experienced layoffs,” says Basson. “Although investing in mine wastewater recycling can potentially repay itself in about 18 months – with the client’s savings continuing well after that – the current financial climate means that mines don’t want to be seen laying out capital expenditure – even if it does ultimately save them money.”

This is another reason why new mines need to consider implementing wastewater recycling systems from the start. It overcomes the negative perceptions associated with capital expenditure while compounding savings over a mine’s entire life cycle.

By recycling its own wastewater, BRPM’s monthly cash savings on its water utility bill have been astounding

In implementing any wastewater recycling system, mines can look forward to considerable savings. Basson recalls a project he was involved in for the Bafokeng Rasimone Platinum Mine (BRPM) in Boshoek, 30 minutes northwest of Rustenberg. “The engineering consultant performed a preliminary

feasibility study and then the project was put out to tender as an International Federation of Consulting Engineers Yellow Book design-and-build contract.” AquaPlan was awarded the tender to execute the full design, build, civils, mechanical, process and electrical work. Construction began in 2014, and in 2015, the plant began operation for an initial three-month trial period.

“We were initially contracted to train some of the mine’s own operators. BRPM’s engineering manager, Grant Magano, then asked us to train some of the local community members who were employed during construction. So we took four local people and trained them up to the point where they could operate the plant. Based on that, the mine awarded AquaPlan a two-year operational contract. We now operate the plant in its entirety for the client,” he explains.

Rustenburg is a particularly dry part of the country, so the mine wanted to be able to reuse water from its tailings facility as gland service water.

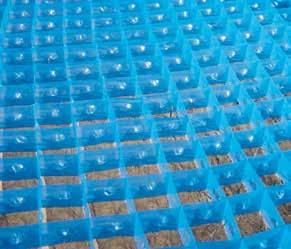

“The new plant treats water pumped from the tailings dam using dissolved air flotation (DAF) technology to remove all the suspended solids and other similar contaminants. From there, it’s transferred to the concentrator plant

where it’s used as gland service water,” says Basson. “Previously, the mine had used potable water from Magalies Water for this purpose. By recycling its own wastewater, BRPM’s monthly cash savings on its water utility bill have been astounding. An added benefit is that there is now more potable water available to surrounding communities and industry. There are obviously environmental advantages as well, because the mine is reusing water,” he adds.

Site specifics

The BRPM plant has a treatment capacity of up to 4 Mℓ/day. “Currently, we’re running at about 3.2 Mℓ/day or 3.3 Mℓ/day. That’s limited by the existing

By combining key project delivery services with manufacturing capabilities, the company is able to provide a cost-effective, quick, accurate and professional offering to its clients

pipeline only. The plant was built 6.5 km from the tailings plant and uses the existing pipe network. We upgraded the pump station and installed new pumps,” explains Basson.

Although the plant is operating below its original design capacity, the limitation arises from site conditions. The mine is looking at installing a new pipeline shortly. “For the plant’s electricity supply, we had to tie in to BRPM’s existing reticulation links. So, we installed an overhead line that linked to its systems,” he adds.

Multidisciplinary approach

AquaPlan is a multidisciplinary engineering firm with more than 100 years’ combined practical experience. By combining key project delivery services with manufacturing capabilities, the company is able to provide a costeffective, quick, accurate and professional offering to its clients.

In the case of the BRPM plant, everything was manufactured in-house, with the exception of the air compressors, which were purchased from Kaeser. “We fabricated everything else, including the saturators and pressure vessels,” says Basson. AquaPlan also has

extensive experience and capabilities in fabricating medium-term packaged treatment plants. Although mainly rolled out to the municipal market for raw water treatment, these plants can also be configured for mine water treatment, as well as other industrial applications. These plants boast a 20-year expected service life and can be turned around in the factory in six to eight weeks.

The next Water Institute of Southern Africa Biennial Conference and Exhibition will be held from 24 to 27 June 2018 at the Cape Town International Convention Centre. Dr Lester Goldman, CEO of WISA, discusses the impact the conference has made on social upliftment over the years, as well as what attendees can look forward to.

“Today, WISA introduces the WISA 2018 Conference to the sector and listens to stakeholders about what we can do to ensure yet another successful WISA Conference and Exhibition. This is our first sponsorship breakfast ahead of the event but we expect to hold more in other city centres as the need arises.

“For next year’s conference, we’re excited about extending its sphere of influence beyond the delegates and WISA

At the first WISA 2018 sponsorship breakfast, held at the Protea Hotel in Midrand on 16 August this year, WISA’s organising committee met with key stakeholders in the water sector to present them with the opportunity to support this important industry event.

By Frances Ringwood

members, so that it becomes a space for generating solutions to some of the crises we currently face,” he explains.

Conference themes

The central theme for the conference is ‘Breaking boundaries – connecting ideas’, which the organisers chose as a way to address past and future resource challenges concerning collaboration, cooperation and integration.

Six sub-themes are being used for the technical programme, namely:

• Sink or swim: Preparing our cities for the future

• Uncharted waters: Developing solutions through science and technology

• Waste not want not: Optimising processes for treatment and reclamation

• Under the microscope: How do we join the dots?

• Bridging the gap: Sustainable finance for improved delivery

• Pooling together: Enabling participation through good governance.

“All six themes are vitally important. Personally, I most look forward to the governance-related themes because I think they are extremely topical,” says Goldman. “Some of our members have already voiced enthusiasm about the event’s practical components, so we will be giving delegates more opportunities to engage through workshops and technical tours. This is without losing focus on what the conference has become renowned for, which is its technical and academic papers,” he adds.

Lasting legacy

WISA conferences have left lasting legacies among nearby communities. Next

year’s conference will be no different, and Goldman invites organisations that work in the interests of the public good to speak to the local organising committee (LOC) about their ideas for social engagement and community upliftment.

“We want to leave a positive, lasting legacy in Cape Town as part of our responsibility as a good corporate citizen. To this end, I appeal to the public to let us know how we can make a difference,” says Goldman. “In jest, I have suggested that those who come from outside Cape Town should bring ‘water doggy bags’ – in spite of this light-hearted comment, I want to emphasise that WISA takes its responsibility to leave a positive legacy extremely seriously,” says Goldman.

Cape coincidence

Natasia van Binsbergen, chairperson of WISA 2018’s LOC, discusses the providence of next year’s conference happening in Cape Town – currently South Africa’s most water-stressed city.

“The Cape Town drought has focused the public’s awareness on water scarcity, as well as on the new technologies that can be used to sustain us all. Everyone is taking about it – at school, in the home and at work,” she says.

“It was a complete coincidence that we planned for the conference to be held in Cape Town, before the city became as affected as it is. I think this drought will mean that the event is going to attract many more delegates from overseas than previous years. American visitors are especially likely to be interested because of the similar conditions they currently face,” she adds.

WiSa Western Cape

According to Van Binsbergen, WISA’s Western Cape branch members have been extremely busy with finding proactive solutions to the crisis. “I think there is a misconception out there that the city isn’t doing anything. The truth is: there is only so much that can be done in the face of such unpredictable weather events of the kind we are now seeing as a result of climate change,” she says.

Some of the solutions being investigated by the city include desalination, wastewater reuse at the Bellville Wastewater Treatment Works, as well as groundwater studies of the Table Bay aquifer and the use of boreholes.

“We may have had some light rain this winter but it’s nowhere near enough. Right now, we’re just hoping the snowmelt we rely on from the mountains in the Theewaterskloof area is going to find its way to our reservoirs in time, although it’s already late in the season,” says Van Binsbergen.

Given the high levels of public interest among Capetonians concerning all things water, the organisers are considering getting the public more involved. Carolyn Melnick, of conferencing and events company Scatterlings and project manager for WISA 2018, says, “We are considering opening the exhibition to members of the public on the last day. The idea behind this is to give people who are not delegates the opportunity to interact with the exhibitors and get a feel for the solutions that are out there.” It is not yet confirmed whether

The following sub-Themes run ThroughouT The wisA 2018 progrAmme

Sink or Swim: Preparing our Cities for the Future Uncharted Waters: Developing Solutions through Science and Technology Waste not Want not: Optimising Processes for Treatment and Reclamation

Bridging the Gap: Sustainable Finance for Improved Delivery Pooling Together: Enabling Participation through Good Governance

Under The Microscope: How do we Join the Dots?

It is not yet confirmed whether the exhibition will be open to the public, and other ways to reach a wider swathe of South Africans are still being investigated

The central theme for the conference is ‘Breaking boundaries –connecting ideas’, which the organisers chose as a way to address past and future resource challenges concerning collaboration, cooperation and integration

the exhibition will be open to the public, and other ways to reach a wider swathe of South Africans are still being investigated. WISA has confirmed that all learnings from the conference will be made public after the event.

Keynotes and abstracts “We have confirmed three keynote speakers, whose details will be published shortly,” promises Melnick. “The abstract submission deadline has passed but applications for hosting workshops will open in the next two months – definitely before October,” she adds.

The exhibition space will be fairly large but it is important to note that companies who attend WISA’s pre-conference events will have first choice when it comes to booking their spots. Other exhibition and sponsorship opportunities will be posted on the www.wisa2018.org.za website.

The WISA 2018 Conference logo was designed based on the Ishihara test – the first test of its kind used to detect colour blindness. It echoes the need to be more aware of water and how it impacts life on earth and human progress. The colours selected for the logo also each reflect a special significance:

Yellow symbolises the discovery of gold in Langlaagte in 1886, which is ultimately the reason WISA came to be established.

Green indicates life, renewal, nature and energy; used here, it represents progress and the fact that – with foresight – better access to improved water and sanitation for all is possible.

Blue is the colour of the sky, sea and rain; its universality linked to the need to access water as a basic human right and a basic freedom necessary for life.

Dr valerie Naidoo, WISA president and WRC research manager, addresses what the change from MDGs to SDGs means for the water and sanitation sector.

world leaders from 189 countries, in 2000, committed to eight Millennium Development Goals (MDGs), which focused on areas such as poverty, disease and health, child mortality, and gender equality. These goals provided focus for a call to action around common global issues and set a target date for its completion by 2015.

Progress was made but not all countries were able to achieve all the goals and, by June 2012 at the Rio +20 conference, a process was set in motion to transition countries from the MDGs to the Sustainable Development Goals (SDGs). A proposal containing 17 SDGs was approved in 2015, laying out a people-centred and partnership approach until 2030. SDG 6, which aims

to ensure the availability and sustainable management of water and sanitation for all, is the primary goal that the water (and sanitation) sector focuses on.

On 22 March 2017, South Africa’s president, Jacob Zuma, gave new focus to the water and sanitation sector by acknowledging our country’s commitment and role in achieving the SDGs. This was a recommitment to providing access to improved water and sanitation for all – a journey South Africa has been on for over two decades post 1994. Our national vision for water and sanitation and the SDGs are also tied to the vision set out by the African Union in its 2063 agenda, which seeks sustainable development on the African continent over the next 50 years. What makes the SDGs transformative on a global scale is that they not only call for the provision of access to water and sanitation facilities but build in a foundation for sustainability. In the research domain, these foundations include concepts like the circular flow of nutrients, reuse, recycling and reduction of waste, and waste to resource, which have been investigated globally for several decades.

Three factors are responsible for not moving some of these sustainability and resource recovery options forward. These are: the tidy box of the regulator called ‘end of pipe’ management of waste and effluent (essentially regulating what is within their mandate and control);

the business case linked to public sector institutions’ limitations around stimulating new types of businesses with different servicing, delivery and financing models; and the perceived lack of policy. I say “perceived” because, as water sector professionals, we create the evidence that allows us to shift to new paradigms, new practices, new policies and new financing mechanisms.

Traditional linear fiscus arrangements across departments working within neat and tidy mandates and policy environments need to change. Two useful examples that illustrate these points are: i) the opportunity to generate from renewable energy (biogas) from sewage waste, and ii) the restriction of sludge to landfills. These are driven by two separate government departments: Energy and Environmental Affairs (DEA).

Biogas policy

South Africa’s energy policy may not provide for renewable energy from biogas. Large supply-side options with fewer incentives around demand management and efficiency solutions are the norm. The amount of energy generated from sewage is small in comparison to other energy grid options and the economics of investing at local government level, especially those with low revenue generation and high grant dependency, is low. As a result, support is required for new technology as well as capability building

within municipalities for such solutions to become more widely accepted.

Banning landfill sludge

Similarly, the DEA recently banned sludge to landfills, which can be considered a good regulatory trigger to seek new solutions. However, this has come with little support for new technologies, policies and financing. Such measures would enable municipalities to transition to managing more complex services through contractors. More importantly, resource recovery of higher-value products from

On 22 March 2017, President Jacob Zuma gave new focus to the water and sanitation sector

waste requires new market linkages. Therefore, support is required from various commercial partners and public-sector departments other than the line department that issues the policy or regulation. In this regard, government should consider implementing large projects at one or two sites to create a blueprint for all other municipalities to follow.

SdG 6

Finally, SDG 6 – which calls for sustainable water and sanitation services – cannot be seen in isolation of the remaining 16 SDGs. Water and sanitation sector professionals also need to ensure that, in addition to water and sanitation services, water becomes an enabler to economic growth and development. This would, in turn, drive inclusivity and innovation. Water also has a significant role to play in ensuring

equity and strengthening the productive use of water for agriculture and food security – not only for commercial agriculture but also through equitable access to emerging and marginalised farmers and communities. Finally, water and sanitation efforts must balance service with conservation in order to realise sustainability.

Such sustainability can only be achieved through effective climate action that strengthens modelling, planning and forecasting, builds resilience in communities and institutions, and implements adaptation and mitigation measures. Ultimately, the SDGs can only be fully achieved through integrated planning, policy and funding alignment, collaboration across national departments and institutions, and partnerships between public and private sector.

August was Women’s Month in South Africa. In recognition of the important role women play in the water sector, the South African Young Water Professionals (YWP-ZA) network is celebrating women who drive the YWP nationally and further afield. By Nora Hanke-Louw and Frances

anya eilers, branch chairperson, YWP-Za Western Cape

What do you currently do?

I am currently completing the final stages of my master’s degree in hydrogeology at Stellenbosch University. I have also had the privilege of serving as the vicechair of the YWP WC branch for 2016, and as chair for 2017. September marks a new adventure in my life, as I will be moving to Ethiopia to start an internship at the Global Green Growth Institute (GGGI), in the water sector, under the Policies Division. As the branch in Addis Ababa is one of its oldest and most active, it will be an exciting opportunity to contribute to GGGI’s Climate Resilient Green Economy project, as well as collaborate with partner organisations WRI and IWMI.

Preyan

arumugamNanoolal, treasurer, YWP-Za

As a 10-year-old, what did you want to be when you were “all grown up”?

A heart surgeon! Although today, I am pursuing a PhD in civil engineering at the Pollution Research Group at the University of KwaZulu-Natal, Durban. My master’s is in zoology, so the transition to engineering was a challenge. My current research investigates the use of vertical flow constructed wetlands in decentralised wastewater treatment systems focusing on design, operation and maintenance. Recently, I was elected as treasurer for the YWP-ZA, after serving a year in the YWP KwaZulu-Natal chapter (May 2016 to May 2017).

Ringwood

Jo Burgess, research manager for the Water Research Commission and former YWP chairperson

What role has YWP played in your life to date?

It has changed my life in a wonderful way. The YWP programme provides an instant network where I can access the knowledge of the crowd, and a safe space where no question is stupid. If you ever feel like you’re overwhelmed or alone, it’s the best place to say so. And it’s also the best place to find out that you are needed – when anyone else says they have a question and you know the answer you realise you are on the right road yourself.

dr inga JacobsMata, research group leader for the integrated water solutions research group at the CSiR and former YWP chairperson

How do you balance work/personal commitments?

This was not easy; before I became a mother, I must admit I wasn’t very good at maintaining a work/personal life balance. But having a one-year-old hanging on your leg for attention really jolts you out of your work bubble and into the “here and now”. Also, it’s a bonus having a good employer – one that supports you to grow and develop holistically, and helps you to grow in the areas you are passionate about, as well as challenge you in the areas you’re not.

Nora Hanke-Louw, YWP-Za chairperson and water sector manager at the energy and Water Sector education and Training authority

How are women’s experiences in the water sector different from men’s? I don’t think all women’s experiences are vastly different from all men’s and I don’t think the water sector is unique. What I do know from personal experience is that some men in the sector are considered “creepy” and women tell each other to beware.

Inappropriate and unsolicited sexual advances are in fact so common that nobody says anything other than in private. Women seem to feel disempowered to the extent that almost no cases of harassment are filed. I think that if all women in the water in the sector would write down their experiences, the sector would be in for a shock. I imagine that most men in the sector do not experience this personally to the same degree.

Suvritha Ramphal, YWP-Za vicechairperson and programme officer at the danish embassy in charge of promoting and supporting bilateral cooperation between the water ministries and other stakeholders in South africa and denmark

What are the main challenges for implementing water and sanitation for all?

People’s current behaviour and attitude towards becoming more resilient in all aspects of water and sanitation, for me, is considered the main challenge. This may not be the case in developed countries but, in a country like South Africa, with the water scarcity challenges we face, it is the responsibility of each and every one of us to be conscious of our use and disposal of water – and make decisions not in the moment but for the future.

Zanele Precious Sifundza, YWP Mpumalanga branch chairperson and water care technician at the department of Public Works

What has your journey as a water sector professional been to date?

It has been a rollercoaster. Straight after my tertiary education, I did quite a lot of marketing work that included door-to-door sales. Without luck for two years, I finally ended up being hired as an assistant resident engineer in a consulting firm working on water and sanitation projects for schools. With the passion I have for the water sector, I took a leap of faith and left my well-paying job to take up a graduate development programme as a process controller because I wanted to add more value to the sector. Today, I am a registered Professional Process Controller with the Water Institute of Southern Africa and am extremely happy in my work.

The bulk of the water industry is made up of municipalities that pay their SETA levies to the Local Government SETA. This means EWSETA has had to be resourceful in how it manages its funds so as to continue providing the skills vital for SA’s future economic growth. By Nora Hanke-Louw

Skills development is the cornerstone of “a skilled and capable workforce that shares in, and contributes to, the benefits and opportunities of economic expansion and an inclusive growth path”, as stated in the National Skills Development Strategy (NSDS) III. The Energy and Water Sector Education and Training Authority (EWSETA) Discretionary Grant (DG) projects have undoubtedly made a real difference in the lives of countless people nationwide; they build self-confidence and leadership skills by allowing students to use their unique gifts and talents. Yet, as one of the smallest and lowest-levy-income Sector Education and Training Authorities (SETAs), EWSETA struggles to fulfil its numerous and competing subsector responsibilities

– we therefore urge all sector partners to come on board as trainers, workplaces, bursary-granters, mentors, and ultimately life transformers.

EWSETA has relatively few levy-payers, which is linked to the market structure of the energy and water sector, as well as the distribution of the Sector Industry and Classification (SIC) codes. To briefly explain how the SETAs receive their income: every employer in South Africa registered with the South African Revenue Service (SARS) is allocated to a SIC Code. As per the Skills Development Levies Act (No. 9 of 1999), employers pay 1% of the salary bill to SARS, which diverts the money to the Department of Higher Education and Training (DHET). The DHET then allocates the levies with 20% to the National Skills Fund (NSF) and 80% to various SETAs depending

on which SETA covers that employer’s SIC code. The rationale is: you pay the levy as per your industry and, in turn, can expect the applicable SETA to know your skills needs and fund relevant training programmes to grow your industry.

Consider the need

EWSETA’s income comes from a meagre 809 levy-payers, only 132 from the water sector. These are the companies with an annual turnover of R500 000 and above per annum (smaller employers are exempt from the levy). The total levies received by EWSETA in the 2016/17 financial year amounted to R286 million, which is a small amount considering our mandate and magnitude of need. On the one hand, EWSETA covers the most basic services

We hope that the sector is willing to pull alongside us, take on and support learners, and sees this as a long-term strategy to support the country and ultimately grow their market

Sector Industry Classification (SIC) codes are a system for classifying all economic activities in South Africa and are widely used by countries around the world.

EWSETA covers electricity, renewable and nuclear energy, oil and gas, water collection, purification and distribution, waste and sewage services, as well as refuse and sanitation services.

(water, sanitation, waste and electricity) and on the other hand, the number of SIC codes and employers EWSETA covers is very small compared to other, larger SETAs. In addition, the energy and water sector leans heavily towards public entities. In the energy sector, Eskom is by far the largest employer.

In the water sector, municipalities, in bulk, are the largest employer, especially at the intermediary-, technical- and vocational-skills levels, which SETAs overwhelmingly fund. Yet, municipalities pay their levies to the Local Government SETA (LGSETA) – a stark fact that remains rather concerning for us given our mandate within the energy and water sector.

industry support

The other side of EWSETA’s work is the sector skills planning mechanism, which is largely reliant on Workplace Skills Plans (WSPs) and Annual Training Reports (ATRs) of employers. In the previous financial year, we received only 16% for the water subsector. This is an

intolerably low number of submissions from industry and begs questions around why companies are not interested in the incentive-based mandatory grant they get back when submitting.

That notwithstanding, the DHET, at the National Skills Conference held in March 2017, also indicated that, at national level, only 15% of industry is actively involved in skills development interventions.

In light of our financial and planning difficulties, EWSETA is doing very well. In 2016/17, we registered more than 5 000 learners on various pivotal learning programmes linked to our scarce and critical skills list, as identified in the EWSETA Sector Skills Plan.

As SETAs, we are restricted by law from using more than 10.5% of our annual budget on administrative costs. The rest of the funding goes to Discretionary Grant funding (i.e. pivotal programmes). This is also one of the reasons EWSETA is going “back to basics” by focusing on our core business: skills development as per our sector analysis.

people. Please be in touch with our water sector team, who are happy to answer any inquiries you might have.

*Nora Hanke-Louw is the EWSETA water sector manager.

Nora Hanke-Louw

+27 (0)11 274 4700

norah@eseta.org.za / info@eseta.org.za www.ewseta.org.za

The total levies received by EWSETA in the 2016/17 financial year amounted to R286 million, which is a small amount considering our mandate and magnitude of need

We hope that the sector is willing to pull alongside us, take on and support learners, and sees this as a long-term strategy to support the country and ultimately grow its market by reinvesting in

In spite of funding difficulties, EWSETA registered 5 000 learners in the 2016/17 financial year

South Africa’s water measurement and distribution systems are becoming increasingly automated. While this is a positive trend, protecting the country’s most productive centres from the effects of climate change and severe water shortages, it also comes with a built-in element of risk. The first line of defence against the new risk introduced by these systems is as simple as making sure employees read the subject lines of their emails before opening them.

Half a decade ago, the types of email headlines associated with cyberattacks could be discerned easily by all but the least internet-savvy members of society.

Popular among these were phishing attacks engineered by some scam artist (notoriously Nigerians), headed with familiar phrases like: “I come to you not by chance” and “Please in godsname (sic) Help, Amen”. These would then usually follow a set format where the sender would relate a sad tale about a prince or professor or emperor (possibly all three) trying to reclaim their lost inheritance, with the email recipient being the only one who could assist in

The catch-all buzzword ‘Industry 4.0’ is changing the way South Africa’s water distribution systems work. Everything, from water meters to the machines that test pipe durability have some sort of built-in smart functionality. What kind of security risks does this enhanced functionality introduce? By Frances Ringwood

Cybercriminals are becoming more and more sophisticated, compelling people to be increasingly careful when opening their emails

rectifying the sender’s predicament. Said help would generally involve a request for money in return for a larger financial reward. The ultimate goal of these attacks would be to get the cyberattack victim’s bank account details and then drain their account. Another way to tell these messages weren’t genuine was their characteristic bad spelling and grammar.

Attacks such as these are similar to SMS and WhatsApp messages sent directly to victims’ cell phones, informing them that they have won some overseas

lottery they had not known they had entered. Again, a small fee is requested to deliver the recipient’s winnings and, again, the ultimate goal is for scammers to get their mark’s banking details.

Updated attacks

The cyber scammers of today are generally much more subtle. For starters, email subject lines usually have a bland heading like “Invoice for your approval” or just “Proof of payment attached”. The only clue that these emails might carry an attachment harbouring malware is that the sender’s name is usually as bland and English-sounding as Molly Thomlinson or Charles Jones – although even these aliases are starting to sound more and more genuine. As these types of attacks

• Have a cyber defence policy in place

• Ensure the policy is implemented

• Encourage a culture of accountability

• Be vigilant when it comes to internal threats, i.e. disgruntled employees and ex-employees

Emails and memory sticks are the two most common ways malware finds its way on to PCs DefenDing informATion

have grown more difficult to detect, a general rule of thumb is not to open emails from people you don’t know. The new professionalism in hacking coincides with a new trend emerging where large scamming syndicates operate out of China. This type of professional criminal scammer is also less likely to wait for a reply to their email and more likely to use aggressive malware to hack into individuals’ email addresses so that they can steal and use any personal data for financial gain.

Email hosting services are forced to spend billions each year upgrading their offerings to minimise the risks associated with this type of privacy invasion. Even so, there is nothing that can be done when users are careless with their email inboxes.

Logging on to one’s email at internet cafes, print shops and other publically accessible PCs where a Trojan or key logger

The

cyber scammers of today are generally much more subtle. For starters, email subject lines usually have a bland heading like “Invoice for your approval” or “Proof of payment attached”

• Limit employee access to only what is needed for the job

• Limit machine access to only what is needed for its function

• Use a network architecture that limits the crossover between IT and operational equipment where possible

• Do not open emails from unfamiliar sources

• Use easy-to-remember personal passwords that are difficult to guess

may be installed is one of the most common ways hackers get access to people’s personal accounts. Even without sophisticated technology, a hacker can gain access through these public portals when individuals forget to log out of their email after a session. Perhaps the most prevalent attack threatening South Africa is ransomware. This type of attack can result in hefty financial losses. In the water sector, the net effect will be that money earmarked for capital or operational expenditure on improved water and sanitation services instead gets diverted to paying what is effectively a bribe in order to get an IT system back online.

An example of a particularly vicious piece of ransomware hit industry hard when the WannaCry attack of 12 May this year wrought financial havoc on the UK’s National Health Service, Dacia Mioveni in Romania and FedEx here in South Africa.

WannaCry, short for the WannaCrypto virus, allowed attackers to gain access to victims’ data in their folders, which they then encrypted, refusing to allow access to those folders until victims paid to have their data back. Worse still, once some companies paid the ransom, they were seen as soft targets for similar future attacks, meaning that one company could end up being hit two or three times by the same scammers.

Emails remain one of the primary ways hackers gain access to an organisation’s

system. This type of attack isn’t limited to car and courier companies; any water sector organisation, from water boards to manufacturers and service providers, is just as vulnerable. The best way for organisations to protect themselves from these sorts of attacks is to be vigilant. Attacks can come from outside, but they can just as easily come from inside an organisation, either from disgruntled employees or just innocent ones who are not sufficiently computer literate. For example, probably the most well-known cyberattack is the Stuxnet virus and its infiltration of the Bushehr nuclear power plant in Iran. Spread through Windows operating systems, the legend goes that the computer virus found its way on to heavily protected state computers because an office worker plugged in a memory stick without knowing what was on it.

Particularly noteworthy about this type of attack for the local water sector is that it not only gets into office files, but actually affects programmable logic controllers (PLCs). PLCs are smart machines used ubiquitously to manage processes across various sectors, including many water applications.

Similarly, in 2014, a German steel mill fell victim to a cyberattack that saw its control systems seized. The German Federal Agency for Security in Information Technology has released very few details about the incident, other than relating it as a cautionary tale illustrating about how hackers are now

• Limit Switches: OsiSense XC

• Pressure Switches: OsiSense XM

• Inductives: OsiSense XS

• Photo-electrics: OsiSense XU

• Ultrasonic: OsiSense XX

• Forks: OsiSense XUV

Explore more

www.tesensors.com

able to cause substantial infrastructure damage. Drawing conclusions for the water sector from these examples means that a dosing PLC or Scada system at a water or wastewater treatment plant becoming infected could affect water quality. This could see contamination levels rising to levels that could harm human health. The cost of hacking water infrastructure is much higher than most other sectors and begins to cross into the realm of terrorism.

According to Christo Buys, business manager for control systems, Rockwell Automation sub-Saharan Africa, the answer lies in a solution the company calls in-depth defence. “Picture defence being like an onion with different layers, with your sensitive information, hopefully, safe at the centre of the onion,” he explains.

“We typically recommend multiple levels of defence, both internally and externally. For example, security policies and procedures need to be in place, as well as a policy for how to proceed in the event of a cyber security breach. A holistic approach means that 20% of your defence will be technology-based and 80% will be based on policy, procedures

If dosing levels at a plant were to be affected by a virus crossing into operational systems, at a mine for example, the environmental and even legal costs could be punishing

and on people implementing those procedures.” Buys points out that there is a misconception that procedures are not as important as policy setting and implementation. This is not the case, and an important part of an organisation’s cyber policy must include some way to limit employee and contractor access to files that are not in use and also limiting which PCs are networked with the process machinery on-site.

“The network that connects these machines is of particular importance and Rockwell Automation, in conjunction with Cisco, leaders in IT infrastructure, has developed free reference materials for keeping network architectures safe and secure,” says Buys. These are available in the form of webinars, educational videos, downloadable collateral and white papers.

The cost of hacking water infrastructure is much higher than in most other sectors and begins to cross into the realm of terrorism

recently been overturned. The original source of wisdom for this formula, Bill Burr, recently put out a statement in the Wall Street Journal where he explains that, as a mid-level manager at the National Institute of Standards, he was forced to come up with a policy towards passwords and he now regrets that trying to remember these passwords “drives people bananas”.

He further emphasises the importance of application, authentication, authorisation and accountability measures, again in order to limit access between information and operation functions within an organisation.

The old wisdom that passwords needed to be overly complicated and include letters, numbers and obscure characters has

The new wisdom is that passwords should be easy to remember, usually something personal that would not be easy for anyone else to guess – one’s own birthday, children’s names and birthdays, spouse’s name and birthday, the street you grew up on, mother’s maiden name or pet’s name are still too easy for hackers to guess though. Favourite lyrics or a punchline to a joke have been flavour of the month lately in experts’ blog posts but being original is always the best way to go.

In conclusion, cyber security is mostly about getting the basics right. Hackers generally look for a soft target and following a few basic precautions makes a big difference when it comes to keeping company information and equipment safe and secure.

Process analysis for the water and wastewater industry –technology driven by KROHNE

• Extensive portfolio of analytic sensors, also with integrated transmitter technology, and complete measuring systems

• Reliable analysis of parameters directly in the process, e. g.:

– pH, conductivity, dissolved oxygen, turbidity, temperature

– sedimentation monitoring, sludge zone tracking

• Mounting assemblies and accessories, approvals from drinking water to Ex

• Wide range of mounting assemblies and accessories

KROHNE South Africa

8 Bushbuck Close, Corporate Park South Randjiespark, Midrand, Tel.: +27 113141391

Fax: +27 113141681, Nirisha Harinarain, n.harinarain@krohne.com, www.za.krohne.com

Four new level transmitters for liquids applications – including agitated and corrosive liquids and narrow tanks with internal obstructions – have been launched to market by German industrial process and instrumentation company Krohne. Two additional level transmitters are also available for solids applications.

Part of Krohne’s Optiwave series of frequency modulated continuous wave (FMCW) radar level transmitters for liquids, these 24 GHz and 80 GHz transmitters feature two-wire 4 mA to 20 mA HART 7 communication and come with an extensive choice of process connections, starting from three-quarter inch. They feature a large, backlit LCD display with four-button keypad, and a quick set-up assistant for easy commissioning.

Standard applications

The Optiwave 3500 is an 80 GHz FMCW radar aimed at hygienic applications in the food, beverage and pharmaceutical markets. It has a wide range of hygienic connections and can measure right up to the process connection.

Thanks to its narrow beam angle and small dead zone, it is capable of measuring in small and narrow tanks, even with agitators. The Optiwave 5400 is a 24 GHz FMCW radar for liquids in basic process. It provides accurate readings in closed tanks, in open-air applications such as rivers or dams, and even in processes with fast-changing levels.

Harsh environments

Optiwave 7400 is a 24 GHz FMCW radar designed for liquids in harsh environments such as tanks with agitators containing corrosives or in non-explosive applications of up to 700°C. Optiwave 7500 is an 80 GHz FMCW radar aimed at harsh liquid applications (150°C, 40 bar) in small and narrow tanks with internal obstructions like agitators or heating coils, as well as tanks with long nozzles.

New 24 GHz and 80 GHz FMCW radar level transmitters for liquids and solids

The Industrial Internet of Things (IIoT) has huge potential: predictive maintenance, asset information management and device configuration are just some examples of the opportunities digitalisation has in store for companies.

Process automation

company Endress+Hauser is driving IIoT forward through innovative products and solutions, as well as by working with partners. This dedication saw the company winning this year’s Digital Champion Award for a proven digital platform.

Endress+Hauser also presented its digital offering at this year’s German Digital Summit, where it presented a unique offering for driving industry excellence through a new partnering platform.

digital Champion 2017

Endress+Hauser’s Memosens is a pioneering sensor technology for liquid analysis in various industries – such as chemical, power and energy, food and beverage, and water and wastewater – which was introduced over 10 years ago. Memosens sensors measure the pH value in liquids, for example, and transform it into a digital signal while

Memosens was presented with the Digital Champion Award in the Digital Products and Services category in June 2017

Award-winning technology: Memosens sensors can be calibrated and regenerated in the laboratory

still in the sensor. The data is then passed on via a contactless system and provides extremely accurate, reproducible and reliable measurement results. Furthermore, the technology combines high process and data security with simple handling: it can withstand corrosion and moisture, can be calibrated in the laboratory, and enables predictive maintenance.

Memosens was presented with the Digital Champion Award in the Digital Products and Services category in June 2017. The award is a joint initiative of German telecommunications provider Telekom and the business magazine WirtschaftsWoche, which was set up in 2016 with the aim of awarding

A platform for Industry 4.0 in chemistry: together with BASF, SAP, Pepperl+Fuchs and Samson, Endress+Hauser presented the opportunities of digitisation to German chancellor Angela Merkel

prizes to significant projects by medium-sized companies.

Endress+Hauser also demonstrates its commitment through its work with partners: the company created a platform through which data can be exchanged together with BASF, SAP, Pepperl+Fuchs and Samson. This was presented for the first time at the Digital Summit of the German Federal Ministry for Economic Affairs and Technology. The event took place in June 2017 in the metropolitan Rhine-Neckar region and saw over 1 000 participants, including the German chancellor Dr Angela Merkel.

The platform enables new forms of data-based cooperation. The effectiveness and efficiency in chemical production can be increased significantly, allowing new business models to be created.

The ability to gather data on the condition of devices and components and exchange this data with all those involved with the process helps to: determine maintenance requirements, plan maintenance work more efficiently and reduce plant shutdowns.

Adam Lovell, executive director of the Water Services Association of Australia (WSAA), provides a snapshot of how water utilities in Australia and New Zealand are focusing on liveable cities for global competitiveness.

By Frances Ringwood

The WSAA is an organisation representing water utilities and private companies from Australia and New Zealand. Members include the likes of Sydney Water, Melbourne Water and Wellington Water, as well as private members such

as Trility, Suez and Veolia. “A few years ago, the WSAA board decided on some big strategic focus areas,” says Lovell. “Among those priorities were the use of benchmarking and putting numbers to the water sector’s contribution towards liveable cities,” he adds.

catchment management to recycled water and desalination.

Benchmarking breakthrough “Elevating performance is all about benchmarking and our members have been benefitting from benchmarking across a number of areas of their business. For example, last year, 20 of our members got together, bringing along their general ledgers, and plugged all of their opex spending into 100 different categories,” Lovell explains. These categories covered everything from

Adam Lovell, executive director of the Water Services Association of Australia

“Some of the more interesting findings concerned the effect of scale. Our data suggests that for every tenfold increase in the size of your storage, there’s about a 60% decrease in your operational costs at raw water storage facilities. This provides food for thought in relation to decentralised systems” says Lovell. On water treatment, the effects of scale proved even more dramatic. “For every

People relaxing and taking in the sun on Christmas Day at Bondi Beach in Sydney, Australia, in 2012. Bondi Beach is the most well-known beach in Australia and one of the most famous in the world. By upgrading four cliff-face sewer outfalls to deep-sea outfalls, Sydneysiders’ property values soured, alongside beach tourism and recreation

We’re gradually seeing a push, where water utilities are trying to open up the conversation saying that stormwater needs to be part of the total urban water environment

tenfold increase in a water treatment facility, a 70% reduction in treatment costs results,” says Lovell.

“More interesting, I think, is the huge price involved in going from secondary to tertiary treatment – around 80%. Why is this interesting? Because, what we typically find in Australia is that an Environmental Protection Agency representative will ask for the highest level of treatment without taking into account the negative effects of stormwater

run-off entering a river system.

Gum trees and blue skies at sunset in Toowoomba, Queensland. Australasian water utilities are looking into the mental health benefits of opening up more green spaces

“I’m not arguing that tertiary treatment is bad but this data suggests that there is a bigger conversation to be had with our customers and communities about levels of treatment and the outcome you want to achieve in a particular receiving water body. It may be that downstream water is being abstracted for drinking water and so tertiary treatment is required. It may mean that you are discharging to a recreational water body. All I’m saying is that the data suggests the conversation needs to change,” says Lovell. “Our research has had a hugely positive impact for individual members. For example, one utility discovered that

Water Treatment

Don’t let algae ruin your day. From causing odours and unsightly mats to inhibiting swimming and other recreational activities, algae can ruin many water uses. The Cutrine™ product range helps to keep your water clear and allows you to make the most out of a day on the water.

– Unique chelated copper formulation – Treated waters may be used for swimming, fishing and animal/livestock consumption

– Contact one of our Water Specialists for more information

ROCLA is South Africa’s leading manufacturer of pre-cast concrete products. Surpassing 100 years of product excellence, including pipes, culverts, manholes, poles, retaining walls, roadside furniture, sanitation and other related products within infrastructure development and related industries.

their insurance costs were astronomical. Two weeks later, they came back saying they’d saved A$700 000 after renegotiating all their insurance costs,” he adds.

Shifting gears to talk about liveable cities (and communities), Lovell noted that this is typically a hot-button issue for the transportation sector, and the water sector needs to exploit the opportunities it presents or lose out.

“Given Australia and New Zealand’s remoteness, our competitive advantage is to have liveable cities. We attract top-class knowledge workers from across the globe on the basis of having liveable cities. And the data that we’ve pulled together proves that. “Our liveability is often referred back to transport and the gridlock that is transport in Australia. But the bigger problem is infrastructure planning.

“The idea we want to get across is that water is the last municipal service with its feet under the table when it comes to infrastructure planning and spend – and it quite often doesn’t get its feet under the table at all. The idea of liveable cities is capitalised on by transport and everybody else that might be able to hang on to the ride. But that’s got to stop.

“Urban water services create value through a number of channels. These include physical and mental health, recreational activities and many more. But first, we’ve got to see ourselves as master planners, not master plumbers. To this end, we developed a paper called ‘Next Gen Urban Water: The role of urban water in vibrant and prosperous communities (2017)’,” explains Lovell.

The paper touches on a number of important ways in which water utilities can make cities more liveable, demonstrating a dollar value where possible for each of these initiatives. These include stormwater management, capital uplift (or an investment credit), health benefits, reducing the heat island effect, measuring mental health benefits, and mapping utilities’

Australia is fairly close to a privatised water model, given that for every A$1 spent, about A$0.90 goes to the private sector

“It’s not just about SDG 6. Many of Australia and New Zealand’s utilities are structuring their business around all of the SDGs.”

performance against the Sustainable Development Goals (SDGs).

“The big problem we have in Australia is that stormwater is not the business of water utilities, and we’ve let councils run it. The fact is that councils have got their own concerns, like local planning, maintaining roads and playgrounds, so stormwater is typically an expensive and problematic issue they worry about. We’re gradually seeing a push, where water utilities are trying to open up that conversation with local government to collaborate by saying that stormwater needs to be part of the total urban water environment,” explains Lovell. “We can’t continue to ignore issues of flooding and pollutant management and at the same time create environmental flows and great recreational spaces for physical and mental health benefits.”

He adds that being climate-resilient and achieving water security means that stormwater reuse needs to be part of the conversation. “But it can only be part of it if it has a funding and pricing framework,” he says.

“Sydney Water did a study last year where they valued clean beaches at A$1.2 billion per year. They came to this figure by looking at how three cliff-face sewage treatment plant outfalls were extended to become deep water outfalls in the 1990s – all three discharging 4 km off the coast at a depth of 120 m,” explains Lovell. The environmental improvements were clear, resulting in a capital uplift of about A$350 000 per property for those lucky enough to close to the beachfront. The health benefits of not having to

An aerial view of the Sydney, Australia, CBD. The concept of liveable cities is used to justify investment in Australia’s infrastructure – the WSAA argues that the water sector needs to seize this opportunity

swim in polluted seawater was valued at around AS$140 000 per annum. The research also showed that over 10% of prospective highly skilled immigrants valued clean beaches and water ways as a top priority.

Reducing the heat island effect

“Just after the Second World War, Mediterranean immigrants brought a trendy construction method called pebblecrete to the shores of Melbourne. As a result, virtually everything in Melbourne became cemented over overnight, resulting in a heat island effect,” explains Lovell. “What the local utility did was to start on a programme about five years ago that actually paid residents to rip out the cement and pebblecrete, and plant trees.

This resulted in an average temperature reduction of between 1°C and 2°C on hot days,” he adds. Additionally, green space has increased, and Melbourne is aiming for a further 20% increase by 2030.

Measuring mental health

“I think the other interesting thing about the Melbourne case study is the mental health aspect associated with living in green spaces that we often disregard,” says Lovell.

“A recent New York study put a value on the mental health benefits of spending time in a park, among green trees. It’s an emerging area of study and we’re working to put a value on the physical and mental health aspects of providing green spaces for recreation,” he adds

SdG mapping

“It’s not just about SDG 6. Many of Australia and New Zealand’s utilities are structuring their business around all of the SDGs. For example, SDG 5 tackles gender equity. One of our members has a goal of 50% women in senior management by 2020,” notes Lovell. A common misconception about the SDGs it that they’re only for developing countries. However, when Yarra Valley mapped its business against the SDGs, it was able to see where it was succeeding as well as its own gaps and areas for improvement.

“For Australia, it’s also important to note that we provide a lot of aid to South East Asia and the Pacific. So, by having an idea of where we are in terms of the SDGs, we can help our South Pacific members through twinning arrangements – where a utility excelling in one area will work openly with another that may be a little weaker in that area,” explains Lovell.

The Australian and New Zealand water utility market is all about being globally competitive. Market leaders want to be part of the infrastructure planning process early on and they are able to enter discussions with hard data on how to make their communities liveable and investible.

When drought hits, governments need to put emergency action plans into place to ensure enough water for those affected. Emergency measures cost money. As drought subsides across most of the SADC region, the challenge now is to recover money spent.

World Bank backs

$145.5 million for water

The World Bank has approved a US$145.5 million loan to Botswana for water projects, Minister of Finance Kenneth Matambo has said. According to the minister, the project was prepared in response to last year’s (and the 2015) El Niño-related droughts, and considered the worst in the last 34 years. The loan is expected to fund the government’s emergency water security and efficiency project, at a total cost of $160 million. The government will also mobilise other partners including equity loans for the remaining $14.5 million. The project will improve the availability of water supply in drought-vulnerable areas, strengthen wastewater management in selected systems and improve the operational efficiency of the Water Utilities Corporation. Some 177 000 people will benefit from improved

Botswana will be undertaking a water security project to the value of US$160 million

wastewater treatment systems and 460 000 will benefit from the rehabilitation or expansion of water supply systems.

Source: MedAfrica

More EU Funding in Inhambane EU ambassador to Mozambique Sven von Burgsdorff has announced the grant of an additional €500 000 (about R7.1 million), to be spent over the next 18 months for a water supply, sanitation and hygiene programme in the towns of Morrumbene, Homoine and Jangamo, in Inhambane province. The programme, known as Aguasani, began in 2008, and was initially budgeted

at about €10 million. It is an initiative of the Mozambican government, supported by the EU and UNICEF. Recent data from UNICEF indicates that only one in four Mozambicans have access to improved sanitation, and that access to latrines of any kind is so poor that two out of every five Mozambicans defecate in the open.

Aguasani, which seeks to overcome the lack of water supply and sanitation services in the three towns, was initially planned to end

in the second half of this year. The increased funding and extended time for the programme (a further 17 months) are intended to expand the number of households and institutions benefitting from it.

Source: Mozambique News Agency

new water agency for namibia

Namibia’s Minister of Agriculture, Water and Forestry, John Mutorwa, has inaugurated a new Water Regulator for the country. The Water Regulator comprises five individuals: Joseph Iita, Nathalia Goagoses, Pedro

US$145.5 million R7 billion €500 000

The value of an approved World Bank loan for water projects in Botswana

The grant to be spent over the next 18 months for a water supply, sanitation and hygiene programme in Mozambique

The amount Swade has been able to mobilise to develop 116 new businesses in the form of smallholder farmers in Swaziland

Maritz, Olga Katjiuongua and Luther Rukira. It has been instituted under the authority of the Water Resources Management Act (No. 11 of 2013), Section 12, but its main functions are executed under Section 7 of the NamWater Act (No. 12 of 1997). Mutorwa has described the new regulator’s mandate as falling under NamWater’s legal obligation to “determine and levy, in consultation with the minister, tariffs on a full cost-recovery basis for water supplied”.

At the inauguration ceremony in Windhoek, the minister described the new regulator’s duties: “to carry out efficiently and in the best interests of the Republic of Namibia, the primary business of bulk water supply to customers, in sufficient quantities, of a quality suitable for the customers’ purposes, and by cost-effective, environmentally sound and sustainable means; and the secondary business of rendering water-related services, supplying facilities and granting rights to customers upon their request.

Source: Namibia Economist

Calls for probe into R2.5 billion cash crisis South Africa’s bankrupt Department of Water and Sanitation is deep in the red and has been called to account for millions spent in wasteful expenditure by Parliament’s Standing Committee on Public Accounts.

In April, it was reported how Minister Nomvula Mokonyane’s portfolio was slapped on the wrist by Treasury for going bankrupt. The Water Trading Entity

(WTE), which falls under the department, was responsible for several high-level projects, including the Lesotho Highlands Water Project. It had been bleeding millions and operating at a loss.

A senior National Treasury official said the department had run out of money and this was flagged almost a year ago.

Director-general Dan Mashitisho appeared in Parliament where he responded to questions about the department’s cash irregularities. Scopa is also due to call Mokonyane to account. Mashitisho has been accused of not providing enough detail by the Democratic Alliance opposition party. The EFF also expressed disappointment in Mashitisho’s handling of the report.

Source: The Citizen

El Niño-related droughts have affected livestock and wild animal deaths across the Southern African region

political, business and cultural landscapes for business competitiveness seminar held at the University of Swaziland. The parastatal, under the Ministry of Agriculture, is funded by international development agencies through government and also receives a subvention from government.

Swade mobilises R7 billion to assist community businesses

The Swaziland Water and Agricultural Development Enterprise (Swade) has been able to mobilise about R7 billion to assist businesses in communities.

This was revealed recently by Swade CEO Samson Sithole during the economic,

“To date, a total of about R7 billion has been mobilised by Swade and this was used to develop 116 new businesses in the form of smallholder farmers,” Sithole said. He added that the financial support received by the parastatal over the past years has enabled it to roll out a total of nine projects that assisted different chiefdoms in alleviating poverty. Two of those projects employed over 2 000 individuals under the Komati Downstream Development Project and the Lower Usuthu Smallholder Irrigation Project. Sithole said access to potable water and sanitation contributes to the improvement of livelihoods and health in the Swade project areas’ communities.

Source: The Swazi Observer

Government needs to teach public to pay for water Central government should push the public to accept that water is a commodity that should be paid for, as most still see it as ‘freebie’, Harare Acting Town Clerk Josephine Ncube has said. She made the comment during a World Banksponsored workshop titled ‘Service Level Benchmarking’ held in Mutare recently. The workshop was attended by town clerks and two other focal persons from all the country’s 32 urban councils. The programme is aimed at improving service delivery by urban councils in Zimbabwe. Among other issues discussed were urban water supply and waste management.

“We have politics of the water. There is no push from central government to ensure that people see water as a commercial commodity. Most people still think water from the council is free. They don’t want to pay,” said Ncube.

Source: NewZimbabwe.com

The raising of the Tzaneen Dam spillway will provide much-needed additional capacity for the town the dam borders, as well as the surrounding industrial and agricultural sector, which is one of the main vegetable producers in South Africa. By Alastair Currie

Acategory three dam, Tzaneen Dam was completed in 1976 and the design made provision for the raising of the spillway at a later date. That time is now drawing nearer as the construction implementation programme gathers momentum on a strategically important infrastructure upgrade, with the main raising works scheduled to commence in April 2018.

The dam raising forms part of the Department of Water and Sanitation’s Groot Letaba Water Development Project (GLeWaP), which includes the construction of the new Nwamitwa Dam situated some 40 km downstream. Nwamitwa Dam, located on the confluence of the Groot Letaba and Nwanedzi rivers, will

have a wall height of around 36 m and a storage capacity of approximately 144 million cubic metres. Blackhead Consulting is the appointed professional service provider (PSP) for the raising of the Tzaneen dam. The team is headed up by the project manager, Hilton Sparks, Blackhead’s technical director and a civil engineer with more than 40 years of project management experience. He is assisted by Harry Lyimo, a civil and structural engineer at Blackhead Consulting. As implementing agent for the Department of Water and Sanitation, Lepelle Northern Water appointed Blackhead Consulting for the design of the raising works in November 2015. The design team is backed by a highly

experienced group of subconsultants:

• The APP is Dr Quentin Shaw of ARQ Consulting Engineers.

• The dam engineer is David CameronEllis of ARQ Consulting Engineers.

• The structural engineer is Don Midgley of Ritchie Midgley Consulting Engineers.

• The hydrologist is Hendrik Peens of Peens and Associates.

• The environmental control officer is Bradly Thornton of Kongiwe Environmental.

The feasibility studies and the environmental process for both the Nwamitwa and Tzaneen dams had already been

completed, with a record of decision in place, which was due to expire on 26 September 2016, so the preparation for the construction programme needed to be accelerated.

“The raising of Tzaneen Dam by 3 m serves two purposes: first, to act as a storage backup for the Nwamitwa Dam and, second, to ensure additional storage capacity over the long term,” explains Sparks. Tzaneen Dam’s capacity will be increased from 150 to 193 million cubic metres.

Spillway design study

The starting point for the project was to reevaluate the feasibility study completed in 2008 for Tzaneen Dam in terms of the hydrology. The feasibility considered four spillway options, namely the original ogee spillway, fuse gates, a labyrinth weir, or a PK weir.

Model studies were undertaken at the Department of Water and Sanitation’s laboratories in Pretoria West to determine the optimal design approach from cost and project timeline perspectives. ARQ tested the viability of retaining the current ogee crest, or opting for a PK labyrinth weir. Tzaneen’s current spillway is approximately 100 m long, and the non-overspill crest around 1 km in length.

“We needed to carry out a cost-benefit analysis for different configurations of the spillway. In the end, our studies showed that opting for a conventional labyrinth was the most feasible option – this following extensive analysis by the dam engineer. This provides a cost-effective and low-maintenance solution,” explains Lyimo, the assistant

project manager. If the ogee approach had been selected, this would have required the raising of the spillway and non-overspill crest by the same height, namely 3 m. “However, by adopting the labyrinth weir method, it was determined that we could get the same quantity of water over the spillway for less height,” Lyimo continues. “This now means that the height of the nonoverspill crest only needs to be raised by 1.5 m, requiring approximately 20 000 m3 of material.”

A detailed design of the new labyrinth spillway has been completed and a tender document drawn up. The raising of the spillway will be carried out by an external contractor still to be appointed by the Department of Water and Sanitation.

initial works: stockpiling and demolition When initial construction commenced in early September 2016, Tzaneen’s dam level was down to 13%. Blackhead took advantage of this opportunity to excavate the required material for the raising of the earthfill embankments from the dam basin and stockpile it for the main raising works. These works were carried out by Construction North, the Department of Water and Sanitation’s construction wing. Then cyclone Dineo hit in February 2017 and the dam level has now risen to around 60%. Fortunately, the stockpiling operations were completed in the same month.

The maximum capacity threshold during the construction of the spillway is 72% with diversion works in place. A coffer dam will also be established

downstream as part of the spillway works to carry out dam toe foundation inspections and improvements.

In preparation for the raising of the spillway, the existing ogee structure is being demolished by 4 m down to the level suitable to anchor the raising, and will then be raised by a total of 7 m, a net raising of 3 m. A platform was built on the upstream side to access the spillway with mechanical breakers.

The original drawings indicated that the spillway was composed entirely of mass concrete. However, a nominal amount of steel reinforcing was encountered, which has required some blasting to speed up the demolitions. Demolition will be completed in August 2017 and work on the raising of the spillway is expected to commence in April 2018, with construction due for completion in September 2019.

Programme management

To track the construction programme, Blackhead Consulting is employing an innovative cloud-based project monitoring system using tablets, which has already been successfully applied by the firm on human settlements projects. Daily site instructions are completed and signed on the tablet and uploaded to the Cloud, enabling the project management

team to download this information and monitor progress in real time for specified categories – e.g. demolitions or stockpiling, with monthly reports generated automatically. This is combined with the deployment of a drone to complete aerial photos and video. When the main construction commences, all stages will be colour coded for specific monitoring requirements and to keep the project on track and within budget.