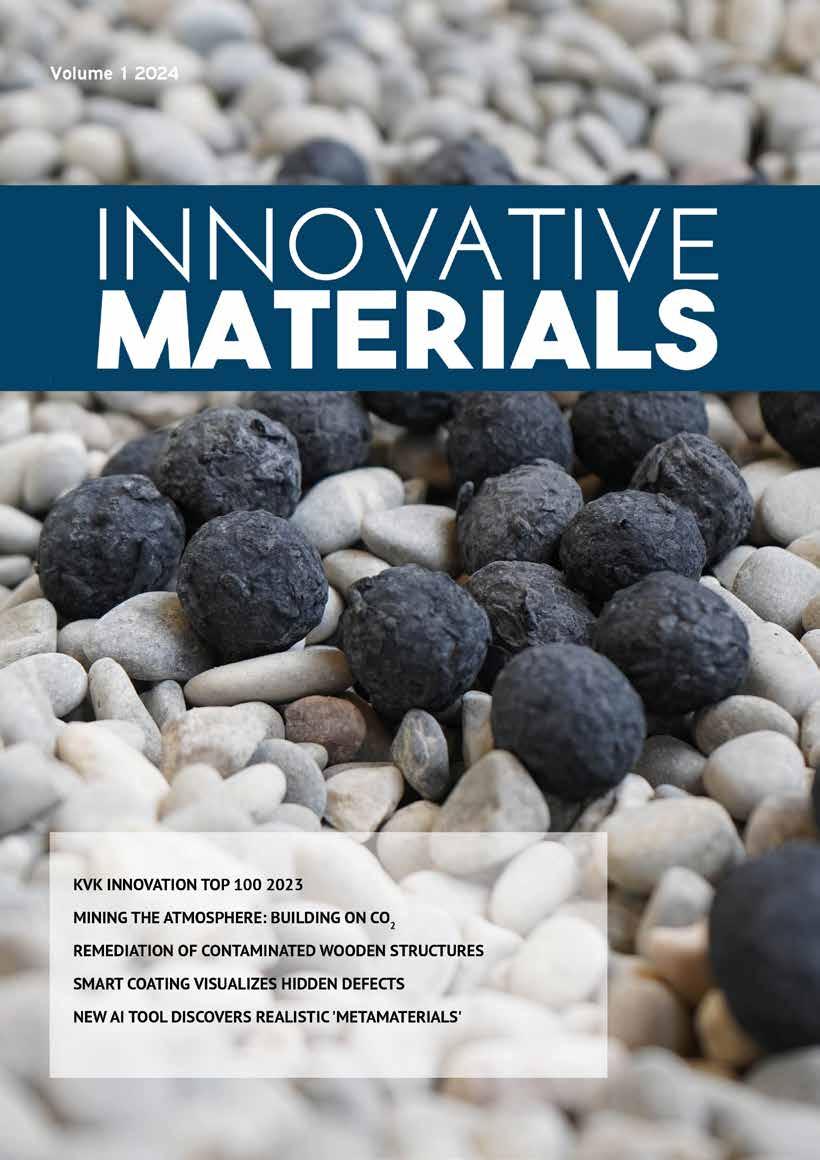

SUMMARY VOLUME 1 2024

KVK INNOVATION TOP 100 2023

MINING THE ATMOSPHERE: BUILDING ON CO2

REMEDIATION OF CONTAMINATED WOODEN STRUCTURES

SMART COATING VISUALIZES HIDDEN DEFECTS

NEW AI TOOL DISCOVERS REALISTIC ‘METAMATERIALS’

KVK INNOVATION TOP 100 2023

MINING THE ATMOSPHERE: BUILDING ON CO2

REMEDIATION OF CONTAMINATED WOODEN STRUCTURES

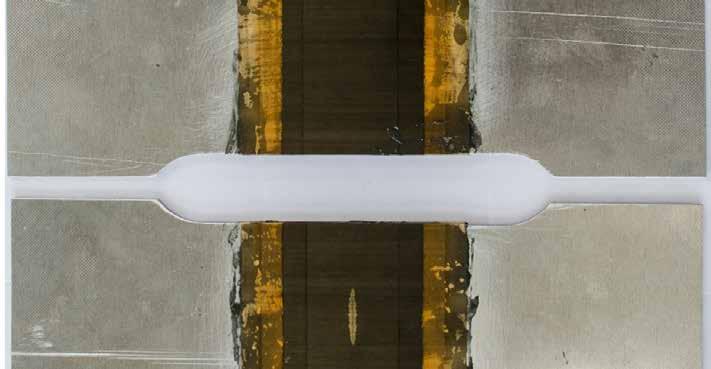

SMART COATING VISUALIZES HIDDEN DEFECTS

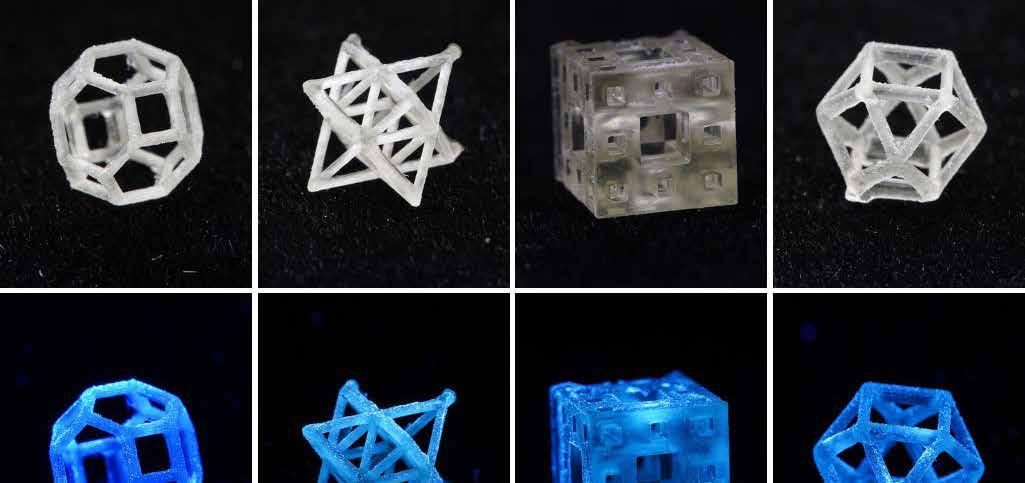

NEW AI TOOL DISCOVERS REALISTIC ‘METAMATERIALS’

This is a summary of the most recent edition of Innovative Materials. Would you like to read the entire articles? You will find more information about subscriptions HERE.

A research team led by materials scientists by Edmund T. Pratt Jr. School of Duke University has developed a method to quickly create a new class of materials to develop heat and electronic resistance are that they enable devices to operate at extreme temperatures can work.

American scientists have a new method developed to convert CO2 into carbon nanofibers (carbon nano fibers, CNF). Carbon nanofibers are promising materials in many areas, such as photocatalytic, nanocomposites, energy devices, filtration, sensors, tissue engineering and high-quality composites.

Wastewater often still contains sugars, fatty acids and starches can be converted by bacteria into PHA bioplastic. Interreg project WOW! already showed several years ago that it is possible to make PHA from sewage water; now the focus was on residual flows from food processing industries. But how to turn a residual flow into a product? MNEXT published a white paper about it at the end of 2023.

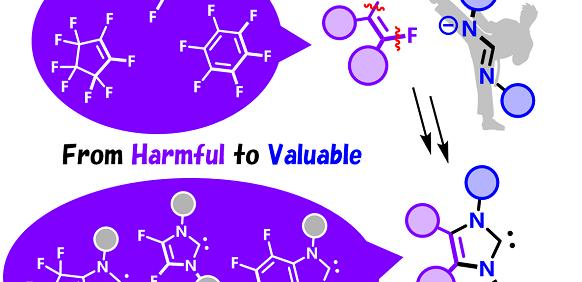

PFAS are known as ‘forever chemicals’, and are notorious because they persist in the environment and in our bodies. Chemists at Osaka Metropolitan University may put an end to the ‘forever’ life of PFAS with their simple yet innovative technique that converts these harmful substances into valuable compounds.

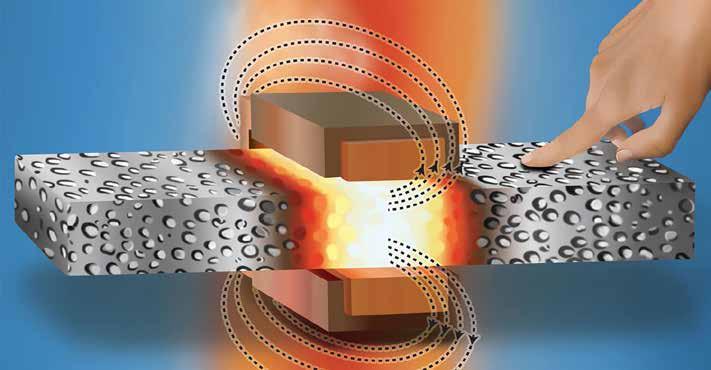

Composite metal foam (CMF) is foam consisting of hollow, metal balls of materials such as stainless steel or titanium - embedded in a metal matrix made of steel, titanium, aluminum or other metal alloys Researchers from North Carolina State University (NSCU) have developed a welding technique that can be used to weld CMF components together without the properties of the material are affected.

Compressor-based cooling techniques, such as air conditioning systems, work well against heat stress, but place a strain on energy networks. Passive cooling, which requires little or no energy to remove heat, is an environmentally friendly alternative. Scientists from King Abdullah University of Science and Technology (KAUST) developed a technique that combines radiative and evaporative cooling without the need for additional chemicals or energy.

Electrical energy can be sustainably extracted from nature in various ways, for example with solar panels or wind turbines. Researchers from the US developed an energy harvester that uses multiple sources (e.g. wind and rain) to generate energy.

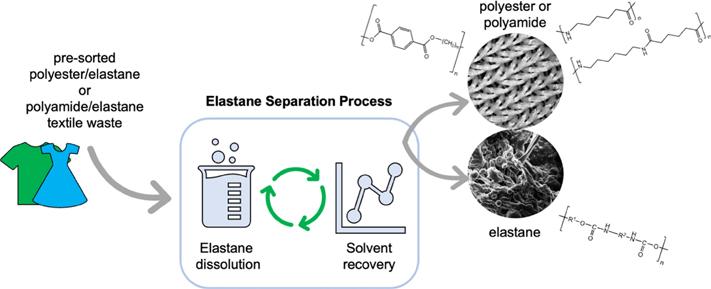

Recycling mixed textiles is difficult, especially if they contain elastane. TU Wien (Vienna) has developed methods that can not only detect elastane better and in a more environmentally friendly way than before, but can also separate it in a ‘gentle’ way, so that other fibers can also be left undamaged.

Swedish researchers have developed a new alternative architectural material from nanocellulose and algae. According to the Swedish scientists, the study offers opportunities for the development of large, 3D printed nanocellulose membrane constructions.

With high chemical and thermal resistance, metal pads are a good alternative to elastomeric components in load-bearing machine parts. The elasticity and damping of the wire mesh is based on the interaction of individual wire segments during deformation.

MIT researchers have developed an additive manufacturing technique that can quickly print with liquid metal, allowing relatively large parts such as table legs and chair frames to be produced in minutes. The method - liquid metal printing (LMP) - involves depositing molten aluminum in a bed of small glass beads along a predefined path. The aluminum quickly hardens into a 3D structure.

Researchers at the Georgia Institute of Technology have created the world’s first functional semiconductor from graphene, a single sheet of carbon atoms held together by the strongest bonds known.

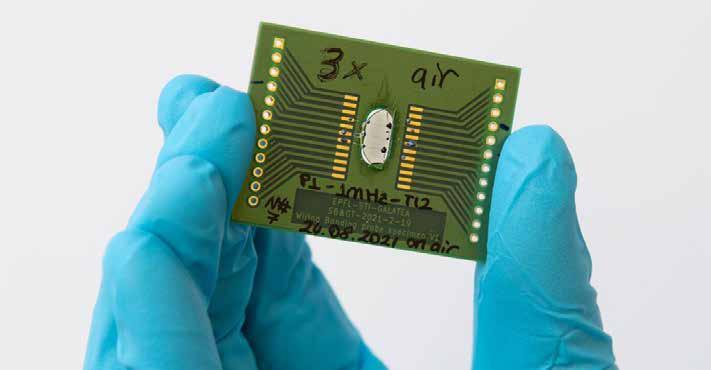

Researchers from the École Polytechnique Fédérale de Lausanne (EPFL) developed a new way to make photoconductive circuits, in which the circuit pattern is applied directly to a glass surface with femtosecond laser light.

Every year, the Dutch Chamber of Commerce (KVK) presents the KVK Innovation Top 100 to show what Dutch SMEs are capable of. The new ranking was announced at the end of 2023 and again this year contained a serious number of innovations in the field of materials and material applications.

Natural dyes have been used by humans for centuries. Indigo, carmine, purple and ultramarine have been known since ancient times and were only replaced by synthetic dyes during the industrial revolution. The Research Institute for Textile Chemistry and Textile Physics in Dornbirn has been researching natural dyes for over 25 years. Despite a trend towards ecological raw materials, natural dyes have not yet been able to establish themselves in the textile industry.

The construction industry as a CO2 sink? Researchers at from the Swiss Materials Institute Empa Concrete & Asphalt lab are working on this. By incorporating biochar into concrete, they are exploring the potential of CO2-neutral or even CO2-negative concrete. For optimal applicability, they process the biochar into pellets and use them to replace conventional aggregates.

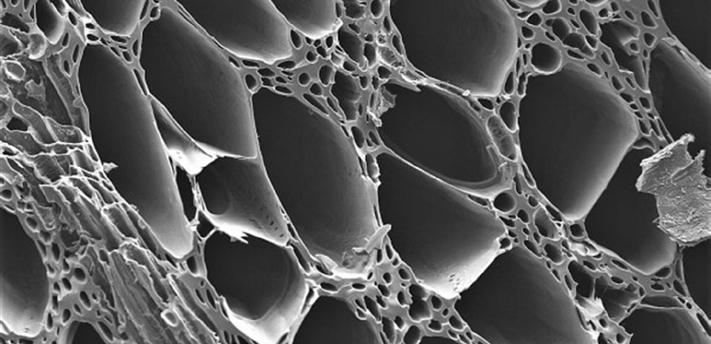

In Germany, there are around three million buildings that are contaminated with the toxic wood preservatives lindane and pentachlorophenol (PCP). In the CycloPlasma project, researchers at the Fraunhofer Institute for Building Physics IBP are developing a new type of process to remove these decades-old contaminants - in the air as well as in contaminated wooden structures

Last November, Respyre presented an innovative, sustainable facade cladding: VertiScape. These are facade panels made of sustainable concrete with living moss. The concrete mixture from which it is made is 90 percent circular. This gives old rubble a new purpose and reduces CO2 emissions. In addition, during the life of the facade, CO2 is absorbed in the concrete as lime, making it a CO2-negative material.

TNO has developed a process - ‘EnerChar’ - to make ‘clean’ (or ‘green’) carbon. Carbon is a widely used material, but usually comes from fossil sources. The new method makes it possible to produce biocarbon on a large scale with precisely adjustable properties. According to TNO, the use of biocarbon can make a major contribution to reducing fossil carbon use and therefore to reducing CO2 emissions.

Researchers from TU Delft are working on an innovative cost-effective coating material that changes color as an early warning system, thus making vulnerabilities visible well in advance.

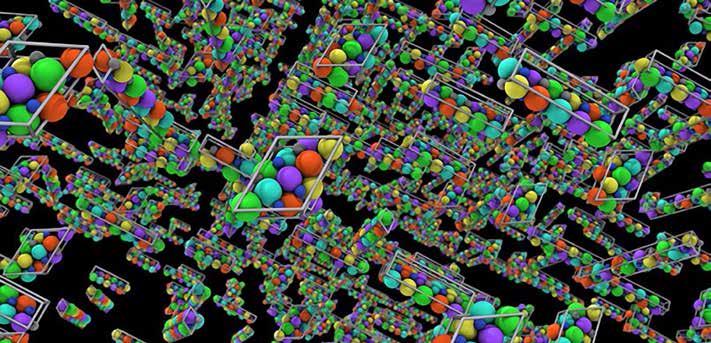

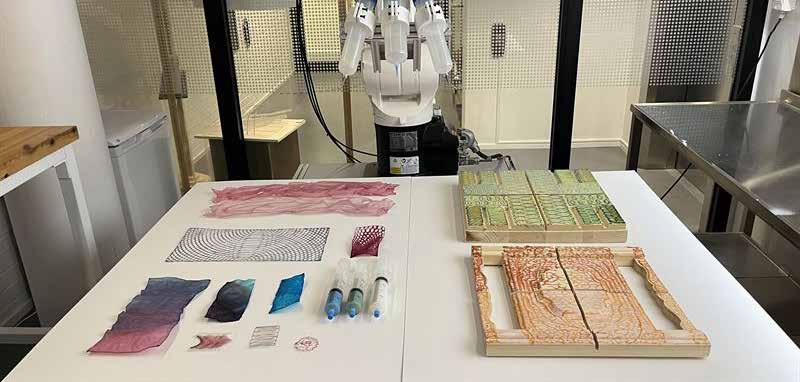

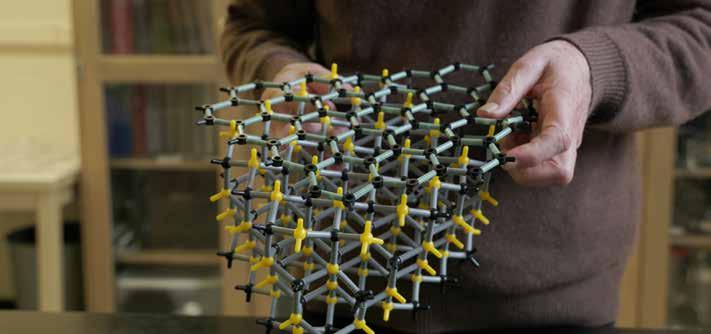

Researchers from TU Delft have now developed an AI tool that not only can discover extraordinary metamaterials but also makes them fabrication-ready and durable. This makes it possible to create devices with unprecedented functionalities. They publish their findings in Advanced Materials.

An American research team has developed a ‘supramolecular ink’ that can be used to 3D print OLED (organic light-emitting diode) displays. The new supramolecular is made with cheap elements instead of scarce and expensive metals. It could enable more affordable and environmentally sustainable flat panel displays and electronic devices.

17–18

Cellulose Fibres Conference 2024

13 - 14 March 2024, Cologne

Fensterbau Frontale

19 – 22 March 2024, Nuremberg

Silicon PV 2024

15 - 19 April 2024, Chambery

Manufacturing Technology Conference

16 April 2024, Veldhoven

Maintenance Gorinchem

16 - 18 April 2024, Gorinchem

CO2 based Fuels and Chemicals Conference 2024

17 - 18 April 2024, Cologne

Hannover Messe 2024

22 - 26 April 2024, Hannover

Schweissen 2024

23 - 26 April 2024, Wels

Ceramitec

23 - 26 April 2024, Munich

Intermat 2024

24 - 27 April 2024, Paris

Betontage 2024

14 - 16 May 2024, Ulm

Rapid.Tech 3D

14 - 16 May 2024, Erfurt

GrindingHub 2024

14 - 17 May 2024, Stuttgart

Maakindustrie Expo 2024

15 - 16 May 2024, Hardenberg

Carrefour international du Bois

28 - 30 May 2024, Nantes

SurfaceTechnology Germany

4 - 6 June 2024, Stuttgart

Intertool 2024

4 - 7 June 2024, Wels

Architect@work Germany

5 - 6 June 2024, Munchen

Achema 2024

10 - 14 June 2024, Frankfurt am Main

Renewable Materials 2024

11 - 13 June 2024, Cologne

PCIM Europe

11 - 13 June 2024, Nuremberg

Challenging Glass 9

19 - 20 June 2024, Delft

Plastic Recycling Show Europe 19 - 20 June 2024, Amsterdam

SolGel 2024 International Conference 1 - 6 September 2024, Berlin

Wij leveren complete installaties voor ontstoffing, luchtreiniging en pneumatisch transport

Technieken voor o.a.:

- Ontstoffing van productieruimtes (MAC)

- Reduceren van geuremissies (NER)

- Reduceren van stofemissies (NER)

Componenten die wij o.a. kunnen leveren:

- Natfilters & Droogfilters

- Cyclonen

- Gaswassers

- Topsteen- / Frogreinigers

- Naverbranders

Projecten kunnen turn-key worden uitgevoerd

Wij garanderen de emissie & grenswaarden

Engineering, bouw en onderhoud in eigen beheer

Mesys Industrial Air Systems BV

Molenstraat 27, 6914AC Herwen

+31 (0) 316 248744

www.mesys.nl

Info@mesys.nl

Hoog vacuüm stofzuiginstallatie

Natfilter met slibtransporteur

Hoog vacuüm stofzuiginstallatie

Natfilter met slibtransporteur

for materials characterization.

Independent, dedicated, objective research and consultancy. ISO 17025 accredited.

We are pleased to support you with research and analysis of your innovative materials. Call us on +31 26 3845600 or email info@tcki.nl www.tcki.nl

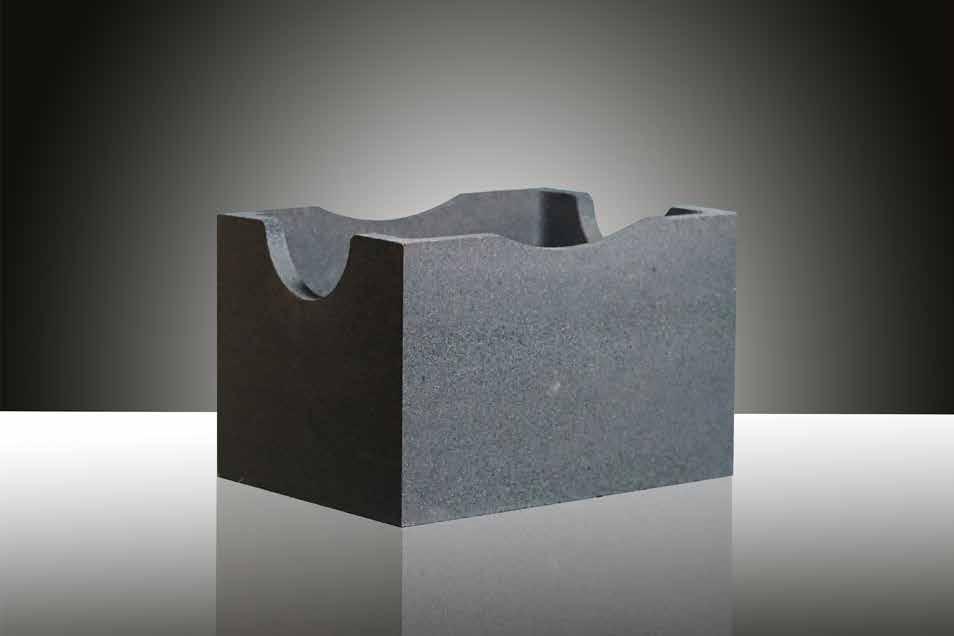

Refratechnik specialises in the development of innovative refractory systems. With over 70 years of experience, we work closely with our customers to provide tailor-made solutions for industrial furnaces and other industrial applications in a wide range of sectors. We mainly supply the ceramics, aluminium, iron and steel industries.

Our product portfolio for the heavy clay industry includes wall, ceiling and kiln car systems with all the necessary kiln furniture. This makes Refratechnik the only supplier in the world that can supply complete refractory systems for tunnel kilns. We offer kiln furniture and complicated special formats for the refractory protection of industrial plants for various branches of industry. With our precise dry pressing technology, we achieve the dimensional accuracy required for smooth plant operation. Our products are specially designed for high temperatures and aggressive atmospheres to ensure long refractory life. We use high quality material compositions. In technical ceramics, for example, we use high-purity materials based on corun-

dum, mullite or silicon carbide. Our firing capsules withstand strong chemical influences at very high temperatures.

At Refratechnik, we place great emphasis on energy-saving solutions to

meet the demands of sustainability and decarbonisation. Our pioneering grades and formats for tunnel kilns, such as the low-density BURCOLIGHT® material and REFRATHERM® Eco, a CO2-neutral, highly efficient insulation, enable significant energy savings and a reduction in the carbon footprint.

Our team will be happy to advise and work with you to find the optimum solution for your needs.

Hall A4, Booth 319/418

Refratechnik Ceramics GmbH

Barkhausener Strasse 55

D-49328, Melle

T 0049 5427 81 0

F 0049 5427 81 102

E ceramics@refra.com

www.refra.com