Bhushan Bhad Managing Editor

Bhushan Bhad Managing Editor

he business space has traversed through a roller

Tcoaster ride. From agrarian society to the industrial ecosystem and further escalating into the digital revolution, scientific innovations have revamped the business community like never before.

Sprouting from an age where hammering a kneel was a difficult task, technological innovation and IT marvels have transformed the manufacturing space. Today, an industry requires to possess software systems and mechanical components rather than accommodating a vast workforce to even move a bulky log of wood.

This development has not been an overnight success but a resilient effort while putting consistent steps towards technological innovation, creative IT solutions, and a farsighted vision that steps into the future.

Once considered as the science fiction: Terminator, The Transformer, Automata, and much more, cinema portrayed an idea that focuses on the robotics of human interaction. But from fiction to industry, the journey had been of many ups and downs.

As a technologist, entrepreneur, or business disruptor, there are many functionalities, challenges, and throughput invested in bringing up a single mechanic component to its live function.

As technology is taking its toll and developing the manufacturing space, Artificial Intelligence and Machine Learning have not been left behind. Today automating an industry workflow is an integrated process that combines technology, software, mechanics, and IT systems. But these innovative efforts and creative solutions are rarely discussed and acknowledged among the common masses and business community.

Understanding these ignored corners and connecting the dots of the automation industry is our new edition, “10 Most Disruptive Automation Companies to WatchVolume II .” Scouting across the globe, we have researched and curated top disruptors that have pioneered the automation industry and is exemplifying the business community with their unique technology leadership hacks.

While you start your journey and stall around these inspiring stories, make sure to lean on the cover story and realize the innovative hand and scientific expertise required to establish a business in the automation space.

As you flip through the pages, read the insightful articles crafted by our in-house editorial team.

I hope you have a happy read!

- Bhushan Bhad,As technology is advancing every business sphere, incorporating automation in industry workflow will prove to be the future of corporate world.

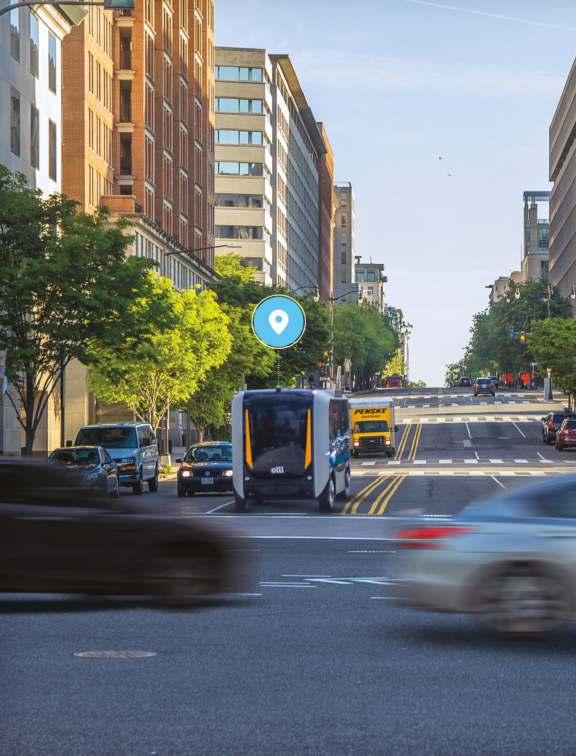

At the Forefront of

the EnergyIndustry

Augmentus augmentus.tech

Daryl Lim Co-FounderAugmentus is a robot programming software platform that allows anyone to program industrial robots in minutes without needing code and CAD.

AXYN Robotics axyn.fr

doks. Innovation doks-innovation.com

FRANK ANJEAUXCEO and Founder

Mike Becker (Co-Founder, Head of Software) and Christian Sproedt (Strategic Sales Manager)

Easy Energy Systems easyenergysystems.com

Eiratech Robotics eiratech.com

Mark GaalswykFounder and CEO Alexey Tabolkin CEO

Axyn Robotique is a French company that designs and manufactures telepresence robots.

doks. Innovation optimizes inventory processes in intralogistics with modern technology, for example drones, and software that processes visual data.

Energid Technologies energid.com

Fizyr B.V. fizyr.com

PaR Systems par.com

Neil Tardella

CEO and Co- founder

Herbert ten Have CEO

Easy Energy Systems (EES) is passionate about providing dynamic solutions to the world's energy problems.

Reveal Group revealgroup.com

Tom Pohlad CEO Ian Crouch Business Improvement Expert and CEO

Eiratech Robotics is an end-to-end solutions provider armed with a portfolio of autonomous solutions to tackle complex supply-chain challenges.

Energid's robot control software, Actin®, is built to meet the requirements of industrial, commercial, collaborative, and consumer robotic systems.

Fizyr offer the best pick and place solution to every system integrator worldwide.

PAR Systems is a world leader in providing full-life-cycle automation solutions for critical material handling and robotic applications that drive customer quality, safety, and productivity.

Reveal Group specializes in deploying and scaling Intelligent Process Automation programs. It is revolutionizing Operational Management with innovative software.

SL Controls Ltd slcontrols.com

Keith Moran CEO

SL Controls helps its customers optimise their manufacturing processes, improving OEE and productivity, delivering efficiency savings, and simplifying compliance.

Mark Gaalswyk Founder and CEO Easy Energy

Mark Gaalswyk Founder and CEO Easy Energy

The debate on climate change has continued for over a century now. The discovery thwas first done by scientists in the 19 century when ice ages and other natural changes were suspected in the environment. The effect of CFCs emitted by human activities started deteriorating the environment to a point where the UN finally had to put a foot down and call for the first conference on the environment in Stockholm in 1972.

Since then, many goals have been set by these yearly environmental conferences held by the UN to reverse the worsening climate situation. In this effort to save mother earth, many individuals, and organizations, leveraging the powers of science, started coming up with ways in which economic growth and sustainability could go hand-in-hand.

One such company, at the forefront of providing dynamic solutions to the world’s energy problems is Easy Energy Systems

In the following interview, Mark Gaalswyk, the Founder and CEO elaborates on the inception story of the company and how it has been disrupting the energy industry by providing cutting-edge energy solutions.

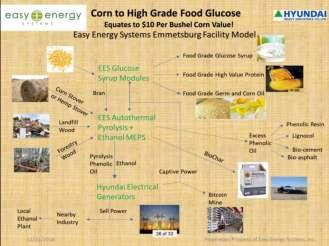

Please brief our audience about EES, its MEPS®, and how it is currently positioned as a leading player in the bioenergy space.

Easy Energy Systems, Inc. has developed and patented a factory-built modular technology that can be rapidly deployed worldwide to help solve the problem of climate change for the world. It will do so by enabling the rapid commercialization of cutting-edge technologies for

converting many greenhouse causing wastes into bioenergy and other value-added products.

Unlike most technologies, the selfcontained automatic modular processes are combined differently for different waste feedstocks to create value-added green energy and biomaterials from all of the various otherwise waste by-products. This enables the financial models of most of the Easy Energy waste feedstock systems to provide for a complete system payback within five years or less – without government subsidies (Although I am sure our customers will take them if offered).

Shed some light on EES’s offerings and how are these making an impact on the industry and your clients?

Most distribution of biomass, waste food products, dead trees causing forest fires, landfills, waste seaweed, palm fronds, and various other waste products are widely distributed across a region. Instead of placing one large centralized ‘mega plant’ system in one location – and then transporting the waste to the mega plant; the smaller scale Easy Energy Systems, Inc. distributed modular plants can be deployed much closer to the waste.

This may be a clearing in a forest for cleaning up the dead trees causing forest fires, besides large industrial manufacture creating food or paper waste, adjoining a municipal landfill, corn stalks near an ag cooperative, or next to an ocean shore for converting seaweed into valuable products.

Easy Energy Systems, Inc has an exci�ng modular technology for North American Ag Coops:

Converts the “food – white portion” of a kernel of corn to food or medical grade glucose.

Converts the “nonfood – yellow portion” of a kernel of corn along with the corn stalk itself into biofuels, bio electricity and other value add products. This holds potential to bring to the rural communities of each state an extra $3 Billion dollars per year!

The major advantage of this method is that you do not emit more greenhouse gases and energy transporting the waste than the value-added of the waste. The utilization of the patented modular technologies of Easy Energy Systems, Inc. allows for each individual process module to be removed and upgraded in the future to an even more modern and efficient process – should new technologies be developed.

This would be similar to how we all removed our 300 baud modems from our computers and installed 1200 baud or ethernet as the computer industry evolved. This solves the otherwise large problem of obsolescence in the emerging field of bio ‘green’ technologies for the end-user systems can be easily updated to the latest technology – like a ‘Lego ’ simply removing one module and inserting a different updated process into its place.

This solves the problem of otherwise ‘obsolete’ inefficient systems littering the landscape – which has hindered the Bioenergy arena.

Mark, please brief us about yourself, your journey in the industry, and how you have contributed to the company's success.

I am a ‘farm boy’ from southern MN, with training in physics, mathematics, and computer science from St Olaf College. When I returned to the family farm to help my brothers crop farm on

our family's 4,500-acre farm and raise hogs - I was becoming a bit bored in the Winter months. Thus, I started my company (now known as Easy Automation, Inc.) in 1986 to perform programming and design services for others.

My early endeavors included performing contract work developing innovative technologies, including systems to perfectly aerate grain, the very first field soil mapping and variable rate fertilizer systems, and technologies to automatically validate systems for testing cables on military missiles and aircraft.

Instead of continuing to just do contract development work for others

and then watching them develop largescale businesses from my inventions – I decided to focus my efforts inward on technologies that I could build and sell myself.

As I needed a feed mill on my own farm, I decided to develop and build my own. I really did not like all of the manual bookkeeping associated with such a mill, I made it capture and store all needed information automatically so that all of my reports could be generated with the touch of a button.

The early years were not easy. I remember many nights of sitting out on the floor of the feed room, weeping because things were not going as planned. Not sure what it was, but I kept on going through this tiring time. While I now have approximately 20 patents today, my early patents were related to allowing a feed mill to automatically mix the perfect combination of ingredients according to a predefined perfect model.

This removed the ‘guesswork’ from feeding groups of animals. It would do

are a company that gives everything we have to deliver the best customer service we possibly can.

I also take to heart the wise words stated by a business associate who had built up a very large successful company. I was invited to present at the annual meeting for his employees on our technology. Before I spoke, he stated – Staff, we as a company don’t sell anything. Our job is to listen to the problems of our customers and focus on helping them solve all those we can possibly help them with (even if not necessarily related to the products we sell). If we do that, our customer’s response will be to then buy from us because we brought solutions to their problems.

Can place Modules in a remote clearing with NO Natural Gas or electricity utilities needed…clean up and convert all dead trees in a remote area…then pick up and move modules.

by precisely weighing and mixing a different set of ingredients into a feed formulation for each week of an animal's life. This was done so that groups of animals could be fed perfectly to create an ideal meat-type under maximized profitability. This patented ‘Automatic Phase Feeding Technology’ enabled the company to grow very quickly, and it received the INC 500 award as one of the fastest-growing companies in the USA.

Today, Easy Automation. Inc has over 3,000 feed mill customers feeding a majority of the nation's swine and many of the nation's chickens and dairy operations. The company, in recent years, has branched into doing very large-scale fertilizer plants that are also needing extreme accuracy and automatic information storage. Easy Automation, Inc., a Welcome, MN-based company, is still 100% owned today by myself and my family with my two sons, Brady and Chris,

running most of the day-to-day operations.

I tell people the company today is not what it is because I was necessarily ‘smart’ – in actuality, I made thousands of mistakes on my journey. It is what it is today because despite making about every mistake I could possibly make in starting and growing a company, I tried my best to learn from those mistakes. Along the way, I have met some great business mentors.

My very first board member was the first engineer ever hired by Medtronic. I remember him telling me in those early years, “Don’t ever let yourself grow so quickly or become so large that you do not have time to be out with your customers.” Thus, I have taken that to heart and spend much of my time out with customers and learning first-hand what problems they have and how I might help them solve them.

Another strong value we have tried to push is integrity and empathy for our customers. When a customer is down, they don’t want to call in and get a voice mail – or be told we can’t get at it for a week. They want it solved now. Thus, we are a company that gives everything we have to deliver the best customer service we possibly can – even 365 days per year and 24 hours per day after-hours support.

These various values make up what we see to be our ‘company culture’. As the CEO, I believe my job is to be visionary, help solve difficult problems, but even more essentially, be sure the values of who we are as a company are upheld throughout everything we do.

Lastly, in the growth of Easy Automation, Inc. – I also was fortunate to have some very talented sons who literally worked beside me as young boys. They have grown up and taken over what I and their mother started and built it even further into what it is today.

This microbe, applied at 4 gallons per acre, “pulls” nitrogen and moisture from the air and releases phosphorus tied up in the ground. Research shows it can increase yields of Tomatoes, Hemp, Flowers, Cannabis by up to 40 percent! This greatly reduces need for commercial fertilizers and irrigation…Look at the difference

Being an experienced leader, share with us your opinion on what impact has the adoption of modern technologies such as AI had on the bioenergy space and what more could be expected in the future?

I have been using a ‘form’ of artificial intelligence in many of the various products I have created in the past. Back then, the term ‘Artificial Intelligence’ was not even a phrase used in the business like it is today. Instead, my philosophy was to not just have our systems ‘automate’ a process but also have it continuously capture and store every piece of actual operating information it could – all the time while the technology was operating.

This information would then be used to allow the automation system to automatically ‘tune’ and improve itself. This would be what today is called ‘Machine Learning’. I was fortunate

enough to be able to patent many of these concepts as they applied to perfectly making and mixing animal feed and now fertilizer. I believe this same concept will also prove critical in making bio-energy technology deployment successful. The reason is that oftentimes new technologies work ‘perfectly’ in the lab, yet when they are deployed into the real world, they end up being multi-million-dollar disasters. A common reason for this is that the deployed did not automatically detect ‘variations’ in the incoming waste streams, outside temperatures, PH, etc., as they changed.

I have made the focus of my bioenergy company ‘Easy Energy Systems, Inc.’ to gather all the information on feedstock and operating variation that we can and then automatically also ‘tune’ and improve itself – just like I did back when I designed the early feed mill automation systems.

While altering and ‘tuning’ its operating parameters based on changing conditions or feedstocks is half the equation – continuously capturing and storing historical operating parameters and values from all operations in a database, the capability is then there to go back and look at all of the data and have the system automatically improve its operation based on the captured historical data.

My vision is for Easy Energy Systems, Inc. to deploy thousands of its factory-built modular systems at customer sites worldwide, and have all of them continuously collect operating data, and then utilize the collection of this varied data of different feedstocks and different operating conditions worldwide back to a central network database to continually develop and improve ideal system ‘settings’ for various feedstocks and conditions for all of the customers as a group.

It is my belief that this is critical for the system to perform correctly, and the lack of this capability is why many other bioenergy technologies fail shortly after deployment in the ‘real’ world.

We can convert the green waste into a valuable soil amendment that can increase crop yields by up to 40%.

possible. So far, we have, for the most part, avoided workplace COVID-19 infections.

What would be your advice to budding entrepreneurs who aspire to venture into the bioenergy solutions market?

This modular system places billions of oxygen nano bubbles in the water. This can instantly clean up wastewater with NO expensive membranes. Notice how it can clean up entire mine tailing ponds in minutes!

It can similarly clean up large ag manure lagoons to quickly create clean water for irrigation. The reason this works is that just like distillation (which uses heat to reduce surface tension and cause product separation) the physics of nano bubbles is that the smaller and smaller you create a bubble, you also reduce surface tension but with much less energy than using heat energy. Membranes are really just fancy ‘oil filters’ that then plug up and are expensive to replace. Nano bubbles are the economical solution!

It also can be used to inject Oxygen Nano Bubbles into water consumed by animals. We are finding animals can gain additional oxygen in their blood streams than was possible via only the lungs

A test was done on 1 million chickens and death loss was reduced by 95 percent and growth increased by 20 percent. Similar results found with a test at a fish farm. This all makes sense as oxygen in air millions of years ago was at 35 percent level.

Today, the earth has a 21 percent oxygen saturation – only 21 percent! We all DIE at 19.5 percent. Thus, is it little wonder that our lungs (designed by God) for 35 percent oxygen level, with the smallest disease, cannot get our bodies enough oxygen into the blood stream. It appears that nano bubbles injected into the water that animals drink helps solve this. We are now doing research tests on Pigs.

Taking into consideration the current pandemic, what initial challenges did you face, and how did you drive your company to sustain operations while ensuring the safety of your employees at the same time?

We immediately told all employees who could, to stay and work from home. Although we needed to update

our ‘remote’ capability systems, this worked better than I had expected for the electrical, mechanical, software engineering departments. It also worked well for our many people performing phone service.

We then divided our manufacturing area into widespread sections of ‘work cells’ to keep people as far apart as

Be ‘mentally’ ready for everyone you know to call you a ‘fool’. In fact, it is interesting that in the case of my very most profitable and industry-changing inventions and technologies, the so-called ‘experts’ told me, “Don’t you know you can’t do that? It will never work.”

My problem now is that since I have been around this development ‘merry go round’ so many times – when I now hear ‘you fool’ – I actually think to myself... Great, this is going to be very profitable and world-changing!

Related to this, never give up. When discouraged, dust yourself off and keep moving forward, even though it can be incredibly ‘lonely’ at times.

How do you envision scaling EES’s operations and offerings in 2021?

I truly believe Easy Energy Systems Inc. has the patented modular technology needed to cure the problem of climate change in the world. Where needed, we have licensed cutting-edge technologies from others. I think of Easy Energy Systems Inc. as if it was the company ‘Lego’.

My patents are around its use of many different process modules, all working together in unison – much like a band conductor leads a band of many different musicians. While we ourselves have patents on various cutting edge ‘Lego Block Colors’, we need the technologies and enhancements of others (just like other

instruments in a band, to truly make the ‘music’ of solving climate change).

As an example, we can turn a dead tree that would have otherwise burned in the forest – into liquid sugar. We have patented technologies that can convert solid dry waste byproducts into readily useable liquids- without the addition of water.

We can convert the green waste into a valuable soil amendment that can increase crop yields by up to 40%. We are now testing a technology to convert seaweed into a valuable feed amendment to remove 82% of the greenhouse gases of cows. We have recently licensed the right to use a nanobubble technology to be able to instantly clean up dirty water and/or enhance animal growth.

We have licensed another technology that can sequesters 50,000 tons of carbon per year. Another technology can convert corn into a valuable product worth up to $10 per bushel of corn. Lastly, we have licensed a technology that can convert biomass into a coal additive that will allow existing coal-fired power plants to keep operating and still meet the Paris accords.

While the last five years have been a tough political and investor climate for green energy companies such as us, we are now feeling a renewed invigoration for our products.

In preparation for the massive onslaught of opportunities we are feeling, I am in the process of completing a reverse merger so we can become a full publicly traded company for those who are interested in helping us on our journey can participate financially. With this, we then expect to bring in 400 people to ramp up the manufacturing activities of our factory-built modular systems.

Over the years, Easy Energy Systems has received various awards, including:

Technology Leader of the Year Award for the State Of MN

Inc 500 award as one of the 500 fastest-growing companies in the USA

Numerous US Ag Engineering Awards for various developed technologies.

One of 4 ‘Top Small Business Leaders in the Nation’ as awarded by the US Congress

Asked to testify on our technology at the White House

Asked to testify on our technology at the US Congress

The software I designed was what stopped the mad cow disease a number of years ago in only 24 hours.

Recipient of the ‘Fire Starter Award’ as one of the ‘Top 12 Most World-Changing Ideas on the Planet’, as selected by 4,000 scientists. (Interestingly, a company called "Tesla" received the award only once year before we did.)

A photo of Mark Gaalswyk, Founder and CEO explaining the EES modular technology:

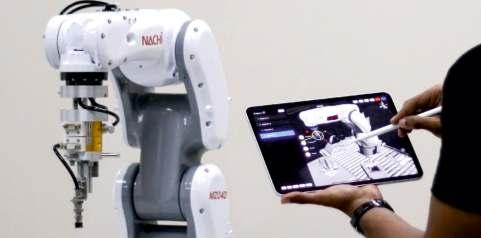

Robotization of manufacturing operations is the next step towards industrial revolution. Robots can operate heavy or complex tasks, small chores, and risky operations according to your commands with the press of a button. The prospects of this idea would interest many, but then reality will hit, and one may ask, “Is this really possible using today's technology?”

For robots to function autonomously or even perform smaller tasks, thousands or even more complicated code lines need to be developed. In such circumstances, it is more likely that people opinionate that robotics-based automation is a complicated road to walk on. Though this is the case, robotic automation can transform every industry and take production scales to the next level.

Several big and small corporations have already started employing robots to automate their daily operations. The difficulty arises when there is a need to upgrade robots’ software to meet the updated hardware requirements. The re-coding of such upgrades could take days or months to complete. During which the work could get strangled or slowed down. Solving these challenges is the Augmentus Pte Ltd.

The idea of Augmentus came to Daryl Lim You Quan (Co-founder ) and his co-founder colleagues from their personal experiences and pain points. Before Augmentus, they led teams to develop robotics solutions for multinational companies. They had to invest incalculable hours in programming and integrating different robots and equipment deployed for commercial projects. It encouraged them to build an intuitive, graphical robotics platform that simplifies and unifies the development and operation of industrial robots.

Augmentus is an AI-robotics software company. It offers the first fully autonomous digital twin creation and robot motion planning system. The platform's simplicity enables even non-technical users to program industrial robots in minutes instead of months.

The platform's intuitive graphical interface and proprietary technology eliminates the need for coding and CAD files in robot teaching. Users can 3D scan their work cells, plot robot waypoints, or select from a library of templates. And, Augmentus's software promises to generate the most optimized robot paths while checking for singularity, reachability, and collision avoidance.

Over the years, the company has formed partnerships with the world's leading robot manufacturers and automation providers to empower manufacturers to recoup ROI faster by lowering the time, cost, and skill barriers in industrial automation. Its clients have already experienced a 70% cost reduction and a 10x increase in deployment times across a wide variety of industrial applications.

Solving the Challenges of Industrial Robotics Programming robots to perform specific tasks requires massive amounts of code and programmers with very specific, in-demand skill sets. With the severe difficulty and heavy fragmentation present in conventional robot programming, different robot manufacturers require the use their respective proprietary languages and require high coding expertise.

As the existing automation processes require system integrators to develop custom solutions due to the fragmented modules, there is 75% of the lifetime costs of each robot being software and programming related. This problem is further exacerbated in high-mix workflows where the component part or process changes frequently, requiring repeated robot reprogramming and teaching.

In order to solve this perennial problem, the use of AI and smart automation is crucial and intelligence in automation solutions is needed to dynamically adjust to rapid changes in production processes and part to part variation. “We use such technologies in our platform where the system is able to quickly adapt to changes in parts and processes through 3D scanning while our proprietary technologies around auto-calibration and auto-path generation instantaneously

generates robot programming without the need for technical expertise,” says Daryl.

COVID-19 presented several key challenges for the Augmentus team. Daryl expresses, “As a robotics company, we needed to do site demos and integrations. Safe distancing restrictions have increased our lead times. To ensure the safety of our employees, we have converted 80% of our demos and integrations to virtual, drastically reducing the risk of contagion. ”

The future of automation will be more focused on flexibility and collaboration. There has been an increasing trend towards soft automation, with more SMEs and MNCs having high-mix workflows that require automation. Such changes in processes have always been a shortcoming of conventional automation that is more suited to low-mix, high-volume operations. When we asked Daryl about the

Augmentus is an AI-robotics platform used by the world's leading robotics and advanced manufacturing companies.

Daryl Lim You Quan Co-founder Augmentus Pte Ltd.

automation industry's post-pandemic future, he answered, “With advances in technologies around AI and robotics, a new paradigm shift in automation is likely to ensue in the coming years, enabling the mass adoption of robotics and automation globally ”

Working in the robotics industry for years, Daryl has personally conquered so many challenges that occurred while making robots. When asked about what advice he would like to give to aspirants in the robotics industry, he puts, “The most important thing for budding entrepreneurs is to deeply understand and empathize with their target audience. This will allow your team to identify a niche and build a go-to-market strategy around that niche. ”

“There are many problems around the world, and with limited resources and time, it is important to be focused and have a clear direction, ” concludes Daryl

Plans of Expansion for 2022 and Beyond

Augmentus has wide-ranging plans for scaling its operations in different parts of the world, commenting on the progress of expanding its reach in coming years. Daryl said, “We have scaled beyond Singapore and have begun deploying in countries such as Germany, Denmark, Japan, and the USA ”

“We are doubling down on global expansions in 2022 with remote teams to support the increasing demand for easy and rapid automation, ” he concluded.

Daryl Lim You Quan is the Co-founder of Augmentus, and together with his co-founders, Yong Shin, and Voon Foo, he has built the company to become one of the leading players in the robo�cs so�ware space.

Daryl is a radical opportunist who is always on the lookout for thought-provoking talks and prac�cal skills that will help him broaden his cogni�ve awareness. By pu�ng himself at the vanguard of the fourth industrial revolu�on, he hopes to create a sustainable future that is interes�ng and mo�va�ng for the next genera�on.

Winner of IEEE STARS Award 2021

Winner of IMDA Techblazer Award 2021.

Winner of Corporate Innova�on Challenges Such As: Fujitsu Accelerator Programme Hyundai & Kia's Accelerate the Future Challenge

The A*STAR Advanced Manufacturing startup challenge.

What do you think the world will look like in 10 years? Imagine what changes would come in people's lives? And how will these changes transform the world?

To answer these questions, one will have to look at how things have changed in the past ten years. Anyone can easily tell that so many transformations have taken place across the globe. Today's changes are brought about by the tech industry and businesses working together. It has resulted in a revolutionary shift in the way the world works.

It can be said that technology will play a major role in the future too. Depending on the technological innovations, businesses will rewrite the way things work in the world in the coming decade. The last decade was more about businesses getting their hands on various technology solutions for enhancing their operations. This decade, starting from the year 2020, is more about merging technological advancement with machines to bring automation into the industrial arena.

Many corporations have been pushing for automation in their everyday operations since the start of the COVID-19 pandemic. The reasons for this drive are numerous.

Increased competition, meeting supply demands, speeding up operations, reducing human errors, safety, etc., are some of the main reasons for enterprises to opt for automation.

Based on the type of business, the automation trends are shaping up industry and the most prominent automation trends are listed below.

The year 2022 has emerged as one of the most significant years for cloud computing platforms. A recent study conducted by the Infosys Knowledge Institute of 1000 hightech and manufacturing companies observed that the core shift has taken place in manufacturing strategy during the past year.

Businesses have rapidly started adopting cloud computing technology as a key strategy for the way forward. It is projected by experts that the future of cloud networks and embedded systems will be interlinked in the coming years. There will be a significant increase in efficiency, mobility, business productivity, and capability because of cloud computing.

Artificial Intelligence (AI)

Making the most out of data is the goal of every company these days. Artificial intelligence (AI) technology can improve human understanding of unstructured data in better ways. AI is helping manufacturers recognize the trends in industrial data.

This data can be used further by professionals to make datadriven manufacturing decisions. AI is helping companies with better inventory management, supply chain visibility, asset tracking, accuracy, etc.

Machine learning, or ML, is a subset of AI. It is an algorithmic framework that learns automatically from experience. Businesses are looking to incorporate ML into their manufacturing process so that high-scale production can be achieved with speed. Also, ML would prove to be

more efficient in reducing human errors in the manufacturing process.

The Internet of Things (IoT) is one more technology that has caught the interest of industrialists across the manufacturing industries. It helps manufacturers connect and monitor different components of their operations. The combined power is helping industries generate valuable data insights that can be used to upgrade, optimize, and enhance every area of their production process.

Effective management of the supply chain is one of the most important aspects for businesses. During the last two years, many businesses introduced different technologies to their supply chain management. It enabled them to automate many processes while saving costs as well as delivering goods to the people as per their deadlines.

With the help of advanced technology, processes like procurement, inventory management, assembling products, logistics, transportation, and sales are all being automated.

The inclusion of robots in various sizes and shapes can help manufacturers to speed up production. They can also work better where human workers do not have access due to the risks involved.

With time, robots are becoming more helpful in raising the standards of production. Robots are enabling companies to automate the key areas of manufacturing. Moreover, they are built in such a way that they can be used for collaborative work with the human workforce.

3D printing, or additive manufacturing, can now build parts and products layer upon layer with the help of computeraided design (CAD) software. Along with this, 3D printing is also helping in producing prototypes, models, lost-waxcastings, or specific delicate components of the final finished products.

Additive printing is one of the most popular trends in the manufacturing industry as it can significantly save time and money.

Working together, robots and humans can get things safely done in much faster and more efficient ways. Traditional product picking and shifting from one place to another place wastes a lot of time. With the help of automated smart robots, this issue can be solved. As robots are being built to

be capable of handling companies' logistics operations, they can smartly pick the products and assemble them at the desired locations.

Usage of Drones Manufacturing factories are generally spread over larger areas and buildings. The ground robots cannot be used to shift the material as there are so many chances of interference. To tackle this issue, drones can be more effective. Drones can help industries move their materials or products from one location to another in minutes.

Also, drones are currently being commercially used for delivering products to customers' doorsteps. And with time, they can become more useful for industries to automate their operations efficiently.

The popularity of Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR) technology are rising in different industries. They support professionals to access the complex manufacturing process more closely by providing a virtual or mixed reality environment.

Also, these technologies give corporations the ability to pre-plan every process in detail. One can walk through every minute factor using AR/VR/MR technologies so that everything goes smoothly at the time of the actual manufacturing process. AR, VR, and MR will play a significant role in helping industries on their automation journey in the coming years.

All in all, it can be said that various advanced automation tools have started to emerge since the beginning of this decade. However, the automation trends mentioned above are just entering industries on a broad scale, and they have a long way to go.

It will be interesting to see how these technology tools collaborate with the human workforce in the coming years to bring efficiency to industrial operations. In the end, all these technologies were developed by humans, and they are expected to empower people to achieve new milestones.

- Vishal Golekar

Technology has emerged as a blessing, making our life easier and simple, and robotics is one of the significant examples. Even during the pandemic, robotics and automation has provided excellent results in every field whether it is healthcare, education, or logistics.

One prominent European leader in the robotics space is Axyn Robotique , promoting the concept of 'Robotics for Human' .

In the following interview, Frank Anjeaux the Founder and CEO sheds light on the company's journey, the current industry scenario, and his vision for the company's future.

Please brief our audience about Axyn Robotique, its USPs, and how it is currently positioned as a leading provider of automation solutions. Axyn Robotique is a French-based start-up created around the project of proposing innovative robotic solutions to the many. The whole DNA of the company is written around the objective of creating real usage value rather than sophisticated but purposeless technical objects.

We have therefore designed our products only after in-depth consultation with real players in various fields such as Education, Health, or Industry 4.0 sectors. Axyn is today one of the prominent European leaders in telepresence robots. We intend to reach very soon a similar position in the intelligent logistic robots offering.

Tell us more about the products and services through which you have ascertained your stronghold within the automation space.

Today we offer to the European market two main types of robotic solutions:

One of Axyn's strongholds in the automation market today is the capacity to merge both its strong points such as telepresence and autonomous robot into one single combined solution.

1-The Ubbo Range of telepresence robots (Ubbo Maker, Ubbo Expert, and Edmo) and 2-The Lobo Range of autonomous logistic devices.

All these products are entirely designed and manufactured at Axyn's premises near Aix-en-Provence in the South of France. They all have in common their high versatility. As a matter of fact, we take the benefits of our fully modular robot base to custom-build a version for each specific application.

This is how we have developed Edmo to meet specific needs around the education sector in conjunction with the French Ministry of Education. A version of Ubbo Expert was developed to meet the need of the fast-growing Industry 4.0 has been elaborated with Capgemini or another one was proposed to meet the specific need in senior houses and various players of the silver economy.

There are as of date over 800 robots in action in those various fields. One of our strongholds on the automation market today is the capacity of Axyn to merge both our strong points such as

telepresence and autonomous robot into one single combined solution that offers a unique ability to create unprecedented usage value in several different applications.

Being an experienced leader, share your opinion on why the adoption of technologies such as AI and machine learning is necessary for the automation services industry and how you have leveraged these technologies to deliver your products/services/solutions?

The adoption of AI and machine learning technologies is not a necessity, at least today. Several manufacturing processes and industries fundamentally do not need artificial intelligence. It is therefore essential for the success of this transition not to go overboard in wanting to switch to all ‘AI’.

On the other hand, its paced and careful introduction can revolutionize the industrial world as it is today. The important factors on which it is necessary to impact are the arduousness of human work and the cost of labor. AI with robotics can go a long way to improving this.

Today, the low cost of labor has allowed countries like China to develop tremendously, becoming in a few decades' major world economic players. This has not been without causing significant ecological problems, a considerable reduction in the industrial activity in Europe and North America, and therefore economic dependence vis-à-vis these same countries.

Artificial intelligence coupled with mechatronic devices such as robots allows and will increasingly allow the performance of automatic tasks. This automation will lead to considerable reductions in labor costs.

But this transition must be made in a thoughtful way by focusing on tasks that have a significant ROI and those that have no real added value, such as repetitive, daunting, and/or dangerous tasks. It is indeed necessary to consider the human side.

The use of artificial intelligence and automation should not have the objective of replacing man but of relieving him in his daily life. Otherwise, the use of AI could cause more problems than it solves, such as unemployment.

If these considerations are considered, artificial intelligence will revolutionize the global industry. For example, it will be possible for a small company to acquire a multi-tasking industrial system capable of carrying out in-situ what today requires several processes carried out by several

manufacturers and hence further reduce costs.

It will thus be possible to produce industrial products as easily as prototypes. The number of parts to be manufactured can then be less impacting on their unit price.

Considering the COVID-19 pandemic, what challenges did you face, and how are you currently driving your company to sustain operations while ensuring the safety of your employees?

COVID-19 is at the same time an opportunity and a challenge for us. It is an opportunity in the way that it has stressed the need for efficient long-distance communication media actively helping to maintain social and professional links and interaction without physical presence.

Our telepresence robots are currently helping many patients to connect with their distant families and many distant workers to interact with their distant companies and colleagues. As far as internal organization is concerned, although we remain a relatively small-scale company COVID has been a challenge.

We have implemented all regulatory safety measures (and beyond) and did not experience a significant impact on our production flow. Some of our components and parts have suffered delays in deliveries but not to the extent of significantly impacting the production cycle.

It must be pointed out that we have received large and very helpful support from both public and private sector partners/vendors that have greatly helped Axyn in those difficult periods.

What would be your advice to budding entrepreneurs who aspire to venture into the automation solutions niche?

The crucial point is not to neglect the industrialization phase. With today's tools such as 3D printers, easily programmable and inexpensive electronic boards, it has become very easy to go from an idea to a working prototype.

This has allowed many innovative solutions to emerging and has helped the creation of many startups. This ease of implementation has nevertheless had a negative effect on some entrepreneurs who believe that, if their system works, it is then enough to sell it.

However, industrialization, which is the intermediate stage between the two phases (creation and market introduction),

is essential for the success of the project. It optimizes the product to allow profitable manufacturing in greater or lesser quantities.

This can generate tooling and manufacturing costs that must be considered in the ROI. Besides that, there is the normative aspect that should not be overlooked, especially in automation. The safety of people, the materials used, the actual usages are factors to be considered for the success of the project.

How do you envision scaling your company's operations and offerings in 2022?

The year 2022 will be a scale changer for Axyn. The Lobo range of autonomous robots will enter its first full production year with a serial version to be released in the market.

Several large projects that were maturing in 2020 and 2021 with prestigious partners such as Orange (French Telecom operator), Capgemini, Schneider Electric, and several others will reach their full potential in this coming year. This will lead to a significant increase in both volumes of production and obliviously turn-over.

In the Health sector:

The direct testimony of Dr. Pascal Meyer, Anesthetist Physician at Forcilles Hospital (Cognacq-Jay Foundation):

“We used the Ubbo robot in the post-intensive care rehabilitation unit during confinement when family visits were prohibited. Our patients are people with a tracheostomy. Most have a physical disability that does not allow them to hold a smartphone. We have allowed many people to see their loved ones and have expanded the possibilities of visitation. A videoconference was made over 3500 kilometers. This visit would never have happened without the robot. It has many advantages:

For family and caregivers, it is easy to use. The family opens an account on the AXYN website. The procedure is very simple. The role of caregivers is limited to turning on the robot and bringing it to the patient's room. Videoconferencing does not generate an additional workload that would affect other activities.

- Second: The practical aspect of communication. Indeed, the head of the robot is placed at a suitable height for a bedridden person or in an armchair. So that the sick person does not have to make the effort of turning his head to direct his sight. The robot's head is mobile, controlled by the pilot, in our case, the family. It is much more practical than fixed head solutions that require human intervention to control the screen.”

In the industry sector: Feedback from Virginie Rigaudeau, Hub Manager at Schneider Electric (France):

“We use the Ubbo robot for formal or informal interaction between distant users and factory team members on a regular basis in many different locations within the factory. It can be internal users, distant customers. They can enjoy a truly immersive interaction with the personnel on-site.”

“We really have the feeling that the distant user is with us. A real nice and simple solution for an actual interaction between the local team and distant users.”

Evidently, the digital transformation has opened the doors to numerous opportunities and possibilities for various sectors, and the logistic industry has not been devoid of these digital changes. Today, the inefficiencies in the processes have been reduced, more packages are being delivered, production has become costeffective, and whatnot.

All these changes come down to where all the goods are stored. And thus, driving digitization in the warehouse becomes of utmost importance. If the question arises, how can it be implemented, doks.innovation has got all the answers.

doks.innovation is breaking new grounds in warehouse management with inventiveness and pioneering spirit.

We at Insights Success caught up with Mike Becker, the Co-founder and Senior Software Developer, and Christian Sproedt, the Strategic Sales Manager, to learn more about doks.innovation..

Below are the highlights of the interview:

Please brief our audience about your company, its USPs, and how it is currently positioned as a leading provider of automation solutions. doks.innovation GmbH was Founded in 2017 located in the central EU (Kassel, Germany). In doks, about 30 employees are working in two central product lines (Inventory and Summary).

We build and provide autonomous solutions for intralogistics. Yearning to digitize the world of logistics, it aspires to contribute to the growing Industry 4.0. The world of logistics is constantly facing new challenges. Our products are strived to solve these challenges and

revolutionize the world of logistics. The products aim to drive the supply chain efficiently with autonomous technologies, decrease expenses, and increase safety in warehouses.

Tell us more about the products and services through which you have ascertained your stronghold within the automation space.

In doks, there are two product lines - inventory and summary

Inventory XL:

Autonomous inventory management system within a warehouse (pallet rack) consisting of an AMR (autonomous mobile robot) and a drone. The drone and the AMR relate to a powerline to provide five hours operation time of the system. The only element which needs to be put as fixed infrastructure is the charging station.

Summary Sky:

Outside drone and software system for inventory management of block storage or overview of large storage areas (empties). With the help of drone images and artificial intelligence different types of crates can be recognized and counted.

Summary Gate:

The gate creates all necessary documentation and damage detection of an object moving through the gate. It provides all the solutions to Inbound and Outbound control, a sensor system for automated damage detection, loading scans, incoming goods inspections, conveyor systems plausibility, and completeness check.

Summary Ceiling: Optical inventory system for block storage in indoor warehouses. Multiple battery-powered camera modules are

Christian Sproedt Strategic Sales Manager

Christian Sproedt Strategic Sales Manager

We take your logistics to the next level and prepare your company for the challenges of a digitized future.

attached under the ceiling to create a top view of the warehouse. With the help of images and artificial intelligence different types of crates can be recognized and counted.

Brief us about the featured person(s), their journey in the industry, and how they have contributed towards the company's success.

Mike Becker: I am the Co-founder of doks with 8 years of experience in the drone industries mainly involved in Software and Hardware. I am leading the software team to create the best solution for autonomous inventory management on the market.

Christian Sproedt: I am Christian Sproedt, have been in the logistics industry for 10 years. Master of Technical Logistics and hold positions in project planning and purchasing, last position is head of contract logistics at consulting company.

I am totally convinced that logistics must be more open to new technologies and autonomous solutions. Logistics service providers not doing this will vanish from the market.

Being an experienced leader, share your opinion on why the adoption of technologies such as AI and machine learning is necessary for the automation services industry and how you have leveraged these technologies to deliver your products/services/solutions?

It is getting tougher and tougher to get staff to do many jobs, especially in the logistics industry. With AI and machine learning many tasks can be automated and the staff

can focus on more valuable tasks. Especially the stocktaking process is a non-valuable task, which must be done. Automize these tasks leave the staff more room to add value to the company.

Considering the COVID-19 pandemic, what challenges did you face, and how are you currently driving your company to sustain operations while ensuring the safety of your employees?

COVID was and is challenging as the option for testing at warehouses and presenting our products are mainly reduced. Therefore, the development of new features was slowed down as the testing time was reduced.

On the other hand, it is a great opportunity to show and prove that automated and autonomous solutions have a huge benefit – as no one must attend. Overall, we would say the autonomous concepts become more accepted during the pandemic phase.

What would be your advice to budding entrepreneurs who aspire to venture into the automation solutions niche?

Find a process to automate and just try it. There is always room to improve processes.

How do you envision scaling your company's operations and offerings in 2022?

Currently, focus on nearby customers with a focus on Central EU and the UK to have a high level of support and end of 2022 add Scandinavia and the first oversea regions. Central for us is that we can offer a product that does not need daily service or support but can operate the whole year with only a yearly check-up.

Inventory management by flexible drone is starting to gather serious weight as a workable concept and will scale up with each positive comment of customers using it on a regular basis.Of course, there will be also a new feature, which is in development. For example, we plan to detect rack damages with the systems and do box counting.

One of the famous buzzwords of the century is Automation. Machines are doing more and more tasks as work grows. Workers become more estranged from one another and alienated from their laborwhether it is factory robots assembling vehicles or algorithms that detect ailments and find you the cutest cat pictures on the Internet.

It is easy to understand how this could put workers at risk; ththe 20 century is littered with examples of humans losing their employment to faster, more efficient robots. What is less evident is the potential this gives for the left to use technology to the advantage of the world.

While Automation has advanced at breakneck speed in recent years, it does not appear to be slowing down. As we automate more corporate activities, we are approaching an intriguing long-term paradox: despite a century of developing machines to do our work for us, the number of individuals with jobs has continually increased over the past 125 years. And that is beneficial for business as well as the human workers.

RPA (Robotic Process Automation) enables businesses to disrupt their sectors by surpassing the competition and investing in innovation. Organizations should instead focus their emphasis on harnessing their in-house human expertise to develop answers. That will enable them to rise to market leadership by outsourcing the tedious, repetitive, but necessary admin-type chores to bots.

This form of disruption is beneficial to the economy as a whole. It will produce new types of labour that we have yet to envision replacing the old jobs that have been displaced by technological development. Automation savings will be invested in more research and development to generate new goods and services, resulting in more job opportunities overall.

The introduction of ATMs is a good example of this. Automatic Teller Machines (ATMs) were first launched 45 years ago with the intention of replacing human bank tellers. But, as we all know, it did not happen. Instead, ATMs made it less expensive for banks to open new branches, which they did, and the count of bank tellers in the US has increased from 2000 to 2010.

In dystopian films like Terminator, pessimistic predictions about what the future of labor automation could mean for humanity come to fruition. Beyond that, there is a widely held but incorrect belief that widespread Automation will supplant human workers.

However, such predictions are unlikely to come true. Because Automation's future depends on its ability to blend with how humans work, Automation will increasingly be used to assist people in working smarter rather than harder. It will automate the boring, repetitive, and tiresome tasks that humans today perform, allowing workers to focus on higher-level tasks involving creativity, interpretation, and empathy.

Humans still have the upper hand when it comes to human contact, or ‘soft skills’, as they are now known. Active listening, speaking, critical thinking, reading comprehension, and monitoring are the top five most indemand job abilities in Canada from 2019 to 2022, according to a recent analysis from the Royal Bank of Canada (RBC) titled ‘Humans Wanted’.

Humans are still more reliable and efficient than technology when it comes to these critical labor skills. Maintaining and strengthening your abilities in these fundamental areas will serve you well even if you change industries halfway through your career.

Employee retraining or ‘reskilling’ is not only more costeffective for employers but also promotes employees' long-

term personal development. Looking ahead a few years, education will become even more important than today. As technology advances, the existing labour must continually reinvent themselves, ‘reskilling’ on the job to learn new systems.

Younger generations must learn legacy systems as well as to adapt to evolving technologies as the older generation departs. Job-hopping is becoming increasingly popular, so any programme that promotes employee training, personal growth, and education will provide employees with another reason to stay.

The left will have to grapple with the reality of Automation, which is something that the entire globe is grappling with. Workers around the world are facing a few troubles in adapting, but there is a bright side to working along with Automation.

Automation isn't on its way; it's already here. There is a future in which everyone benefits from the fruits of mechanized labor. To bring about this better world, the left must provide a vision of the future that we desire.

We need to plan for that future. Our legislators must ensure that everyone shares equally in the reward. A better world is possible, and it is only around the corner, but we must all act if we want to enjoy it.

- Rahul Thakar

There were the days when industrialization was a synonym of textile industry only, and the artisans were the industrial workers. But the industrial revolution invented power looms, and the juggernaut of automation began its journey. Back-to-back industrial revolutions transformed the medieval world into the modern age. The first three of them, i.e., the steam engine, age of science, and mass production, accelerated the worldsaving human efforts, costs, and money.

However, the juggernaut of automation kept traveling, and today, it has reached the station, where the globe is digital –the fourth industrial revolution. Human efforts were first replaced by animals, animals replaced by machines, and to control these machines, robots arrived. Today, these robots are deployed in every sector, especially to perform repetitive tasks. These robots can move in six degrees of freedom and operate in X, Y, and Z planes.

In this fast-paced world, time is money, and these robots help to save time by performing repetitive tasks. However, they follow the path which is inscribed by the software programs. Looking at the growing market, many companies started to provide software to automate robotic movements. Fizyr is one such company that offers a standardized software product, based on artificial intelligence, that allows robots to cope with high variation of objects in automated picking and placing applications.

In our quest for ‘ 10 Most Disruptive Automation Companies to Watch ’, Mr. Herbert Ten Have, CEO of Fizyr, shared his endeavor with us. He elaborated on the company's work culture and the future aspects. Following are the details of the interview:

Please brief our audience about Fizyr, its USPs, and how it is currently positioned as a leading provider of automation solutions.

Fizyr designs, builds, and installs a standardized computervision software that detects unknown objects varying in shape, size, colour, material or stacking. Its robust algorithms provide over 100 applicable grasp poses each second, including classification to handle objects differently, while performing quality controls. Just as the camera and gripper are the eyes and arms of a robot, the vision software is the brain that analyzes the image and directs the robot to move accordingly. Fizyr is trusted as a strategic partner by global leading integrators, thanks to its fully scalable and proven software-only product, for which we provide full insight and control to install, manage, update and support. We empower system integrators to build cutting-edge solutions for the industry’s end users, in multiple high-demand industries, such as e-commerce, micro-fulfilment, parcel handling and more.

Fizyr’s CEO, Herbert Ten Have, joined Fizyr (previously called Delft Robotics) in January 2017. Delft Robotics started as a robotics integrator. Within a month of Herbert’s arrival, the company won the prestigious Amazon Picking Challenge. This led to the company pivoting towards a deep-learning computer vision software-only product and re-branding to Fizyr. Herbert is an innovative business leader with more than three decades of experience in building high-tech products and services.

Thanks to his expertise and knowledge of the industry, he geared the brilliant Delft Robotics team towards success, thus, leading to an unprecedented impact on the automation industry. He proactively engaged the company in recognizing industry problems and solving them while staying committed to building the best vision software product and provide cutting-edge robotic picking solutions for the logistics industry.

Tell us more about the products and services through which you have ascertained your stronghold within the automation space.

In such a rapidly growing market, logistics companies expect robots to perform their tasks as predicted and agreed. Applying Fizyr’s product is a strategic choice for which we provide full insight and control to install, manage, update and support. We license a standardized product for automated picking, placing, and stacking to system integrators and end users. Our computer-vision software is trained with a unique dataset with millions of images of challenging logistics environments, proposing the best possible grasp poses. Applied in production all over the world, it empowers the robotic automation of leading system integrators and end users, in online retail, warehousing and parcel services. Fizyr’s software is also hardware agnostic, giving clients the freedom to choose the best camera, robot, and gripper for their automated picking cell. We believe in the value of Fizyr’s independency and want our clients to be able to use open standards and choose their hardware to assemble the best possible picking cells.

Although the company purely focuses on software, Fizyr also licenses the designs to modify, 3D print, and assemble its proprietary gripper. This gripper can handle challenging situations, ensuring ease in integration with any robot in a picking cell.

Being an experienced leader, share your opinion on why the adoption of technologies such as AI and machine learning is necessary for the automation services industry and how you have leveraged these technologies to deliver your products/services/solutions?

The items and parcels tend to have a huge variation in terms of sizes, materials, colors, and placement, which traditional logistics systems cannot account for. In e-commerce, there are millions of SKUs (Stock Keeping Units), thousands of which cannot be programmed. Therefore, the adoption of technologies such as AI and deep learning has the potential to change the face of the industry.

Fizyr’s neural network is trained to classify an object, strategize the pressure required to pick it, and propose the best possible grasp poses to singulate it from bulk. One of the initial projects managed by Fizyr in 2017 involved enabling robots to work 24/7 and fold up to 720 towels per hour with Laundry Robotics. Fizyr’s computer vision algorithms were able to propose over 100 grasp poses each second on unknown objects.

Considering the COVID-19 pandemic, what challenges did you face, and how are you currently driving Fizyr to sustain operations while ensuring the safety of your employees?

One of the major challenges faced by the company was the termination of a project by an Italy-based client due to the dire consequences at the start of the pandemic. Consequently, other clients hesitated to continue project operations as they required hardware components, such as cameras, grippers, robots, etc., to conduct research and development. The first few months were uncertain, and later, several clients saw the opportunity for growth in in ecommerce, micro-fulfilment and parcel handling.

Those clients motivated Fizyr to scale up its processes even faster and offer robotic solutions to the dynamic industry. Meanwhile, the Fizyr team was working from home and would only work from the office if absolutely necessary. At that time, the huge office space in the pandemic was reserved for specific purposes. With the restrictions easing down in the Netherlands and the high vaccination rate, people are moving back to the office on a flexible basis.

What would be your advice to budding entrepreneurs who aspire to venture into the automation solutions niche?

Herbert highlights the importance of validating assumptions, pushing the product to the market, and creating value

for the clients in the quickest way possible. The quicker the entrepreneurs identify opportunities, the better they get to approach the clients in an early phase and acquire the market before facing any consequences later. Understanding the requirements of the clients from the beginning can stimulate company growth, improve partnerships, and help build relations with potential clients.

How do you envision scaling Fizyr’s operations and offerings in 2021?

The fast growth of e-commerce and parcel handling has exacerbated the human labor shortage, which is expected to keep rising. As a response, an increasing number of companies have started to adopt robotic automation and implement solutions for automating picking and placing applications both in e-fulfilment and parcel handling. We believe we have solved one of the biggest challenges in logistics and we hope to empower as many integrators and end users worldwide as possible, in an effort to relieve the pressures of the industry. The product and market are ready, so we plan to scale exponentially in the upcoming years, reflecting such a rapid growth.

Fizyr remains dedicated to training, upskilling, and helping employees thrive in the fast-moving industry of AI and logistics. The company aims to focus on predictable and scalable processes to resolve challenging situations and contribute to the industry.