Evaluation

The

58

Evaluation

The

58

Corrosion can cause serious issues. Preventing corrosion, and protecting products, surfaces and structures from the damage it can cause is easy – but only if you know the right combination of coatings to choose. That’s where we come in. Interpon Redox takes the complicated science and makes it simple. It comprises a portfolio of tough and durable multi-layer powder systems to suit the widest range of substrates and applications, while our simple ‘System Finder’ helps you find the perfect combination for your particular project and deliver the ultimate corrosion protection. With thousands of colors to choose from, and the largest range of Ready to Ship products available, we’ve got the winning formula of colors, textures and finishes to ensure you remain unbeatable. Interpon. Your personal best.

All of the products within the Interpon Redox range are designed to be highly durable, delivering superior longevity for C4/5 environments compared to other coating solutions. Efficiency is also key: our products are easy to select – our guide is based on ISO 12944:2018 corrosivity categories – and similar easy to apply, with shorter curing times to enable projects to be completed on time, every time.

Powder Coatings by AkzoNobel

Powder Coatings by AkzoNobel

+39 0383 43345 - voghera@donelli.it

CX Plant - Via Francesco Somma, 32, 20012 Cuggiono (MI) +39 02 97240792 - cx@donelli.it

MXP Plant - Via Quarto, 48, 21010 Ferno (VA)

+39 0331 879174 - mxp@donelli.it Ravenna Plant - Via del Bragozzo, 7, 48122 Ravenna (RA)

+39 0544 436438 - eos@donelli.it

Wehaveworkedhardtoensureaunitarycustomer experience developing the “Donelli identity”. This is what you find in all 5 plants...

Alessia Venturi Editor-in-chief

Alessia Venturi Editor-in-chief

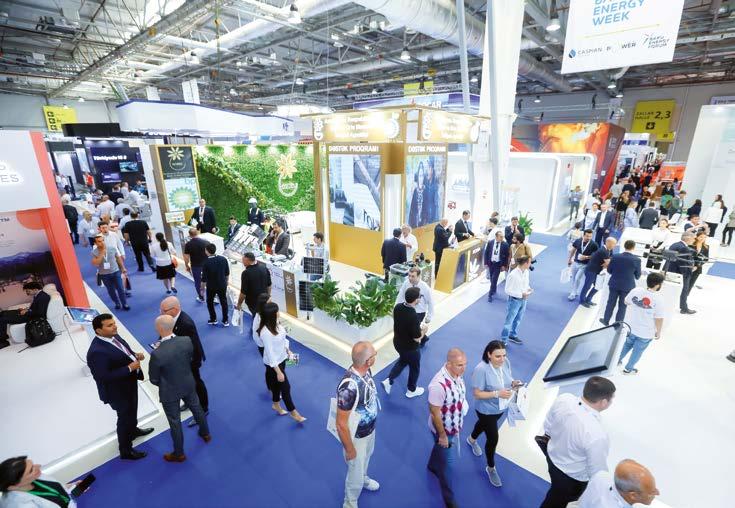

The energy sector is undergoing a profound transformation: traditional energy sources will continue to grow in the coming years despite their volatile price environment and the increasing market share gained by renewables. That is demonstrated by the launch of new investment projects worldwide, first of all in the Americas but also in the Middle East and Asia. According to Roland Berger’s report on Perspectives and strategic options for the operators of the Oil & Gas industrial valve sector1 – presented at the Valve Industry Think Tank 2023, an event that is a prelude to the fifth edition of the Industrial Valve Summit, to be held in Bergamo (Italy) on 15 and 16 May – in the two-year period 2023-2024, investments in new Oil & Gas plants are expected to grow by 16% over 2022, when the global situation stabilised after the rebound in 2021 from the significant contraction recorded in 2020.

control solutions, which is currently enjoying excellent development prospects in light of growing investment. Europe – with a focus on Italy, the leading country with a market share of over 30% – is the strongest continent in the production and export of industrial valves.

As strategic safety components of industrial power generation plants, where they ensure efficient and safe flows, these valves must undergo rigorous corrosion protection cycles to withstand exposure to aggressive environments, harsh operating conditions, and corrosive agents.

This April issue of Corrosion Protection includes a focus on innovations, studies, and successful application cases of corrosion prevention and protection technologies in the Oil & Gas sector and especially in the industrial valve sector, as this international magazine will once again be a media partner of Italy’s IVS - Industrial Valve Summit.

On the other hand, liquefied natural gas (LNG) is expected to face a general decline in investment. In contrast, global demand for hydrogen is growing: by 2030, announced green hydrogen projects worldwide are expected to reach a capacity of around 450 GW. Europe is going to be at the forefront of this global development in terms of both number of projects (468 compared to 60 in South America, the second in the ranking) and capacity (151 GW compared to 76 GW in North America). Nuclear power is also on the rise: currently, 58 reactors are under construction worldwide.

Uniting all these areas of the energy industry is the sector of industrial valves and flow

1 https://theenergyrepublic.com/ivs-summit-plays-central-role-inoil-gas-sector-bringing-together-delegations-across-the-world-lucapandolfi/

This April issue of Corrosion Protection includes a focus on innovations, studies, and successful application cases of corrosion prevention and protection technologies in the Oil & Gas sector and especially in the industrial valve sector, as this international magazine will once again be a media partner of Italy’s IVS - Industrial Valve Summit, the most important international event for industrial valve technologies and flow control solutions, an unmissable meeting point for the entire global supply chain.

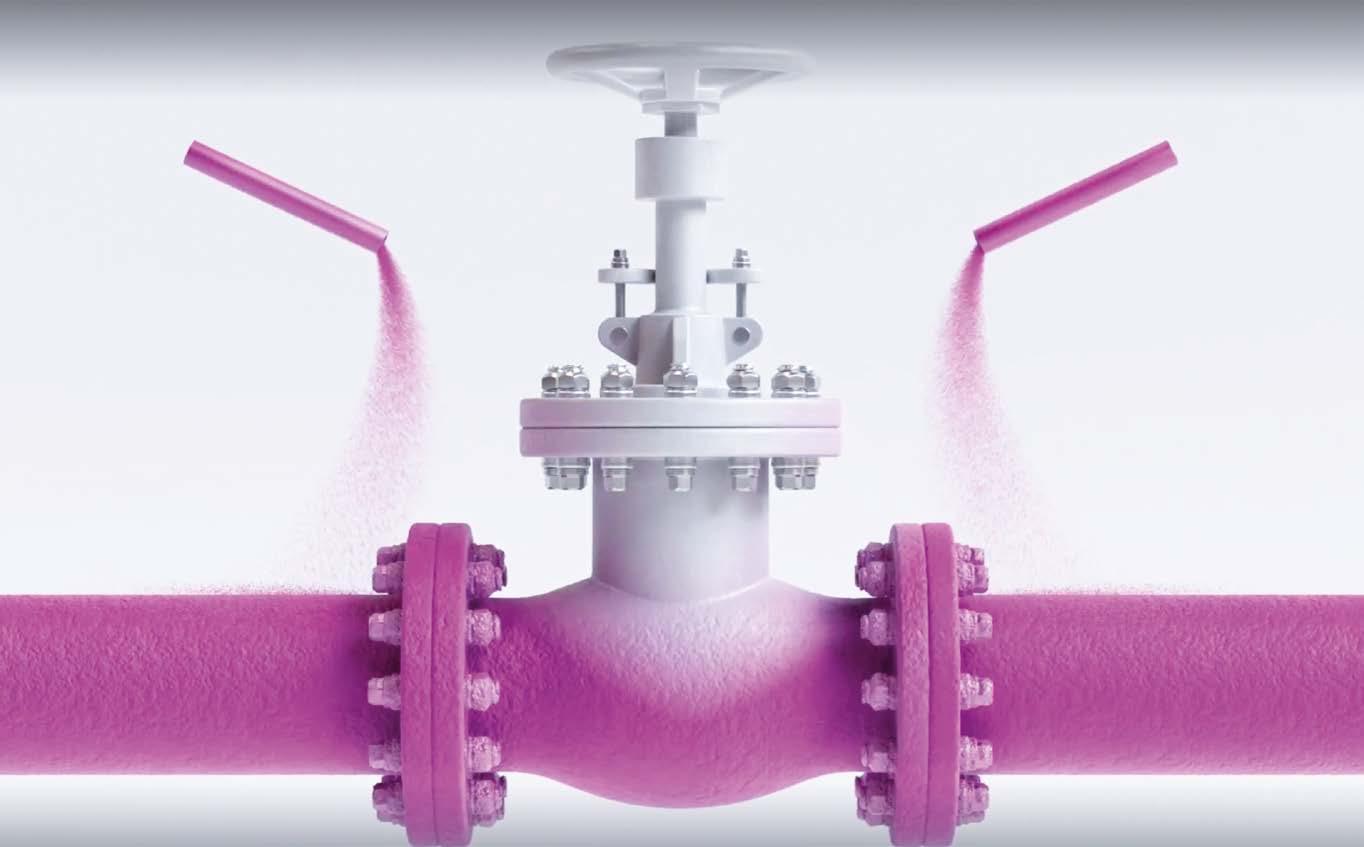

Besides valve protection, in this issue, we also deal with new technologies for protecting pipelines, which are another critical component for the energy industry, and assessing the impact certain environmental conditions have on them.

Off-topic, there is also a wonderful insight into the “state of health” of the steel making up one of Europe’s symbols, the Eiffel Tower, and the presentation of a revolutionary product for cleaning high-voltage insulators.

Finally, we present a new, brilliant research study on the origin of corrosion.

Enjoy your reading.

The global coatings manufacturer Hempel A/S has recently introduced Hempatherm IC to control maintenance costs and manage corrosion under insulation (CUI). The new coating, seamless and with excellent film-building capabilities, offers superior protection and mitigation of CUI - significantly reducing the risk of water ingress and retention. Hempatherm IC consists of Hempatherm IC 170 and Hempatherm IC 175 and is designed to replace several conventional insulation coatings in the critical CUI temperature range. Furthermore, it provides both thermal insulation and CUI mitigation, thus maximising the service life of industrial equipment and assets. “Process industry operators are constantly looking for solutions that reduce the risk of CUI, while managing their personnel safety and energy consumption in a responsible way. They want robust solutions to minimise disruption and deliver long-term value. The Hempatherm IC system offers just that. It is designed with our customers’ need for energy conservation in mind, without the risk of associated CUI. Coatings provide a simple and elegant alternative to meet this requirement, while promoting cost competitiveness, productivity, and sustainability over its service life for all stakeholders across the value chain,” has stated Zechariah Lim, Product Manager CUI/High Heat & Insulation at Hempel. Hempel can provide superior insulation solutions for process control and energy saving thank to this new solution - thus enabling industries to achieve optimal operational performance, including:

Film with the highest thickness per layer compared to other

insulating coatings;

Prevents water entry and retention on insulated equipment, thus eliminating the risk of CUI;

Airgel filler provides low thermal conductivity, capable of replacing many types of conventional mechanical insulation in the critical CUI temperature range of -25°C up to 177°C;

Resistant to temperatures and cyclical fluctuations;

Non-flammable formulation allows safe application to hot surfaces for quick maintenance and ensuring assets are kept in service with minimal disruption to operations;

Easy installation without the need to handle the metal coating and applicable even on complex geometries;

Prevents solar heat accumulation with minimal thickness.

“Hempel is excited to be part of the market shift from mechanical insulation to an advanced insulation coatings system. Insulation coatings have over 25 years of proven performance, but up until now, limitations on coating film thickness have limited thermal insulation coatings as a comparative alternative. Our Hempatherm system provides one of the market’s highest film builds per coat, with a material engineered to maintain thermal performance over the service life, often in the range of 15-25 years,” has added David Hunter, Segment Development Manager, CUI/High Heat & Insulation at Hempel.

www.hempel.com

The global supplier of organic, inorganic and anti-corrosive pigments Heubach Group, affected by the recent condition on the Red Sea and Suez Canal, has passed on the surcharges that global carriers have imposed on their shipments.

“Heubach has been monitoring the situation closely in recent weeks and has adopted its business to ensure there is as little impact as possible on supply of our pigments, preparations and dyes. But the short-term changes and new routes adopted add not only additional time in transit, but also cost,” has stated Tyler Kilgannon, Senior Vice-President of Sales for Europe and the American regions. The price of the product has been supplemented with a temporary transport surcharge of between EUR 0.10/kg and EUR 0.25/kg for

pigments and preparations. This surcharge was calculated based on the logistics routes, the origin of the raw materials and the location of the plants. Furthermore, the price of the surcharge may increase or decrease depending on the escalation or conclusion of the conflict in the Red Sea. “After the logistic price increase in Europe and the Americas and recently also in Asia we are committed to keep all cost drivers under control and the impact on our customers at a minimum. But after significant reflection, we can no longer absorb these higher logistic costs”, has added Takayoshi Miyatani, Senior Vice-President of Sales for the AMEA region.

www.heubach.com

OCSiAl appoints Peter Cuneo as Chairman of the board of directors

OCSiAl, the global leader in the industrial synthesis of graphene nanotubes, announces the appointment of Marvel’s ex-CEO, Peter Cuneo, as Chairman of the Board of Directors. As President and CEO of Marvel Entertainment, Peter Cuneo orchestrated the legendary turnaround of a just-out-of-bankruptcy, struggling superhero franchise to an entertainment industry powerhouse, with the stock price rising from a low of $0.96 to $54 per share paid by Disney in 2009. Cuneo’s distinguished career also includes such roles as President and CEO of Remington Products, President of Black & Decker’s Security Hardware Group, and President of Bristol Myers Squibb pharmaceuticals group in Canada. He brings to OCSiAl his wealth of strategic leadership experience and a proven track record of investment in many industries. Cuneo said, “I am thrilled to be joining OCSiAl which has the potential to become a world leader in nanotechnology.”

Konstantin Notman, CEO of OCSiAl, commented, “I am delighted to welcome Peter to the Board. His depth of experience and strategic leadership are exactly what OCSiAl needs as it looks forward to the next steps in its rise from a unicorn tech company to a global player.” OCSiAl is dedicated to enhancing select properties of all base materials used by the global industry. The company develops universal nanotube solutions that allow its customers to add nanotubes to materials as part of standard manufacturing processes. Collaborating with customers and partners, OCSiAl creates new generations of nano-augmented materials and end products that have previously unattainable properties. These groundbreaking products set new market standards and will play a crucial role in accelerating the transition to a carbon-neutral future.

https://ocsial.com

Maintain steel integrity

Motivated by the toughest of conditions, we constantly seek to solve the problems that lie ahead. As a trusted maintenance partner, we offer innovative products and technologies that deliver exceptional performance for steel assets.

Support efficient operations

Reduce hazards and risk

Minimise environmental impact

jotun.com

PPG launched NEXEON 810 ultra-low friction antifouling coating

The international paints and coatings supplier PPG, through its Protective and Marine Coating Division, has launched NEXEON™ 810, an innovative copper-free antifouling coating developed with a strong emphasis on vessel performance, emissions reduction and sustainability. NEXEON™ 810 can reduce fuel consumption and greenhouse gas (GHG) emissions, enabling ships to sustain higher speeds, helping shipowners and operators remain compliant with the Organization’s Carbon Intensity Indicator (CII) requirements international maritime. As a matter of fact, the coating’s unique formula can achieve up to a 25% total reduction in greenhouse gas emissions and supports 60 days of downtime resistance with minimal loss of speed.

“PPG Nexeon 810 coating provides the ultimate combination of advanced coatings technology with improved vessel performance and responsible environmental protection. Thanks to PPG’s sustainably advantaged product development process, our customers can enjoy easier application and improved coating performance across the operating life of their vessels,” has stated Joanna van Helmond, PPG global product manager, antifouling coatings, Protective and Marine Coatings. NEXEON 810’s binder technology ensures controlled and predictable solubility, ensuring high performance throughout the operational life of the vessel. Furthermore, the coating’s copper-free technology features a significantly reduced biocide content, while its binding technology allows for gradual biocide release and close-to-surface use. Upon entering the water, the combined effects of sunlight and ocean bacteria trigger the decomposition of these organic biocides. Lastly, PPG’s new solution also allows for electrostatic application, a significant advantage that is not available in traditional antifouling coatings. Excellent transfer efficiency, achieved through electrostatic spraying, provides a uniform, ultra-smooth film as well as decreased overspray and waste - resulting in significantly reduced paint consumption and improved health and safety benefits compared to airless spraying.

www.ppg.com

At a major blue-chip nickel mine in Australia, Rezitech (authorised distributor of Belzona) has provided a full turnkey solution to combat corrosion under insulation on a tank. Within the space of 24 hours, the 9.5 m diameter tank, with a height of 2 metres from ground level, has been repaired and protected against corrosion thanks to the industrial composite wrap system Belzona SuperWrap II. The customer’s stainless steel feed tank exhibited corrosion under insulation and chloride-induced stress corrosion cracking. The company needed a solution that would restore the integrity of the substrate and protect the asset from future corrosion damage. Additionally, as the tank operates at high temperatures of around 70°C and handles highly corrosive media, the repair solution must be able to withstand harsh conditions. The customer placed their trust in the range of metal epoxy repair composites and industrial repair coatings offered by Belzona. Following an inspection by Heath Westell, Sales Engineer at Rezitech, the Belzona SuperWrap II composite wrapping system was specified. “This composite wrapping system consists of a fluid grade resin system, a custom-made hybrid reinforcing sheet made of glass fibre and carbon fibre, as well as a release film to compact and consolidate the application. The system is specially formulated to restore the strength of punctured, weakened and corroded pipes and tank walls, making it the ideal solution for long-term protection of the asset from corrosion under insulation. Additionally, due to the cold-curing properties of the composite winding system, this reduces the need for hot work, making it a reliable alternative to soldering,” said Heath Westell.

All traces of oil and grease contamination have been removed using a suitable Rezitech degreaser. In parallel, the surfaces were grit-blasted to provide a surface cleanliness compliant with ISO 8501-1 SA 2½, with a minimum rough corner profile of 75 μm. Once the surface was prepared, Belzona 9381 reinforcement sheet was first measured and moistened with Belzona resin and then applied to the areas to be repaired. Next, Belzona reinforcement sheets were applied to the tank in three layers, while compression film was added to the top of the application area.

The Belzona SuperWrap II composite wrapping system was rolled and compressed onto the surface of the tank using a roller, and then left to cure for approximately eight hours.

Lastly, by investing in Belzona’s composite wrap system SuperWrap II, the customer was able to successfully overcome the need to replace the corroded asset and extend its life for years to come - resulting in significant savings in both time and money.

www.rezitech.com.au/products/belzona

Sensorlink has been awarded a corrosion monitoring contract with Shell Trading and Shipping Company for the Northern Lights Joint Venture (JV).

The contract includes the provision of Swarm® UT sensors in CO₂ tanks onboard three ships currently under construction. Strategically installed at low spots of the tanks where water is most likely to accumulate, these sensors are designed to detect and monitor corrosion. They will provide online, high-accuracy wall thickness data directly to the ships’ control rooms, enabling early detection of corrosion.

Kjell Wold, Business Development Director at Sensorlink, said, “As part of the energy transition, there is an increase in the transportation of CO₂. While CO₂ itself is not corrosive, the presence of small amounts of water combined with contamination

Our shot blasting systems are made to measure. We take into account the available space, needs and objectives of our customers to structure a product that is functional and that responds to all processing requirements.

can lead to significant internal corrosion. We are enthusiastic to see that our technology and solutions also add value in targeted efforts to reduce greenhouse gas emissions.”

Shell is an international energy company with expertise in the exploration, production, refining and marketing of oil and natural gas, and the manufacturing and marketing of chemicals. The company uses advanced technologies and takes an innovative approach to help build a sustainable energy future.

Northern Lights delivers CO2 transport and storage as a service, enabling decarbonisation of European industrial emissions and facilitating carbon removal from the atmosphere. The company is a Joint Venture owned by Equinor, Shell, and TotalEnergies.

www.sensorlink.no

Eurotherm S.p.A. based in Turin, Italy

PLANT 1: 4.700 m2 of offices, metal work production and painting.

PLANT 2: 5.300 m2 for production, preassembling, warehouse and logistics.

Sherwin-Williams launched Repacor™ SW-1000 for offshore maintenance and repair

The international paints and coatings manufacturer Sherwin-Williams has recently launched Repacor™ SW-1000, an innovative 100% volume solids coating designed for safe, rapid, and economical steel structural maintenance tasks.

“Repacor™ SW-1000 is the result of a three-year research project to develop a coating solution that would simplify maintenance and repair work on offshore wind steel structures. This innovative new product has been developed with the safety of the applicator at the top of mind, as potentially dangerous high-level rope access coating applications can be made easier. Compared to the 2-3 layers needed with traditional technologies, it requires only a single layer coating, dispensed easily using a simple application gun, without the need for mixing,” has stated Claus Ackfeld, product manager at Sherwin-Williams.

Repacor™ SW-1000 is a one-coat solution that possesses all the properties of anti-corrosive coatings and durable finishes, with a dry film thickness of 500 microns. This solution could potentially mimic the original performance of structure coating systems used in offshore wind structures. In addition, Repacor™ SW-1000 also boasts a cure time of approximately four hours, faster than

alternative aerosol systems. The unique cartridge application process allows the applicator to work quickly and compactlyminimising packaging waste.

Repacor™ SW-1000 complies with NORSOK M-501, the offshore industry standard for coating material selection, surface preparation, application procedures and inspection of protective coatings, meeting the highest standards of anti-corrosion protection. It is also completely free of VOCs, carcinogenic, mutagenic and reprotoxic (CMR) substances.

“Repacor™ SW-1000 is transforming the maintenance and repair of wind turbines. However, although it is used predominantly offshore, it is also an excellent solution for onshore industrial environments if a simple to apply, high performance, durable and cost-effective coating is required. The fact that a single coat gives the same anti-corrosion and durability performance as a two or three coat aerosol system makes Repacor™ SW-1000 a genuine game changer,” has concluded Neil Wilds, global product director at Sherwin Williams.

Henkel has recently announced that it has completed the acquisition of Seal for Life Industries LLC, a company based in the United States of America and specialised in providing protective coating and sealing solutions for a broad variety of infrastructures in the renewable energy, oil and gas pipelines and water distribution sectors.

The signing of the transaction took place in February 2024. As infrastructure ages and sustainability gains ever more prominence, the necessity for repair solutions that enhance asset longevity is becoming more apparent. Consequently, maintenance and repair solutions for industrial, civil and municipal applications are gaining heightened importance.

The acquisition of certified protective coating technologies and the complementary applicator network seamlessly aligns with the expanding Maintenance, Repair and Overhaul (MRO) portfolio of Henkel, by introducing complementary repair solutions that significantly bolster the commitment to advancing the sustainability megatrends and facilitating advancements in retrofitting, smart maintenance and civil infrastructure development.

“MRO represent a pivotal growth sector for our organisation, presenting significant opportunities for pioneering solutions that protect, retrofit and digitally monitor infrastructure while advancing sustainability objectives. This strategic transaction represents another crucial milestone in our ongoing efforts to cultivate a robust growth platform within our MRO business to add more value to the operations of our customers and help them reach their targets,” has stated Kourosh Bahrami, the vice-president of Henkel.

“Coupled with the Critica Infrastructure acquisition closed in 2023 and our strong Loctite MRO solutions, we are well positioned to deliver on our strategy.”

Seal for Life operates on a global scale with a worldwide production network that comprises innovative coating and sealing solutions, including heat-shrink sleeves, viscoelastic coatings, epoxy and urethane paints and fire protection, insulation and sound-dampening solutions that allow to protect and retrofit several infrastructures, such as pipelines and piles.

www.henkel.com

The international chemicals supplier Evonik has recently launched Ancamine® 2844, an epoxy cure hardener designed for plural component spray applications.

As a matter of fact, this new highly-functional aliphatic amine-based hardener has ultra-fast curing properties and rapidly develops its properties in harsh conditions of low temperature and high humidity, as well as in marine and protective coating applications.

“Our focus has always been on innovation and performance and Ancamine® 2844 continues our track record of providing solutions that meet the evolving needs of our customers. With this latest curing agent, we are offering a product that not only enhances productivity for applications that require quick turnaround times, but also maintains the quality of the finish and protection, even Evonik developed a new hardener for protective and marine coatings

in the most demanding environments,” has stated Christian Schmidt, Head of the Crosslinkers business line of Evonik. The ultra-fast drying speed of Ancamine® 2844 allows for operations at temperatures as low as 5°C, making it ideal for winter coating applications.

The combination of low viscosity and load, with the high solids content, ensures easy application and a flawless finish. Additionally, the high chemical and corrosion resistance of Ancamine® 2844 effectively protects surfaces and can withstand salt spray testing with up to 3,000 hours of exposure – thus making it a robust solution for fast-curing protective and marine coatings.

https://corporate.evonik.com/en

DONELLI ALEXO INAUGURATES A NEW PLANT FOR APPLYING FBE POWDER LININGS ON OIL & GAS AND DRINKING WATER VALVES

by

The Donelli Group, a pioneer in corrosion protection since 1911, has opened an innovative factory in Ferno (Varese, Italy): Donelli Alexo MXP. Equipped with stateof-the-art technology, it will be the company’s hub for the application of powders, including FBE powder coatings, on valve, tank, and pipe internal surfaces and of liquid paints on both these components and actuators for the oil & gas and drinking water sectors.

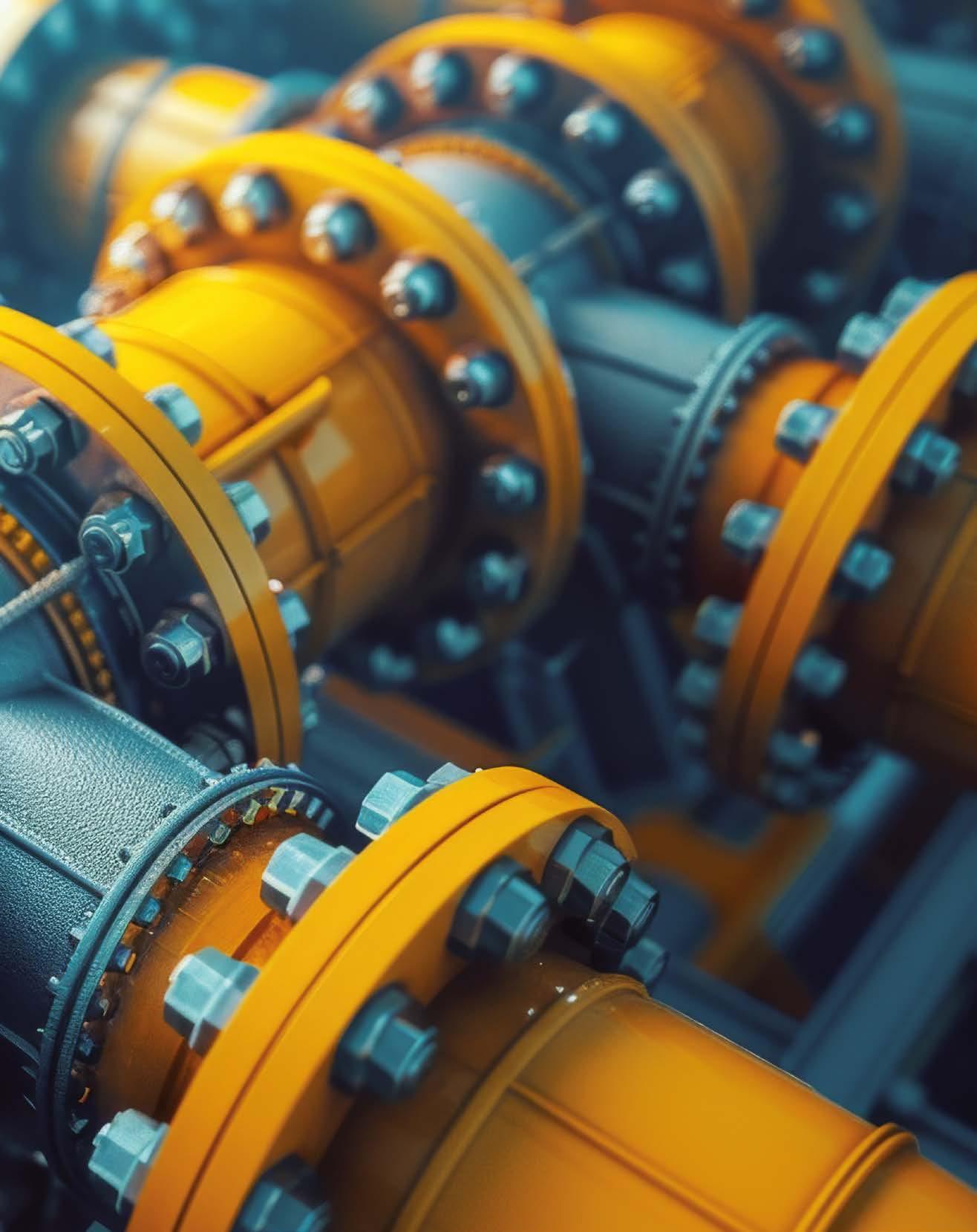

In the petrochemical industry, valves play a key role in the extraction, transport, and refining of fluids because they ensure a safe and efficient flow. However, they are often exposed to harsh environmental conditions and aggressive corrosive agents. Such constant exposure can seriously compromise their structural and operational integrity, putting plant safety at risk and generating malfunctions that can cause costly and potentially dangerous operational interruptions. Corrosion protection is, therefore, a crucial factor that can never be underestimated as it is closely linked to the longevity and reliability of infrastructure.

In this scenario, companies specialising in corrosion protection clearly play a vital role. One of them is Donelli Alexo Srl, a company based in Cuggiono (Milan, Italy), which for decades has been offering anti-corrosion coating, fire protection, and insulation services for plants and structures in the energy, oil & gas, chemical, and offshore sectors. Recently, Donelli Alexo has further expanded its market presence by opening a new site in Ferno, in the province of Varese, just one year after its CX site, a satellite of the main one in Cuggiono. This expansion reflects the company’s commitment to meeting the growing needs of the industry through advanced and fully customised corrosion protection solutions. At this new location, Donelli Alexo can apply a wide range of coatings, including FBE linings, powders, and liquid paints, mainly on valves and actuators for the petrochemical and drinking water industries.

Established in 1911, the Donelli Group stands out in the field of protective and cosmetic-protective treatments for a wide range of substrates and infrastructures, including industrial, petrochemical, and chemical plants, power plants, and civil, residential, and commercial structures. It stands out especially for its state-ofthe-art technology, high quality standards, professionalism, and respect for the environment and operators’ safety.

Donelli Alexo, one of the eight companies that make up the Donelli Group, thanks also to the twenty-years experience and technicalcommercial collaboration of an external consultant, AMPP Senior Certified Coating Inspector Luca Calore, in recent years has been developing an FBE powder lining service for valves intended for contact with drinking water, in compliance with the main KIWA, AWWA, and WRAS standards, and with hydrocarbons up to 95 °C, in accordance with the most stringent specifications of end users such as SAUDI ARAMCO and SWCC (APCS-102A, APCS-102B, APCS-102C). It also coats the external surfaces of fittings with both single-layer FBE and double-layer FBE (DLFBE) solutions, with the possibility of also applying top coats with high abrasion resistance (Abrasion Resistant Overcoating, or ARO). “Over the years, our company has increasingly consolidated its presence in the market, becoming one of the leading players in the corrosion protection sector,” states Donelli Alexo CEO Alessio Trisolino.

“Just one year after the opening of the CX plant1 in Cuggiono (Milan, Italy), we inaugurated a new site in the province of Varese, near the international airport of Malpensa – hence its name, MXP. We had noticed a growing demand for the application of FBE powder products – this acronym stands for Fusion Bonded Epoxy – for the outer coating and inner lining of valves in a variety of industries, especially from companies operating in the Middle East, which is one of our main markets to date. Indeed, in recent years, our customers have been showing increasing interest in the FBE technology and entrusting us with more and more orders, including large ones. Therefore, to meet these demands and thanks to the experience gained at our primary plant in Cuggiono, where FBE coatings were already applied successfully, we decided to expand our production capacity by opening this new site,” says Trisolino.

“The achievement of this important milestone is part of a corporate strategy to position ourselves as the benchmark company in the corrosion protection sector. Especially when dealing with large orders, end customers are often concerned about delivery delays, which leads many of them not to rely

1 The technical description of the Donelli Alexo CX plant was published in issue no. 43 of ipcm®_ Protective Coatings: https://www.ipcm.it/en/open/protective-coatings/2022/43/24-31.aspx

exclusively on one coater but rather turn to several suppliers to mitigate potential delays and finishing quality issues.” However, Donelli Alexo has taken a different approach, structuring itself so that end customers see it as their one-stop shop. “With three sites devoted to valve coating, we can guarantee greater flexibility and reduce the risk of delivery delays. We optimise work by managing orders through all our plants, distributing them among the three sites or concentrating them in one depending on production requirements, thus ensuring greater adaptability and efficiency. End users also recognise and value process homogeneity among our plants, which translates into high consistency of the end products’ quality,” notes Trisolino.

Donelli Alexo’s core business is the surface treatment of valves intended for the petrochemical industry and for contact with drinking water. Before reaching the coating process, which takes place in a manual plant, each valve undergoes a series of critical steps. These include cleaning, degreasing, and a thorough mechanical surface preparation check, followed by a sandblasting stage, carried out also in one of the tunnel machines supplied by Cogeim (Casorezzo, Milan).

“At the end of the sandblasting process – using abrasives in different types and with different grain sizes depending on the surfaces to be treated and the specifications of the customer’s technical data sheets – we proceed with lining the inside of the valves by applying the Scotchkote™ FBE epoxy powder coating,” explains Alessio Trisolino.

The FBE powder application system was designed and installed by Eurotherm (Volpiano, Turin, Italy), a plant manufacturer that had already collaborated with Donelli Alexo in the past for the supply of the Cuggiono CX site’s coating line. “When we took over the Ferno plant, it was already equipped with a Eurotherm plant, which we decided to keep precisely because we were aware of the high quality of its technology and the skills of this company’s technical team. At the same time, we subjected it to a major revamping process, especially in terms of control devices, to ensure compliance with the most stringent specifications, such as those required by ARAMCO, with minimal tolerances for the dew point of the air used for powder application.”

Known for its effective corrosion protection properties, the Scotchkote™ FBE coating is mainly used for oil & gas pipelines, including their joints and, of course, valves. Depending on the intended use of such components, FBE coatings may require several processing steps.

“For valves intended for the petrochemical industry, we apply a phenolic primer after cleaning and grit blasting. This is followed by a pre-heating stage in an oven at the temperatures indicated by the product’s technical specifications. We then apply the FBE coating and end the process with an oven-curing phase.

Donelli Alexo’s valve lining cycle is a rigorous, tailor-made process designed to ensure optimal corrosion protection and long service life, in line with the specific needs of each customer and industry,” adds the CEO.

Another significant advantage of the Scotchkote™ XC-6171 product is the possibility of subjecting already coated valves to subsequent machining operations. “This means that we can apply the coating to the entire inner surface of the valves, including the sealing areas in contact with the fluid, and restore the finish with mechanical tooling operations. That distinguishes this product from many competitors as it also guarantees impermeability after machining, which is not always guaranteed by other certified products.”

KNOWN FOR ITS EFFECTIVE CORROSION PROTECTION PROPERTIES, THE SCOTCHKOTE™ FBE COATING IS MAINLY USED FOR OIL & GAS PIPELINES, INCLUDING THEIR JOINTS AND, OF COURSE, VALVES. DEPENDING ON THE INTENDED USE OF SUCH COMPONENTS, FBE COATINGS MAY REQUIRE SEVERAL PROCESSING STEPS.

For Donelli Alexo, Fusion Bonded Epoxy powder coatings are an advantageous solution for protecting both internal and external surfaces. “Although powders are an established technology for the lining of inner surfaces, we anticipate that they may also find fertile ground for the protection of outer surfaces. This fits in with our vision of the ecological transition since we expect powder coatings to completely replace solvent-based liquid products within five to fifteen years. However, we recognise that this change will take time as it is necessary to create an industrial culture that fully embraces this technology and its related processes,” says Marco Malandra, a board member and the coordinator of the technical and regulatory development office (ISO and Qualisteelcoat). “In addition to increased sustainability, powder coatings offer many advantages. Their durability is remarkable, reducing the need for frequent maintenance and its related costs and extending the service life of equipment and infrastructure. In addition, they can be applied electrostatically and in fluidised beds, enabling to coat even the most difficult-to-reach surface areas,” indicates Donelli Alexo’s CEO.

At its Ferno site, Donelli Alexo performs not only the FBE powder lining of valves’ internal areas but also the coating of their external surfaces with liquid-based paint products.

“After inner lining, the valves are shipped to the customer for machining (assembly, coupling, and so on) and then returned to us for outer coating. In the corrosion protection sector, very strict specifications govern 95% of projects. Therefore, customer specifications often determine the coating cycle and the paint products used.” “The plant we have installed at the new Ferno site is designed for manual coating and includes a cluster grit blasting machine supplied by Cogeim, a curing oven supplied by Eurotherm, and 6 manual coating areas, soon to become 9 as 3 more are currently being installed,” indicates Trisolino. The system can handle large-sized valves weighing up to 25 tonnes.

“We recently completed a very sophisticated project engineering-wise, involving the coating of 53 100-inch valves for the transport of drinking water in Mecca (Saudi Arabia).”

IN ADDITION TO INCREASED SUSTAINABILITY, POWDER COATINGS OFFER MANY ADVANTAGES. THEIR DURABILITY IS REMARKABLE, REDUCING THE NEED FOR FREQUENT MAINTENANCE AND ITS RELATED COSTS AND EXTENDING THE SERVICE LIFE OF EQUIPMENT AND INFRASTRUCTURE. IN ADDITION, THEY CAN BE APPLIED ELECTROSTATICALLY AND IN FLUIDISED BEDS, ENABLING TO COAT EVEN THE MOST DIFFICULT-TO-REACH SURFACE AREAS.

Every Donelli Alexo site has embraced the mission of pursuing continuous growth and researching ever-more advanced anti-corrosion products and processes. “We are committed to providing our customers with the highest coating quality and reliability, and this new plant tangibly embodies that commitment. The Ferno facility is also equipped with a traditional powder coating plant that will enable us to guarantee even higher quality standards,” states Trisolino. “We understand coating as much more than a mere protective solution. We intend to expand our range of services in the powder coating sector by exploring new international markets and applying three-coat systems to achieve aesthetic and protective results of the highest quality,” says the CEO of Donelli Alexo.

“To provide our customers with impeccable service, we are obtaining Qualisteelcoat certification and have already received ISO 9001, 14001, and 45001 quality, safety, and environmental certification for this plant. Our Donelli Alexo CX site in Cuggiono has also obtained ISO 9100 certification for the aerospace and military sectors. In addition, implementing advanced technologies to monitor each stage of the coating process guarantees uncompromising quality. Finally, the installation of state-of-the-art instrumentation such as differential scanning calorimetry (DSC) in our Cuggiono CX plant’s laboratory enables us to perform thermal analysis on coated samples directly in-house, demonstrating our commitment to ensuring the highest quality in every aspect of our work,” emphasises Marco Malandra. “These steps will enable us to provide our customers with an even higher level of quality within a shorter time frame, consolidating our position as their one-stop shop and point of reference for all their corrosion protection needs,” remarks Alessio Trisolino. ‹

Subsea oil and gas pipelines are frequently constructed by joining concrete-coated segments together. During construction, concrete-coated pipe may sit for six months to several years before installation. Capital spares are often ordered at the same time as the initial pipes but with a designed preservation life measured in decades of idle time. To ensure that these capital spares do not deteriorate prematurely, Cortec® shares several technologies and tips for preserving concrete-coated pipes from corrosion.

Subsea pipe spares are often stored near the coast due to material handling difficulties. An incredibly long storage period and an aggressive environment combine to pose a frequently overlooked risk for long-term integrity. Although the concrete coating will initially protect the outside of each steel pipe segment, the concrete will absorb moisture, chlorides, and carbon dioxide over time, eventually leading to corrosion. Extreme temperature swings and sporadic inspection intervals can exacerbate the problem. To complicate matters, the concrete coating makes it difficult to access and treat the OD (outer diameter) of the steel pipe.

Migrating Corrosion Inhibitor™ (MCI®) Technology is typically used to protect reinforcing metals embedded in concrete because of its ability to travel through concrete pores to reach the surface of the underlying metal. The same mechanism makes MCI® suitable for protecting the metal pipe OD of concrete-coated pipe. Migrating Corrosion Inhibitors applied to the outside of the concrete pipe can gradually migrate as much as several inches into the concrete to form a protective anticorrosive molecular layer on the steel OD.

Preservation of spare concrete-coated pipes should be done as soon as possible. Any delay gives moisture and chlorides a chance to start attacking the concrete and steel. Although preservation can be done later, additional rust removal and cleaning may be needed by then. In worst case scenarios, preservation may be neglected so long that corrosion compromises the integrity of pipe segments and new ones must be purchased, defeating the purpose of capital spares.

If integrity is confirmed and surfaces are clean, the concrete surface may be treated with MCI®-2020. This topical solution has the highest concentration of Migrating Corrosion Inhibitors compared to other surface applied corrosion inhibitors (SACIs) on the market. For further protection, a water repellent can be added to hinder the entrance of additional moisture and chlorides while trapping the MCI® inside. Alternatively, MCI®-2018, which contains MCI® in a 100% silane water repellent, can be used alone or (for maximum protection) in conjunction with MCI®-2020. Both MCI®-2020 and MCI®-2018 are certified to meet ANSI/NSF Standard 61 for use in drinking water system components, making them attractive for those laying pipeline in environmentally protected waters where dangerous leachates are a concern for sea life.

Often, several inches on each end of a subsea pipe are not coated with concrete. Here, MCI® CorShield® can be applied to protect the exposed metal. This water-based removable coating provides excellent protection in unsheltered outdoor environments and cures to a soft non-tacky film that eventually hardens. If the capital spares need to be installed, the coating can be removed with an alkaline cleaner, if desired.

The inner diameter (ID) of the pipeline segment should also be protected by fogging it with CorroLogic® Fogging Fluid VpCI®-339. This chemistry is similar to MCI® and migrates through void spaces to form a molecular protective layer that remains as long as the void stays closed. To meet this requirement and keep debris out, workers should cap the ends of each pipe segment with a material such as MilCorr® VpCI® Shrink Film, a heavy-duty plastic that also contains corrosion inhibitors. Once this is done, the spares can be left alone and checked once or twice a year.

Even though the need to install concrete-coated pipe spares may be unpredictable, these capital spares should remain on-call for emergency or routine replacement. Proper preservation helps oil and gas companies do so, keeping pipeline segments ready to use on short notice. ‹

Easy to apply, touch-safe, and eco-friendly new Evonik’s TEGO® Therm range to enhance the performance against CUI

The Coating Additives business line at Evonik has introduced a new series of high-performance granules and a heat-resistant binder specifically designed for thermal insulation coatings under the TEGO® Therm product range. When combined with a suitable primer, they provide improved corrosion protection and are effective in preventing corrosion under insulation (CUI) on metal structures. Alessia Venturi, Editor in Chief of Corrosion Protection Magazine, interviewed Niko Haberkorn, Global Head of Business Development

Industrial & Transportation Coatings at Evonik Coating Additives, to know future developments and potential applications of this new product range.

What are the requirements of the engineering, marine, and construction industries as far as thermal insulation is concerned?

In the engineering, marine and construction industries, thermal insulation must meet several critical requirements to ensure operational efficiency, durability, and safety. For chemical processing facilities, oil and gas operations, energy efficiency is essential. This involves minimizing energy losses in high and low temperature processes, which in turn reduces CO2 emissions and supports the sustainability of industrial processes while reducing energy costs. Thermal insulation systems should be easy to apply to keep maintenance costs low. This includes the ability to apply insulation without the need for shutdown and the ability to apply complex three-dimensional shapes, possibly by spray application. Another key factor is durability. Thermal insulation must be able to withstand extreme weather and temperature conditions over a long service life, maintain its effectiveness, and prevent moisture ingress that can lead to corrosion under insulation (CUI). And let’s not forget occupational safety as another important aspect of thermal insulation. Surfaces exposed to both extreme hot and cold temperatures, such as piping or vessels in industrial plants, must be adequately insulated to prevent unintentional contact injuries to workers. Moreover, it is essential that insulation materials utilized in the industrial, marine, and construction sectors possess fire-resistant and non-combustible properties to inhibit flame propagation and preserve structural integrity.

Can you please present Evonik’s TEGO® Therm product range?

Evonik’s TEGO® Therm range is a set of products designed to improve the performance of thermal insulation coatings (TICs). The range includes two types of microporous silica-based granules, TEGO® Therm HPG 4000 and TEGO® Therm HPG 6806, and a heat-resistant silicone-based binder, TEGO® Therm L 300. The granules feature a microporous structure, optimized density and superior hydrophobicity, all of which contribute to provide excellent insulating properties in coating formulations. In combination with the binder TEGO® Therm L 300, these granules enable high filler incorporation, robust adhesion to various substrates and long-term mechanical stability even at temperatures up to 250°C. Incorporating TEGO® Therm products into coatings allows to significantly reduce energy loss and make hot surfaces touch-safe, promoting a safer work environment. In addition, these coatings are userfriendly and can be easily applied to complex shapes, providing a more practical solution than traditional insulation methods such as mineral wool.

What are the corrosion protection performances of TEGO® Therm?

TEGO® Therm thermal insulation coatings, when combined with a suitable primer, provide improved corrosion protection and are effective

in preventing corrosion under insulation (CUI) on metal structures such as pipelines, vessels and other equipment. These coatings differ from conventional insulation systems, such as mineral wool, in that they help minimize the risk of CUI by preventing condensation. They maintain the surface temperature of the coating above the dew point, which helps prevent moisture buildup. In addition, the strong bond between the coating and the primer layer acts as a barrier, preventing moisture from penetrating and reaching the underlying metal surface, providing additional protection against corrosion.

Our TEGO® Therm coatings contribute to sustainability in several key ways. Firstly, they are waterborne, which means they have a low volatile organic compound (VOC) content. This is beneficial because it reduces the need for harmful solvents that can contribute to air pollution and have a negative impact on the environment. Moreover, the insulating properties of TEGO® Therm coatings lead to a decrease in energy consumption. By providing effective insulation, these coatings minimize heat loss from equipment and piping, which in turn reduces the amount of energy required to maintain desired temperatures. This energy efficiency translates into lower greenhouse gas emissions, as less fuel is burned to produce the necessary energy.

Evonik’s Life-Cycle Management team has conducted studies to quantify these energy savings in practical applications. The findings suggest that by using TEGO® Therm coatings on areas that are typically not insulated with traditional methods, such as valves and complex piping, there can be a substantial reduction

in energy loss. The result is a significant decrease in greenhouse gas emissions, which underscores the coatings’ contribution to environmental protection.

In summary, our TEGO® Therm toolbox offers solution for the formulation of long-lasting and effective insulation coatings, enabling a reduction in energy use and greenhouse gas emissions, and thus supporting global sustainability efforts.

The focus of the corrosion protection market is currently on ease of application, reduced curing time, reduced maintenance: what TEGO® Therm can offer to these respects?

Our TEGO® Therm range and its application in insulation coatings effectively supplements corrosion protection requirements, emphasizing ease of application, prevention of condensation and CUI, and therefore reduced maintenance needs. Thermal insulation coatings (TICs) based on TEGO Therm have been successfully implemented in a variety of applications across Evonik’s global production sites. With their low thermal conductivity and robust structural integrity, TEGO® Therm-based coatings are suitable for diverse applications, both indoors and outdoors.

The coatings are engineered to ensure touch safety, enhance energy efficiency, and prevent CUI. They are highly versatile and can be applied swiftly and effortlessly, even on complex surfaces. This streamlines the insulation process, cutting down on the time and effort typically required for application and significantly reducing the need for extensive maintenance. The result is a product that not only protects but also contributes to operational efficiency and longevity of the equipment it covers. ‹

Insulation Coatings based on TEGO® Therm components are easy to apply to all kinds of complex geometric shapes by time-saving spray application. The super insulation TEGO® Therm granules provide an outstanding low thermal conductivity characteristic, which significantly reduces the loss of energy. The coating also ensures personnel protection by reducing the surface temperature to an acceptable limit.

TEGO® Therm HPG 4000 are silica-based granules with superior low thermal conductivity, high hydrophobicity and reduced flammability:

Particle size d50 ~300 μm

Superinsulation properties

High hydrophobicity.

TEGO® Therm HPG 6806 is a finer powder which also provides excellent insulation functionality, enhances mechanical performance and features smooth & even surfaces of insulation coating:

Particle size d50 ~30 μm

Excellent insulation properties

Less thickening and easy incorporation in coatings.

TEGO® Therm L 300 is a liquid waterborne silicone hybrid binder with excellent heat & mechanical stability:

Liquid binder with solid content ≈50%

Broad compatibility with acrylic emulsions

Ambient film forming.

MI-PAC, a Spanish company specialising in complete solutions for civil works and physical branding, is one of the first applicators approved in AkzoNobel’s Interpon Redox Excellence network at the end of 2023, thanks to its excellent powder coating process that guarantees corrosion protection up to the C5H class.

Belonging to the Spanish network Redox Excellence –which means being approved as a certified applicator of AkzoNobel’s Interpon brand – is not just a matter of prestige but also of contributing to efforts to promote powder coatings and opening up new business opportunities. Indeed, Redox Excellence is the quality mark that certifies the application of anti-corrosion and functional coating systems on steel structures, and the applicators belonging to this network of excellence guarantee the application of corrosion protection products complying with resistance classes from C4H to C5H. Using AkzoNobel powder coatings is not enough to be part of the network: it is necessary to have implemented equipment

and processes that, by combining surface preparation, paint application, and quality control procedures, ensure corrosion specifications are achieved in compliance with ISO 12944. AkzoNobel’s powder coatings division directly selects this network of applicators, strategically distributed in several Spanish regions and communities. Offering complete solutions for civil engineering works and the creation and assembly of corporate image and physical branding elements since 1990, Obras y Montajes MI-PAC S.L. is currently the only company in the Castile-La Mancha community that has all the necessary processes, procedures, and skills to achieve the C5H resistance class with a powder coating line, without outsourcing any step.

MI-PAC can apply two-layer powder, two-layer liquid, and two-layer mixed (liquid primer and powder top coat) protective systems in accordance with customer requirements.

“In the late 1980s, in this area of Castile-La Mancha, there was much demand for the construction of service stations,” says Francisco Paco Sobrino, the founder’s son and the company’s current owner. “My father established this business with his partner Miguel de Toro in 1990, initially focussing on civil works and the production and installation of physical branding elements in service stations throughout the peninsula. Back then, everything was done on site: they had no specialised workshops where they could cut, machine, weld, and paint the metal components needed for the construction work or pre-assemble the physical branding materials required by the service stations. Hence, our idea to build such metal structures in a dedicated industrial hall and then bring the processed material to the construction site for faster assembly. Since then, MI-PAC has been striving for excellence in civil works and physical branding elements production and installation, combining state-of-the-art technology with creativity

to bring unique, visionary projects to life.”

“Our first 2,000 m2-wide premises were located in the urban core of Bolaños de Calatrava (Ciudad Real), where we began to produce all kinds of metal structures and corporate branding elements,” adds Paco Sobrino. “As we continued to grow, we moved to the Polígono Industrial El Salobral hub in 2000, expanding our infrastructure to 30,000 m2 with 7 factory halls covering 8,500 m2, where we carry out all our activities. In 2007, we integrated a powder coating plant, thus ultimately insourcing all stages of our production process.”

In particular, MI-PAC manufactures and paints any type of physical branding element, from furnishings and identifying marks to vehicle graphics, billboards, monoliths, and supports. In its premises in Bolaños de Calatrava, MI-PAC carries out its entire production process in-house, from design to shot blasting, from liquid to powder coating, and from milling, bending, and welding to electrical connections and graphic design.

OBRAS Y MONTAJES

MI-PAC S.L. IS CURRENTLY THE ONLY COMPANY IN THE CASTILE-LA MANCHA COMMUNITY THAT HAS ALL THE NECESSARY PROCESSES, PROCEDURES, AND SKILLS TO ACHIEVE THE C5H RESISTANCE CLASS WITH A POWDER COATING LINE, WITHOUT OUTSOURCING ANY STEP.

The finishing process of metal parts entirely performed in-house

“For iron, we can choose between mechanical pre-treatment in a manual shot blasting cabinet and chemical pre-treatment in a 5-stage tunnel: we mechanically pre-treat or clean each part depending on its coating needs and quality requirements. Aluminium components, on the other hand, are all subjected to cleaning. Subsequently, we apply a zinc-rich liquid or powder primer, depending on the material we are treating. For the application of the former, we have a double booth painting parts up to 20 metres in length. For the latter, we use an automatic plant with a monorail overhead conveyor, a 5-stage pre-treatment tunnel, a drying station, a pre-heating tunnel, an automatic application station with a manual touch-up booth, and a curing oven,” indicates Sobrino.

“This means that MI-PAC can apply two-layer powder, two-layer liquid, or two-layer mixed (liquid primer and powder top coat)

protective systems in accordance with customer requirements, the intended use of parts, the corrosion class to be achieved, and the type of substrate. Aluminium always undergoes chemical treatment and powder coating, whereas iron, if not galvanised, is subjected to mechanical or chemical pre-treatment, protection with a zinc-rich primer, and top coat application. As a rule, we use liquid corrosion protection systems for heavy workpieces that cannot be hung on the automatic plant’s chain, for small batches, and for anything that would not be sufficiently productive to powdercoat.”

MI-PAC has been collaborating with AkzoNobel Coatings, S.L.U. (Vallirana, Barcelona) since 2007. Such a longstanding collaboration has enabled both companies to profitably exchange skills and experience and mutually grow from a technical perspective.

MI-PAC is also one of the first applicators approved in the Interpon Redox Excellence network at the end of 2023 and is the only powder coating company in the Castile-La Mancha community that can achieve the C5H corrosion class on black steel with S.A. 2 ½-grade shot blasting.

MI-PAC’s work is highly customised, and the metal structures it produces can be installed in any environment, whether on the seafront or in the centre of Castile.

“MI-PAC can currently manage projects in both Castile-La Mancha and Andalusia, and also has contacts in the Madrid and Levante area,” notes Juan José Sánchez Maqueda, AkzoNobel sales representative in Castile. “It has achieved these results because it has all the necessary processes in place to apply verified protective systems capable of achieving a degree of resistance up to the corrosion class C5H in compliance with ISO 12944. Indeed, there is no need to apply many microns of paint, but it is important to have “weapons” available that can be combined to obtain effective corrosion protection finishes. As Paco mentioned, in particular, MI-PAC can perform chemical pre-treatment, mechanical pre-treatment, liquid paint application, powder coating application, pre-set quality control procedures, and a vertically integrated production process with very tight control over every step: in other words, everything necessary to provide the market with the guarantee of excellent corrosion protection.”

“In terms of powder coating products from the AkzoNobel range, MI-PAC usually works with the zinc-rich primer Redox P.Z., the barrier-effect epoxy primer Redox Plus, and Qualicoat Class 1 or 2 top coats for aluminium and iron,” states Juan José Sánchez Maqueda from AkzoNobel.

“We do not manufacture standard products,” explains Paco Sobrino. “We specialise in providing customised solutions: we support our customers from the development of their physical branding elements to their production and finishing. Our processes are highly customised, and the metal structures we produce can be installed in any environment. We can manufacture products to be placed as much on the seafront as in the centre of Castile. The

added value of our work is that we can cover all types of applications. Another advantage is that we have a supplier like AkzoNobel, which offers excellent service and top-quality products. We have never had a single problem with AkzoNobel’s coatings.”

Being approved as an Interpon Redox Excellence applicator was a further step towards quality for MI-PAC. “Besides prestige and the certainty of doing a good job, the biggest advantage of the Redox Excellence brand is the reputation it brings within the powder coating industry. Now, all companies in our area know they can count on us for any corrosion protection requirement up to the C5H class,” concludes Paco Sobrino. ‹

MI-PAC HAS ACHIEVED THESE RESULTS BECAUSE IT HAS ALL THE NECESSARY PROCESSES IN PLACE TO APPLY VERIFIED PROTECTIVE SYSTEMS CAPABLE OF ACHIEVING A DEGREE OF RESISTANCE UP TO THE CORROSION CLASS C5H IN COMPLIANCE WITH ISO 12944. INDEED, THERE IS NO NEED TO APPLY MANY MICRONS OF PAINT, BUT IT IS IMPORTANT TO HAVE “WEAPONS” AVAILABLE THAT CAN BE COMBINED TO OBTAIN EFFECTIVE CORROSION PROTECTION FINISHES.

Pacific Basin leads the largest adoption of graphene-based coating in the dry bulk segment ©

Pacific Basin has decided to apply XGIT-PROP, a sustainable graphene-based propeller coating developed by GIT Coatings, across its entire fleet.

In a proactive move towards energy efficiency and environmental sustainability, Pacific Basin, a leading dry bulk shipping company, has decided to apply a sustainable graphene-based propeller coating, XGIT-PROP, across its entire fleet. This innovative coating, developed by Canadian company GIT Coatings, has demonstrated the potential to enhance vessel performance by up to 4%, which also makes it a highly effective solution to improve CII and RightShip GHG ratings. Following successful application and observing positive results on one of its Supramax dry bulk vessels, Pacific Basin has started the rollout of XGIT-PROP across 40 vessels scheduled for dry dock maintenance in 2024.

This decarbonisation initiative marks the largest adoption of graphene-based propeller coating in the dry bulk segment, showcasing Pacific Basin’s leadership and strong commitment to sustainability through innovative solutions. It parallels the pioneering efforts of industry counterparts like Stolt Tankers and Eastern Pacific Shipping, amongst many others. Sanjay Relan, the General Manager of Optimisation & Decarbonisation at Pacific Basin, remarked, “Since 2007, we have been coating our vessels’ propellers with silicone paint to proactively maintain a smooth propeller surface and avoid the frequent need for polishing to recover lost performance. However, we have not been able to avoid edge damages to the silicone coating on the propellers, which requires the entire propeller coating to be stripped and reapplied at every docking. By adopting XGIT-PROP hard coating for our entire fleet, we are taking a proactive step towards more sustainable practices. We hope to maintain a damage-free, smooth propeller surface and improve efficiency

over longer periods. At a fleet-wide level, we anticipate significant reductions in both environmental impact and operational expenses.”

A biocide-free hard foul release coating, XGIT-PROP is designed to withstand the rigorous conditions faced by propellers, overcoming the shortcomings of conventional, biocide-based soft foul release coatings that release silicone oils and often peel away from propeller blades. Combining a strong adhesive primer with a hard foul release topcoat, XGIT-PROP ensures the propeller’s surface stays smooth over the drydocking cycle. In a fuel efficiency study conducted by Stolt Tankers in 2022, it was proven that XGIT-PROP has the potential to reduce fuel consumption by up to 4%. In addition to improved CII ratings, shipowners in the dry bulk sector are leveraging XGIT-PROP’s efficiency gains to improve their vessels’ RightShip GHG ratings. Maiko Arras, Director of Business Development at GIT Coatings, commented, “Collaboration with Pacific Basin marks another important milestone in our growth. While we have established fleet supply agreements with many other shipping companies, Pacific Basin stands out as the largest to fully integrate XGIT-PROP across a fleet of dry bulk vessels. We’re glad to see first movers selecting this innovative yet simple solution to drive the industry towards a sustainable future.”

The fleet agreement between Pacific Basin and GIT Coatings highlights the shipping industry’s ongoing shift towards sustainability. Faced with the need to meet environmental goals, reduce costs, and maintain efficiency, shipowners who are open to change can find help in innovative solutions like graphene-based coatings offered by GIT. ‹

Hydrogen atoms that penetrate inside the crystal lattice of metals and particularly steels can cause their fracture, leading to the phenomenon commonly known as "Hydrogen Embrittlement" (HE). This article examines the effects of environmental and mechanical parameters on the outcome of tensile tests conducted on cylindrical samples, employed to study HE susceptibility.

Hydrogen plays a relevant role in the decarbonization process that Europe started in the last decades. Its possible employment as a low-carbon footprint energy vector and energy storage means it is still considered a feasible option. During the first transition phase towards using this new energy vector, while no specific infrastructure for its transport is available, a small percentage of gaseous hydrogen could be blended with NG in the already dedicated transport and distribution network.

Several problems arise from such gas blending, particularly the compatibility of the existing pipelines with high-pressure hydrogen. In fact, it is well known that hydrogen, due to its electronic structure and small atomic size, can penetrate inside the crystal lattice of metals and particularly steels, endangering their integrity in several ways, which is commonly referred to as hydrogen embrittlement (HE).

To study the susceptibility of steel alloys to HE, there exist many different methods, which offer different kinds of information about their behaviour in the presence of a high-pressure hydrogen environment. This paper focuses on tensile tests performed on cylindrical samples, employed to study HE susceptibility. Tensile tests are indeed a very common way to study the hydrogen-alloy interaction under strain conditions.

The effects of environmental and mechanical parameters on the outcome of the tensile test will then be discussed, as well as the observations that can be deduced from the rich literature available on the subject, which is sometimes contradictory and, therefore, requires careful interpretation.

Introduction

Hydrogen plays a relevant role in the decarbonization process that Europe started in the last decades. Its possible employment as a low-carbon footprint energy vector and energy storage means it is still considered a feasible option. During the first transition phase towards using this new energy vector, while no specific infrastructure for its transport is available, a small percentage of gaseous hydrogen could be blended with NG in the already dedicated transport and distribution network. The percentage of hydrogen that can be mixed with NG at this first stage does not exceed 20%: first of all, to avoid the need to modify utilization equipment such as burners and boilers and, secondly, not to penalize the energy efficiency of

the whole transport system, taking into account that hydrogen carries about one-third of the energy of NG per unit volume with all other parameters (pressure, temperature and flow velocity) being equal. It is also known that molecular hydrogen can dissociate in its atomic form, penetrate and diffuse through steel, given its small size and electronic structure, causing a degradation of the mechanical properties of these materials, which is commonly referred to as hydrogen embrittlement (HE).

The industry, and in particular the chemical sector, has long experience in the production and use of hydrogen and hydrogencontaining gas mixtures; in fact, an estimated amount of hydrogen in the order of 1012 m3 (108 tons) is produced each year worldwide without detecting significant problems in its handling. However, it should be noted that, in the industrial plants mentioned before, low-grade steels (SMYS 52 ksi/360 MPa) with a low design factor (f=0,3-0,5) are used for hydrogen containment at room temperature and high pressure. On the contrary, in the case of the widespread use of hydrogen as an energy carrier, the use of higher SMYS steels with design factors approximately equal to those adopted today for NG will have to be envisaged to limit the problem of low energy density per unit volume.

In order to assess the suitability of new steels for use with hydrogen, numerous different types of tests can be employed, either provided for by international standards or proposed in the technical literature. These tests are carried out in a hydrogen environment of very high purity (99.9999%), with a very controlled

content of certain specific contaminants, such as oxygen or water, at the maximum pressure expected for actual operation and at ambient temperatures. The difficult experimental conditions, the need for complex instrumentation and the precautions to be taken in order to conduct the test under safe conditions make these tests very expensive, and only a relatively limited number of laboratories have the appropriate equipment and experience to carry them out. In this note, we will deal with the tensile test, which is in general very well known for the mechanical characterization of materials but which requires some specific considerations if it is to be used for the above-mentioned purpose. The tensile test is widely used in the technical literature for the evaluation of the behaviour of steels in a hydrogen gas environment, especially in the research phase where, as will be seen, it allows highlighting the effects of specific significant parameters on the response of metallic materials to the hydrogen environment. As far as standards are concerned, on the other hand, only ANSI/CSA CHMC 1 [1] provides for their use for the certification of materials with the possibility of using both smooth and notched specimens.

For smooth tensile specimens, the current literature states almost unanimously that hydrogen has no relevant effects on Yield Stress and Ultimate Tensile Stress. On the other hand, hydrogen clearly impacts ductility parameters. i.e. elongation (El) and reduction of area (RA). As can be observed in Figure 1, the

hydrogen test curves deviate from the reference curve in air only after reaching the UTS, when the necking begins and, within the volume of constricted material, the decohesion phenomena that will ultimately lead to fracture also begin. To assess the sensitivity of the material to hydrogen embrittlement, RA values in hydrogen and air are compared. Duncan et al. [3], also reporting data from other Authors, provide the following table of values of the tensile properties of four different materials (Table 1). As the table reads, the value of RA decreases in the presence of hydrogen for every alloy, between 14%-39% of its original value. Elongation at break, on the other hand, is much less sensitive to hydrogen presence. In one case (A516 steel), the material shows even higher elongation in hydrogen compared to air. Nanninga et al. [4], [5] performed similar tests on X52, X65 and X100 pipeline steels, obtaining respectively a RA ratio (RRA) of 0.50, 0.72 and 0.78 in hydrogen environment, with RRA being the ratio between the reduction of area in hydrogen environment (RAH) and the reduction of area in inert environment (RAR):

RRA is more severe for higher-grade alloys. Stalheim et al. [6], in tests on four materials, conclude that the material grade does not have a specific effect on embrittlement while the microstructure is more relevant: the best behaviour is with a microstructure of equiaxial ferrite plus approx. 10% acicular ferrite, while the worst

The difficult experimental conditions, the need for complex instrumentation and the precautions to be taken in order to conduct the test under safe conditions make these tests very expensive, and only a relatively limited number of laboratories have the appropriate equipment and experience to carry them out.

is with a ferritic/pearlitic microstructure.Now, we will delve into a rapid analysis of the two most impacting test parameters: hydrogen pressure and strain rate.

Partial pressure determines the total amount of hydrogen absorbed by the material when in equilibrium with the gaseous environment, if the metallic material has been in service for a sufficiently long time such that all the phenomena of absorption, diffusion, reaction with trap sites, etc. have reached their equilibrium conditions.

A typical trend of ductility as a function of hydrogen partial pressure is shown in Figure 2; ductility decreases rapidly

as hydrogen partial pressure increases until it reaches an approximately constant value in the cases presented for pH2 values of 5-10 MPa. Ductility loss in the presence of hydrogen is rather variable. Stalheim et al. [3] and Nanninga et al. [6] reported values around 50% for pressures above 10 MPa (Fig. 3), while Meng et al. [7] performed similar tensile tests on an X80 steel, reporting a decrease of El and RA up to 20% in the most severe conditions applied (pH2=60 MPa). Bertini et al. obtained similar El and RA reduction, never higher than 15%, when performing tensile tests on X52 smooth specimens pre-charged at 5, 10 and 15 MPa of gaseous hydrogen pressure. Although the results might be scattered, all these Authors agree on the fact that a hydrogen pressure increase leads to a decrease in ductility parameters El and RA; ductility decreases rapidly as hydrogen partial pressure increases until it reaches an approximately constant value, in the cases presented for pH2 values of 5-10 MPa.

Another test parameter that greatly influences the result is the strain rate applied during the test, as in the example in Figure 3 [2]. Usually, tensile tests with hydrogen are conducted as prescribed by ASTM G 192, “Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking” [8].

This test was originally developed to study Stress Corrosion Cracking (SCC) phenomena, but it turned out to be also well suited to hydrogen embrittlement conditions where the phenomenon is controlled by the penetration and diffusion of hydrogen atoms into the metal, which are inherently slow processes; in an extremely slow test, therefore, solid-state diffusion phenomena are able to keep pace with and influence the dislocation generation and creep phenomena responsible for the plasticization of materials and ultimately of fracture processes. As can be seen in the example shown in Figure 4, the El of the material decreases as the strain rate decreases over a wide range from 5.5x10-1 to 5.5x10-7 s-1, but the most significant effects occur for strain rates below about 10-4 s-1, while the RA is relatively constant in the range of 5x10-3 to 5.5x10-7 s-1 rates with a decrease of 63-68% compared to the test in an inert environment (N2).

For notched tensile specimens, the matter is slightly different. In this case, the parameter employed for the evaluation of hydrogen embrittlement is notch tensile strength (NTS), defined as the ultimate tensile strength of the notched specimen, and the dominating parameter of the specimen’s geometry is its notch tip radius.

In the case of notched tensile specimens, the parameter employed for the evaluation of hydrogen embrittlement is notch tensile strength (NTS), defined as the ultimate tensile strength of the notched specimen, and the dominating parameter of the specimen’s geometry is its notch tip radius.

Song et al. [9] performed tensile tests on severely notched X70 samples with a notch tip radius of 0.083 mm. The tests were performed in He and 10 MPa hydrogen at different crossbeam displacement speeds.

The hydrogen embrittling effect reaches the maximum value for a displacement speed of 1x10-3 – 5x10-4 s-1, and in this interval, the NTSloss parameter, defined by the authors as:

NTSloss = (NTSHe – NTSH) / NTSHe x 100

assumed values between 13-15% (Fig. 4).

The ANSI/CSA CHMC 1 standard [1] defines the ratio (RNTS) between the average values of notch tensile strength in hydrogen (NTSH) and in inert environment (NTSR):

and for this parameter, it sets a lower limit of 0.90.

By the simple relation:

NTSloss = 100 – RNTS

we obtain RNTS = 85-87%, slightly below the acceptance threshold RNTS ≥ 90% required by the ANSI/CSA CHMC 1 standard. Nguyen et al. [10], [11], [12], on the same steel grade (X70), on notched specimens with a notch tip radius of 0.083 mm, but with a strain rate of 2x10-2 mm/s that does not comply with the prescriptions of the ANSI/CSA standard mentioned above, in an atmosphere of pure hydrogen at 10 MPa, obtained RNTS values of 0.97 with respect to air and 0.92 with respect to helium, demonstrating the critical relevance of test parameters on the results. The tests of these Authors, while critical for the aspects already pointed out, highlight the relevance of this parameter for the outcome of tests on notched specimens. Using radii of 0.083, 1.5 and 6 mm, they obtained the results shown in Figure 4 [11], where the “Stress Concentration Factor, Kt” is a parameter inversely related to the notch tip radius (r) and equal to 1.26, 1.82 and 5.59 for r values equal to 6, 1.5 and 0.083 mm, respectively (Figure 5).

The effect of the Kt factor significantly impacts the RRA parameter, which decreases to about 40/50% for severe notching, while, also for the reasons previously highlighted, the value of NTS loss is modest and always less than 5%.

One of the most widely employed ways to evaluate the HE susceptibility of steel alloys is to perform in-situ tensile tests on smooth or notched specimens. Some general considerations can be made:

When tensile tests are performed on smooth specimens, hydrogen does not cause any relevant modification to YS and UTS but only to ductility parameters, El and RA.

RRA can reach values up to 50% at a pressure of 10 MPa; RRA increases with the increase of the steel alloy’s mechanical properties.

RRA increase is particularly steep in the first 5 MPa of hydrogen partial pressure and slowly approaches an asymptotic value for higher pressures.

RRA also increases when the displacement speed decreases. For displacement speed values lower than 10-4 s-1, the RRA remains mostly constant. This is a direct consequence of the intrinsic speed of the solid-state diffusion of hydrogen.

When tensile tests are performed on notched specimens, hydrogen affects the ultimate tensile strength value, but the RNTS is always relatively low (≤ 15%), and it is difficult to directly correlate it to HE susceptibility. RRA is strongly dependent on the notch tip radius; lower notch tip radii lead to dramatically higher RRA when all the other conditions are kept constant. ‹

One of the most widely employed ways to evaluate the HE susceptibility of steel alloys is to perform in-situ tensile tests on smooth or notched specimens.

Bibliography

[1] “ANSI/CSA CHMC 1 - Test methods for evaluating material compatibility in compressed hydrogen applications - Metals.” 2014.

[2] I. Moro, L. Briottet, P. Lemoine, E. Andrieu, C. Blanc, and G. Odemer, “Hydrogen embrittlement susceptibility of a high strength steel X80,” Materials Science & Engineering A, vol. 527, no. 27–28, pp. 7252–7260, 2010, doi: 10.1016/j.msea.2010.07.027.