International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN:2395-0072

1Assistant Professor, Department of Mechanical Engineering, Arifa Institute of Technology, Nagapattinam, Tamilnadu, India.

2Assistant Professor, Department of Mechanical Engineering, Krishnasamy College of Engineering and Technology, Cuddalore, Tamil Nadu, India.

***

Abstract:

Inthisexperiment,a direct solardryerframethatismadeupofa rectangularsteel gridisused.Thedirectsolar dryeriswell-insulatedwithasuitableinsulatingmaterial.Theexperimentiscarriedoutbyusingthermalenergystorage using sensible heat, which is implemented inside the copper tube presented in the experimental setup, which involves storingheatinasolidorliquid.Theperformanceofthedirectsolardryerwiththermalenergystoragewillbeevaluatedin terms of the drying rate, energy efficiency, and quality of the dried produce. The results of this study will be useful in developing a low-cost and sustainable drying system for small-scale farmers to improve their income and reduce food waste

Keywords: solardryingsystem,thermalenergystorage,ANN,Massflowrateofair.

Theprojectaimstodesignanddevelopadirectsolardryerwiththermalenergystoragetoaddressthechallenges facedbysmall-scalefarmersindryingtheiragriculturalproduce.Thedirectsolardryerutilizessolarenergytodrycrops, andthethermalenergystoragesystemensuresthatthedryeroperatesevenduringcloudyornon-sunnydays.Thedesign of the direct solar dryer involves solar radiation directly radiating inside the cabinet and heating the product inside the cabinet tray. The thermal energy storage system, on the other hand, is composed of a sensible heat storage material that storestheexcessheatduringthedayandreleasesitatnightorduringcloudyperiods.

In agricultural drying processes such as drying fruits and vegetables, elimination of product spoilage, heat preservation processes, etc. So, the direct solar drying system is well suited for these applications because it is simple, compact,weightless,quiet,doesnotuseopendryingorotherconventionaldryers,andalsorequireslittlemaintenance.

The main objective of this project work is

1. To make the experimental setup of the direct solar drying system with the necessary components and measuring instruments.

2. Toexperimentwithdifferenttemperaturesfordryingrate.

3. To find the maximum temperature as well as moisture content, the efficiency of the system, and the performance of thedirectsolardryingsystem.

4. Tocomparetheefficiencybyusingwithoutandwiththethermalenergystorage.

5. Toanalyzethesystemefficiencywiththehelpofanartificialneuralnetwork(ANN)inMATLABsoftware.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN:2395-0072

Formulation and Experimental Methods

Themainsourceofsolarenergyisradiatedfromthesun,andthesolarradiationisallowedtofallonthesolardryer. Thedirectsolardryerconsistsofaninsulatingchamberthattrapsthesolarradiationinsidethedryingchamber,andthe top surface of the dryer is covered with toughened glass to facilitate easy entry of radiation. This leads to an increase in temperatureatthedryingcabinet.Insidethedryingcabinet,thetraysarearrangedonebyonetoplacethedryingproduct, whichismadeofaluminum.Atthedryingchamber,aninletportandanoutletportareprovidedforeasyairflowwiththe help of a DC fan. This solar drying system uses the forced convection airflow system. The DC fan works with the help of solarpanelswithoutanyexternalpowersource.Inthedirectsolardryer,thermalenergystorageisincludedatthebottom ofthetrays;inthisexperimentalsetup,sensibleheatstorageplaysanimportantroleindryingtheproduct. Sensibleheat storage isan energy storage medium that absorbs solar radiation in the daytime andreleases heat at night. The sensible heatstorage system consistsof a thermal energy storage material.In this experiment, engine oil isused asTES,which is included in the copper tube. Then the experiment was conducted in the method of with and without thermal energy storage,andthedirectsolardryerexperimentwasconductedbyincludingwithloadandwithoutload.Thedryingsample isusedas1kgofonionslices,andthetabulationreadingsarenotedandcalculatedforthemoisturecontent,dryingrate, andsystemefficiency.

FORMULA’S USED:

HEAT AVAILABLE PER UNIT AREA IN (KJ/hr.m2)

Heatavailableperunitarea(KJ/hr.m2)=

HEAT AVAILABLE IN THE SOLAR DRYER (KJ/hr)

×3600 (1)

Heatavailableinthesolardryer=Heatavailable/unitarea×Areaofthecollector (2)

TOTAL HEAT GAINED BY THE AIR (KJ/hr)

Totalheatgainedbytheair = mCP∆T KJ/hr (3) where,

m–Massflowrateoftheair(kg/hr)

CP–Specificheatofair=1.005(kJ/kg.K)

∆T–Temperaturedifference(K)

MASS FLOW RATE OF AIR (kg/hr)

Massflowrateoftheair=ρ×A×V×3600 (4)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN:2395-0072

where,

ρ–Densityoftheair(kg/m3)

A–Areaofthedryingchamber(m2)

V–Velocityoftheair(m/s)

EFFICIENCY (%)

RESULTS AND DISCUSSION

Inthisstudy,artificialneuralnetworkshavebeenusedtomodeltheeffectsofthreeimportantparameters,namely, solarintensity,inlettemperature,andoutlettemperature,topredicttheperformanceofthedirectsolardryer.

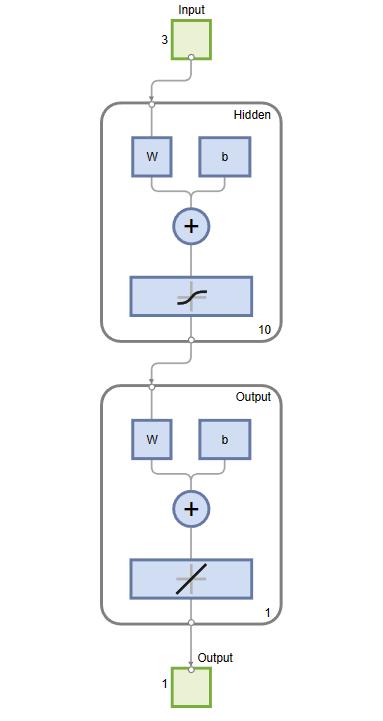

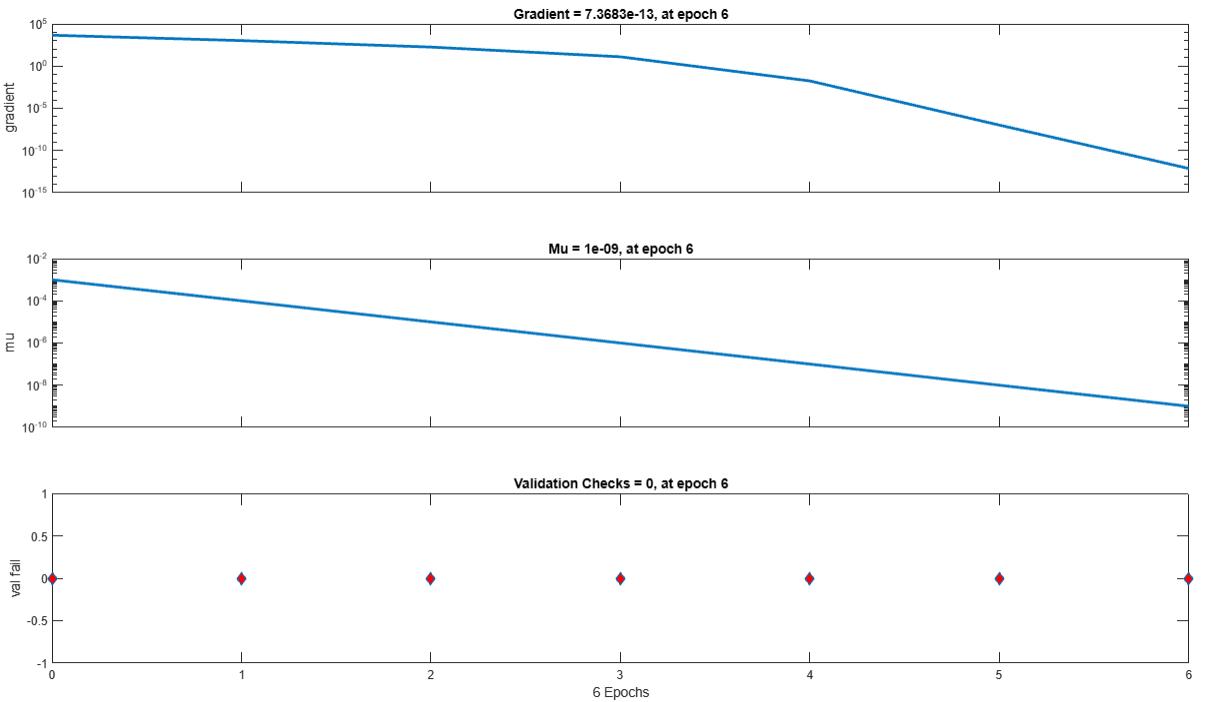

Inthisapproach,experimentaldatahavebeenusedtotrainandvalidatetheneuralnetworkmodelwithMATLAB (R2021) with the neural network fitting toolbox software. In this model, the input is solar intensity, and inlet and outlet temperature are building the neural network structure. Based on experimental data, the efficiency performance of the direct solar dryer has been predicted by three input parameters. That contains up to a few hundred weights, and the Levenberg-Marquardt(LM)algorithmattainsthefastestconvergenceandthehighestaccuracy.Therefore,LMwaschosen asthenetworktrainingmethod.Fig2.showsthestructureoftheneuralnetwork.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN:2395-0072

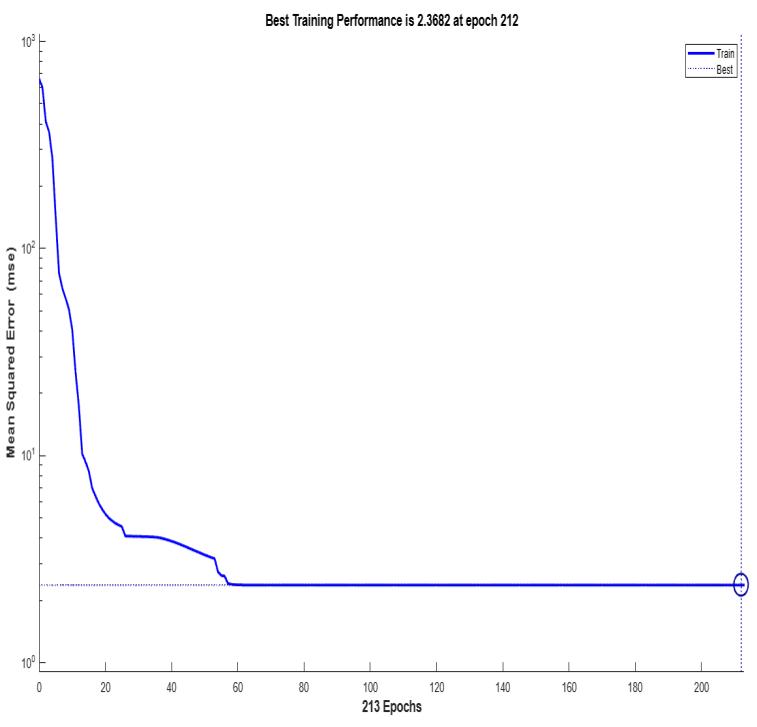

Figure3.showstheperformancecurveoftheneuralnetwork.Thebesttrainingperformanceis2.3682atepochs212.

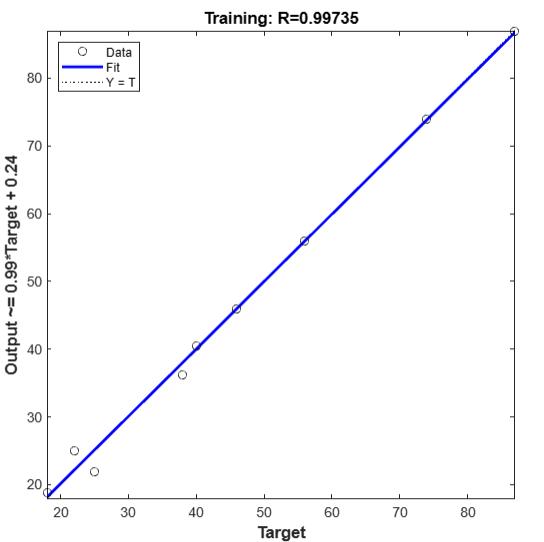

In this study, ANN has been used to investigate the effects of three important parameters (I, Ti, and To) on the dryingefficiencyperformanceofthedirectsolardryer.Figure5.showsthelinearregressioncurveoftheneuralnetwork. TheoverallR-valueof0.99736showsthatthisANNmodelfitswiththeexperimentvalue.

2024, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page95

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN:2395-0072

From Fig 6. and Fig 7. The graphical representation was used to analyze the efficiency and comparisons of the differenttimesinthisdesign.AndalsocomparedwithexperimentalandANNworkingmodelsimulationvalues.

CONCLUSION

Asaresult,thedryingtimeisreduced,leading tohigherthroughputandimproved productivity.Additionally,the performance evaluation may reveal that the direct solar dryer with thermal energy storage exhibits superior drying performancecomparedtotraditionaldryingmethods.Thecontrolledheatsourceandoptimizedairflowwithinthesystem ensureuniformdrying,preservationofproductquality,andpreventionofspoilageordegradation.Thesefactorsmakeita suitable solution for various applications, including food processing, agricultural products, and timber drying. In this experimentalsetup,weknowthattheusageofTES(87.25)andnon-usageofTESmaterial(87.27)differmoreatthepeak hours. So, we conclude that efficiency, which is compared with the help of MATLAB (R2021) software to compare the efficiencyanddatapredictionvalue,is(65.29)&(94.60).

REFERENCES

1. Jain,D.,andTiwari,G.N.(2003),‘Thermalaspectsofopen-sundryingofvariouscrops’,Energy,Vol.28,pp.37–54.

2. Mekhilefa, S., Saidurb, R., Safari, A., 2011. A review on solar energy use in industries Renewable and Sustainable EnergyReviews,15,pp.1777–1790.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN:2395-0072

3. Abene A,DuboisV,LeRay M,OuaguedA.Studyofa solarairflatplatecollector:useof obstaclesandapplicationfor thedryingofgrape.JournalofFoodEngineering2004;65(2004):15–22.

4. SharmaAK,AdulsePG.RaisinproductioninIndia.Pune:NRCforGrapes;2007.

5. EissenW,MuhlbauerW,KutzbachHD.Solardryingofgrapes.DryingTechnology1985;3(1):63–74.

6. S. Dhanushkodi, Vincent H. Wilson, K. Sudhakar, Mathematical modeling of drying behavior of cashew in a solar biomasshybriddryer,Resource-EfficientTechnologies(2016),doi:10.1016/j.reffit.2016.12.002.

7. P. Murugan, S. Dhanushkodi, K. Sudhakar, and Vincent H. Wilson. Tech Science Press, EE, 2021, vol. 118, no. 3. DOI: 10.32604/EE.2021.013491.

8. Abhishek Gautam, R.P. Saini. A review on sensible heat-based packed bed solar thermal energy storage systems for low-temperatureapplications.SolarEnergy207(2020)937–956.

9. El-SebaiiAA,Aboul-EneinS,RamadanMRI,ElGoharyHG.(2002)Experimentalinvestigationofanindirecttypenatural convectionsolardryer.EnergyConversManage,43(16):2251–66.

10. AvesahemadHusainy,P.R.Kumari,Designdevelopmentandperformanceevaluationofanindirectforcedconvection solar dryer for grapes, International Journal of Scientific Research and Development, Vol. 3, Issue 03, 2015 (ISSN: 2321-0613).