International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN: 2395-0072

Anisha J1, Swetha S2, Dr K M Pachiyappan3, Dr R Divya4, Sharmila M5

1,2 PG Student, 3Dean, School of Applied Science,4Associate Professor,5 PhD Research Scholar Department of Costume Design and Fashion, PSG College of Arts and Science, Coimbatore. ***

Abstract - Handloom weaving represents a rich cultural heritage and a vital source of livelihood in many regions around the world. This study explores theintricatetechniques, socio-economicimpacts,andculturalsignificanceofhandloom weaving in contemporary inIndiansociety.Throughablendof ethnographic research, technical analysis, and market evaluation, the research highlightstheresilienceoftraditional handloom practices in the face of modernindustrialization.By examining case studies from various handloom communities the research addresses the challenges faced by handloom weaving in the modern era, including competition from industrial textile production, and explores efforts to preserve and revitalize this ancient craft. The study also covers the government schemes and initiatives for the welfare of handloom weavers in India.

Key Words: Handloom Weaving, loom, yarn, weavers, schemes, Textile Patterns, fabric, craft, power loom, technology

India's handloom industry boasts a rich legacy of exceptionalcraftsmanship,showcasingthecountry'svibrant culturalheritage.Renownedgloballyfortheirexpertisein hand spinning, weaving, and printing, Indian artisans continuetopreservetraditionaltechniques.Thishouseholdbased industry, spread across thousands of towns and villages, relies on family members working together to create unique products. Skills are passed down through generations, empowering rural and semi-urban artisans, particularlywomenandeconomicallydisadvantagedgroups. The handloom industry contributes a relatively small portiontoIndia'sglobalexports.Tounlockitsfullpotential, effortsareneededtopromoteandchannelitsofferings.This study aims to highlight the cultural significance of handloomsbyexploringtheirhistory,problemsandcurrent scenario of handloom industries. Tamil Nadu handloom weaversworkonavarietyoflooms,includingordinarypit looms, pit looms with dobby and jacquard attachments, framelooms,andframeloomswithdobbyandjacquard.The handloom sector, however, faces major challenges in ensuring consistent employment for weavers. To address this,boththecentralandstategovernmentshaveintroduced several measures aimed at improving the livelihood and sustainability of this sector through various schemes designedtosupporthandloomweavers.

Aloomisamachineordeviceusedtocreatewoven fabric and serves as the central element in the cloth production process. In simple terms, a loom is a tool designedtoweaveyarnorthreadintotextiles.Loomscome inawiderangeofsizes,fromlargefree-standinghandlooms and small handheld frames to massive automated mechanical machines. The term "loom" can also refer to a wiring loom in electric line construction. The primary functionofaloomistoholdthewarpthreadsundertension, facilitatingtheinterweavingoftheweftstrands.

2.1.1.

Aprimitiveloomisgenerallybysinkingtheframe intothegroundandtheworkinsidethepitbybothfeet.The frameworkisofbamboo.Thisloomhadbeenknowntobein use in 5000 to 6000 years B.C. This loom is still used for weavingsilkpieces,silkshirting,andsarees,Muslim,etc.by derivativeweavers.(6)

2.1.2.

Thisloomiscreatedbysunkenfourpostersintothe ground and with an overhang sley. The threads operate insidethepit,allowingthewarpthreadstoabsorbmoisture, whichleadstoimprovedweavingquality.In,thisloomsthe combinationofsley&shuttleboxes.In1733A.DJohnKayof Bury,Englandinventedthe”FlyShuttle”.Thisinventionwas an extremely important event in the history and developmentofweaving.

2.1.3.

Frameloomsalmosthavesimilarmechanismsthat groundloomshold.Theloomwasmadeofrodsandpanels fastenedattherightanglestoconstructaformsimilartoa box to make it more handy and manageable. This type of loomisbeingutilizedevenuntilnowduetoitseconomyand portability.(6)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN: 2395-0072

The Chittaranjan loom, also known as the Japan loom,isasemiautomaticloomofrobustconstructionmade fromironandwood.ItiscommonlyusedinBengal.

In1856,HattersleyandHillofKeighley,Yorkshire, designed a loom thatfunctionssimilarlyto a powerloom, exceptforthemovementofthesley,whichcanbeoperated either manually or by motive power to the top shaft. However,thisloomisbuiltwithalighterstructure.

By the turn of the nineteenth century, as British industrializationadvanced,Indianweaversencounteredtwo majorchallenges:thecollapseoftheirexportmarketandthe declineoftheirlocalmarkets,whichwereoverwhelmedby aninfluxofcheap,importedBritishgoods.Thedeclineofthe Indianweavingindustrybegan assoonastheBritishEast IndiaCompanysecuredmonopolyrightsoverIndiantrade. Inthepre-colonialperiod,Indianweavershadaprosperous industry,producinghigh-qualitytextilessuchasmuslin,silk, and cotton that were in great demand across Europe and Asia.Weavershadautonomyindeterminingtheirpricesand enjoyedhealthycompetitionamongbuyers.AftertheEast IndiaCompanygainedcontrol,itstartedbeganexploitingthe weaversby

TheCompanyimposedunfaircontractsonweavers. Theywereoftenforcedtoselltheirproductsexclusivelyto theCompanyatpricesfarbelowmarketrates.

3.2.

Weavers were often provided advance payments, butinreturn,theywereboundtosupplyfinishedproducts totheCompanyatdictatedprices.Iftheyresistedorsoldto otherbuyers,theyfacedseverepenalties.

TheCompanyestablishedcontroloverthesupplyof rawcotton,creatingartificialshortagesorinflatingpricesfor Indian weavers. This was especially crippling, as raw materials became unaffordable for local artisans, further pushingthemintodependencyontheCompany.

3.4.

AsBritishindustrializationprogressedintheearly 19th century, cheap, machine-made textiles from Britain wereexportedtoIndiainlargequantities.Theseproducts

were sold at much lower prices than hand woven Indian fabrics.

The British systematically destroyed the local markets by flooding them with mass-produced goods, drasticallyreducingthedemandforIndian-madetextiles.

3.6.

Bysecuringmonopolyrights,theBritishstifledany localcompetition.TheIndianeconomywassystematically drained as India became a supplier of raw materials for BritishindustriesandaconsumerofBritishgoods,leaving littleroomforindigenousproductionandmarkets.

3.7.

This shift had a devastating impact on the Indian economy, particularly on the livelihoods of millions of handloomweavers,whowereforcedintopovertyorhadto switchtolow-payingjobsintheBritishfactories.

4.

4.1.

Handloom weavers face competition from power loommillsandothermachine-madeproducts.Powerloom industriesoftenreceivesubsidies,whichcancreateunfair competition.

4.2.

Weaversstruggletoaccessessentialrawmaterials suchasyarnanddye,oftenhavingtotravelgreatdistances toprocurethem.Thesupplyofessentialrawmaterialslike cotton,silk,anddyeswasdisruptedastransportationmay behalted.Thismadeitdifficultforweaverstocontinuetheir production. Even when raw materials were available, the prices increased due to limited supply and higher transportationcosts,furtherstrainingweavers’finances.(8)

Inthecurrentscenario,thehandloomsector'smajor challenge is the lack of access to good-quality yarn at affordable prices. Most weavers come from economically disadvantagedfamilieswithlimitedaccesstomarketsthat supplyhigh-qualityyarn.

4.4.

Marketingplaysavitalroleinpromotingproducts andservicestoaspecifictargetaudience.Unfortunately,the handloom industry suffers from limited visibility due to

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN: 2395-0072

weak marketing strategies. While expanding the market reachisnecessary,government-sponsoredexhibitionsalone arenotenoughtocreatewidespreadawareness.

Many weavers, especially in rural areas, have limited access to formal banking and credit facilities. This forces them to rely on informal sources, such as moneylenders, who charge high interest rates, further worseningtheirfinancialcondition.

The pandemic severely disrupted the handloom sector,pushingmanyweaversintopovertyandthreatening thesurvivaloftheircraft.Thelockdownsandrestrictionsled toabreakdowninthesupplyofrawmaterialssuchasyarn, dyes,andotheressentials.Weaverscouldnotprocurethese materials,haltingproductionforlongperiods.Withphysical marketsandexhibitionsclosedduetolockdowns,weavers lost their primary sales outlets. Many weavers, especially those from rural areas, were not familiar with online platforms,limitingtheirabilitytoselltheirproductsduring the pandemic. The economic downturn caused by the pandemicledtoasignificantdropindemandforhandloom products, both domestically and internationally. Luxury items,includinghandloomtextiles,werenotprioritizedby consumersfacingfinancialuncertainty.

Thisschemehasbeenintroducedtooffernational and international competitive opportunities to handloom weavers'products,focusingonsustainabilityandreliability. It provides weavers with essential infrastructure support, technicalassistance,andguidanceforproductdiversification anddesignenhancement.Additionally,theschemefacilitates connectionswithrawmaterialbanksandofferssupportin marketingandpromotingtheirproducts,alongwithvarious other components vital for the long-term sustenance of handloomweavers.[AshimaAnandet.al,2022]

In2016,toenhancetheeasyandtimelyaccessto rawmaterialsforhandloomweavers,theNationalHandloom DevelopmentCorporation(NHDC)launchedtheEnterprise Resource Planning (ERP) system and the e-Dhaga mobile app.TheERPsystemfacilitatesfastermaterial delivery to weavers,whilethee-Dhagaappallowsthemtoplaceorders and make online payments directly through the platform. Additionally,theGovernmentofIndiaintroducedtheYarn SupplySchemetocapitalizeontheemploymentpotentialof

thehandloomsector,ensuringyarnavailabilityatMillGate Pricesforweavers[Khatoon,2016].

YarnSupplyScheme(YSS)GovernmentofIndiais implementing Yarn Supply scheme to make available all types of yarn at Mill Gate Price to the handloom weavers. TheschemeisimplementedthroughtheNationalHandloom Development Corporation, a Government of India Undertaking[RRaviKumaret.al,2020]

TheGovernmente-Marketplace(GeM)waslaunched onAugust 9, 2016, by theCommerce & IndustryMinister. This online platform enables handloom weavers and handicraft artisans to sell their products directly to government departments and organizations. As of 2021, over 1.5 lakh weavers are registered on the GeM portal, whichoffersmorethan7,400productsacross150different categories[7].

TheMinistryhasbeenimplementingtheTechnology Up-gradation Fund Scheme (TUFS) since 1999 to boost productivity, quality, investment, and employment in the textile sector. TUFS is a credit-linked initiative, providing subsidiesoneligibleinvestmentsthroughapprovedlending agencies. In 2012, the scheme was restructured and renamedbyitcalledRevisedRestructuredTechnologyUpgradation Fund Scheme (RRTUFS). Later, in 2016, the AmendedTechnologyUp-gradationFundScheme(ATUFS) wasintroducedwithupdatedguidelines.Theschemenow covers segments such as weaving (including brand new shuttle-less looms, weaving preparatory, and knitting), processing,aswellasthejute,silk,andhandloomsectors.[9]

Aatma Nirbhar BharatAbhiyaan waslaunched by the Government of India to provide financial support to Indian artisans, businesses, and enterprises, including MSMEs,helpingthemrecoverfromlossesincurredduring theCOVID-19pandemic.Aspartoftheinitiative,thePrime Ministerannouncedaneconomicpackageof₹20lakhcore aimed at making India self-reliant. The Aatma Nirbhar Bharatschemealsosoughttoconnecttextileartisanswith retailersand exportersacrossthecountry throughvirtual platforms, bringing their products and skills to a global audience.(10)

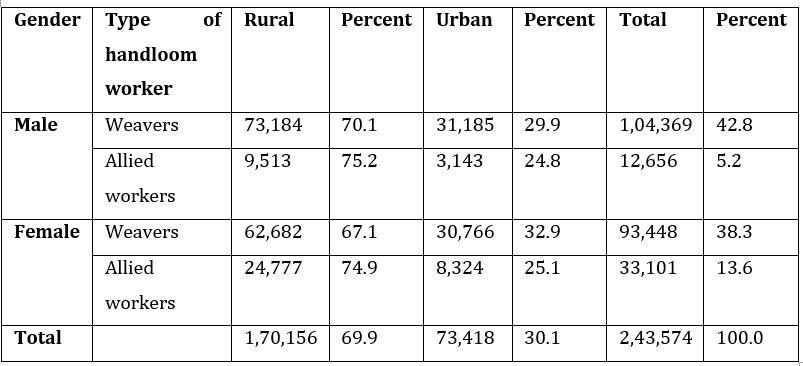

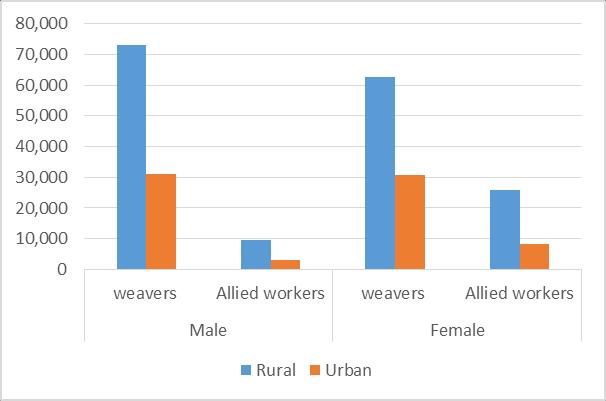

Thesignificanceofhandloomiswellrecognisedin termsofprovidingjobopportunityandvalueadditiontothe economy. there are 1139 handloom weavers cooperative

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 10 | Oct 2024 www.irjet.net p-ISSN: 2395-0072

societiesinthestateoutofwhich,1053arecottonprimary weavers cooperative societies, and 86 are primary silk weavers cooperative societies.2.69 lakh handlooms are registeredunderthesecooperativesocietieswhichaccount foraround65%oftotalhandloomcapacityofthestate(11). Handloom weavers face significant challenges, including competition from power looms and synthetic fabrics, changing consumer preferences toward fast fashion, and low, unstable incomes. Many rely on middlemen, limiting theirprofits,andstrugglewithlimitedaccesstomarketsand technology. Rising raw material costs and poor quality furtherimpacttheirearnings.Governmentsupportisoften poorlyimplemented,andmanyweaverslacksocialsecurity. Traditionalskillsaredecliningasyoungergenerationsmove awayfromthecraft.

identification of the problems facing by the handloom industryrelatedtoproduction,finance,andmarketingandto suggest the suitable measures for development and advancement of industry. As a result of effective government intervention through financial schemes, the handloomsector,tosomeextentasbeenabletotideover theseproblems/constraints,ifproperattentionispaidfor thedevelopmentofthissectoritmaycontributesignificantly tothegenerationofincome,output,employmentandforeign exchangeearnings.

1. RRaviKumaret.al,2020,“overviewofTamilNadu handloom industry: a study from government reports”, International journal of research and analyticalreviews,volume7,issue1,66

2. Ashima Anand et.al, 2022, “Indian handloom: presentscenarioandfuturedirections”,IISUniv.J.A, vol10(3),346.

3. Khatoonet.al,”MakeinIndia:APlatformtoIndian Handloom Market”, IOSR Journal of Business and Management(IOSR-JBM),volume18(9),2016,3640.

4. MinistryofTextiles,2018-19,AnnualReport,“New Delhi:MinistryofTextiles”,GovernmentofIndia.

5. NCAER,2010.HandloomCensusofIndia2009–10. Survey.MinistryofTextiles,GovernmentofIndia

6. https://textilevaluechain.in/in-depthanalysis/articles/basics-of-textiles/types-of-handloom#:~:text=PRIMITIVE%20OR%20VERTICAL%2 0LOOM.,-A%20primitive%20loom

7. https://gem.gov.in/aboutus#:~:text=Government% 20e%20Marketplace%20(GeM)%2C,and%20speed %20in%20public%20procurement

8. https://textilevaluechain.in/newsinsights/industry-cluster-news/supply-of-qualityraw-materials-for-promotion-of-handloom

9. https://handloom.odisha.gov.in/sites/default/files/ 2020-02/7_TUFS.pdf

10. https://en.wikipedia.org/wiki/Atmanirbhar_Bharat

11. Dept. of Handlooms and Textiles, 2018-19. Policy Note.AnnualReport.Chennai:Govt.ofTamilNadu

7. CONCLUSION

Handloomwasonceathrivingcottageindustryin India.InIndia ithadroyal patronagefromancientperiod. This sector still continues in spite of many hurdles and competition. Many weavers lack knowledge of modern techniquesinproduction,packaging,design,andpromotion. Forthedevelopmentandpromotionofhandloomindustryit is the need of the economy to make a study on the topic Further it is suggested more studies are required for