International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

SAHANA P1 AND RASHMA SHETTY2

1PG Student, Environmental Engineering, University BDT college of Engineering, Davangere, Visvesvaraya Technology University Belgavi, Karnataka, India

2Assistant Professor, Department of Civil Engineering, University BDT college of Engineering, Davangere, Visvesvaraya Technology University Belgavi, Karnataka, India

Abstract - The dairy industry is generally considered to be largest source of food processing. These industries wastewater is characterized by high COD, Turbidity, nutrients etc. In the present study, dairy waste water was treated by Aloevera gel and Neem gel. The initial pH, TDS, EC, Turbidity, COD were 8.7, 527ppm, 810ms/cm, 52.5NTU, 728.5mg/l respectively. The maximum removal efficiency of TDS, EC, turbidity, and COD by Aloevera gel is 55.80% (at pH 8, at optimum dose 50 mg/l, 100RPM, contact time 60 min), 96.83% (at pH 6, optimum dose 40mg/l, 100RPM, 30 min), and 95.74% (at pH 6, at optimum dose 60mg/l, 100RPM, 30 min) respectively. The maximum removal efficiency of TDS, EC, turbidity, and COD by Neem gel is 55.64% (at pH 8, at optimum dose 30 mg/l, 100 RPM, contact time 60 min), 90.78% (at pH 6, at optimum dose 40mg/l, 80 RPM, 60 min), and 96.43% (at pH 8, at optimum dose 40mg/l, 100 RPM, 60 min) respectively. Compared to Neem, Aloevera exhibits greater removal efficiency in TDS, turbidity, EC, and COD from dairy waste water under ideal circumstances.

Key Words: Natural coagulants, Turbidity, COD, EC, TDS, Dairywastewatertreatment,Aloevera,Neem.

Thedairybusinessisamongthemostpollutinginthefood industry.Asignificantamountofeffluentwasteisproduced daily by the dairy industry. These businesses release wastewater, which contains large amounts of nutrients, organic and inorganic substances, chemical and biological oxygendemands,andothercharacteristics[1].Anumberof pretreatments are necessary in order to offset the effects. Different coagulation techniques, such as chemical and natural coagulation, as well as biological treatment processes,suchasaerobicandanaerobictreatment,areused totreatdairyeffluent.Thecleaningandwashingprocesses in the milk processing facilities are the main source of wastewaterinthedairysector.Approximately2%ofallmilk is thought to be poured down sewers. High levels of COD, BOD and lactose, together with other nutrients and sanitizing agents, are characteristics of dairy effluent. The organicmaterialsinthewaterareeitherpresentinmilkin theiroriginalformorhavebeenprocessedintoaformthat has deteriorated [2]. A range of acidic and alkaline

detergents,aswellassterilizingchemicals,maybepresent in dairy cleaning fluids. Thus, depending on the cleaning techniqueused,thewastewater'spHcanvarygreatly.Global dairymarketvolume:USD489.74billion.Milkproduction worldwideeachyearis600millionmetrictons.Asiamakes only22%oftheworld'smilkproduction,butitaccountsfor 60%oftheworld'spopulation.Totalglobaloutputexceeds 530 million tons for a population of approximately 400 billiontons,withanaverageyearlypercapitaaccessibilityof 100 kg. India is the world's leading country in milk manufacturing, contributing 23 percent of all milk manufacturing globally. Milk manufacturing in the United Stateshasdevelopedatacompositeannualgrowthrateof approximately 6.2 percent, reaching 209 million tons in 2020–21 from 146.31 million tons in 2014–15. Three percent of the five million liters of milk produced were wasted due to an unreliable power supply. Karnataka produces an estimated 1.6crore liters of milk per day, of which1.2crorelitersaresoldasamarketablecommodity. Approximately80millionliters,ornearly70%ofthemilk produced, are procured by KMF[2]. Prior to the implementation of the incentive plan, KMF acquired over half of the milk products in the state, including ice cream, butter, peda, ghee, and other items. With the lockdown in place,otherthanhoneyandbutter,theremaininggoodsin thebouquetarenotsold,whichleadstothestockpilingof raw milk. Currently, there are 13484 dairy cooperatives operating within the boundaries of 14 district milk federations,with23.78lakhfarmersenrolledasmembers,of which8.37lakhfarmersareactivemembers.Thefirstdairy cooperative that became the Kodagu district's KMF was established in Kudige in 1955[2]. The Karnataka dairy developmentcooperative,orKDDC,wasestablishedin1974 with the goal of implementing a project overseen by the WorldBankfordairydevelopment.Dairywastewatercan havemanynegativeeffectsontheenvironment,including: Water pollution, Breeding ground for disease-carrying insects,Toxictofishandalgae,Nutrientrunoff,Pathogens, Antibiotics and hormones, Sewage pipe clogging Gaseous emissions, Dust and odors [1]. Dairy waste water can be treated using a variety of methods, including: chemicalcoagulation,biologicaltreatment,electrochemical treatment, natural coagulation [1]. The aloevera plants requireverylittlewater for growth because 98% of it is

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

found in its leaves. It has about 75 nutrients and 200 activemolecules,includingvitamins,enzymes,aminoacids, andminerals.Thepurposeofthisstudywastoexaminethe qualities of Aloevera gel and determine the spectrum of natural clarifying agents that can be utilized. Using a gel madeofaloeveraasacoagulantforthetreatmentoflow-and high-turbidwaterisanothertopicofthisstudy. Neemleaf juice is added to wastewater as a naturally occurring coagulant.Byapplyingthevariousdosagesofthecoagulant Azadirachta indica, An experiment was carried out to ascertain its efficacy as an absorbent in the treatment of dairy effluent. One of the world's most significant food processing industries is the dairy sector [2]. In this study optimumdosageofcoagulantsareconsidered.

2.1 Sample collection

DairywastewaterwascollectedfromBhatidairyindustryin Davanagere. The physio – chemical characteristics of samples were analyzed. Samples of dairy effluent were collectedincleancontainersandprecautionsweretakenfor collectionofwastewater.

2.2 Adsorbent preparation

2.2.1 Preparation of Aloevera Gel

Theentirealoeverawasthoroughlywashedtoeliminateany dirtorcontaminants.Theedgesoftheleafweretrimedand it was cut into pieces. Then the gel was removed with a spoon,and50mlofaloeveragelwasstirredwith500mlof distilled water. The extract was obtained by filtering the sample using whatsman filter paper. The collected filtrate waskeptina refrigeratoruntil it wasused, whichwas no longerthanaweek[8].

2.2.2 Preparation of Neem Leaves

The neem leaves were dried under the sun to remove moisture. They were processed into a fine powder. Once more, the powder was stored under direct sunlight and removeanyremainingmoisture.Alltheleaveswerepulled out and dried. The preparation of coagulant extract were donebymixing500gofneempowderwith500mlofdistilled water.Theextractwasobtainedbyfilteringthesampleusing whatsman fiter paper. The collected filtrate was kept in a refrigeratoruntil itwasused,which wasnolongerthana week[1].

Table -1: The Operational Parameters Considered in this Study are.

VALUES RANGE

RPM 80rpm,100rpm

Contacttime 30min,60min

Dosage 20mg/l,30mg/l,40mg/l,50mg/l,60mg/l, 70mg/l.

3. RESULTS AND DISCUSSIONS.

The dairy waste water was collected from the Bhati dairy industry Davanagere. The table 2 shows the initial characteristicsofdairywastewater.

Table 2: Initial Characteristics of Dairy Waste Water PARAMETERS

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

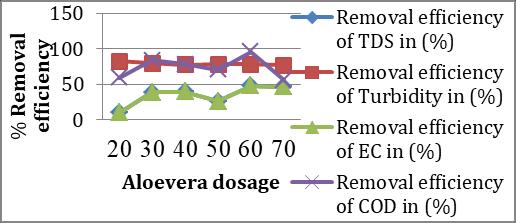

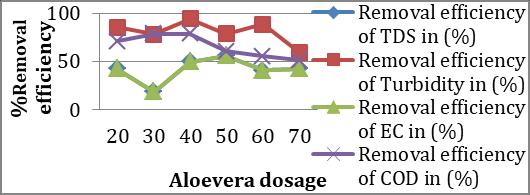

Chart 1: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem(pH6, 100rpm,Contacttime30min).

Thechart1showsthevariationofTDS,Turbidity,EC,COD fordifferentdosageofAloeveraandNeematpH6,at100rpm and Contact time 30 min. Aloe vera is a natural coagulant thatworkswellwhencomparedtoneemfortreatingdairy wastewater at pH 6. It often exhibits a greater removal efficiencyforturbidity,especiallyatlowerdosages.Onthe otherhand,NeemexhibitssuperiorTDSandECremovalat specificdoses,especiallyat20mg/l,indicatingitspotential as a robust adsorbent. While Neem's effectiveness varies greatly across dosages, aloevera performs best at higher dosages (60 mg/l), with a nearly total reduction in COD elimination. Aloevera is generally better at reducing turbidityandCOD,whileneemisbetteratremovingTDSand EC.

Removalefficiency ofTDSin(%)

Removalefficiency ofTurbidityin(%)

Removalefficiency ofECin(%)

Removalefficiency ofCODin(%)

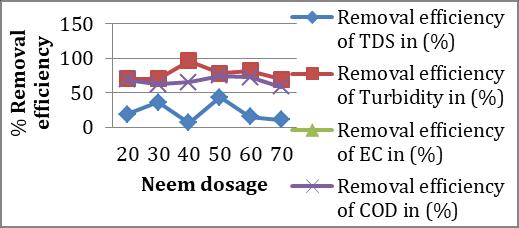

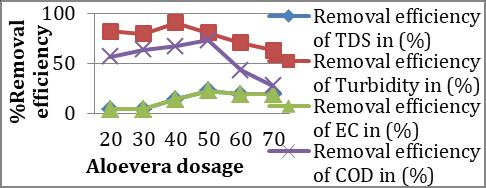

Chart 2: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem(pH6, 100rpm,Contacttime60min).

Thechart2showsthevariationofTDS,Turbidity,EC,COD for different dosage of Aloevera and Neem, at pH6, at 100rpm, Contact time 60 min. With notable removal efficiencyforTDS,turbidity,EC,andCOD,aloeveraandneem

areusefulnaturalwastewatertreatmentagents.At40mg/L, aloeveraremovesturbiditytothegreatestextentpossible (96.83%) and reduces COD to the lowest possible level (85.17%).At30mg/L,neemdemonstratessignificantTDS removal (50.66%),whileat50mg/L,itexcelsinturbidity reduction (84.76%). The differing efficacies between dosageshighlighthowcrucialdosageoptimizationistothe efficientremovalofpollutants.Allthingsconsidered,these plantspresentviableoptionsforenhancingwaterqualityin anenvironmentallyfriendlyway.

%Removal efficiency

50

0

100 20 30 40 50 60 70

Neem dosage

50 100 20 30 40 50 60 70

%Removal efficiency Aloevera dosage

Removalefficiency ofTDSin(%)

Removalefficiency ofTurbidityin(%)

Removalefficiency ofECin(%)

Removalefficiency ofCODin(%)

Removalefficiency ofTDSin(%)

Removalefficiency ofTurbidityin(%)

Removalefficiency ofECin(%)

Removalefficiency ofCODin(%)

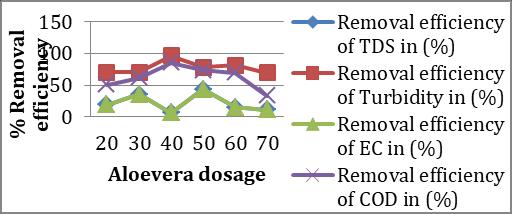

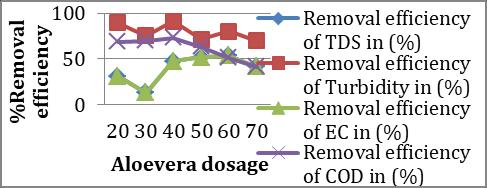

Chart 3: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem(pH6, 80rpm,Contacttime30min).

Thechart3showsthevariationofTDS,Turbidity,EC,COD fordifferentdosageofAloeveraandNeem,atpH6,at80rpm, Contact time 30 min. When used in conjunction with aloe vera and neem, water contaminants can be effectively removed under certain conditions (pH 6, 80 rpm, and 30 minutesofcontacttime).At40mg/L,aloeveraexhibitspeak removal rates for turbidity (80.33%) and TDS (54.46%), whereasat60mg/L,CODremovalreaches93.25%.Neem exhibits good removal of TDS (52.07%) and turbidity (90.27%)at40mg/LinadditiontoefficientremovalofCOD (82.67%).Thevariationineliminationefficiencyemphasizes howimportanttherightdosageistoimprovingtreatment results.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

efficiency

Removalefficiency ofTDSin(%)

Removalefficiency ofTurbidityin(%)

Removalefficiency ofECin(%)

Removalefficiency ofCODin(%)

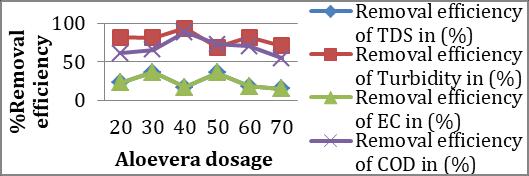

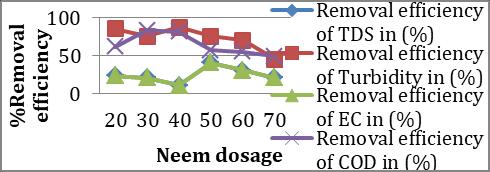

Chart 4: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem(pH6, 80rpm,Contacttime60min).

Thechart4showsthevariationofTDS,Turbidity,EC,COD fordifferentdosageofAloeveraandNeem,atpH6,at80rpm, Contacttime60min.Inwastewatertreatment,aloeveraand neemshownotableefficaciesineliminatingpollutantsatpH 6, 80 rpm, and 60 minutes of contact time. At 40 mg/L, aloeveramayremoveupto93.20%ofturbidityand88.05% ofCOD.Neemperformsadmirablyaswell,removing54.85% TDSandreducingCODby90.78%atthesamedosage.The potential for environmentally friendly water filtration technologyisdemonstratedbybothplants.

%Removal efficiency Aloevera dosage

20 30 40 50 60 70

Removalefficiency ofTDSin(%)

Removalefficiency ofTurbidityin(%)

Removalefficiency ofECin(%)

Removalefficiency ofCODin(%)

Removalefficiency ofTDSin(%)

Removalefficiency ofTurbidityin(%)

Removalefficiency ofECin(%)

Removalefficiency ofCODin(%)

Chart 5: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem (pH8,100rpm,Contacttime30min)

Thechart5showsthevariationofTDS,Turbidity,EC,COD for different dosage of Aloevera and Neem, at pH8, at 100rpm, Contact time 30 min. When used in wastewater treatment, Aloevera and Neem demonstrate efficient pollutant removal at pH 8, 100 rpm, and 30 minutes of contacttime.Aloeverademonstratesitspotencyinclarifying water by achieving its maximum turbidity removal of 92.78%andCODreductionof88.60%at40mg/L.Neemis alsoeffective;at50mg/L,it mayremoveupto55.64% of TDSandreduceturbidityby92.33%.Whencombined,these

plants offer viable, sustainable solutions for raising the qualityofthewater.

efficiency Neeem dosage

20 30 40 50 60 70

Removalefficiencyof TDSin(%)

Removalefficiencyof Turbidityin(%)

Removalefficiencyof ECin(%)

Removalefficiencyof CODin(%)

Chart 6: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem(pH8, 100rpm,Contacttime60min).

Thechart6showsthevariationofTDS,Turbidity,EC,COD for different dosage of Aloevera and Neem, at pH8, at 100rpm, Contact time 60 min. Aloevera and neem exhibit encouragingpollutantremovalefficiencyatpH8,100rpm, and60minutesofcontacttime.Aloeveraexhibitssignificant coagulationcapabilitiesasitachievesitsgreatestturbidity removalof94.38%andTDSreductionof49.40%at40mg/L. Neem also works well, efficiently clearing water with a maximumturbidity removal of96.43%at40 mg/L.When combined,theseplantsprovidelong-termwaystoraisethe qualityofthewater.

Removal efficiencyofTDS in(%)

Neem dosage

Removal efficiencyof Turbidityin(%)

Chart 7: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem(pH8, 80rpm,Contacttime30min).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

Thechart7showingthevariationofTDS,Turbidity,EC,COD for different dosage of Aloevera and Neem, at pH 8, at 80rpm,Contacttime30min.Effectivepollutantremovalis demonstratedbyAloeveraandNeematpH8,80rpm,and 30 minutes of contact time. At 40 mg/L, aloe vera may remove up to 90.66% of turbidity and reduce COD by 72.82%, demonstrating its potent ability to clarify water. Neemexhibitsgoodperformanceinwastewatertreatment, asevidencedbyitspeakturbidityreductionof88.76%and CODremovalof79.27%at40mg/L.Whentakenasawhole, theyofferlong-termfixesforraisingwaterquality.

Chart 8: GraphsshowingthevariationofTDS,Turbidity, EC,CODfordifferentdosageofAloeveraandNeem(pH8, 80rpm,Contacttime60min).

Thechart8showingthevariationofTDS,Turbidity,EC,COD fordifferentdosageofAloeveraandNeem,atpH8,at80rpm, Contact time 60 min. Aloe vera and neem are natural coagulantsthatworkwellfortreatingwater.Theyhavebeen showntoremoveturbidity,chemicaloxygendemand(COD), electricalconductivity(EC),andtotaldissolvedsolids(TDS) withnotableefficiency.Aloeverademonstratedsubstantial flocculatingcharacteristics,asseenbythehighestremoval rates, with 91.29% turbidity reduction at a dosage of 40 mg/l.Neemexhibitsnoteworthyperformanceaswell,with an 83.25% removal rate in COD reduction at 30 mg/l, underscoringitspotentialforlong-term,sustainablewater filtration.Overall,theseplantsofferpracticalsolutionsfor improvingwaterqualityinanenvironmentallyresponsible way.

A number of variable factors, including pH, dosage, contact time, and agitation time,weretakenintoaccount throughouttheexecutionofthisinvestigation.Aloeveraand neem were used as natural coagulants. All of the experimentalresults,figures,andobservationsareincluded. Conclusionshavebeendrawnbasedontheseperformances.

The maximum removal efficiency of Aloevera on EC, turbidity, and COD are 55.80% (at pH 8, dose 50 mg/l, 100RPM, contact time 60 min), 96.83% (at pH 6, dose 40mg/l, 100RPM, 30 min), and 95.74% (at pH 6, dose 60mg/l,100RPM,30min)respectively.

The maximum removal efficiency of Neem on EC, turbidity,andCODare55.64%(atpH8,dose30mg/l,100 RPM,contacttime60min),90.78%(atpH6,dose40mg/l, 80 RPM, 60min),and96.43% (atpH8,dose 40mg/l,100 RPM,60min)respectively.

ComparedtoNeem,Aloeveraexhibitsgreaterremoval efficiency in TDS, turbidity, EC, and COD under ideal circumstances.

The cost and availability of Neem and aloevera are more affordable and widely available, making them a sensibleoptionforwidespreaduse.

Additional investigation may enhance their utilization and exploremoreextensiveuses.

[1]UtkarshVSurwase,SagarBDevakar,PranavSDaharade, TusharSPawar,SohelMNayab(2020).“Use of Aloevera as Natural Coagulant”. International journal of engineering research and technology. Volume7. Issue8 Pageno 43624365.

[2] Namrata S Naragundakar, Naghma N, Basanth Kumar U,(2022) “DairyWasteWater Treatment by using Natural Coagulants”, Internationaljournalofengineeringresearch andtechnology.Volume10,Issue11,Pageno532-535.

[3] Gulmire Amruta, G.R. Munavalli, (2016) “Use of Aloe Vera as Coagulant aid in Turbidity Removal”, International journal of engineering research and technology,volume10,pageno314-317.

[4] S. Deswal, (2022) “Use of Aloevera as Natural Coagulant”. International journal of engineering research andtechnology.Pageno962-968.

[5]ChidanandPatil,Ms.ManikaHugar,(2015) “Treatment of Dairy Wastewater byNatural Coagulant”. International research journal of engineering and technology, volume2, issue4,Pageno1120-1125.

[6]BenaliaAbderrezzaq,DerbalKerroum,KhalfaouiAmel, A. Pizzi Pizzi (2021) “The Use of Aloe Vera as Natural Coagulant in Algerian Drinking Water Treatment Plant”, International journal of engineering research and technology. volume13,issue15,Pageno1522-1552.

[7] Dr. Derbal Kerroum (2021) “Use of Aloe vera as an Organic Coagulant for Improving Drinking Water

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

Quality”, International journal of engineering research anditechnology,volume2,issue4,Pageno373-386.

[8] Chinchu K George, Anitha K (2017) “Use of Aloevera juice for Wastewater Treatment by Coagulation and Flocculation”, Internationaljournalofengineeringresearch andtechnology volume2,issue8,Pageno1105-113.

© 2024, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page749