International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

Desai Saeera Premanand

Student, Department of Electronics & Telecommunication Engineering, Goa College of Engineering, Farmagudi, Ponda - Goa, INDIA

Abstract - Supervisory Control and Data Acquisition (SCADA) systems keep an eye on and manage vital industrial infrastructure. Ensuring the accuracy of measured valuesand alarm signals conveyed from the field to the SCADA control room or other remote monitoring systems and thecorrectness of the data displayed is imperative while commissioning or remodeling a substation. The HumanMachineInterface(HMI) present in the substation shows the status and alert signals. Generally, an engineer present at the substation triggers an alert on a field device. He confirms that the local HMI is displaying the alert correctly. He then inquiries from the operator present in the control room if the same alert is displayed on the screen in the control room. This makes it a tedious task. Automating substation procedures is the goal of the proposed methodology. The principal objective of the suggested concept is to demonstrate the automation of field devices in a particular controlled system.

Key Words: Automation,HumanMachineInterface,WinCC SCADA,InTouchSCADA,DeltaPLC

Asubstationautomationsystemisanassemblyofhardware andsoftwarepartsusedforbothlocalanddistantelectrical systemmonitoringandcontrol[1].Inadditiontoautomating certain laborious, repetitive, and mistake-prone tasks, a substation automation system also boosts the system's overall productivity and efficiency [2]. An electrical corporation has traditionally prioritized an electrical substation's high availability and continuous operation. Moreerrorsresultinmorecustomerserviceinterruptions and lower income, which is undesirable for any business. Industrial automation has several benefits that manufacturers,andindustrial operationscanusetoboost operational effectiveness [3]. Data from monitoring helps ensure that new automated solutions achieve their objectives like improved worker safety, increased productivity,higherquality,andbetterdecisionmaking

ASupervisoryControlandDataAcquisition(SCADA)system can automate the supervision task based on predefined parametersandalgorithms[6].Itcanalsogatherinformation from multiple IEDs in an electrical system using various communication methods [14]. Finally, it can control and monitortheIEDsusingvariousvisualizationtechnologies[7]

Every substation has a Human Machine Interface (HMI) installedtogiveoperatorsthelocalcontrolandmonitoring tools that are frequently required for substation

configuration,commissioning,ormaintenance[8].Products forsubstationautomationareagroupofsystemsthatoffer completeautomation,protection,andcontroloverelectrical substations. By offering quick communications, flexible automation, and rapid protection, these solutions are intended to increase the substation's safety and dependability [9]. They consist of a variety of gadgets, including automation controllers, power quality meters, signalingunits,andmore

Theaimoftheproposedmethodistoimprovesystemswith SCADAautomationwithuserHMIfunctionstocontroland validate various functions of the products. Based on the aboveinformation,ourobjectivesareasfollows:

1. To design and implement automation for substation automationproducts.

2. To enhance the automation of an existing system integratedwithSCADA.

The research papers referred served as a foundation for understanding how to create an HMI screen with WinCC SCADA software. As per the methodology proposed in the researchpapers,appropriatetagdevelopmentforthescreen elementstomimictheindustrialplant'sreal-timestatusleads tosuccessfulprogrammingoftheintendedHMI[3].Areliable connectionbetweenthePLCandtheHMIismadepossibleby thetaggingsystem[5].Themanualandautomaticmodesof operation are availed by pushing the soft-touch controls. Withouthumaninteraction,automatedmodeisguaranteed byproperdesign[4].Inthisproject,theautomationofthe certainindustrialprocessesisimplementedwiththehelpof PLC,SCADAanditsvariousproperties.Implementationofthe processautomationisbetterforincreasingthespeedofthe process,aswellasitprovidesdatamonitoringandstorage.

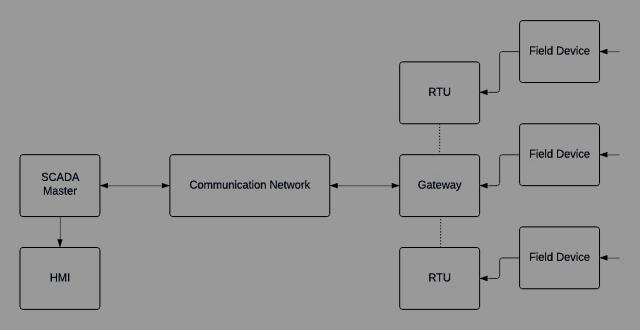

3.1 Block diagram of the proposed idea

AsshowninFig-1,theindustrialsubstationincorporates avarietyoffielddevices,suchasSensors,Actuators,Circuit Breakers, etc., and a group of related field devices are connectedtoaparticularRemoteTerminalUnit(RTU)[10] TheRTUservesasagatewaytotransferdata betweenthe fielddevicesandtheSCADAorviceversa.Acommunication

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

network such as MODBUS, the IEC 60870-5-104 communicationprotocol,etc[11].makesthisdatatransfer possible.SCADAmastercontainsthesoftwareprogramthat managesthefielddevicesbasedonthedatareceived.Human Machine Interface (HMI) is used to manage the field using touchcontrols[12].TurningONorOFFthefielddevices,data collection,monitoringaparticularparameterinthefield,and checking alert signals in the field are feasible using HMI screens[13]

3.2 Virtual simulations in SCADA

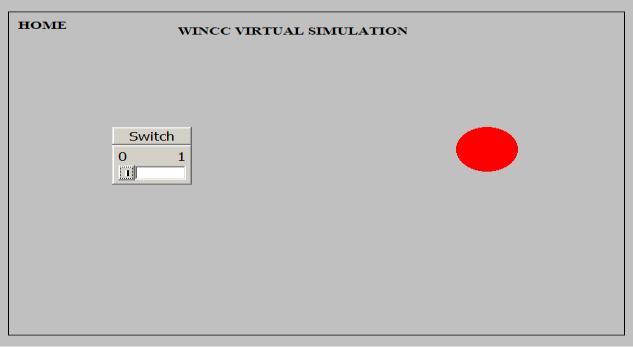

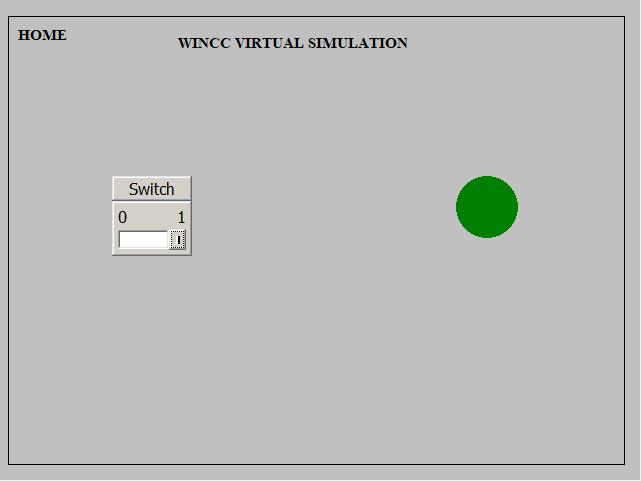

Asimpledigitalsystemconsistingofalampandaswitch isdesignedasshowninFig-2(a)andFig-2(b).Thefunction ofthiscontrolledsystemistoturnONalampusingaswitch.

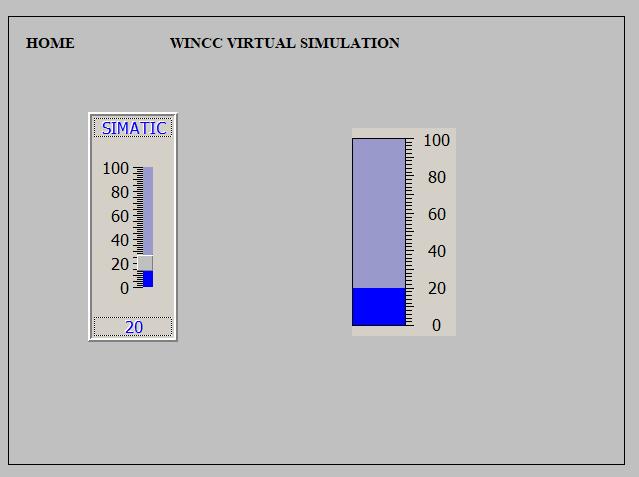

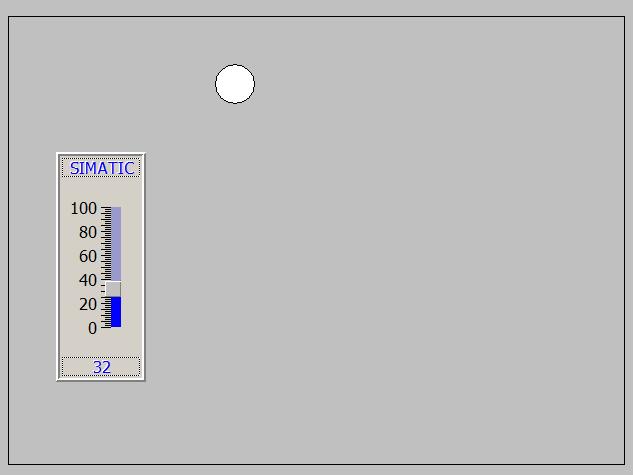

Asimpleanalogsystemconsistingofasliderandabaris designedasshowninFig-3.Thefunctionofthiscontrolled systemistodisplaythevalueselectedusingaslideronthe bar.

Fig -3:Runtimepageofthevirtualsimulationwhenthe value20isselectedontheslider

A simple animation is designed as shown in Fig -4, whereinaballismovedbyacertaindistancewiththehelpof aslider.

-4: Runtimepageofthevirtualsimulationwhenvalue inbetween0to100isselectedontheslider.

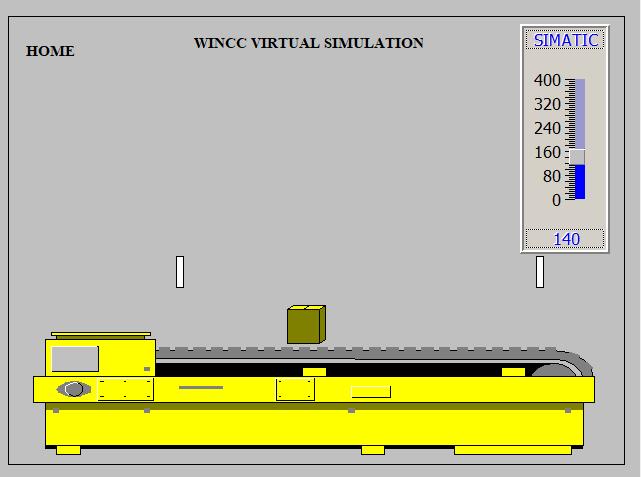

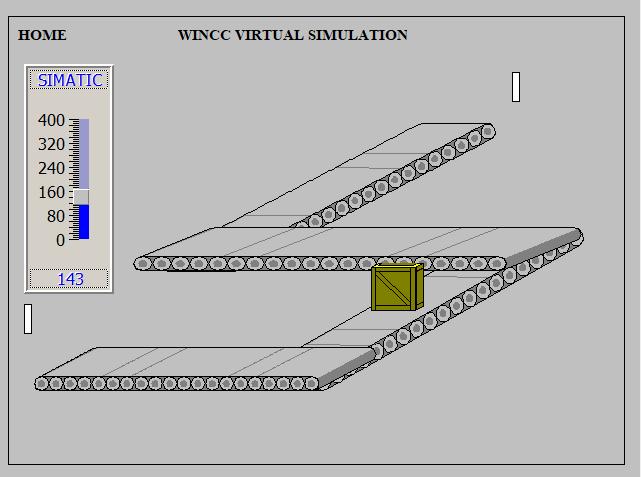

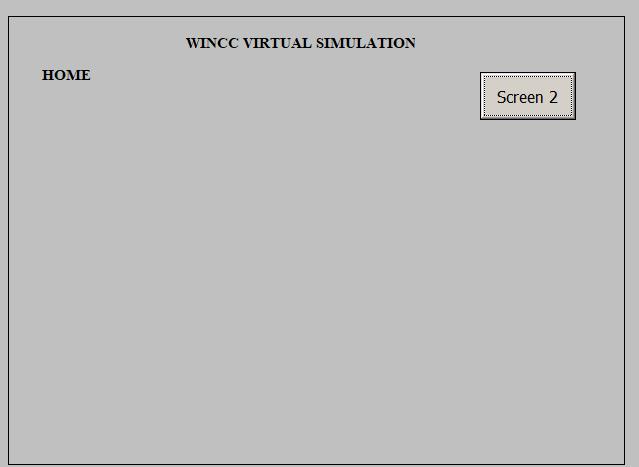

AnanimationisdesignedasshowninFig-5,wherein a container is moved a certain distance with the help of a conveyorbeltusingaslider.Onemoreanimationisdesigned whereinacontainerismovedupwiththehelpofaconveyor belt using a slider as shown in Fig -6 using the visibility concept.Screenactivationisdesignedwherein,afterpressing abutton,“Screen2”getsactivatedfromthe“Home”screenas showninFig-7(a)andFig-7(b).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

Fig -5:Runtimepageofthevirtualsimulationwhenthe sliderisbetween0and400.

Fig -6:Runtimesimulationwhentheslideriswithinthe rangeof101to200

Fig -7(a):Runtimesimulationshowing“Home”screen

Fig -7(b):Runtimesimulationshowing“Screen2”when thebuttonisclicked

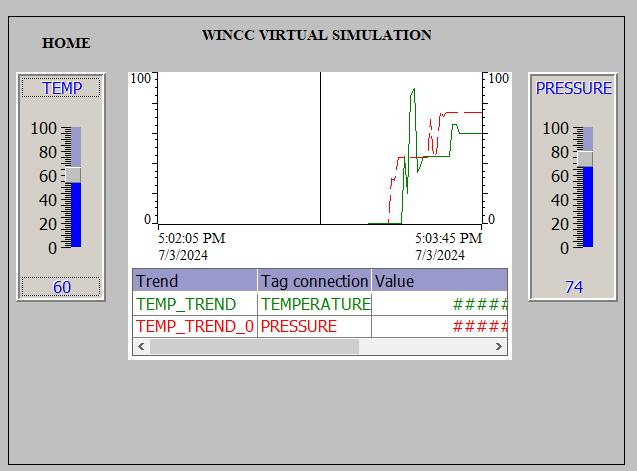

Real-time monitoring of a physical quantity using graphicalrepresentationcanbeachievedusing“Trends”[15] Twoslidershavebeenchosen,oneforthetemperatureand the other for the pressure. As per the level shown on the sliders,the data is shown as a plot on the graph as canbe seeninFig-8

Fig -8:Thetemperatureandpressurereal-timegraphical representation

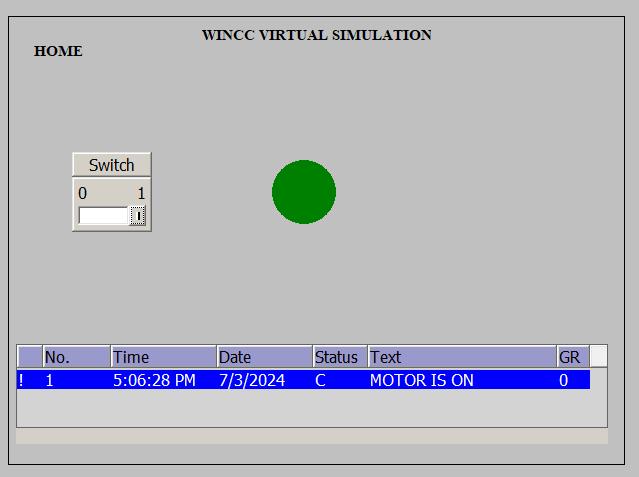

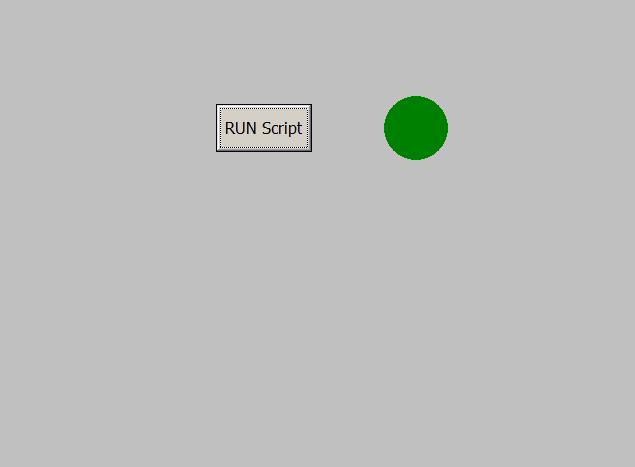

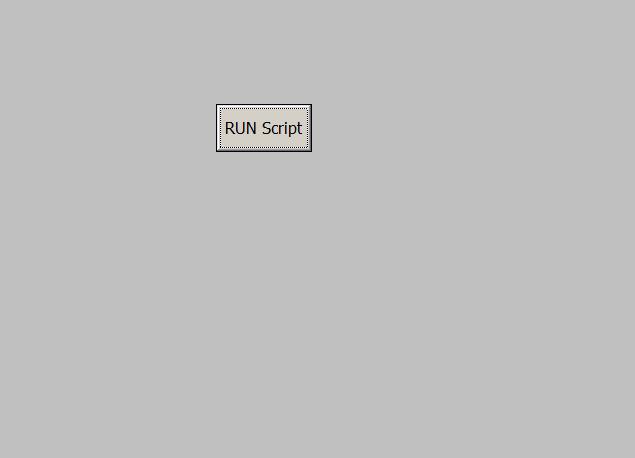

A virtual simulation is created, as shown in Fig -9, whereinamotorturnsONwhentheswitchisturnedON,and oncethemotorturnsON,analarmisshownthat“Themotor isON”.AsimpleanimationisdesignedasshowninFig-10(a) and Fig -10(b), wherein a ball is vanished on pressing the “VANISH”button.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

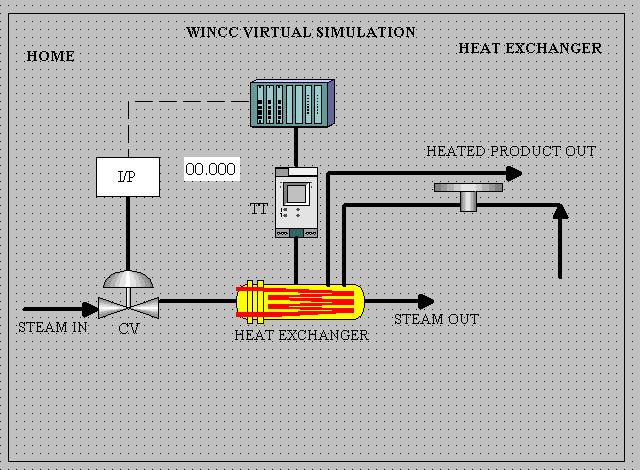

Aheatexchangerisasystemthattransfersheatfromone medium to another. When the two objects are stored isolatedfromtheirsurroundingsinaheat-resistantbox,the heatlostviathewarmobjectisequaltothewarmthreceived bythecoldobject,andtheheattransfertakesplaceuntilthe temperatureofeachobjectturnsequal[16].Thisisreferred

toastheprincipleofheatexchange.Thedesignoftheheat exchangersystemhasbeenshowninFig-11.

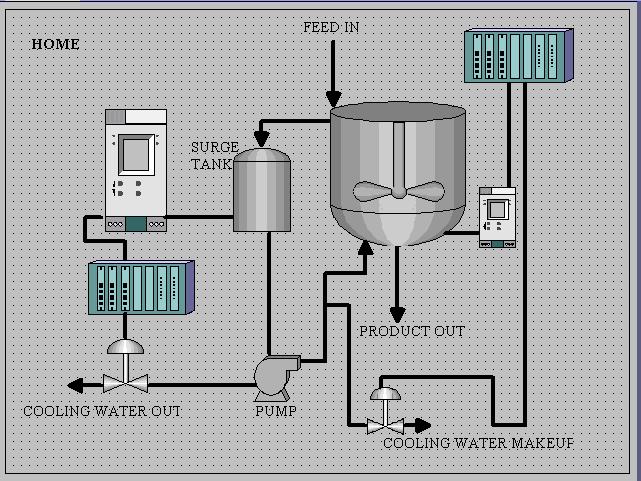

Aclosedcontainerwhereinachemicalreactioniscarried outisachemicalreactor.Industrieshavetomakesurethat thereactiontakesplaceasefficientlyaspossibletowardsthe required output, leading to the best yield. Energy input, energydisposal,thecostoftherawmaterials,costoflabor, and other charges are all part of the regular operational expenses [17].Thereactantsandtheproductsareusually fluids(gasesorliquids).Thedesignofthechemicalreactor hasbeenshowninFig-12.

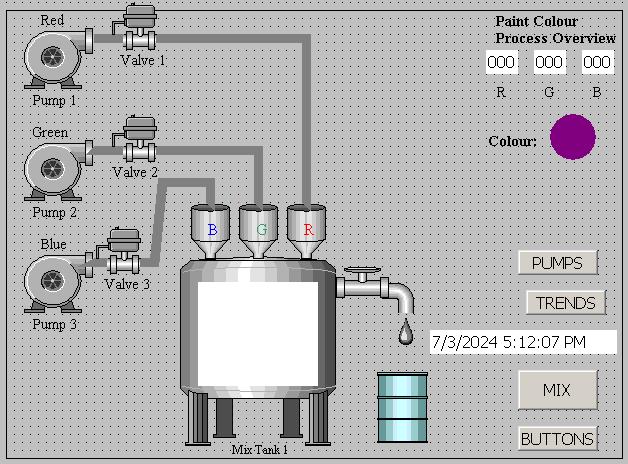

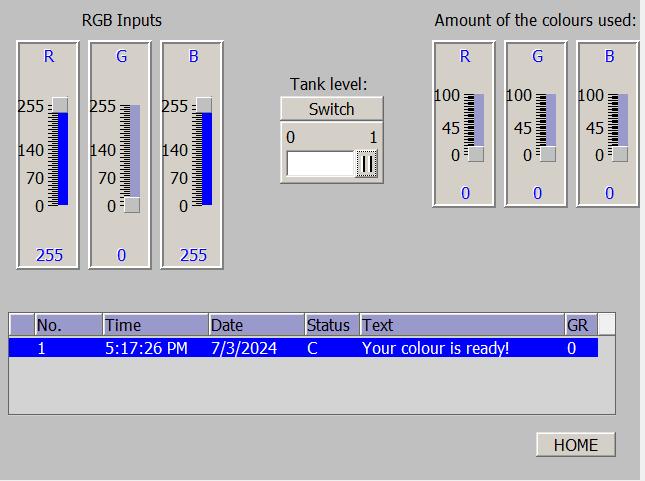

Apaintcolourprocesshasbeendesignedwherewecan obtainthedesiredcolourbyselectingasuitablelevelofthe red,green,andbluecolours[19].ThedesignisshowninFig13(a).Itpossessesthefollowingproperties:

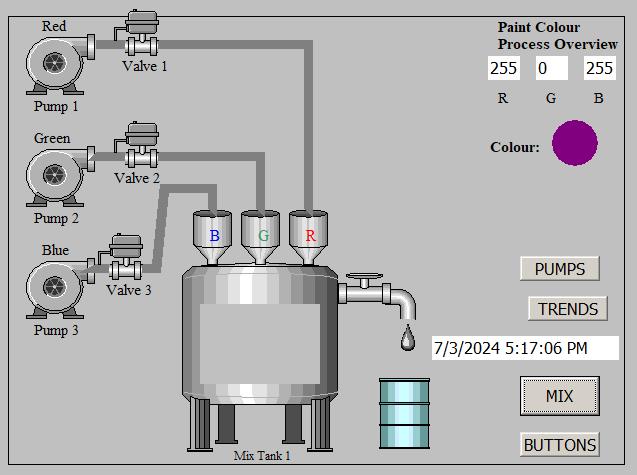

Upontheselectionofasuitablelevelofred,greenand blue colour, and after pressing the button “Mix”, the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

requiredcolourisobtained,whichisshownonthehome screenasshowninFig-13(b).

The input RGB values are also displayed on the home screenascanbeseeninFigure13(b).

An alarm is generated when the colour mixing is over andthecolourisreadyasshowninFigure13(c).

If the amount of colour in the red, green or blue tank reduces,thenanerrorisshownthatthetankisemptyas showninFigure13(d).

Real-time data and time are displayed on the home screenascanbeseeninFigure13(a).

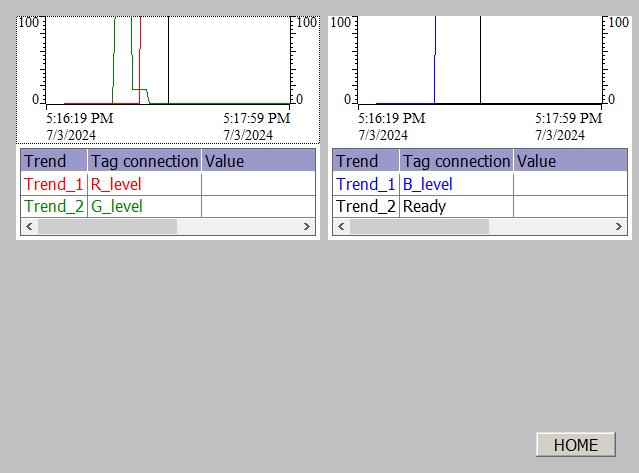

Four graphical views are used to track the amount of usageoftheRGBcoloursaswellastheleveloftheoutput colourasshowninFigure13(e).

Fig -13(e):Real-timegraphicalrepresentationofthe amountoftheRGBcolourusedandthecolourgenerated

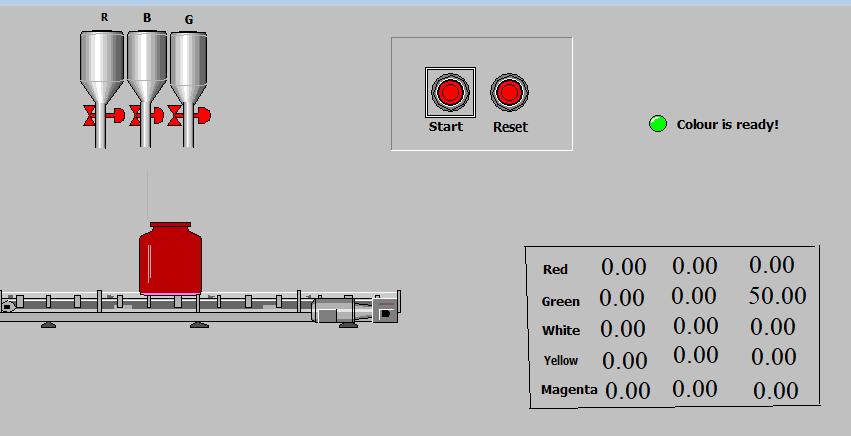

3.6 Paint colour making process in InTouch SCADA

ApaintcolourmakingprocessasshowninFig-14,has been designed wherein with the use of the three primary

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

colours-red,greenandblue,therequiredcolourisformed. The required colour input is given using the PLC input buttons and accordingly the valves of the primary colour tanksareturnedONforasuitableamountofduration,such that the required colour is obtained [18]. Once the colour getsready,analarmisshownontheSCADAwindow.

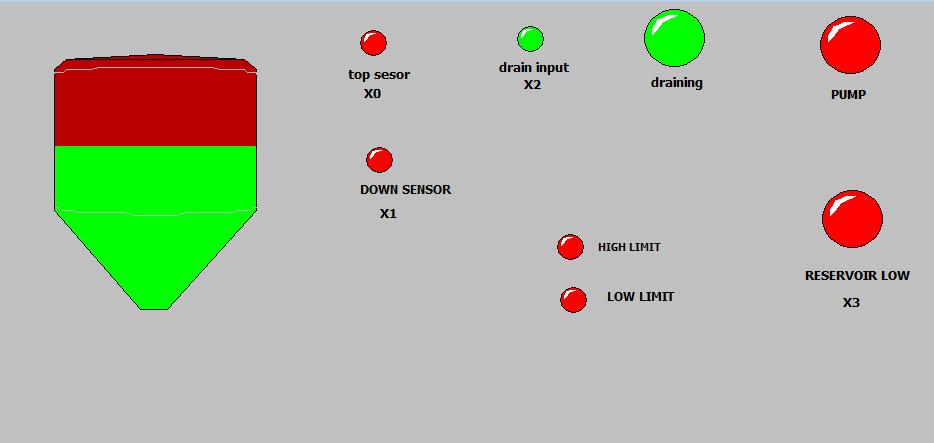

3.7 Water level monitoring system in InTouch SCADA

A system has been designed using two reservoir tanks as showninFig-15.Onetankisonthegroundandtheotheris anundergroundtank.Whentheuserdrainsthewaterfrom the ground-level tank, and the water reaches its low limit sensor,thepumpstartsandthewaterfromtheunderground reservoir starts flowing in the ground-level tank till the water level in tank reached the high-level sensor. If the underground tank water level reaches below its low-level sensorwhilethewaterisgettingfilledfromtheunderground tankintotheground-leveltank,thenthepumpautomatically stopstopreventdryrunningofthepump[20].

Inthisresearch,theautomationofthesubstationprocedures have been accomplished for certain field procedures. The designofdigitalandanalogsystems,animationsusingaball or a conveyor belt and a container, use of the visibility concept, screen activation, use of trends in real-time observation of the parameters, alarms and Visual Basic scriptinghasbeenaccomplishedinWinCCSCADAsoftware.

Inadditiontothat,heatexchangersystem,chemicalreactor and paint color process has also been designed using the variouspropertiesoftheWinCCSCADAsoftware.

SCADA is a technology that gives manufacturers and industrial organizations control over machinery and operationsbyfusinghardwareandsoftware.Process-related data is collected by the system from various devices and equipmentinsidetheoperation,whethertheyaredispersed throughoutmultiplesitesorasinglefacility.Thedataisthen usedbySCADAoperatorsandsupervisorstokeepaneyeon processes,maintainandenhanceproductivity,boostquality and profitability, cut down on waste, and swiftly and effectivelyidentifyissuesandemergencies.SCADAsystems are used in a vast variety of companies and sectors worldwide, ranging from small businesses to some of the biggest.Forbusinessestoeffectivelymanage,regulate,and keep an eye on physical operations taking place at one or morelocations,SCADAsystemsareessential.

[1] Dimitris Mourtzis, John Angelopoulos, Nikos Panopoulos.(2023).”TheFutureoftheHuman-Machine Interface (HMI) in Society 5.0”. Future Internet 2023, (https://doi.org/10.3390/fi15050162).

[2] Erwin, N., Francis, H., Ofosu, R. A. (February 2014). ”Developing a Human Machine Interface (HMI) for Industrial Automated System using Siemens Simatic WinCC Flexible Advanced Software”. Journal of Engineering Trends in Computing and Information Sciences,Vol.5,No.2(ISSN2079-8407).

[3] Groumpos, P. P. (2021). ”A Critical Historical and ScientificOverviewofallIndustrialRevolutions”.20th IFAC Conference on Technology, Culture, and InternationalStabilityTECIS2021,Volume54,Issue13, Pages 464-471 (https://doi.org/10.1016/j.ifacol.2021.10.492).

[4] Houda, M., Zouhaira, A., Olfa, E. (February 2023). ”Human Machine Interface Design of Industrial Automated Machine using SIMATIC SCADA System”. International Journal of Industrial Engineering, 30(2), 435-450, 2023, ISSN: ISSN 1943-670X, (DOI: 10.23055/ijietap.2023.30.2.8561)

[5] Htet, H.A., Thae,T. E.(August2019).”Simulationand Implementation of PLC based for Nonstop Filling ProcessusingPLCSIMandHMI”.InternationalJournalOf Creative and Innovative Research In All Studies (IJCIRAS),Vol.2,Issue3(ISSN(O)-2581-5334).

[6] Liang Wang, Xiuting Wang. (2012). ”Research on the SCADA System Constructing Methodology Based on SOA”.2012InternationalWorkshoponInformationand Electronics Engineering (IWIEE),

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

(doi:10.1016/j.proeng.2012.01.535). ETC Engg. Dept., GEC - 2023-24 Page i Industrial Automation ManagementusingSCADA.

[7] Matei,G.,Ales,J.,Peter,H.(2019).”AutomationofSCADA SystemDevelopment”.ACTATECHNICACORVINIENSIS –BulletinofEngineering,Fascicule2(ISSN:2067-3809).

[8] Mihai, I., Gheorghe-Daniel, A., Nicolae, M. (May 2009). ”SCADAsystemforacentralheatingandpowerplant”. 5thInternationalSymposiumonAppliedComputational Intelligence and Informatics (SACI ’09). Timisoara, Romania:(DOI:10.1109/SACI.2009.5136232).

[9] Piyush Kumar Prajapati, Lalitesh Kumar. (Novembe 2018).”ApplicationbasedStudyoftheArchitectureofa SCADASystemandOperationalStages”.International Conference on Advances in Engineering Science and Management. Agra: (ISBN: 978-81-931974-0-0) T R Publication.

[10] Shahid Ali, Ruchita Dahiya. (December 2019). ”Importance of Manual and Automation Testing”. 9th InternationalConferenceonAdvancesinComputingand Information Technology (p. (DOI:10.5121/csit.2019.91719)).

[11] Anon. “Industrial Automation Solutions- Human Machine Interface”, www.ti.com/general/docs/ge tliteature.tsp,2011.

[12] SiemensAG.,“PC-basedAutomationPlantVisualisation with WinCC Flexible and Visual Basic.NET”,www.support.automation.siemens.co m/WW/view/en/,2011.

[13] Anon.,“DesigningEffectiveControlInterfaceSystems”, www.ewark.com/pdfs/techarticles/ea,2012.

[14] Anon. (2011b) ,“Krono Tech Instrumentation and Control”, www.kronotech.com/HMI/advantages.ht m, 2011.

[15] Kalogeraki, E.-M.; Papastergiou, S.; Mouratidi, H. and Polemi, N.: A Novel Risk Assessment Methodology for SCADA Maritime Logistics Environments. Appl. Sci., 8 (1477),1-32,2018.

[16] SiemensAG.SIMATICHMIWinCCV7.4-GettingStarted. EntryID:A5E37531782-AA,236pages,February2016.

[17] Ujvarosi,A.:EvolutionofSCADAsystems.Bulletinofthe TransilvaniaUniversityofBraşov,9(58),No.1,63-68, 2016.

[18] M. Elango, Shantanu L. Kulkarni, “DEVELOPMENT OF PLC BASED CONTROLLER FOR BOTTLE FILLING MACHINE”, International Journal Of Innovations In

Engineering Research And Technology, [ijiert] issn: 2394-3696volume3,issue4,apr.-2016.

[19] Tanmay Sharma1, Dhruvi Dave2 and Hinal Shah3,”ImplementationofAutomaticColorMixingand FillingUsingPLC&SCADA”,ISSN2278-6856Volume6, ,Issue3,May-June2017.

[20] Agarwal, T. and Fatima, Z. (2002). Master Station Architecture of a SCADA System. IETE Journal of Education, 43(3): 121-126, https://doi.org/10.1080/09747338.2002.11415771.

© 2024, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

|