International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

Shivendra Yadav1 , Chandra Shekhar Patel2 , Abhishek Kumar Yadav3, Akash Kumar Vaishya4

1,2,3,4 Department of Civil Engineering, Rajkiya Engineering College Mainpuri-205001 India ***

Abstract - In this study, the use of waste plastic and recycled concrete aggregate (RCA) as cutting-edge, sustainable materials for road pavement construction is investigated. The purpose of the study is to assess waste plastic bonded with aggregate to be used in the surface course and RCA performance in the GSB (Granular Subbase) layer of flexible pavement for the building of sustainable road infrastructure. The waste plastic is broken up into small pieces, coated in aggregate, combined with heated bitumen, and utilized to create a mixture that is used in the surface course. The analysis is carried out on the plastics used from PET bottles that are considered waste after their use. Bitumen is replaced with plastic at percentages of 3%, 5%, 10%, and 15%. The present study also investigates the results obtained by partially replacing the natural aggregates of the GSB (Granular Subbase) layer of traditional flexible pavement with recycled concrete aggregates by comparing the results of proctor test and CBR values with the specifications and guidelines provided by the Ministry of Road Transport and Highways, Government of India. The physical and mechanical properties of recycled concrete aggregate are almost similar when compared to natural aggregate. The combination of plastic-modified bitumen and recycled aggregates in flexible pavements represents a significant step towards creating more sustainable and resilient road infrastructure.

Key Words: FlexiblePavement,Plasticwaste,Recycledmaterial,Sustainability,Environmentfriendly,Durability,Strength, Reducedthickness,Costeffective.

Theglobalinfrastructureindustryhasbeendealingwithtwomajorissuesinrecentyears:effectivelymanagingplasticwaste andsustainablyusingconstructionmaterials.Innovativemethodsarebeinginvestigatedtoincorporatewastematerialsinto constructionprocessesinordertoaddressthesechallenges,withthegoalofimprovinginfrastructureperformancewhilealso protecting the environment. This project centers on using waste plastic and recycled concrete aggregate (RCA) in the constructionofflexiblepavements,anessentialpartoftransportationinfrastructure.Flexiblepavementsarecreatedtoendure themovingloadscausedbyvehiculartrafficwhileofferinglongevityandusabilitythroughouttheirlifespan.

AhmadM.AbuAbdoandS.J.Jung,(2019)havementionedthatofficialsinRasAlKhaimah(RAK),UnitedArabEmirates arefacingariseinsolidwaste. UAEareassessingalternativesforreusingthesematerialsinsteadofdisposing ofthemin landfills.Moreover,busyandslowertrafficiscausingprematurefailureofasphaltpavementsinRAKpairedwithscorching temperaturesinthesummer.Tohelpwiththeattemptstofindasolutionthisresearchwascarriedouttoexaminetheimpact ofincludingwasteplasticontheseissuesIncorporatingsyntheticfibersintoHotMixAsphalt(HMA).Experimentswerecarried outonatypicalHMAusingtwodifferentgradesofasphaltbinderandtwolevelsofwasteplasticfibercontent(0.5and1%of mixweight).ThefindingsindicatedthattheresistanceofHMAtofractureattemperaturesof−10and21.1°C,aswellasrutting, wasobserved.Theadditionofwasteplasticfiberscausedanincreaseinresistanceatatemperatureof54.4°C.Optimizing wasteplasticfibershasledtoanoverallenhancementintheperformanceofasphaltpavement.Themixturewasdeterminedto contain0.5%ofthecontentbyweight.ByincorporatingwasteplasticfibersintoHMA,enhancementofasphaltpavements performancebyimprovingresistancetoruttingandcracking.Reusingdiscardedplasticwastecouldhaveabeneficialimpacton theenvironment.

M.A.DalhatandH.I.Al-AbdulWahhab(2015)havebeenfoundthattherehasbeenasignificantincreaseinwaste producedbyplasticbottlesandsimilaritemsinthecountryofSaudiArabia.Theincreasedlevelofindustrialactivityhasledto this outcome. packaging because of quick industrialization and rapid urbanization in the nation. The cost related to the handlingofthesesolidwasteshasalsoincreasedduetothegrowingcomplexityandsizeofthetask.Theimpactofrecycled plasticwastes(RPW)suchaspolypropylene,high-densitypolyethylene(HDPE),andlow-densitypolyethylene(LDPE)hasbeen studied.Researchhasinvestigatedtheviscoelasticpropertiesoftheasphaltbinderinthearea.Theplasticsthatwererecycled wereachievedbytearingandcrushingtheRPWintoasuitablesizetofacilitatemixingwiththeasphaltfolder.AllRPWsleadto enhancedruttingperformance.TheupperPGlimitofRPW-modifiedasphaltswillalsobeimproved.Inmostinstances,thereis aminimumone-levelincreaseforevery2%riseinRPWcontent.Ariseof55hasbeenobserved.A9%differenceinresilient modulus(MR)wasfoundbetweenPP-,HDPE-,andLDPE-madeasphaltconcrete,withPPshowinga19%variation.(AC),inthat

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

order.TherelationshipbetweentheMRoftheACandthenon-recoverablecreepcompliance(Jnr)iscorrelated.Theasphalt binder was installed. The viscoelastic properties of the RPW-modified binder were determined. employed to simulate a standardpavementstructurewiththeAASHTOmechanisticempiricalpavementdesignguidesoftwarecalledME-PDG.The anticipatedissueswiththesimulatedpavementdisplaynotableruttingandenhancedfatigueresistanceforpavementmade usingtheRPW.PolymersoftheelastomerictypeareneededtobeaddedtotheseRPWtohelpthemmeettheelasticrecovery requirementofAASHTOTP.AnzarHamidMirJEng,2015Theyhavementionedthatalmost5%ofMunicipalSolidWaste (MSW)ismadeupoftoxicplasticandanimportantissueatpresentisthemanagementofplasticwaste.Thesepollutantsare notabletobebrokendownbylivingorganisms,leadingtoenvironmentalcontaminationandsanitationissues.Experiments conductedatvariousinstitutionshaveshownthatwasteplasticcanbeusedintheprocessofpavingroads.Utilizingthese wastematerialsinbuildingroadsisinfluencedbyeconomic,technical,andecologicalfactors.InIndia,theauthor'shomeland, millions of metric tons of plastic waste are generated annually as an example. If these waste materials are effectively incorporatedintoroadbuilding,theissuesofdisposalandpollutioncanbegreatlyreduced.Bitumenisutilizedasabinder duringtheprocessofconstructingroads.Plasticwastepiecescanbeaddedtobitumentocreateamixturesuitableforasurface courseofflexiblepavement,withimprovedbinding,stability,density,andwaterresistance.

YashMenariaandRupalSankhla(2015)havestatedthattheutilizationofplasticinflexiblepavementshasbeenalongstandingpracticetoenhanceroadstability,durability,andreduceconstructioncostsbyreplacingaportionofbitumenwith wasteplastic.Theadditionofwasteplasticinbitumenresultsinimprovedpropertiessuchaspenetrationandsofteningpoint, contributingtoenhancedroaddurabilityandstability.Plasticroadscanbeconstructedinhigh-temperatureareas,showcasing theversatilityandapplicabilityofthistechniqueinvariousenvironmentalconditions.Plasticinbitumenhelpsincompensating airvoids,bindswithaggregate,andprovidesstabilitytothepavementstructure,contributingtoimprovedroadperformance. RaghvendraBajpaiet.al.(2017)Theauthorsdemonstratedthataround5%ofmunicipalsolidwasteconsistsofvarioustypes ofplastic,whichmayhavetoxicproperties.Seeingusedplasticbagsandothertypesofplasticpackagingscatteredonroadsand drainsisafrequentoccurrenceinurbanandruralareas.Becauseitisbiodegradable,itleadstowaterstagnationandhygiene issues.Experimentshavebeenconductedtoseeifwasteplasticcanbeeffectivelyreusedinroadconstructiontoaddressthis issue.Experimentsconductedatvariousinstitutionshaveshownthatincorporatingwasteplasticintohotaggregatewillresult inathinplasticcoatingontheaggregate.Whenthisplastic-coatedaggregateiscombinedwiththebinder,itshowsincreased strength,improvedwaterresistance,andbetterlong-termperformance.Hence,thesuggestionistoutilizewasteplasticfor buildingruralroads.

S.L.Hakeet.al.(2019)addressedabouttheglobalissueofwasteplasticdisposal,highlightingitsnon-biodegradability andenvironmentalimpact.Itdiscussestheuseofwaste plasticinroadconstructiontoenhancemechanicalpropertiesof bituminous mixes, focusing on replacing bitumen with plastic in flexible pavements. The paper mentions the process of grindingupplasticgarbageintosmallpieces,meltingit,andcoatingitoverhotaggregatestocreatepolymer-coated-bitumen aggregateforroadconstruction.Costanalysisindicatesa5.18%costreductioninmaterialmixusingplasticblendscompared totraditionalbitumen,makingitacost-effectiveandenvironmentallyfriendlyoptionforroadconstruction.PrakharDuggalet. al. 2020 highlighted that recycled low-density polyethylene plastic can enhance the durability and fatigue life of flexible pavements.Plasticheatingat165°Cdoesnotreleasetoxicgases,butdecompositionstartsabove270°C.Theuseofwaste plasticasabitumenmodifierhasshownimprovementsinfatiguelifeandabrasionresistanceofpavements.Theoptimalplastic contentinthebitumenmixisfoundtobe5-10%byweightofbitumen.

R.ManjuAnandandSathya.S(2017)haveinvestigatedthatthewasteplastic,suchaspolyethylene,polypropylene,and polystyrene, can be shredded, coated over aggregates, and mixed with hot bitumen to create a mix that strengthens the pavementandincreasesitsdurability.Thepresenceofplasticinbituminousmixesreducestheformationofvoidsandmoisture absorption in the pavement, leading to a decrease in ruts and preventing pothole formation. The use of plastic waste in bituminous mixes reduces the need for bitumen by around 10%, resulting in a more sustainable and eco-friendly road constructionprocess.JoséEduardoSalcedoFontalvoet.al.(2023)hasemployedtheLosAngelesabrasionvalueandCalifornia bearingratio(CBR)teststoevaluatethemechanicalbehavior ofthegranularsub-base(GSB)withvaryingpercentagesof recycled concrete aggregates (RCAs) blended with natural aggregate. Particle size distribution analysis of the GSB was conducted in accordance with the ASTM D6913 standard, comparing the results with established limits for the material. Compaction characteristics were assessed following the standard Proctor methodology with a compaction energy of 600 kJ/m3,testing threesampleswithdifferent moisturecontents.Construction,anddemolition (C&D)wastesarea growing concern globally due to increased construction activities, leading to ecological issues by N. Yadav and R. Kumar (2023). RecyclingC&Dwasteintorecycledconcreteaggregates(RCA)forpavementbaseandsub-baselayersisaviablesolutionto address this problem. The study evaluates the application of RCA in the construction industry using microstructural characterization,laboratorytesting,andeconomicanalysis.Thesub-baselayerconstructionutilizing50%RCAand50%NA resultedina17.86%materialcostdecrease,demonstratingthefinancialadvantagesofadoptingRCA.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

InhisstudyofSampatMandlikandP.L.Naktode(2023)havementionedtheuseofIITPAVEsoftwareforanalyzing linearelasticlayeredpavementsystems.Thesoftwarecalculatesstresses,strains,anddeflectionscausedbyloadsondifferent pavementlocations,aidingindesigningsafeandfunctionalpavements.Itsuggeststhatreducingthethicknessofpavement layerswhilemaintainingsafestrainlimitsisfeasible,enhancingpavementdesignefficiency.ShrutikaUgalmugaleet.al.(2021) havediscussedtheapartialsubstitutefortraditionalbitumeninroadconstructionwithwasteplasticandrubber,asperthe literaturereview.VariouspercentagesofrubberandPETwereaddedtobitumen,withtheoptimalcontentfoundtobe6%by weight of bitumen. The study concluded that using PET bottles was the most effective method for improving pavement stability.Over2000kmofroadshavebeenconstructedinBangaloreusingwasteplastic,showinggoodperformance.

Usingwasteplasticinbituminousmixturesandrecycledconcreteaggregateingranularsubbaselayerscanhelpmeet environmentalandengineeringneedsinpavementconstruction.Itoffersasustainablemethodformanagingwasteplastic while also improving the characteristics of the asphalt mixture. The use of plastic-modified bitumen has demonstrated enhancementsinflexibility,fatigueresistance,andruttingresistance,whichcouldpossiblyprolongthelifespanof flexible pavements.Furthermore,incorporatingrecycledconcreteaggregateinthegranularsubbaselayerhelpslowertheneedfor natural aggregates, preserving natural resources and lessening the environmental effects linked to aggregate extraction. AdvancedcomputationaltoolsliketheIITPAVEsoftwareareusedtoassesstheeffectivenessofthesuggestedroaddesignthat includeswasteplasticandrecycledconcreteaggregate.Thissoftwareassistsinanalyzinganddesigningflexiblepavementsby consideringfactorsliketrafficloads,material properties,andenvironmental conditions.Theprojectaimsto evaluatethe structuralintegrity,durability,andsustainabilityofthedesignedpavementsystemthroughin-depthanalysis

2.1. Natural Aggregate

Theprimarybuildingblockforaroad'sconstructionisaggregate,aninertmaterial.Bitumenholdsthesenaturallyoccurring stonestogether,astheyhaveverylittlereactivity.Additionally,largerrocksareartificiallypreparedbybeingbrokenintotiny pieces.Wehaveutilizedvariousaggregatesizesindifferentratiosbasedonthegradingneededfortheflexiblepavement's wearingcoursedesign.

2.2.

Bitumencanbeproducedartificiallythroughchemicalprocessesorobtainedasaby-productofcrudeoildistillation.Theyhave anextremelydensestructureandaremadeupofcomplexhydrocarbons.Theirmeltingpointrangesfrom80to120°C.To create a surface, bitumen serves as a binding agent, holding the aggregates together. Bitumen is easily utilized for road constructionbecauseofitsductility,lowmeltingpoint,andbindingability.Itcouldrepelwateraswell.Bitumencomesin variouspenetrationgrades, suchas30/40,60/70,and 80/100.Viscosity parameter-based classificationofbitumenisan additionalmethod.ThebitumengradeweareusingforourmajorprojectexperimentisVG-30havingapenetrationgradeof 60/70.

Inthisproject,thebituminousmixtureusedtocreatetheflexiblepavementincorporateswasteplastic.Thiscreativesolution reducestheamountofplasticwastethatendsupinlandfills,recyclesit,andimprovesthequalitiesofbituminousmix.The bitumenthathasbeentreatedwithplasticshowsbetterflexibility,moreresistancetoruttingandcracking,andmayeven lengthenthepavement'slife.Roads,garbagetrucks,landfills,compostingfacilities,andwastepurchasersprovidedthewaste plasticbottlesandtheircaps,whichwerecollectedforRs.5–6perkg.Fortheproject,householdplasticslikeusedplasticbags andemptymilk cartonswerealsogathered.Thegatheredplasticwastewasdivided intocategoriesbasedonthe needed thickness.Typically,thesubsequentprocedureusesPolyethyleneTerephthalate(PET)withamicronsizeof30-150microns.

RecycledConcreteAggregate(RCA)isasustainableconstructionmaterialproducedbycrushingoldordemolishedconcrete structures.Crushedconcretefromoldordemolishedbuildingsisrecycledconcreteaggregate,orRCA,asustainablebuilding material.Bytakingwastefromlandfills,thisprocessreducesitsnegativeenvironmentaleffects.ThequalityofRCAvaries,but qualitycontrolisapplied.Itaddstostrengthandisusefulinnewconcretemixesandroadconstruction.RCAhasfinancial benefitsinadditiontoenvironmentalones.Itsperformancecharacteristicsarethesubjectofresearchtoguaranteeadherence tosafetyregulations.Respectingtherulesisessentialforsustainableandethicaluseinabuilding.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

Asoilsamplewastakenfromtheconstructionsitetoguaranteetheflexiblepavement'sprecisedesignandfunctionality.This sample'sload-bearingcapacitywasassessedusingtheCaliforniaBearingRatio(CBR)test.Thistestisessentialbecauseitoffers importantinformationaboutthestabilityandstrengthofthesubgradesoil,whichhasadirectbearingontheoverallstructure ofthepavement.TheCBRtestresultswillguidethedesignprocess,ensuringthatthepavementisbuiltinawaythatbestsuits thesite'suniquegeotechnicalcharacteristicsandmaximizingitsperformanceandlongevity.

3.1.

At higher temperatures (160°C–170°C), less micron plastic is easily mixed with bitumen. It is clean after dusting and, if necessary,washing.Plasticthathadbeencollectedwaschoppedasfinelyaspossible.Afterpassingthrougha4.75mmsieve, theplasticfragmentswerecollectedatthe2.36mmsieve.First,themeltingpointofbitumenwasreached,whichisbetween 160oCand170oC.

Inpavementconstruction,therearebasicallytwomethodsbywhichplasticcanbeaddedtobitumenconcrete:

1.Drymixmethod

2.Wetmixmethod

In the dry mix method, plastic is melted and combined with bitumen at a highly controlled temperature. This mixture is combinedwiththeaggregatestopreparebitumenconcrete.Thismethodismorecost-effectivesinceituseslessaggregatein themix.Toensureuniformityandconsistency,thedrymixpreparationiscarriedoutundercarefullymonitoredcircumstances, whichmayincludetemperaturesandmixingtimes.ThepreparedspecimensareloadedintheMarshalltestsetupasshownin belowFigure1.

The process of adding recycled concrete aggregate (RCA) to the granular subbase layer of flexible pavement starts with gatheringandreadyingconcretewastefromdemolitionareas,thencrushingittocreateRCAofappropriatedimensions.Lab testsareconductedontheRCAtoevaluateitsphysicalandmechanicalfeatures,includingparticlesizedistribution,specific gravity,waterabsorption,andaggregatecrushingvalue,inadditiontoitsstrengthanddurabilityproperties.Acombinationis formulatedforthegranularsubbaselayerbymixingRCAandnaturalaggregates,tofindthebestratioofRCAformeeting specificperformancestandards.Samplesofthemixedmaterialarepreparedfortesting,andcompactiontestsarecarriedoutto determinetheidealmoisturecontentandhighestdrydensity.AsshowninFigure2,therecycledaggregateisacquiredforthe testingpurposeafterbeingovendriedfor24hours.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

FollowingIRC:37requirements,astress-strainstudyofthecompletedflexiblepavementutilizingIITPAVEsoftwareentails severalcrucialprocedures.Toascertainthesubgradequalities,soilsamplesarefirsttakenfromtheconstructionsiteand subjectedtovarioustests,suchastheCaliforniaBearingRatio(CBR)test.Foruseinthepavementlayers,recycledconcrete aggregateandbituminous mixturesmodifiedbywaste plasticarealsomadeassamples.Next,incompliance withIRC:37 criteria,thepavementstructureisdevelopedwiththeproperlayers,utilizingwasteplasticinthebituminousmixtures,and recycledconcreteaggregateinthegranularsubfoundation.Eachlayer'sthickness,Poisson'sratio,andmodulusofelasticityare calculatedandenteredtheIITPAVEsoftware.Environmentalfactorsincludingmoisturecontentandtemperaturefluctuations, aswellastrafficloadingcircumstanceslikethekindandfrequencyofvehicleloads,arespecified.Toverifycompliance,the analyticalfindingsarecomparedtoIRC:37requirements.Ifrequired,pavementdesignoptimizationisperformedtoimprove durabilityandperformance.

The numberof vehiclesusingtheroadeachdayand thedesign trafficintermsof thetotal number ofstandard axlesare calculated using the traffic data gathered from the traffic volume counts survey. IITPAVE software is used to assess the pavement,whichiscreatedinaccordancewithIRC:37-2018criteria.

TheInitialTrafficinyearofcompletionofconstructionofpavementisgivenbelow,

Where,P=Numberofcommercialvehiclesasperlastcount

x=Numberofyearsbetweenthelastcountandtheyearofcompletionofconstruction.

N=Cumulativenumberofstandardaxles,MSA

A=InitialTrafficinyearofcompletionofconstruction,CVPD

r=Growthrateinpercentage

n=Designlifeinyears(15years)

D=LaneDistributionFactor

VDF=VehicleDamageFactor-IRC37:2018

Fordesignpurpose,growthrater=5%andlanedistributionfactorD=0.75-IRC37:2018

International Research Journal of

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net

4.1. Tests on Natural Aggregate

Table1highlightsthetestfindingsforthenaturalaggregatesusedinthepavementconstruction,givingimportant informationfordeterminingtheirperformanceandacceptability.

Table -1: Testsonnaturalaggregate

4.2. Tests on Bitumen

Toassessthebitumen'sperformanceandqualities,keyinformationisprovidedinTable2,whichsummarizesthetest findingsforthebitumenusedinthepavementconstruction.

Table -2: TestsonBitumen

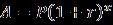

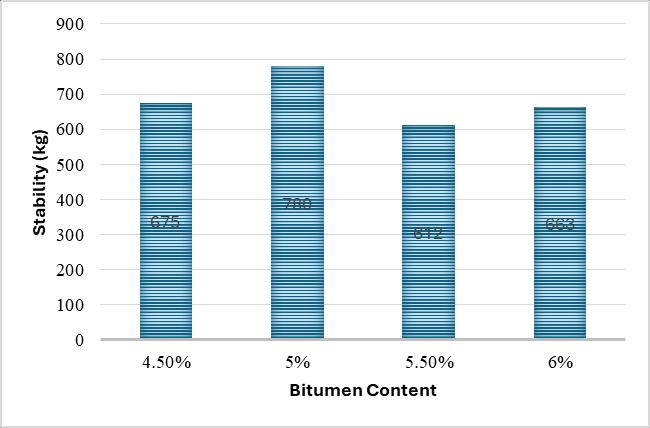

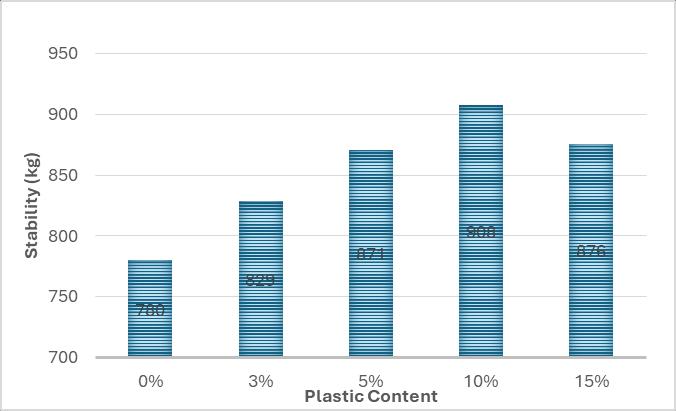

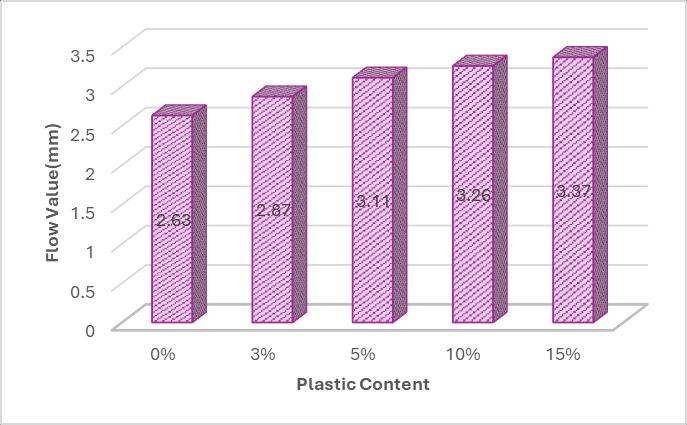

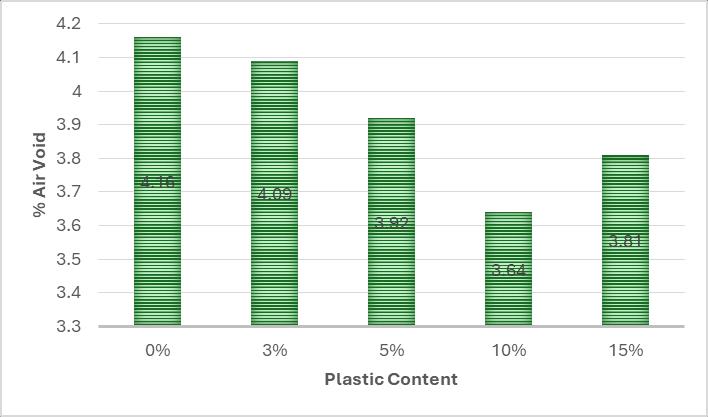

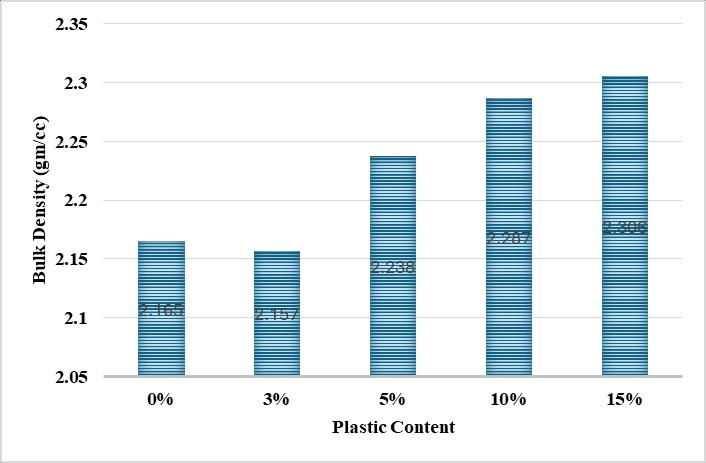

TheMarshallStabilityofaspecimenduringtestingisthehighestloadthatcausesfailureinthespecimen.Heatedtoaspecific temperaturebeforebeingpositionedinauniquetestingfixture,theloadsteadilyincreasedataconstantrateof5cmper minute.Duringthestabilitytest,adialgaugeisutilizedtomeasuretheverticaldeformationofthespecimen.TheMarshallFlow valueofthespecimenisthedeformationatthefailurepointmeasuredinincrementsof0.25mm. Initially,variousspecimens arepreparedwithvaryingbitumencontent.ThespecimenshowingthelargestMarshallstabilityisconsideredforfurtherstudy withitsgraph between bitumenand stabilityvalue (Chart1)and flow value(Chart 2),whichare depicted below.Plastic percentagesof3,5,10,and15%areincludedtoexaminehowreplacingplasticimpactstheMarshallcharacteristicsofthe bitumenmixture.Therelationshipbetweenplasticpercentageandstability(Chart3),flowvalue(Chart4),airvoid(Chart5), andbulkdensity(Chart6)indicateshowtheplasticpercentageinbitumenaffectsitsproperties.Theevaluationindicatesthat theMarshallStabilitytestdemonstratesadecreasewhentheplasticpercentageincreasesto15%inplasticreplacement.The graphillustratesthevariationinwasteplasticpercentageusedasareplacementforbitumeninbitumenconcretemixesandits correspondingeffects.Theresultsforplasticsubstitutionaredepictedinthesegraphs

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

-5: Air Void (%) vs Plastic Content

4.4. Tests on Recycled concrete aggregate

4.4.1. Standard Proctor Test

-6: Bulk Density(gm/cc) vs Plastic Content

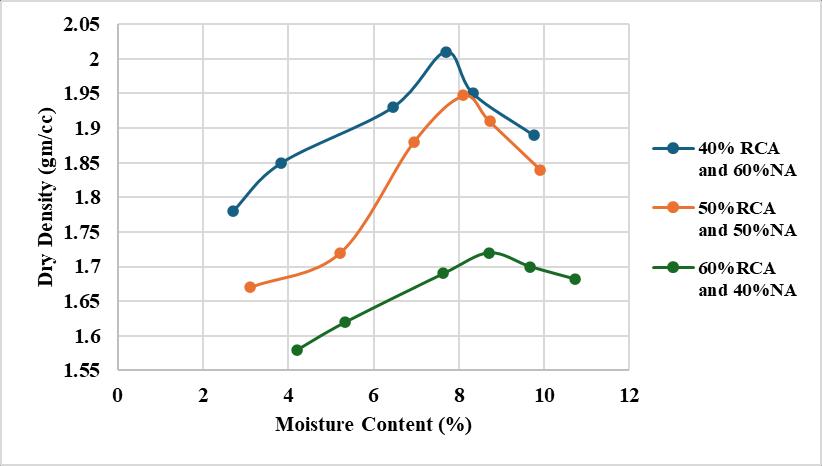

Thecompactionpropertieswereassessedusingthestandardproctortestandthreetestswereconductedonsampleswith varyingmoisturelevels,andtheoutcomesfortheassessedmaterialsaredisplayedinthefigure.ThebelowTable3showsa detaileddrydensityandoptimummoisturecontentvaluesatvariouspartiallyreplacedsamplesforGSB.

RCAhashigherwaterabsorptionascomparedtonaturalaggregate. Thedataclearlyshowsthispatternwiththeoptimal moisturecontentincreasingwithincreasingRCAcontentwhichcanbeeasilydemonstratedusingchart7 Ontheotherhand,it was anticipated that the dry density of samples decreases as the content of RCA increases in comparison to natural GSB becauseRCAhasalowerdensitythanthenaturalaggregate.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

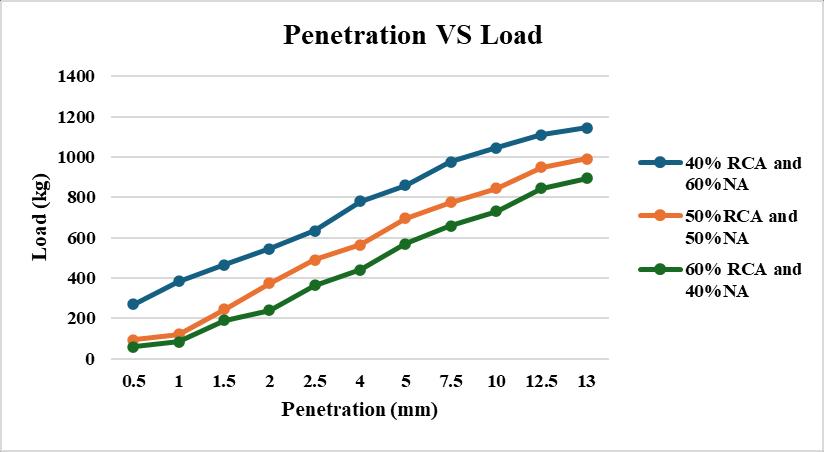

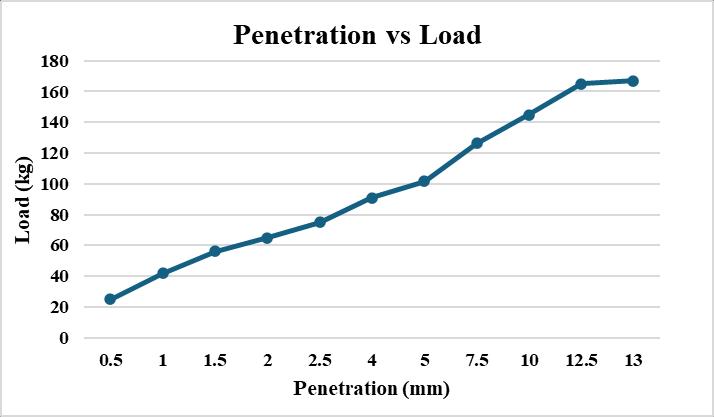

AccordancewithASTMD-1883,theCBRofthematerialsat56blowspercompactionlayer(fivelayers)wasusedtoassesstheir resistance.Theidealmoisturecontentdiscoveredintheappropriatestandardproctorcompactiontestwasusedtopreparethe samples.Theoutcomeswerecontrastedwiththestandard'sminimalrequirementsforGSB.Thepenetrationvs.loadcharts wereusedtocalculatetheCBRofthethreepartiallyreplacedGSBsamples.Thesamplecontaining60%Recycledconcrete aggregate(RCA)and40%naturalaggregate(NA)showedaCBRvalueof35.60%,followingthesamplescontaining50%RCA and50%NAand40%RCAand60%NAshowingaCBRvalueof45.90and59.49%,respectively.Chart8showsthecomparison betweenpenetrationvsloadforvarioussamples.

4.5.1. Standard Proctor Test

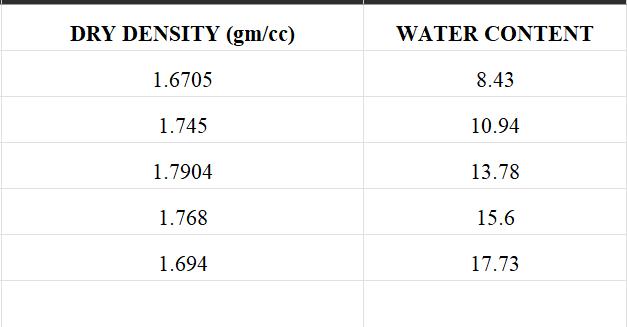

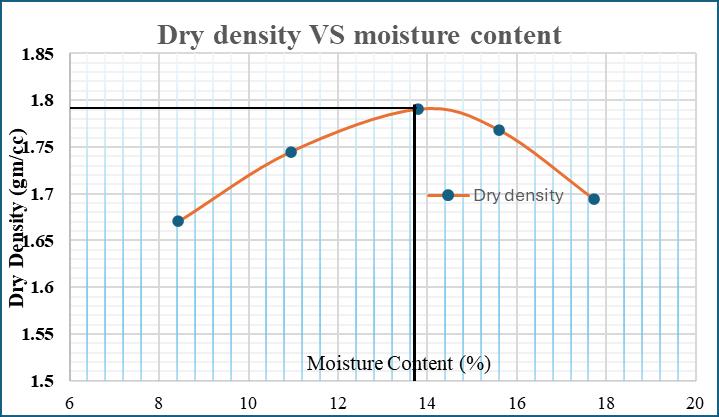

ThedrydensitycorrespondingtowatercontentofthesoilisshowninTable4withitsgraphinchart9

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

TheCBRtestdeterminedthesoil'sabilitytosupportweightandverifiedthatthesubgradewouldbesuitable.RefertoTable5 andchart10fortheCBRvaluesandcorrespondingpenetration-loadcurveofthesoil. MaximumDryDensity

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

CBR at 2.5mm= 7.58%

CBR at 5mm = 6.33%

Table -5:MaximumdrydensityandCBRvalueofSubgradesoil

4.6 Pavement analysis

Table -6:Trafficdataandotherparametersrequiredforpavementdesign.

Section Design Life CBR Initial traffic [by equation (2)]

SHIKOHABAD ROAD

Cumulative number of standard axles [by equation (1)]

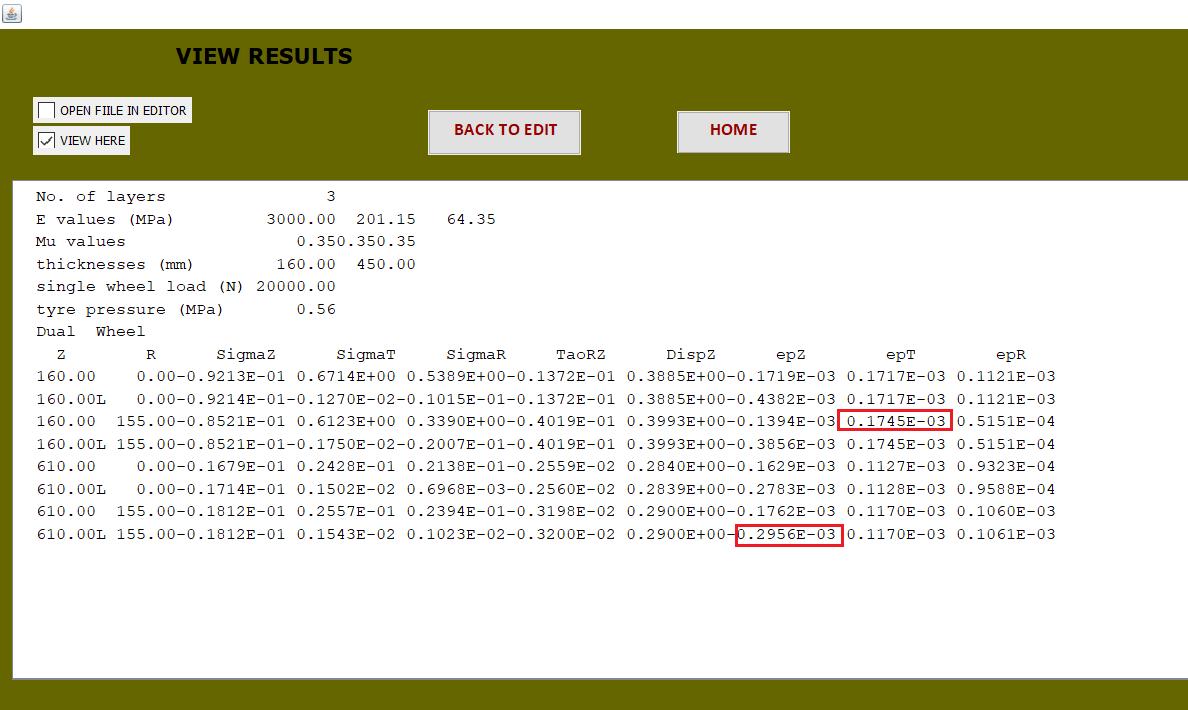

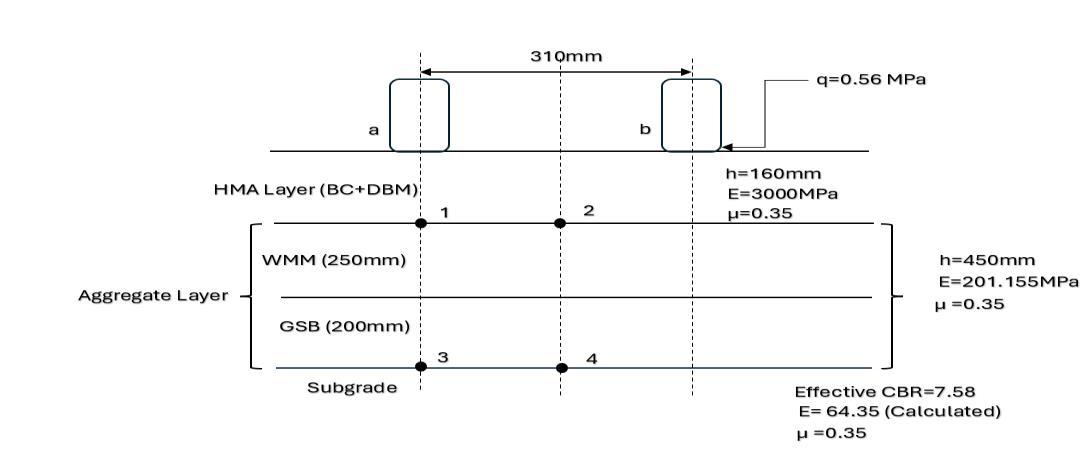

ThepavementisexaminedusingtheIITPAVEprogramonceithasbeendesignedinaccordancewithIRCguidelinestoseeifthe thicknessofeachlayerhasbeenchosentoadequatelysupporttheloadandstrainsthatthepavementhasdeveloped.Table6 showstheparametersrequiredforthedesignofflexiblepavementwithitsstress-strainanalysisinFigure3.

Maximumstraindevelopedattheanalysispointsareasfollows:

a.Tensilestrainatbottomofbituminousconcretelayer(Surfacecourse)=174.5µ <176.22µ

b.Compressivestrainattopofsubgradelayer=295.60µ <386.50µ

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net

Thefollowingconclusionsandobservationshavebeengeneratedinconsiderationofthefindingsreportedinthispaper.

Bitumen and aggregates are mixed with plastic to enhance the performance of the roads. The plastic coating on aggregatesdecreases the emptyspacesand absorption of moisture. This leadstodecreased grooves in the road, preventingtheformationofpotholes.Ecoflexpavementcanendureheavytrafficandismoredurablethantraditional flexiblepavement.Usinga plasticmix,thethicknessofthesurfacecourseofpavementcouldbereducedandthe bitumen content can also be lowered by 10% while enhancing the road's strength and performance. This newly developedtechnologyisenvironmentallyfriendly.

Theutilizationof10%wasteplasticinsemidensebituminousconcretemixesshowedimprovedMarshallresults, suggestingthepotentialrecommendationfortheuseofwasteplastic.Nevertheless,thisneedstobecorroboratedby additionallabtestsandfieldperformancestudies.

Thepropertiesofbothbitumenandaggregateincreasewiththeadditionofplastic.

UtilizingRCAintheGSBlayerpromotessustainableconstructionpracticesbyrecyclingconcretewasteandreducing thedemandfornaturalaggregates.

TheRCA-blendedGSBlayer'sCBRvaluesshowarespectableload-bearingcapacitythatisonlevelwithtraditional aggregates,suggestingthatitcanbeusedtobuildpavements.

Thethicknessofeachlayerofpavementcanbereducedbyacertainamountinordertoreducethestraindifferences obtainedbyusingtwomethods:onefromformulasaccordingtoIRC37:2018,wherethevaluesofmaximumtensile strainandmaximumcompressivestrainarecalculatedusingairvoidsandotherparametersthatarementionedabove inthetables,andtheothermethodinvolvesthecalculationofthevaluesoftensileandcompressivestrainbyputting thevaluesofeachlayer.

[1] AbuAbdo,A.M.,&Jung,S.J.(2020).InvestigationofreinforcingflexiblepavementswithwasteplasticfibersinRasAl Khaimah,UAE.RoadMaterialsandPavementDesign,21(6),1753-1762.

[2] SampatMandlikandP.L.Naktode(2023).AnalysisofFlexiblePavementUsingIITPaveSoftware,InternationalJournal ofEmergingTechnologies,andInnovativeResearch,10(6),140-144.

[3] Bajpai,R.,Khan,M.A.,Sami,O.B.,Yadav,P.K.,&Srivastava,P.K.(2017).Astudyontheplasticwastetreatmentmethods forroadconstruction,InternationalJournalofAdvanceResearch,IdeasandInnovationsinTechnology,3(6),559-566.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

[4] Dalhat,M.A.,&Al-AbdulWahhab,H.I.(2017).PerformanceofrecycledplasticwastemodifiedasphaltbinderinSaudi Arabia.Internationaljournalofpavementengineering,18(4),349-357.

[5] Duggal, P., Shisodia, A. S., Havelia, S., & Jolly, K. (2020). Use of waste plastic in wearing course of flexible pavement. InAdvancesinStructuralEngineeringandRehabilitation:SelectProceedingsofTRACE2018,177-187.

[6] Hake, S. L., Damgir, R. M., & Awsarmal, P. R. (2020). Utilization of plastic waste in bitumen mixes for flexible pavement.TransportationResearchProcedia,48,3779-3785.

[7] IRC:37.(2018).Guidelinesforthedesignofflexiblepavements.InIndianRoadsCongress,NewDelhi,India.

[8] Manju,R.,Sathya,S.,&Sheema,K.(2017).Useofplasticwasteinbituminouspavement.IntJChemTechRes,10(08),804811.

[9] Menaria, Y., & Sankhla, R. (2015). Use of waste plastic in flexible pavements-green roads.Open Journal of Civil Engineering,5(03),299.

[10] Mir,A.H.(2015).Useofplasticwasteinpavementconstruction:anexampleofcreativewastemanagement.JEng,5(2),5767.

[11] Yadav,N.,&Kumar,R.(2024).PerformanceandEconomicAnalysisoftheUtilizationofConstructionandDemolitionWaste asRecycledConcreteAggregates.InternationalJournalofEngineering,37(3),460-467.

APPENDIX

Thefollowingsectionpresentsthedesignprinciplesandparametersthatareusedfortheanalysisofpavementwithitscrosssectionasshowninfigure4.

1.DesignCBRofSubgrade=7.58%

2.DesignTraffic=50MSA

3.Bitumenused=VG-30

4.PavementComposition

Fig -4: Cross-sectionofdesignedflexiblepavement.

5.ResilientModulus(MR)ofSubgrade=17.6*(CBR)0.64 =64.35MPa

6.ResilientModulus(MR)ofAggregateLayer(WMM+GSB)=0.2*h0.45 *MRofsubgrade =201.155MPa

7.Poisson’sRatioforsubgrade,WMM,BCandDBMistakenas0.35-IRC37:2018

8.Singlewheelloadistakenas20000Nandtyrepressure=0.56MPa

9.Percentageairvoid=3.64(Fromchart5correspondingtoMarshall’sspecimenwithhigherstabilityvalue)

10.Pointstakenforstressanalysis=4.0

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

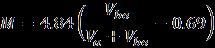

11.Asperparametersobtainedfrommaterialpermissibleallowablestrainsfordesignedtraffic-

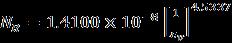

TensileStrainatthebottomofbituminousconcretelayerisgivenbyEquation–

(For90%reliability)

=176.22µ

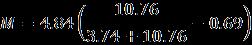

AllowableCompressiveStrainattopofsubgrade–

(For90%reliability)

εv =386.50µ where,

Nf=standardaxlesloadthatcanbeservedbythepavementbeforethecriticalcrackedareaof 20%,takenas43MSA(fromtable6).

C=10M

M = 0.2769

Vbe=%volumeofeffectivebitumeninthemix

Va =%volumeofairvoidinthemix

MRm =resilientmodulusofthebituminousmixusedinthebottombituminouslayertakenas 3000MPa.

NR=standardaxlesload(80kN)thatcanbeservedbythepavementbeforethecriticalrutdepthof20mmoccurs,takenas 43MSA(Fromtable6).

BIOGRAPHIES

Shivendra Yadav BachelorofTechnology DepartmentofCivilEngineering

RajkiyaEngineeringCollege MainpuriUttarPradesh

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 11 | Nov 2024 www.irjet.net p-ISSN: 2395-0072

Chandra Shekhar Patel

BachelorofTechnology

DepartmentofCivilEngineering

RajkiyaEngineeringCollege

MainpuriUttarPradesh

Abhishek Kumar Yadav

BachelorofTechnology

DepartmentofCivilEngineering

RajkiyaEngineeringCollege

MainpuriUttarPradesh

Akash Kumar Vaishya

BachelorofTechnology

DepartmentofCivilEngineering

RajkiyaEngineeringCollege

MainpuriUttarPradesh