International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net

A. Abdelaal 1

1First Automotive and tractors Technology Dpt, Faculty of Technology and Education, Helwan University, 11282 Cairo, Egypt ***

Abstract - In this study, the thermal performance and pressure drop characteristics of the vehicle radiator are investigated experimentally using nanofluids in Cairo, Egypt's hot, dry climate. Many factors, including working fluid flow rate, working fluid temperature and nanofluid concentrations are examined in this paper. Different nanofluid (Al2O3/water) concentrations of 0.02, 0.05, and 0.1 by volume are investigated. The experiments are conducted for a radiator with a fixed air velocity of 0.6 m/s and working fluid flow rate of 3, 5, 7.5,10 and 12.5 LPM with Reynolds number ranges of 3633≤Re≤22×103. The temperature of working fluid in the reservoir is varied from 80 to 95°C. With specific reference to pure water, the effects of Al2O3/water are evaluated using a Nusselt Number for heat transfer performance and friction factor for pressure drop characteristics. The results show that the Al2O3/water performs better thermally than water. The thermal performance increased as Reynolds number and concentration ratio increased. The results showed that with Reynolds number of 12,500 Nusselt number at concentration of 0.1%, 0.05% and 0.02% is higher than pure water by 16%, 10% and 7% respectively. At the same Reynolds number, the friction factor at concentration of 0.1%, 0.05% and 0.02% is higher than pure water by 60 %, 54% and 38% respectively. At Reynolds number of 12,500 the friction factor at 95oC is lower than that of 90oC, 85oC and 80oC by 7%, 10% and 18% respectively. At a certain Reynolds number of 12,500 Nusselt number at 95oC is higher than that of 90oC, 85oC and 80oC by 6%, 25% and 37.5% respectively.

Key Words: vehicle radiators; nanofluid; performance characteristics

Fornanofluids,Becauseofitshighheattransfercoefficients andabilitytoaccommodatealargeheattransfersurfaceina short space, cooling radiators are widely employed in severalindustrialapplications.Carsandtruckscontinually need greater heat rejection because of trends towards stronger outputs. Heat transfer has a direct influence on engineperformance,fueleconomy, materialselection,and emissions.Numerousscholarshaveexaminedthethermal efficacyofradiators.W.Yu,etal[1]Thefollowingaresome advantagesofenhancedradiatorandheattransfersystems employingnanofluids:smallercomponentsthattakeupless spaceunderthe bonnetand give designersmore freedom

whenitcomestoaerodynamicstyle,lowerweightthatwill increasefuelefficiency,moreefficientcoolingandlengthen componentlifeDustinR,etal[2].Towardstheconclusionof theusefullifecycleofheattransfersystems,thesize-related solidwastedisposalissueislessened DevendraVashistetal [5].%AL2O3nanoparticlestowaterincreasedthethermal conductivityoftheNanofluidby21.4%.Theyalsoimproved the viscosity of the liquid by dispersing ultrafine particles K.Y. Leong, et al [4]. An Argonne National Laboratory research team was the first to examine the usage of Nano scale particles. One of the most significant technological issues that many companies, including those in the automotive,electrical,andindustrialsectors,mustdealwith iscoolingHardikV.Patel,etal[5].Thethermalloadscreated bynewtechnologicaladvancementsarerising,necessitating quicker cooling Rashmi Rekha Sahoo, et al [6]. Fins and micro channels, the traditional means for accelerating cooling, have already reached their physical limits Seth DanielOduro,etal[7].Toaccomplishthishighperformance cooling, new and creative coolants are therefore urgently needed.S.C.Tzeng,etal[8]Traditionalheattransferfluids, such engine coolants, have relatively poor thermal conductivitiesW.M.Yan,etal[9].Industriesurgentlyneedto produceheattransferfluidsthataremorethermallyefficient thanthosealreadyonthemarketduetorising worldwide competition A.J. Torregrosa, et al [10]. In certain nations, official organizations like the Environmental Protection Agency are also enforcing stricter standards for pollution andvehicleemissionsJ.P.Holmanetal[11].Thelargerheat exchanger/radiatorcapacityofthenewcoolants,together withtheirimprovedthermalperformance,mayresultina Reduction in vehicle fuel consumption. A fresh idea is nanofluidsW.Duangthongsuk,S.Wongwises[12].Theseare heattransferfluidswithnanoparticlessuspendedinthem thatwerecreatedtohandlemoredifficultcoolingdifficulties X. Wang, X. Xu [13]. A brand-new category of solid-liquid composites called nanofluids is made up of solid particles with a size of 100 nm or less suspended in heat-transfer fluids including water, ethylene, and propylene glycol Y. Xuan, W. Roetzel [14]. Convective heat transfer has been demonstratedbyseveralstudies.Experimentalstudiesthe possibilityforhighertemperaturecoolantsandmoreheat rejection in vehicle engines is made possible by nanomaterials W. Yu, H. Xie [15]. Just 25% of heat is transformed to usable electricity, while the rest is lost as heat.N.Masoumi,etal[16]. Byboostingheattransferand expandingtheheattransferarea,radiatorheattransfermay

Volume: 11 Issue: 07 | July 2024 www.irjet.net

be made better. In order to increase the heat transfer coefficientandtheheattransferrateinthecoolingsystemof the engine radiator and with the use of Nano coolants, AluminumOxide(Al2O3)inwaterwasusedasananofluid M.Kole,etal[17].Inthepresentstudy,theperformanceof thealuminumoxide(Al2O3),whereReynoldsnumberand volumeconcentrationsareraised,Furthermore,compared toconcentrationsandpurewaterasacoolant. Withafixed volumefraction,byincreasingthepressureofthenanofluid, theradiatorpressuredroprises.Experimentationwasdone ontheuseofnanofluidascoolantsinenginestostudyheat transfer. Finally, the paper focuses on the performance criteria of the vehicle engine cooling system using Al2O3/H2O,Howdoafewratiosof Al2O3/H2Oaffectthe heat transfer performance of the vehicle radiator? What impactwhendifferenttypesofnanoparticlesareaddedto water,doesthethermalperformancechangecomparedwith thebasefluids?Thesearesomeimportantquestionswhich havebeenansweredalongthisinvestigationinaddition,to study the effects of key design and operating parameters suchas;coolanttype,nanofluidconcentrations,nanoparticle types,coolantmassflowrateandtemperaturevariationson characteristics of the vehicle radiator. Pumping power, effectiveness, number of transfer units, and performance index are also discussed. Correlations of Nusselt number, effectiveness,andfrictionfactorofthevehicleradiatorare alsodeveloped.

Thethermalperformanceofvehicleradiatorisinvestigated using the test apparatus as shown schematically and graphically in Fig. 1 and Fig. 2, respectively. Experimental setupisconsistingof0.5m3insulatedwatertankwhichis provided with 1.5 kW immersed electric water heater (regulated by thermostat) and agitator. 0.5 Hp water centrifugal pump for working fluid circulation. Vehicle radiator,finandtubeheatexchangertypeprovidedwithDC fansuppliedbybattery.Dimensionaldataandgeometrical characteristicsforvehicleradiatorareindicatedintable(1 and 2), respectively. In addition to piping network with required ball valves that connecting different parts of the system.Volumeflow ratesare measuredbyusingfloating flowmeterswithanaccuracyof±0.5LPM.AmercuryU-tube manometer is connected to the inlet and outlet of the radiatorforpressuredropmeasurements.Thetemperatures aremeasuredby35 type–Kcalibratedthermocouplesare placedindifferentpointinthesystem.Volumeflowratesare measuredbyusingfloatingflowmeterswithanaccuracyof ±0.5LPM. Thehot wireanemometerisused toobtain the average air velocity with an accuracy of ±0.1 m/s, which were0.6m/sandconstantduringallexperiments.

Geometrical characteristics

Radiatorcoredimension,(mm3)

Tubedimension,(mm2)

Tubelength,Ltu,(mm)

Tubethickness,δtu,(mm)

Numberoftubes,Ntu

Numberoffins,Nf

Numberofrows,Nr

Numberofcolumn,Nc

Tubecrosssection

Tubesarrangement

Tubematerial

Radiator configuration

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Table -2: Geometricalcharacteristicsofthefindesign parameters

Geometrical characteristics Fin configuration

Finlength, Lf,(mm)

Findepth, Wf,(mm)

Finpitch, λf,(mm)

Finthickness, δf,(mm)

Numberoffins, Nf

Transverse pitch, α(mm)

Staggeredoffset, β(mm) Fin

Table -3: Matrixoftheexperimentalinletconditions

Variables/Unit Range

Hotfluidinlettemperature(Twf),°C

Fluidflowrate(m wf)kg/s

Airinletvelocity(va),m/s

Al2O3,(φ),%Vol.

2.1. Measurements uncertainties and accuracy

The error analysis method of estimating uncertainty in experimental results has been presented by Kline and McClintock, which described. The method is based on a careful specification of the uncertainties in the various primary experimental measurements [3:–3;].The dependent variable (R) is illustrated as a function of the independentvariablesx1,x2,x3,…,xn;thus:R=R(x1,x2,x3, …,xn).LetUrtheuncertaintyintheresultandu1,u2,u3… UN is the uncertainties in the independent variables. Therefore,theuncertaintyintheresultisgivenby[42]:

The accuracy and uncertainty of the instruments and measurementParametersaregiveninTable4.

Table -4: Accuraciesandestimateduncertaintiesof measurements

Instruments/Para meter Unit Accurac y Uncertainty

Flowmeter Digital

type

thermocouples

U-tube

manometer

Hotwirevelocity

anemometer

Weighing balance

Reynolds number

frictionfactor

Nusselt number

Number of transferunits

Performanceindex

2.2. Nanofluid preparation and properties

2.2.1. Preparation

The Al2O3 is the only nanoparticle employed in this experiment. Obtain the Al2O3 nanoparticles by adding nanoparticles in a certain concentration to a base fluid [AL2O3/water] with various weight mixing ratios, the nanofluidsarecreated[43].Duringaround15to20minutes, amechanicalstirrerisemployedtoproduceahomogeneous solution for each nanofluid concentration. After that, the solutionisrunthroughultrasonicmachineryforaperiodof around4-6hourstodisperseanysedimentagglomerations [44]. Following, the hot water tank is filled with various nanofluid samples that have been subjected to various scientifictesting[45].Byutilizinganagitatormotorinthe heatingtank,nanofluidsarecontinuouslyflippedwhilebeing employed as a homogeneous solution [46–47]. For Al2O3, the nanofluid concentrations are set at particle volume concentrations of 0.02, 0.05, and 0.1%. Volume concentrationratio,Table5.

2.2.2. Nanofluid physical properties

Inaccordancewithcertainratios,theAl2O3nanoparticles aredisseminatedinabasefluid(waterorboth).Thesystemwidedistributionofthenanoparticlesisuniformandwellsprayedinthemixture[48–49].Severalformulaehavebeen proposedtocalculatethedensity,specificheatcapacity,and thermalconductivityofthenanofluidasthefollowing

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

• The mean fluid temperature was used to determine the properties.

Theworkingfluidsideheattransferratecanbecalculatedas [53]:

Qwf=mwf .cwf (Twfi_Twfo) (7)

ByapplyingNewton'scoolinglawontheworkingfluidside, the

The method described below has been used to calculate forcedconvection

Asfollowsforworkingfluidflowsideheattransfer[54]:

Qwf=hwf.As.ΔTLMTD (8)

(6)

Where∅theweightconcentrationofnanofluid/water.

Table -5: thephysicalpropertiesofwaterandAL2O3 nano-particles

Specification

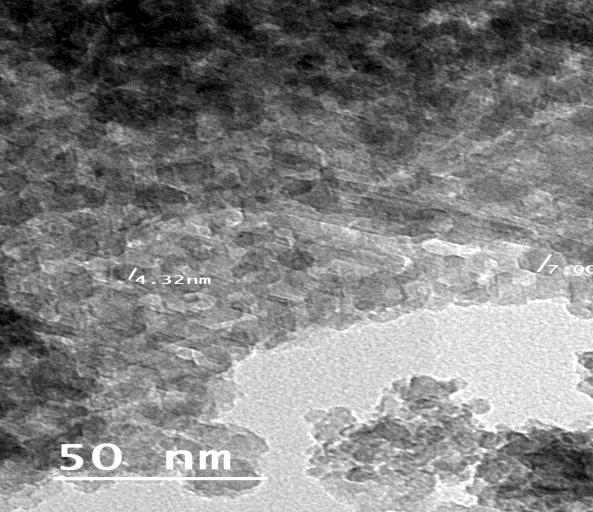

AL2O3nano-particleshaveaveragediameterof55nmFig.3 [4;–52], which are checked with transmission electron microscopy(TEM).

forAL2O3nano-particles

3.

The following pre assumptions have been taken into considerationwhenrecordingtheexperimentaltestfindings inordertostudyandevaluatetheperformanceofavehicle engine cooling system under various designing and operatingconditions:

•Steadyflowofcoolantandair.

•Thetestsection'sradiatorinsulatesalloftheheatthatis rejectedfromthecoolant.

Wherehwfisthetypicalradiatorcoolantsideheattransfer coefficient, as well as the radiator's interior heat transfer surfacearea,

AndΔTLMTDisthedifferenceinmeantemperaturebetween thecoolantandairsides.

Dimensionlessgroupparametersofworkingfluidflowside; (Rewf), (Nuwf) and (Prwf) are provided in turn by the correlations [55]: Rewf= (9) Nuwf= (10) Prwf= (11)

Where(Dhy)accordingtoK.GoudarziandH.Jamaliisthe hydraulicdiameteroftheradiatortubes,andthefollowing equationisfoundas[56]: (12)

Wherethevolumeoftheradiatortubescanbecalculatedby [57]:

VRa=Ntu.Atu.LRa (13)

TheDarcyfrictionfactorforradiatortubesiscalculatedby DarcyWeisbachequationas[58]:

Fwf= (14)

4.1. Validation of the experimental results

Themostapplied equation ofGnielinskiiscomparedwith thedataofthepresentresearchas:

Forthepurposeofassessingthereliabilityandaccuracyof theexperimentaldesign,itisnecessarytovalidateoneofthe results using diverse data from open literature [38-37]. Furthermore, a theoretical comparison should be made betweentheresultsandthreedistinctempiricalcorrelations

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

thatarewidelyrecognized.Thiscomparisonshouldconsider thedegreeofcompatibilitybetweentheempiricalequations used for establishing boundaries and the ongoing investigation.[ 62-5; ].

To compare the outcomes with the current data, the following renowned empirical equation proposed by V. Gnielinski [66]: The correlation is limited for a range of 2333≤Re≤5×136and 0.5<Pr<2000.

(15)

Thecorrelationislimitedforarangeof2333≤Re≤5×136and 0.5<Pr<2000.

Thefrictionfactorintheregionofturbulentflowisvalidated usingthemorewell-knownPetukhovcorrelationas[ 65-63 ]:

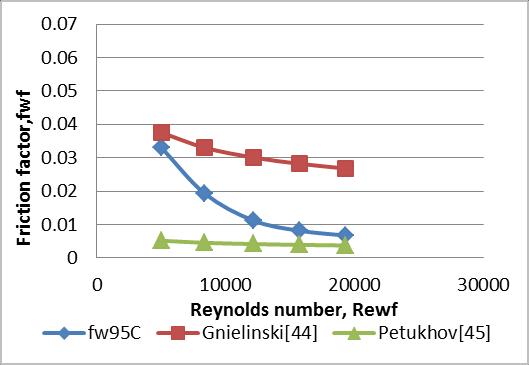

Chart -2:Resultsoffrictionfactorofthepresent experimentaldatawithpureWaterandV.Gnielinski[66], Petukhov[67].

f= (38)

The correlation is applicable within the range of 3333≤Re≤5×136. Chart -2 demonstrates the consistent results of friction factors obtained from the current experimentsusingpurewater,alongwiththeresultsfromV. Gnielinski[44]andPetukhov[45].Thecomparisonrevealsa strong agreement between the findings. The deviations betweenthepresentstudyandV.Gnielinski[44]amountto 6%,whilethedeviationswithPetukhov[45]arefoundtobe 4%.

The experimentisconductedatconstantairspeedsof 0.6 m/s with concentration ratios of 0.02, 0.05, and 0.1% vol. comparedtopurewater.Chart-4showshowtheworking fluid friction factor (fwf) varies for pure water and Al2O3/waterasafunctionoftheReynoldsnumber(Rewf). Based nanofluids with constant VA=0.6 m/s with concentration of 0.1% vol at inlet working fluid temperaturesof95°C.Asseenfromthefiguretheradiator tubes' friction factor is decreasing when the Reynolds number increases in all cases. By considering the fundamental Darcy equation, it is evident that changes in velocity have an impact on the friction factor. Specifically, the square of velocity signifies that higher fluid velocities tend to result in lower friction factors, establishing an inverserelationshipbetweenvelocityandfrictionfactor.At certain Reynolds number of 12,500 the friction factor at concentrationof0.1%,0.05%and0.02%ishigherthanpure waterby60%,54%and38%respectively.

Chart -1:Comparisonofthepresentexperimentaldatafor purewaterat ;7 °CwiththeV.Gnielinski[66],Petukhov [67].

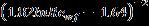

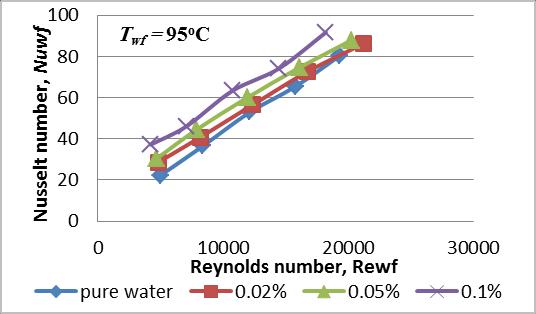

Chart-3demonstratestherelationshipbetweentheNusselt number and the Reynolds number for several fluids, includingpurewaterandAl2O3/waternanofluids,atinlet temperatureof95oC.Nusseltnumberforallconcentrations increases as the Reynolds number rises. This is while the heat transfer is directly dependent on the thermal conductivity which increases by increasing of nanofluid concentrations. At certain Reynolds number of 12,500 Nusseltnumberatconcentrationof0.1%,0.05%and0.02% ishigherthanpurewaterby16%,10%and7%respectively. Thevariationofoverallheattransfercoefficientwithvolume flow rate of working fluid at different working fluid concentrationand95oCindicatedinChart-5.Asindicated, theoverallheattransfercoefficientincreasesasvolumeflow rate increases for all working fluids concentrations pure water. At working fluid flow rate of 7.5 LPM, overall heat

Volume: 11 Issue: 07 | July 2024 www.irjet.net

transfer coefficient at concentration of 0.1%, 0.05% and 0.02% is higher than pure water by 35 %, 25% and 16% respectively.

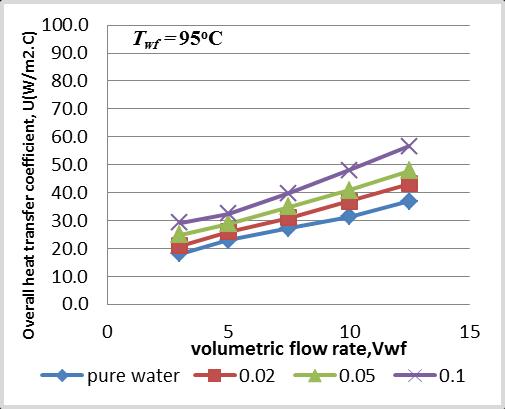

Chart -6 indicates the relation of Number of heat transfer units vs. volume flow rate for different nanofluid concentrationand95oC.Numberofheattransferunit’srises correspondingtorisinginvolumeflowratethatduetothe increasing of overall heat transfer coefficient. At working fluidflowrateof7.5LPM,overallheattransfercoefficientat concentrationof0.1%,0.05%and0.02%ishigherthanpure waterby37%,17%and8%respectively.

concentration

-6: Numberofheattransferunitsvs.volumeflow ratefordifferentnanofluidconcentration

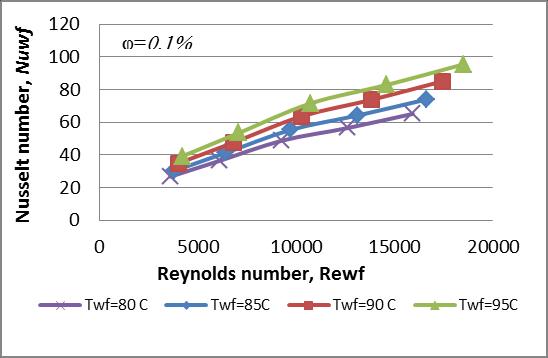

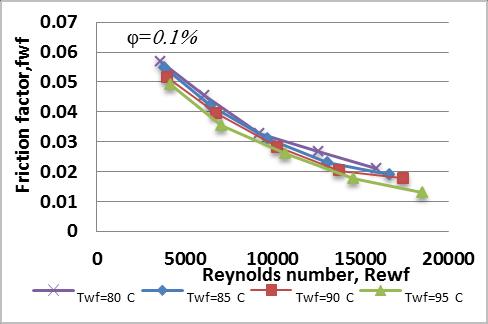

Inordertoperformtheimpactoftemperaturevariation ontheheattransferandpressuredropcharacteristics,the testsareconductedatworkingfluidinlettemperaturesof 80, 85, 90, and 95 °C with 0.1% AL2O3/water nanofluid concentration.Chart-8showstherelationbetweenfriction factorandReynoldsnumberat0.1%AL2O3/waternanofluid concentrationanddifferentworkingfluidinlettemperature. Theresultsreportedthatthefrictionfactordecreaseswith increasingofReynoldsnumber.Additionally,astemperature and fluid velocity increase, the viscosity of the fluid decreasesatagreaterratethanthedecreaseinfluiddensity. Consequently,thisresultsinthedevelopmentofathinner boundarylayer. AtcertainReynoldsnumberof12,500the frictionfactorat95oCislowerthanthatof90oC,85oCand 80oC by 7%, 10% and 18% respectively. The relationship betweenNusseltnumberandReynoldsnumberisdepicted inChart-7.ItisobservedthatNusseltnumberincreasesas the Reynolds number increases. At a certain Reynolds number of 12,500 Nusselt number at 95oC is higher than

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

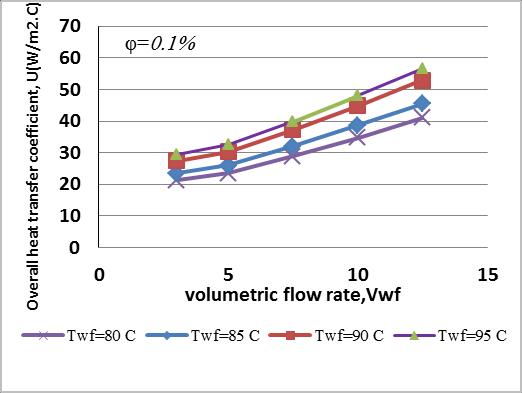

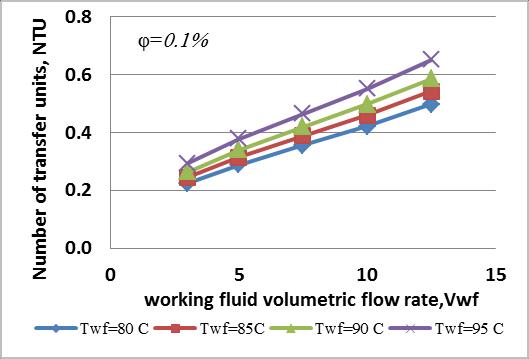

that of 90oC, 85oC and 80oC by 6%, 25% and 37.5% respectively. On the other side the overall heat transfer coefficient increased as working fluid volume flow rate increasedwhichcanbeseeninChart-9.Atacertainvolume flowrateof7.5LPMoverallheattransfercoefficientat95oC ishigherthanthatof90oC,85oCand80oCby5%,25%and 30% respectively. Chart -10 performs the variation of the numberofheattransferunitsandworkingfluidvolumeflow rates.Asperformedinthefigure,thenumberofheattransfer unit’sincreaseswithincreasingofworkingfluidvolumeflow rates.Atacertainvolumeflowrateof7.5LPMthenumberof heattransferunitsat95oCishigherthanthatof90oC,85oC and80oCby9%,13.6%and20%respectively.

Chart -7:TheNusseltnumbersversusnumberfor differentinletworkingfluidTemperature

Chart -8: Variationbetweenfrictionfactorversus ReynoldsnumberfordifferentInletworkingfluid temperature

Chart -9: Theimpactofnanoparticlevolume concentrationsatT=950contheconvectiveheattransfer coefficient

Chart -10: Nusseltnumbervs.Reynoldsnumbervariation forconcentrationsbasedwaterandnanofluid

The performance of heat transmission and pressure drop characteristicsofavehicleengineradiatorareexaminedin the current study under Cairo, Egypt's climatic circumstances. Across a broad range of coolant Reynolds numbersof 5822–Rewf–44000,manyparametersaretested. Effects of hot fluid temperature, fluid mass flow rate, nanomaterial type, nanoparticle concentration ratio. Discussions included Nusselt number, friction factor, and numberofheattransferunit’s.Thefollowingsummarisesthe keyconclusions:

Higher Reynolds number and concentrations of nanomaterials improve the heat transfer characteristics of thevehicleradiator.

PressuredropcharacteristicsincreasedasReynoldsnumber increasedduetohigherfrictionrates.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

AtcertainReynoldsnumberof12,500thefrictionfactorat concentrationof0.1%,0.05%and0.02%ishigherthanpure waterby60%,54%and38%respectively.

With Reynolds number of 12,500 Nusselt number at concentrationof0.1%,0.05%and0.02% ishigherthanpure waterby16%,10%and7%respectively.

AtReynoldsnumberof12,500thefrictionfactorat95oCis lowerthanthatof90oC,85oCand80oCby7%,10%and18% respectively.

AtacertainReynoldsnumberof12,500Nusseltnumberat 95oCishigherthanthatof90oC,85oCand80oCby6%,25% and37.5%respectively.

Atacertainvolumeflowrateof7.5LPMoverallheattransfer coefficientat95oCishigherthanthatof90oC,85oCand80oC by5%,25%and30%respectively.

[1]W.Yu,D.M.France,S.U.S.Choi,J.L.Routbort,Reviewand Assessment of Nanofluid Technology for Transportation and Other Applications (No. ANL/ESD/07-9). Energy System Division, Argonne NationalLaboratory,Argonne,200.

[

4]DustinR.Ray,DebendraK.Das,Superiorperformanceof nanofluidsinanAutomotiveradiator,J.ThermalSci. Eng.Appl.6(2014)1–16.

[5] Devendra Vashist, Sunny Bhatia, Ashish Kalra, Some studiesontheperformanceofAutomotiveradiatorat higher coolant temperature, J. Basic Appl. Eng. Res. 1(2014)41–46.

[6]K.Y.Leong,R.Saidur,S.N.Kazi,A.H.Mamun,Performance investigationofanAutomotivecarradiatoroperated withnanofluid-basedcoolants(nanofluidasaCoolant in a radiator), Appl. Therm. Eng. 30 (2010) 2685–2692.

[7] Hardik V. Patel, Dattatraya G. Subhedar, Dr. Bharat Ramani,andNumericalInvestigationofPerformance for Car Radiator Oval Tube Materials Today: Proceedings,vol.4,(2017),pp.9384–9389.

[8] Rashmi Rekha Sahoo, Pradyumna Ghosh, Jahar Sarkar, Performance comparison of Various coolants for louveredfintubeautomotiveradiator,Therm.Sci.21 (2017)2871–2881.

[9]SethDanielOduro,JoshuaAmpofo,Effectofradiatorfins blockage by clay soil on The engine cooling temperature,Int.J.Eng.Technol.6(2012)1002–1010.

[;] W.M. Yan, P.J. Sheen, Heat transfer and friction characteristicsoffinandtubeheatExchangers,Int.J. HeatMassTransf.43(2000)1651–1659.

[32] A.J. Torregrosa, A. Broatch, P. Olmeda, C. Romero, Assessment of the influence of Different cooling systemconfigurationsonenginewarm-up,emissions and fuel Consumption, Int. J. Automot. Technol. 9 (2008)447–458.

[33] J.P.Holman,Experimental MethodsforEngineers,7th edn,McGraw-Hill,NewYork,2001.

[34] W. Duangthongsuk, S. Wongwises, Effect of thermophysicalpropertiesmodelsonthepredicting of the convective heat transfer coefficient for low concentrationnanofluid, Int. Commun. Heat Mass Transf.35(2008)1320–1326.

[35] X. Wang, X. Xu, Thermal conductivity of nanoparticlefluidmixture,J.Thermophys.HeatTransf.13(1999) 7.

[36] Y. Xuan, W. Roetzel, Conceptions for heat transfer correlationofnanofuids,Int.J.HeatMassTransf.43 (2000)7.

[37] W. Yu, H. Xie, A review on nanofluids: preparation, stability mechanisms, and Applications, Nanomater (2012)1.

[38]N.Masoumi,N.Sohrabi,A.Behzadmehr,Anewmodelfor calculatingtheeffectiveViscosityofnanofluids,J.Phys. D.Appl.Phys.42(2009)491–501.

[39] M. Kole, T.K. Dey, Viscosity of alumina nanoparticles dispersedincarengineCoolant,Exp.ThermalFluid Sci.34(2010)677–683.

[3:] M.M. Elias, I.M. Mahbubul, R. Saidur, M.R. Sohel, I.M. Shahrul,S.S. Khaleduzzaman, S. Sadeghipour, Experimentalinvestigationonthe thermophysical properties of Al2O3 nanoparticles suspended in car radiator coolant, Int.Commun. Heat Mass Transf.54(2014)48–53.

[3;] T.V.R. Sekhar, Gopal Nandan, Ravi Prakash, Marisamy Muthuraman, Investigations On viscosity and thermal conductivity of cobalt oxide-water nanofluid,Mater.Today5((2018)6176–6182.

[42]R.R.Sahoo,P.Ghosh,J.Sarkar,Performancecomparison of various coolants for Louvered fin automotive radiator,Therm.Sci.21(2017)2871–2881.

[:] S.C. Tzeng, C.W. Lin, K.D. Huang, Heat transfer enhancementofnanofluidsinrotarybladecouplingof four-wheel-drivevehicles,ActaMech.179(2005)11–23.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

[43]F.W.Dittus,L.M.K.Boelter,HeatTransferinAutomobile Radiators of Tubular Type, University of CaliforniaPress,Berkeley,CA,1930,pp.13–18.

[44]F.M.White,FluidMechanics,fourthed.,McGraw-Hill,Inc, NewYork,2001.

[45]OlietC,OlivaA,CastroJ,SegarraCDP.Parametricstudiesonau tomotiveradiators.ApplThermEng2007;27:2033–43.

[46]LeeS,ChoiSUS,LiS,EastmanJ.Measuringthermalconductivi tyoffluidscontainingoxide nanoparticles.JHeatTransf1999;121(2):280–9.

[47]PeyghambarzadehSM,HashemabadiSH,JamnaniMS,Hosei niSM.Improvingthecooling performanceofautomobileradiatorwithAl2O3/wat ernanofluid.ApplThermEng2011;31:1833–8.

[48]ParkKW,PakHY.Flowandheattransfercharacteristics inflattubesofaradiator.NumerHeatTransf2002; 41:19–40.

[49] LeongKY,SaidurR,KaziSN,MamunAM.Performance investigation of an automotive car adiatoroperated with nanofluid based coolants (nano fluid as a coolant in a radiator).ApplThermEng2010;30:2685–92.

[4:]HwangKS,JangSP,ChoiSUS.Flowandconvectiveheat transfer characteristics of water basedAl2O3nanofluidsinfullydevelopedlaminarflo wregime.IntJHeatMassTransf2009;52:193–9.

[4;]MaigaS,PalmSJ,NguyenCT,RoyG,GalanisN.Heattransfer enhancement by using nano fluids in forced convection flows.IntJ Heat Fluid Flow 2005; 26(4):530–46.

[52] HusseinAM, BakarRA, KadirgamaK ,SharmaKV. Experimentalmeasurementsofnanofluidsthermal properties.IntJAutomMechEng2013;7:850–64.

[53] XieWY,YangL,LifeiC.Discussion on the thermal conductivity enhancement of nano fluids Huaqing.NanoscaleResLett2011;6:1–12.

[54] SyamSundarL, Sharma KV. An experimental studyon heat transfer and friction factor of Al2O3nanofluid.JournalofMechanicalEngineering andSciences.1(2011)99-112.

[55] SyamSundar L, Sharma KV. Laminar Convective Heat transfer and friction factor of Al2O3nanofluid in circular tube fitted with twisted tape inserts. InternationalJournalofAutomotiveandMechanical Engineering.3(2011)265-78

[56]YogeswaranM,KadirgamaK,RahmanMM,DevarajanR. InternationalJournalof AutomotiveandMechanical Engineering.11(2015)2272-81.

[37]S.P.JangandS.U.S.Choi,“Effectsofvariousparameters onnanofluidthermalconductivity,”JournalofHeat Transfer,vol.129,no.5,pp.617–623,2007.

[38]Hammad,EtAl.''Anexperimentalstudyontheeffectof diameter on thermal conductivity and dynamic viscosityofFe/waternanofluids''ResearchPaperin Akade’miaiKiado´,Budapest,December2314.

[59] I. Gherasim, G. Roy, C. T. Nguyen, and D. Vo-Ngoc, “Experimental Investigation of nanofluids in confinedlaminarradialflows,”InternationalJournal ofThermalSciences,vol.48,no.8,pp.1486–1493, 2009.

[5:] S. M. Peyghambarzadeh, S. H. Hashemabadi, M. S. Jamnani, and S.M.Hoseini, “Improving the cooling performance of automobile radiator with Al2O3/water nanofluid,” Applied Thermal Engineering,vol.31,no.10,pp.1833–1838,2011.

[5;]T.H.Tsai,L.S.Kuo,P.H.Chen,andC.T.Yang,“Thermal conductivity Of nanofluid with magnetic nanoparticles,” Progress In Electromagnetics Research Symposium, vol. 5, no. 3, pp. 231–234, 2009.

[62]DasSK,ChoiSUS,YuW,PradeepT.Nanofluids science andtechnology.Wiley-Interscience;2008.

[63]XuanY,LiQ.Heattransferenhancementofnanofluids. InternationalJournalofHeatandFluidFlow2000; 21:58–64.

[64]CKannan,JaysinghTRaja,2314.“AnExperimentalstudy ontheinfluenceofoperatingparametersontheheat transfer characterstics of an automotive Radiator withNanofluids”

[65] Adnan M. Hussein, R. A. Bakar, K. Kadirgama, 2014. Studyofforcedconvection nanofluidheattransfer in the automotive cooling system. International JournalofThermalEngineering2,50–61

[44]V.Gnielinski,Newequationsforheatandmasstransfer intheturbulentflowin Pipesandchannels,NASA STI/ReconTechnicalReporta75(1975)22–28.

[45]BetukhovB,Heattransferandfrictioninturbulentpipe flow with variable physical Properties, Adv. Heat Tran.6(1970)503–564.