International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

S Kavia Padmashali1, Mr. Pravek Sahu2

1Research Scholar, M. Tech. (Structural Engg.)

2Assistant Professor, Department of Civil Engineering, Jhada Sirha Government Engineering College, Jagdalpur Chhattisgarh India.

Abstract - Compared to ordinary concrete, lightweight concrete is an innovative building material that offers numerous benefits. Its reduced density which is typically between 10% and 40% lower leads to improved thermal insulation and energy efficiency. This experimental study investigates the properties of lightweight concrete using expanded polystyrene (EPS) pellets as the aggregate. EPS beadswereaddedtotheconcretemixindifferentproportions to replace traditional coarse aggregates. We evaluated the impact of EPS beads on concrete's density, compressive strength, workability, and thermal conductivity in both its fresh and hardened states. The findings showed that there were significant drops in density (up to 40%) and thermal conductivity (up to 50%) when the number of EPS increased. Compressive strength decreased with increased EPS content, although it remained within permissible limits for structural applications.ThestudyemphasizesthepotentialofEPS-based lightweight concrete for energy-efficient and sustainable construction, with potential applications in building insulation, foundation systems, and structural elements.

Key Words: thermal conductivity, compressivestrength, aggregates, expanded polystyrene beads, lightweight concrete, and sustainability.

1.INTRODUCTION:

Moderninfrastructure,buildings,andstructuresarelargely constructedwithconcrete,amaterialthathasbeenaround forgenerations.Itisacomplicatedcompositematerialmade of cement, water, fine and coarse aggregates, and admixtures. These ingredients work together to create a materialthatisrobust,adaptable,andlong-lasting.Because ofitsspecialqualitiesandbenefits,concreteisnowacrucial partofcontemporary building, beingutilizedforanything from roadways and ornamental elements to high-rise structures and bridges. The high weight, thermal conductivity, and environmental effects of traditional concretearesomeofitsdrawbacks.Usingunconventional materialsandmethods,researchersandengineershavebeen investigating creative ways to overcome these obstacles, suchascreatinglightweightconcrete.

1.1 Light weight concrete:

Varietyofconcretethatcontainsanexpandingagent,which addsvolumetothemixture andimpartsotherproperties,

includingabilityandreduceddeadweight.Whenpouredon thewall,lightweightconcretekeepsitsvastspaceswithout creatingcementfilmsorlaitancelayers.Theperformanceof aerated lightweight concrete served as the foundation for this study. For cement and water to cohere sufficiently, though, a suitable water-to-cement ratio is essential. Concrete may become less strong due to a lack of cohesiveness between the particles brought on by insufficientwater.Similarly,excessivewateringcanleadto cementrunoff,causinglaitancelayerstoform,whichthen losestrength.

1.2 Expanded Polystyrene (EPS) and its benefits:

Onecommoningredientinenhancedconcreteaggregateis polystyrene, a light-weight, rigid foam. Blending concrete with EPS blocks or beads creates a unique composite material with unique properties. Reduced density and weight.improvedcapacitytoinsulateIncreasedbuoyancy (for maritime applications) enhanced workability and finishability.Potentialforreducedmaterialcosts.

2. AIM AND OBJECTIVE:

Examine the potential applications of EPS-based lightweight concrete for building structures, insulation,andinfrastructuredevelopment.

Consider the potential cost savings, improved thermal insulation, and reduced environmental effectsofusingEPSinconstruction.

For lightweight concrete with an M30 grade, developamixusingEPSinsteadofcoarsematerial. Analyzethevariationsinlightweightconcretewith EPSperformanceversusconventionalconcrete.

3. LITRATURE REVIEW:

Mohsin Mushtaq Khan, and Anuj Sachar

The concrete made of lightweight aggregates which reduce self and density of concrete is called as lightweight concrete. The density of lightweightconcreterangesfrom1440kg/m3 to 1840 kg/m3. It includes expanding agents which increase the volume of concrete thus

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

reducingself-weightofconcrete.Theminimum strength for structural lightweight concrete should not be less than 17 Mpa. Lightweight concretereducestheself-weightofconcreteby about 25 to 35%. In this study we have used pumiceStoneandThermocolbeadsaspartial replacementforcoarseaggregateandflyashas partial replacement for cement in producing lightweightconcrete. Afterthecompletionof tests on fresh concrete, certain tests were performed on hardened concrete samples which include compressive strength test and flexuralstrengthtest.Theseriesoftestsonthe samplesweredoneandcalculatedthevalueof strengththatconcretecanwithstandtheloads applied on compression and flexure on cube andbeamrespectively.Followingarethetests doneandtheirresultsareshownasbelow

Lightweight concrete keeps up its huge voids and doesn't shape laitance layers or cement pictures when put on the separator. This disquisitionwaspredicatedontheprosecution ofcirculatedairthroughlightconcrete.Inany case, acceptable water cement proportion is imperative to produce satisfactory cohesion between cement and water. shy water can begetneedofcohesionbetweenpatches,hence mischanceinqualityofconcrete.also,aswell important water can beget cement to run off totaltomakelaitancelayers,hencedebilitates in quality. Hence, this pivotal disquisition reportisreadytoappearexercisesandadvance of the light concrete. Centered were on the prosecution of circulated air through lightweight EPS beads concrete similar as compressive quality tests, water assimilation andconsistenceandsupplementarytestsand

comparisonsmadewithotherfeathersoflight concrete. To determine the workability and consistency of EPS Beads concrete, it is recommended to consult the relevant standards, guidelines, or research papers specific tolightweightconcreteincorporating EPS beads. These resources will provide you with detailed information on the appropriate testingmethodsandacceptancecriteriaforEPS Beads concrete in your specific application. Theadditionofpolystyrenetoaconcretemix generallyresultedinincreasedworkability.It wasobservedthatasthepercentageofcoarse aggregate replaced by polystyrene increased, theworkabilityofthemixesalsoincreased.In other words, higher levels of polystyrene replacementledtohigherlevelsofworkability.

Slump test results SLUMP VALUE

10%replacement 65

20%replacement 68

30%replacement 70

40%replacement 75

50%replacement 81

4.1 Cement Content:Thisexperimentusedcementofgrade OPC-53, whichhasa specific gravity of3.16anda cement finenessof6%TestforConsistency30%.

4.2 Coarse Aggregate: The aggregate was used in a uniformlygradedaggregategradethatwasconsistentand hadanominalsizeof20mm.Ithasa2.98specificgravity,a 3.44finenessmodulus,anda0.5%waterabsorptionrate.

4.3 Fine Aggregate: ZoneIInatural riversandisusedfor thiswork.Thespecificgravityofis2.44,itsfinenessmodulus is 2.7, its water absorption is 2.2%, and its nominal fine aggregatesizeis4.75mm.

4.3 Water: It is an essential component of concrete and plays a significant role in the mixing, placing, and curing processes, ensuring the strength and longevity of the concreteedifice.

4.4 EPS (Expanded Polystyrene): 0.011 bulk specific gravityWaterAbsorption:3.5%byvolumeDensity:6.88kg percubmeterandParticleSize:Diameterof8–10mm.

5.

As Indian standard recommended method for concrete basedon{IS10262-2019}.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

(a) Steps for mixed design for concrete:

1.GradeofConcrete=M-30

2.Cement=OPC-53

3.NominalSizeofaggregate=20mm

3.Degreeofsitecontrolcondition=Good

4.ConditionofExposure=Severe

5.Workability=75mm

6.Methodofconcreteplacing=manualmixing

7.Minimumcementcontent=320kg/m3

(b) Test result for material:

1.Specificgravityofcement=3.16

2.Specificgravityofcoarse-aggregate=2.98

3.Specificgravityoffine-aggregate=2.44

4.Waterabsorptionofcoarse-aggregate=0.5

5.Waterabsorptionforfine-aggregate=2.2

6. Zoneofsand=II

(c) Target mean strength for M-30 grade = 38.25N/mm2

(d) Selection of water-cement ratio = 0.45

(e) Selection of water content = 207.567 kg/m3

(f) Cement content =425.20 kg/m3

(g) Coarse aggregate (per m3) = 1124.628 kg

(h) Fine aggregate (per m3) = 630.235 kg

5. TEST ON CONCRETE:

Workability test of Concrete: for better workability of concreteConsistencyofconcreteisdeterminebytheslump conetestC:S:A::1:48:2.64isthemixratioforconventional concrete,andC:S:A::1:63:3.03isthemixratioforexpanded polystyrene concrete. The Slump Values of Conventional Concrete 81.25 mm and slump value for EPS concrete is 84mm

6. RESULT AND DISCUSSION:

The sample of concrete were cast in accordance with IS 10086-1982. The cube, cylinder, and beam samples were curedinawaterpondforaperiodof28days.Atsevenand twenty-eight days, the strength metrics of self-compacted

concrete were compared to those of conventionally cured concrete.

6.1 TEST OF SAMPLE:

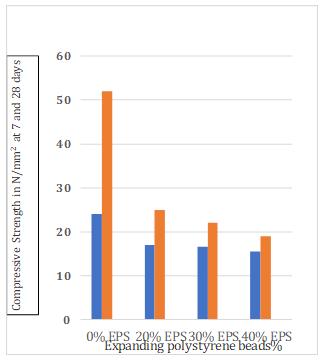

Compressive Strength test: A 150 × 150 × 150 mm concrete cube was cast, and it was tested for seven and twenty-eight days. Compressive Strength is equal to P/��, whereAisthecross-sectionalarea(150×150x150mm) andPistheappliedload.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

TABLE-3:CompressiveStrengthresultsofConcrete:

Chart-1: Compressivestrengthofconventionalconcrete after7,and28-daysvsexpendedpolystyreneconcrete

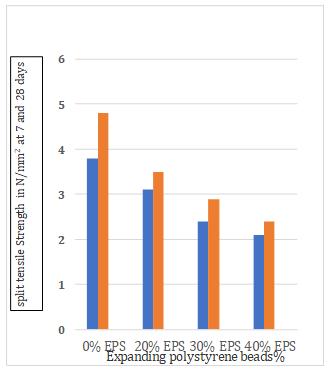

Split tensile strength test: Upon casting, the cylinder underwent testing. Using cylinders that are 150 mm in diameterand300mmhigh,in7and28days.Theformula forsplittensilestrengthis2P/πDL,wherePistheload,Dis thecylinderdiameter,andListhecylinderlength.

TABLE-4:CompressiveStrengthresultsofEPSConcrete.

of M30

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

TABLE-5: TensileStrengthresultsofConcrete:

Grade of M30

TABLE-6: TensileStrengthresultsofEPSConcrete:

of M30

flexural strength test of concrete in UTM

Table-4:FlexuralStrengthresultsofConcrete.

of M30

Chart-2: Tensilestrengthofconventionalconcreteafter7 and28-daysvsexpendedpolystyreneconcrete.

Flexural Strength test: At the age of 7and 28 days, A universaltestingequipmentappliesa2000KNforcetoa150 x 150 x 700 mm beam specimen to generate bending f strengthisequaltoWL/bd.

|

Table-5:FlexuralStrengthresultsofEPSConcrete.

Grade of M30

Concrete with EPS %

strength

2 at 28 days

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

7. Indian Standard code456:2000 of practice for general structural use of plain and reinforced concrete.

8. IS456,2000”Concrete,PlainandReinforced,“Bur. Indian Stand. Delhi, pp.1-114, 2000. Bengin M A Herki(2020)

9. AbdulkadirKan&RamazanDemirboga,etal(2009) “A NOVEL MATERIAL FOR LIGHTWEIGHT CONCRETEPRODUCTION”www.elsevier.com-489495.

10. AbhijitsinhParmar,Chahiljoshietal(2015)“Effect of cement and EPS beads ratios on compressive strength and density of lightweight concrete”Asian International Conference on Science, Engineering & Technology AAICSET ISBN: 9780993-909238

11. LinchangMiao,JunhuiLuo, Jiaqi Wang, and Yinan Chen,etal(2016)”DurabilityofModifiedExpanded PolystyreneConcreteafterDynamicCyclicLoading” Volume 2016 | Article ID 2391476 https://doi.org/10.1155/2016/2391476

Chart-3: flexuralstrengthOFConventionalconcreteafter 7and28-daysvsExpendedpolystyreneconcrete.

7. CONCLUSION:

1. Concrete's density has been lowered without sacrificingthesubstance'scompressivestrength.

2. When compared to traditional concrete, the ideal dosageofexpandedpolystyrenebeadsresultsina 20%reductioninthedensityoftheconcrete.

8. REFERANCES:

1. IS383:1970Codeforfineandcoarseaggregatefor concrete

2. ConcreteTechnology:TheoryandPracticebyM.S. Shetty

3. ConcreteTechnology:TheoryandPracticebyM.L Gambhir.

4. ConcreteTechnology:byS.S.Bhavikatti.

5. IS 10262:2009 Recommended Guidelines for ConcreteMixDesignBureauofIndianstandardNew Delhi.

6. BureauofIndianStandardsIS516:1959Methodsof TestsforStrengthofConcrete.

12. VandaleAmarDiliprao,Dr.V.V.Patil,etal(2019) “Making of Lightweight Concrete by using EPS Beads as Replacement of Coarse Aggregate” (IJSRDV)Volume:7,Issue:3ISSN828-832

13. Jaydeep Singh, Sangeeta Dhyani (2017) “LIGHT WEIGHT CONCRETE USING EPS” international journal of research and technology and managementISSN2454-6240