International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Sai Jadhav1, Atharva Kamble2

1Student, Dept. of Mechanical Engineering, VIIT Pune, Maharashtra, India

2Student, Dept. of Mechanical Engineering, VIIT Pune, Maharashtra, India

Abstract -

The paper delves into the notable progressions in mechatronics sinceitsinception,particularlyintherealms oftechnologyandprocessingpower.Itexplorestheevolving landscapeofproductsandsystemsacrossdiversedomains, highlighting the impact of strategies such as concurrent engineering and intelligent tools in design processes. The author's intention is to incite discourse on mechatronicsrelatedmatters,refrainingfromofferingdefinitiveanswers orproposingnovelmethods.Thedocumentispresentedasa discussion piece grounded in personal experience and perspective.Thereisadiscernibleshiftintheutilizationof laboratory work from mere illustrations of theoretical concepts to opportunities for collaborative, group-based learning. The objective is to furnish students with a more comprehensive understanding by addressing real-world phenomena. The proposal underscores the preparation of students for scientific or technical careers through cooperative group work aimed at achieving project goals. ThepassageintroducesaneducationalV-modelspecificto mechatronicsdesign,aimedattraininggraduatesincrafting cost-effective, high-performance mechatronicsproducts. Theapproachintegrates structural design methodology, simulation, and practical implementation. Students engageinaprocessencompassingconceptualanddetailed design, simulation for feasibility verification, and the integrationofcomponentsintoacompletephysicalproduct or system. More than a decade ago, automated grading facilitiesforfruitsandvegetableswereintroduced.Recent advancements in machine vision, near-infrared (NIR) technologies,mechatronics,andcomputertechnologieshave bolstered these facilities, expanding their application to various agricultural products. Robot technology plays a pivotalrole,delicatelyhandlingproductswithprecisionand gatheringinformationforaseasonalproductdatabase.

Living in a world characterized by constant and rapid change,wherethelifespanofknowledgeisshorterthanever and competitiveness is a crucial asset, necessitates a revaluation of classical education methods for students in technical domains. Memorization is becoming inadequate due to the exponential growth of information in various fields. The internet enables quick access to meaningful information,eliminatingtheimmediateneedfortextbooks or lecture notes. Students are now preparing for lifelong learning,acquiringskillsthatenableadaptabilityinafield destined to change. The U.S. Bureau of Labor Statistics revealsthatworkersbornbetween1957and1964hadan average of 11.3 jobs in different fields, emphasizing the dynamic nature of professions, especially in engineering. Today'sstudentsanticipatemultiplecareers,underscoring theimportanceofcriticalthinkingandinterpersonalskills. Education,particularlyinengineering,shouldprioritizethe 4Cs creativity, critical thinking, communication, and collaboration.Students,especiallyinengineering,mustlearn how to learn, navigating vast information sources. Universitiesareadaptingwithlearner-centeredapproaches that encourage participation and interaction. Embracing modern learning methods and tools, such as

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

interdisciplinary and project-based learning, is crucial for keepingpacewithrapidchangesinscienceandtechnology. Educatorsshouldleveragetechnologytocreatepersonalized learning environments, emphasizing core concepts, communication, collaboration, adaptability, non-routine problem-solving,self-managementandsystemsthinking.

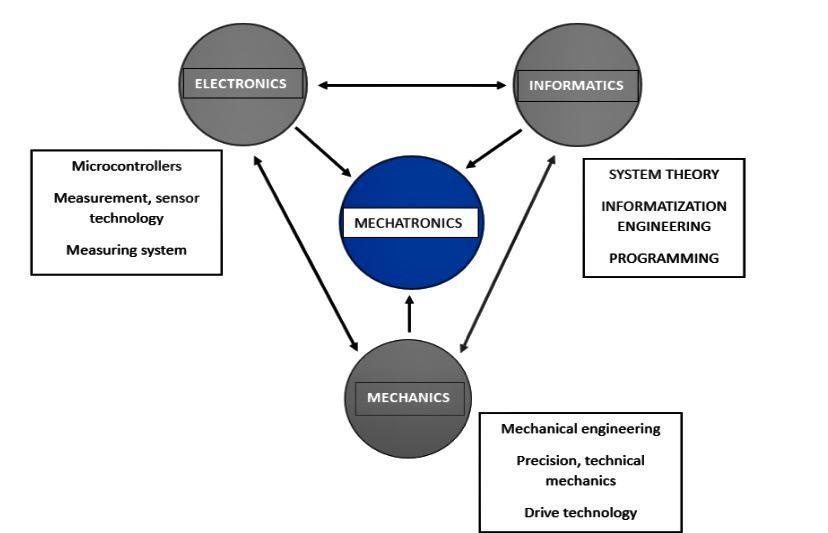

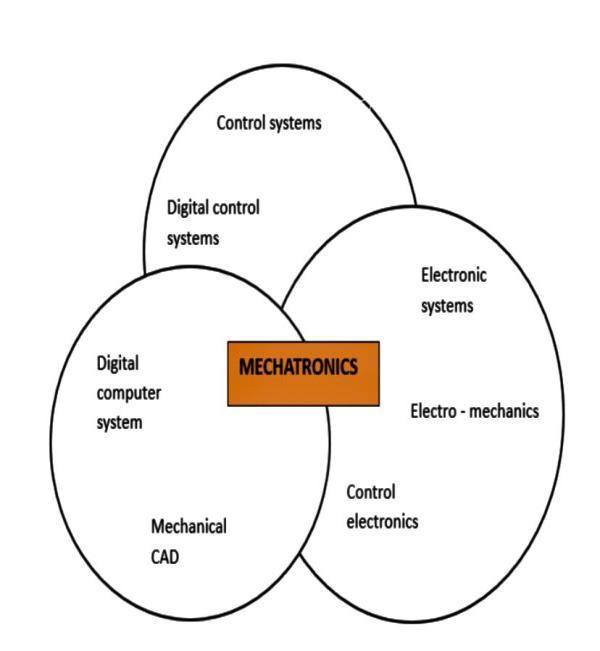

Fig.no.2: Mechatronics

II.SECTION BIT

2.1 Key Aspects of Design Education

1.Learning the Process: The central objective is to teach students the step by-step process of design, including conceptualization, ideation, prototyping, and implementation.

2.Creativityand Innovation: Designeducationemphasizes fostering creativity and innovative thinking, encouraging studentstoapproachproblem-solvinginuniqueways.

3.Theory and Principles: Students delve into the theoretical foundations and principles of design, understandingthehistoricalcontextandevolvingtrends.

2.2 Key Aspects of Industrial Applications:

1.Product and System Development: Industrial design involves creating products and systems that meet specific needs within various industries, such as manufacturing, technology,consumergoods.or

2.Efficiency and Functionality: Thefocusisondesigning solutionsprioritizingefficiency,functionality,andusability, inadditiontoadheringto

3.Market and User Considerations: Industrial designers consider market trends, user preferences, and practical constraintswhendevelopingdesignsformassproduction.

Design education typically covers the entirety of the academicjourney,rangingfromfreshmentosenioryears,in accordancewithcurriculumrequirements.Theprimarygoal istoequipstudentswiththeskillof"howtodesign."These coursesfocusonguidingstudentsthroughthestepby-step

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page260

process,encouragingthemtounderstandthefundamentals, methodologies,andcreativethinkinginvolvedindesign.On the flip side, industrial focus in design places a direct emphasis on the act of "design" itself. In an industrial context,thepriorityistheapplicationofdesignprinciplesto createproductsandsystems.Thisdistinctionpromptsusers, whether they are students or professionals, to seek out differentbooksandreferencesbasedontheirspecificneeds. Someresourcesaremoreadeptatelucidatingtheintricate process of design, while others are tailored to providing insightsintothepracticalapplicationofdesigninindustrial settings.In essence, the crucial difference betweendesign educationandindustrialdesignfocusliesintheorientation toward either learning the design process or directly applyingdesignprinciples.Users,dependingontheirgoals, navigatediverseresourcestoeithermastertheintricaciesof design methodology or comprehend how design is implementedintheindustriallandscape.

In the realm of mechatronics, my teaching philosophy centersonfundamentalprinciples,hands-onexperience,and mathematical integration, particularly in modelling and simulation. The goal is to provide students with a comprehensiveunderstandingoftheseconceptsandtheir roleindesigningmechatronicsproducts.

1.Foundational Understanding: Prioritizing a deep comprehension of mechatronics fundamentals. Ensuring students grasp the core concepts of modelling and simulationforeffectivedesignprocesses.

2.Practical Experience: Offeringhandsonexperiencesto create practical models for mechatronics products. Encouragingstudentstoapplytheoreticalknowledgetorealworldscenariosthroughsimulations.

3.Mathematical Integration: Integrating mathematical procedures into modelling, stressing accuracy in representingreal-worldbehavior.Equippingstudentswith skills to apply mathematical techniques in describing and analyzingmechatronicssystems.

4.ParametricAnalysisandOptimization: Guidingstudents throughparametricanalysisandoptimizationbasedonwelldefinedproductrequirements.Instillingtheunderstanding that optimization enhances efficiency and performance alongsideachievingdesiredoutcomes.

5.Critical Thinking and Problem Solving: Nurturing criticalthinkingforindependentevaluationandrefinement of models. Encouraging a problem-solving mindset to identifyandaddresschallengesinmodellingandsimulation processes.

6.Continuous Learning and Adaptability: Instilling a commitmenttocontinuouslearningintheevolvingfieldof mechatronics.Teachingadaptabilitytopreparestudentsfor newchallengesandinnovationsinmechatronicsdesign. Emphasizing clear communication for presenting and discussingdesignmodels.Cultivatingtheabilitytoarticulate

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

complex mechatronics concepts in a comprehensible manner.

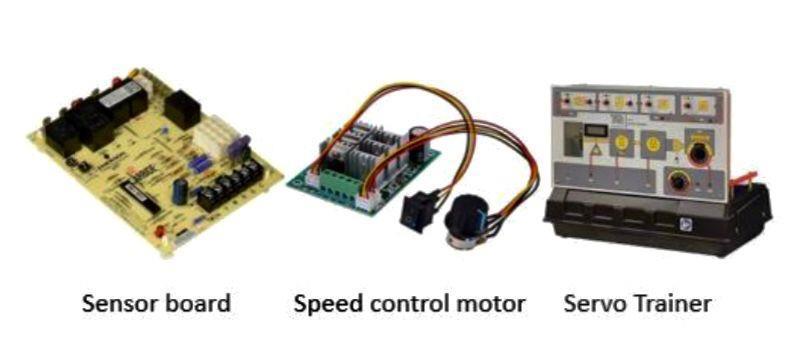

Fig.no.3:Tools

The mechatronic paradigm is centered on addressing benchmarking and emerging issues within the realms of engineering,science,andtechnologythatremainunresolved. Thisorientationreflectsnoticeabletrendsinfundamental, applied,andexperimentalresearch,alongwithadjustments in curricula, in response to persistent challenges, the demandsofengineeringandtechnologicalprogress,andthe continuous evolution of requirements. Mechatronics, as encapsulated in this paradigm, entails a comprehensive studyofintelligentandhigh-performanceelectromechanical systems and products. It integrates Fig no. 3 Tools integration, in conjunction principles from mechanical engineering, electronics, computer science, and control engineering to devise and craft intelligent systems and products. In essence, the mechatronic paradigm encapsulatesaholisticapproachtostudyingandadvancing electromechanical systems, with a specific emphasis on intelligenceandhighperformance.Hardwareandsoftware in microcontroller education addressing the hardware challenge in mechatronics/microcontroller education involvesselectingamicrocontrollerthatiswidelyusedand acceptedintheindustry.Thecriteria forselectioninclude essential functions for student understanding and cost effectiveness. Given the multitude of microcontroller options, consideration is crucial. careful On the software front, the difficulty arises as mechanical engineering students lack instruction in script programming until entering the microcontroller course. Currently, their programmingeducationprimarilyutilizesvisuallanguages like Mathcad and LabView, supported by college site licenses.TeachingscriptlanguagessuchasAssemblyorC++ for microcontroller programming requires starting from basic principles to bridge the gap in students' scripting knowledge.

Theabilitytoseamlesslyincorporatemechatronicsintothe design process is critical for creating innovative and sustainablesolutions.Whetheroptimizingenergysystems, improving transportation, advancing healthcare,

manufacturing,theorenhancingintegrationofmechatronics contributes to holistic and efficient system development. This with developments in materials technology, ensures thatengineeringdesignremainsresponsiveandeffectivein thefaceofevolvingchallenges.

1.Essential Integration: Mechatronicsplaysacrucialrolein seamlessly incorporating mechanical and electronic elementsintothedesignprocess.

2.Versatile Applications: Its application spans diverse fields such as optimizing energy systems, improving transportation, advancing healthcare, and enhancing processes.manufacturing

3.Holistic System Development: The integration of mechatronics contributes to holistic and efficient system development, ensuring that different components work togetherseamlessly.

4.Adaptability: In conjunction with developments in materialstechnology,mechatronicsensuresthatengineering designs remain responsive and effective in the face of evolvingchallenges.

5.Innovation Backbone: Mechatronics isn't just about makingthingsmove;it'saboutinfusingpurposeandfinesse intotheirmotion,pavingthewayforinnovativesolutions.

6.Sustainability Focus: Thecombinationofmechatronics and materials technology is instrumental in creating sustainable solutions, addressing both functionality and environmentalimpact.

7.Progressive Evolution: This dynamic duo ensures that ourtechnologicalsolutionsnotonlyfunctionefficientlybut also evolve alongside the ever changing landscape of challenges

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

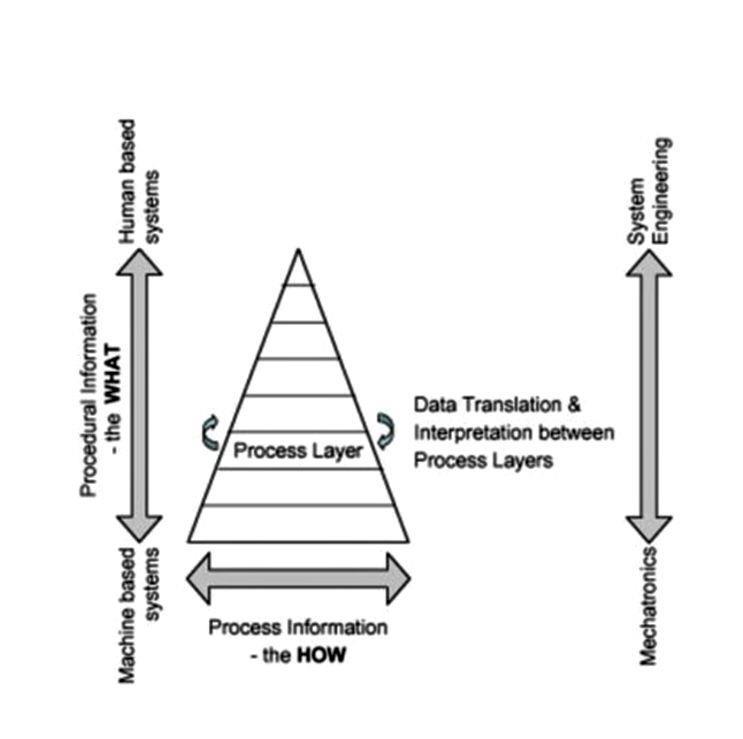

In recent times, there has been a significant surge in the complexity of devices and systems, prompting a shift towards a system-level approach in mechatronics design. This approach allows engineers to seamlessly integrate mechanicalandcontroldesign,conductefficienttesting,and reuse algorithms within the final embedded delivery framework.Theimpetusforthissystem-leveltrendarises from substantial investments in fields such as medical renewable sciences, energy, life and sciences, industrial machinery. It enhances the overall design process by amalgamating best practices and technology, leading to a more streamlined approach to design, prototyping, and implementation. The adoption of parallel threads in the designprocessfacilitatesamoreefficientcreationprocess, eliminatingtheneedtowaitforapracticalprototypebefore developingacontrolalgorithm.Engineerscannowleverage virtualprototypesbasedonconceptmodelsandsimulation data,expeditingthedesignprocess.Thisapproachnotonly reduces development time and associated costs but also fosters collaboration between design teams, providing valuablefeedbackonsystemefficiencyindevelopment. The evolving role of software plays a crucial part in mechatronicsandfutureembeddedsystems.Softwaretools provide a comprehensive system-level view of various designfactors,abstractingthecomplexitiesassociatedwith emergingtechnologies.Thisempowermentallowsengineers todevelophigh-performancesystemscapableofmeetingthe challengesofthefuture.

Toexpediteproductiontimeduringdeployment,engineers face trade-offs, such as developing a component-level tailored control system or deploying on embedded commercial-off-the-shelf (COTS) systems. "System ready" subsystemsareoftenutilizedforprototypingorasadelivery platform before transitioning to a cost optimized custom design. The industry is witnessing a shift towards customizableembeddedplatforms,exemplifiedbyNational Instruments'RIOplatform,whichcombinestheversatilityof customconfigurationswiththerapiddeploymentassociated withCOTShardware.

Inconclusion,thefutureofmechatronicsappearspromising, driven by the integration of emerging technologies and interdisciplinary collaboration. This approach not only revolutionizesindustriesbutalsoenhancesourdailylives, particularlyinareaslikemedicine.Theefficiencyandcosteffectivenessofmechatronicdesigncreateacompellingedge over traditional methods, emphasizing the need for rapid technological progress. While celebrating these advancements,it'scrucialtoremainvigilantaboutpotential negative impacts. Future research should focus on identifyingandmitigatinganythreatsthatmayarisefrom thewidespreadadoptionofmechatronictechnologies.This

proactive approach will ensure that the benefits of mechatronicscontinuetoenhancereliability,protection,and affordabilitywithoutcompromisinglongtermsustainability. Engagingininterdisciplinarytrainingduringthesenioryear of engineering education is a strategic choice that encourages collaboration across various technology and engineeringfields.Thistrainingtakesplaceinadedicated laboratory setting, providing students the opportunity to expandtheir knowledge by workingalongside peers from different majors. The focus on complex projects in this environment not only sharpens technical skills but also demonstrates the ability to thrive in interdisciplinary settings,whichisattractivetopotentialemployers.Rather than relying on conventional approaches, the paper advocatesforadeparturefromtraditionalmethodologiesin Favorofdiscoverymechanisms.Thesemechanismsaimto instillconfidenceandautonomyinstudentsbychallenging them to solve increasingly complex projects. The paper emphasizesmechatronicsandroboticsprojects, reflecting the prevalent integration of electronics in modern mechanical products. The incorporation of embedded programmable circuits, such as microprocessors or microcontrollers, lays the foundation for designing intelligent systems like industrial robots, medical devices, assemblylines,andautonomousvehicles.

The illustration of a robot arm project, using the Lynx motionroboticarmcombokit,servesasanexampleofthe proposed approach. The accompanying laboratory works cover mechanics, electronics, and computer science, including tasks like building the arm, studying gears and machine parts, analyzing kinematics, handling wiring and connections,andprogramming.Thisapproachensuresthat studentsarenotonlywell-versedintheirrespectivefields but also adept at navigating the challenges posed by collaborative,real-worldprojects.

[1] Amerongen,J.v.(2003).Mechatronicdesign. Sciencedirect,1045-1066.

[2] Bishop, R. H. ( 2017). Mechatronics. Boca Raton: CRC Press.K.Elissa,“Titleofpaperifknown,”unpublished.

[3] Bradley, D. (2004). What is Mechatronics and Why Teachit?InternationalJournalofElectricalEngineering &Education,275-291.

[4] Harashima, F., Tomizuka, M., & Fukuda, T. (1996 ). Mechatronics-"WhatIsIt,Why,andHow?"Aneditorial. IEEE,1-4.

[5] Ishihara, H., Arai, F., & Fukuda, T. (1996). Micro mechatronicsandmicroactuators.IEEE,68-79.

[6] M. Acar, R. P. (1996). Engineering education for mechatronics.IEEE,106-112.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

[7] Onwubolu, G. (2005). Mechatronics Principles and Applications.Burlington:BritishLibrary.

[8] Tomizuka, M. (2002). Mechatronics: from the 20th to 21stcentury.Sciencedirect,1-10.

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page263