International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Aayush Saraniya1 , Kishan Jayswal2 , Aakash Suthar3

1M. Tech Student, L.J. University, Ahmedabad.

2Kishan Jayswal, Assistant Professor, Civil Engineering Department, L.J. University, Ahmedabad, Gujarat, India.

3 Aakash Suthar, Assistant Professor, Civil Engineering Department, L.J. University, Ahmedabad, Gujarat, India

Abstract – Thisresearchinvestigatestheenhancementof concretestrengththroughfibrereinforcement,synthesizing insights from five prominent research papers. The focus centers on the impact of various fibres, such as steel, polypropylene, and glass, on concrete properties like strength, durability, and crack resistance. In conjunction with the literature review, a practical experiment was conducted involving the controlled breaking of 150x150x150mm concrete cubes And 700x150x150mm Beam.The brokencubeswere thenmeticulouslyrepaired using Fibre Reinforced Concrete (FRC) to assess the effectiveness of FRC in improving strength. Preliminary results indicate a substantial increase in compressive strengthandenhancedresistancetocrackingintherepaired cubescomparedtothecontrolgroup.Thesefindingsalign with trends observed in the literature, highlighting the positive influence of fibre reinforcement on concrete performance. The research contributes valuable insights, withthepracticalexperimentemphasizingtheapplicability ofFRCforrepairingandstrengtheningconcretestructures.

Key Words: Fibre Reinforced Concrete (FRC), Concrete strength enhancement, Fibre types (steel, polypropylene, glass), Durability, Crack resistance, Compressive strength, Concrete repair

1.INTRODUCTION

In recent years, the enhancement of concrete properties through fibre reinforcement has garnered significant attentionincivilengineeringresearch.Thisstudydelvesinto therealmoffibre-reinforcedconcrete(FRC),focusingonits profound impact on the strength, durability, and crack resistanceofconcretestructures.Bysynthesizingfindings fromprominentresearchpapers,thisinvestigationexplores theeffectsofvariousfibres,includingsteel,polypropylene, andglass,onconcreteperformance.

Centraltothisresearchisapracticalexperimentdesignedto assess the efficacy of FRC in enhancing concrete strength. The experiment involved controlled breakage and subsequentrepairof150x150x150mmconcretecubesand 700x150x150mm beams using Fibre Reinforced Concrete (FRC).Initialresultsfromtheexperimentrevealpromising outcomes, indicating a notable increase in compressive

strengthandimprovedresistancetocrackingintherepaired structurescomparedtothecontrolsamples.

Thesefindingsnotonlycorroboratetrendsobservedinthe literaturebutalsounderscorethetransformativepotential ofFRCinreinforcingandrepairingconcretestructures.By bridgingtheoreticalinsightswithpracticalapplication,this research contributes valuable knowledge to the field, emphasizingthepracticalviabilityandeffectivenessofFRC as a sustainable solution for enhancing concrete performance.

1. Comprehensive Analysis of Strengthening Techniques:

- Evaluateandanalyzeawiderangeofstrengthening techniques applied to reinforced concrete structures, encompassing both traditional and innovativemethodologies.

- Investigate external and internal reinforcement approachestoprovidea holistic understandingof theavailableoptions.

2.MechanicalBehaviorAssessment:

- Critically assess the mechanical behavior of reinforcedconcretestructures,focusingonflexural, shear, and axial capacities under various loading conditions.

- Exploreanddocumentdeformationcharacteristics resulting from the application of different strengtheningtechniques.

3.Long-termDurabilityConsiderations:

- Investigate the long-term durability aspects of strengthened structures, specifically examining resistance to environmental factors such as corrosionandchemicalexposure.

- Identify optimal strengthening strategies that contribute to the longevity of reinforced concrete elements.

4.ApplicationtoReal-worldScenarios:

- Incorporatepracticalcasestudiestoexemplifythe successful implementation of strengthening techniquesindiversestructuralsettings.

- Assesstheimplicationsofstrengthenedstructures onsustainability,consideringboth environmental andeconomicaspects.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

5.SynthesisofCurrentKnowledge:

- Providea comprehensive synthesisofthecurrent state of knowledge in the field of reinforced concretestrengthening.

- Consolidate information from previous research, identify gaps in existing literature, and propose avenues for future research and innovation in structuralengineering.

6.ContributiontoPracticalDecision-making:

- Bridgethegapbetweentheoreticaladvancements and practical applications by showcasing the adaptability and effectiveness of various strengtheningtechniquesthroughreal-worldcase studies.

- Empowerengineeringpractitionerswithactionable knowledgetofacilitateinformeddecision-makingin the planning and execution of strengthening interventions.

7.AddressingChallengesofAgingInfrastructure:

- Deepentheunderstandingofchallengesassociated with aging infrastructure by examining the mechanical behavior and durability aspects of reinforced concrete structures undergoing strengthening.

- Provide a holistic perspective considering the broader implications on the resilience and sustainabilityofthebuiltenvironment.

2. METHODOLOGY

Flexural and Tensile Strength

Castingthebeam

MaterialsandEquipment

Cement:OrdinaryPortlandCement(OPC)43grade.

FineAggregates:RiversandconformingtoIS383.

CoarseAggregates:Crushedstonewithamaximumsize of20mm.

Water:Clean,potablewater.

Fibers:(asper:is148712001)

i. Naturalfibers:Jute(0.5%byvolume).

ii. Synthetic fibers: Polypropylene (0.1% by volume).

iii. Composite fibers: Composite mix (0.75% by volume).

Molds:Steelmoldswithinternaldimensionsof700 mmx150mmx150mm.

ReleaseAgent:Oilforcoatingthemolds.

MixingEquipment:Concretemixer.

CuringTank:Forwatercuringofthespecimens.

VibratingTable:Forcompactionofconcrete

Concrete Mix Design: (24 Beam sample for each grade)

M30

Water = 192 x 0.378 = 72.58 kg (Water-Cement Ratio:0.45)

Cement=427x 0.378=161.16kg

FineAggregate(Sand)=645x 0.378=243.81kg

CoarseAggregate=1110x0.378=419.58kg

M35

Cement:170.1kg

Water:72.39liters(Water-CementRatio:0.45)

CoarseAggregate:401.1kg

FineAggregate:259.98kg

M40

Cement:185.01kg

Water:70.29liters(Water-CementRatio:0.45)

FineAggregate(sand):277.52kg

CoarseAggregate:462.53kg

Step-by-Step Procedure

• Weigh the required quantities of cement, fine aggregates,coarseaggregates,andwateraccording to the mix design for each concrete grade (M30, M35,M40).

• Dry Mixing: In the concrete, first add the cement, fine aggregates, and coarse aggregates. Mix them thoroughlyindryformtoensureevendistribution

• Wet Mixing: Gradually add water while mixing to achievethedesiredworkabilityandconsistency.

• AddingFibers

• Clean the molds and apply a thin layer of release agent on the internal surfaces to facilitate easy removaloftheconcretebeamsaftercuring.

• Pourthemixedconcreteintothepreparedmoldsin 3layers.Eachlayershouldbeaboutone-thirdofthe moldheight.

• Compaction: After placing each layer of concrete, compact it using a vibrating table to remove air bubblesandachievepropercompaction

11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Fig -2.5 vibratingtable

• Fill the molds to the top and smooth the surface usingatrowel.

• Leave the molds undisturbed for 24 hours in a controlledenvironmenttoallowtheconcretetoset.

• After 24 hours, carefully de-mold the concrete beams.

-2.6 De-mold

• Placethebeamsinacuringtankfilledwithwater. Ensurethatthebeamsarefullysubmerged

•

LOADING TEST USING UNIVERSAL TESTING MACHINE

• Positioning the Beam: Place the beam on the supportfixturesoftheUTM.

• The supports should be positioned at equal distancesfromeachendofthebeam,typicallywith

a spanlength(L)ofabout600mm (with 50 mm overhang on each side).

• Placing the Load Fixtures: Position the loading pointssymmetricallyaboutthecenterofthebeam. The distance between the two loading points (a) shouldbeone-thirdofthespanlength(L/3).Fora 700mmspan,theloadpointswillbe233mm(250 taken)apartandcentered.

Fig -2.8 50mmoverhangoneachside

• InitialLoadApplication: Apply a small initial load to seat the beam and eliminate any slack in the system.

• Apply Load Gradually: Start the UTM and apply loadgraduallyataconstantrate.Theloadshouldbe applied through the two loading points. 30n/m loading rate

• Monitor and Record Data:Continuouslymonitor andrecordtheloadandcorrespondingdeflectionat regularintervals.Notetheinitialcrackingloadand anysignificantchangesinthebeambehavior.

Fig -2.9 Applyloading

• Remove the Beam:Carefullyremovethebroken beamfromtheUTM.

• Measure Crack Widths andrecordthecrack widthsandpatternsusingaruler.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Calculations

FlexuralStrengthCalculation:

if"a"isgreaterthan20cmfor15cmspecimen: Flexuralstrength (fb) = PL/BD2

if"a"islessthan20cmbutgraterthan17cmfor 15cmspecimen:FlexuralStrength fr=3PL/2BD^2

Where“a”isminimumdistancebetweencrackto Support

• fr FlexuralStrength

• P istheload

• L istheSpanlength

• b isthewidth

• d isthedepth

TensileStrengthCalculation: Ft=k*fr

• ft isthetensilestrength,

• fr istheflexuralstrength,

• k isaconversionfactorthatdependsonthe materialanditscondition. Fortypicalconcrete,theconversionfactor k isoftentaken tobearound0.7to0.75.

3. OBSERVATION

Avg. peak load

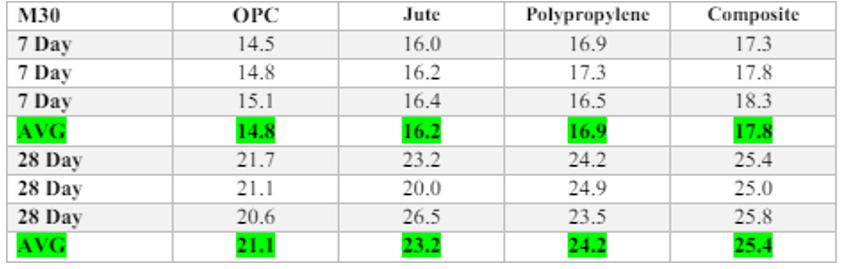

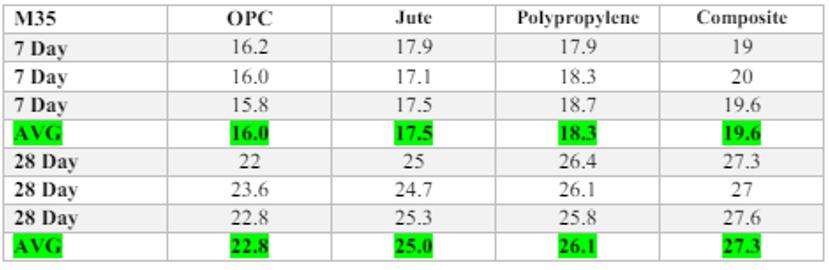

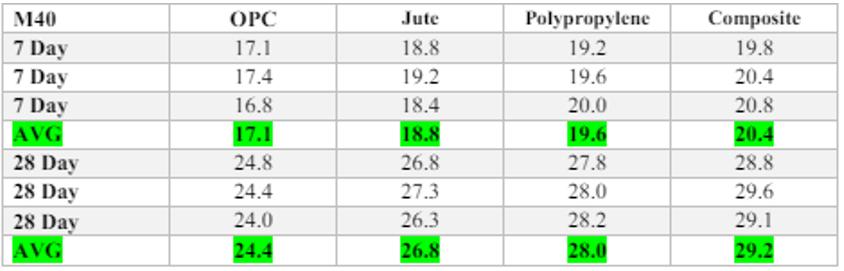

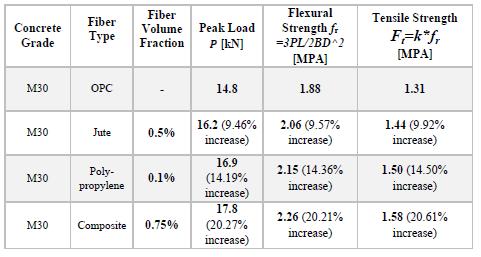

Table -3.1: Avg. Peak Loading for M30

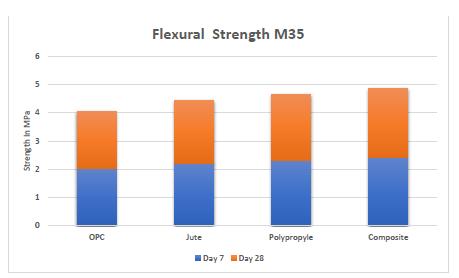

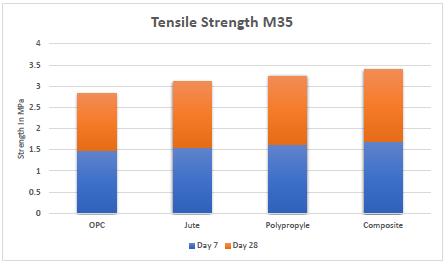

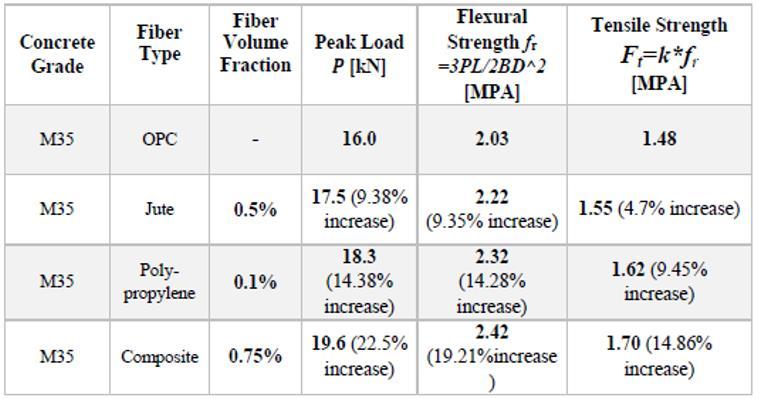

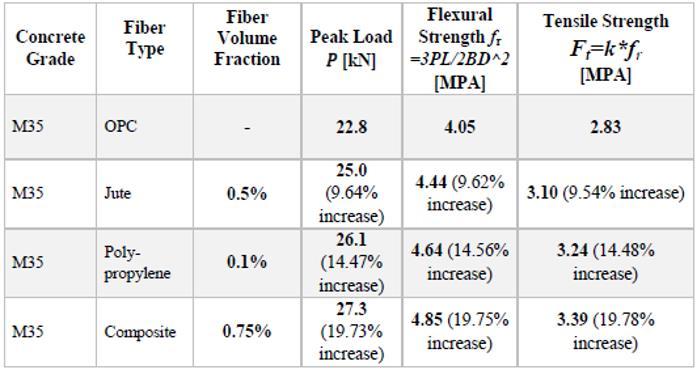

Table -3.2: Avg. Peak Loading for M35

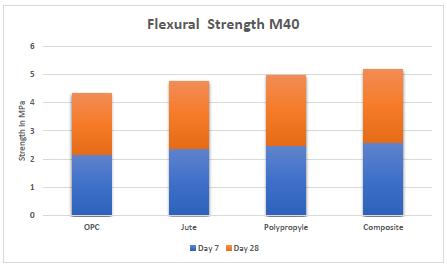

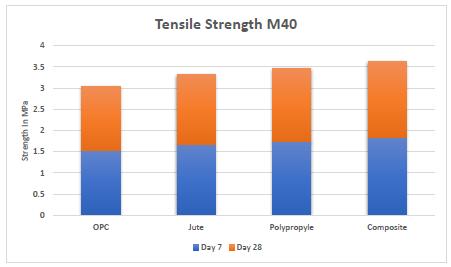

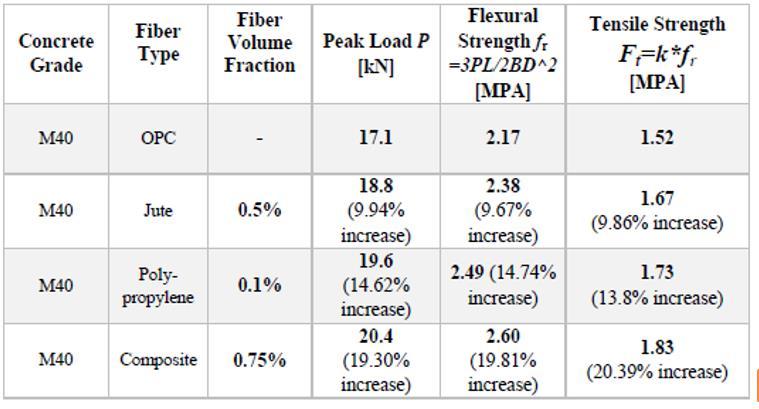

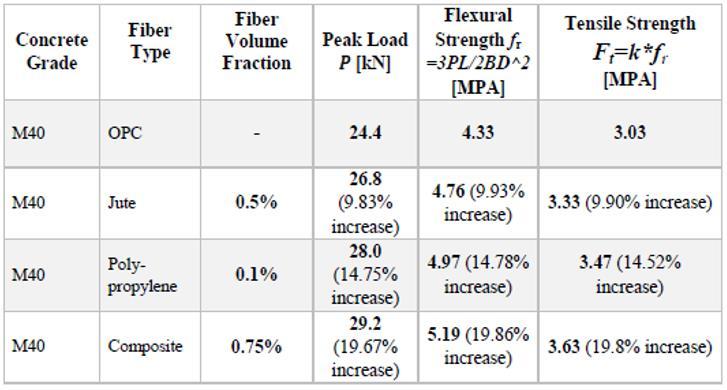

Table -3.3: Avg. Peak Loading for M40

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Day 7 observation

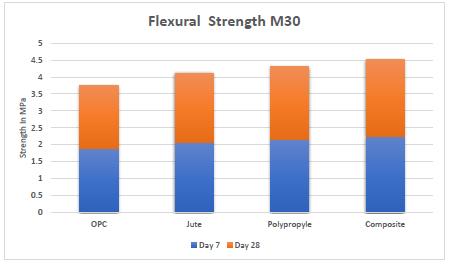

Table -3.4: Flexural and Tensile Strength of M30 on day 7

Table -3.5: Flexural and Tensile Strength of M35 on day 7

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Table -3.6: Flexural and Tensile Strength of M40 on day 7

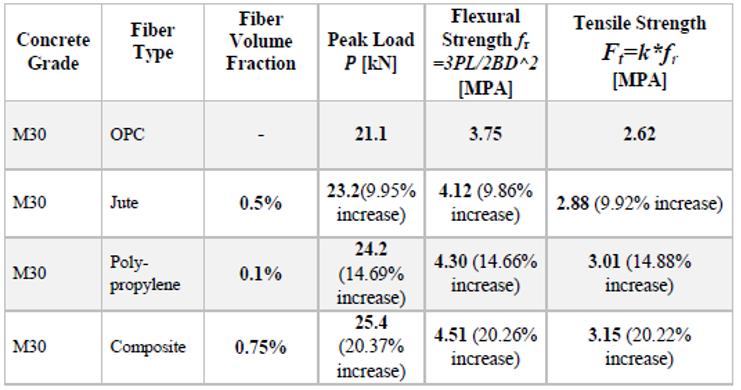

Table -3.7: Flexural and Tensile Strength of M30 on day 28

Table -3.8: Flexural and Tensile Strength of M35 on day 28

Table -3.9: Flexural and Tensile Strength of M40 on day 28

• Enhanced Strength: Fiber reinforcement in concrete significantly improves its flexural and tensile strengths comparedtoconventionalconcrete.

• Optimal Fiber Volume: Composite fibers at a 0.75% of volumefractionshowedthehigheststrengthgainsamong allfibertypestested.

• TheCompositeFiberIncreasesStrengthUpto20%for7 dayand28days.

• The Jute fiber is the cheapest fiber in our study and it increases strength up to 10%. But You cant add high amount of jute because its effect more on workability comparetoPolypropylen.

• Superior Performance of Composite Fibers: Composite fibersconsistentlyoutperformedJuteandPolypropylene fibersinbothflexuralandtensilestrengthtests.

• Grade Variation: The improvements in mechanical propertieswereevidentacrossallconcretegrades(M30, M35, and M40), demonstrating the versatility of fiber reinforcement.

• Early Strength Gain: Even at 7 days, fiber-reinforced concrete samples showed noticeable improvements in strength,indicatingearlystrengthgain.

• Long-term Benefits: At 28 days, the enhancements in strength were more pronounced, suggesting that fiber reinforcementcontributestolong-termdurability.

• UniformDistribution:Propermixingandcompactionare crucialtoensuretheuniformdistributionoffiberswithin theconcretematrix.

• Cost-EffectiveSolution:Fiberreinforcementcanbeacosteffective way to enhance concrete properties without significantlyincreasingthematerialcost.

• PracticalApplications:Fiber-reinforcedconcreteissuitable forstructuralapplicationswhereincreasedload-bearing capacityanddurabilityarerequired.

• Environmental Considerations: The use of natural fibers likeJutecanbebeneficialforenvironmentallysustainable constructionpractices.

• Future Durability Studies: Further investigation into the long-term durability of fiber-reinforced concrete under variousenvironmentalconditionsisrecommended.

• ImplementationGuidelines:Thefindingssuggestpractical guidelines for incorporating fibers into concrete mixes, optimizingbothperformanceandcost-efficiency.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

[1] https://www.sciencedirect.com

[2] https://www.mdpi.com/

[3] https://www.hindawi.com/

[4] https://www.google.com/

[5] ACICommittee318,1995,

[6] “Building Code Requirements for Structural Concrete (ACI 318-95) and Commentary (318R95),”

[7] American Concrete Institute, Farmington Hills, Mich.,369pp.ACI-ASCECommittee426,1973,

[8] “The Shear Strength of Reinforced Concrete Members Chapters1to4,”

[9] Proceedings, Journal of the Structural Division, ASCE, V. 99, No. ST6, June, pp. 1091-1187. Jay H. Paul, S.E., P.E." Repair, Renovation and StrengtheningofConcreteStructures".

[10] “Evaluation and Rehabilitation of Concrete Structures”MexicoCity,September11-13,2002.

[11] AndersCarolin."CarbonFibreReinforcedPolymers forStrengtheningofStructuralElements".

a. Ph.D. Thesis, Department of Civil and MiningEngineering,DivisionofStructural Engineering, Luleå University of Technology,Sweden,2003

2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008