International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Aanchal¹, Anuj Verma Sir²

¹Student Scholar, Civil Engg. Deptt. RIMT Bareilly ²Asst. Professor & (HOD), Civil Engg. of Deptt. RIMT Bareilly

The healing of actual representative by way of diffusing colorless odorless gas into it under argued pressure and hotness is individualofthewell-knownarrangementsofelevatedhelpingcure.Theapproachletstheco2towordyintothefactualand proceed through carbonation. The carbonation someday results in thermodynamically powerful calcium carbonate outputs. Cementresultbymyselfdonatesto5%oftheglobalco2issuances.Thisdischargedco2maybeincompletelyreusedandused toremedyconcrete wholes. Therefore factual healing accompanyingtheaidof colorlessodorlessgas promotes tenable explanation. Theobjectdefinestheplanandcapabilitiesinthefollowingthehabitofco2forhealingactualfundamentals.This paper summarizes a current gaze at at on addition of hardened and the pipe gasoline colorless odorless gas grown from cement oven maybe usefully applied in actual production to lower element issuance, boost up early electricity, and improve persistence of the brand. In connection with cement content material, element uptake in four-stage carbonation reaches 28 dayssubstancedonebyutilizingusualcuringmeans.

Key Words: CO2exercise, Carbonation Curing, EarlyCuring.

Thedevelopingcarbondioxidegasolinemindfulnessinsidetheenvironmentisbyandbyaggravatingthenormal composition oftheco2nurserygasses,Sinceofhumanandanthropogenicsports.Besides,afewcontendthattheclimaticco2development iscausingauniversaltemperatureboom.Asthetemperatureincrements,additionalwatervapor,whichismoreoveranursery gas is propelled into the environment. Most researchers concur that the soil is warming at a speedier rate than at any time interior the closing 10,000 a long time, and that this warming is due to developing sums of carbon dioxide and distinctive nurserygassesinsidetheearth'senvironment.Therearevariouspotentialresultsandimpactsanticipatedtoconclusionresult from a upward pushed in worldwide temperature. The sea water level is expected to rise and undermine numerous coast citieswithsurgessinceofdissolvingicesheets,dissolvingAntarcticicecaps,andthewarmexpansionoftheseawater.Inthe tropic zone, the desertification is anticipated to be a visit trend. The impact of world warming on individuals and nature is strongly, and seem aggravate the conceivable and at ease environment. Carbon dioxide is the prevailing nursery. Finding valuablemakesutilizeofas-capturedorrecoupedco2isintenseandfundamentaltonurserymitigation.Onecapabilityerais toapplythecapturedorrecoupedco2asacuringoperatorinfabricatingofcarbonatedconcreteitems.Thestrategyisalluded toascuringcarbonation.

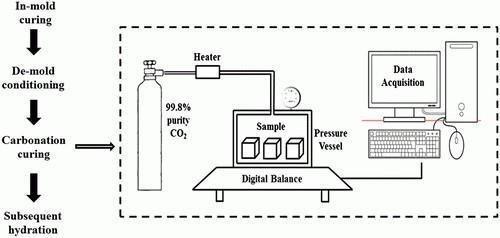

2.1.General working principle

For the coordinate utilize of as captured vent gasoline without division is closed contraption is responsible. pipe fuel, containing14%co2,wascollectedfromacementoven.Toworksofartwithmooconsiderationventgas,acyclicinfusionway turned into progressed. The vent gas turned into infused into the chamber at a gage strain of 500 mpa (72 psi). The higher gasolineweightisutilizedtomakebeyondanydoubtthatsufficientcarbondioxideisaccessibleforresponse.Thechamber’s channelvalveisatthatpointclosedtoallowthereactiontotakeareaoveraassignedlengthof30tofortyminutes.Sincethe airtight gadget is closed after pressurization, each the co2 concentration and the gas weight in the chamber will drop as the concreteretainsco2.Aftertheparticulartimeperiod,thebuildupgasisdischargedtotheenvironmentthroughawatertank

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

and vent fuel is once more infused into the chamber for a moment cycle. Ordinary strain and temperature bends of cement glue compacts subjected to seven cycles of vent fuel carbonation with a 30–40-minute time period in step with cycle over a total of five hours. The cement compacts with w/b of zero.15 have been press shaped at eight mpa (1.2 ksi). For the reason thatreactionbetweencementandpipegasolineco2isacarbonutilizationmethod,italongtheselinesdecreasesthegasstrain andco2mindfulnessinsidethechamber.Thus,theweightdropsandmindfulnessmarkdownineachcyclearedemonstrative ofthecarbontake-upmethod.Thecuringhandlemustbeendedwhereastheweightandconsiderationareobvioustoremain consistent, which seem recommend that no advance carbonation response is taking put. This can be taken into thought a pseudo-dynamic machinewith the vent fuel having a quantifiable house time interior the chamber. The gas weight and time period of each cycle must be decided by utilizing the measurements of fabricating. In this method, carbon seize and sequestrationaresuccessfullyBlended intoa singlestep withuseful concrete items servingsincethesequestrationmedium. In evaluation to immaculate fuel carbonation, longer reaction times are required for pipe gasoline carbonation since of the lowerco2concentrationandlowerresponseperformance.

2.2.Actual working principle

1. Firstoffwetakealltheequipment,materialwhichisnecessaryforthisworkingprinciple likecement,sand,fineand course aggregate, water, concrete mould (150mm X 150mm X 150mm), carbon dioxide container, air tight vessel (CO2 curingtank/container).

2. M20mixblockofconcreteiscastedbywayofputtingthemixtureofabovematerialsi.e.concreteintoconcretemould and checkafter24hours.

3. Nowassembletheairtightvessel(orcontainer)forcuringofCo2.

4. In Place 3 we put concrete blocks into tank of water curing , 3 blocks put into CO2 air tight container and place 3 blocksputin everydayroom(foraircuring).

5. Closethecontainerof CO2 Curing withcapandsticktapefornopossibilitiesofanydisturbanceofCO2gas.

6. ThanOpenthevalveofcontainerofCO2 toinlettheCO2gas(for2.5hours).

2.1

7. AfteropenthevalveAfter2.5hoursclosethevalveand thecontainerleavefor4hours.

8. Byabsorbing theCO2gascuringofconcretecubesarecompleted.

9. Put off thetapeandopenthecontainer.

10. ThecompressivestrengthofconcretecuringcubeCompletedbyCompressiontest.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

11. After28days,wetakealookatthecompressionstrengthofwatercuringandaircuringconcretecubes.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

12. ThanCompareallthreetypescubesofcuringconcrete.

2.3.Carbon cure concrete

Thecall carbontherapyis determined fromtheofficecarbonremedy,Canada,thatmakes utilizeofthefeasible era ofcuring the concrete with the help of presenting carbon dioxide into shimmering concrete. This era is securing thank worldwide as they do presently not create unused carbon-dioxide for this curing. On the other hand , they reuse the co2 transmitted from trade and fabricating gadgets. The period captures co2, which advances carbon sequestration. It hence inserts the carbondioxideinteriorconcretetotallythatfutureoutflowsofco2areblocked.

Advantage and disadvantage

Advantage:

1. ByuseofCO2gascuringwecanachieveRapidstrengthofconcrete.

2. By presence of CaCO3 cement in cement. The cement shows stabilities so use of CO2 gas which is more stable, CaCO3 showsinbindingofcementtoothermemberofconcrete.

3. InincrementofglobalwarmingCO2 also includes, soCOcanbeusedascuringagentforconcreteresults.

4. Mosteffective 4hours curingofCo2is sufficient,forgains rapidStrength.

Disadvantage:

1.ItCannotbe usedforRCCstructure.

2.Cardboardofconcrete, concrete blocks must regioninsurroundingfCO2.

3.InRCCstructureprovidedreinforcementbarscorrodedduetoCO2.

Curing of concrete is a strategy through which the concrete is secured in resistance to misfortune of dampness required for hydration and put away interior the supported temperature assortment. Curing will increment the vitality and diminish the porousness of solidified concrete. Curing moreover empowers in moderating warm and plastic splits, which can altogether affect sturdiness of frameworks. A curing work out includes protecting the concrete clammy or damp until the hydration of concrete is whole and control is accomplished. Curing of concrete require to start rapidly after preparatory setting time of concrete or formwork/shuttering is evacuated and should to hold for a sensible time outline as in line with the required necessities, for the concrete to accomplish its favored vitality and sturdiness. Uniform temperature require to be kept up all throughtheconcrete-segmentprofunditytokeepabsentfromwarmshrinkagecracks.Shieldingmeasurestooarerequiredto control water misfortune from the concrete floor to spare you plastic shrinkage breaks. In a nut shell, curing concrete is a prepareplannedregularlytoholdtheconcretedamptillthehaltofhydrationbyobservingneedofdampnessandwaterfrom thebodyofconcrete,atafewpointofthegiventerminwhichitpicksupelectricity.

Why curingofconcreteisnecessary?

1. Enhancehydration ofconcretetogetwantedstrength.

2. Improvedsturdiness ofconcrete bydiminishingcracks.

3. Higherserviceability executionthrough expandingscrapedarea resistance.

4. Improvedmicrostructurewith the help of developing higher hydrategels and strongmass.

4.1. Chemical admixtures for accelerated curing

4.1.1. Calcium

Traditionally, the habit of calcium, specifically in the shape of calcium chloride, curve into idea expected an active spurring approach in concrete. But, many questions as a consequence of the addition of calcium-chloride in actual mixes has done in allure ban from use in hardened in abundant countries about the realm (levitt, 1982). The addition of calcium chloride in

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

supportedandpre-botheredfactualcanbeintenselyhurtful,causethechloridecancreategiftsextensivelytocorrosionofthe augmentingmineral.

Nevertheless,researchhaveprovedthatcalciumchloridehasamammothaffectearlypowerbenefitofconcrete.Thecustom of1%ofcalciumchlorideconcerningtheburdenofcementinajoinhasdevelopedinanincreaseofstrengthlater24hoursof threehundred%(levitt,1982).Ontheotherhand,verysmallconcentrationsofcalciumchloride,similar0.0005-nothing.05% by way of pressure of cement, manage have a extreme retarding affect the hydration method. In programs at which point fortify is not entrenched in actual, the use of calcium chloride as an machine for giving charged particles high velocity remnantspermitted.Extradirectionshavingtodowiththeuseofcalciumchlorideasanmachineforgivingchargedparticles high velocity involve in impossible the usage of concentrations extra than 2% accompanying the aid of cement burden, and being cautious when the habit of it in factual assign steam healing, if employed in factual holding diversified metals, in hardened slabs supported on never-ending inspire fortify forms, and in coloured hardened (kosmatka and panarese, 1988). Calciumchlorideshouldnotanymorebeutilizedinpre-emphasizedfactualonaccountofdoabledisintegrationemergencies, in concrete holding entrenched aluminium, in factual endanger salt-aggregate backlash or uncovered to sulphates in floor plate engaged to get dry-quiver gird finishes, all at once concrete. Irrespective of these potential troubles, the custom of calciumchloride,usuallynamed by way of the builder,still takesplaceaccompanyingremarkablecommonnessintheUnited States of united states of america presently. Extra styles of calcium that has happened secondhand,even though not as effectively,thatwillboostuphelpingcurearecalciumformateandsodiumnitrite.

Even though immediately not technically distinguished as accelerators, excessive-type water threatening (hrwr) admixtures enhance,“hugewillincreaseinearlyfactualsubstancesbelowbothcommonandextendedhelpingcuresituations,”.Theuseof those admixtures results in two together manifolded concrete practicability event maintaining a target capacity level, or comprehensivecapacitywhilepreservingapopularpracticability.Inwell-known,awater-reducingblendingresultsinabated water demands for a given join. Conventional water deteriorating admixtures comprised lignosulfonic acids, hydroxylated carboxylic acids, or processed carbohydrates; these were proved to offer nearly about beautiful% discount in mix water necessities even as custody the equal workability (hester, 1978). More recently, hrwr admixtures were working that maybe composed of, “unaffected polymers, two together sulphonated melamine or sulphonated naphthalene chemical compound condensates, and may luxuriously reduce the combination water content of up to twenty-25% event continuing the favorite slump,”inaddition,disintegrationworriesarenotknowingaboutaccompanyingtheuseofhrwradmixtures,astheydonow notcomposeadditionalchlorides.SothatitwillexaggeratethebenefitsofHRWRadmixtures,additionaljoinblueprintlooks, alongwithjoiningaccumulation, blendingdosage,aggregateranking,andcementkindShould bedeliberate.In standard,the consequences of hrwr admixtures are leading as long as few put off 'tween joining of join water and the addition of the blending isworking;a 30-602nddelayhashappened encouragednotcompletely(hester,1978).Inagreementsofhardened programs,theadmixtureportionofdrugorotherconsumableisparticularlyessential.Testshaveexplainedthat,“ultimately, incrementally better blending dosages stop to make offerings to further substance happening.Certainly, they may create a offeringtoharshretardation,”(hester,1978).Someotherjoinfeaturethatinfluencestheefficiencyofhrwradmixtures,andto an magnitude commission of power benefit, is the most aggregate time for cement rich road, that are usually employed in hardened programs. Reducing ultimate combination capacity consequences is an enhanced mixture surface domain, that agrees to an elevated often with sticky material-aggregate separation energy and an move something forward transition district, happening in raised usual strength. For cement lean mixes (beneath 517 lb/yd3), it is owned by growth the rate of exceptionalmixtureinanefforttoaccomplishanalogousscopesofenergy(hester,1978).

Arelatedproductconcerningusingamazinglysuperiorhrwradmixturesisself-combining,orself-compactingconcrete(SCC) FirstofallleadinginjapaninsidetheNineteenEightiesinbacklashtoalackofskilledsocietyforsituatingunoriginalconcrete, “sccisahugelyachievableConcretethatmayfloatvialaboriouslyreinforcedorgeometricallyfundamentalelementsbeneath allurebelongingtoindividualburdenandrightfillaccompanyingwithoutsegregationorexcessivegrievingaccompanyingout the want for for quivering to combine it,” (lanier et al., 2003). The growth of this amount has the potential to remarkable change the precast concrete industry. Concerning raised curing, the use of scc has generally an unintended competency impact.Theuseofscccanmateriallylessenmomentoftruthforplacingconcrete.Toanrange,thiscanconceivablereducethe want for expanded helping cure (lanier et al., 2003). While it's far not going that the want for revised helping cure can be

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

removed completely, it's far doable that the process will demand lesse strength and for that reason come extra budget companionable. Using scc is one of the most recent change With in the precast concrete manufacturing , and will plausible havethebiggestimpactattheevolutionoftheundertakingintheforthcomingfate.

An manifolded helping cure temperature will cause success an extended price of capacity benefit. But this development in temperaturenearlysurelimits.AfterthisconfinethisboominhotnessdoesNolongeraffectthecompressivestrengthbutcan break up the fundamental apartments of concrete. Common helping cure mean hotness is 700 c. Major disadvantages of increasingthishotnessisextendedcommissionofhumidnessloss tothe encircling surroundings,thatcaninfluenceextreme decrease and cracking. Every other question is the fast exchange of hotness inside factual participants, developing in conceivablylargewarmstresses.Whileusingextendedhotnessesthatadmitsyoutoboomthehealingfeeofhardened,three main materials must be thought-out: rate of hotness upward thrust, maximum curing hotness, and warming period. Historically, it has happened concept that early strength gains are counterbalance accompanying the aid of lower 28-era strength.Assuch,specscommonlyconfinemaximum helpingcurehotnessestoamong650and700c.Anmanifoldedhealing hotnessstillconsequencesinanraisedrateofmoisturedeficittotheatmosphere.Assuch,“alleffortsmustoughtforfear that thedissolutionofwaterfromthefloorofthesampleforoneuseofaappropriateprotecting,”(ancientpastet.Al,2000).Ifthe effectofdampnessdisplacedtotheenvironmentisn'tmanagedatthesametimeoftheraisedhelpingcureprocess,theeffect onlengthy-termcompressivesubstancemaybeunfavorable(mehtaandmonteiro,2001).Usingadmixturesintransitboostup the curing process maybe likewise subdivided into utilizing mineral and synthetic admixtures. Calcium chloride has settled expected a legitimately powerful machine for giving charged particles high velocity; nevertheless, by way of disintegration issues,itsuseinfactualaccompanyingentrenchedsilveryisn'talwaysurged.Themostacceptednotorganicblendingusedas an machine for giving charged particles high velocity is calculating silica, or silica seethe. While flee ash is repeatedly secondhandthatwillraiseotherresidencesoffactual,ithasaretardingaffectthepreliminarysetandearlypowerbenefit of concrete, and bear not be secondhand for raised healing functions. A few chemical admixtures, in addition to overdonedifference water reducers (hrwr), or amazing plasticizers, were used as slanting accelerators, usually on account of their competencetoreducethewaterdemandforalikelyblend.

4.2.1. Conduction/converting used for accelerated curing

One of ultimate fundamental methods for rapidly increasing the healing hotness of actual is through the employment of smoothbroadcast/changeofpossessiondesigns.Thetemperatureoftheformsmayberaisedtwotogetherelectricallyorwith theaidofdrainingwarmlubricateorwarmwaterbywayofrulingclass(gerwick,1993).Thedirectcontactamongthefactual andthefilingaccompanyinganraisedtemperatureresultsinconductiveheatswitch.Throughemployingchangeofpossession as properly, inside the form of abounding warm lubricate or water, the price of warm energy switch is manifolded, with increasing the rate of healing temperature tumor. As accompanying all increased helping cure strategies concerning widespread hotnesses, precautions should surrender to determine enough humidity to sustain you drying of the actual, and rightpaddingoftheformworkwillcausesuccessaextrapoweradepttumorinhealinghotness.

4.2.2.

Electrical opposing healing includes the custom of singular coils of twine that is, the electronics of heat via energetic opposition. Through impressive an energetic present day through strengthening hardware, or thru extra wires, heat is produceintheconcretebywayofthesuppliedenergeticfighting,ensuinginanextendedhelpingcurehotness.Whilemetallic formsaresecondhand,thisarrangementcanfurtherbeutilizedbyaskingenergeticcurrentspromptlytotheformwork,orby way of Attaching electric opposition determinants to the forms. It has existed confirmed that the results of elevated watercementpercentageoncompressivepowerarelessforactualthathashappenedelectricallycuredwhiledistinguishedtoactual that has happened cured under inexact environments (education, 2000). Parent 1 desires a courting between compressive powerandwater-cementpercentageeachelectricallycuredandmainlyhealedactual.Theelectricallyhealedconcreteshown adecreaseinpowerofnearly28%whilstthewater-cementpercentageTurnedintomanifoldedfrom0.55tonothing.7,event thenormallyhealedactualpresentedalowerinpowerofapproximately83%fortheequalalternate.Itisunsureifthiseffect isaeffectoftheenergeticcuringmethod,orutterlyaconsequenceoftheraisedcuringhotness.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Steam helping cure is a method at which point improved healing hotnesses and the adding of dampness throughout the healing process are each secondhand in an exertion to boost up the price of energy benefit. Those methods maybe used together,withanboominhotnessasanimmediateresultofenergydose,orinmyview,whereincaseanpreliminaryhotness promotionisactedbywayofafewalternatemeansandisfollowedbywayofanboominmoistureviaenergyInjection.Lowpressure energy healing is frequently used in very dry climates and in programs when the ruling the aridity is authoritative (gerwick, 1993). The elementary method of energy healing at meteorological strain, mainly, follows the alike ranges in the directionofsomeextendedcuringprocessincludingmanifoldedhealinghotnesses.First,anpreliminaryputoffevent,mainly of 3 to four hours, is essential for the actual to harvest allure initial set. Next, a warming event, accompanying a hotness upward thrust of forty to 60 f in accordance with time, is working that admits you to reach a most curing hotness, usually betwixtindividualhundredfortyandahundredandsixtyf.Thisisfollowedbywayofascaldingdistance,normallyenduring six hours event custody the maximum healing temperature. Subsequent, a chilling ending is working, concurrently with an activitywhichstageit'sfaroccasionallylivelyinitiatetheboundaryrestraintsoftheadministration,prestressingtendons,and manyremainderofsomething.,thatadmitsyoutosaveyouharmfromthebetteringofwarmstresses.Infamous,thefactual factorsarehoweverclosedaccompanyingtheenergyhoods,oraccompanyingtarps,concurrentlywithanactivitythisprocess. Soonerorlater,astageparticulartoenergycuring,anuncoveringending,isessential.

4.2.4.

Eventhoughmainlysilentfortheresultofconcretecraftofmasonpartsintheunitedstatesofamerica, extreme-strainenergy healing,alsocalledsterilize,hasexistedrightworkinginsidetheresultofpre-badgeredprecasthardenedaspectsinpaintand germany (gerwick, 1993). In the course of this style, the development of healing temperature and humidness are oppose an increaseinstress;essentially,determinantsinthisplacemannershouldbehealedinfewsomewhatencircledcontainer.This restriction limits the use of the approach to clearly limited components for established uses. One of the benefits concerning thismethodisthatintenselytidewhenwaterislowest-cementpercentagesMaybeusedintheprimaryblendlayout.Within the case of factual blocks, the determinants are Produced by way of banishing machines, accompanying out the use of formwork, utilizing no-stoop concrete. Via making use of overdone-stress energy helping cure, adequate dampness lively to completethehydrationprocessisdelivered to theactual details(polisnerandsnell,1985).Afew mainconcernsconcerning utilizingsterilizedosurvive.Pressurerestofpretensionedbarscanbeasalotas20%duringthewholeofsterilize,andshould beexplainedatfewstageinthedesignsection(gerwick,1993).

4.3. Mineral admixture for accelerated curing

4.3.1. Cement

Each period fast capacity advantage is of question, in addition to in hardened bundle, kind iii portland cement must be secondhand so individual can maximize early strength accomplishment. Type iii portland cement is two together chemically andconcerning mattercomparabletotypei portlandcement;thenumber onefeatureisthattypeiiiportland cementpieces had happened floor more delicate. The use of type iii cement, when oppose some if the numerous supplementary healing policiesdefinedbeneath,canresultintheaccomplishmentofveryoverdonesubstancesinverykeendurationsmomentary.

4.3.2. Silica fumes

Micro-silica,orsilicaseethe,isaverysensitive,pozzolanicmaterial.Inasinglesneakalookengagedcurveintosecondhandas a cementsubstituteforthe championreasonofincreasingaveragefactual compressivestrength(kiss et.Al,1998).Notmost persuasiveactedtheresultsdisplayanincreaseinlongtermsubstance,neverthelesstheymarkedanboominfactualstrength at each age. Demonstrates the Relationship between compressive power and opportunity for the factual accompanying the dependancyofcalculating-silicaasdistinguishedtoconcreteaccompanyingoutcalculating-silica.Intheseexams,7.5%byway of pressure of cement was exchanged with calculating-silica. It may be seeable that the merger of heat healed factual accompanyingtheadditionofcalculating-silicahasabundancebiggerearlystrengththanonetheoppositecombinations.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Like silica exhalation, flee ash can be secondhand as a cement alternative material. Fly ruins is individual of the by utilizing-products molded next to up-to-date energy plants; it's far a bitumen-explosion derivative, and is accumulated by meansof electrostatic precipitators used to dribbleout explosion smoke.In contrast to silica fumes, but, flee ruins does not cause success advanced early energy of actual. In reality, the results of the equal gaze at at refertopreviouslyinwhatwaysilicaexhalationenhanceproventoboomhardenedpowerdisplaythatthesubstitute of cement by way of flee ash happened in diminished early substances (french and others., 1998). For wet-healed samples, the lower in compressive substance became enclosed to pretty early a while, until a hundred and eighty days, event almost all the samples commit heat-helping cure shown lower compressive strengths at all age (nearly individual year). At the same time as the use of flee ruins can furthermore improve various residences of hardened, expresslytheplasticityofthecombination(corcoran,2004),thetalkofthat'sfurthertheopportunityofthispaper,it shouldimmediatelynotbesecondhandasacuringaccelerator.

This factual helping cure approach demands big bulk of water. In this technique, water is completed activity to the hardenedlateranclanguagemomentary.Thewaterneedexpectedsteadilyusedinorderthatthehardeneddoeswet out.

Advantages

1. Concreteneverdriesaswateris usedrepeatedly.

2. Thistechniquecan besecondhandinsomesurfacethatislevel,upright.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Disadvantages

1.Thistechniquedemandsgiant amountofwater,soitisasomecostly

5.2. Ponding method

Pondingtechniqueafavoriteandusualconcretehelpingcuremethod.Concreteishealedbywayofputtingwateronthelevel aircraftthatis,rod,ceiling,paththus.Afterhardenedcasting,theflooriscoveredaccompanyingpicture.After24hours,theart isdetachedandwaterisfilledoutsmallfour-sidedpanels.Aedgeislikelythoroughlyofthe4facetsbecausethewatercannot go with the flow and stocked because the actual below the water is healed properly. Ponding helping cure arrangement is betterthantheremainderofsomethingbutitenhancestroublesometosmoothafterhelpingcureisachieved.

Advantages

1. Betterarrangementdistinguishedtopossiblechoice maximumposition

2. Advantageous forlevelsurface.

3. Feasibleincementhydrationprocess.

Disadvantages

1. Pondingapproach cannotbesecondhandinupright surface.

2. Again,this technique demandsgoodabundanceofwater.

3. Afterconcretecuringis achieved,itishard tosmooththesurface.

5.3. Membrane curing

In this helping cure approach, the concrete surface is shielded accompanying water-proof sheath. Membrane hardened curingwilltakenearlypertemporallengthofeventorentity'sexistence.Theprinciplepurposeofthisprocesssearchout face up to the hardened dissolution. Wax emulsion, bituminous substanced oil, water-proof bituminous substanced paper

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

and plastic covering thus are used as sheet in this place technique. This is still refer to as sealing compound. In sheet helpingcure,concretesubstanceadvantageisinferiorthefactualmoisturizingmethods.

Advantages

1. Reduced evaporation.

2. Easytouseinlevel surface.

3. Protects hardenedsurfacefromweathering.

Disadvantages

1. Concretestrength isdiminished.

2. Membranehelpingcureapproachiswellasfuller emulsion,bituminoussubstancedandmanyaddedissecondhand.

5.4. Steam curing

Steam is completed activity in narrow precast colleagues and the concrete takes less opportunity to healing nicely. In this factualhealingarrangement,thecuringmethodisamassedabove22°hotness.Youkeeptakealookatthisbulletinforpopular actualcuringhotnessbelowExceptionalpositions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Advantages

1. Concretecuringopportunityisinferiortheremainderofsomething

2. Steamcuringisbetterinvery coldweather

3. Inlimited hardened members, thistechnique favorable.

Disadvantages

1. Steamcuretechniquecan’tbeapplied inlargesurface.

2. Itispricelessashelpingcure completedintemperatureabove22°C.

5.5. Sealed curing

The standard objective concerning this method is to preserve you the dissolution of hardened and contain the dampness. Water resistant paper, flexible bed sheet and healing membranes are ultimate extensively secondhand cloth for secured helpingcure.Everyofthosematerialsabsolutelyreducestheamountofwaterunrecoverabledissolution.Therulingbenefit istheskillofapplicationtosomeexpansiveassortmentofstylesandsizesofactualstructures.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Advantages

1. Protects hardenedsurfacefromenduring.

2. Faceuptoevaporation ofconcrete.

Disadvantages

1. Hardlyeverused.

2. Costlyarrangementasitentail wateropposingpaper,flexiblesheetsandmanyother.

6.CARBONATIONOFCONCRETE

6.1. Carbonation process

Carbonationoffactualisbureaucracyofbacklashamongthecementhydrationmerchandiseandtheclimaticelement-di-group of chemical elements. Subsequently, the actual plans aren't new to the carbonation process. It's far a herbal response happeningwhilethehardenedisexposedtometeorologicalco2andrefertoasenduringcarbonation.Weatheringcarbonation is a dull cause it decreases the ph price of the actual systems happening in the disintegration of hardware support. While duplicate-explainedcarbonationprocessisperformedinareservedmaterialconditioninaroomontheearlystagesofactual helpingcureandsubstancegain,it'sfarpopularasthehealingcarbonationprocedure.Thehealingcarbonationprocessisan widespreadhelpingcureway thatinjectscolorlessodorlessgasintothevesselplacetheactualdeterminantsarehealed.The colorless odorless gas is subtle inside the gleaming hardened beneath reduced strain. For the duration of this method, the cement bogues compound c3s and c2s, and the by way of-crop of hydration ca (oh) 2 respond With colorless odorless gas givingdependablecalciumcarbonates(caco3)atatmospherehotness.

Ca(OH)2 +CO2 =CaCO3+H2O (1)

C3S+3CO2+H2O=C-S-H+3CaCO3 (2)

C2S+2CO2+H2O=C-S-H+2CaCO3 (3)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Carbonation Curing Process of a Procedure Fly Ash Concrete The hydration produce form at a increaserate,andthe curinghelpincreasedstrengthgain.

6.2. Features of carbon dioxide cured concrete

Theactualhealedbywayofcolorlessodorlessgasdoesnottransferanyhazardouseffecttotheactualascomparedtothe ordinarilyhealedfactual.Onehigh-qualityspotlightoftheuseconcerningthisprocedureistheformationofacontinuous, continuouscompoundcaco3thatplainestallowsinfaststrengthbutalsoconfineaddingco2diffusions.Carbon-di-groupof chemical elementsbeinga goodjudgegreenhousepipe fuel;allureemission Within theenvironmentisdiminishedatthis momenttechnique.Consequentlyelementremedyconcreteisatenablecreationexercis

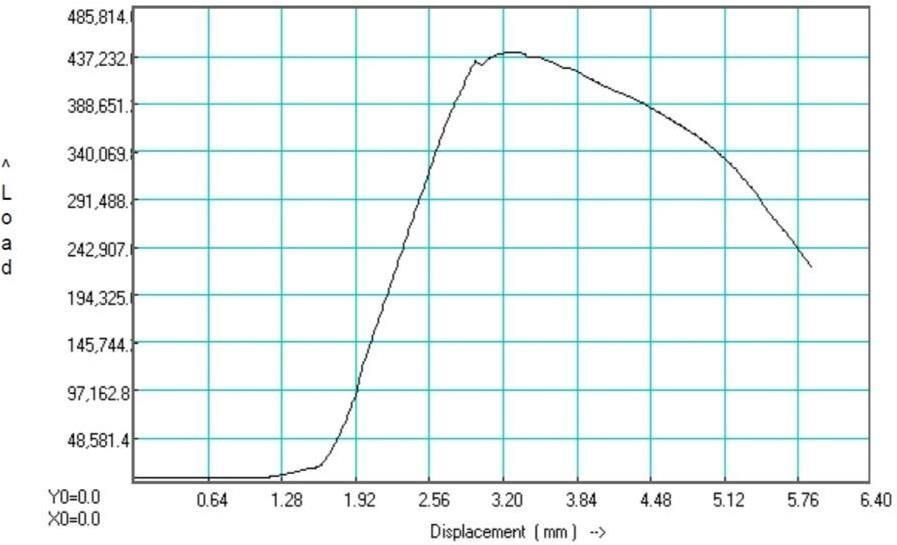

The compression strengths of carbonated cubes had existed judged accompanying UTM apparatus and theload rate curve intosteady0.5mm/mintimeperiod tillfailure.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

Consequence advicethat the4hourscure byCO2ofconcrete building blockgivesa meanstrengthof19.5MPafor M20 mixture of concrete. Since M20 Mixture Concrete gives 20 MPa compressive strength following in position or tme 28 daysofcuringinwateraccompanyingtheaidofcommonapproach.

Feasibility of colorless odorless gas rude answer by way of actual merchandise through early age helping cure became intentional.Theafterconclusionsmaybefatigued:

1. It is possible to carbonate the cao generally located cementious materials in 4 hours to fast produce factual constructing merchandise accompanying enough energy and certain pile of colorless odorless gas uptake. In general, better colorless odorless gas consideration, longer carbonation opportunity, bigger co2 pressure can produce more powerful amount and promotemorecolorlessodorlessgasassimilation.

2.Thenon-stopcolorlessodorlessgastransfermethodconfirmedexpectedtechnicallypowerfulandnearlylikelyincomplete scalehardenedproductionutilizingcarbonationcuring.Thecontinuouscolorlessodorlessgasdeliverincarbonationprocess offset thecolorlessodorlessgasdiminishingroboticallyandadvancedthecolorless odorlessgasabsorptionby factual tothe maximum.

3. Portland cement judged to be the exceptional cover for co2 incorporation for two together mass benefit and substance incident. Ladle slag and floor waste cement have existed immediately not top for strength, but consumed certain quantity of thecolorlessodorlessgasfuel.Amixturesystemtocombinationcementaccompanyingslagorwastecementhopefuladeptfor carbonatedactualmerchandisetodevourextraco2andmaintainnotcompletelythesamecapacity.

4.Porosityisanmainlimitforcarbonation.Mortarmixwithsoiltransformedintoextraporousthantheglueblend.Thegluing blenddevelopedanalogoussubstanceaspastejoinneverthelessreceiveda betterportionofcolorlessodorlessgasuptake.It determinedthecarbonationordermightbeagenuinelyperfecthelpingcureapproachforconcretebuildingblockproduction bywayofallureporouscharacterofthedevice.Compared Tothepresentlysecondhandenergycuring,carbonationdoesnot anymoredemandpre-placingeventandthereforecanshortenthehelpingcureopportunityconsiderably.

5. The vicinity of water in carbonation is fault-finding. The wet colorless odorless gas might be sporadic method to improve thecarbonationactanddemandsasimilarlysearch

References

[1].Corcoran,James,(2004).ConcreteTechnologyCorporation,1123PortofTacomaRoad,Tacoma,WA98421.Telephone interviewon3/15/04.

[2]. French,Catherine,A lireza Mokhtarzadeh, TessAhlborn,Roberto Leon,(1998). "High-StrengthConcreteApplications to Prestressed Bridge Girders,' Construction and Building Materials, Vol. 12, Elsevier Science ltd., Great Britain, pp. 105-1 13

[3]. Gerwick, Ben C. Jr., (1993). Construction of Prestressed Concrete Structures. Second Edition, John Wiley & Sons, Inc., NewYork,NY,pp.19-23,91-94.

[4]. Heritage,Ian,FouadM.Khalaf,andJohnG.Wilson.(2000)."ThermalAccelerationofPortlandCementConcretesUsing DirectElectronicCuring,'ACIMaterialsJournal,January-February,2000,pp.37-40.

[5]. HIester, Weston T., (1978). ""High-Range Water- Reducing Admixtures in Precast Concrete Operations, PCI Journal, July-August,1978,pp.68-85

[6]. Kosmatka, Steven H., and William C. Panarese (1988). Design and Control of Concrete Mixtures, Portland Cement Association,Skokie,Illinois,pp.16,66-67.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN:2395-0072

[7]. Lanier, Michael, PCI SCC FAST Team, "Interim Guidelines for the Use of Self-Consolidating Concrete in PCIU Member Plants,'PCIJournal,May-June,2003,pp.14-18.

[8]. Levitt, M., (1982). Precast Concrete, Materials, Manufacture, Properties and Usage, Applied Science Int J Adv Engg Tech/Vol.V/IssueIJan.-March.,2014/49-53

[9]. Bukowski, J.M. and Berger R.L. (1979), "Reactivity and Strength Development of Activated Non- Hydraulic Calcium Silicates",CementandConcreteResearch.Vol.9,pp57-68.

[10] Simatuparg,M.HandHabighorst,C.(1995),InvestigationstheInfluenceoftheAdditionofCarbononDioxideonthe ProductionandPropertiesofRapidlySetWood-CementComposites,Cement&ConcreteComposites,17,pp187-197.

[11]. Teramura, S. and Isu, N. (Nov.2000), "New Building Material from Waste Concrete by Carbonation", Journal of MaterialsinCivilEngineering,pp288293.

[12]. yixin,ShaoandHilalEl-Hassan(CO2UtilizationinConcrete-McGillUniversity,Canada,AmericanUniversityofDubai, UAEDepartmentofCivilEngineering,McGillUniversity,Montreal,CanadaH3A2K6).

[13]. J. Monkman and A. J. Boyd (Recycling Carbon Dioxide into Concrete: A Feasibility Study-Berger, R. L., Young, J. and Leung, K. 1972. Acceleration of hydration of calcium silicates by carbon-dioxide treatment. Nature: Physical Science, 240: 16-18).

[14]. kou Shi-Cong, Zhan Bao-iia, Poon Chi-Sun (Use of CO2 as curing agent, Department of Civil and a Environmental Engineering,TheHongKongPolytechnicUniversity,HongKong,Cement&ConcreteComposites45(2014)22-28.

[15]. Carbon Dioxide Information Analysis Center http://cdiac.ornl.gov/pns/faq.html Marceau, Medgar L., Nisbet, Michael A.,andYanGeem,MarthaG.LifeCycleInventoryofPortlandCementManufacture,SN2095b,PortlandCementAssociation, Skokie,IL,2006,69pages.

[16]. Bostami, V. Shao, Y. and Boyd, A. (2012) Carbonation curing versus steam curing for precast concrete production, JournalofMaterialsinCivilEngineering,24(9),1221-1229.