International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Mrs. P. Amsalega¹, Adarsh J. Nair², Harsh Kumar Maity³,

1Author and Assistant Professor, Department of Civil Engineering, Achariya College of Engineering Technology, Puducherry

2,3 Co – Author and Student, Department of Civil Engineering, Achariya College of Engineering Technology, Puducherry

Abstract - In the age of sustainability it is necessary to prevent the depletion of natural sources to maintain the needs andecology.Hence,intheprocessofmanufacturingbiobricksarewidelyused.Theexperimentwascarriedoutatvarious ages of brick in order to determine the physical and mechanical properties of brick such as compressive strength , water absorption, hardness. The brick tested showed comparatively better properties then the conventional brick and hence the are good to beusedintemporaryconstructions.Thedisposalofagriculturalwastesuchassugarcanebagasse asaraw material for bio brick production. The process involved the extraction of cellulose fiber from bagasse , followed by the integrationofthesefibresintobindermatrix.Themechanicalproperties,thermalstabilityandenvironmentalimpactofthe resulting bio bricks are assessed through various test including compressive strength analysis. The findings demonstrate the potential of sugarcane bagasse derived bio bricks as sustainable alternatives to conventional construction materials, offeringbothenvironmentalbenefitsandeconomicopportunitiesforagriculturalindustries.Buildingconstructionisoneof thefastestgrowingindustriesinIndiaanditputsahugeburdenonitslimitednaturalresources.

Key Words: (RedSoil,SandySoil,Sugarcanebagasse,CompressiveStrenght).

The bio bricks made up of sugarcane bagasse which are lighter then the traditional bricks and 15-20% less polluting in termsof emissions.BioBrickscancastwallsdirectlyonsitesandasa wallorroofcladdingpannel.Itwas foundthatbio brickshelptosolvemultipleissuesofenvironmentalairpollution,soildegredationandagrowastedisposals.Presentlyin sugarfactoriesthebagasseisburntasafuelsoastotheirboilers.Instead, thesugarcanebagassewastecanbeusedasthe constructionmaterials.

Thebio-bricksisasustainablebuildingmaterialfromagriculturalwasteasanalternatetoburntclaybricks.

Theproductservesthedualpurposeofwastemanagementanddevelopmentofeco-friendly,sustainable buildings.

Goodinsulationtoheatandsoundandhelpsinmaintaininghumidityinabuilding.

Wastematerialsfromsugarmillcanbeconvertedintoconstructionmaterial.

Thebagasseashbrick’scompressivestrengthmaybecomparedtotheflyashbrick’scompressivestrength.

Attainmaximumstrength.

ShouldbeeconomicalandEco-friendly.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

1.RedSoiltakenfromAuroville,Pondicherry

2.SandysoiltakenfromRockBeach,Pondicherry

3.SugarcaneBagassewastetakenfromVillanur,Pondicherry

4. METHODOLOGY

Color Test – Abrickshouldpossessbrightanduniformcolorthroughoutitsbody.

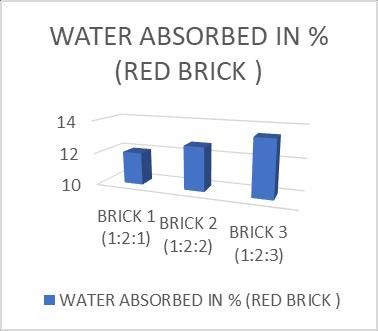

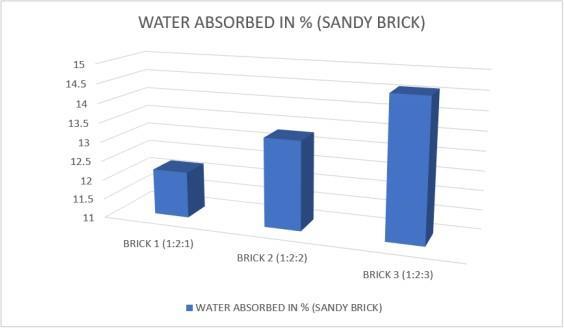

Water Absorption Test -Brickissubjectedtoanabsorptiontesttodeterminehowmuchmoistureitcan absorb.Dry bricks are placed in an oven at temperature of 40°C till they attain constant mass. The weight (W1) of the bricks is written after cooling them to roomtemperature. Afterthat,waterthatis27°Cintheroomisimmersedbehindthebricks. The sample was then removed from the water and cleaned for 3 minutes using a moist cloth beforebeingrecordedasW2oncemore.

ThewaterabsorptioninPercentage(%)=(W2-W1)/W1X100

Impact Test –Inthistestthebricksaredroppedfromtheheightof1m.Ifbricksarebrokenitindicateslowimpact valueandarenotacceptableforconstructionwork.

Shape and Size Test – Theshapeofbrickshouldbepurelyrectangularwithsharpedges.

Soundness Test –Thesoundproducedshouldbeclearandbrickshouldnotbreak.

Efflorescence Test - Agoodqualitybrickshouldnotcontainanysolublesaltsinit.Ifsolublesaltsarethere,thenitwill causeefflorescenceonbricksurfaces.

Toknowthepresenceofsolublesaltsinabrick,placeitinawaterbathfor24hoursanddryitin shade.Afterdrying,observethebricksurfacethoroughly.Ifthereisanywhiteorgreycolordeposits, thenitcontainssolublesaltsinitandisnotusefulforconstruction.

Test performed on soil -

SieveAnalysisonRedSoil

SieveAnalysisonSandySoil

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Table -1: Sieveanalysis(sand)

Cummulative%retained=

335Emptyweight = 120g

Sampleweight =2000g Finenessmodulus =335/100 =3.35

Table -2: Sieveanalysis(redsoil)

REDSOILFINENESSANALYSIS

Cummulative%retained=

351Emptyweight = 120g

Sampleweight =2000g Finenessmodulus =351/100= 3.51

Volume: 11 Issue: 07 | July 2024 www.irjet.net

Table -3:WaterAbsorptionTeston

:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Thistechnologyisataproofofconceptstageandneedtobeupscaledandaccelerated andinfutureitwouldbeoneofthe leading eco-friendly constructions. These bio-bricks are basically water proof and a good choice for an environment friendly constructions. The bio-bricks can be used in making of green buildings for providing more eco-friendly environment. Thus, the future roadmap for Bio-Bricks is to scale manufacturing and revenue generation by collaborating with appropriate agencies and providing hands-on workshops and training facilities to various stakeholders. Recycling is thebestoptionoverdisposal.Ithelpsinreducingdisposalcosts,conservesnaturalresources.Substitutionof conventional materialsbyrecycledwastematerialshelpsinefficientuseofwastematerialandsustainableuseofnaturalresources.

[1] BhavyaRana:-theyperformedtheexperimentofusingsugarcanebagasseassustainablebuildingmaterials.

[2] MangeshV.Madurwar,Sachin,A.Mandavgane:-theexperimentalstudyon calculatingthefeasibilityofsugarcane bagasseashbricks.

[3] Rohan Rajput, Mayank Gupta:- they carried out the experiment of utilizing sugarcane bagasse as building material.