International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 p-ISSN:2395-0072

Volume:11Issue:08|Aug2024 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 p-ISSN:2395-0072

Volume:11Issue:08|Aug2024 www.irjet.net

Aaryash Amit Joshi1

Abstract - This paper explores sustainable supply chain strategieswithintheautomotiveindustry,withaparticular focusonelectricvehicles(EVs)andthecirculareconomy.It delves into sustainable sourcing, material recycling, and waste reduction, highlighting how these practices contributetoenvironmentalsustainability.Additionally,the paper examines the role of digital technologies and collaboration among stakeholders in enhancing supply chain efficiency and transparency. The study underscores the significance of these strategies in reducing the automotiveindustry'scarbonfootprint,optimizingresource use, and providing a competitive edge. Through comprehensiveanalysisandcasestudies,thisresearchoffers actionable insights for industry practitioners and policymakers.

Key Words: Sustainable Supply Chain, Automotive Industry, Electric Vehicles (EVs), Circular Economy, SustainableSourcing,MaterialRecycling,WasteReduction SupplyChainTransparency.

1.1BackgroundandSignificance

The automotive industry is facing increasing pressure to adopt sustainable practices due to regulatory requirements and growing consumer awareness about environmental issues. The shift towards electric vehicles (EVs) represents a significant change, aimed at reducing carbonemissionsanddependenceonfossilfuels.However, achieving sustainability goes beyond the production of EVs; it extends to the entire supply chain, necessitating a holistic approach that includes sustainable sourcing, recycling,andwastereduction.

1.2Objectives

This paper aims to explore sustainable supply chain strategies within the automotive industry, with a particularemphasisonEVsandthecirculareconomy.The primaryfocusisonsupplychainpracticesratherthanthe automotive products themselves, providing a detailed analysis of how these strategies can enhance environmentalsustainabilityandoperationalefficiency.

1.3ResearchQuestions

How can sustainable sourcing practices be effectively implementedintheautomotivesupplychain?

What are the key challenges and benefits of material recyclingandwastereductioninthecontextofEVs?

How can digital technologies and stakeholder collaboration enhance supply chain transparency and efficiency?

What role does the circular economy play in shaping sustainable supply chain strategies in the automotive industry?

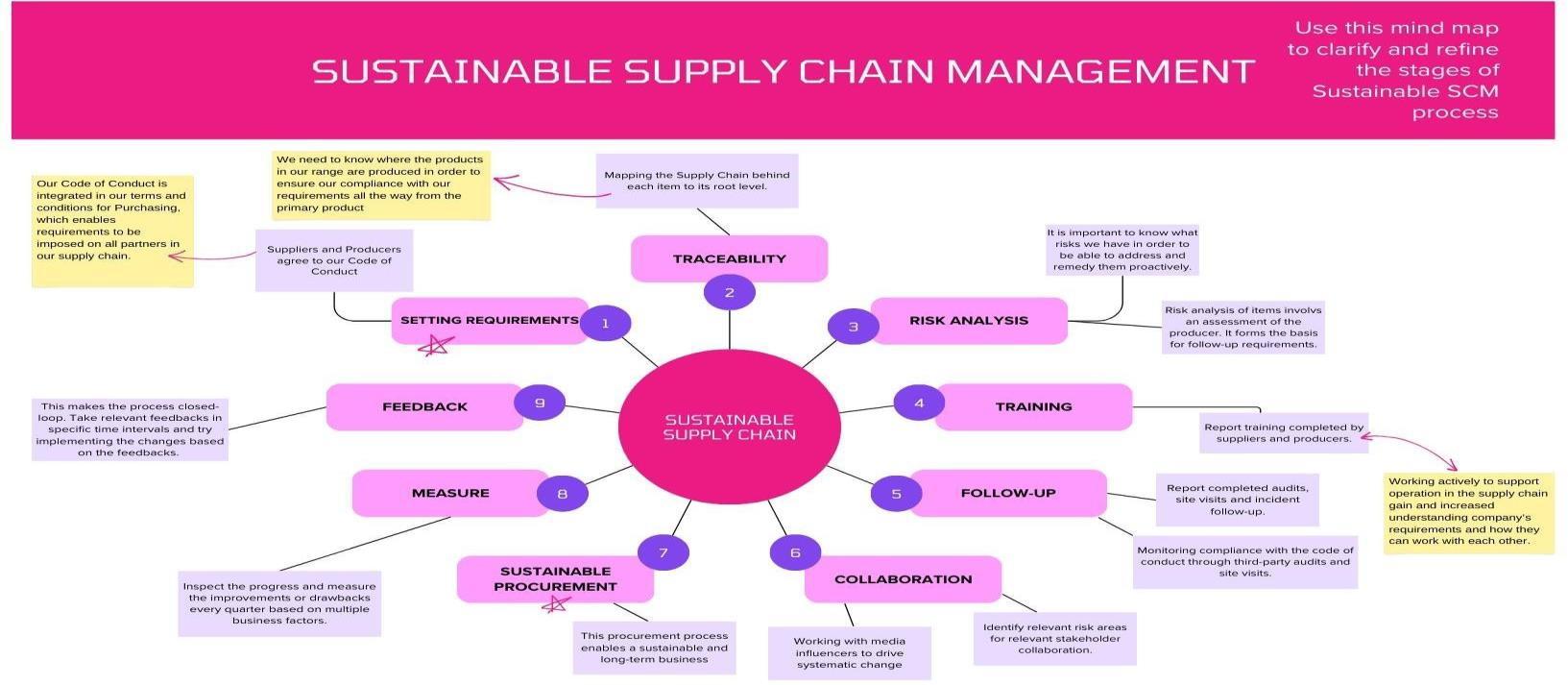

2.1SustainableSupplyChainManagement

The concept of sustainable supply chain management involves integrating environmental and social considerations into supply chain operations. This section reviews key frameworks and models used to assess and improvesustainabilityinsupplychains,includinglifecycle assessment(LCA)andclosed-loopsupplychains.

2.2CircularEconomyPrinciples

The circular economy aims to minimize waste and make themost ofresources.Thissection discusseshowcircular economy principles can be applied to the automotive supply chain, emphasizing practices such as recycling, reusingmaterials,anddesigningfordisassembly.

2.3ElectricVehiclesandSustainability

EVs are often highlighted as a sustainable alternative to traditional internal combustion engine vehicles. This section examines existing research on the environmental benefitsofEVs,aswellasthesupplychainchallengesthey present, suchassourcingof rare earthmetalsandbattery recycling.

3.1ResearchDesign

Thissectionoutlinestheoverallresearchdesign,including the qualitative and quantitative approaches used. The studyemploysamixed-methodsapproach,combiningcase studies, interviews, and surveys to gather comprehensive data.

3.2DataCollection

Case Studies: Detailed analysis of automotive companies thathaveimplementedsustainablesupplychainstrategies. Criteria for selecting case studies include industry reputation,sustainabilityinitiatives,andavailabilityofdata.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 p-ISSN:2395-0072

Volume:11Issue:08|Aug2024 www.irjet.net

3.3Interviews

Semi-structured interviews with industry experts, supply chain managers, and sustainability officers to gather insightsonbestpractices,challenges,andopportunities.

3.4Surveys

Distribution of structured questionnaires to a broader audience within the automotive industry to quantify perceptions and practices related to sustainable supply chains.

3.5DataAnalysis

A.Qualitative Analysis: Thematic analysis of interview transcriptsandcasestudydatatoidentifycommonthemes, challenges,andbestpractices.

B.QuantitativeAnalysis:Statistical analysisofsurveydata to identify trends, correlations, and significant factors influencingtheadoptionofsustainablepractices.

4. ANALYSIS AND DISCUSSION

4.1SustainableSourcing

Overview Sustainable sourcing involves selecting suppliers based on their environmental and social performance,inadditiontotraditionalcriteriasuchascost and quality. This section explores the key considerations for sustainable sourcing in the automotive industry, particularlyforEVs.

4.2BestPractices

4.2.1SupplierCertification:

Many automotive companies require their suppliers to obtain certifications, such as ISO 14001, to demonstrate their commitment to environmental management. This section discusses the various certification schemes and theirrelevancetotheautomotivesupplychain.

4.2.2SupplierAudits:

Regular audits are conducted to ensure that suppliers adhere to sustainability standards. This section explores the challenges of conducting audits, particularly in developing countries, and the measures companies can taketoensurecompliance.

4.3ChallengesandOpportunities

4.3.1CostImplications:

Sustainable sourcing often involves higher costs, particularly when sourcing from certified suppliers. This section discusses the cost implications and the strategies companies can use to mitigate them, such as long-term contractsandcollaborativerelationships.

4.3.2InnovationandCollaboration:

Sustainable sourcing can drive innovation and create opportunitiesforcollaboration.Thissectionexploreshow

companies can work with their suppliers to develop new materialsandtechnologiesthatsupportsustainability.

4.4MaterialRecyclingandWasteReduction

4.4.1RecyclingInitiatives

A.MaterialRecovery:

The recovery of valuable materials, such as metals and rare earth elements, from end-of-life vehicles is a key aspect of sustainability. This section discusses the technologies and processes used for material recovery and thechallengesassociatedwiththem.

B.UseofRecycledMaterials:

Many automotive companies are increasingly using recycledmaterialsintheirproducts.Thissectionexplores the benefits and challenges of using recycled materials, includingqualityconcernsandregulatoryrequirements.

4.4.2WasteReductionStrategies

A.LeanManufacturing:

Lean manufacturing principles, such as waste elimination and continuous improvement, are widely used in the automotive industry. This section discusses how lean principles can be applied to reduce waste in the supply chain.

B.DesignforDisassembly:

Designing vehicles for disassembly can facilitate recycling and reduce waste. This section explores the principles of design for disassembly and the challenges of implementingthemintheautomotiveindustry.

4.5 Digital Technologies and Stakeholder Collaboration

4.5.1DigitalTechnologies

A.Blockchain:

Blockchain technology can enhance supply chain transparency and traceability by providing a secure and immutable record of transactions. This section discusses the potential applications of blockchain in the automotive supply chain and the challenges associated with its implementation.

B.IoTandReal-TimeMonitoring:

TheInternetofThings(IoT) enables real-timemonitoring of supply chain activities, from production to delivery. This section explores how IoT can be used to improve efficiencyandreduceenvironmentalimpact.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 p-ISSN:2395-0072

Volume:11Issue:08|Aug 2024 www.irjet.net

4.5.2StakeholderCollaboration

A.CollaborativeNetworks:

Collaboration among stakeholders, including suppliers, manufacturers, and regulators, is essential for achieving sustainability goals. This section discusses the benefits of collaborative networks and the strategies for building them.

B.Public-PrivatePartnerships:

Public-private partnerships can play a crucial role in promoting sustainability in the automotive industry. This section explores how governments and private companies canworktogethertosupportsustainablepractices.

4.6CircularEconomyModels

4.6.1PrinciplesofCircularEconomy

A.DesignforLongevity:

Designing products for longevity and durability is a key principle of the circular economy. This section discusses how automotive companies can design vehicles that last longerandareeasiertorepairandmaintain.

B.ProductasaService:

Theproduct-as-a-servicemodelinvolvesofferingproducts asa serviceratherthansellingthemoutright. Thissection explores how this model can be applied tothe automotive industry and the benefits it offers, such as reducing waste andpromotingrecycling.

4.6.2ImplementationChallenges

A. EconomicViability:

Implementing circular economy models can involve significant costs, particularly in the short term. This section discusses the economic challenges and the strategies companies can use to make circular economy modelseconomicallyviable.

B.RegulatoryandPolicySupport:

Regulatory and policy support is essential for promoting circular economy practices. This section explores the role of government policies and regulations in supporting the transitiontoacirculareconomy.

5.CASE STUDIES

5.1 Case Study 1: Tesla Inc. - Sustainable Sourcing and MaterialRecycling

5.1.1ActionsTaken

Tesla Inc., a pioneer in the electric vehicle (EV) market, has been at the forefront of implementing sustainable supply chain practices. The company’s approach to sustainability is multifaceted, focusing on responsible sourcing of raw materials, investment in closed-loop recycling,andinnovationinbatterytechnology.

Sustainable Sourcing: Tesla has developed a comprehensive Supplier Code of Conduct, which sets stringent environmental and social standards. The company collaborates closely with suppliers to ensure that materials such as lithium, cobalt, and nickel are sourced responsibly. Tesla uses blockchain technology to enhance transparency and traceability in its supply chain, particularly for cobalt, whichisoftenassociatedwithhumanrightsconcerns.

Closed-Loop Recycling: Tesla has invested in advanced recycling processes at its Gigafactories. The closed-loop system allows the company to recover valuable materials from end-of-life batteries and reuse them in new battery production.Thisnotonlyreducesthedemandforvirginraw materialsbutalsominimizeswaste.

Innovation in Battery Technology: Tesla continuously innovates to improve the efficiency and sustainability of its batteries. The company has introduced new battery chemistries that reduce reliance on rare and environmentallyproblematicmaterials.

Supply Chain Transparency: Ensuring the traceability of materials like cobalt, which is often associated with human rights concerns, posed significant challenges. Establishing reliable tracking mechanisms and verifying supplier compliancerequiredsubstantialeffortandresources.

Cost of Sustainable Practices: Implementing sustainable sourcing and recycling practices can be more expensive, impactingoverallproductioncosts.Thehighcostsassociated with ethical sourcing and advanced recycling technologies weresignificantbarriers.

Technological Limitations: The efficiency of recycling processes for complex materials, such as lithium-ion batteries, remains a technical challenge. Developing costeffective and scalable recycling methods required ongoing researchandinnovation.

Reduced Environmental Impact: By using recycled materials and sustainable sourcing, Tesla has significantly minimized its ecological footprint. The company reported substantial reductions in carbon emissions and resource consumption.

Improved Supply Chain Resilience: The focus on sustainability has strengthened supplier relationships and reduced risks associated with material shortages. Enhanced transparency and collaboration with suppliers have led to morestableandreliablesupplychains.

Volume:11Issue:08|Aug 2024 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 p-ISSN:2395-0072

Enhanced Brand Image: Tesla’s commitment to sustainability has bolstered its reputation as an environmentally responsible company. This positive brand image has attracted environmentally conscious consumers andinvestors,furthersupportingthecompany’sgrowth.

5.2 CaseStudy2: BMWGroup-CircularEconomyandLife CycleAssessment

5.2.1ActionsTaken

TheBMWGrouphasembracedcirculareconomyprinciples, focusingonreducingresourceconsumptionandminimizing waste throughout the vehicle lifecycle. The company's strategy involves using secondary (recycled) materials, implementing comprehensive life cycle assessments (LCA), andpromotingend-of-lifevehiclerecycling.

"Secondary First" Approach: BMW prioritizes the use of secondary materials over primary raw materials. The companycollaborateswithsupplierstosourcehigh-quality recycled materials,particularlyforcritical componentslike aluminum and plastics. BMW’s supply chain integrates advancedsortingandprocessingtechnologiestoensurethe purityandperformanceofrecycledmaterials.

Life Cycle Assessment (LCA): BMW has developed a robust LCA framework to evaluate the environmental impact of its vehicles from production to end-of-life. This holistic approach considers factors such as CO2 emissions, energy consumption, and resource use, enabling BMW to identifyareasforimprovementandtrackprogresstowards sustainabilitygoals.

End-of-Life Recycling: BMW has established comprehensive recycling programs for end-of-life vehicles. The company works with certified recycling partners to recover valuablematerials,ensuring thatcomponentssuch as batteries, metals, and plastics are reused or recycled in anenvironmentallyresponsiblemanner.

5.2.2ChallengesFaced

Material Availability: Ensuring a consistent supply of high-quality recycled materials was a key challenge, particularly for rare earth metals and specialized alloys. Sourcing sufficient quantities of recycled materials to meet production demands required significant effort and innovation.

Regulatory Compliance: Navigating varying environmental regulations across different markets added complexity to implementing circular economy practices.

Adheringtodiverseregulatorystandardswhilemaintaining

operational efficiency was a challenging aspect of BMW’s sustainabilitystrategy.

Consumer Perception: Convincing consumers of the benefitsandqualityofvehiclesmadewithrecycledmaterials required effective communication and marketing. Overcoming skepticism and building trust in the performance and durability of recycled components was crucialforsuccess.

5.2.3OutcomesAchieved

Resource Efficiency: BMW achieved significant reductions in the use of virgin materials, cutting down on resource consumption.The"SecondaryFirst"approachcontributedto substantial savings in raw material costs and reduced environmentalimpact.

Environmental Benefits: The LCA framework helped BMW reduce its carbon footprint and manage waste more effectively. The company reported notable decreases in CO2 emissionsandenergyuseacrossthevehiclelifecycle.

Market Leadership: BMW’s proactive stance on sustainability positioned the company as a leader in the automotive industry’s transition to a circular economy. The company’s innovative practices and commitment to environmental responsibility enhanced its reputation and competitiveadvantage.

5.3 Case Study 3: Nissan - Digital Technologies in Supply ChainManagement

5.3.1ActionsTaken

Nissan has integrated digital technologies into its supply chainmanagementtoenhancesustainabilityandoperational efficiency.Thecompanyemploysblockchain,IoT(Internetof Things), and AI (Artificial Intelligence) to improve transparency,traceability,andpredictivemaintenance.

Blockchain for Transparency: Nissan uses blockchain technology to ensure transparency and traceability in sourcing materials,particularlyfor electricvehicle batteries. Blockchain’s immutable ledger provides a reliable way to track the origin and journey of raw materials, ensuring ethicalandsustainablesourcingpractices.

IoT for Real-Time Monitoring: Nissan has deployed IoT devices across its supply chain to gather real-time data on production processes, inventory levels, and transportation. This data is used to optimize operations, reduce waste, and enhancesupplychainvisibility.

Volume:11Issue:08|Aug 2024 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 p-ISSN:2395-0072

AI for Predictive Maintenance: AI-powered predictive maintenance systems analyze data from IoT devices to identify potential equipment failures before they occur. This proactive approach reduces downtime, extends equipmentlifespan,andminimizesmaintenancecosts.

5.3.2ChallengesFaced

Technology Integration: Implementing advanced digital technologies required significant investment and overcoming technical challenges. Integrating new systems with existing infrastructure and ensuring interoperability acrossthesupplychainwasacomplexprocess.

Data Management: Managing and securing large volumes of data generated by IoT devices and blockchain systems was a complex task. Ensuring data integrity, privacy, and security required robust cybersecurity measures and data governancepractices.

Stakeholder Engagement: Coordinating with multiple stakeholders, including suppliers, regulators, and customers, to ensure widespread adoption of new technologies. Building trust and fostering collaboration among diverse stakeholders was essential for successful implementation.

5.3.3OutcomesAchieved

EnhancedTransparency: Blockchaintechnologyprovideda reliablewaytotracematerials,ensuringethicalsourcingand reducingtheriskoffraud.Enhancedtransparencyimproved supplier accountability and compliance with sustainability standards.

Operational Efficiency: The use of IoT and AI enabled Nissan to optimize production processes, reduce downtime, and minimize waste. Real-time monitoring and predictive maintenance contributed to significant improvements in operationalefficiencyandcostsavings.

Sustainability Goals: Digital technologies helped Nissan move closer to its sustainability targets, including reducing emissions and promoting responsible resource use. The companyreportedsubstantialprogressinitseffortstocreate amoresustainableandresilientsupplychain.

Volume:11Issue:08|Aug2024 www.irjet.net

6.1SummaryofFindings

The comprehensive analysis in this research elucidates the essential role that sustainable supply chain strategies occupy within the automotive industry, particularly regarding electric vehicles (EVs) and circular economy frameworks. Through detailed examination, several key findingsemerge,sheddinglightonthemultifacetedaspects ofsustainability:

6.1.1SustainableSourcing:

The study emphasizes the necessity of identifying and collaborating with suppliers who maintain rigorous environmentalandsocialstandards.Sustainablesourcingis critical not only for minimizing the ecological impact but also for ensuring the ethical procurement of essential materials.Thisstrategyisfundamentalinaddressingissues such as resource scarcity and ethical concerns associated withmaterialextraction.

6.1.2MaterialRecycling:

Theresearchhighlightstheconsiderablebenefitsofmaterial recycling, including the reduction in demand for virgin resources,significantwasteminimization,andoverall lower environmental footprint. However, it also identifies substantialchallenges,suchasthehighcostsassociatedwith recycling processes and the technological limitations inherent in recycling complex materials like lithium-ion batteries. These challenges necessitate continuous innovationandinvestmentinrecyclingtechnologies.

6.1.3DigitalTechnologies:

The integration of digital technologies, such as blockchain, IoT, and AI, plays a crucial role in enhancing supply chain transparency, operational efficiency, and predictive maintenance capabilities. These technologies facilitate realtimemonitoringanddata-drivendecision-making,whichare essential for optimizing supply chain operations and reducingenvironmentalimpact.

StakeholderCollaboration:

Effective collaboration among stakeholders including suppliers, customers, regulators, and industry partners is paramountforthesuccessfulimplementationofsustainable supply chain practices. The study underscores the importanceofbuildingcollaborativenetworksandfostering open communication to drive sustainability initiatives forward.

6.2PracticalRecommendations

To translate these findings into actionable strategies, the followingpracticalrecommendationsareproposed:

6.2.1EncourageCollaboration

Fosteringcollaborationamongallrelevantstakeholdersisa cornerstoneforachievingsustainabilitygoalswithinthe

automotiveindustry.Companiesshouldfocusoncreatingand maintaining robust collaborative networks that engage suppliers,customers,regulators,andotherkeyplayers.

SupplierEngagement:

Building strong partnerships with suppliers who prioritize sustainability is crucial. Companies should work closely with their suppliers to improve environmental and social standards across the supply chain. Regular audits and assessments canhelpensurecomplianceandfosteraculture ofcontinuousimprovement.

CustomerInvolvement:

Educating customers about the benefits of sustainable products and practices is essential. Companies can engage customers through transparent communication about their sustainabilityeffortsandbyofferingproductsthatalignwith consumers'environmentalvalues.

RegulatoryCollaboration:

Working collaboratively with regulators can help ensure compliance with environmental regulations and promote the development of supportive policies. Companies should activelyparticipateinregulatorydiscussionsandadvocatefor policiesthatfacilitatesustainablepractices.

6.2.2InvestinDigitalTechnologies

Investing in digital technologies is a critical step toward enhancing supply chain transparency, efficiency, and overall sustainability. Companies shouldprioritize the integrationof advancedtechnologiessuchasblockchain,IoT,andAI.

Blockchain:

Implementing blockchain technology can significantly improve traceability and transparency within the supply chain. By providing an immutable record of material origins andmovements,blockchainhelps verify ethicalsourcing and enhancesaccountability.

IoTandAI:

Utilizing IoT devices and AI algorithms enables real-time monitoring and predictive maintenance. These technologies can optimize production processes, reduce operational downtime, and minimize waste. Investing in IoT and AI infrastructure will provide companies with the tools needed toachievetheseefficiencies.

SkillsandInfrastructureDevelopment:

To fully leverage the benefits of digital technologies, companies must invest in the necessary skills and infrastructure.Thisincludestrainingprogramsforemployees, upgradingtechnologicalinfrastructure,andfosteringa culturethatembracesinnovationanddigitaltransformation.

6.2.3Support Regulatory and Policy Frameworks

Governmentsandindustryassociationsplayavitalrolein promoting sustainable practices through supportive regulatoryandpolicyframeworks.Theseframeworkscan

International Research Journal of Engineering and Technology (IRJET)

Volume:11Issue:08|Aug2024 www.irjet.net

providethenecessaryincentivesandstandardstodrive industry-widesustainabilityefforts.

IncentivesforSustainability:

Financial incentives, such as tax breaks or grants, can encourage companies to adopt sustainable sourcing and recycling practices. These incentives reduce the financial burden of sustainability initiatives and motivate companies to invest in environmentally friendly technologies and processes.

Standardization:

Developing and implementing industry-wide standards for sustainability and circular economy practices ensures consistencyandaccountability.Standardizedguidelineshelp companies align their practices with best-in-class sustainability benchmarks and facilitate the broader adoptionofsustainablestrategies.

PolicyAdvocacy:

Companiesshouldactivelyadvocateforpoliciesthatsupport long-term sustainability goals. This includes lobbying for regulations that mandate the use of recycled materials, promote extended producer responsibility, and incentivize theadoptionofsustainabletechnologies.

FutureResearchDirections

The study on sustainable supply chain strategies in the automotive industry, particularly focusing on electric vehicles (EVs) and the circular economy, has uncovered numerous avenues for future research. Addressing these future research directions can provide deeper insights and enhancetheunderstanding ofsustainability practicesinthe automotivesector.

1.AdvancedRecyclingTechnologies

Development and Optimization: Future research should focus on developing and optimizing advanced recycling technologies for key materials used inEVs, such as lithiumion batteries, rare earth elements, and high-strength aluminumalloys.

ScalabilityandCost-Effectiveness: Investigatemethodsto scale up these technologies to industrial levels while ensuring they remain cost-effective. This includes studying theeconomicfeasibilityandenvironmentalimpactsoflargescalerecyclingoperations.

2.Sustainable Sourcing and Ethical Supply Chains

Blockchain Applications: Expand research on the applications of blockchain technology to improve traceability and transparency in sourcing raw materials. This includes examining the integration of blockchain with otherdigitaltoolsanditsimpactonsuppliercomplianceand accountability.

SupplierRiskAssessment: Developrobustframeworksfor assessing and mitigating risks associated with the sourcing ofcriticalmaterials.Thisincludessocial,environmental,and geopoliticalrisks,particularlyinregionsknownforcomplex supplychainissues.

3.CircularEconomyModels

e-ISSN:2395-0056 p-ISSN:2395-0072

Lifecycle Analysis: Conduct comprehensive lifecycle analyses (LCAs) for different components of EVs to identify opportunitiesforimprovingmaterialefficiency. Material efficiency is very much important and plays a vital role while selecting the different components of electric vehicles,mayitbeatanylevel.

Image1:Mindmap-SSCM

1. TeslaInc.(2023). SustainabilityReport2023. Tesla Inc. Retrieved from https://www.tesla.com/sustainability

2. BMW Group. (2023). BMW Group Sustainable Value Report 2023. BMW AG. Retrieved from https://www.bmwgroup.com/en/sustainability/strate gy.html

3. Nissan Motor Co., Ltd. (2023). Nissan Sustainability Report 2023 Nissan Motor Co., Ltd. Retrieved from https://www.nissan-global.com/EN/SUSTAINABILITY/

4. Geissdoerfer, M., Savaget, P., Bocken, N. M. P., & Hultink,E.J.(2017). TheCircularEconomy–A new sustainability paradigm? Journal of Cleaner Production, 143, 757-768. doi:10.1016/j.jclepro.2016.12.048

5. Kalmykova, Y., Sadagopan, M., & Rosado, L. (2018). Circulareconomy-Fromreviewoftheories and practices to development of implementation tools. Resources, Conservation and Recycling, 135, 190-201. doi:10.1016/j.resconrec.2017.10.034

6. Luthra,S.,Govindan,K.,Kannan,D.,Mangla, S. K., & Dhull, R. S. (2017). Barriers to renewable/sustainable energy technologies adoption: Indian perspective. Renewable and Sustainable Energy Reviews,66,364-371.doi:10.1016/j.rser.2016.08.030

7. Porter, M. E., & Heppelmann, J. E. (2014). How smart,connectedproductsaretransformingcompetition. HarvardBusinessReview,92(11),6488