International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

Amruth raj B. R1, Darshan. R2, Hemanth Kumar. M. S3 , Venkatesh. T. M4 , Varun. S5

1,2,3,4, UG Students , Dept. of Civil Engineering , Maharaja Institute of Technology Mysore. 5Assistant Professor, Dept. of Civil Engineering , Maharaja Institute of Technology Mysore ***

Abstract - Granular column reinforcement stands as an appealing mitigation strategy widely embraced in geotechnical engineering for bolstering bearing capacity, minimizing settlement, and expediting consolidation. The utilization of industrial byproducts like titanium gypsum with steel slag in soil stabilization not only presents an environmentally friendly approach but also proves costeffective in managing solid waste disposal. Previous studies have extensively explored the bearing capacity and settlement of ground improved by titanium gypsum with steel slag granular columns, with or without geosynthetic encasement.

However, a paucity of research has delved into the response of ordinary stone columns without encasement and the potentialofgeosyntheticencasedtitaniumgypsumwithsteel slagcolumnsunderlateralloadingconditions.Inthispaper, we investigate the lateral load capacity of titanium gypsum with steel slag granular column-soil composites, exploring the integration of titanium gypsum with steel slag for enhanced reinforcement. To achieve this, a comprehensive series direct shear tests were conducted on the column-soil composites.

These tests encompassed titanium gypsum with steel slag columns, ordinary stone columns with or without geosynthetic encasement. Our study specifically delves into analysing the impact of column material type titanium gypsum with steel slag and sand, and the introduction of titanium gypsum to the steel slag mixture. Parameters such ascohesionandstiffnessweremeticulouslymeasuredduring thesetests.Theexperimentalfindingsdistinctlydemonstrate the efficacy of employing titanium gypsum with steel slag columns,especiallywhenaugmentedwithtitaniumgypsum, in significantly improving the lateral load-bearing performance of soil.

Numerousstudieshaveexploredthepotentialofindustrial wasteincivilapplications,seekingcost-effectiveandecofriendly alternatives for construction materials. For instance,researchhasdelvedintovariouswastematerials like fiber waste, fly ash, blast furnace slag, stone waste, rubbershreds,zeolite,andwasteplastics,examiningtheir utility in ground improvement, concrete production, brickmaking,mortar,andsubgradeconstructionforroads.

Steelslag,abyproductofsteelmanufacturingfrombasic oxygen or electric arc furnaces, finds extensive use as aggregates in concrete and road construction. With the surge in steel production, steel slag generation has increased significantly. Efforts to repurpose this waste have led to its utilization as replacement material in asphaltic concrete, road construction, and as a soil improvement agent when mixed with activators like quicklimeandsodium metasilicate.Studiesdemonstrate thatincorporatingsteelslagfinesenhancessoilstrength, durability,andreducessoilexpansionpotential.

Further investigations explore the integration of pulverized steel slag into various soil types, showcasing reducedplasticityandswellingpotentialwhileenhancing permeability and cured strength. Combinations of steel slag, rice husk ash, and lime have effectively stabilized expansivesoil,withoptimummixesresultinginsubstantial increasesincompressivestrengthandstiffness.Moreover, introducing slag-based composites demonstrates significant improvements in expansive soil properties, particularlyinreducingswellingpotentialandenhancing overall strength. The addition of steel slag to cementstabilized dredged sludge has been studied, indicating optimalsteelslagcontentstobolstershearstrength.Insoil engineering, traditional methods like granular (stone) columns have been crucial in augmenting strength, permeability,andreducingcompressibilityinweaksoils.

Mohammad Javad Rezae et.al., (2022): Utilisation of industrial wastes in civil engineering applications as a construction material is cost effective and environment friendly.Thisstudyfocusedontheutilisationofsteelslag materials as granular columns to improve problematic soils.Ontheotherhand,theeffectsofpropertiesofcolumn materials,diameterofcolumn,wereinvestigated.Inthis study, a series of large direct shear tests were done to study the response of granular column-soil composites with or without the geosynthetic encasement under a lateralloadingcondition.

Lufan Li, et.al., (2022): This paper aims to comprehensivelyreviewtheenvironmentalimpactcaused bythereutilizationofSS,particularlyfromtheperspective ofthelifecycleassessmentmethod,asystematictechnique

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

to quantitatively evaluate environmental performance. Moreover, the environmental benefits and drawbacks causedbycarbonationtreatmentandheavymetalleaching havebeendiscussedindetail.Thefollowingconclusions canbedrawn:

1.MostLCAstudiesconsidered‘cradle-to-gate’asasystem boundary,butfactorsinusagestagepotentiallyinfluence the total emissions, such as maintenance, rehabilitation, andfuelconsumption.Specialattentionshouldbepaidto theinvestigationofsystem expansion and the allocation method,sincetheysignificantlyaffecttherationalityand accuracy of LCA results, not only for SS, but also other wastematerials.

2. Global warming is the most popular life cycle impact categoryandcementproductionisthemaincontributor. Retainingthemechanicalanddurabilitypropertieswhile reducing the usage of cement is the top priority. Energy intensiveactivitiessuchaslongcarbonationdurationand highcarbonationtemperatureshouldbefurtheroptimized to avoid unnecessary energy consumption and emission outputduringcarbonation.

Xiao-yu Li et.al., (2023): Thispaperdiscussestheprocess ofTGproductionandthebeneficialusesofTG.Titanium gypsumcontainshazardouselements,andthereforethere is a need for more comprehensive short-term and longterm risk assessments to ensure that it does not cause harmtotheenvironmentbeforeitiswidelyused.Research into the use of TG has focused on three main areas: extractionofusefulmaterialsandgenerationofsynthetic materials, generation of building materials, and soil applications. Extraction of useful materials can produce high value-added products, but harsh preparation conditionsandhighlevelsofimpuritiesmakeitunsuitable forlarge-scaleapplications.Theexplorationoflarge-scale applications and the generation of high added value are urgentissuesfortheusageofTG.Inbuildingmaterials,TG is mainly used to replace cement clinker, while in soil applications, TG is mainly used to improve soil fertility, increasecropyieldandreduceheavymetalactivityinsoil. According to the composition and physicochemical propertiesofTG,thedirectuseofTGorthemodificationof TGwillfurtherexpandthedevelopmentandapplicationof TG.Inthefuture,processingTGintonewkindsofgypsum products, further strengthening the development and application of TG in building materials, such as the productionofTGsupersulphatecement,andutilizationof TG to develop new materials, such as the production of calcium sulphate whiskers, gelling materials and soil conditioners,arepromisingareasofTGapplication

Fusheng Zha et.al., (2021): Thepotentialapplicationof TG,a by-productof thetitanium dioxideindustry, in the stabilizationofexpansivesoilswasstudied.Toimprovethe stabilization efficiency, TG was pretreated by a process comprisingcrushing,drying,sieving,calcining,andagingto

enhance its properties. Subsequently, the macroscopic engineeringpropertiesandmicrostructuralpropertiesof the stabilized soil were investigated to evaluate the stabilizationeffectandelucidatethemicroscopicreaction mechanism.Themainconclusionsareasfollows:

1.TheadditionofTGtoexpansivesoilleadstochangesin thephysicalpropertiesofthesoil.WiththeincreaseinTG incorporation in stabilized soil, the cohesive particles decreaseandthecoarseparticlesincrease,resultinginan increaseinplasticityandadecreaseintheplasticityindex.

2.Thedeformationcharacteristicsofexpansivesoilscanbe effectively restrained by mixing TG into expansive soils. Stabilized expansive soil shows a suppressed swelling potentialandlinearshrinkageandcompressionindexwith anincreaseinTGcontent.

Gamil M.S. et.al., (2021) : This study raises serious inquiries regarding new issues in HPPM management in KSA, due to the COVID-19 pandemic. Following the outbreak of the novel coronavirus, logistical problems arose for HPPM management in KSA, while other environmental, technological, and financial concerns subsided during the COVID-19 crisis. In this regard, governmentassistanceisneeded,andpublichealthshould takeprecedenceoverallotherconcernsduringtheCOVID19pandemic.Inmostdevelopingcountries,includingKSA, there is considerable uncertainty about the course of economic recovery. There may be a change in people’s habits, which affects HPPM generation and should be discussed in future works. From waste separation and storage guidelines in homes and hospitals to waste collection team safety protocols during the pandemic, significantsystemicchangesinwastemanagementinKSA are needed. The separation, storage, and recycling of HPPM, including medical waste, from both hospital and non-hospital sources should be emphasized as national priorities. This paper suggests a new method for minimizing pandemicrelated waste in Saudi Arabia by recycling used healthy personal protective materials (HPPM)inenhancinggeotechnicalengineeringofthesilty sand soil covering large areas in the Kingdom of Saudi Arabia and the world for using as subbase layer in road pavementstructures.

Collecting samples of black cotton soil, steel slag, and titaniumgypsuminvolvescarefulstepstoensuretheyare suitablefortesting.Blackcottonsoilistakenfromfieldsor constructionsiteswhereitnaturallyoccurs,preservingits unique swelling and shrinking properties. Steel slag, a byproductofsteelproduction,iscollectedfromsteelplants after it cools and solidifies. Titanium gypsum, created during titanium dioxide production, is obtained from chemicalplants,ensuringitremainsuncontaminated.Each

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

sample is stored properly to maintain its natural properties,ensuringaccurateresultsinlaboratorytests.

3.1 Black Cotton Soil :Theblackcottonsoilsamplewas collectedfromNanjangudu,situatedatKarnataka571119, India, lat 12.099452˚ long 76.76954˚. The sampling site waschosenduetoitstypicalrepresentationofblackcotton soil characteristics, such as high swelling and shrinkage propertieswhichcanbeseeninFig3.1BlackCottonsoil surfacelevel.

Thesoilwasexcavatedfromadepthofsurfacelevelto3ft toensurea uniformsample. Approximately75kgofsoil was collected using clean, sterilized tools to avoid contamination.Thesoilwasthenplacedinlabeled,airtight containers to maintain its moisture content and prevent anyexternalcontamination.

Upon collection, the samples as shown in Fig 3.2 Excavatingsoilweretransportedtothelaboratoryunder controlledconditionstopreservetheirnaturalproperties forsubsequenttestingandanalysis.

3.2 Steel Slag : Thesteelslagsamplewascollectedfrom JSWBellaryPlant,locatedatBellary,Karnataka,India,lat 15.203176˚, long 76.659122˚. The sampling site was selected because it is a typical source of steel slag, a byproductofthesteelmanufacturingprocess.

The slag was collected after it had been cooled and solidifiedintheslagpits.Approximately50kgofslagwas gathered from various points within the slag heap to ensurearepresentativesample.

Thecollectedslagwasthenplacedinlabelled,sturdybags tomaintainitsintegrityandpreventcontaminationduring transport.Thesamplesweretransportedtothelaboratory undercontrolledconditions,ensuringthatthematerial’s propertiesremainedunchangedforsubsequenttestingand analysis.

3.3 Titanium Gypsum : Thetitaniumgypsumsamplewas importedfromVVTi Pigmentschemical plantlocated in South Veerapandiapuram, Thoothukudi, Tamil Nadu 628002. This source was selected due to its reliable production of titanium gypsum, a byproduct of the titaniumdioxidemanufacturingprocess.Howeverwewere not able to get pure titanium gypsum we were able to secureFerroGypsum.

Approximately 50 kgs of titanium gypsum was secured. The material was carefully packed in airtight, labeled containersbythesuppliertopreventcontaminationand preserveitspropertiesduringtransport.

Thesampleswerethentransportedtothelaboratorywhile maintainingthepackagingtoensure noalterationofthe material'sproperties.Thetitaniumgypsumwashandled with care throughout the process to ensure it remained uncontaminatedandrepresentativeofthesourcematerial, readyforsubsequenttestingandanalysis.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

Plasticity index

Theplasticityindex(PI)isameasureofasoil'splasticity, calculated as the difference between its liquid limit and plastic limit, indicating the range of moisture content withinwhichthesoilremainsplasticandmoldable.

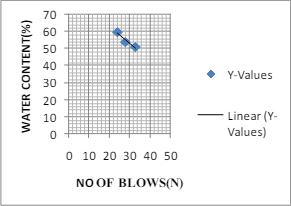

Liquid Limit:

The liquid limit is the moisture content at which soil transitionsfromaplasticstatetoaliquidstate,indicating thethresholdatwhichthesoillosesitsshearstrengthand flows.Thevaluescanbeseenintable intableandgraph canbeseeninfig4.1&Table4.1

behaviorandcanbemoldedwithoutcracking.Thevalues canbeseenintable4.2.

Table 4.1 Observationofliquidlimit

Plastic Limit:

The plastic limit is the moisture content at which soil transitions from a semi-solid state to a plastic state, markingthepointwherethesoilbeginstoexhibitplastic

LIMIT(MEANVALUE,%)=28%

Table 4.2 Observationforplasticlimit

Specific Gravity

Thespecificgravityasshowninfig3.9SpecificGravityTest and dry density of soil were determined through laboratory tests, providing crucial information about its composition and compactness, essential for engineering analysis and construction design values can be seen in table4.3.

Table 4.3 ObservationofSpecificgravity

5. DIRECT SHEAR TEST

A direct test was conducted to evaluate the combined effectsofblackcottonsoil,steelslag,andtitaniumgypsum ontheengineeringpropertiesofthesoil.Thetestaimedto

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

improve the soil's stability and load-bearing capacity by incorporating these industrial byproducts. First, black cotton soil was mixed with varying proportions of steel slagandtitaniumgypsumtoprepareseveraltestsamples. Each mixture was thoroughly homogenized to ensure uniformdistributionoftheadditives.Theresultsindicated that the inclusion of steel slag and titanium gypsum significantly enhanced the soil's mechanical properties, reducing its plasticity and improving its strength and stability. These findings suggest that such combinations could be effectively used in construction and soil stabilization projects, offering a sustainable solution by recyclingindustrialwastematerials.

Herearethetests

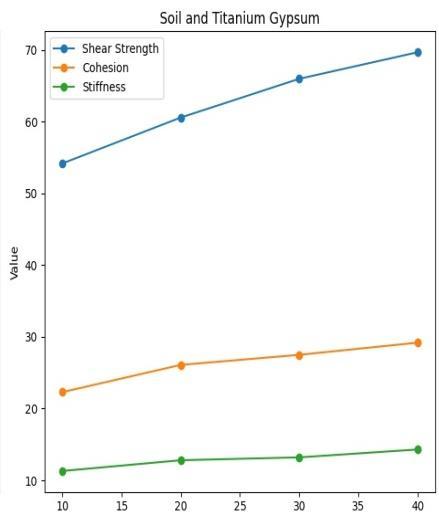

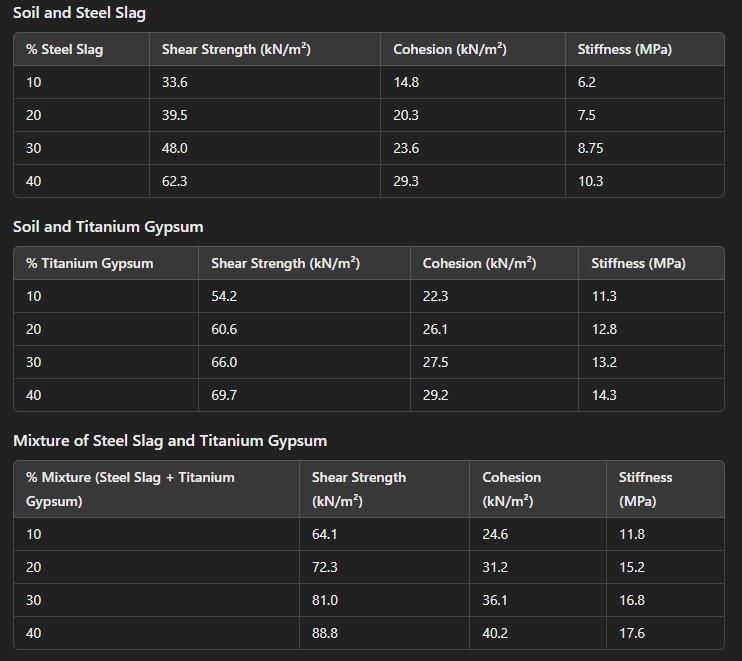

First Titanium Gypsum with Black Cotton Soil

1.10%TitaniumGypsum:

-ShearStrength:54.2kPa

-Cohesion:22.3kPa

-Stiffness:11.3MPa

2.20%TitaniumGypsum:

-ShearStrength:60.6kPa

-Cohesion:26.1kPa

-Stiffness:12.8MPa

3.30%TitaniumGypsum:

-ShearStrength:66.0kPa

-Cohesion:27.5kPa

-Stiffness:13.2MPa

4.40%TitaniumGypsum:

-ShearStrength:69.7kPa

-Cohesion:29.2kPa

-Stiffness:14.3MPa

This can be seen in fig 5.1 Graph for Soil and Titanium Gypsum

5.1 GraphforSoilandTitanium

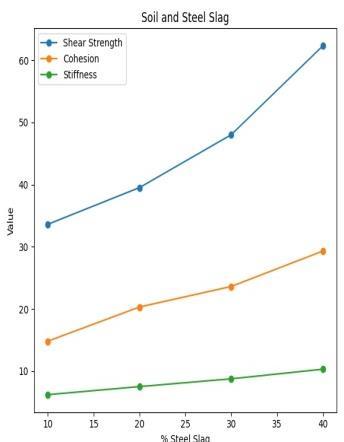

Second Steel Slag with Black Cotton Soil

1.10%SteelSlag*:

-ShearStrength:33.6kPa

-Cohesion:14.8kPa

-Stiffness:6.2MPa

2.20%SteelSlag*:

-ShearStrength:39.5kPa

-Cohesion:20.3kPa

-Stiffness:7.5MPa

3.30%SteelSlag*:

-ShearStrength:48.0kPa

-Cohesion:23.6kPa

-Stiffness:8.75MPa

4.40%SteelSlag*:

-ShearStrength:62.3kPa

-Cohesion:29.3kPa

-Stiffness:10.3MPa

Thiscanbeseenfig5.2GraphforSoilandSteelSlag

Fig 5.2 GraphforSoilandSteelslag

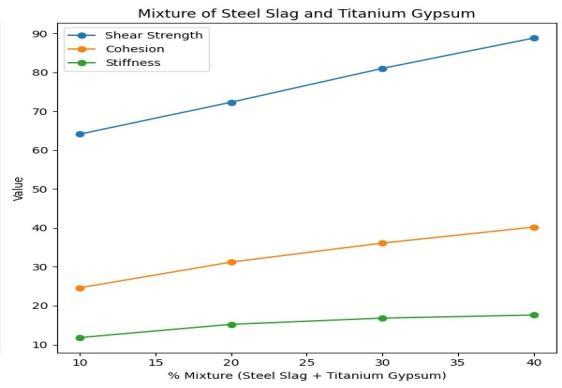

Lastly Mixture of Steel Slag and Titanium Gypsum:

1.10%Mixture(5%SteelSlag+5%TitaniumGypsum):

-ShearStrength:64.1kPa

-Cohesion:24.6kPa

-Stiffness:11.8MPa

2.20%Mixture(10%SteelSlag+10%Titanium Gypsum):

-ShearStrength:72.3kPa

-Cohesion:31.2kPa

-Stiffness:15.2MPa

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

3.30%Mixture(15%SteelSlag+15%Titanium Gypsum):

-ShearStrength:81.0kPa

-Cohesion:36.1kPa

-Stiffness:16.8MPa

4.40%Mixture(20%SteelSlag+20%Titanium Gypsum):

-ShearStrength:88.8kPa

-Cohesion:40.2

-Stiffness:17.6MPa

Thiscanbeseeninfig5.3GraphformixtureofSoil,Steel SlagandTitaniumGypsum

Thecomparisonofthethreegraphsfromthedirectshear strengthtestsasshowninfig3.11Comparisonof3graphs, highlights the effectiveness of different mixtures in enhancingthepropertiesofblackcottonsoil.Thegraphfor blackcottonsoilmixedwithsteelslagshowsamoderate increaseinshearstrengthcomparedtotheuntreatedsoil, indicatingthatsteelslagcontributestoimprovedstability.

The graph for black cotton soil mixed with titanium gypsum also demonstrates an improvement in shear strength,slightlyhigher thanthemixture withsteel slag alone, suggesting that titanium gypsum is effective in enhancingsoilproperties.However,thegraphcombining blackcottonsoilwithbothsteelslagandtitaniumgypsum showsthemostsignificantincreaseinshearstrength.

This mixture outperforms the other two combinations, indicating a synergistic effect that maximizes the soil's stabilityandstrength.Thus,thecombineduseofsteelslag andtitaniumgypsumwithblackcottonsoilyieldssuperior results, making it the most effective mixture for soil stabilization.

The tests conducted on the black cotton soil sample revealeditsinherentweaknesses,confirmingitasaweak

soiltype.Theplasticityindextestshowedahighplasticity index, indicating significant swelling and shrinkage potential with moisture variations. Compaction tests demonstrated low maximum dry density and high optimum moisture content, highlighting the soil's poor compaction characteristics. Shear strength tests further revealedlowstrengthvalues,indicatinginadequateloadbearing capacity which can be seen in table 6.1 Test Results of Soil. This mixture outperforms the other two combinations, indicating a synergistic effect that maximizes the soil's stability and strength. Thus, the combineduseofsteelslagandtitaniumgypsumwithblack cotton soil yields superior results, making it the most effectivemixtureforsoilstabilization.

The graph for black cotton soil mixed with titanium gypsum also demonstrates an improvement in shear strength,slightlyhigher thanthemixture withsteel slag alone, suggesting that titanium gypsum is effective in enhancingsoilproperties.However,thegraphcombining blackcottonsoilwithbothsteelslagandtitaniumgypsum showsthemostsignificantincreaseinshearstrength.

Theseresultscollectivelyunderscorethesoil'sinstability andpronenesstovolumechanges,makingitunsuitablefor constructionprojectswithoutstabilization.Consequently, blackcottonsoil,initsnaturalstate,poseschallengesfor engineering applications due to its weak structural propertiesasshownintable.

Integrating steel slag and titanium gypsum into black cotton soil significantly enhances its geotechnical properties.Testspredictmarkedimprovementsinshear strength, cohesion, and stiffness at varying mix percentages, with higher percentages yielding greater enhancements.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

Thedirectshearstrengthtestsyieldedinsightfulresults,as plotted in three different graphs comparing the performance of black cotton soil alone, black cotton soil mixedwithsteelslag,blackcottonsoilmixedwithtitanium gypsum, and a combination of all three materials can be seen in the above table 3.11 Test Results for Mixture of Soil,SteelSlagandTitaniumGypsum.

The graph for black cotton soil with steel slag showed a noticeable improvement in shear strength, indicating enhancedstability.Similarly,the black cottonsoilmixed withtitaniumgypsumexhibitedincreasedshearstrength, demonstratingitspositiveeffectonsoilpropertiesasshow intable.However,themostsignificantimprovementwas observed in the graph where black cotton soil was combinedwithbothsteelslagandtitaniumgypsum.This mixture yielded the highest shear strength values, reflectingasynergisticeffectthatsubstantiallyenhances thesoil'sstructuralintegrity.

examines the use of steel slag and titanium gypsum as materials for granular columns to improve problematic soils. Various factors were investigated, including the propertiesofcolumnmaterials,columndiameter,number of columns, column arrangement, and geosynthetic encasement on the lateral load capacity of granular column-soilcomposites.Directsheartestswereconducted to assess the performance of these composites under lateralloadingconditions.Thekeyfindingsare:

1.Theinclusionofsteelslagortitaniumgypsumcolumns insoilincreasesshearstrength.Largercolumndiameters significantlyenhancethiseffect.Theoverallfrictionangle of composites increases with column diameter, independent of encasement, while cohesion increases notably with encasement and larger column diameters. More columns increase the cohesion of coarse granular composites more than fine ones. Overall, these columns showhighershearstrength,especiallyunderhighnormal stress.

2. The arrangement pattern of granular columns has minimal impact on shear strength. However, columns arranged parallel to the shearing direction yield higher overallcohesionduetoshadowingandedgeeffects.

3.Steelslagandtitaniumgypsumcolumn-soilcomposites exhibit greater shear strength than sand column-soil composites, demonstrating their effectiveness for soil stabilization.

[1]Abdullah,G.M.,&AbdElAal,A.(2021).Assessmentof thereuseofCovid-19healthypersonalprotectivematerials in enhancing geotechnical properties of Najran's soil for road construction: Numerical and experimental study. Journal of Cleaner Production, 320,128772.

[2]Abukhettala, M., & Fall, M. (2021). Geotechnical characterization of plastic waste materials in pavement subgrade applications. Transportation Geotechnics, 27, 100472.

[3]Aline, R., Tejeda, M. E. L., & Gimenez, B. M. E. (2022). Reuseofwatertreatmentplantsludgemixedwithlateritic soil in geotechnical works. Environmental Challenges, 7, 100465.

These results conclusively demonstrate that the combinationofblackcottonsoilwithbothsteelslagand titanium gypsum provides the greatest improvement in shear strength, making it a superior choice for soil stabilizationinconstructionprojects.

Utilizingindustrialwastesincivilengineeringisbothcosteffective and environmentally friendly. This study

[4]Brandi,I.V.,Barbosa,M.R.,dePaula,R.G.,Araújo,R.N., deMoura,R.S.V.,&deLima,H.M.(2019).Instrumented geotechnicalmonitoringofanaturalcaveinanearmine operation–Towardsasustainableapproachtominingand preservation of speleological heritage. Journal of Cleaner Production, 239,118040.

[5]Chen, R., Congress, S. S. C., Cai, G., Duan, W., & Liu, S. (2021).Sustainableutilizationofbiomasswaste-ricehusk

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

ash as a new solidified material of soil in geotechnical engineering: A review. Construction and Building Materials, 292,123219.

[6]Dandin,S.,Kulkarni,M.,Wagale,M.,&Sathe,S.(2022).A review on the geotechnical response of fly ash-colliery spoilblendandstabilityofcoalminedump. Cleaner Waste Systems,100040.

[7]Islam,S.,Islam,J.,Hoque,N.M.R.,&Hasan,K.(2023). Improvinggeotechnicalpropertiesofsoilofhillockslope using crushed recycled concrete aggregates. Journal of Engineering Research,100139.

[8]Kazmi,D.,Serati,M.,Williams,D.J.,Qasim,S.,&Cheng,Y. P. (2021). The potential use of crushed waste glass as a sustainablealternativetonaturalandmanufacturedsand in geotechnical applications. Journal of Cleaner Production, 284,124762.

[9]Li, L., Ling, T. C., & Pan, S. Y. (2022). Environmental benefit assessment of steel slag utilization and carbonation: A systematic review. Science of The Total Environment, 806,150280.

[10]Li, X. Y., & Yang, J. Y. (2023). Production, characterisation, and application of titanium gypsum: A review. Process Safety and Environmental Protection

[11]Nath, H., Kabir, M. H., Kafy, A. A., Rahaman, Z. A., & Rahman, M. T. (2023). Geotechnical properties and applicabilityofbentonite-modifiedlocalsoilaslandfilland environmental sustainability liners. Environmental and Sustainability Indicators, 18,100241.

[12]Noaman,M.F.,Khan,M.A.,Ali,K.,&Hassan,A.(2022). A review on the effect of fly ash on the geotechnical propertiesandstabilityofsoil. Cleaner Materials,100151.