International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

EXPERIMENTAL ANALYSIS OF EMISSION AND PERFORMANCE

CHARECTERISTICS OF NEEM BIODIESEL AND ETHANOL WORKING ON DIESEL ENGINE WITH EGR

SANJANA M1 , DR P RATHNAKUMAR2 ,

1 M.Tech Scholar in Thermal Power Engineering, Department of Mechanical Engineering, NIT College of Engineering,Raichur-584103 VTU Belgavi, INDIA

2Professor and Head in Department of Mechanical Engineering, NIT COLLEGE OF Engineering Raichur-584103 ***

Abstract - The objective of the current study was to examine the emission characteristics of compression ignition (CI) engines using neem biodiesel in combination with ethanol and varying percentages of exhaust gas recirculation (EGR). This experiment involved varying the EGR percentage from 0% to 20% in a four-stroke, air-cooled, single-cylinder diesel engine that could produce 5.2 kW of rated power. The purpose of the study was to examine the emission characteristics of engine and compare them to diesel fuel. According to the experiment, there is a decrease in the emissions of nitrogen oxides as the EGR percentage in the fresh mixture increases. The highest possible percentage of nitrogen oxide reduction as compared to diesel running alone. Carbon monoxide and hydrocarbon emissions can be reduced by employing ethanol at different EGR rates.

Keywords Biodiesel, EGR, emission, compression ignition

1.INTRODUCTION

This Biofuels are substances that may be transformedto liquidfuelseitheruseintransportation or heating. Bioethanol is produced from starchy agricultural products such as corn, sugarcane, beets, wheat, and sorghum, as well as cereal crops like corn. To produce biodiesel, one can use oil or tree seeds such as rapeseed, sunflower,soy,palm,andcoconut.

Given the serious problems associated with fossil fuels such as their scarcity, rapid price increases, nonrenewability,environmentalcontamination,anddetrimental effects on biological systems the search has gained momentumforanalternativefuelthatcancoexistpeacefully involves energy management, conservation, efficiency, sustainabledevelopment,andenvironmentalprotection. In emerging nations like India, where 30% of the country's foreigncashis spentonoilimports,70%ofthenecessary fuelisimported,thesituationisquitedire. Inlightofthis, researchers discovered and examined a many energy sources,suchasLNG,CNG,ethanol,methanol,andbiodiesel. Ofthesealternativefuels,biofuelhasthemostpotentialfor developmentinIndia.

Scientistsfromvariousbackgroundshaveeffectively experimenting with blending diesel fuel with oil from vegetables.Oilfromvegetablesanddieselfuelcanbemixed exactlytorunanengine.Withaninjectionpressureof180 bars,theoilisblendedat20%,40%,60%,80%,and100% with diesel. The best blends are then selected, and an additive wechosetoadd5%with10%&5%EGR(Exhaust GasRecirculation)dependingonvolume isadded.After that, the mixture is examined and contrasted with diesel. Testsareconductedonblends'performance,emissions,and combustion characteristics under varied loads at a steady 1500 rpm rated speed. Diesel is used to compare the outcomes.

2.EXPERIMENTAL SETUP

ThisprojectFortheexperimentalinvestigations,AsinglecylinderKirloskar-typewater-cooled,naturallyaspirated5.2 kW engine with a constant pressure of 180 bar was used, and it ran at 1500 rpm. During testing, diesel and neem biodiesel as fuel sources were taken into account. The experimental setup for EGR is prepared to reduce the amountofNOxintheexhaustgas.PuredieselwithEGR,pure biodiesel without EGR, and 5%, 10%, were used in the studies, all running on regular engines. The efficiency, emissions,andcombustioncharacteristicsofcleanbiodiesel withandwithoutanEGRareevaluatedandcomparedtothe resultsofusingonlypurediesel.

Constant injection pressure of 180 bar, constant speed of 1500rpm,&EGR(recirculationofexhaustgases) at5%and 10%,thevariedtestsarecarriedoutfor0,1,2,3,4,and5 kW.

Exhaustgastemperature(EGT),volumetricefficiency,The engine's performance is assessed using brake thermal efficiency(BTHE)andspecificfuelconsumption(SFC).Next, theengine'semissioncharacteristicssuchasCO,CO2,NOX, and HC are assessed, and the combustion characteristics. Pressure,crankangle,netheatreleaserate,andcumulative heat release rate are among the variables included in the evaluation. These attributes are compared with the diesel fueloutcomes

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

ExperimentalsetupwithEGR

PhotographofExperimentalSetup

Table-1:EngineSpecifications

Parameters

Specifications

Manufacturer Kirloskar Oil Engines Ltd., India,

Model TV–SRII,naturallyaspirated

Engine Singlecylinder,DIwatercooled

Bore/stroke 87.5mm/110mm

Compressionratio 16.5:1

Speed 1500r/min,constant

Ratedpower 5.2kW

Workingcycle Fourstroke

Injectionpressure 200bar/23°degBTDC

Inlet valve opens/inlet valvecloses 4.5°BTDC/35.5°ABDC

Exhaust valve opens/ Exhaustvalvecloses 4.5°BTDC/35.5°ABDC

Table-2:propertiesofneembiodiesel,ethanol,diesel

Properties

Sp.Gr.At25°C 0.834 0.919 0.79

Flashpoint,°C 78 178 14

Firepoint,°C 85 195 26

3.RESULT AND DISCUSSION

3.1 PERFORMANCE CHARECTERISTICS

Brake thermal efficiency

Fig 1: Differencesinbrakingpowerandthermalefficiency betweendieselandvariousmixes

Neem biodiesel and mixtures thereof braking thermal efficiencyConsideringbrakepower,isdisplayedinFigure1. It demonstrates that for nearly all load levels, the brake thermalefficiencyofallmixesarelower.Thehighestthermal efficiency achievable with mixes B40% and B20% was determined to be 26.56% and 25.9%, respectively, and 26.8%fordiesel.Becauseoftheblends'highviscosity,poor atomizationresultsinalossinbrakethermalefficiencyas neembiodieselconcentrationrises.Thethermalefficiencyof puredieselbrakesismorecloselyresembledbythemixes B40%andB20%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

Fig-2 Brakeforceisusedtovarybrakethermalefficiency forblendsB20%with5%ethanolandnoEGR,5%,and 10%EGR

Fig-3 B40%blendswith5%ethanolandnoEGR,5%and 10%EGR,thechangeinthebrakethermalefficiency takingbrakepowerintoconsideration

ThecontrastbetweentheB40%andB20%mixesofneem biodieselandfivepercentethanol,10%EGR,andFigures2 and 3 indicate pure diesel in terms of braking power and brakethermalperformance.SinceBrakepowerdetermines brakethermalefficiency,itimprovesatconstantpressureof 180barastheengine'sloadincreases.Itwasdiscoveredthat blendsB20%andB40%with5%EGRand5%ethanolhave brake thermal efficiency of 24.80% and 24.70%, respectively, at maximum load In comparison to diesel's 26.8%, the figures for blends EGR at 5% and ethanol at B20%andB40%10%weredeterminedtobe26.62%and 25.8%, respectively. Blends B40% and B20% with 5% ethanol and no EGR were found to have maximum brake thermal efficiencies of 25.62% and 24.40%, respectively. BlendB20%,including5%ethanol and10%EGR,ismore akin to the diesel value at higher blends. This may be because of its increased heating value, greater fuel consumption,andlowercombinedlowcalorificvalue.The BTHE of blends including neem biodiesel was lower than thatofdiesel

Specific fuel consumption

Fig-4 VariationinDieselandDifferentBlends'Specific FuelConsumptionComparedtoBrakePower

The relationship between brake power and the fuel consumptionofneembiodieselanditsmixturesisdepicted inFigure4.Byaddingmoreneembiodieseltotheblend,the fuel's viscosity rises and, as a result of inadequate fuel atomization, the specific fuel consumption rises. For all blends, the variances are noticeable under part load situations.Atfullload,theneem'sSFCwaslowerthanthe diesel's.Neemhasalowercalorificvaluethandieselwhen the proportion of biodiesel in blends rises. The graph indicates that the B20% blend closely mimics the diesel whentheloadiscompletelyapplied.BecauseB20%hasan SFCof0.38kg/hrcomparedtoD100's0.41kg/hr,itisthe optimalmixforlowfuelusage.

Fig-5 varianceinthespecificfuelconsumptionwith brakingpowerforblendB20%,whichincludesboth5% and10%ofethanolwithEGRand5%ofethanolwithout

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

Fig-6 Variationinfuelconsumptioncomparedtobraking powerforblendsB40%withethanol,5%withoutEGR,and 5%and10%withEGR

Figures5and6comparetheprecisefuelusageandbraking force of mixesof neem biodiesel andfivepercentethanol, 10% EGR, B20%, and B40%, as well as pure diesel. The specific fuel consumption found that the full load specific gravityofblendsWith5%ethanolandnoEGR,B20%and B40%hadrespectiveratesofboth0.38and0.4kg/kW-hr;It was noticed that the mixes values B20% and B40% were specifically, 0.41 kg/kW-hr and 0.43 kg/kW-hr with 5% ethanolandwith5%EGR;TheB40%andB20%blendswith 10%EGRand5%ethanolwerefoundtohavespecificfuel consumptionsof 0.37and0.43kg/kW-hr,inthatorder; the purediesel,ontheotherhand,establishedat0.42kg/kW-hr. Becauseofitslargerbulkmodulus,lowerheatingvalue,and increasedviscosity.B20%hasalowSFCof5%ethanoland 10% EGR at higher load and burns less fuel than other blendsduetoitshighlatentheatvaporisation.Comparedto other blends, this one uses more gasoline. Out of all the mixes,B20%with5%ethanoland10%EGRisthemostfuelefficientcombination.

Exhaust gas temperature

Fig-7 Differencebetweenbrakingpowerandexhaustgas temperaturefordieselandvariousmixes

The exhaust emission temperature variation with braking powerfordieselandvariousneembiodieselmixesisshown inFigure.7.Thegraphmakesitclearthatallofthebiodiesel blends had higher exhaust emission temperatures than

diesel.SincetheexhaustgastemperaturesforD100%and theotherblendsfordifferentloadsareratherparalleltoone another,theymaybeseenandreported.Thetemperatureof theexhaustgasriseswithincreasingloadforallblends,even 100%diesel.Ithasbeendiscoveredthatduringfullload,the temperatureoftheexhaustgasreachesitsmaximum.Thisis asaresultofthechemicallyrightair-to-fuelratioisusedat fullload,whichcausesthecylindertogeneratealotofheat.

Fig-8: Temperaturechangeofexhaustgaswithbraking powerforblendsB20%,5%,and10%EGRcontaining5% and10%ethanolwithoutEGR.

Fig-9: Temperaturefluctuationofexhaustgaswith brakingpowerforblendsB40%with5%ethanolandno EGR,and5%and10%withEGR.

TheB20%andB40%mixturesofpurediesel,5%ethanol, 10% EGR, and neem biodiesel are examined in terms of exhaust gas temperature and brake power as shownin Figures8and9.With5%ethanolandwithoutanEGR,B20% and B40% exhaust gas temperatures were, respectively, 408.26 °C and 416.64 °C. Under full load and constant pressureof180bar.Theexhausttemperatures foundthat the temperatures combining B40% and B20% with 5% ethanolandEGRwere419.98°Cand354.06°C,respectively. at full load. At a constant pressure of 180 bar, it was discoveredthattheresiduetemperaturesatfullloadvalues, thetemperaturesoftheB20%andB40%mixeswithethanol 5% and EGR 10% were 435.89 0C and 383.38 0C, respectively. It was discovered that pure diesel has an

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

exhausttemperatureof417.690C.Underallloadconditions, thetemperatureoftheemissiongasesforB20%witha10% EGRblendanda5%ethanolcontentwashigherinbiodiesel than in diesel due to a longer burning period. The comparatively higher oxygen availability in biodiesel for combustion and the fact that the chemically proper air to fuelratioisemployedatfullloadmaybethesourceofthis temperatureincrease.Additionally,thechemicallycorrect airtofuelratioresultsinsignificantheatgenerationinside thecylinder

Volumetric efficiency

Fig-10: Variationinbrakeforcevsvolumetricefficiency fordieselandvariousblends

It follows that under smaller loads, volumetric efficiency achievesitsmaximum.basedonthegraph,whichshowsthat diesel has a higher volumetric efficiency than blends of biodiesel. Hence, volumetric efficiency is merely a measurementofhowwellanenginedrawsinair,anditwill decreasewitheveryactionthathinderstheengine'sability todrawinair.Volumetricefficiencyincreasesatmaximum loadandsubsequentlyprogressivelydecreases.

Fig-11: Volumetricefficiencychangeswithrespectto brakingpowerforblendB20%,whichcontains5% ethanolwithoutEGR,5%EGR,and10%EGR.

Fig-12: Volumetricefficiencychangewithbrakingpower forblendsB40%withethanoland5%,5%,and10%with exhaustgasfiltration

Figures11and12illustratesthevolumetriceffectivenessin relation to brake power for neem biodiesel mixtures of B20%andB40%thatcontain5%ethanoland5%,10%EGR andpurediesel.Thegraphsshowthatvolumetricefficiency reachesitspeakatlowerloads.Blendsincluding5%ethanol and 10% EGR, for instance, as 71.63% and 70.97% of the blends,respectively.Puredieselisdeterminedtobe73.38% becauseofitslargerbulkmodulus,higherheatingvalue,and greaterdensity.Thevolumetricefficiencyundercontinuous pressureof180barethanol5%atfullloadofblendsB20% andB40%withoutEGRweredeterminedtobe,respectively, 73.25%and73.10%. Atlargerloads,B20%inconjunction withethanolhasgoodvolumetricefficiency

EMISSION CHARECTERISTICS

CARBON MONAXIDE

Fig-13: VariationsinCarbonMonoxideEmissionfor DifferentBlendsofDieselinRelationtoBrakePower

Figure 13 illustrates how various combinations, carbon monoxide changes with load; CO emission increases with load. According to the graph, there is a larger carbon monoxideemissionfrom100%biodieselwhencomparedto otherblends.Thisisexplainedbytheneembiodiesel'shigh viscosityandlowatomizationpropensity,whichleadtopoor combustionandhighercarbonmonoxideemissions.When the air-fuel ratio exceeds the stoichiometric value, CO emissionsriseDieselemitsmorecarbondioxidethanblends

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

ofbiodieselunderallloadingconditions.Biodieselcontains O2, which aids in full combustion. B20% indicates lower carbonmonoxideemissions.

Fig-14: VariationsinCOemissionswithbrakingpowerfor blendB20%withethanol.5%withnoEGR,5%withEGR, and10%withEGR

Fig-15: ChangeinCOemissionswithbrakepowerfor blendsB40%withethanol5%withoutEGR,5%withEGR, and10%withEGR

The CO emissions for blends of Pure diesel and neem biodieselinmixturesofB20%andB40%withEGRof10%, 5%,and5%arecontrastedwithbrakepowerinFigures14 and15.Thecarbonemissionswithethanol5%withoutEGR weremeasuredin180barinjectionpressureatfullloadfor B40%andB20%blendsofneembiodiesel.TheCOemissions oftheseblendsEGRof5%andethanolof5%equal1.25% and1.20%,respectively.Thesemixeswith5%ethanoland 10% EGR were found to have CO emissions of 0.97% and 1.10%, respectively, while 1.2% was found to be the CO emissionsofpurediesel.Incomparisontodiesel,theB20% with5%ethanoland10%EGRemitslessCOemissions.This isbecauseethanolalcohollowerstheproportionofcarbon monoxide

Unburnt

Hydrocarbon Emission

Fig-16: DisturbanceinUnburnedHydrocarbonEmission inRelationtoBrakePowerforDieselandDifferent Mixtures

Figure 16 displays the difference in brake power vs the changeinHCemissions.Theincompleteburningofblends' carboncomponentsisthecauseoftheexhaustofunburned hydrocarbon.Accordingtothegraph,the100%dieselblend emitsmoregreenhousegases(HCs)thantheotherblends bothatfullloadandunderpartload.TheHCemissionvalue fallsasthefuelmixes'fractionofbiodieselincreases.LowHC iscausedbyahighcetanenumberandO2content%.TheHC emissions from B80 and B60 are lower than those from diesel.

Fig-17: Differencesintheamountofunburned hydrocarbonreleasedwithbrakingpowerforblendB20% withethanol5%withoutEGR,5%withEGR,and10% withEGR

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

Fig-18: Changesinunburnedhydrocarbonemissionswith brakingpowerforblendsB40%withethanol5%,5%with andwithoutEGR,and10%withandwithoutEGR

BrakepowerandunburnedhydrocarbonFigures17and18 ComparetheB40%andB20%neembiodieselblendswith 5% ethanol. 10% EGR, and pure diesel. Biodiesel emits higherunburnedhydrocarbonemissionsthandieseldoes.in bothgraphs.At180barinjectionpressureandalargerload. BlendsB20%andB40%containing5%ethanolandnoEGR were found to have values of 51 ppm and 68 ppm, respectively.TheresearchshowedthatmixturesB40%and B20%containing5%ethanoland5%EGRhadvaluesof61 ppm and 92 ppm, in that order. B20% and B40% are combinedwith10%EGRand5%ethanolyieldedfindingsof 86ppmand96ppm,respectively. Thegraphsdemonstrate howsomeoftheunburnedhydrocarbonoutputisreduced bythe5%ethanolalcoholutilisedintheB20%withethanol 5%withoutEGR.Sinceitreducestheworkingfluid'soxygen contentandflametemperatureinthecombustionchamber, theEGRisacommonlyuseddevicetoreduceandcontrolthe emissionofoxidesofnitrogen.Moreemissionsofunburned hydrocarbonsaretheresultofthis.

Oxides of Nitrogen

Fromtheair, nitrogenand oxygencombine withheatand pressure to generate NOx. Increased pressure and heat produce more NOx. The temperature and length of the combustionflamecausedbytheburningofmixedfueland airaretheprimarycausesofincreasedNOxproduction.The engine'sappliedloadincreases,whichraisestherateofNOx emissions.Dieselemits50ppmatfullload;B20%andB40% emit164ppmand184ppm,respectively.TheEGRtechnique is utilised to further reduce the rate of NOx emission. By returningapartofexhaustgasfromanenginebackintothe cylinders of the engine, the EGR engine conditioning technique reduces NOx emissions. As a result, there is typically less extra oxygen throughout the combustion process. This produces a more favourable outcome in bringingtheNOxratedowntoaminimum

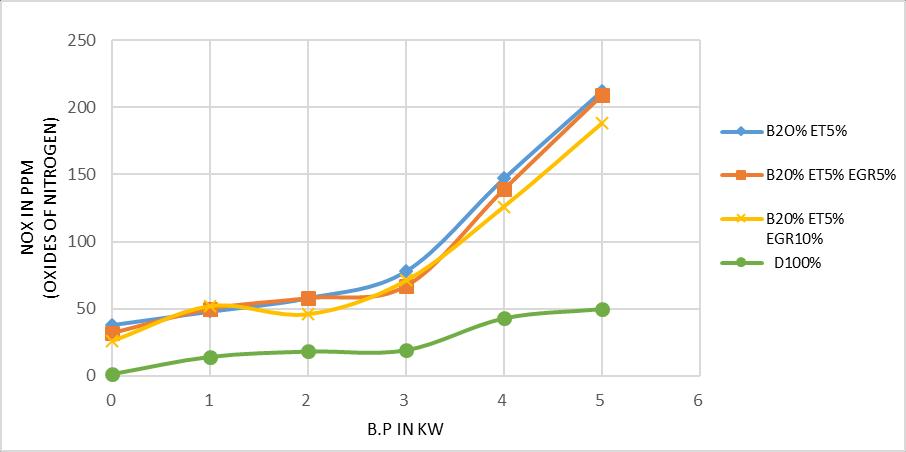

Fig-20: Differencesinnitrogenoxideemissionswith brakingpowerforblendsB20%,10%,and5%withEGR andethanol

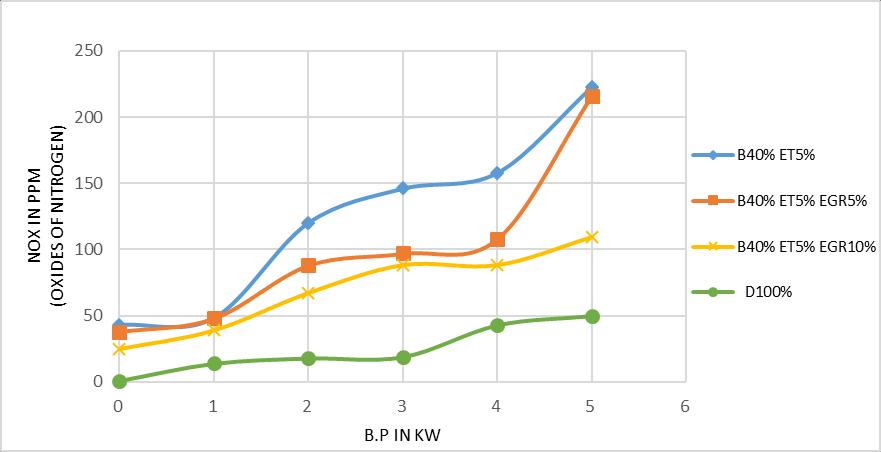

Fig-21: BrakepowerdifferencesforBlendB40%with5% EthanolWithoutEGR,5%EGR,and10%EGRinrelationto nitrogenoxideemissions

Figures20and21Comparethemixesofpurediesel,B20% andB40%10%EGR,andneembiodieselwith5%ethanolin terms of NOx and brake power. 180 bar of continuous pressure. It has been noted that when load and nozzle

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

openingpressureincreased,sodidtheemissionsofNOx.The Blendscontaining5%ethanolandnoEGR,B20%andB40%, were discovered to have 223 ppm and 212 ppm of NOx emissions, respectively, at maximum load. The mixtures B20%andB40%with5%ethanoland5%EGRexhibitedfull loadvaluesof209ppmand 216ppm,respectively.Itwas foundthat,atfullload,themixes'B20%andB40%values, with10%EGRand5%ethanol,were188ppmand109ppm, respectively. Theclear

Carbon Dioxide Emission

Fig-22:VariationsinCarbonDioxideEmissionforDiesel andDifferentBlendsinRelatedtoBrakePower

ThefluctuationofCO2concentrationswithbrakingforcefor variousblendsofdieselandneembiodieselisdisplayedin Figure22.Whentheloadgrows,CO2 emissionsriseaswell; at full load, CO2 emissions are higher, although B20% produceslesser emissionsthandiesel.Diesel hasa higher CO2outputthanallotherblendscombined.Thisresultsfrom the fuel burning through to the end. When compared to otherblends,theB20blendemitsfeweremissions

Fig-23: Changesincarbondioxideemissionswithbraking powerforblendsB20%andethanolthatcontain5%,5%, and10%ofEGR.

Fig-24: VariationinCO2 emissionswithbrakingpowerfor blendsB40%withethanoland5%,5%and10%withand withoutexhaustgaseliminators

Fig 23 and 24 Compare the CO2 emissions of pure diesel, 10%,andmixesofneembiodieselmixedwith5%EGRand 5% ethanol versus braking power at constant pressure of 180bar.BlendsItwasdiscoveredthatB20%andB40%with noEGRand5%ethanolhaveCO2emissionsof4.01%and 4.27%, respectively, at full load. It was discovered that blends5%ethanolwith5%EGRinB20%andB40%have CO2emissionsatfullloadof4.48%and4.52%,respectively. It was discovered that Blends B20% and B40% with 10% EGR and 5% ethanol have CO2 emissions of 4.92% and 4.98%,respectively,atfull load.Diesel wasdetermined to havea2.66%CO2emissionatfullload.Dieselreleasesfewer greenhousegasesintotheatmospherethanbiodiesel.This blend of biodiesel, B20% without EGR, exhibits lower emissions.WithEGR,CO2emissionsrise.Thisisbroughton byalackofoxygen.

3. CONCLUSIONS

The transesterification procedure used to make biodieselfromneemoillowersthebiodiesel'sviscosity, Thisreducesthecalorificvalueofdieselandisfoundto behigher.

WhenanengineisequippedutilisinganEGRsystem,the highestpossiblebrakethermaleffectivenessisattained. Diesel fuel is more economical than fuel made from biodiesel.However,theengine'sefficiencyiswellwithin theexpectedrangewhilerunningonbiodieselfuelwith anEGRsetup.

ThehighlatentheatvaporisationofEGRcausesSFCto belowat180barpressure.Theblendthatusestheleast fuelisB20%with5%ethanoland10%EGR.

During the full load of operation, the CO and HC emissions from a Neem biodiesel without an EGR are lessthanthosefromatypicaldieselengine.AstheEGR rises,sodotheCOandHCemissions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 08 | Aug 2024 www.irjet.net p-ISSN: 2395-0072

TheNOxemissionpeaksandthenlevelsoffastheload increases. With the exception of a small portion of componentload,DieselandNOxemissionsarealmost thesame. WhentheEGR israised,theamountofNOx producedisgreatlydecreased.ReducedNOxemissions by10%and5%,respectively.

The characteristics of 20% biodiesel are strikingly comparabletothoseofdieselwhencomparedtoother blends.

It is discovered that, without requiring significant modifications,AnalternatefuelforDIdieselenginesis 10%EGR,5%ethanol,and20%neembiodieselat180 barofpressure.

It is evident from the aforementioned study that DI dieselenginesmayrunonbiodieselequippedwithEGR. Thecompatibilityofneembiodieselinanenginewithan EGR isdemonstratedbyits combustion,performance, andemissioncharacteristics.

REFERENCES

[1] www.Energyrevoluation,Co.Za/Biodiesel/advantages

[2] www.Energyrevoluation.Co.Za/Biodiesel/disadvantages

[3] vivek Pathak International Journal of Modern

Engineering Research (IJMER) www.ijmer.com Vol. 3, Issue.5,Sep-Oct.2013pp-2792-2796ISSN:2249-6645 ExperimentalInvestigationofPerformance&Emission CharacteristicsofDieselEngineWorkingOnDieseland NOMEwithEthanolandTriacetinBlends

[4] Lovekush Prasad, Dr. Alka Agrawal “Experimental investigationofperformanceofdieselengineworking on diesel ad neem oil blends” ISSN: 2278-1684.OL.-1, ISSUE4.

[5] Sri Harsha Tirumala, A.V. Rohit, Sivakrishna, Sudipta Saha”SynthesisofneemoilBiodiesel”ISSN-0976-3945.

[6] Novel Production Of Biofuels From Neem Oil K.V.Radha1,*,G.Manikandan11Departmentofchemical Engineering, Anna University, Chennai, India * Correspondingauthor.Tel:+9104422359124,E-mail: radha@annauniv

[7] G.Sucharitha,A.Kumaraswamy/InternationalJournalof Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com Vol. 3, Issue 1, JanuaryFebruary2013,pp.320-325

[8] Copyright © 2014, Statperson Publications, InternationalJournalofRecentTrendsinScienceAnd Technology,ISSN2277-2812E-ISSN2249-8109,Volume 11, Issue 1 2014Study of Engine Performance and EmissionwithNeemOil(NOME)BasedBio-Diesel

[9] SutharDineshKumarL.,Dr.RathodPravinP.,Prof.Patel Nikul K ,(2014). “The performance of multi cylinder dieselengineFuelledwithblendofdieselandneemoil Biodiesel”, International Journal of Advanced Engineering Research and Studies Vol. II/ Issue III/April-June,2013/28-34.

[10] Ajay Gahadwa & Sanjay Yadav “Experimental Investigation of Emission Characteristics of CI Engine fuelled with Blends of Neem Biodiesel and Diesel”, International journal of research, Volume 2, Issue 11, November2015.

2024, IRJET | Impact Factor value: 8.315 | ISO 9001:2008