International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN: 2395-0072

Shreyas

Gaikwad1 , Rohit Pawar2 ,

Shriyash

Bendake3

123 UG Student, Department of Mechanical Engineering, K.I.T.’s College of Engineering, Kolhapur, Maharashtra, India ***

Abstract - Manual seed planting leads to lower efficiency, back pain for labors, low seed yields limits the amount of field that may be planted. The cost of imported seed transplanter machine has gone beyond the purchasing power of the majority of our farmers. Worker agriculturists can significantly increase grain production by reducing or eliminating the need for rigorous work during planting, To optimize seed transplanter machine performance, consider upgrading the machine's structure and determining the necessary parts to meet yield requirements. The need for rice transplanting machine is growing these days since it notably emphasizes planting in an appropriate manner and course of action. Using rice transplanter machine for seeding reduces the labor intensive work significantly, also the buyer of this machine is mainly small to medium scale farmers and they don't have much money to invest for imported machine or highly automated machine. Requirementismachineshouldbe budget friendly which gives solution on labor intensive work This paper provides highlights of advancements in rice farmers applied in India. Planting riceis exceptionallyveryold method that dates back many years and has long history since many years, and this decade has seen changes in their riceplanting tactics. Application the number of rice transplanter machine is growing, the present models are expensive. Thus, the main focus of this project is to develop feasible design, structure and lower that machine's cost.

Key Words: Rice Transplanter Machine, Farmers, Rigorous Work, Advancement, Feasible Design, Lower Cost

India is known to be a cultivating nation. In India, almost 71% of the population depends on immediate or indirect cultivation.Farmershavebeenusingcomparabletechniques and equipment for centuries. In order to advance the techniques and equipment, things must alter as the time does. In this way, the expanding efficiency of cultivation increases. Similarly, agribusiness plays a crucial role in India'seconomy.ItspresentGDPcommitmentistoincrease one-sixthofthetotal.Additionally,theIndiangovernment hasmadeprogressinorganizinganumberofinitiativesto educatefarmersabouttheuniquecultivationtechniques.A farmer simply needs to precisely complete five stages in ordertoincreaseproduction.Thefollowingdescribesthese fivestages:Harvesting,sifting,irrigation,plantingseeds,and plowing.Ithasbecomeevidentthatriceisavitalfoodsource

inIndia.Bettergeneration,Goodquality,Lessworkrequired, Savestime,Lowexpense.

Approximately one-fourth of the entire planted area is covered by rice, a significant food crop that feeds half of India'spopulation.InIndia,2.2tonsofriceisproducedper hectareonaverage.Temperatureandhumidityaretwokey climatefactorsthataffectriceproduction.Itisthoughtthat ricefarminghaspotentialinNorthEasternIndia.Just5.9% ofIndia'stotalriceproductionisproducedinNorthEastern India, which possesses 7.8% of the country's total rice cultivation land. However, because of labor-intensive activity,riceoutputinthisregionistrailing.Thefollowing elementismostlyresponsibleforricecultivation:ageofthe variety, availability of moisture, climatic conditions, Availabilityofinputsandlabors.

Amongthesefactors,manpowerandinputavailabilityare majordeterminantsofriceproductiontechnique.Numerous efforts have been undertaken to automate the process of paddytransplantationthroughtheintroductionofdifferent transplanters, and ongoing research aims to lower production costs while minimizing labor fatigue. While mechanical transplanters need energy to drag the transplanter through puddled fields, local transplanters mustfrequentlybendoverandstraightenupthroughoutthe transplantationprocedure.Asmall-scalefarmerisunableto purchase a non-subsidized automated paddy transplanter due to the high cost of such a machine. An affordable and efficient manual rice transplanter machine has been attemptedtobeconstructed.

AsweknowinIndia,almost71%ofthepopulationdepends onimmediateorindirectcultivation.Inournation,anareaof 43.86millionhectaresisusedforricecultivation.About1.70 millionhectaresoflandareusedtogrowriceinMaharashtra. Transplantingrequiresagreaterlaborrequirementroughly8 to9laborsperacreareneeded.Additionally,alaborscarcity frequently results in transplanting being delayed, which graduallylowersyield. Inordertosavelaborandtimewhen plantingriceseedlings,amechanicalmethodformovingthe seedlingsfromthenurserytothefarmfieldshouldbeused. Currently,riceseedlingsaretransplantedmanuallybyhand in India, which is a labor intensive and time-consuming process.

Whenitcomestothistechnique,transplantingproducesa considerablybetterrateofproductionthandirectseeding.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN: 2395-0072

Forexample,1acreofricecanproduceabout2400kgofrice by direct seeding, whereas 3360 kg can be produced by transplanting.

3.1 Direct seeding/sowing Method

Forgerminationandestablishment,directplantingentails sowing seeds directly into the ground. Almost any combination of vegetation may be replicated manually or mechanically.

TransplantingofseedlingscanbedonebyeitheruseofMan powerorbyTransplantingbyMachines

3.2.1 Transplanting by Man power

Thiscallsforasignificantamountoflabor,andthereforeis only appropriate in locations with an adequate supply of labor. Relocating seedlings consistently in the field is a challengingtask thatisbest suited forsmall andmarginal farmersalone.Thistransplantingtechniqueischallenging forbothlargescalecultivationinvastfieldsandlarge-scale manufacturing.Soratherthanbymanpower,transplanting bymachinewillbecomemostfeasibleandsuitablemethod.

3.2.2 Transplanting by

Assimilarprocessliketransplantingbymanpowerbuthere is major difference is occur when seedlings are kept in transplantingmachineandsownbythismachineitself. It requireshardly1to2laboursforoperationofmachine

Inordertogetthisprojectstarted,welookedforavarietyof transplant-related information sources and reviewed the literatureonseveralresearchpapers.Ourevaluationofthe literatureisbrokendownintoseveralareasofinvestigation, such as the theoretical development of rice transplanting machines, the performance of self-propelled rice transplanters and their impact on crop output, and the ergonomic-economicanalysisofvariouspaddytransplanting operations. This study was carried out to provide the parameters, specifications, issues that have arisen with transplantersthatarealreadyinuse,andthedevelopment anddesigntechniqueoftransplanters.

Rajvir Yadav et al. (2007)

Hehadbeencomplementedbyanergonomicassessmentof amanuallyoperatedriceplanterwithsixrows. Hecarried out an ergonomic assessment of a manually operated rice transplanterwithsixrows.Accordingtotheirresearch,the transplanters field capacity was greater than that of the

conventionalapproach,andtheaverageforceneededtolift theItwasdeterminedthatthetransplanterwas130.32Nfor maleindividualsand145.12Nforfemalesubjects.Japanwas the first nation to create a unit termed rice planters, according to a research by Han et al. (1971), who’s the patent, was acquired as early as 1898.In 1960, the first machine for transplanting paddy seedlings was unveiled. Thedeviceismadeupofaseedlingtray,forks,handleand skids.

Dinesh Patil et al. (2016)

Thedemandforricetransplantermachinesisrisingthese daysduetoitsspecialabilitytoseedriceinanorganizedand systematic manner. Using a rice transplanter to seed rice savesalotofhumanlabor.Farmersarethetypeofpeople whousethisequipment,andtheytypicallycomefromlowincome backgrounds. Guidelines for advancements in rice transplantersusedinIndiaareprovidedinthisdocument. Plantingriceisveryancienttechniquethatdatesbackalong way, as well as their techniques for cultivating rice are alteredinthecurrentdecade.Whileusingricetransplanter machines is a recent trend, the machines that are now in high cost of buying. Therefore, the primary goal of this projectistoreducethatmachine'scost.

A.K. Goel et al. (2008)

He had carried out an experiment on three rice transplanters: Yanji, CRRI, and OUAT. They came to the conclusionthat,inlinewiththesplitplotdesignofthetests, sedimentationdurationof32hourswasappropriateforthe manualtransplanterand56hoursfortheYanjitransplanter. Foroptimaluseofwater,nutrients,andpestcontrol,theSRI (System of Rice Intensification) transplanting method recommends planting one seedling per hill, spaced 25 cm apart.

G. Singh et al. (1985)

Hehadstudiedamechanizedmanualricetransplanteratthe farm and reported that the machine worked effectively there, with a field capacity of 0.034 hectares per hour at differentwaterdepthsandwithseedlingsofvaryingages.

5. BENEFITS OF RICE TRANSPLANTER COMPARED TO TRADITIONAL METHOD

Whencomparedtomoreconventionaltechniqueslikedirect seedingandhandplanting,usingamanualricetransplanter has a number of advantages. The following are the main benefitsofutilizingamanualricetransplanter:

5.1 Enhanced Efficiency

The efficiency of the transplanting procedure is greatly enhanced by manual rice transplanters. When opposed to manualhandplanting,farmerscancoverbiggerareasfaster with a transplanter machine since it can transplant one seedlingatonceintworowsrespectively Timelyplanting

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN: 2395-0072

results in improved crop establishment and synchronized

Achieving consistent plant spacing is one of the main problemswitholderapproaches.Thisproblemissolvedby manual ricetransplanters, whichhaveadjustableplanting spacing settings. By keeping seedlings uniformly spaced apart, farmers may encourage even growth and maximize the use of available resources. Maintaining uniform plant spacingalsomakesitsimplertocontrolweeds,waterplants, andapplyfertilizersandpesticides.

5.3

Manualricetransplanterdecreasestimeandlaborcostsby simplifyingthetransplantingprocedure.Withfewerworkers and greater efficiency, farmers can cover a greater area while transplanting seedlings. Labor spending costs are reducedasaresultofthis.Furthermore,bysavinguptime forothercrucialfarmingtasks,farmersareabletoincrease totaloutput.

5.4

Manual labor is a major component of traditional transplantingtechniques,whichcanbeproblematicinlight oflaborshortagesorthescarcityofcompetentworkers.The labor-intensivenatureofricetransplantationisreducedby thesubstantialreductioninlaborintensiveworkbymanual transplanters.Thisisespeciallyhelpfulinareaswherethere is a manpower shortage since it enables farmers to get aroundlaborlimitationsandguaranteetimelytransplanting.

Rice transplanter’s mechanized design allows for more accurate and consistent planting, which improves crop uniformity. Farmers are able to administer inputs like fertilizer,irrigation,andpestcontrolmoreevenlyoverthe fieldbecausetothisprecision.Higher-qualityricecropsand increasedproductivityaretheendresults.

Aswediscussedwithfarmerstoknowaboutthericefarming wearediscussedwiththemabout,whatistheprocessofrice transplanting so they said that there are two methods of seedingthatisdirectseedingandricetransplanting. The rate of productivity is much different in about two differentmethodsconsidereddirectseedingmethodgives you production around 2400 kg per acre wherever transplantingusedyouproductionaround3360kgperacre but the case is initial cost and labor work required for transplantingishigherthandirectseeding.

8Laboursarerequiredwiththeir350/daywagesfor1acre transplantingand thisprocessrequiredcompleteone day with8labours.

Ifyoucandesignedthemachinewhichisabletotransplant that Seedling 2 to 3 acres per day with maximum 2 to 3 labours and the cost of around 15000 it will be very beneficialforfarmersandagriculturalsector

7.

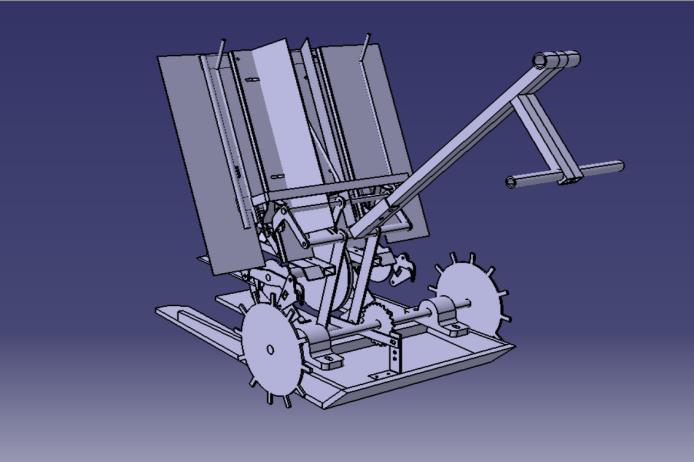

Seedlingsarekeptinthetrayandallowedtoflowdown undergravity.

The fork which is attached to shaft picks up the seedlings from the tray and keeps it in horizontal positionontheskid.

Themotionforshaftsisgivenbywheelitselfusingchain andsprocketarrangement.

On the rotating wheels small plates are welded for achievingrequiredheightinskidandalsoitishelpful foreasyworkinginskid.

Longhandleisprovidedforcontrolandgivingdirection formachine.

Arrangementconsistsprocket,linkages,wheels&Bars.

8. MATERIAL SELECTION

COMPONENTS MATERIAL

WheelsandShafts MildSteel

WheelBlade FlatSteelBars

SeedTray GalvanizedSteel

Frame HollowSteelPipes

BoltsandNuts StainlessSteel

Bearing DeepgrooveBallBearing (Code-61804)

BasePaddy EdgeWood

Table -1: MaterialSelection

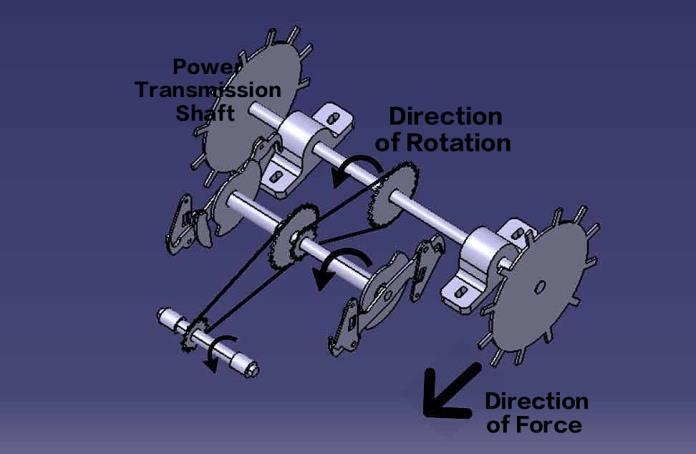

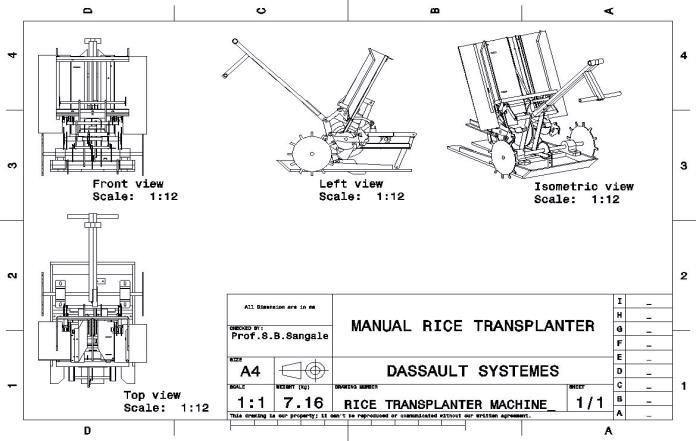

9. KINEMATIC LINKAGES AND DRIVE MECHANISM

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN: 2395-0072

Thisfigureshow,kinematiclinkageanddrivemechanismof themachineasperthatpowertransmissionistobecarried out.

10.1 Wheel Shaft

AxialStress(σ)=F/A

ConedShaft

Radius=9.5mm=0.0095m

Length=0.52m

Pullingforce=7Kg=68.6N

Torque=FXR=68.6X0.0095=0.6517N-m

Bendingmoment=68.6X6.733X10-7 m3 /0.0095m =4.861X10-3 Nm2

Axialstress=Force/Area

Area=πXd2/4=283.5275 =2.835X10 -4

AxialStress=68.6N/2.835X10 -4 =241975.3086N/m2 =24.19KN/m2 =0.2419N/mm2

BendingStress=MXC/I

M=BendingMoment

C=Distancefromneutralaxistopointofinterest

I=momentofinertia

I=πX0.0194/64=6.39X10-9

BendingStress=MXC/I

=4.861x10-3x0.26/6.39X10-9

BendingStress=0.000197787N/mm3

NoTorsionalstressbecausenotwistingoccur

10.2 Pick and Claw Shaft

R=7.5mm=0.0075mm

L=0.3m

Pullingforce=7kg=68.6N

Torque=FXR=0.5145Nm

Bendingmoment=68.6X3.31X10-7/0.0015 =3.027X10-3

Axialstress=Force/Area

Area=πXd2/4=1.767X10 -4

AxialStress=68.6/1.767X10 -4 =388206.66N/m2 =0.38N/mm2

BendingStress=MXC/I

I=πXd4/64=2.485X10-9

BendingStress=MXC/I

=3.27x10-3x0.15/2.485X10-9

BendingStress=0.0001827N/mm3

10.3 Specifications

Mildsteelisacommonmaterialthatusedforshaftsdueto itspropertieslikestrength,ductility,andaffordability. Here aresometypicalmaterialpropertiesofmildsteel:

Young'sModulus(E):200GPa(Gigapascals)or29,000ksi

(kipspersquareinch)

ShearModulus(G):79.3GPaor11,500ksi

Poisson'sRatio(v):0.3to0.33

YieldStrength(σ_y):250to350MPaor36to51ksiUltimate

TensileStrength(σ_u):400to550MPaor58to80ksi

ElongationatBreak:20%to25%

Dependingontheparticulargradeorspecificationofmild steelbeingutilized,thesevaluesmaychange.Foraccurate andcurrentinformationontheexactmildsteelgradeyou intendtouseforyourshaftapplication,itisessentialthat youexamineapplicablestandardsandreferencesorreferto thematerialspecifications.

10.4 Bearing Selection

Fr=70N

Shaftrotatesat=n=30rpm

d=20mm

Step1:Dynamicloadcapacity,

Thebearingissubjectedtopureradialload.

P=Fr=70N

L10=60nL10h/106 =60(30)(10000)/106 =18millionrev.

C=P(L10)1/3 =70x(18) 1/3 =184N

So,FromManufacturersCataloguewehaveselected DeepGroveBallBearinganditsdesignationis61804

d=Boredia.=20mm

D=Outsidedia.=32mm

B=Width=7mm

10.5 Area and Time Calculation of Rice Transplanter

A tachometer is used to measure the rotational speed of wheel shaft while it was being manually cranked. It was foundthatthewheelshaftrevolutionsaveraged30rpm.The followingoutcomeswerenotedfromthemanuallyoperated paddytransplanterthatisnowinuse.

Hilltohillspacing=0.15m

Rowtorowspacing=0.25m

Fieldcapacity=100sq.m

During one revolution of the shaft, the transplanting operation occurred twice, i.e. covering a length of (0.15+0.15)=0.30m.

Hencetheareacoveredinonerevolutionoftheshaftwas, =0.30mx0.25m=0.075m2

Therefore, to complete an area of 100 m2, the total no. of revolutionsrequiredwere, 100/0.075=1334Rev 1334/30=45min

Soaspercalculation45minarerequiredfor100sq mrice transplantingfield.

Theshaftofthetransplantingarmrevolvesataspeedratio of2:1withthewheelshaftspeed.

Hencethespeedofthetransplantingarmwastakentobe60 rpm.

Research

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

12.1 Ground Wheels

Thewheelsareincontactwiththemudorskid.Itmounted on driver shaft. It gives motion to the Four Bar Linkage throughthechaindrive.

12.2 Sprockets

Themainfunctionofsprocketsistotransmittorquethrough chain.Therearefoursprockets–oneonwheelshaftanother twoonpickingshaftandoneondeepdownclawshaft

12.3 Chain

The function of chain is to transmit torque from driver to drivensprockets.Thechainissimplextype

12.4 Four Bar Linkage

In this four bar linkage one link is fixed and other three linkagesareinmotion.Thelinksareconnectingrod,crank andplantingPick & Sowmechanism.Itismountedonthe drivenshaft.

12.5 Tray

This is used to store the rice seedlings from where the planting fingers pick the seedlings and deep down in the skid.Thistrayhastwoverticalcutslotsforguidepurpose withspringlockingarrangement.

12.6 Sowing Claw

Thesowingclawisthemainpartwhichisresponsibleforthe sowingofthenurseryseedlings.Ithastheparticularshape which picks the nursery seedlings and plant in skid. It oscillates at specific angle and it is known as fixed fork mechanism.

To effectively move rice seedlings from a nursery bed to sowing ofall seedlingsatfield,a manual ricetransplanter operatesbyfollowingasetofprocedures. Here'sadetailedexplanationofhowittypicallyfunctions:

13.1 Seedling Tray:

Thericeseedlingsareplacedonaseedlingtrayorholderfor transplantation as part of the transplanter. Usually, the transplanter'strayissituatedatthefrontortop.

13.2 Seedling Release Mechanism:

Astheoperatoradvances,amechanismonthetransplanter releases the seedlings one by one. As per design of the transplanter,thismechanismiscontrolledmechanically.

13.3 Depth Adjustment:

To regulate how deeply the seedlings are planted in the ground, transplanter has a depth adjustment feature. By

International Research

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

doingthis,youcanbeconfidentthattheseedlingsareplaced attherightdepthformaximumgrowth.

13.4 Handle and Wheels:

A handle on the transplanter allows the user to grip and controlthedevice.Tomakemovingoverthefieldeasier,it alsocontainsrunnersorwheelsatthebottom

13.5 Planting Motion:

The transplanter is pushed along the rows where the seedlingswillbeplantedbytheoperatorastheygoforward inthepaddyfield.Asingleseedlingisreleasedandplaced into the soil when the transplanter moves, activating the seedlingreleasemechanism.

13.6 Spacing and Alignment:

To control the alignment and spacing of the seedlings, certainmanualricetransplanterscomeequippedwithextra capabilities. These characteristics guarantee that the seedlings are positioned according to the proper planting patternandatthesuitabledistancefromoneanother.

13.7 Continuous Operation:

Repeating the planting procedure, the operator walks forward until all of the seedlings in the tray have been transplanted. It is necessary to periodically refill the transplanterwithseedlingsfromthenurserybed.

Whenutilizingamanualricetransplantermachineinsteadof ahandtransplanting,thetransplantingprocedurebecomes less labor-intensive and more efficient. Farmers can plant morequicklyanduniformly,savingthemtimeandlabor.To guaranteecorrectandefficientfunctioning,itisrequiredto adheretothemanufacturer'sspecificinstructionsforeach modeloftransplanter

14. FIELD TRIAL

Fieldtrialisanimportantphaseofprojectatwhichweget actualresultofourresearchanddevelopment. Also,wegetsomeimprovementpointsforsureasafuture scopeofdevelopment

Figure-5 shows field is prepared for trial, as basic requirement of field should be plane to the surface with enoughwaterabsorbedbythemudforbettercrop.

Figure-6showsarrangementofriceseedlings fortrial,we madenurseryatanotherplacewithbetterclimateandother resourcesforbetterseedlings.

Figure-7 shows developed machine is loaded with rice seedlingsandreadyfortrial

Figure-8showscommissioningofmachineatfield,aswesee in the figure as a result proper working of machine with sowingofseedswithrightspaceatrightlength.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN: 2395-0072

Thericetransplanterwhich wedesigned isfoundtobein Goodworkingperformance

Thecostischeapthanmotorandhandcrankedmechanical ricetransplanterisaddedadvantage

Afterfurtherimprovement,thistworowpaddytransplanter can be transplant 2 to 3 acre/day while manual hand operatedgives1to2acre/daybyconsidering8hoursper dayofworking.

Transplanterhelpstoacquirelessercostofproductionwith higher yield and production moreover the quality of producedriceisalsogood.

Thetotalcostwhichincludematerialandfabricationcostis Rs.14500andeasytooperate.Thecost will reduceto Rs. 12000withmassproduction.

Thereareotherareaswherethemanual ricetransplanter canbeimprovedandexpandedinthefuture.Thesearesome possibledirectionsforfurtherstudyanddevelopment.

16.1 Design Optimization

To improve the transplanter's durability, efficiency, and ergonomics,moredesignoptimizationandrefinementmay beinvestigated.Thisentailsenhancingtheoverallstructural design, handle ergonomics, insertion mechanism, and seedling holder. To decrease weight, boost strength, and extendlifespan,researchcanalsobedoneontheapplication ofcutting-edgematerialsandproductionprocesses.

16.2 Precision and Automation

Theprecisionanduniformityofriceplanterplacementcan be increased by incorporating automation and precision technologies. This could entail using robotic devices, computervision,orsensorstopreciselylocateandidentify seedlings in the ground. Automation may improve consistency,lowerthepossibilityofhumanerror,andboost outputevenmore.

16.3 Adaptability to Different Rice Varieties and Field Conditions

Different rice varieties and field conditions can be accommodatedbydesigningmanualricetransplanters.This couldentailmovableormodularpartsthatcanbetailoredto fit particular rice-growing techniques, including varying plantingdensityorrowspacing.

16.4 Economic Viability and Affordability

Prioritizingtechnologyinnovationsshouldnotovershadow the need to guarantee small-scale farmers' access to and affordabilityofmanualricetransplanters.Researchcanbe donetocreateaffordablemanufacturingprocesses,lookat financialsolutions,orinvestigatesubsidyschemestomake thetransplanteravailabletoavarietyoffarmers.

Byinvestigatingthesepossibilities,thepotentialapplications of manual rice transplanters in the future may result in enhanced production, decreased labor needs, enhanced efficiency,andsustainablericefarmingmethods.

1. Ergonomic Evaluation of Manually Operated Six-Row PaddyTransplanter,RajvirYadav,MitalPatel,ISSN147157,2007

2. ObulammaUandReddyR.2002.Effectofspacingand seedling number on growth and yield of hybrid rice. JournalofResearch,ANGRAU,30(1):7678.

3. M U Singh. Design, Developed and Evaluation of a ManualDrawnMulticropDrumSeederforDryland.In M.Tech Thesis, Agricultural and Food Engineering Department,IndianInstituteofTechnology,Kharagpur, 2000.

4. PankajkumarsinghInt,JournalofEngineeringResearch andApplicationISSN:2248-9622,Vol.7,Issue6,(Part-4) JUNE2017

ShreyasNarsingraoGaikwad shreyasgaikwad5454@gmail.com Student

K.I.T’s College Of Engineering, Kolhapur

RohitRajendraPawar Student

K.I.T’s College Of Engineering, Kolhapur.

ShriyashNarendraBendake Student

K.I.T’s College Of Engineering, Kolhapur.