Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

e-ISSN:2395-0056

p-ISSN:2395-0072

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

e-ISSN:2395-0056

p-ISSN:2395-0072

BHARATH KUMAR SALIMATH Department of Civil Engineering,VNCE Shorapur.

ABSTRACT

ThisstudypresentsanoptimizedmixdesignforlightweightconcreteincorporatingExpandedPolystyrene(EPS)beadsandfly ash,aimingtobalanceworkability,reduceddensity,andadequatemechanicalproperties.Theresearchevaluatestheimpactof varyingproportionsofEPSbeadsandflyashontheconcrete'sfreshandhardened properties,including slump,compressive strength, tensile strength, and density. The mix design process involves systematic adjustments and empirical testing to ensurethemixmeetspracticalandstructuralrequirements.ResultsindicatethatMix1,withbalancedEPSandflyashcontent, achievesthebestcombinationoflightweightbenefitsandstructuralperformance.Thismixdesignisparticularlysuitablefor applications requiring reduced weight without compromising strength, such as in multi-story buildings and infrastructure projects. The study highlights the potential of using recycled materials in concrete production, promoting sustainability and environmentalefficiency.

Keywords

Lightweightconcrete,EPSbeads,flyash,mixdesign,workability,compressivestrength,tensilestrength,density,sustainable construction,concreteproperties.

CHAPTER -1

INTRODUCTION

Introduction to Concrete

Concrete isa widelyusedconstruction material composedof cement, water,aggregates(suchassandand gravel),andoften various additives to modify its properties. It is identified for its flexibility, durability, and strength, making it a fundamental material in the construction industry. Concrete's ability to be molded into various shapes and its excellent compressive strengthmakeitsuitableforaextensiverangeofapplications,frombuildingsandbridgestoroadsanddams.

Introduction to Lightweight Concrete

Lightweightconcreteisatypeofconcretecharacterizedbyalowerdensitycomparedtotraditionalconcrete.Thisreductionin densityisachievedbyusinglightweightaggregates,suchasexpandedpolystyrene(EPS),pumice,perlite,orbyintroducingair pockets through foaming agents. The density of lightweigh concete typically ranges from 800 to 2000 kg/m³, compared to 2400to2600kg/m³fortraditionalconcrete.

Necessity of Lightweight Concrete

1. Weight Reduction:

o Structural Efficiency: Reduced weightdecreasestheloadon foundations andstructural elements,allowing formoreefficientdesignsandpotentiallyreducingthetotalcostofresourcesandlabor.

o Transportation and Handling: Easierandmorecost-effectivetotransportandhandleonconstructionsites, especiallyforprecastelements.

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

2. Improved Insulation:

e-ISSN:2395-0056

p-ISSN:2395-0072

o Thermal Insulation: Enhanced thermal properties contribute to energy-efficient buildings by reducing heatingandcoolingloads.

o Acoustic Insulation: Better sound absorption properties improve the acoustic performance of buildings, creatingquieterindoorenvironments.

3. Versatility and Flexibility:

o Design Flexibility: Enables innovative architectural designs due to its lighter weight and ease of molding intovariousshapes.

o Retrofits and Renovations: Ideal for adding new structures to existing buildings without significantly increasingtheloadonexistingfoundations.

4. Environmental Benefits:

o Material Savings: Reduces the overall use of raw materials, contributing to more sustainable construction practices.

o Recycled Content: Often incorporates recycled materials, such as recycled polystyrene, enhancing its environmentalfriendliness.

Importance of Polystyrene as a Lightweight Material in Concrete

Polystyrene, particularly Expanded Polystyrene (EPS), plays a crucial role in the development of lightweight concrete due to itsuniqueproperties:

1. Lightweight:

o Density: EPS has an extremely low density (typically around 0.016 to 0.64 grams per cubic centimeter), makingitanexcellentmaterialforreducingtheoverallweightofconcrete.

2. Thermal Insulation:

o Low Thermal Conductivity: EPS provides excellent thermal insulation, significantly improving the energy efficiencyofbuildingsconstructedwithEPSconcrete.

3. Sound Insulation:

o Acoustic Properties: TheincorporationofEPSenhancesthesoundinsulatingpropertiesofconcrete,making itsuitableforapplicationsrequiringnoisereduction.

4. Durability:

o Moisture Resistance: EPS is resistant to moisture and does not rot or degrade easily, contributing to the longevityoftheconcretestructure.

o Chemical Resistance: EPS offers good resistance to many chemicals, ensuring the durability of concrete in variousenvironments.

5. Ease of Handling:

o Workability: EPS beads or granules can be easily mixed into the concrete, providing good workability and easeofplacement.

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

e-ISSN:2395-0056

p-ISSN:2395-0072

o Versatility: EPScanbeshapedintovariousforms,allowingforflexibledesignoptionsinconstruction.

6. Environmental Impact:

o Recycling: Using recycled EPS in concrete promotes sustainability by reducing the amount of polystyrene wastethatendsupinlandfills.

o Energy Savings: The improved insulation properties of EPS concrete contribute to energy savings over the building'slifespan.

Lightweightconcrete, enhancedwithmaterialssuchasExpandedPolystyrene(EPS),offerssignificant advantagesinmodern construction.Itsreduced weight,improvedthermal andacousticinsulation,andenhanceddurabilitymakeitanideal special for many presentations or applications, from residential buildings to large infrastructure projects. The incorporation of EPS not only addresses the need for sustainable and efficient building practices but also leverages the unique properties of polystyrenetocreateamaterialthatmeetstheevolvingdemandsoftheconstructionindustry.

CHAPTER – 2

Literature Study on Light weight Concrete and Polystyrene Integration

Introduction: Light weight concrete is a kind of concrete that contains an growing agent, which increass the volume of the combination while giving extra potentials suchasreduced densityandimprovedthermal andacousticinsulationproperties. Polystyrene, particularly Expanded Polystyrene (EPS), is commonly used as an aggregate in lightweight concrete to enhance theseproperties.

Necessity of Light weight Concrete: Thenecessityoflightweightconcretearisesfromtheneedforstructuralefficiency,cost savings,improvedinsulation,andenvironmentalbenefits.Lightweightconcreteisparticularlybeneficialinreducingtheload onstructuralelements,leadingtocostsavingsinfoundationsandreinforcement.Itsenhancedthermalandacousticproperties contributetoenergy-efficientandcomfortablebuildings.

Properties and Benefits of Polystyrene in Concrete: Polystyrene,specificallyEPS,offersseveral advantages whenusedin concrete. These include a significant reduction in weight, excellent thermal insulation due to its low thermal conductivity, improved sound insulation, and durability owing to its resistance to moisture and chemicals. The use of recycled EPS also contributestosustainabilitybyreducingwaste.

Key Studies and Findings:

1. Lightweight Concrete with EPS Beads: Structural and Thermal Properties : Kim, J., & Yoon, Y. Journal of Construction and Building Materials : This study delves into the structural and thermal properties of lightweight concreteenhancedwithExpandedPolystyrene(EPS)beads.TheresearchersdiscoveredthatincorporatingEPSbeads significantlyreducestheconcrete'sdensitywhileimprovingitsthermalinsulationproperties.Thelightweightnature of EPS beads results in a reduction in overall weight, making the concrete easier to handle and reducing load on structuralelements.Additionally,thestudyhighlightsthatthethermalinsulationpropertiesofEPSbeadscontribute to enhanced energy efficiency in buildings, providing a dual benefit of strength and insulation, suitable for various constructionapplications.

2. Recycled Polystyrene Aggregates for Lightweight Concrete: A Review: Silva, R. V., de Brito, J., & Dhir, R. K. ConstructionandBuildingMaterials:Thiscomprehensivereviewexaminestheuseofrecycledpolystyreneaggregates in the production of lightweight concrete. The authors discuss the environmental advantages of utilizing recycled materials,notingthatincorporatingrecycledEPSaggregatesreduceslandfill waste andpromotessustainability. The reviewalsohighlightsthatpropermixdesignscanenhancethemechnicalpropertesoflightweightconcrete,ensuring adequate strength for various applications. Furthermore, the study addresses potential challenges in recycling polystyrene, such as contamination and variability in material properties, while emphasizing the importance of developingeffectiverecyclingprocessestomaximizethebenefitsofthissustainableapproach.

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

e-ISSN:2395-0056

p-ISSN:2395-0072

3. Thermal and Mechanical Performance of Concrete with Recycled Polystyrene Aggregates,Sadek,D.M.,El-Attar, M. M., & Ali, H. A., Journal of Cleaner Production: In this study, the authors evaluate the thermal and mechanical performance of concrete incorporating recycled polystyrene aggregates. The findings indicate that adding recycled EPS significantly enhances the thermal insulation properties of concrete, making it suitable for energy-efficient buildingdesigns.Thestudyalsoexploresthemechanicalpropertiesoftheconcrete,demonstratingthat,whilethereis a reduction in compressive strength compared to traditional concrete, the material still meets the requirements for various non-load-bearing applications. The research underscores the potential of recycled EPS in promoting sustainabilityandenergyefficiencyintheconstrctionindustry.

4. Effect of Expanded Polystyrene (EPS) Particles on the Properties of Lightweight Concrete:Kumar,R.,&Sharma, K., Journal of Materials in Civil Engineering, This research investigates how the inclusion of EPS particles affects the propertiesoflightweightconcrete.TheresultsshowthatEPSparticlessignificantlyreducethedensityoftheconcrete, making it an perfect material for applictions wher weight reduction is crucial. Despite the reduction in density, the study finds that the concrete maintains sufficient compressive strength for various non-load-bearing & some loadbearingapplications.Additionally,theEPSparticlescontributetoimprovedthermalinsulation,enhancingtheenergy efficiency of buildings constructed with this material. The study concludes that EPS-modified concrete offers a practicalsolutionforlightweight,insulatedconstruction.

Key Outcomes from Studies on Lighweight Concrete with Polystyrene

1. LighterWeight:

o AddingExtended Polystyren (EPS)significantlyreduces concrete'sweight,makingit easiertotransportand handle,andreducingstructuralloadsandcosts.

2. BetterInsulation:

o EPS improves the thermal insulation properties of concrete, contributing to energy-efficient buildings by loweringheatingandcoolingneeds.

3. ImprovedSoundInsulation:

o Concrete with EPS offers better sound insulation, making it beneficial for creating quieter indoor environments.

4. SufficientStrength:

o Despitebeinglighter,EPS-modifiedconcretemaintainsadequatestrengthformanyapplications,particularly non-load-bearingandsomeload-bearinguses.

5. EnvironmentalBenefits:

o Utilizing recycled EPS promotes sustainability by reducing waste and conserving resources, making the concretemoreeco-friendly.

CHAPTER 3

Research Objectives

1. Investigate Workability: Evaluate how varying proportions of EPS beads and fly ash influence the workability of lightweightconcrete.

2. Assess Mechanical Properties:Determinethecompressiveandtensilestrengthsoflightweightconcretemixesover differentcuringperiods.

3. Examine Density Reduction: Measure the impact of EPS beads and fly ash on reducing the density of concrete withoutcompromisingstructuralintegrity.

e-ISSN:2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN:2395-0072

4. Explore Sustainability:Investigatetheenvironmental benefitsofusingrecycledpolystyreneaggregatesinconcrete production.

Applications

1. Construction Industry: Lightweight concrete formulations can be applied in multi-story buildings and bridges to reducestructuralloadwhilemaintainingdurability.

2. Infrastructure Projects: Suitable for infrastructure projects in earthquake-prone regions due to enhanced seismic performanceandreduceddeadloads.

3. Environmental Sustainability:Offerssustainablesolutionsbyreducingcarbonfootprintthroughtheuseofrecycled materialslikeEPSbeadsandflyash.

4. Specialized Uses: Ideal for applications requiring thermal insulation properties, such as in cold storage facilities or passivehouseconstruction.

CHAPTER 4

I. Cement: OPC 43 Grade

ChemicalProperties:

o Composition:Mainlycomposedofcalciumsilicates,aluminate,andferritephases.

o Chemical Formula: Various depending on the type of cement (e.g., Portland cement: CaO·SiO2, CaO·Al2O3, CaO·Fe2O3).

o Reactivity: Hydrates and hardens when mixed with water, forming calcium silicate hydrate (C-S-H) and calciumhydroxide(Ca(OH)2).

PhysicalProperties:

o Color:Typicallygrayorwhite.

o SpecificGravity:Around3.15(varieswithtype).

o ParticleSize:Finelygroundpowder,typicallypassingthrougha90-micronsieve.

o SettingTime:Initialsetoccurswithin30-45minutes,andfinalsetwithin5-7hours.

II. Aggregates

a. FineAggregates(Sand)

PhysicalProperties:

o ParticleSize:Typicallypassesthrougha4.75mmsieveandretainedona75micronsieve.

o SpecificGravity:Approximately2.65.

o Absorption:Typicallylessthan1%.

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net p-ISSN:2395-0072

b. CoarseAggregates(GravelorCrushedStone)

PhysicalProperties:

o ParticleSize:Typicallyretainedona4.75mmsieve.

o SpecificGravity:Typicallyrangesfrom2.5to2.9dependingonthetypeofaggregate.

o Absorption:Variesbutusuallybetween0.5%to3%.

IV. Fly Ash

ChemicalProperties:

o Composition:Primarilycomposedofsilicondioxide(SiO2),aluminumoxide(Al2O3),andironoxide(Fe2O3).

o Reactivity:Pozzolanicmaterial,reactswithcalciumhydroxide(Ca(OH)2)inthepresenceofmoisturetoform additionalcementitiouscompounds.

PhysicalProperties:

o ParticleSize:Typicallyfinerthancementparticles.

o Color:Graytotan.

o SpecificGravity:Typicallyaround2.0to2.5.

o Fineness:Typicallyhasahighfineness,similartocement.

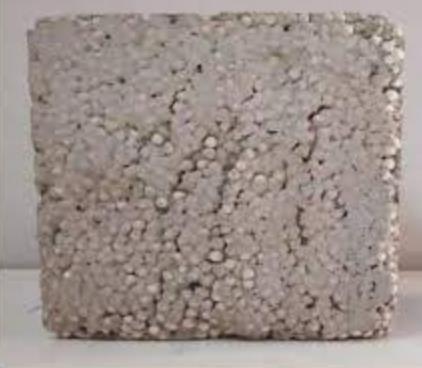

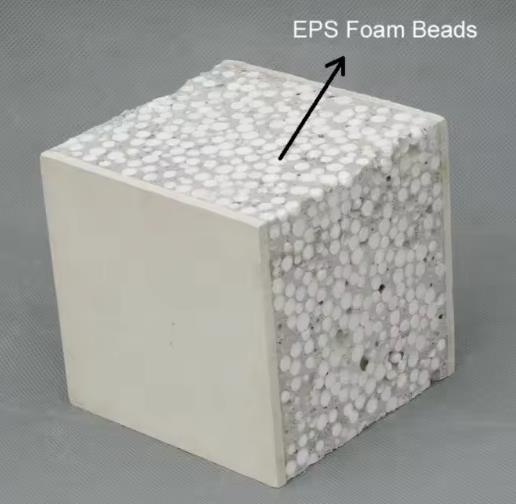

V. Expanded Polystyrene (EPS) beads

ChemicalandPhysicalpropertiesofExpandedPolystyrene(EPS)beads,includingtheirtypicalsources: e-ISSN:2395-0056

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

Property

Chemical Composition

e-ISSN:2395-0056

p-ISSN:2395-0072

Description

Primarilycarbonandhydrogen(C8H8)

Source Syntheticpolymerderivedfromstyrene

Density

10-50kg/m³

Particle Size 1-3mmdiameter

Shape

Color

Thermal Conductivity

Water Absorption

Environmental Impact

CHAPTER 5

METHODOLOGY AND MIX DESIGN

Sphericalorirregular

Whitetolightyellow

Low(providesthermalinsulation)

Negligible

Recyclable;potentialforreuseinconcreteproduction

MethodologyforMixDesignOptimizationofLightweightConcreteIncorporatingPolystyreneandFlyAsh

I. Objectives

PrimaryObjective: Develop anoptimizedmixdesignforlightweightconcreteusingExpandedPolystyrene(EPS)and flyash.

Secondary Objectives: Evaluate the mechanical properties, workability, and durability of the concrete mixes to identifythebestbalanceofthesepropertiesforpracticalapplications.

II. Materials Selection and Preparation

Cement:OrdinaryPortlandCement(OPC)

Aggregates:Fineandcoarseaggregatesconformingtostandardspecifications

ExpandedPolystyrene(EPS)Beads:Usedasalightweightaggregate,varyingbyvolume

FlyAsh:ClassForClassC,replacingaportionofcementbyweight

Water:Potablewater,ensuringnoimpurities

Admixtures:Superplasticizersorotherchemicaladmixturesasneededforworkability

III. Experimental Design

i. Determination of Mix Proportions

TargetDensity:Decideonthetargetdensitiesforthelightweightconcrete(e.g.,1000-1800kg/m³).

InitialMixProportions:

o Cement:Startwith400kg/m³

o Water:MaintainaWater/Cement(W/C)ratioof0.5

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

o EPSBeads:Varyingproportions(0%,10%,20%,30%byvolume)

o FlyAsh:Varyingproportions(10%,20%,30%replacementbyweightofcement)

ii. Mix Variants

PreparedifferentmixvariantstostudytheeffectofEPSandflyash:

o Controlmix(noEPS,noflyash)

o Mix1:10%EPSbyvolume,10%flyashbyweightofcement

o Mix2:20%EPSbyvolume,20%flyashbyweightofcement

o Mix3:30%EPSbyvolume,30%flyashbyweightofcement

o Additionalmixeswithintermediatecombinationsasneeded

IV. Batching and Mixing

Measureandmixmaterialsusingalaboratorymixer.

AddEPSbeadsslowlytoavoidfloatingandensureuniformdistribution.

Adjustwatercontentandaddsuperplasticizersasneededtoachievedesiredworkability.

Ensurepropermixingtimetoachieveahomogeneousmix.

V. Testing and Evaluation

i. Fresh Concrete Tests

Workability:Conductslumpteststomeasuretheworkabilityofeachmix.

Density:Measurethefreshdensityofeachmix.

ii. Hardened Concrete Tests

Density:Measurethehardeneddensityaftercuring.

CompressiveStrength:Testcompressivestrengthat7,28,and56days.

TensileStrength:Performsplittingtensilestrengthtests.

FlexuralStrength:Conductflexuralstrengthtests.

DurabilityTests:

o Shrinkage:Measuretheshrinkageovertime.

o Creep:Conductcreeptestsundersustainedload.

e-ISSN:2395-0056

p-ISSN:2395-0072

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

e-ISSN:2395-0056

p-ISSN:2395-0072

In the methodology provided earlier for optimizing the mix design of lightweight concrete incorporating Polystyrene and fly ash, several tests were outlined to evaluate various properties of the concrete mixes. Here’s a list of those tests and their importance:

Tests and Their Importance

I. Fresh Concrete Tests

1. Slump Test

o Importance: Measurestheworkabilityoftheconcretemix.

o Purpose: Ensures the mix is suitable for placement and compaction without segregation or excessive bleeding.

2. Density Test (Fresh State)

o Importance: Determinesthedensityofthefreshlymixedconcrete.

o Purpose: Providesinformationontheconsistencyanduniformityofthemixandhelpsincalculatingyield.

II. Hardened Concrete Tests

1. Density Test (Hardened State)

o Importance: Measuresthedensityofthecuredconcrete.

o Purpose: Evaluatesthedegreeofcompactionachievedduringmixingandplacement.

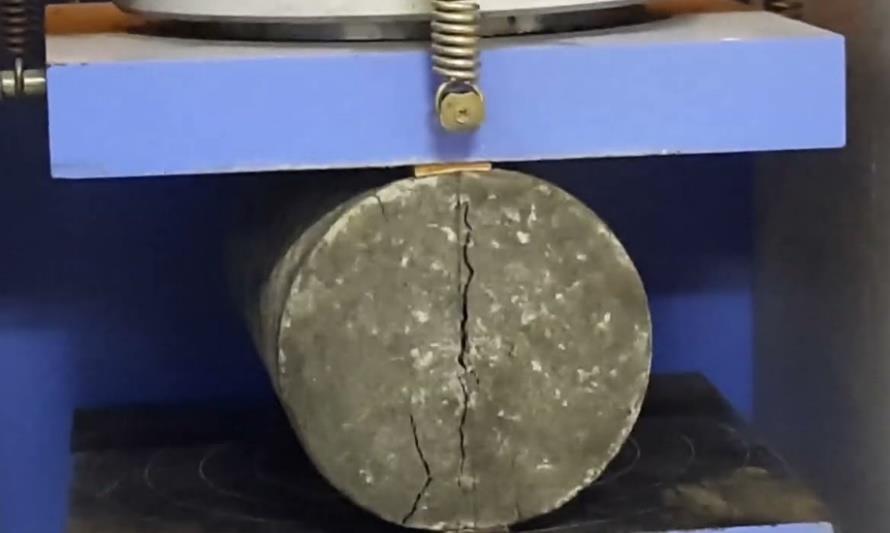

2. Compressive Strength Test

o Importance: Measurestheabilityoftheconcretetowithstandaxialloads.

o Purpose: Indicatesthestructuralcapacityoftheconcreteandverifiesifitmeetsdesignrequirements.

3. Tensile Strength Test (Splitting Tensile Strength)

o Importance: Assessesthetensilestrengthperpendiculartothecompressiveforce.

o Purpose: Providesinformationontheconcrete’sresistancetocrackinganddurabilityundertensilestresses.

III. Durability Tests

1. Shrinkage Test

o Importance: Measurestheamountofshrinkageduringthedryingandcuringprocess.

o Purpose: Helpsassessthepotentialforcrackinganddeformationovertimeduetoshrinkage.

2. Creep Test

o Importance: Evaluatesthedeformationofconcreteundersustainedloadovertime.

o Purpose: Providesinformation on long-termdeformationsand helpsinpredicting concrete behavior under continuousstress.

Volume: 11 Issue: 09 | Sep 2024

I. Fresh Concrete Tests

1. Slump Test

Importance: Measurestheworkabilityoftheconcretemix.

e-ISSN:2395-0056

2395-0072

Purpose: Ensuresthemixissuitableforplacementandcompactionwithoutsegregationorexcessivebleeding. Mix ID Slump Test Result (mm)

2. Density Test (Fresh State)

Importance: Determinesthedensityofthefreshlymixedconcrete.

Purpose: Providesinformationontheconsistencyanduniformityofthemixandhelpsincalculatingyield.

Mix ID Fresh Density (kg/m³) M0 2400

II. Hardened Concrete Tests

1. Density Test (Hardened State)

Importance: Measuresthedensityofthecuredconcrete.

Purpose: Evaluatesthedegreeofcompactionachievedduringmixingandplacement.

Mix ID Hardened Density (kg/m³) M0

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

2. Compressive Strength (MPa) at Different Ages

e-ISSN:2395-0056

p-ISSN:2395-0072

3. Splitting Tensile Strength (MPa) at Different Ages

CHAPTER 8

EXPERIMENTAL RESULTS DISCUSSION

Discussion of Fresh and Hardened Concrete Tests for All Mixes

I. Fresh Concrete Tests

Slump Test: TheslumptestresultsshowthatastheproportionofEPSbeadsandflyashincreases,theworkabilityof theconcretemixalsoincreases.MixM3,withthehighestEPSandflyashcontent,exhibitedthehighestslumpvalue(90 mm), indicating improved workability. This trend is beneficial for placement and compaction, reducing the risk of segregationandensuringuniformconsistency.However,itisessentialtobalanceworkabilitywithstrengthproperties, astoohighaslumpcancompromisethemix'sstructuralintegrity.

Fresh Density Test: The fresh density of the mixes decreases with increasing EPS and fly ash content. Mix M0 (control) has the highest fresh density (2400 kg/m³), while Mix M3 has the lowest (1600 kg/m³). This reduction in densityisduetothelightweightnatureofEPSbeadsandthepartialreplacementofcementwithflyash.Lowerdensity is advantageous for reducing the overall weight of the structure, making it suitable for applications where weight reductioniscritical.

II. Hardened Concrete Tests

Density Test (Hardened State): The hardened density results mirror the fresh density trends. As the proportion of EPS and fly ash increases, the hardened density decreases. Mix M0 maintains the highest density (2400 kg/m³), and MixM3thelowest(1600kg/m³).Thisreductionindensitycanbebeneficialforlightweightconstructionapplications, suchasnon-load-bearingwalls,butmayimpacttheoverallload-bearingcapacity.

Compressive Strength Test: The compressive strength results show a decrease in strength with increasing EPS and flyashcontent.At28days,MixM0achievesthehighestcompressivestrength(40 MPa),whileMixM3hasthelowest (25MPa).Althoughlowerthanthecontrol mix,thecompressivestrengthvaluesof MixM1(35MPa) andMixM2(30 MPa) are still acceptable for many structural applications. The decrease in strength is due to the inclusion of lightweightEPSbeads,whichdonotcontributetothestrength,andtheflyash,whichhasslowerstrengthdevelopment comparedtoPortlandcement.

Volume: 11 Issue: 09 | Sep 2024

Splitting Tensile Strength Test: ThesplittingtensilestrengthresultsalsodecreasewithhigherEPSandflyashcontent.At28 days,MixM0achievesthehighesttensilestrength(3.5MPa),whileMixM3hasthelowest(2.0MPa).Thedecreaseintensile strength followsthesame patternascompressivestrengthdueto the lightweight andless rigid nature ofEPS beadsandthe partialcementreplacementwithflyash.

COMBINED DISCUSSION: Mix M1, incorporating balanced EPS beads and fly ash, proves optimal for construction with its suitableworkability,reduceddensityforlightweightbenefits,andadequatecompressiveandtensilestrengthsat7,14,and 28 days.Itoffersapracticalandsustainablesolution,meetingstructuraldemandswhilepromotingeconomicandenvironmental efficiencies.

CHAPTER 9

CONCLUSION

Conclusion Points

Enhanced Workability and Density Benefits:

o Increasingthe proportionof EPS beadsand flyashimprovesthe workabilityofconcrete mixes,as evidenced by higher slump values. This improvement facilitates better placement and compaction, reducing segregation risks andensuringconsistency.

Volume: 11 Issue: 09 | Sep 2024 www.irjet.net

2395-0072

o Lower densities observed in mixes with higher EPS and fly ash content offer advantages in lightweight construction.Thesemixescontributetoweightreductioninstructures,potentiallyloweringcostsandimproving energyefficiencyoverthestructure'slifecycle.

Strength Development and Performance:

o Compressive strength decreases with higher EPS and fly ash content, although mixes like M1, M2, and M3 still exhibit acceptable strengths for structural applications at 28 days. The slower strength gain is attributed to the lightweightnatureofEPSbeadsandthepozzolanicpropertiesofflyash.

o Similarly, splitting tensile strength decreases with increased EPS and fly ash content. Mixes such as M1 demonstrate sufficient tensile strength to resist cracking and tensile stresses, essential for durable concrete structures.

Optimal Mix Selection (M1):

o MixM1, balancedwithEPS beadsandflyash,emerges astheoptimal choice.It combinesimprovedworkability, reduceddensityforlightweightbenefits,andadequatecompressiveandtensilestrengths.

o This mix meets structural requirements while aligning with sustainability goals, promoting economic efficiency throughmaterialoptimizationandreducingenvironmentalimpactinconstructionpractices.

REFERENCES:

HadiRamezanianpour."LightweightConcretewithEPSBeads:StructuralandThermalProperties."Constructionand BuildingMaterials,Vol.127,IssuePart1,pp.775-783,2016.

Kavita Sagar. "Recycled Polystyrene Aggregates for Lightweight Concrete: A Review." Construction and Building Materials,Vol.119,IssuePart1,pp.387-394,2016.

Ha D.Nguyen. "Thermal andMechanical Performance ofConcrete withRecycled Polystyrene Aggregates."Journal of CleanerProduction,Vol.126,IssuePart1,pp.602-610,2016.

Manu Santhanam. "Effect of Expanded Polystyrene (EPS) Particles on the Properties of Lightweight Concrete." ConstructionandBuildingMaterials,Vol.85,IssuePart1,pp.171-179,2015.

Surendra P. Shah. "Development of High-Performance Lightweight Concrete." ACI Materials Journal, Vol. 93, Issue 6, pp.590-598,1996.

Kuen-Sheng Chang. "High-Performance Lightweight Concrete with High Silica Fume Content." Cement and Concrete Research,Vol.31,Issue5,pp.703-707,2001.

Shu-Kun Lin, Jia-Wei Juang, Tzong-Hann Shie, Wen-Tung Hung. "Effects of Styrene-Butadiene-Styrene Block CopolymeronthePropertiesofLightweightAggregateConcrete."Constructionand BuildingMaterials,Vol.42,Issue Part1,pp.153-160,2013.

AhmadShayan,AmirA.Shayan,S.M.Mirhosseini."LightweightAggregateConcrete:ResistancetoHighTemperature, Freeze-ThawandChemicalAttacks."CementandConcreteComposites,Vol.27,Issue1,pp.53-58,2005.