Harness

Harness

Editor:

Sarah Peiper

Contributors:

Marissa Bankert

Wendy Christie

Jason LaMonica

Anthony Milia

Mark Phelps

Tim Saddoris

Louise Scott

Ted Sherritt

Ed Young

Proofreader:

Marsha Jo Scott

Design: V2 Marketing & Management

Printing and Distribution:

LSC Communications

Photos in this publication may not depict proper safety procedures for creative purposes. ISFA and Countertops & Architectural Surfaces magazine support the use of proper safety procedures in all cases and urge readers to take steps to institute such procedures.

Photography/graphics provided by:

ActionFlow

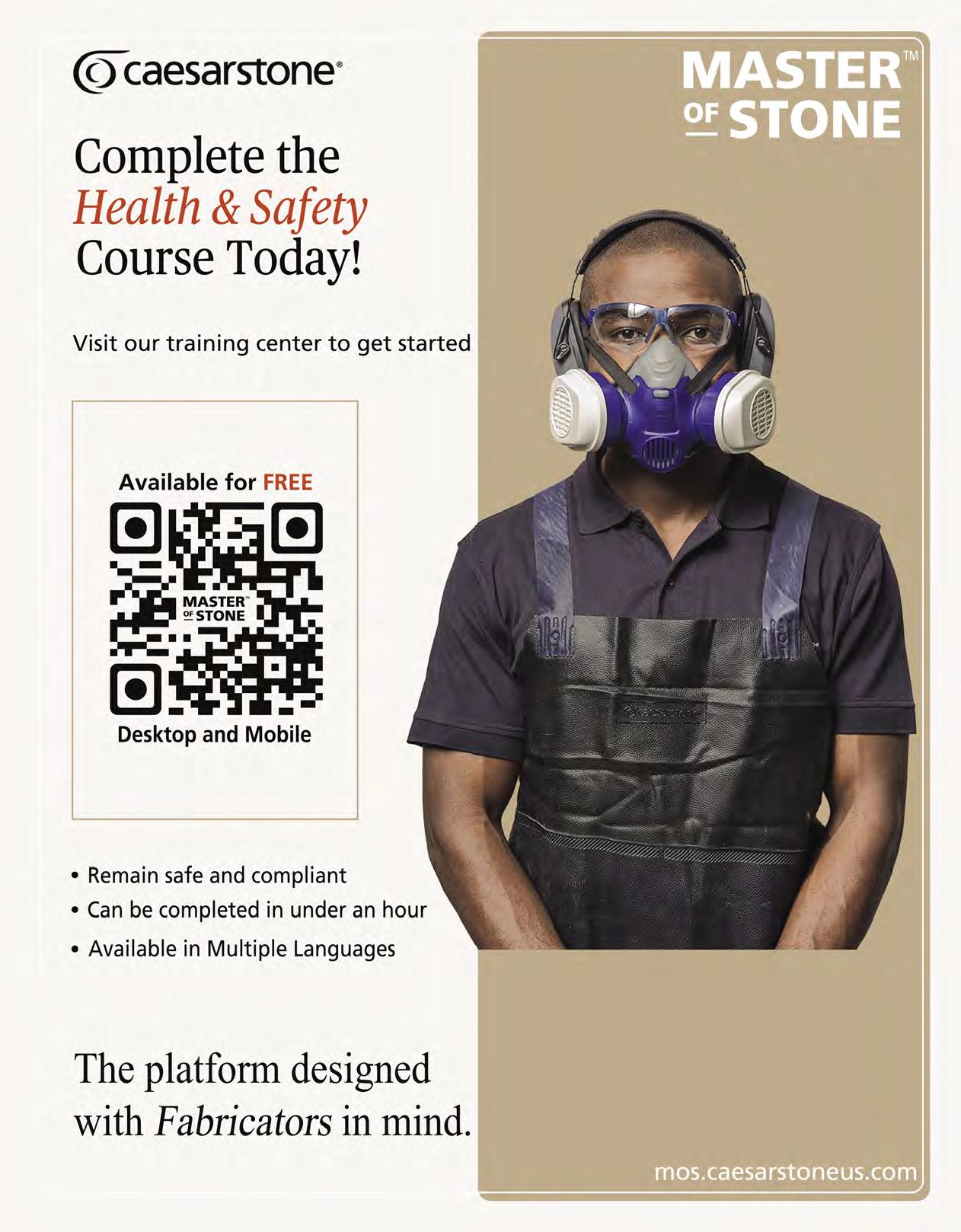

Caesarstone

Wendy Christie

Cosentino

Durat

Countertops & Architectural Surfaces (ISSN 2372-983X) is published quarterly by the International Surface Fabricators Association (ISFA), with a fifth edition, a Buyers Guide, publishing in October.

Individual copies of Countertops & Architectural Surfaces magazine are available at the nonmember newsstand price of $14.95. Countertops & Architectural Surfaces magazine is also available by annual subscription (five issues) for $30.00. ISFA members receive a complimentary annual subscription with every membership renewal. Special rates and charges apply for orders outside of the United States. To subscribe, call (888) 599-ISFA.

For change of address, please include old label with new information, including both old and new ZIP codes. Allow 3-6 weeks for address change to take effect.

Countertops & Architectural Surfaces magazine is proudly printed in the United States of America. Copyright © International Surface Fabricators Association 2024. All rights reserved. No part of this publication may be reprinted or otherwise reproduced without the publisher’s written consent.

Countertops & Architectural Surfaces magazine and the International Surface Fabricators Association assume no responsibility for unsolicited manuscripts or photographs. Materials will be returned only if accompanied by a stamped, self-addressed envelope.

Opinions expressed by contributors in this magazine are not necessarily the opinions of Countertops & Architectural Surfaces magazine or the International Surface Fabricators Association, but rather those of the individual writers.

Fabricator’s Choice

Flexijet

FreePower

GMD Surfaces

Integra Adhesives

Jason LaMonica

Laser Products Industries

LX Hausys

Anthony Milia

Moraware

Neolith

Park Industries

Mark Phelps

Prodim Systems

Tim Saddoris

Slabsmith

SlabWare

StoneGrid

Vadara Quartz Surfaces

Wetwall

Ed Young

POSTMASTER: Send address changes to:

LSC Communications

c/o Countertops & Architectural Surfaces magazine 3401 Heartland Drive Liberty, MO 64068

THE OFFICIAL PUBLICATION OF THE INTERNATIONAL SURFACE FABRICATORS ASSOCIATION

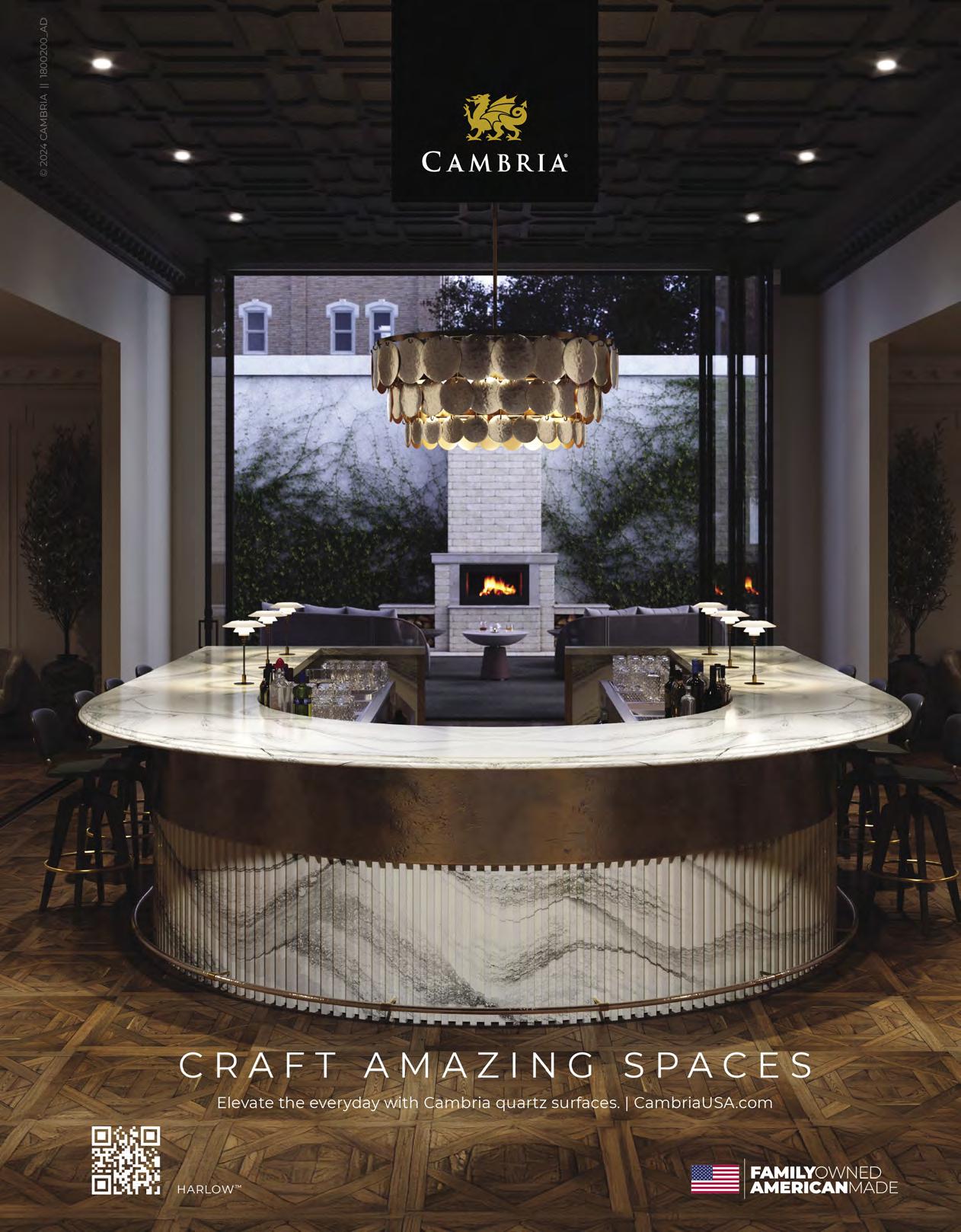

24 How Artificial Intelligence Can Improve Your Fabrication Business

Don’t think you have the technical chops to harness artificial intelligence? Take a deep dive into how AI is easier to use than you think.

28 Workflow Wonders: Software

Innovations for Surface Fabricators

Read about a dozen of the most popular software solutions, designed to streamline processes, monitor material inventory, track jobs, review metrics and provide a richer experience for your customers.

34 Choosing the Right Adhesives for Kitchen & Bathroom Installations

When it comes to countertops, selecting the right adhesive and sealant for each application is crucial to ensuring a durable, long- lasting, aesthetically pleasing finish.

38 ISFA Fabricator Profile: GMD Surfaces

Since 2007, GMD Surfaces has become one of Chicago’s premier surface fabricators. Learn how Owner Omar Chahin integrates cutting-edge technology and strict quality control measures to ensure meticulous craftsmanship.

44 Improving Work-Life Balance

in Blue Collar Industries

The skilled labor pool isn’t as shallow as you think, but finding and retaining employees requires a shift in mentality if you want to stay afloat.

Photo

Bonding a Variety of Surfaces with Integra Adhesives.

Integra Adhesives manufactures a complete range of color-matched seaming and assembly adhesives, as well as a range of color-matched sealants for the surfacing industry. Whether you’re bonding surfacing materials like solid surface or porcelain, assembly components like wood, fiberglass or steel, or tackling an outdoor project, Integra Adhesives offers time-tested, reliable products to complete the job. Integra’s seaming adhesives not only save time and money but also provide stronger joints, perfect for the latest thinner sheets. Additionally, they ensure a safer workplace and customer environment by being free of styrene and isocyanates. To learn more, visit www.integra-adhesives.com.

A special thanks to FloForm Victoria and VI Granite & Quartz Nanaimo for their assistance with sourcing the materials that appear in this issue’s cover image.

46 Onboarding the Next Generation:

A New Approach to Employee Orientation

Handling the new generation of employees requires a different approach to onboarding an approach that focuses on engagement right from the start.

8 Editor’s Note

10 Calendar of Events

12 Industry News

14 Sales & Marketing

36 Sustainability Matters

48 Perspectives: Marissa Bankert

49 ISFA News

52 ISFA Associate Member Directory

56 Product News

58 Perspectives: Ted Sherritt

Artificial intelligence (AI) has rapidly emerged as one of the most transformative technologies of the 21st century. While its impact is widely felt across almost all sectors, its dual nature as both a threat and a boon cannot be overlooked. As it continues to evolve, AI is reshaping industries in unprecedented ways, creating challenges for some while offering new opportunities for others.

AI’s capability to perform tasks with high precision and efficiency has led to significant disruption in several traditional industries. One of the most affected sectors is manufacturing. The advent of AI-powered automation and robotics has revolutionized production processes, replacing human labor with machines in many instances. This shift has resulted in job losses, particularly for low-skilled workers whose roles are increasingly being performed by robots. For example, assembly line jobs that once required human intervention are now managed by AI-driven systems that can work around the clock without fatigue.

While AI poses a threat to certain industries, it simultaneously elevates others, particularly the construction and remodeling industry. AI technologies enhance planning, project management and safety. Drones and AI-powered software are used to survey sites, monitor progress and ensure adherence to safety protocols. AI’s integration into the fabrication industry has also brought about a paradigm shift in worker safety. Through predictive maintenance, improved ergonomics, environmental monitoring, automation of hazardous tasks, enhanced training and real-time analytics, AI is making our shops safer and more efficient. On the business side, it helps us improve communications, manage employees, track jobs and more (page 24). Doesn’t sound like a threat to me.

That’s because the core of the work still relies heavily on skilled humans. As AI takes over administrative and planning tasks or automates fabrication, there’s still a skilled worker behind the machines, who now can focus on the craftsmanship and technical aspects of their trades, leading to higher-quality outcomes and increased demand for their expertise.

That said, the dichotomy of AI as both a disruptor and

an enhancer necessitates a strategic approach to workforce development. Industries facing disruption must invest in retraining and upskilling their employees. Governments and educational institutions play a crucial role in this transition by providing accessible training programs that equip workers with the skills needed for emerging roles in the AI-driven economy. This issue’s fabricator profile features GMD Surfaces of Mokena, Illinois (page 38). Owner Omar Chahin has leveraged automation, AI and a group of industrial engineering students to help him harness the power of technology to improve his workflow. Pretty smart.

AI’s impact on industries is a complex interplay of threats and opportunities. While some sectors experience displacement and disruption, others, particularly skilled trades, see growth and elevation. The key to navigating this transformation lies in adaptability, continuous learning and strategic workforce development. As AI continues to advance, embracing its potential while mitigating its challenges will determine the future landscape. Through a balanced approach, industries can harness AI’s power to enhance human capabilities, drive innovation and create a more resilient and dynamic industry.

As a writer, I am not threatened by AI. I often use ChatGPT, and I’m not ashamed to admit it. There’s no pride or authority lost in working smarter, not harder. I use it as a sounding board, a fact finder that helps me capture general information that inspires me down a creative path. I bounce ideas off it, spin phrases, and ask for rewrites to find more creative hooks. I do this so I can focus on the tasks that only I can complete.

For example, I asked it to “Write 10 headlines about a software and technology feature for fabricators” (page 28). In 3.5 seconds, it spit out 10 clever(ish) headlines back at me. None of them was what I wanted, but the results helped me look at different word usage and phrasing that could have had me brainstorming all afternoon. It’s a tool in my arsenal that fosters efficiency, but it cannot fully replace what I produce, which still requires the unique perspective and context I have that comes from living and breathing in this industry.

International Manufacturing Technology Show September 9-14

Chicago www.imts.com

Submit your event for consideration in Calendar of Events by emailing Editor Sarah Peiper, Sarah@ISFAnow.org.

ISFA Fabricator Forum September 11-12 St. Louis www.ISFAnow.org

ISFA MemberConnect Meeting September 19 Virtual www.ISFAnow.org

Ohio Stone Summit: Dynamic Intentionality September 19

MSI Surfaces Columbus, Ohio www.naturalstoneinstitute.com

Cersaie September 23-27 Bologna, Italy www.cersaie.it

Marmomac September 24-27 Verona, Italy www.marmomac.com

ISFA Porcelain Fabrication Training September 26-27 Austin, Texas www.ISFAnow.org

Digital Stoneworking Expo by Park Industries October 4 Honolulu www.parkindustries.com/dse

POLYCON 2024 October 7-9 Springfield, Massachusetts www.theicpa.com

Washington Stone Summit: Fabricator Town Hall October 10

MSI Surfaces Kent, Washington www.naturalstoneinstitute.com

Chicago Build Expo October 22-23 Chicago www.chicagobuildexpo.com

Kitchen + Bath Canada 2024 October 22-24

Mississauga, Ontario www.kbcexpo.com

Solid Surface Fabrication Training October 22-23 Boston www.ISFAnow.org

BACA BASH by BACA Systems November 6-7

Orion Township, Michigan www.bacasystems.com

Texas Stone Summit: Know Your Business November 7 Arizona Tile Dallas www.naturalstoneinstitute.com

ISFA Annual Conference November 6-8 Miami www.ISFAnow.org

ISFA MemberConnect Meeting November 14 Virtual www.ISFAnow.org

The International Surface Event (TISE) January 28-30 Las Vegas www.intlsurfaceevent.com

Marmomac Brazil February 18-20

San Paulo, Brazil www.marmomacbrazil.com.br/en/

Kitchen & Bath Industry Show (KBIS) February 25-27

Las Vegas www.kbis.com

International Builders Show (IBS) February 25-27

Las Vegas www.buildersshow.com

Xiamen Stone Fair March 16-19

Xiamen, China www.stonefair.org.cn

Coverings 2025 April 29-May 2 Orlando www.coverings.com

HD Expo+Conference May 6-8

Las Vegas www.hdexpo.hospitalitydesign.com

A recent report by Angi, a comprehensive solution for improving and maintaining homes, highlights a trend that stands in stark contrast to anxieties in many sectors: high job satisfaction in the skilled trades.

According to Angi’s data, 90% of tradespeople are satisfied with their careers. “Jobs across industries — from software development to media to research to education — could face job loss as a result of AI, but skilled home professionals are resting easy,” said Angie Hicks, co-founder of Angi. “The significant majority have no concerns about AI taking over their jobs; in fact, half of the pros we surveyed are excited to see how AI innovation can help them serve homeowners better.”

• Safe from AI: 65% of surveyed pros believe that their job in the trade labor market is safe from being threatened by AI while only 11% have concerns.

• Job satisfaction: 90% of tradespeople are satisfied with their choice of work, increasing from 83% since the pandemic. Labor shortage woes: Over 66% of pros agree that they would be able to grow their business if they could

Park Industries will hold its upcoming Digital Stoneworking Expo (DSE) on October 4, 2024, in Honolulu, Hawaii. This highly anticipated event will provide countertop fabricators with an unforgettable island experience filled with education, machine demos and exclusive tours of local fabrication shops.

For over 15 years, Park Industries has been hosting Digital Stoneworking Expos across the country, bringing together industry experts and fabricators to share knowledge, network, and experience live demonstrations of cutting-edge CNC machinery. The upcoming DSE in Honolulu promises to continue this tradition, offering valuable insights and educational sessions tailored to help fabricators grow their businesses and stay competitive in an evolving market.

Event Highlights include:

• Tour digital stone fabrication shops (Top Priority

find more quality skilled workers, and nearly 40% of pros said they could not find employees to fill open positions. In order to attract employees, pros said they were offering incentives like health insurance, above average wages and flexible work schedules.

• Younger generation outlook: Nearly 70% of tradespeople view the labor shortage as a problem vs. 77% since the pandemic. Workers aged 25-44 tend to be more optimistic about the future of the shortage, yet they are more likely to say younger people are not joining the trades due to stigmas surrounding trade roles.

• Solutions: Pros cited the top two reasons for scant entrants to these fields as a lack of exposure to trade careers paths in high school and historical stigma. Sixtyfive percent of pros said increased investment in high school trade preparation programs would help address this; 54% felt more should be invested in trade schools. The Report identifies a pressing challenge — a skilled labor shortage impacting the industry. To read the full Skilled Trades in America Report, visit www.research.angi.com/ research/__skilledtrades/.

and Todd Branson Stoneworks) and see the JAVELIN, SlabVision and more in action.

• Educational sessions with experienced fabricators.

• Interactive workshops on mitering, the digital process and more.

• Engaging roundtable Q&As.

“We are thrilled to bring the Digital Stoneworking Expo to Honolulu,” says Meagan Hegland, national sales director. “DSEs have always been about providing fabricators with the tools and knowledge they need to succeed, and we look forward to engaging with fabricators in such a vibrant setting.”

There is no charge to attend the Digital Stoneworking Expo, but space is limited and expected to fill up quickly. For the event agenda, the latest updates and to register, visit www.parkindustries.com/dse.

The ZOLLER Open House and Technology Days in June drew manufacturing professionals from across the United States, Canada and Mexico to the company’s headquarters in Ann Arbor, Michigan, to explore solutions to enhance efficiency.

This year’s event featured customer success stories, expert talks and demos of ZOLLER presetting, measuring, inspection, heat-shrinking, balancing, tooling, automation and tool management solutions.

The event also offered a preview of the ZOLLER booth for the International Manufacturing Technology Show (IMTS) to be held September 9-14 in Chicago. Open House attendees watched a sneak peek video of the »coraMeasure LG« automated tool measurement system that will make its North American debut at IMTS.

“ZOLLER’s nearly 80-year history of pioneering solutions that drive manufacturing excellence is rooted in our dedication to our customers,” said ZOLLER President Alexander Zoller. “Those who attended our Open House experienced first-hand our passion for supporting customers on their journey to greater efficiency. We look forward to continuing this journey at IMTS.”

To emphasize the “Integrate. Success.” theme of the Open House, customers shared powerful accounts of ZOLLER technology transforming their manufacturing processes. The event further underscored the importance of partnerships ZOLLER has cultivated to expand the application of its technology, as well as prepare young people for careers in manufacturing. A panel discussion with education partners from Washtenaw County, Michigan, highlighted ZOLLER apprenticeships, internships and other initiatives to train and mentor the next generation.

Cutting Edge Countertops, a premier countertop fabricator for the Midwest with five showrooms and three service centers across Ohio, Michigan and Indiana, recently announced the immediate acquisition of L.E. Smith Company, known as a leading laminate fabricator since 1950. The acquisition expands Cutting Edge Countertops’ ability to serve the commercial market through the fabrication and installation of hard surfaces, while also expanding the product offering with laminate and solid surface in multi-family commercial work.

“L.E. Smith appealed to Cutting Edge Countertops as part of our strategic growth plan, similar company values and deep roots in the commercial space,” said Brian Burns, Cutting Edge Countertops’ coowner and founding partner. “We are excited to welcome the L.E. Smith employees to the Cutting Edge Countertops family.”

“Cutting Edge Countertops is a perfect fit for L.E. Smith,“ commented Mari Ivan, L.E. Smith CEO. “Our current offerings of laminate and solid surface will be enhanced with hard surface materials including granite and quartz to further serve our

combined customers and their growing needs.”

Cutting Edge Countertops has experienced steady growth since opening its doors in 2006. The company expanded its service area through a strategic acquisition in 2016 to include locations in Noblesville and S. Indianapolis, Indiana, and Wixom, Michigan. This was followed by an additional acquisition in 2022 in Delaware, Ohio, to expand its footprint into the Columbus and Dayton markets.

Growth in the commercial space continues as young families are starting out and empty nesters downsize. Demand for multifamily housing has increased to 31% of all U.S. housing, according to the National Association of Home Builders. Multi-family homes are providing a more affordable housing option that often include communities with fitness centers, community pools and other amenities.

The acquisition adds 65 L.E. Smith employees to Cutting Edge Countertops’ workforce. L.E. Smith will continue to operate under its current name, as a subsidiary of Cutting Edge Countertops.

By Ed Young, Fabricator’s Business Coach

Sales management isn’t just about closing deals; it’s the backbone of any successful business operation. From setting targets to motivating your team, effective sales management is the key to driving revenue, fostering customer relationships and ensuring long-term growth. However, in today’s competitive landscape and uncertain economic climate, simply having a sales team isn’t enough. It’s crucial to master the art of sales management to maximize your team’s potential and propel your business forward.

Sales management encompasses a wide range of activities, from setting objectives and forecasting to motivating and empowering your sales team. It’s the engine that drives your business forward, fueling growth and profitability. A wellmanaged sales function generates revenue and builds strong customer relationships while enhancing brand loyalty and driving innovation. Effective sales management is essential for staying ahead of the competition and achieving sustainable success.

Many business owners struggle with managing their salespeople because they think salespeople are different or that making a sale is an isolated event. The truth is that salespeople aren’t any different than the rest of your employees. They need to know what is expected of them; they need goals; they need real-time feedback on performance; they want to do meaningful work; they want to be recognized and rewarded for their contributions to the company.

Making a sale is not an isolated event. It is the culmination of a process — a series of events. Just like a successful countertop installation depends on successful prior events,

getting the order depends on successful prior events. Sales management is about managing those events and the people who perform them effectively.

The sales process starts with lead generation. Typically, that includes social media ads, digital ads, email campaigns, traditional marketing and outside sales calls. Tracking metrics for each activity is essential.

Which social media and online ads generate the most clicks, form submissions and leads? What are the response rates to your email campaigns? How many sales calls are your outside salespeople making, and how many are successful? How is your lead acquisition cost trending? Tracking and trending these metrics will help you evaluate and improve your lead-generation process.

Follow-up is where most fabrication shops blow it. They will do many of the right things to generate new leads but fail to follow up on them.

To manage the follow-up process well, you need to define your process. What happens when you get a new lead? How quickly do you follow up? What is your follow-up process? How much of that process is automated (text, email) and personal (phone call, visit)? What is your follow-up sequence and timing (the order of texts, emails, and calls, and how far apart)? At what point do you consider the lead dead, and what happens to the lead then?

Tracking follow-up timing along with successful contact rates by salespeople is a great way to manage this phase of the sales process.

It’s obvious that you can’t get orders if you don’t generate quotes. How many quotes do each of your salespeople create each day? What is the average quote amount? What is the total quote volume each day, and is it enough to keep your shop well-fed? Breaking down this data by market segment, material type, quote amount, and salesperson will give you great insights into how well your process is working and where you need to improve. Note that follow-up is just as important after the quote as after receiving the initial lead. Tracking the same metrics here is critical.

Many shops have an idea of their average quote-to-order conversion rate. However, few actually track the data and trend it over time. Breaking this data down by salesperson, market segment, material type, and amount can give you valuable insights into which markets are the most lucrative for your business.

Setting clear expectations is crucial for aligning your team’s efforts and driving performance. Define your objectives, processes and performance metrics in detail. For example, when it comes to quote follow-ups, outline each interaction’s timing, communication methods and content. Documenting these expectations ensures clarity and accountability within your team.

Communication is key. Share the documented processes with your team, solicit feedback, and provide ongoing training and support. Effective follow-up involves regular feedback on performance and maintaining accountability. Solid tracking systems, such as Customer Relationship Management (CRM) software, are essential for monitoring performance and

ensuring accountability. Using a CRM is the key to managing data and keeping the emotions and assumptions out of the management process.

In addition to the follow-up activities that are part of the sales process, following up on the performance of individual salespeople is a must. You can set expectations, communicate and train process attributes and track data. Simply making individual performance data visible can help raise awareness and create some friendly competition. However, you must also check in with salespeople frequently, or you will lose the opportunity to improve their performance.

When an individual isn’t performing well, a lack of coaching support can create a “doom loop” of decreasing performance. Use the data to create teachable moments where the salesperson is motivated to improve. Structure your coaching time by understanding which part of the process the person struggles with. A little role-playing to practice the preferred behaviors can produce strong improvements in performance.

Effective sales management is a multifaceted endeavor that requires clear expectations, consistent follow-up and the use of technology to maximize efficiency. By setting clear goals, documenting expectations, and implementing structured follow-up processes, you can unlock the full potential of your sales team. In an uncertain economic climate, mastering the art of sales management is the key to sustaining growth and success. So, embrace the power of effective sales management and watch your business thrive in today’s competitive marketplace.

Ed Young is the owner of Fabricator’s Business Coach, a consulting firm designed to strengthen and elevate fabrication shops of all sizes. A former shop manager, Ed fully understands the challenges of today’s professionals. He has consulted with a range of businesses, from one-person startups to international Fortune 100 corporations, covering a broad array of products and processes. As a result, Ed knows that each business needs an appropriate structure for its unique situation. To learn more about how Fabricator’s Business Coach can take your shop to the next level, visit www.fabricatorscoach.com or reach Ed directly at Ed@fabricatorscoach.com.

By Mark Phelps, Synchronous Solutions

Many fabricators in the surfacing industry have had tremendous success using Synchronous Flow to improve their businesses from a production standpoint: reducing lead times, improving first-time quality and more. But can you apply Synchronous Flow to the marketing and sales side of your business? The answer is yes!

Synchronous Flow is the science of improving flow as it relates to information or material. Flow problems exist in all areas of your life. You experience these problems whether you are dealing with rush hour traffic, waiting in queue at your local DMV, or trying to pay your bills and needing a check to clear. The big challenge is trying to accomplish all you set out to get done with limited time and availability. Synchronous Flow brings an array of procedures, policies, tools and techniques to transform the business process from a chaotic, reactive, out-ofcontrol process into a disciplined, proactive and fully-in-control business system. If you’re familiar with Synchronous Flow as it applies to production, then you will see the same concepts applied to sales and marketing.

In sales and marketing, the focus is on the flow of information and people — customers. In this case, leads, prospects, and customers are your raw materials and the communication that occurs between them and your company representatives is the information.

When you run a marketing campaign, your goal is to generate leads. When a lead comes in, you want to ensure they are nurtured as quickly as possible. It’s essential to build a process and train your staff to be effective at it. Maybe you have someone who answers the call promptly, or you have an email inbox that gets monitored. The marketing process is about getting in front of people in your target market and engaging with them in a way that makes them want to do business with you.

Synchronous Flow is about designing the sales and marketing process that allows you to regulate the flow of leads and manage how effective the process is at achieving the company goals. The first step is to know the limits of the process. How many people can say, “Hey, I’m interested,” before the process breaks down? If one person says they’re interested, OK, no problem. If 100 people say they’re interested in a single day, could you handle all those leads with your current process and staff?

It’s crucial to understand: What is the limiting resource? How much is too much for our receptionist to handle? How much is too much for our sales team to handle? What is the constraint to processing new leads and producing quotes effectively? If you overload the production system, it will go into chaos; the same thing will happen if you overload a sales and marketing system.

How do you measure success? One way is to look at quotes. You can see how many leads are coming in, so you should be able to track those quotes and follow-ups. If you see a bottleneck, identify the constraint:

• What is the capacity of the team?

• What would enable the team to do more?

• What are some limits in the process?

With these insights, you can start to (re)define the process from that point forward. The goal is to improve your process continuously.

Your marketing system should get better and better. Every dollar spent on marketing should result in more quotes. Every team member in marketing should be able to handle more demand from the market.

An important thing to understand is what’s constraining your ability to respond appropriately to incoming calls. If someone inquires about a quote on a countertop project and you don’t respond to them in an hour or two, chances are they’ve already called someone else, and you may have lost that lead. You need

to be able to monitor your capacity and your incoming calls and make sure that you have sufficient capacity to answer the phone and respond in the timeframe that the customer expects — as soon as possible, on demand.

Outside sales is about getting new B2B relationships. One of the biggest constraints I see is that an employee is preoccupied with tasks that are not generating new relationships — the crux of their role. For example, I’ve seen outside salespeople responsible for assembling and delivering the samples and maintaining the sample racks. That is not developing new relationships. From a Synchronous Flow standpoint, what is your outside salesperson doing that’s not directly related to developing new relationships? Once you have identified those tasks, apply the process to figure out how to offload them to someone else so that your salesperson can focus solely on building relationships.

Another thing you don’t want your outside salesperson to do is create the paperwork associated with those relationships. Someone really good at talking with people is not always good at documenting the details in your CRM. So, you might need to consider offloading that work so they can focus on what they do well.

Whether they’re inside or outside sales, Synchronous Flow has a lot to offer in terms of how to focus and take your capacity

and your business to the next level. Equally important, or maybe even more important, is what Synchronous Flow has to say about pricing strategies.

Most businesses run off margins, but that thinking can get you in trouble. There is a perception that there is a certain margin a business needs to earn. Understanding what profitability really means and what relative profitability of jobs means is a game-changer.

Once you understand the relative profitability of jobs and what it takes to be profitable, you can empower your salespeople to go out there and buy new customers. How you do this is through aggressive pricing strategies in new markets. Once you’ve built the relationship, over time, you can gradually work the pricing structure up to your regular pricing. Leverage your capacity during a down market or slow times of the year.

One thing that I keep hearing from fabricators is that their constraints are moving from internal to the marketplace. Lots of you went out and hired people and bought new equipment during the pandemic boom, and you’re noticing it’s getting harder and harder to close deals. Yes, there is less demand in the marketplace than there was, but there is still way more demand than any of our clients can serve on their own. If you’re reading this article, you likely have not maxed out your marketplace. The market is still ample. Fabricators are still making money. There’s plenty of business out there. Success depends on how you innovate your processes to make room for opportunities for growth — no matter what the market is doing. C C C C A A A A

Mark Phelps is an owner of Synchronous Solutions, a firm dedicated to helping fabricators maximize their bottom line while on the continuous pursuit of excellence. Synchronous Solutions has helped over 100 fabricators build competitive advantages in their marketplace and grow to break new records, achieving financial control and life balance for their ownership and teams. To learn how Synchronous Solutions can help your business, visit www.synchronoussolutions.com. Have a new product or service announcement? ISFA can help you get the word out! Send press releases to Editor@ISFAnow.org or visit www.ISFAnow.org/advertise for more information about our marketing channels.

By Anthony Milia, owner of Milia Marketing

As a fabricator or surfacing industry professional, measuring the return on your marketing investments is critical to the success and growth of your business. The key lies in understanding the core customer journey — the interactions that lead a prospect to become a loyal, raving fan.

What steps are involved in turning a prospect into a customer? Where do they find out about your business? What actions do they take when they learn about you? What made them choose you? How was their experience after working with you? Would they come back? Would they refer family and friends?

Understanding these different touchpoints is critical in understanding your target audience and maximizing your marketing investments.

A customer journey is the series of interactions and experiences a customer has with your business over time, from initial awareness to becoming a repeat customer. The key elements of a customer journey typically include:

Awareness: How the customer first becomes aware of your products or services through advertising, referrals or online searches.

Consideration: The research and evaluation phase, where the customer gathers information to decide if your company’s offerings meet their needs.

Conversion: The point where the customer takes action, such as making a purchase, signing up for a service, or requesting a consultation.

Retention: The customer’s ongoing relationship and interactions with your business after the initial conversion, including repeat purchases, support and brand loyalty.

Advocacy: When satisfied customers become brand advocates,

recommending your company’s products or services to others.

Every customer who has purchased has gone through at least the first three stages of the customer journey. Many go through it in one day, and some might take a while, but if your business meets their needs, they’re likely to hit all those points on their journey.

A prospect might learn about your business through an advertisement, a social media post, or, most commonly, a recommendation. They might try to find out about your business by asking their friend, visiting your website or showroom, or requesting a quote. They’re trying to find out what services you provide, if your offerings are within their budget, what materials you sell and more.

If they’re satisfied with what they find, they’ll pay for the product or service and can either move on from there, return for more, or refer a friend.

It’s actually a simple process, so why isn’t every shop locking down customers and closing new deals? The answers are simple: competition and a poor understanding of customer behavior — the customer journey.

At every stage of the customer journey — awareness, consideration, conversion, retention and advocacy — different businesses take different actions and achieve different results.

Let’s compare two countertop shops in the awareness stage of the customer journey.

• Has a referral program that incentivizes previous customers whenever they bring a new customer.

• Employs data-driven, programmatic ad campaigns.

• Deploys engaging social media content that showcases their work and brand personality.

• Has strategic partnerships with local home design influencers and bloggers.

• Leverages search engine optimization (SEO) strategy to rank highly for relevant keyword searches.

• Has a presence at local home shows, trade events and community gatherings.

• Has attention-grabbing outdoor/billboard advertising in high-traffic areas.

• Optimizes their Google My Business listing and other local directory profiles.

• Has a billboard advertisement about the business.

• Has an unoptimized website.

• Has an inactive social media account.

Considering the positions of these two businesses, potential customers are more likely to discover Company A than Company B because Company A is taking a more comprehensive and strategic approach to building awareness.

But does that solve the problem of maximizing your marketing dollars? Well, not quite. That’s because the awareness stage is only one out of five in the customer journey. What about the other stages? Are you making it easy for customers to find, reach and buy from you? What exactly is working and what isn’t?

The comparison above shows that Company A has a more comprehensive approach to building awareness than Company B. However, not all of those methods would bring the desired results.

Tracking the customer journey begins with breaking down the customer journey into several touchpoints within each stage and analyzing the results each touchpoint delivers.

For example, Company A uses eight strategies to help prospective customers discover their business. However, they might realize after a thorough analysis that:

• Their website, through a robust SEO strategy, is where 30% of their leads originate.

• Their referral program helps them capture 25% of leads.

• Social media brings in 25% of new awareness.

• Their programmatic ad campaigns drive 20% of leads.

By closely monitoring the performance of each awarenessbuilding tactic, the company can understand which strategies are most effective at attracting new customers. This allows them to double down on the highest-performing channels, fine-tune underperforming tactics, and make more informed decisions about where to allocate their marketing resources

Similarly, the company would want to analyze the effectiveness of strategies at the consideration, conversion, retention and advocacy stages. Some key metrics they may track could include:

• Website engagement and conversion rates.

• Lead generation from product visualization tools.

• Customer questions answered by the sales team.

• Customer satisfaction and loyalty program participation.

• Repeat purchase rates.

• Average customer lifetime value.

• Online booking/ purchase completion rates.

• Revenue generated from sales calls.

• Upsell/cross-sell percentages.

Advocacy Stage:

• Online review sentiment and volume.

• Referral program conversion rates.

• Customer testimonials featured on the website.

By deeply understanding the customer journey and the unique impact of each strategy, you can continually optimize your approach to drive maximum awareness, consideration, conversion, retention and advocacy. This data-driven, customer-centric mindset gives you a significant competitive edge.

Tracking your customer journey involves monitoring and analyzing the various stages a customer goes through, from initial awareness to post-purchase behavior. Here are some key steps to effectively track the customer journey:

• Identify Touchpoints: Map out all potential touchpoints where customers interact with your brand, including online

ads, social media, website visits, email campaigns, customer service interactions and in-store visits.

• Set Up Analytics Tools: Use tools like Google Analytics, systems like ActionFlow, StoneApp, Measure Square, and specialized customer journey mapping tools like HubSpot to collect and analyze data at each touchpoint.

• Track Customer Interactions: Implement tracking codes or customized links in digital marketing efforts to see where customers are coming from and what actions they take on your website. Use heatmaps and session recordings to understand user behavior on your site.

• Analyze Purchase Paths: Examine the paths customers take from initial contact to purchase. Look for common patterns and drop-off points using funnel analysis. Tools like Google Analytics Behavior Flow or Conversion Paths can help visualize this data.

• Gather Feedback: Collect qualitative data through surveys, feedback forms and direct customer interviews. This helps to understand the motivations and pain points behind customer actions.

• Use A/B Testing: Conduct A/B tests on different touchpoints (like website landing pages, email subject lines or ad creatives) to determine which variations lead to better customer engagement and conversion rates.

• Monitor Social Media: Track social media interactions and mentions using tools like Hootsuite, Sprout Social or Brandwatch to understand customer sentiments and engagement.

• Integrate Data Sources: Combine data from various sources (website analytics, CRM, social media, customer service) into a single platform for a holistic view of the customer journey. Data integration platforms like Segment or Zapier can facilitate this process.

• Segment Your Customers: Segment customers based on demographics, behavior and purchase history. This helps in understanding different customer journeys and tailoring marketing strategies accordingly.

• Visualize the Journey: Create visual maps of the customer journey using tools like Smaply, Lucidchart or Microsoft Visio. These maps can help identify key touchpoints, pain points and opportunities for improvement.

• Evaluate and Adjust: Regularly review the data and insights gathered to evaluate the effectiveness of your customer journey strategies. Adjust as needed to improve the customer experience and drive conversions.

Harnessing the insights of digital marketing barriers and create a more simplified tracking approach that lets you track your different touchpoints at the various stages of the customer journey. Here are some ways to track effectiveness from first brand engagement through project completion:

• Track website traffic sources, bounce rates and time on site.

• Monitor social media engagement (likes, shares, comments).

• Measure the effectiveness of advertising campaigns (impressions, clicks).

• Survey customers on brand recall and perception.

• Analyze form submissions, live chat inquiries and phone call volume.

• Track lead sources (organic search, referrals, ads, etc.) and lead quality.

• Monitor lead response time and sales team productivity.

• Implement lead scoring to prioritize high-potential prospects.

• Record appointment scheduling rates and customer no-show percentages.

• Evaluate consultation close rates and average deal size.

• Gather customer feedback on the appointment and consultation experience.

• Identify any friction points in the scheduling or consultation process.

• Track proposal acceptance rates and reasons for lost opportunities.

• Measure project timelines, on-time delivery and customer satisfaction.

• Monitor post-project referrals, online reviews and repeat business.

• Analyze project profitability and identify opportunities to improve margins.

Ongoing Customer Relationship:

• Evaluate customer retention rates and churn.

• Analyze customer lifetime value and upsell/cross-sell effectiveness.

• Gather feedback through surveys, reviews and customer interviews.

• Identify ways to strengthen loyalty and advocacy.

By closely monitoring these touchpoints across the customer journey, you can uncover valuable insights to optimize your marketing, sales and service strategies. This data-driven approach allows them to deliver a seamless, high-quality experience that maximizes customer acquisition, retention and advocacy.

You’ve spent thousands or even hundreds of thousands of dollars this year marketing your business, aiming to reach qualified leads, retarget warm leads and previous customers, and maintain your referral program. Now what?

To optimize your core customer journey, you must first understand which marketing efforts yield results and how much. This understanding will enable you to decide which strategies to keep (if it’s great), discard (if it’s not working), or improve upon (if it has potential).

This leads to the question: How do you calculate your marketing return on investment?

Let’s assume your business ran a one-month digital advertising campaign with the following costs and performance:

Campaign Costs:

• Ad Spend: $20,000

• Ad Management Fees: $3,000

• Total Campaign Costs (Ad Spend + Ad Management Fees): $23,000

Campaign Performance:

• Website Visits: 25,000

• Leads Generated: 52

• Consultations Booked (Qualified Leads): 38

• Projects Sold: 27

• Average Project Value: $5,000

Now, calculate the customer acquisition cost (CAC), or the total expense incurred to acquire a new customer, by dividing the total marketing and sales costs (total campaign cost) by the number of new customers.

$23,000 / 27 = $851.85.

This means that you spent $851.85 to make a $5,000 sale. Now, calculate the revenue generated from the campaign.

(Projects Sold × Average Project Value = Total Revenue)

27 × $5,000 = $135,000

(Total Revenue / Total Campaign Costs = ROI)

$135,000 / $23,000 = 5.87

This means that for every dollar spent on the digital advertising campaign, the business generated $5.87 in revenue.

(Total Revenue – Total Campaign Costs / Total Campaign Costs x 100)

$135,000 - $23,000 = $112,000

$112,000 / $23,000 x 100 = 487%

There are plenty of how-to marketing guides out there, but this one focuses on tried-and-true methods that are essential for every business. No, it won’t walk you through how to set up a social media page, but it will offer you the advice you can implement today to see results like more customers and better performance in your marketing.

The impact of effective marketing is staggering, but incredibly hard to get right. Only by learning from the successes and failures of businesses in recent history can we see a clear path to harnessing marketing’s true power. Reacting to the ever-changing environment around you and using it to your advantage is the best possible strategy.

Marketing Magnifier examines what crucial elements are required to propel your business by examining what has worked and failed for many modern organizations in real-life situations and how to apply them.

This is not just another marketing book … it is the key to growth above and beyond your expectations.

Filled with invaluable knowledge, advice and strategies, this book is a mustread for every business professional looking to climb to the top, carve out a market and bring in more business. Get your copy at www.miliamarketing.com/purchase-marketing-magnifier-book/.

In this example, the return on investment using digital advertising was high, indicating a highly effective and profitable campaign.

Understanding this ROI is crucial for comprehending the customer journey, as it highlights the stages where marketing efforts are most effective. You can identify critical moments in the customer journey that drive engagement and sales by analyzing which touchpoints and interactions lead to high conversions and revenue. This insight allows for more strategic allocation of marketing resources, targeted improvements in customer experience, and refined messaging to enhance customer acquisition and retention.

The most successful businesses take a comprehensive, datadriven approach, diversifying their tactics to maximize visibility and lead generation while strengthening long-term customer relationships and advocacy. This holistic view of the customer journey is a critical competitive advantage in today’s crowded marketplace.

Ultimately, the ability to deeply understand and continually enhance the customer experience separates industry leaders from their competitors. Companies that prioritize this customer-centric mindset will be well-positioned to attract, delight and retain their ideal customers.

C C C C A A A A B B B B 2 2 2 D V V V V

Anthony Milia owns Milia Marketing, an award-winning digital marketing agency specializing in solutions for kitchen and bath dealers and fabrication companies. They help clients build brand awareness, improve lead generation, boost sales, increase audience engagement and enhance customer retention. Anthony’s approach has consistently raised the digital marketing standard, helping companies distinguish themselves in this competitive market. He is also the acclaimed bestselling author of Marketing Magnifier, an actionable guide to effective marketing strategies. Schedule a consultation by visiting www.miliamarketing.com/discovery.

By Tim Saddoris, president of Grand Onyx

Many surface fabricators think it’s too complex or they don’t have the technical chops to harness artificial intelligence, but that’s not true. In a lot of ways, AI is easier than using Google — and even replacing Google in many cases. So, let’s dig into AI and why it’s essential to understand what it can do in our industry.

So, let’s look at the four levels of AI and how you can put it to work for your business.

Level 1: Ask a question. ChatGPT works by responding to user-generated prompts. Prompts are questions that you ask to get answers. Here are some examples of how this plays out.

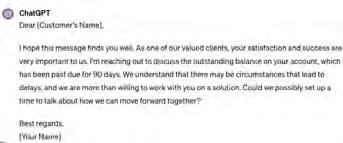

Writing Friendly Past Due Notices: Let’s say you have a customer that is 90 days past due. Ask ChatGPT to write a fivesentence email with empathy, mentioning that you are a surface fabricator business and that they are one of your top customers. It drafts the email in seconds.

Creating Photos for Your Website or Sales Brochure: AI can generate photos. I had a customer who wanted to do inhome consultations for retail sales but didn’t have any photos for their website. So, we had AI generate them for us. The examples below are all AI-generated and immediately improved the professional look on their website as they launched a new service line.

Level 2: Provide Data. AI can also help you sort data and find the key insights you need to make better decisions.

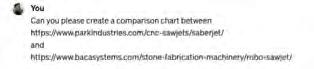

Product Comparison: Maybe you are trying to decide between two different machines. You’re not an automation expert, and they look very similar. So, ask AI.

In seconds, you get the information to compare more easily. The paid version of ChatGPT can go out to websites, pull information, and put together a chart like this:

While this may not be enough information to decide on a significant investment like this, it can give you a quick overview. If you had a PDF of detailed specs, you could upload it and ask AI to go into greater detail. It’s an independent business consultant that can provide basic advice.

You might also ask about the key things you should consider in making such a purchase and get a list of things you should think about. While the list might not be all-inclusive, it can help make sure you’re not missing something important.

Contract Review: Contracts are often laden with lots of

legalese. Want a quick overview? Upload the contract and type in your prompt. ChatGPT will quickly scan all pages and provide you with a list to review, in order of importance.

While it’s not going to replace your careful consideration or your legal adviser, we’re only in version 4 of ChatGPT. Future iterations will only get better. For now, think of it as a tool to help you focus on the big things.

Other ways you can use AI to help guide your business decisions include balance sheet analysis, customer sales trends, dent analysis, and material and inventory trends. Like the contract example, you can upload the data and ask questions to pull out insights or trends you might spend a lot of time parsing yourself or overlook entirely.

Level 3: Create an Avatar. Using AI, you can create an avatar that acts a certain way. For example, almost nobody in the fabrication business has a human resources manager. However, you still have to deal with human resources obligations.

Job Descriptions: Let’s say you need to write a job description. You can train ChatGPT with a sentence like, “You are an HR manager for a surface fabricator.” Provide your website address, and it will learn about your business. Then, you can guide the AI engine in creating your job description. Now, when you ask AI to create a job description for an installer for your business, you might get a result like this:

You can refine the output to get as detailed as you want. Perhaps you want this to be more specific to your company and how you do business. You’re competing with every other

business looking to hire skilled labor, so you need to do a little more selling of what you have to offer to grab someone’s attention. You might prompt ChatGPT with something like this:

Notice what we’re doing here. We are asking ChatGPT what information it needs to improve the quality of its output. In response, you’ll get questions you can answer to help hone the job description.

Aswering these questions will create a more customized output that fits your business and gets people excited about joining up.

Sales Training Sessions: Maybe you want to hold sales training for your team. By defining your avatar as vice president of sales, you can ask ChatGPT for a training itinerary. One of our clients did so and created a structured sales training strategy for a Saturday session. With prompting, It then helped break down the sessions, such as classifying customers when they walk in your door, upselling, closing techniques and more.

Level 4: Process Automation. This is where you bring everything together. For example, I use an AI notetaker in all my meetings. It records the meeting.

At the top of the screen on the left, it even suggested next steps, ideas and open questions that need answering. About 10 minutes after the meeting concluded, it was delivered to my mailbox, letting me search and find key points quickly. Another example is shop floor efficiency. In this image, cameras are monitoring baristas in a coffee shop. On the right side (blue), it’s tracking how many cups each barista produces. On the left (green), it tracks how long each customer has been in the shop.

Think about how this could apply to your fabrication business. Maybe it analyzes fabricator and forklift routes on the shop floor or tracks the amount of manual labor a job takes to ensure you get the margins you need.

How often have you overheard a conversation like this? A customer calls with a question like, “What time do you close?” The salesperson answering the phone says, “We close at 5,” and ends the call. That is not what you want to happen. They missed an opportunity to engage with a customer, get an idea of their project and set an appointment.

We can record and take the transcriptions of all the phone calls and ask AI to analyze all calls. By uploading the data (Level 2), AI can provide the data on what’s being discussed and whether your reps are following up with questions and setting appointments.

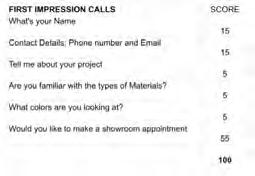

We then apply Level 3, which is creating an avatar. In this case, we might find a well-known sales expert you trust and ask ChatGPT to analyze the data in their style. You can get a scorecard along with recommendations. Bringing it all together in Level 4, you can create a way to improve performance. For every incoming call, you can score calls based on the key questions your AI avatar expert says you need to ask.

Now, let’s score a new call based on these questions. Here’s a typical conversation between a potential customer and Greg, your sales rep:

Agent: Good morning. This is Greg. How can I help you?

Caller: Yes, I was wondering what your price ranges are for granite countertops.

Agent: I would say they probably start at about $100 per square foot, templated and installed, and certainly go up from there.

Caller: Got it. And do you offer financing?

Agent: We do not.

Caller: OK, thank you. Bye.

In this quick conversation — based on the things you want your salesperson to do here — you can score performance on each question and see that they clearly failed.

By doing this on each call, you can help Greg develop the right habits, providing concrete feedback about whether they are following your sales process and drawing customers into the sales funnel.

AI isn’t going to replace Greg. You need that authenticity and human connection, but AI can work as a teaching agent to help improve your sales process.

But wait! There’s more! In this constantly evolving landscape, new developments are unfolding. Here are some AI opportunities that we think can have a big impact on this business:

• Improving your closing rates: analyzing thousands of calls

to find top performers and uncover what they do to generate sales.

• Saw scheduling: pulling data out of your system and helping automate scheduling.

• Inventory predictions: better demand forecasting and inventory reorder points.

• Shortening installs: how you manage client scheduling and reminders.

• Shop floor and efficiencies: optimizing your workflow and improving your margins.

The bottom line: You cannot afford to be left behind when it comes to AI. Many of you in the fabrication business were around before computers or smartphones with cameras, and now those are cornerstones to everyone’s success. AI is the next tool that can help you in ways you never imagined.

Tim Saddoris is the president of Grand Onyx. a firm dedicated to helping stone fabricators increase their revenue by 30% to 300% using proven techniques and a World Class Blueprint System to help you build a more profitable, scalable business. They help companies refine their sales process, uncover insights about better ways to sell, and coach sales teams for greater success. Learn how Grand Onyx can help your business grow at www.grandonyx.pro.

By Sarah Peiper

The surface fabrication industry relies on software and technology solutions to enhance efficiency, precision and creativity. Here are a dozen of the most popular solutions used in this industry, designed to streamline processes, monitor material inventory, track jobs, review metrics and provide a richer experience for your customers — all of which lead to better margins and more sales.

ActionFlow’s intuitive countertop fabrication software simplifies operations through automated task management, end-to-end tracking, and centralized, cloud-based data storage. The advanced insights you gain with our solutions empower you to make better decisions for your business and minimize chaos and disorganization.

Key functionalities include customer relationship management and project management, allowing users to create, assign, and monitor tasks and milestones throughout the fabrication process. Inventory management is another crucial feature, enabling users to keep track of materials, supplies and equipment, ensuring that resources are available when needed.

ActionFlow also excels in production scheduling, providing tools to plan and organize production workflows, assign jobs to specific machines or workstations, and track progress in real time. Its integration capabilities allow seamless communication with other software systems, such as accounting and CAD, ensuring a cohesive workflow. Learn more at www.actionflow.net.

In stone fabrication, accuracy is nonnegotiable.

Flexijet Stone software offers easy and precise measurements, from wall cladding to countertops. Measuring digitally with Flexijet cuts out guesswork, capturing exact scribes even on uneven surfaces. The built-in camera ensures clarity for design and installation.

The new and improved “Find angles between pieces” feature enables operators to easily find angles between complex surfaces and stamp them onto drawings.

Complex projects with multiple planes interacting were challenging in the past. With Flexijet 3D, measure surfaces in 2D and visualize them coming together in 3D to understand how the pieces meet. Flexijet 3D allows operators to measure complex projects efficiently and accurately with multiple angles for cut and assembly.

Flexijet Stone reduces trips, minimizes risk and boosts profitability. For more information, visit www.myflexijet.com/stone.

FreePower provides an approach to powering devices, eliminating the limitations of traditional charging pads. This proprietary technology allows for true position-free charging, enabling multiple devices to charge simultaneously anywhere on the surface. It supports a wide range of devices, from smartphones to wearables, making it versatile for personal and professional use.

Physical spaces are always built with longevity in mind, so future-proofing embedded technologies is crucial. FreePower’s firmware is upgradeable over the air, allowing it to adapt to evolving needs and advancements. It provides peace of mind that this solution will stand the test of time and deliver longterm value to clients. Visit www.freepower.io to discover how you can embed this technology into your next project.

Job Well Done is a comprehensive software solution designed to enhance communication and streamline operations fabrication workflows. It significantly improves communication between field crews and office staff, ensuring information flows smoothly and efficiently. Integrating with Moraware Systemize, Job Well Done reduces reliance on paper, facilitating a more organized and ecofriendly workflow.

Key features include Job Well Done Field and Job Well Done Dox, which provide easy access to job information. Users can log in from any mobile device to view all relevant job details. Job Well Done Ping automates communication through companybranded texts and emails for appointment reminders and post-job follow-ups. For more information, visit www.jobwelldone.com.

LT3Raptor is a new digital templating platform designed with a robust cloud-based management hub to make you faster and more efficient in templating and other areas of your process, including job management, programming and more.

This new platform encompasses myriad functions and tools subscribers can access, including LT3Raptor, LPI Cloud, StoneTag label system and LPI Learning Management System. This evolution is designed to revolutionize LPI’s customer experience, bringing continuous innovation, efficiency and seamless collaboration now and in the future to help grow and sustain their businesses. If you are interested in learning more about LT3Raptor, visit www.lt3raptor.com

Moraware’s tools help countertop fabricators easily create quotes confidently and keep everyone (at the office and in the field) on the same page about every job in the schedule.

With CounterGo, simple drag-and-draw features are used to build precise countertop drawings and calculate costs immediately. Create, print, and show professional quotes on the spot, and easily adjust quotes if needed. Moraware also integrates with QuickBooks.

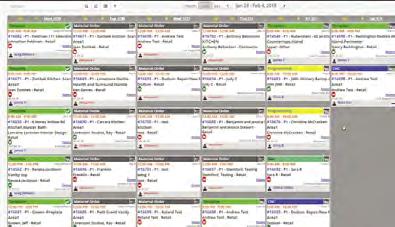

Systemize is an all-in-one-place job scheduling, viewing and management tool. With Systemize, you’ll see every job — and its status — in one master list. See what’s happening, when and where with color-coded calendars for templates, fabrications and installations. See where your crews are working (and where they’re working next) so you can assign jobs more efficiently.

Moraware’s tools are web apps, so there’s nothing to install. You can use a desktop, laptop, tablet or even your phone. Moraware works on a month-to-month contract with no hidden fees or setup costs, and the company offers unlimited support. Learn more at moraware.com.

PHOTOTOP 5 from Fabricator’s Choice just keeps getting better with added capabilities. Functionalities include the ability to auto-create miter strips, autocreate lamination, auto-dimension on PDF output and more. PHOTOTOP 5 makes templating fast and accurate, making the program easy to use. Professional training and online support are available. Integrate templating with office inventory, job management systems and shop equipment. Multiple software licenses are not required to expand PHOTOTOP 5 to additional templaters. Simply order ORGANIZE Field Kits, which include a laptop, camera and markers. The exclusive Organize On-site Tool provides immediate confirmation and file delivery of the most highly detailed digital templates in the business. For more information, visit www.fabchoice.com.

Prodim Factory Software connects field, office and production teams. With four available versions of the software with increasing levels of functionality, businesses can choose the software that best matches their requirements. For instance, the innovative Factory Draw Advanced provides an easy as-is multiple-plane design with insightful 2D and 3D views and solid collision alerts. By entering details like the material type, thickness and glue offset, Factory Draw Advanced can be used to make calculations, identify potential problems and make design decisions. With Factory Full Fabricator, you can even build your digital slab library and match all your slabs in your designs. Prodim’s Factory Fabricator is the complete solution for exactly what it says: Fabrication! For more information and demonstration videos, visit www.prodim-systems.com.

The Basic Bundle of the Slabsmith System includes all essential features and modules necessary for efficient countertop fabrication management. Key functionalities encompass inventory, layout, digital slab creation and more, ensuring a streamlined workflow from start to finish.

Slab Maker is a core component that creates accurate digital slab inventories. It ensures dimensional accuracy and color consistency, minimizing the need for remakes. Slab Maker’s digital inventory facilitates live website updates and allows users to search slabs by size, view stock levels, see committed slabs, and customize queries for sales, manufacturing or accounting purposes. The system can automatically calculate slab values and adjust them when slabs become remnants, providing detailed inventory insights. Perfect Match is the layout software that simplifies arranging slabs. It allows effortless clicking and dragging to position counters and shapes for optimal yield. Job Manager organizes and provides information on all Slabsmith jobs, offering a complete history of processed jobs. Users can find slabs committed to a job, view customer information, change layout statuses and get yield statistics.

To learn how you can decrease operating costs while increasing yield using Slabsmith, visit www.slabsmith.com.

Park Industries has partnered with Taglio Software House to introduce SlabVision, a cuttingedge slab scanning system. This advanced technology enables fabricators to digitize slabs with remarkable detail, using a high-resolution industrial linear camera and an LED lighting system to capture each slab’s true colors and attributes, including thickness, quality and measurements.

SlabVision’s compact design maximizes workspace efficiency, accommodating the needs of modern stone fabrication facilities. Its advanced LED lighting system guarantees consistent image quality by eliminating the impact of environmental conditions like sunlight or shop lighting. The intuitive 24-inch touchscreen interface ensures effortless operation, allowing fabricators to achieve precise results quickly and efficiently. For more information, visit www.parkindustries.com/slabvision.

SlabWare is a software specialized in inventory and sales management for surface fabricator businesses. The solution is designed to transform companies by automating processes, improving organization, and making workflows much more agile and productive.

The company’s goal is to help fabricators minimize pain points. With SlabWise, you can precisely determine slab quantity and seam placement, create professional quotes and invoice customers. Job Tracker helps organize and connect the whole team in a simple and fast way to optimize the fabrication process up to countertop delivery. Users can create and edit packing lists, invoices and more. All features are linked with inventory, so your offerings update automatically online, and all information is accessible from any device. Get a free trial at www.slabware.

StoneApp by StoneGrid is a comprehensive software solution designed to streamline. The app offers multiple modules to enhance efficiency and productivity, covering inventory management, quote management, project management, purchase management and more.

The inventory management feature allows businesses to conduct quick and accurate inventory counts; it integrates with your website, providing real-time inventory to customers and staff alike. For quoting, StoneApp facilitates efficient lead management and conversion. It includes features like web-to-lead forms, follow-up scheduling and the ability to convert leads into quotes seamlessly. The app also allows for detailed countertop drawing and layout. Additionally, StoneApp supports purchase management by generating purchase orders, receiving inventory, and synchronizing with the inventory module to ensure accurate tracking of materials and supplies. This robust solution integrates with QuickBooks, Slabsmith and many other popular tools used by fabricators. Schedule a demo at www.stonegridusa.com.

Explore how software can be as game-changing as new machinery in episode 33 of ISFA’s Behind the Surface podcast. Hear from StoneAPP’s Mickey Gault, a 20-year fabrication veteran, on how to unlock the power of tech and get a roadmap to success.

If you’re considering implementing software or looking for technology that helps you streamline your workflow, this episode is for you. Listen in at www.isfanow.org/podcast-behind-the-surface.

By Louise Scott, Integra Adhesives

When it comes to countertops, selecting the right adhesive and sealant for each application is crucial to ensuring a durable, long-lasting, aesthetically pleasing finish. Adhesives play a vital role in bonding materials where mechanical fasteners fall short. Each countertop application and substrate have unique properties, necessitating a range of adhesives to achieve the best results. By understanding the different adhesives and sealants available, fabricators and installers can make informed choices on which products to use and when.

For undermount sink installations, there are two primary options: a purely mechanical fastening system or a combined mechanical/adhesive fastening system.

Mechanical fasteners use a physical attachment to hold the sink in place. Examples of this type of attachment method include drilling into the underside of the countertop to insert bolts/clips or attaching clips and straps to the wooden cabinetry. Using this method increases installation time and includes the risk of damage to the countertop.

Alternatively, using an adhesive like Component Bonder from Integra Adhesives allows undermount clips to be installed in advance so that onsite, the installer can fasten the clip bolts and fix the sink in place in just a few minutes. The position of the sink can then be easily adjusted, making it easy to apply silicone or MS Polymer to create a watertight seal before tightening it into place. Look for an adhesive with high impact resistance, as sinks are subject to dynamic loads.

Fixing the surface to the cabinet involves bonding two dissimilar materials: the countertop material (solid surface,

quartz or natural stone, for example) and wood (plywood or MDF). The differences in materials bear consideration due to different expansion and contraction rates, moisture absorption, flexion and impact resistance. In these situations, it is best to choose an adhesive with high elongation for flexibility. Fabricators typically consider three options:

• Hot melt glue: Hot melt is quick and easy to remove, making it ideal for templating, but it relies on a mechanical bond, which isn’t suitable for smooth surfaces.

• Silicone: Silicone offers excellent properties for substrate mounting but is slow to cure, with a typical fixture time of 24 hours.

• A specialized product: Substrate Bonder is a specialized product by Integra Adhesives that was developed specifically for this application. It cures in as little as 15 minutes, balances elongation, and has high lap shear strength and speed, making it ideal for this application.

Traditionally, silicone is used for attaching and sealing a backsplash, but unfortunately, it is slow to cure and lacks quick grab. An MS Polymer is a better alternative, offering quick grab and sealant properties in one. Available in a wide range of colors, MS Polymers provide a waterproof and color-matched seal, curing hard for easy cleaning and paintability. These durable products are also excellent for attaching shower panels and creating watertight seals in bathrooms.

Countertop rodding is a technique used to reinforce natural stone. Rodding involves cutting a channel in the stone, inserting

a stainless steel or fiberglass rod, and then encapsulating it. The material thickness, the cutouts and the stone strength determine whether rodding is required. There are a few options for rodding adhesives on the market, but not all are created equal. Essential characteristics are low shrinkage, thixotropic (self-setting) and quick curing for throughput. It’s important to keep in mind that solvent-based adhesives can shrink during the curing process as liquid evaporates. If the adhesive shrinks too much, the channel can pinch in on itself, cracking the stone. It’s also good to use an adhesive that can flow enough to fill the relatively small channel but also sets quickly so as not to make a mess. There are several adhesive options on the market. Three popular choices are:

• Epoxy: offers low shrinkage but has a prolonged curing time, creating bottlenecks in fabrication processes.

• Hand-Mix Adhesives: available options can be wasteful and messy. Incorrect activator-to-adhesive ratios can lead to quick curing, shrinkage and brittleness, reducing the strength of the bond. Thin adhesive consistency is required for application, often resulting in leftover waste and increased fumes during curing.

• Rodding Bonder: a cartridge-based adhesive that cures in less than 15 minutes with virtually no shrinkage. It can be directly injected into channels, minimizing waste and enabling rapid completion.

Color-matched adhesives are essential for creating a seamless look in countertops. Whether you’re pulling a deck seam, lamination or a miter, each type of surfacing material — solid surface, quartz, natural stone, porcelain, laminate and others — has its own adhesive requirements. Fast-curing, high-

strength Methyl methacrylate (MMA)-based adhesives are ideal for solid surface due to their UV stability, moisture resistance and low VOC content. A zero-sag penetrating adhesive is preferable for harder surfaces like quartz, stone or porcelain, especially for onsite seaming with limited space. When working on vertical or mitered angles, a zero-sag adhesive assists with bond strength and reduces mess and waste. For external applications, UV-stable polyurethane adhesives outperform MMA or epoxy in maintaining color and durability. Highvolume shops benefit from rapid-curing MMA-based adhesives to increase production efficiency.

Selecting the appropriate adhesive for each application is vital for achieving durable, high-quality results. Understanding the unique properties of various substrates and applications allows fabricators and installers to make informed choices, ensuring strong, long-lasting bonds and aesthetically pleasing finishes. From undermount sink installations to substrate mounting, backsplash bonding, reinforced rodding and seamless countertops, success depends on using the right adhesive.

Using adhesives over mechanical fixings helps avoid the risk of countertops cracking under dynamic loads, ensuring the longevity and stability of the installation. Additionally, the proper use of adhesives and sealants ensures watertight seals, crucial for preventing moisture damage and maintaining the integrity of kitchen and bathroom surfaces. By leveraging the knowledge and options available, professionals can enhance their craftsmanship, reduce installation time, and ultimately deliver superior results that meet the highest standards of quality and durability.

The principles of the circular economy have guided Finnish manufacturer Durat from the company’s inception. With a desire to use surplus industrial plastics as the raw material for high-end design products, the company is a leader in material innovation and sustainable practices.

By Sarah Peiper