There is certainly a Sammies feel to this issue – as we re ect on a fantastic evening and catch up with some well-deserved winners.

Our sauces and condiments special perfectly illustrates the more exotic avours permeating the market, while our environmental focus examines innovation in labelling and plenty more.

We also o er key advice on handling ingredients, as the weather poses challenges. Cheers!

Editor Alex Bell, Tel: 01291 636349, email: alex@jandmgroup.co.uk

Advertising Paul Steer, Tel: 01291 636342, email: paul@jandmgroup.co.uk

Production Gareth Symonds, Tel: 01291 636339, email: gareth@jandmgroup.co.uk

Subscriptions and Customer Service Tel: 01291 636338, email: subscriptions@sandwichandfoodtogonews.co.uk

Editorial Address Sandwich & Food To Go News, Engine Rooms, Station Road, Chepstow NP16 5PB www.sandwichandfoodtogonews.co.uk

In association with The British Sandwich & Food To Go Association.

PHONE +44 (0) 1291 636338

FAX +44 (0) 1291 630402

WEB www.sandwich.org.uk

EMAIL info@sandwich.org.uk

Paper used in the production of this publication is sourced from sustainable managed forests.

Opinions expressed in this magazine are those of the contributors and not necessarily those of J&M Group Ltd or this magazine. No responsibility is accepted for the opinions of contributors. This magazine is published by J&M Group Ltd. and supports the British Sandwich & Food to Go Association. It is circulated to managers, executives, buyers, retailers and traders in the sandwich industry. © 2024 J&M Group Ltd

ADVISORY

Pages 04-05. Handle with care – Ingredients NEWS

Pages 06-14. Round-up of the latest stories THE BRITISH SANDWICH & FOOD TO GO ASSOCIATION

Pages 16-25. The Sammies 2024 PROFILE

Pages 26-28. Making a di erence – Simply Lunch

Page 56. The gold standard – Ji y Trucks

PREVIEW

Page 30. lunch! show

SAUCES & CONDIMENTS FOCUS

Pages 32-38. Cottage Delight / Creative Foods / Zafron Foods / Real Good Ketchup

ENVIRONMENTAL SPECIAL

Pages 40-54. DTM Print / CSM Ingredients / Protos Packaging / Sabert / Coveris / La Lorraine / Celebration / Prowrap COLD DRINKS

Pages 58-59. A perfect matcha – Delice de France PEOPLE MATTERS

Pages 60-61. Finding a cure to frequent sickness – WorkNest REGULARS

Pages 62-64. New members / New products

Page 66. Classi eds

Page 69. BSA listing index

Jim Winship, the director of the British Sandwich & Food to Go Association, offers advice for the foodservice sector around ingredient storage.

Recent cases of Listeria monocytogenes and E. coli bacteria causing deaths and severe illness highlight the importance of being diligent about maintaining high standards when handling chilled foods.

In the case of the E. coli outbreak,

some 260 people had been affected at the time of writing this article, more than 60 requiring hospital treatment.

Throughout recent weeks, the British Sandwich & Food to Go Association has worked closely with the Food Standards Agency and NHS, with some businesses responsibly

withdrawing products rather than take any risks that ingredients they use might be involved.

None of us want to cause people illness with our products but the reality is that many of these challenging bacteria exist in our businesses and require careful handling if we are to avoid them causing harm.

Listeria, for example, is all around us and unavoidable at low levels –indeed, the bacteria generally do not present a problem. But when they gather on surfaces or around drains

"The maintenance of strict and thorough cleaning regimes, as well as good temperature controls, are the keys to safeguarding customers."

and then multiply, they can become a real hazard for some people, such as the elderly and pregnant women, if they get into the foods we make.

This is why it is so important to keep all chilled products in the right conditions – ideally at below 5°C –as growth will be inhibited at these temperatures. This applies to the ingredients we use, right up to the point when finished products are purchased by consumers.

E. coli is equally concerning as a bacteria, as it also thrives on warm and damp conditions.

The authorities are still seeking to trace the origins of the recent E. coli outbreak but the suspicion is that it came in via Apollo lettuce, highlighting the need to manage ingredients with care. Lettuce, for example, is known to be a potential carrier of some bacteria and must be washed thoroughly, ideally with chlorinated water, and then kept in chilled conditions until used.

In both cases, the maintenance of strict and thorough cleaning regimes, as well as good temperature controls, are the keys to safeguarding customers, as these bacteria generally need warm and damp conditions to grow.

These rules become even more important if the business is adding shelf-life to a product, which is why it is so important to undertake shelf-life tests at end of life to determine that they will remain safe.

For retailers of packaged food to go, a manufacturer or sandwich bar, the same care has to be taken to maintain products at safe temperatures, particularly as consumers may not eat them immediately.

For further information on shelf-life testing or listeria, BSA members can access The Mint Guide. Visit themintguide.co.uk.

The British Egg Industry Council (BEIC) has launched an enhanced Code of Practice for the Production of Lion Quality Egg Products.

The new standard embraces the latest food safety advances, including 64 new criteria, and recognises the fast-moving innovation within the sector. The latest update, Version 3, comes amid ongoing food safety outbreaks linked to eggs and egg products produced outside of the UK.

More than 30 years after the launch of the the processing Code in 1995, it remains the only recognised industry standard for processed eggs in the world. It sets standards across all systems of production, protecting eggs from the moment they are laid to the time they are delivered to food manufacturers and foodservice operators.

In addition to the stringent standards of the British Lion shell egg Code of Practice, which includes over 700 auditable points, processors of Lion Egg Products must adhere to a further wide range of additional standards.

Gary Ford, chief executive of BEIC said: “With food safety incidents continuing to be linked to eggs and egg products produced outside of the UK, maintaining the highest standards remains as important now as it ever was.

“For more than 25 years, the Code of Practice for the Production of Lion Quality Egg Products has provided peace of mind, ensuring retailers, food manufacturers, foodservice operators, wholesalers and other organisations can safely serve UK consumers British egg products without the risk, food miles and challenges of traceability involved in importing egg products.

“I am proud to say that Version 3 pushes the standards even further, incorporating new industry advice and providing specific measures and controls, particularly around some of the new and more innovative products, to ensure that the British public gets the quality, safe and domestically produced egg products they expect and deserve.”

Food safety expert, Sterling Crew, president of the Institute of Food Science and Technology, said: “The announcement of the updated Lion egg processing Code is welcomed by myself and my peers involved in food safety. There’s an assumption that once an egg has been pasteurised that it’s automatically safe but there’s a lot more to it.

“With ongoing food safety incidents involving eggs and egg products produced outside the UK, there are potential risks associated with egg products that aren’t produced to the standards of the British Lion Code of Practice, and I will always insist my colleagues, customers and friends ask for British Lion egg products if they want food safety assurance.”

St. Pancras International undergoes expansion, Premier League footballer unveils sustainability goal and there’s a wealth of new products and openings.

Greggs has entered into a lease agreement for a state-ofthe-art frozen production and logistics facility in Derby.

A strategic growth plan, announced in 2021, set out ambitious expansion targets requiring investment in significant supply chain capacity. As of 12 May 2024, Greggs had 2500 shops trading and it expects to open between 140-160 net new shops during 2024. The longer-term target is to have significantly more than 3000 in the UK.

The new facility is being developed at SmartParc SEGRO Derby on a high-tech food manufacturing site in Spondon. Greggs will occupy a 23-acre plot on the campus. Following the construction by the landlord, Greggs plans to develop the facility and install manufacturing and logistics equipment to optimise efficiency. It is expected to open in late 2026 and create up to 600 jobs.

It will provide additional manufacturing capacity for products – including savoury and sweet production lines – as well as logistics for frozen storage and fully automated robotic shop order picking and distribution solutions from Swisslog. Additional capacity can enable further investments to meet category growth, innovation and development, including the capacity for at least five manufacturing platforms and new production lines to be commissioned to meet volume demand.

The site has been designed with a focus on sustainability, including the use of an on-site shared Energy Centre (a centralised heating and cooling system that recycles heat

from refrigeration plants across the estate), a rainwater harvesting system, PV panels, EV charging points and a secure bike storage to help reduce local emissions.

Roisin Currie, chief executive at Greggs, said: “This purpose-built site offers significant flexibility to add new capabilities and lines as our business evolves. This is a significant step in our supply chain investment and will provide much-needed manufacturing and logistics support to power our ambitious growth plans.”

“It is our ultimate vision that SmartParc SEGRO Derby becomes a hub for forward-thinking food businesses seeking sustainable and efficent operations,” said Jackie Wild, CEO at SmartParc.

Fresh Direct, the UK’s leading foodservice fresh produce supplier, has launched its 2024 summer seasonal range, including around 50 new British lines.

It supports the company’s commitment to driving sales through its Best of British campaign, which champions growers and supports foodservice customers to use more British food on their menus.

Products such as Heirloom Tomatoes from the Isle of Wight, Padron Peppers and British sweetcorn have been added to the range, growing the amount of British produce that Fresh Direct

sells to its highest-ever level.

Paul Nieduszynski, CEO at Sysco GB, said: “Our focus has been on working with customers to increase the proportion of British products on their menus and give them the resources so that they can highlight the provenance of the food they serve from great British growers.

“This year sees us continue to build on our commitment to provide the very best of British produce when it is available and in season. The response from customers has been very positive and the feedback on the early season fruit & veg has been outstanding.”

To support the campaign, Fresh

Direct has produced a range of collateral, including a seasonal brochure, 15 British supplier videos and a bespoke section on its website, all helping to support customers who want to highlight product provenance and share grower stories in their own marketing.

St. Pancras International is rolling out plans to develop its food and beverage offering, welcoming four new permanent retail outlets to the roster. It marks the most significant food and beverage expansion in the Grade 1 Listed building ahead of major international sporting events in Paris this summer.

As part of the station’s capital expansion plans, confirmed openings consist of brands including: Blank Street, Bread & Truffle, Shake Shack and The Breakfast Club. It’s the first time they have set up shop in a UK railway, as more operators consider high-footfall transport locations.

The hub is reacting to demand from customers for a variety of dine-in and takeaway food & beverage options, particularly answering calls for an increased breakfast offering. Market intelligence agency, Mintel, has reported a significant rise in breakfast and brunch occasions nationwide, noting a 6% surge in breakfast dining out experiences in only two years (from 29% in 2021 to 35% in 2023), while levels of customers dining out for lunch, dinner

and snacks remained constant – demonstrating a macro trend of increasing consumer appetite to dine out across the country, propelled by breakfast specifically.

Longer dwell times (now averaging 45 mins) have also contributed towards demand, resulting from a growing number of domestic and international leisure customers, as well as a return to offices for commuters, with St. Pancras servicing the Kings Cross area – host to numerous large office complexes from the likes of Google, Havas and Universal. With experts predicting that train stations will become essential food destinations in 2024 as visitors seek more local experiences, St. Pancras is evolving its response.

Wendy Spinks, commercial director at St. Pancras and HS1 Ltd, said: “We’re delighted to be welcoming four new brands to our portfolio of F&B offerings and are thrilled that each has chosen St. Pancras as their first railway location. Ahead of major international sporting events in Paris this summer, it’s a good time to introduce new brands and provide greater capacity for customers.”

Instant grocery delivery service, Gopuff, has announced a new partnership with Barclaycard, with exclusive offers to help lower the cost of grocery baskets.

Gopuff shoppers using Barclaycards at checkout are eligible for two exclusive offers, making it easier and more affordable to get groceries delivered in minutes.

New Gopuff customers paying with their Barclaycard can now enjoy £10 off their first four orders when they spend a minimum of £25 per order.

In addition, new & existing customers who sign up for Gopuff FAM with their Barclaycard will receive six months of free membership (normally £5.49 per month). Gopuff FAM gives members access to members-only weekly deals, no delivery fees and exclusive discounts on everyday essentials. Customers taking up this offer can expect to see a saving of over £150 over a six-month period, with the top 10% of Gopuff customers saving over £750*.

Leon Tang, director of growth from Gopuff, commented:

“Gopuff has partnered with Barclaycard, as our shared values focus on delivering added value and an optimal experience to customers. In light of the turbulent economic climate, we are continually exploring new ways to offer high-quality products at competitive prices, making our services more accessible to budget-conscious consumers.”

This offer is available to new FAM subscribers and existing Gopuff customers without a FAM subscription. Valid until 6 December 2024.

It’s another industry first from H-Pack - the Hot ‘n’ Fresh range of unique, top quality, kraft food containers.

With an unusual, subtle, octagonal design, our eye-catching, kraft food boxes stand out from other food boxes, providing a different style of sustainable food packaging to the norm.

Available in a selection of sizes, from 300ml and 400 ml to 650ml, 750 ml and 1000 ml, the exclusive containers come with robust PET lids, allowing the contents to be shown off and admired.

Complementing any good-quality food to go offering, the octagonal, kraft box is the perfect solution for those who want packaging that is substantial and high-class.

Chopsticks are being recycled to create statement pieces of interior furniture at a new business which has just opened, led by footballer Tom Davies.

An estimated 80 billion chopsticks are used across the globe every year. ChopValue has diverted over 160 million from landfill, while storing 7,890,770kg of CO2 emissions.

Opening in Liverpool, ChopValue UK has collected close to five million chopsticks. The business is also setting a precedent as the first Microfactory location in the network to operate an electric van for community collections

With growing consumer adoption of sustainable products, ChopValue UK officially opened during Great Big Green Week (8-16 June). In the next year, ChopValue UK is projected to convert 25 million chopsticks into premium climate positive products, saving up to 1,200 tonnes of CO2 emissions from being released into the atmosphere.

The company’s vision is to redefine the term ‘waste’ to ‘resource’, inspiring other businesses to join the circular economy, which is estimated to yield as much as £3.5 trillion in economic benefits over the next decade.*

“We are paving the way for a greener future, where not only waste streams are transformed into valuable products made to last, but we can also source, produce and distribute locally in our communities,” shared Davies, managing director of ChopValue UK.

“I visit the Microfactory and experience the craft behind

Stables Pies is the latest Northern brand to become a Blackburn Rovers Associate Partner. In a deal brokered by sports rights specialist, Eleven Sports Media, the wholesale baker is set to raise its profile as it benefits from the Associate Partnership programme that provides a full range of marketing prospects across multiple engagement platforms.

Benefits include branding in and around Ewood Park, including the Pitch-Facing LED platform and across Eleven’s StadiumTV and StatTV. Stables Pies will also have the chance to expand digital reach, as its branding will feature on Eleven’s online StatZone content and match-led social media posts, via platforms including Facebook and Twitter.

Co-owner of Stables Pies, Callum Robertson, believes that his business is a perfect fit for the Blackburn Rovers Associate Partnership: “We’re in the business of making and selling pies which are, of course, historically the leading food of choice for football fans. Our pork pies are particularly famous in the region and surrounding areas, having won a string of awards. They’ve cultivated quite a following and we are hoping to build on that with this new association and expand our own network of fans.

“This is a chance for us to engage with our regional

our products. I’ve enjoyed getting stuck into every aspect of the business, from literally sorting bags of used chopsticks after collection, to working the laser engraving machine.”

Davies also envisions a tangible route to sustainability for the sports brands he has cultivated strategic relationships with. “As a footballer, I am grateful for the platform my career has provided me and am committed to lead by example. Educating others on subjects like the importance of sustainability and responsible manufacturing is my priority, with the goal of ensuring upcoming generations have the same resources we have been fortunate to have.”

“It’s our mission to leave no chopstick behind and given the extraordinary amount that are sent to landfill every year, there’s a huge job to be done,” shared Neil Sang, UK director of ChopValue UK.

“ChopValue UK not only looks to turn waste into resource but instil the importance of circularity and sustainability into the communities our Microfactory operates in.”

customer base and further raise our profile in the local community. The Associate Partnership is something I am personally proud to shout about as I am a huge Rovers fan.”

Established in 1920, Stable Pies was purchased by the Robertson family three years ago and the owners are keen to run it as it was set up – as a family business. Currently on sale in butchers and delis, the baker is now keen to introduce its full range of pies to new markets, including supermarkets and leisure outlets.

For further information, visit stablespiesltd.co.uk.

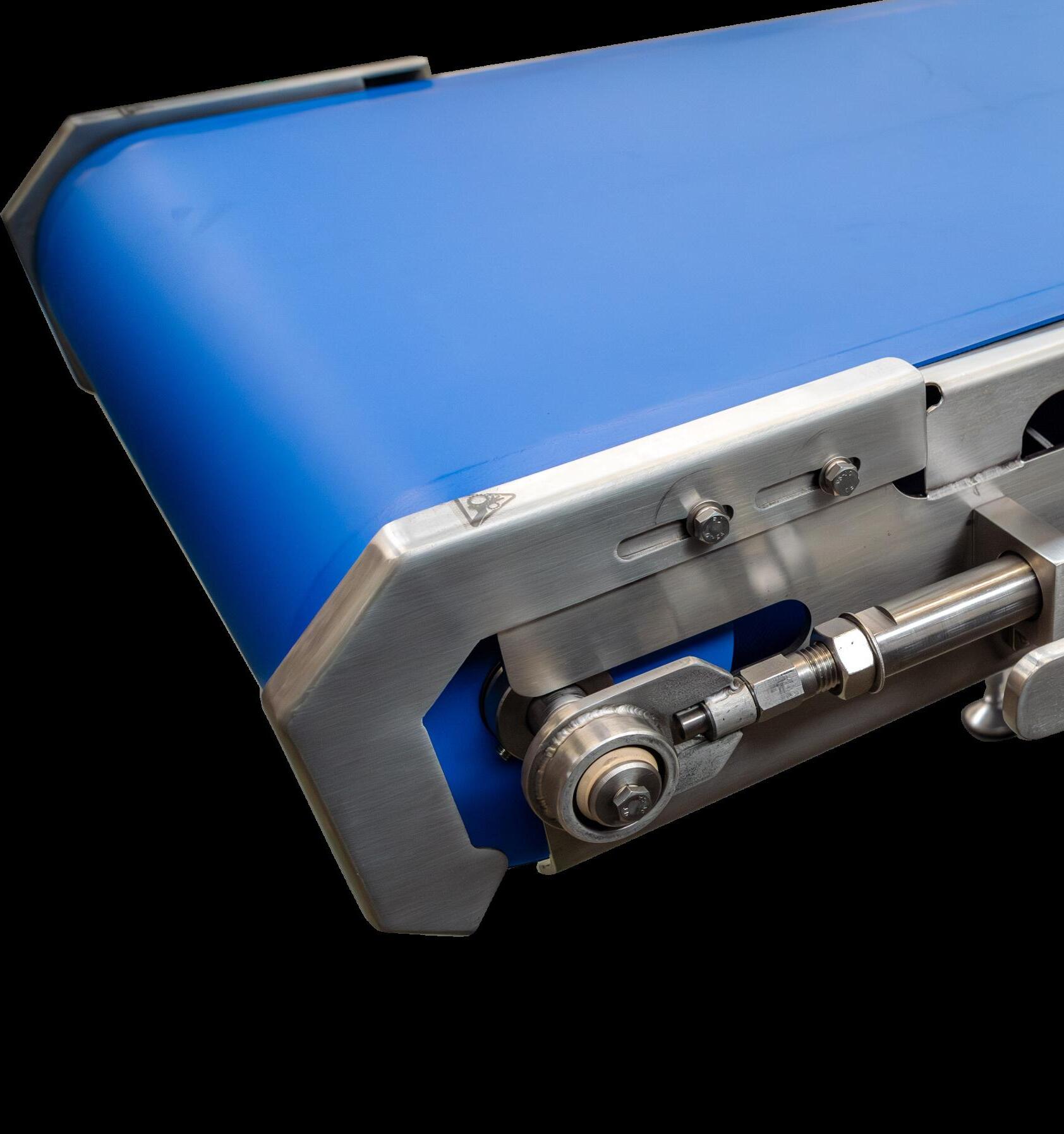

Southwest Sandwich Company has launched its state-of-the-art factory in Cullompton, Devon. It marks an exciting chapter for the company as it expands capacity to produce over 50,000 sandwiches and food to go products per week, meeting growing demand and supporting the retail trade within the territory.

The purpose-built site has worked with Millitec Food Systems and Jenton for Soken products for machinery and general equipment needs, along with Aspen on the factory build. In addition to sandwiches, Southwest Sandwich Company has introduced a range of FTG options, including baps, subs, flapjacks, salad and fruit pots, pies, pasties, sausage rolls and quiches. This expanded menu is crafted to cater to the varied tastes and preferences of customers, ensuring there’s something for everyone.

“We are thrilled to unveil our

new factory and introduce an even wider selection of FTG options,” said Rob Pascoe, director. “With our commitment to quality and convenience, we aim to fully support customers, whether their requirements are a classic sandwich or trying one of our new offerings. Our doors are firmly open for business and we welcome any enquiries on what we can do and of course encourage clients to come and see what we have created in the South West. From our brands to your brand, please contact us to find out more.”

Southwest Sandwich Company operates its own delivery team and

company vehicles, ensuring timely delivery of orders up to seven days a week. This streamlined approach reflects a dedication to providing exceptional service and convenience. In addition to individual outlets and store requirements, Southwest Sandwich Company offers the ability to work with retailers on their specific product requirements.

Fri-Jado’s latest technical innovation is designed to further ease the burden on busy operators and retailers nationwide with its new self-cleaning condenser, available across the allnew Deli Counter (DC) and Modular Convenience Counter (MCC) ranges.

The MCC range is described as an exceptional combination of performance, efficiency and interior visibility, with this latest innovation ensuring that all relevantly equipped DC & MCC units perform better than ever, while offering simpler service cycles and enhanced product safety.

All chilled cabinets feature a condenser in which refrigerant gas is cooled. This unit condenses the cooled refrigerant into a liquid to chill the storage and display areas of the cabinet, before repeating the cycle. This tried and tested technology has functioned for many years but within just a few days of operation, even in brand-new machines, dust build-up can collect within the unit – inhibiting optimum performance and requiring regular cleaning alongside a planned

schedule of preventative maintenance and potential downtime inefficiencies.

An innovative self-cleaning condenser in the new range features a special motor and control unit which reverses during regular defrost cycles, blowing air back over the condenser and helping clear it of the dust which can adversely impact performance. This helps customers by eliminating the need to manually clean the condenser as often, meaning that both the DC and MCC units function more efficiently, consume less energy than if it were clogged with dust and, of course, help to increase operational safety and security.

Alongside these operational and cost-saving benefits, both the MCC and Deli Counter ranges continue to offer Fri-Jado’s internal visibility – showcasing more of the food that customers want to buy, as well as letting operators stock and display the food in the best possible manner.

Gary Thacker, sales director of Fri-Jado UK, said: “We are genuinely committed to investing in technology

that offers our end-users tangible benefits. The self-cleaning condenser installed in our all-new units offers more than just enhanced performance and optimised energy consumption; it offers true peace of mind to users. Once installed, both units will keep on doing their job day in, day out, with minimal intervention from users.

“Not only will you have reduced engineer visits, but energy consumption will decrease – along with a reduction in energy costs – and staff can concentrate on keeping the unit well-stocked and selling more. We know that customers already choose Fri-Jado because of the way our units look, how they showcase the food and perform daily. With a focus on maximising staff time, increasing the whole life value of your equipment, and the high performance demanded by every channel, the new selfcleaning range from Fri-Jado simply means that operators and end-users have one less thing to worry about!”

Find out more at frijado.com.

Marketed as a tastier snack option, Bodega’s continental-inspired snack boxes are available in WHSmith fridges nationwide.

WHSmith is the latest retailer to stock Bodega’s Chorizo and Smoky Salami snack boxes, for customers wanting a satisfying choice on the go.

“This is a very exciting time for Bodega, as we’ll now be able to target an increased number of customers nationwide through WHSmith stores,” explained Dorota Lawrence, category marketing manager at Bodega. “Perfectly portioned in a format that lends itself to any occasion, Bodega can be enjoyed while at your desk or on the go.”

Commented Paige Malyon, buyer for chilled snacking at WHSmith Travel, “Premium, on the go snacking has never tasted so good! Try these two delicious flavours on your travels in WHSmith this summer.”

The boxes combine carefully sourced charcuterie, cheese and crunchy toasts for a treat that is high in protein, a good source of calcium and under 250 calories a pack. There are two options in the range.

Chorizo combines paprika-spiced chorizo, creamy Cheddar and crisp toasts. Bodega’s Spanish chorizo is cured in Murcia, in the south-east of Spain’s Iberian peninsula. It is enhanced with garlic and paprika then carefully matured. Paired with moreish and characterful medium mature, creamy cheddar with its smooth texture and snackable mini toasts, oven-baked for crispness and crunch.

Smoky Salami is a combination of German meat, creamy Cheddar and crisp toasts. From the heart of the North Rhine Westphalia, its smoky German Salami is seasoned with pepper and garlic, then beechwood smoked and slowly matured.

“We have experienced a growing demand for products, influenced by experimental tastes. Snack boxes are the new sandwiches!” said Lawrence.

Available in WHSmith stores nationwide, including at airports, train stations and service stations.

Check out mybodega.co.uk.

Here at Soken Engineering we have 20 years experience, including worldwide sales. Our innovative UK built all electric machines range from low-cost entry level to high throughput production line models.

Increases shelf life (for up to 3 days)

Less food waste

Greener packaging options

Food-to-Go and Convenience packs

Chicken Cottage has revealed ambitious global expansion plans to reach 100 stores by 2027.

The UK-based QSR business, celebrating its 30th anniversary this year, has more than 60 outlets across the UK and a foothold in Kenya. Both are prime markets for additional growth, with further targets in Europe.

Chicken Cottage, which was the first UK QSR to introduce halal chicken in grilled and fried varieties at its Wembley branch, has undergone significant change in recent years under CEO Greg Milne, to enhance customer experience.

Under his watch, the Croydon-based operation has overhauled the brand with a fresh in-store design which is currently being rolled out across the UK, it has introduced in-store digital kiosks, while also creating a consumerfocused mobile app.

These improvements, combined with changes across the management team, have put the business in a strong position to commence its expansion programme, which recently added to its portfolio of locations with outlets in Carnoustie and Hemel Hempstead.

“In the UK alone we’re looking at growing to at least 66 stores this year,” said Milne.

“Our growth for the next three years is set at reaching 100 stores by 2027. It’s an aggressive transition from where we were two years ago to where we’ll be in three years.

“Our target area for growth in Europe is France, Germany and Ireland. We are also looking at Africa, because we’ve got a base there already.”

Chicken Cottage anticipates existing franchise owners will expand their businesses with additional outlets in the UK. However, as part of the programme, Chicken Cottage is looking to bring on a number of new franchisees.

A key location for the business is Kenya, where Express Kitchen, a subsidiary of Hass Petroleum, operates the franchise.

Express Kitchen opened its first location in 2022 and has now reached three stores. Bosses at Chicken Cottage have said the business aims to reach 50 stores in the next 10 years.

Sadaf Kazi, franchise development partner at Chicken Cottage, emphasised the strategic importance of these expansions. “Our focus is on sustainable growth and delivering an exceptional experience for our customers. The confidence our franchisees have in our brand is increasing, and we are dedicated to supporting them as we continue to expand our global presence.”

F M C G F O O D D R I N K

Hosted by comedian Charlie Baker and celebrity chef Theo Randall, the Sammies Awards Dinner was a spectacular celebration to remember.

The glittering event saw 500 retail, manufacturing and supplier peers come together to celebrate another year’s worth of new products, marketing initiatives, environmental strategies and overall positive performance.

With entries at an all-time high across each of the 19 categories, the panel of industry experts had to work hard to whittle down to a shortlist and decide on the eventual winners.

Jim Winship, BSA director, said: “Every year we hold our annual Sammies awards, and we are always wowed by entrants across the plethora of categories. Even with the long-term impact of the pandemic still being seen by many, it’s really promising that the sandwich industry is thriving, and consumers are choosing to spend money on the much-loved staple.

“It was a demanding year for our judges as the entries were just so good! It was a pleasure to present every single winner, from retailers to manufacturers, and suppliers alike.”

The presentations got underway with the Sandwich & Food to Go Designer competition results. Five category winners were announced before the overall winner was revealed. James Burgess from Freshcut Foods blew away the judges with his California Prawn Roll and claimed the title and £2000 prize.

“The Sammies are the benchmark for excellence in our industry, with the range of awards acknowledging new products, marketing creativities, green initiatives, overall performance and so much more.

Hot on the heels of the Sandwich Designer presentations the awards came thick and fast, including Dene’s Deli from Newcastle upon Tyne claiming the Independent Retailer Award; recognition for Dawn Farms’ continued commitment to the environment and Simply Lunch taking away the Manufacturer of the Year Award.

The second section saw big-name winners including Greggs, WHSmith Travel and a trio of awards for the team at M&S.

The presentations concluded with

the Sandwich & Food to Go Industry Award going to Raynor Foods for their outstanding contribution to the industry.

As the formal proceedings concluded, the real fun began with the guests partying into the early hours with DJ to the Stars, Tony Perry.

The final word belongs to Jodie Johnston, category technical manager for M&S, one of the biggest winners on the night.

“We are celebrating three amazing awards and are super proud about the categories that we have won.

Everything we have done this year has been brave, bold and technically challenging, and the recognition from the industry with these trophies means the team and Greencore have been rewarded.”

Presented to a business or individual who the BSA Management or Committee consider deserves recognition for the work they have done to advance the UK sandwich and food to go markets.

WINNER

Raynor Foods

Presented to the overall winner from the five sponsored categories, whose creation was deemed the best by head judge Theo Randall and the other industry experts on the judging panel.

James Burgess, Freshcut Foods

This award shines a spotlight on the independent retailers, leading the way in new trends and tastes.

WINNER

Dene’s Deli, Newcastle upon Tyne

This award will recognise the work being done by the café retailers to develop either the high street or in-store market.

HIGH STREET CATEGORY WINNER

GAIL’s Bakery

Focusing on travel, from forecourts and service stations to airports and trains, this award recognises the work these businesses are doing to develop and drive this sector.

WINNER

BP Wild Bean Cafe

This award will recognise the work being done by the café retailers to develop either the high street or in-store market.

M&S

This award recognises the work being done by the chain retailers in developing the market in the high street.

WINNER

Greggs

This award recognises those retailers who have done the most to develop their business over the past year.

WINNER

M&S

This award recognises the work being done by the convenience retailers to develop the sandwich and food to go market in the high street.

WINNER

Scotmid Co-operative

This award recognises development and innovation in the food to go market by manufacturers and foodservice businesses.

WINNER

Greggs - Mozzarella & Cheddar Bites

This award recognises development and innovation by suppliers within the industry and looks at both ingredients and packaging/equipment.

INGREDIENTS CATEGORY WINNER

Grow Up Farms - Unbeleafable

This award recognises development and innovation by suppliers within the industry and looks at both ingredients and packaging/equipment.

PACKAGING/EQUIPMENT CATEGORY WINNER

Sabert - Snap2Go

Open to any sandwich (not a range) this award rewards innovation within the sandwich market.

This award recognises business developments that have helped progress the industry.

PLANT-BASED CATEGORY WINNER

WHSmith Travel - Bang Bang Chickpea Wrap

Open to any sandwich (not a range) this award rewards innovation within the sandwich market.

COLD CATEGORY WINNER

Booths - Coronation Chicken Wrap

Flexeserve® - Connect by Flexeserve

Open to any sandwich (not a range) this award rewards innovation within the sandwich market.

HOT CATEGORY WINNER

Starbucks Ireland - Holiday Ham & Cheese

This award recognises the work being done to provide consumers with new, interesting and innovative healthy eating products.

WINNER

M&S - Korean Chicken Egg Wrap

Recognising the importance of marketing, this award is presented to a sandwich or food to go retailer, manufacturer or supplier who has initiated a successful and innovative campaign to achieve strategic goals.

WINNER

Subway - Creme Egg SubMelt

This award is designed to recognise the work being done at all levels of the industry to reduce the sector’s impact on the environment and improve sustainability.

WINNER

Dawn Farms - Sustainability For All Our Futures

This award recognises the overall contribution made by manufacturers to elevate and grow the industry.

WINNER

Simply Lunch

9 May 2024. Royal Lancaster, London: In a superb nal, James Burgess of Freshcut Foods stunned the competition and the judges.

A brioche roll filled with fresh, colourful ingredients, including black tiger prawns coated in a passion fruit and mango chilli dressing, fresh avocado slices, pink pickled onions and diced mango earned James the title of Sandwich Designer of the Year 2024.

Named ‘The California Prawn Roll’, the sandwich wowed the judging panel of industry experts, including celebrity chef Theo Randall, Abby Catmull, Waitrose and Dan Barrett, Gails’ Bakery with its fresh ingredients bursting with colours and flavours.

The sandwich is an indulgent sunshine twist on the muchloved prawn cocktail, pulling fresh fruity flavours that work with the sweet delicate prawns.

Talking of the prestige of winning, James said: “It’s an absolute honour to be shortlisted as a finalist, let alone be named the Sandwich and Food to Go Designer of the Year! It was a really tough competition, given every designer put forward their best creations, which were full to the brim with flavour.

“I spent a lot of time working on the three creations which got me to the final. The California Prawn Roll, which won the title, brings Californian sunshine to the UK. I specifically chose

ingredients which were full of colour, to make the creation as vibrant as I could – it really does taste as good as it looks. I also topped the sandwich with some caviar because why not? I don’t think the award win has truly sunk in just yet. All I can say is that I’m very proud!”

Jim Winship, director of The British Sandwich & Food to Go Association, said: “During the competition, we tasted some truly amazing food, with ingredients like pulled spiced lamb, horseradish mayonnaise and crispy cheese crackling. Our chefs have managed to push the boundaries of innovation. All contestants should be enormously proud of themselves.

“James’ creation included ingredients that married together perfectly, and the judging panel remembered them all individually, even many sandwiches later, which made this creation stand out as the clear winner.”

SPONSORED BY

Gorgonzola Piccante Category Winner

Honey, I’m Feeling Blue – This cleverly created sandwich tasted too good not to be awarded. It’s a fusion of sweet and spicy flavours, all placed between slices of Bretzel sourdough bread topped with Gorgonzola Piccante & Port Cranberry. It’s a genius mix of Gorgonzola Piccante, blue cheese bechamel mix, slices of prosciutto, caramelised pear, candied walnuts and finished with hot honey.

JDM Food Group Free From Category Winner

Satay Prawn in the Sea Shell – A complex and creative seafood sensation all placed into a rice paper and seaweed shell. Edvinas combined marinated prawns in a nut-free satay-style paste; alongside a flavoursome ginger pickled daikon and carrot slaw, mixed with a chilli and coriander sprinkle and a dash of lime.

Gouda Category Winner

Mumbai Garam Toastie – Bringing a combination of vibrant flavours and spices together with the clever addition of Gouda, this interesting sandwich is one you won’t forget. It’s a precise blend of Gouda, potatoes, chaat masala, finely chopped red pepper and red onion, mixed with cumin seeds, mint leaves, butter, coriander leaves, and lemon juice all snuggled between a sourdough bloomer.

H. Smith Food Group

Delightful Breaded Chicken Category Winner

Japanese Fried Chicken Wrap – A bold, innovative and tasty wrap inspired by Charlotte’s love for Japanese flavours. This creation includes breaded chicken, pickled coleslaw, spring onions and sliced tomato, all dressed with Yuzu Kosho mayo and filled to the brim in a tortilla wrap.

California Prawn Roll – A totally delectable creation filled with fresh ingredients bursting with vibrant colours and decadent flavours. This roll brings the Californian sunshine to the UK, with its chosen ingredients of black tiger prawns, passion fruit & mango chilli dressing, crisp cos lettuce, avocado, diced cucumber, mango and pink pickled onions all nestled within a brioche sub roll and decorated with caviar and cress no less. What a sandwich!

the recipe for the winning sandwich.

Ingredients

1 Brioche Sub Roll

15g Cos Lettuce

25g Fresh Avocado Slice

95g Chopped Black Tiger Prawn with Passion Fruit & Mango Chilli Dressing

10g Fresh Diced Cucumber

10g Fresh Diced Mango

10g Diced Pink Pickled Onions

3g Caviar

1g Cress

250g Chopped Black Tiger Prawns

60g Cottage Delight – Passion Fruit & Mango Curd

50g Mayo

3g Korean Pepper Flake

15g Lime Juice

Method

1. Mix together the ingredients to make passion fruit and mango chilli dressing and then add the cooked tiger prawns. Make sure you coat the prawns so you get a taste sensation in every mouthful!

2. Cut open a fresh brioche sub roll and spread a thin layer of the curd inside for extra punch.

3. Place the fillings in as follows: dressed prawns, avocado slices, diced cucumber, mango and pickled onions, caviar and top with fresh cress.

The winners of the Manufacturer Award at The Sammies were Simply Lunch. So, we caught up with William Page, marketing & digitalisation director, to talk the past, present and future.

Congratulations on your success at The Sammies. What does this recognition mean to your business? It’s certainly a signi cant milestone

and is incredibly rewarding to be acknowledged for our contributions to elevating the food-to-go industry. This award aligns perfectly with our

vision of becoming the leading FTG manufacturer in the UK.

This recognition is not just about our achievements over the past 12 months – it’s a culmination of our e orts since 1979. We’ve been committed to innovation, quality and excellence, and this award represents all of that. It’s a validation of our journey and motivates us to continue pushing boundaries in the FTG sector.

The awards are hugely competitive. How have you excelled? This has happened through innovative advancements in digital e ciency, operational enhancements and sustainable practices. We implemented a cutting-edge digital Quality Management System, reducing our paper use by 500,000 pieces and streamlining traceability

reports. Our operations have seen signi cant improvements with the introduction of precise wrap cutters, on-line label applicators and depositors, which boost productivity while minimising waste.

Investing in our people and facilities has also been a key priority, introducing a comprehensive Work from Home policy, increased annual leave, and sponsored sta development schemes to foster professional growth. We initiated predictive modelling for shelf life, collaborating with leading UK universities to enhance product quality and safety.

Our commitment to sustainability is evident through our partnership with Wildfarmed, promoting regenerative farming methods to reduce carbon footprint. We also launched a successful campaign with Quorn, raising over £4000 for Meals & More through our Vegan Festive Feast Sandwich.

These initiatives re ect a dedication to innovation, quality and social responsibility, while consistently leading positive change.

FTG demand is as strong as ever. What do you think consumers are prioritising?

There are several factors in relation to the choices they are making. Gut health is a major focus, with a rising demand for foods that promote digestive wellness. Global in uences are also shaping preferences, as consumers seek diverse and exotic avours inspired by international

cuisines. Sustainability remains a signi cant priority, with many choosing options that emphasise ecofriendly packaging and responsible sourcing showcasing provenance.

Attainable luxury is another trend, where consumers look for highquality, indulgent experiences in their on-the-go meals without breaking the bank. Plant-based is increasingly sought after for health bene ts and lower environmental impact.

To dive deeper into these trends, you can check out our latest trend report (see QR code overleaf), which

explores how these consumer priorities are shaping the FTG market and driving innovation in our ranges.

This year has been a great one for Simply Lunch so far. What can we look forward to?

We are gearing up for an exciting few months lled with innovation and initiatives, with several projects in the pipeline – including the launch of our Simply Special baguettes. These cater to the growing trend of attainable luxury, o ering premium quality and indulgent avours at accessible prices.

We are also forming new partnerships to enhance o erings and expand our reach in the market. These collaborations are set to bring unique FTG options to customers.

On the sustainability front, we are rolling out fresh initiatives to further our commitment to eco-friendly practices. These e orts re ect our ongoing dedication to minimising environmental impact while delivering exceptional products.

Obviously, economic times have been challenging. How do you ensure a fair price point for customers? Our commitment is to fair and accessible pricing for customers. We achieve this through e cient operations, strategic supplier partnerships and a focus on innovation. By streamlining production processes and investing in advanced technologies, we reduce waste and enhance productivity, so we manage costs e ectively.

Strong relationships with suppliers ensure that we source high-quality ingredients at competitive prices. Additionally, our commitment to sustainability not only supports the environment but also contributes to cost savings that bene t our customers. We also focus on product innovation, like our Simply Special baguettes, delivering premium quality at accessible prices by aligning

with the attainable luxury trend. By staying aligned to market trends and preferences, pricing strategies are competitive while delivering exceptional value. Everyone deserves delicious, high-quality FTG options that remain a ordable, even in tough economic times.

Can you expand on your relationships in foodservice?

We have built strategic partnerships that strengthen our commitment to sustainability, community support and social responsibility. Our collaboration with Wildfarmed demonstrates our dedication to regenerative agriculture, allowing us to support sustainable farming practices and reduce environmental impact.

We are also proud to partner with MIND Charity, raising awareness for

mental health initiatives throughout our teams. Our Partnership with Quorn re ects a commitment to healthier, plant-based dietary choices, resonating with our values of promoting nutrition and sustainability. Additionally, through our partnership with FairShare, we donate surplus produce to local food banks, aiding in the ght against food insecurity and supporting those in need within our community.

This represents a long-term vision to make a di erence beyond immediate operations, with environmental leadership, community engagement and social impact.

Scan the code for access to latest trends around gut health, emerging global expectations, sustainability, plant-based and plenty more.

Excitement is building for one of the most important shows on the industry calendar – and it’s bigger than ever.

As lunch! enters its 16th year, it continues to solidify its position as the premier trade event for the food-togo industry, cafés, co ee shops and more. Taking place alongside the 10th anniversary of Casual Dining, the show returns to ExCeL London on 18-19 September and will showcase innovation from over 500 exhibitors.

Thousands of decision-makers have registered, including buyers from the likes of Sainsbury’s, Ca è Nero, Center Parcs, Burger King, Tesco, Sodexo, Costa Co ee, Starbucks, SSP, Leon, Coop, Greggs, GAIL’s Bakery, BP, Waitrose, Compass and Marks & Spencer.

Event director, Katie Tyler, said: “This year’s lunch! will be o ering trade visitors an incredible, free, worldclass speaker programme, bringing together the biggest names in FTG. Alongside experts sharing invaluable insights, there will be hundreds of exhibiting suppliers presenting innovative and new products. lunch! 2024 is not to be missed!”

It’s also at the heart of what’s trending. From sandwiches to

lunch!, the de nitive café, co ee shop & food-to-go event, will take place on 18-19 September 2024 at ExCeL London. For more information and to register for a free trade ticket, visit lunchshow. co.uk and quote priority code VLU44 on the registration page.

seasonal salads, indulgent snacks to functional drinks, plus sustainable packaging. New names for 2024 include Lipton Iced Tea, Speedibake (and Scrocciarella), Emmi UK, Fresh Food For Now, Typhoo Tea, Raise Snacks, Drink Tranquillo, Capri Sun, Yeo Valley, Lindt, New Yorker Bagels and Lost Sheep Co ee.

The Innovation Challenge Gallery is a must for operators wanting to see the latest launches. Here, visitors can vote for their favourite new products as part of the popular Innovation Challenge. The brands that receive the most votes on day one then pitch directly to buyers on day two.

Buyers looking to meet the newest brands entering the market should visit the ‘Start-Up Zone’ – with the challenger brands that have been on the market for 18 months or less.

The show is also full of established names returning with their latest ranges, including Bridge Co ee Roasters, GRIND Co ee, Magrini, Pip & Nut, Simply Lunch and more.

Industry leaders will take to the stage for lunch!’s seminar programme, including interviews, data-driven keynotes and panel sessions. Speakers con rmed so far include Julian Metcalfe OBE, Founder of itsu and cofounder of Pret; Emma Woods, chair of Tortilla; Will Stratton-Morris, CEO of Ca è Nero UK; Shereen Ritchie, CEO of buns from home; and Cathy Goodwin, global head of food at Costa Co ee.

The British Sandwich Association will be hosting a panel, looking at customer satisfaction and the critical factors that keep customers coming back. “It’s just a great show to see industry innovation,” said Metcalfe.

Cottage Delight is celebrating an extra-special birthday, with its variety of jams, marmalades, curds, chutneys and table sauces continuing to inspire.

Fifty years of operation is outstanding for any business – especially one in the sauces/condiments space, where competition is fierce. But Cottage Delight is not only looking to celebrate the past… it’s making exciting plans for the future, around its products, people and sustainability model.

“We are proud to say that we never compromise on taste,” said Cottage Delight marketing channel lead, Nicola Campbell. “With a rich heritage, we’ve built a reputation for excellence, and our award-winning status is testament to our commitment to quality. Our passionate and skilled workforce is dedicated to making every product that leaves our kitchen the very best it can be, with a focus on the finest ingredients and traditional artisan techniques.”

Lasting relationships are key, with suppliers sharing the desire for high standards, while working closely with customers to understand their needs – which fosters trust and respect.

“One of our most notable collaborations is with Beatson Clarke, a trusted partner for over 30 years, who supplies our iconic glass jars,” continued Campbell. “We’ve also had the pleasure of working with Staffordshire Brewery for 15 years, providing us with a consistent supply of quality beer products. We have supplied Lakeland for over 25 years, collaborating closely to craft a comprehensive gifting collection that meets the unique needs of their loyal customer base, with them returning year after year.

“By delivering exceptional goods at a commercial price point, we’ve established a mutually beneficial relationship – connections which have helped to shape our business.”

While proudly reflecting on five decades in foodservice, Cottage Delight has headed into 2024 with a series of consumer facing and process driven brand updates,

making a renewed commitment to a sustainable future.

“Our new look sees a step away from the traditional yet waste-heavy paper and rubber band lids, with significant reductions in plastic packaging and virgin plastic usage across our signature glass jar range. These initiatives are eye-catching for the popular products, striking a balance between appealing to existing customers, while capturing the attention of the more environmentally conscious.

“The design still reflects the handcrafted and superior quality of our brand. The wider impact of both changes has allowed us to successfully remove over 22 tonnes of paper and packaging from their processes*, alongside preventing 4.8 tonnes of rubber bands going to landfill**. The updated jar labels now contain a 30% reduction in non-virgin plastic; a figure which the business aims to continue decreasing.

“We have now created a glass jar

range that allows for much easier navigation due to category branded lids, alongside a more contemporary, cleaner look and less wastage for the consumer. This new branding will appeal to a wider audience.”

Not content with these initial changes, Cottage Delight has set a series of both short- and long-term sustainability goals. In recent years, it has officially become a zero waste to landfill business in partnership with Derbyshire-based Peak Waste, as well as baselining current carbon emissions to allow for future monitoring and reduction. Within the food production process, only responsibly sourced palm oil is used, while in the coming years it’s aiming for 100% of electricity from renewable sources and to reduce waste – including packaging usage – across the business year on year, against baseline figures.

“In a world increasingly feeling the impact of irresponsible business practices, it is not enough to make empty promises when it comes to sustainability,” said Vickie Milligan, Cottage Delight managing director. “We take our commitments seriously and work with external consultants to ensure we hit our projected targets.”

While flavours may be continually evolving, Cottage Delight stays true to its core values. “Quality and taste are paramount, which is why we conduct internal blind taste panels against competitor products,” continued Campbell. “We are also committed to innovation, developing products that meet changing tastes, trends and preferences of our customers.

“We occupy a unique position, with the ability to create recipes, manufacture products and own premium brands. This gives us a 360-degree view, selling and marketing our own brands to a wide range of sales channels – from independent and major retailers to foodservice providers and exporters. This comprehensive approach delivers unparalleled insights into consumer behaviour and preferences, as well as the ability to stay ahead of the curve in terms of trends and innovations. In contrast, many manufacturers are limited to a single perspective or focus on a specific channel, leaving them vulnerable.

“And as we navigate seasonal fluctuations in flavour trends, it’s clear that citrus and tropical have been a favourite from spring to summer. Our award-winning Passion Fruit & Mango Curd, in particular, has seen growth in volume, with chefs and foodies alike recommending its ability to add a zesty twist. Across autumn and winter, nostalgia takes centre stage, focused on comfort foods and familiar flavours that evoke a sense of warmth. This is reflected in our best-selling chutneys, such as Caramelised Onion Chutney and Sweet Apple. These condiments are perfect for adding a touch of warmth and depth to any dish.”

In addition, Cottage Delight was a welcome sponsor of The Sammies Awards, across the Chutney & Curd Category in the Sandwich & Food to Go Designer of the Year.

“Many people know us as a familiar face within the independent retail sector, providing to the trade since 1974. But others may not be aware that we have a selection of 12 foodservice SKUs, including handcrafted jams, chutneys and pickles. Each flavour offers chefs versatility and scope to add something different to menus. With the sponsorship of The Sammies, it meant we could network our brand with the right audiences.

“The event was a real success and the cherry on top was that the overall winner, James Burgess, used our Passion Fruit & Mango Curd in his California Prawn Roll,” said Campbell.

*Rubber bands, paper packaging, plastic shrink wrap reduction over typical 12-month period.

**Annual usage of rubber bands no longer required due to new metal lid.

The UK sauces and condiments market is in rude health – with data predictions from Statista backing this up to the tune of annual growth of 4.24% (CAGR 2024-2029).

“When it comes to sauces, we have experienced significant changes, driven by evolving consumer tastes, a growing interest in world cuisines, health-conscious eating habits and sustainability,” said Rachel Shoosmith, marketing manager at Creative Foods.

“Most noticeable are global flavours and fusion sauces. This can be seen in what we expect to be the most popular sauce flavour profiles in 2024:

1. Sweet Heat – Hot honey, sweet chilli, honey sriracha

2. Umami – Truffle, soy, kimchi

3. Smoky – Buffalo, BBQ, chipotle

4. Hot & Spicy – Nduja, sriracha, peri peri, extra hot

5. Asian Inspired – Korean BBQ, gochujang, miso, teriyaki

6. Fruit & Citrus – Mango habanero, lemon pepper, chilli lime

7. Creamy – Garlic & herb, aioli, buttermilk ranch, blue cheese.

“These fit nicely into the consumer desire for impactful touches that elevate a meal. Operators can offer this via special condiments or sauces to make a dish more premium. One popular method is in the form of a dip.

“For pizza dip pots in foodservice, garlic & herb and BBQ continue to come out on top, followed by garlic, tomato & herb, honey & mustard, salsa, hot buffalo and sweet chilli. However, we are also finding more innovative sauces and dips appearing across menus with truffle, nduja and hot honey standing out.

“We are seeing the growth of hot honey on a range of dishes, including pizzas, dough balls, chicken products and wedges. According to a recent Pizza Hut report, ‘sweet and spicy menu pairings are up 38% in the last year, with hot honey projected to outpace other flavours by 2027’.

The pandemic had an impact on consumers, with many becoming increasingly adventurous, seeking out diverse and exotic tastes – authentic, zingier flavours with spices, herbs and citrus notes. “Sriracha, for instance, has become a staple and is often blended with traditional sauces, resulting in unique and exciting fusions such as sriracha mayonnaise and honey sriracha,” continued Shoosmith.

BBQ BUZZ

Global and fusion are key watchwords, as consumers expand their taste horizons.

enhanced with Mexican-flavoured mayonnaises that infuse a traditional mayo with South American-style seasonings, spices and ingredients.”

There is also increased demand for healthier options, including lower sugar, salt and artificial additives. “Organic, gluten-free and vegan are on trend. Additionally, there is interest in fermented sauces, such as kimchi and miso-based dressings.

“And it is peak BBQ season. In a Creative Foods poll, we asked customers for their go-to sauce, and 32% preferred BBQ, followed by ketchup (26%), mayo (22%) and hot sauce (21%). So, our House of Lords Premium BBQ Sauces hit the mark.

“We manufacture a versatile range of delicious sauces, dips, dressings, marinades and glazes, in a variety of pack sizes and formats, offering own label, bespoke and branded sauces and dips to retail, foodservice, wholesalers and B2B customers.”

Mexican cuisine also sits under the umbrella of exotic, with its unique farming methods and native ingredients such as tomatoes and avocadoes. “Street food – like tacos, tortillas, nachos and enchiladas – is popular, and these dishes are

Spicy flavours, new products and factory investment. It’s an exciting time for Zafron Foods – so we caught up with national account controller, Graham Cox.

Food to go is certainly on an upward curve. In terms of your products, what consumer trends are you seeing?

Flavour profiles are changing all the time. With more people going on long-haul destinations for holidays, the demand for different flavours increases. Currently, Far Eastern is trending, especially Korean and Japanese – added into the equation is a heat profile to the sauces. We are seeing an increased demand for products containing high chilli content and increased heat profiles.

Relationship building is essential in foodservice. Can you expand on who you work with and how you continue to offer the best possible service?

The relationship with our customers is vital and we continually work with all our end-users for new flavour profiles and pack sizes. We have seen since Covid that the demand for one-litre bottles has jumped substantially, with sales increasing week by week.

The main reason for this is the move away from the traditional 2.27l jars, where kitchen staff have to decant at least twice to get the product to table. This means there is a high chance of human contact with the sauce and possible contamination. The great thing with the 1l is that it’s ready to go –you can dress plates and fill other receptacles such as ramekins, without touching product. Our bottles can be stored upside down so the product is ready to be used straight away. They are also fully recyclable.

Talk to us about the people involved in your product development and the choices you make.

We have a chef-led NPD team, with many years of experience in our industry and hospitality in general. As we are now part of the wider Solina Group, we can also call on colleagues in both Europe and North America for up-to-date trends and flavour profiles, so we can advise customers on the expected new wave of products, helping them get ready for the demand.

How do you approach health and sustainability, which are so important in terms of consumer choice?

Over the past few years, the demand for both health and

sustainability has grown faster than ever before – and there is a strict protocol towards sustainability and fair trade with suppliers. With this in mind, any product manufactured that contains egg will now automatically contain free-range, as opposed to battery or barn.

What does the future hold for the business?

It’s looking very bright. With major investment within the factories for equipment, we believe we are heading to be the number one choice for all customer demands for mayonnaise, sauces and dressings. We have the capabilities to produce products in all sizes – from sachets to dip pots, tabletop bottles, all the way through to industrial pallecons.

What advice would you give to operators in terms of utilising your sauces – both financially and with regards to menu choices?

Contact us to discuss requirements for front of house and kitchen needs. We are here to help develop your business.

your sandwich with flavour using the uk’s #1 mango chutney www.geetasfoods.com

Explore Urschel Cutting Solutions

Sanitary, stainless steel design, every machine is crafted to Urschel quality standards; backed by service and support for the life of your machine. Operation at a push of a button – to reduce time and labor costs. Machines designed for continuous, uninterrupted production to promote the highest outputs.

Known for its healthier elements and versatility, Real Good Ketchup is looking to shake up the sector.

The raison d’etre at Real Good Ketchup is straightforward – 75% less sugar and 80% less salt than regular ketchups. Ingredients are Top 14 allergen-free, in recyclable packaging and powered by renewable energy. This led to the World Food Innovation Awards’ Best Children’s Product 2021 and recognition in the 2023 Free From Food Awards Child-Friendly Food category. It’s a healthy ketchup twist to food on the go – and for those dedicated vegans, there are no animal ingredients in the supply chain.

“In terms of demand, we are seeking a requirement for greater transparency and clarity on labels, from ingredients to nutrition, and especially allergens,” said Elizabeth Jones, founder of Real Good Ketchup. “Healthier options are definitely top on the list of priorities.”

When it comes to foodservice customers for RGK, most of them are in the education sector and use

the ketchup in breakfast butties and wraps, or as an alternative to sugar-laden ketchups in the dinner hall, serving up to 50,000 pupils nationwide.

But the business wants to expand its impact on foodservice. “RGK is a fantastic base for chefs to add their own twist by stirring in cayenne, chilli and curry spices to create their own signature ketchup! And best of all, they can do that without high levels of salt and sugar. Ours is perfect as a marinade, dip, or for Asian cooking.”

So, what changes can operators incorporate to deliver a healthier offering?

“Read the back labels of products,” continued Jones. “We often find that chefs have not looked at the nutritionals to check sugar and salt levels. When they do, they are often shocked by it. Another problem is that sometimes claims are made on labels to suggest reduced sugar when in fact they are not when compared to other sauces.”

In terms of 2024 for RGK, business has been steady – with ongoing

discussions with several new customers looking to add it to menu offerings. There is also a ‘low sugar & salt’ table sauce in the pipeline for Q4.

“Foodservice is hard work, and it certainly takes time to build a trusted reputation. The offering must have a real point of difference and be competitive on price to be taken seriously.

“But the pandemic had a huge impact on people’s attitudes to healthier condiments and sauces. The awareness now of ingredients and understanding the short- and long-term health consequences of high sugar and salt consumption has grown and continues to be incredibly important.

“We expect attention to ingredients will continue to grow as consumers become wiser to ’so-called’ health claims.”

Real Good Ketchup is sustainably produced in the UK, with fully recyclable packaging, available in 2.7kg catering jars.

For more information, visit realgoodketchup. com.

even more and waste even less

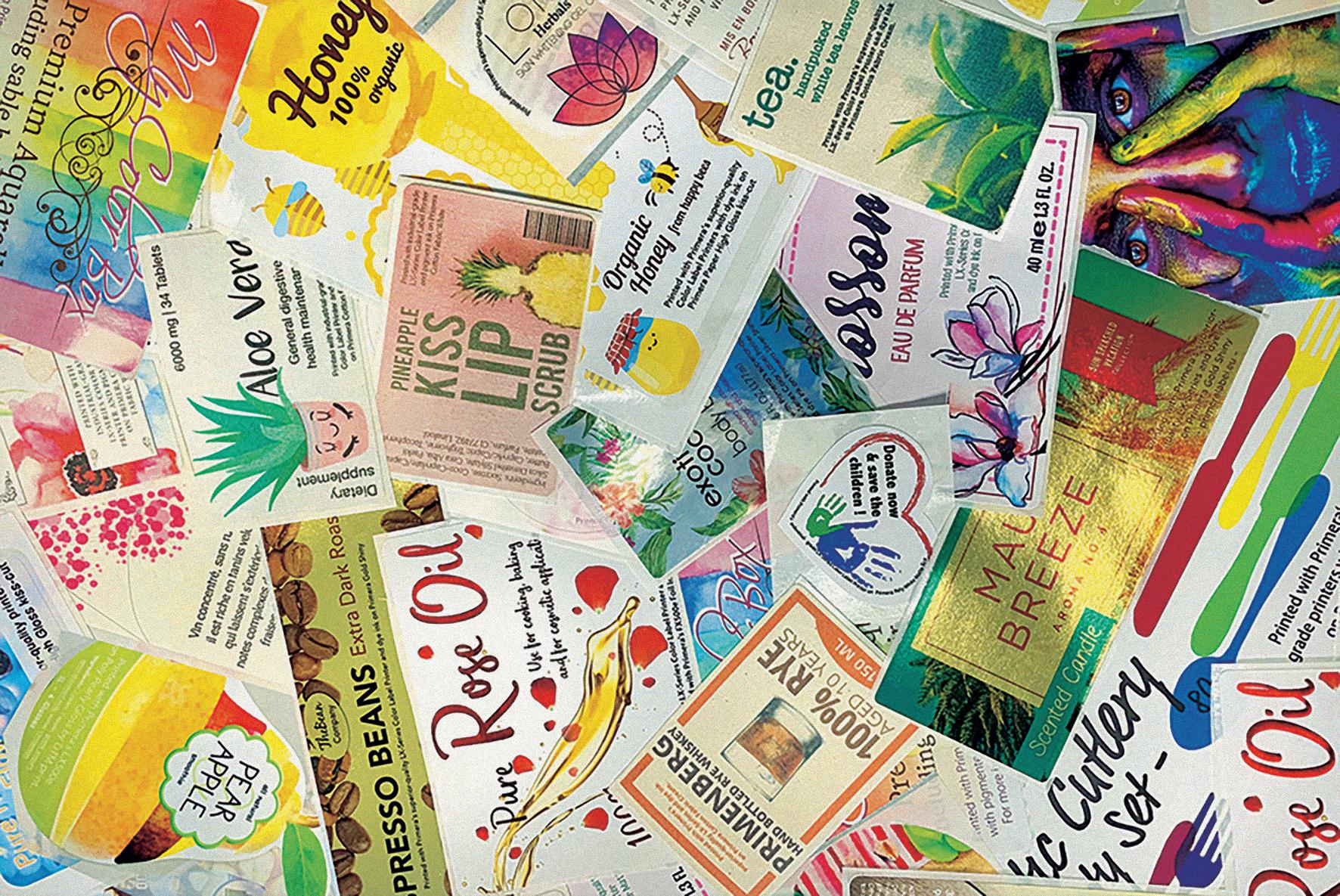

Labelling is a crucial aspect to packaging. It has a strong impact on the consumer purchasing process by drawing attention to a product – whether it’s with a special shape, structure or material, colouring, photo-realistic printing or metallic highlights. Labels also contain information, such as ingredients and allergens, that make all the difference.

Today, more than ever, the sustainability of packaging – from materials used to recycling processes – is a paramount factor. For example, having a paper label on plastic means that these two materials can’t be properly and automatically separated. This would have to be done manually at home.

But with nearly 40 years in the industry, DTM Print can help make the lives of manufacturers much easier.

“The labelling sector has undergone significant changes in recent years, with advancements in technology and products driving innovation,” said Katrin Hoffmann, PR manager, DTM Print.

“One notable development is the availability of desktop printers that are affordable for small businesses, yet offer high-quality, full-colour and durable capabilities. These printers allow companies to create professional-looking labels, reducing costs and turnaround times.

“Another key trend is the rise of on-demand printing solutions for in-house production. This technology enables companies to print labels as required, eliminating the need for large print runs and reducing waste. New or updated labelling regulations require pre-packaged for direct sale (PPDS) businesses to provide full ingredient lists and allergen labelling on the premises, forcing them to rethink their processes.

“Our on-demand inkjet and dry toner-based printers helped those businesses tick those boxes. Other benefits are no turnaround time, label production in real time, plus the ability to instantly react to customer needs and market changes.

“There is a growing focus on sustainability, with solutions that use non-toxic inks and eco-friendly, recyclable materials. This represents a renewed focus on both affordability and efficiency.”

As such an experienced operator, DTM Print has learned key lessons when maintaining key customer partnerships.

“Being innovative and listening to clients,” continued Hoffmann. “This allows you to stay ahead of the competition and adapt to changing trends. You need to constantly seek new ways of improving products or services and finding creative solutions to problems.

“Take Natasha’s Law, which changed the requirements in terms of PPDS, and especially allergens needing to be highlighted on those labels. Even before the law came into effect, we evaluated what businesses in this market would need and request for that use case: the compact, on-demand DTM CX86e Colour Label Printer.

“Additionally, building strong relationships with clients and

providing excellent customer service often leads to repeat business and positive word-of-mouth referrals, which is essential in such a competitive market.”

One such UK distribution partner successfully implemented a DTM CX86e in a fully integrated Point of Sale (PoS) solution.

“This set-up included weighing scales for a retail counter, allowing for the printing and applying of colour labels on-demand. This is ideal for complying with Natasha’s Law and the well-known traffic light system of food labelling, showcasing ingredients, allergens and nutritional information.

“Our label printing solutions are widely used in the food industry, and not limited to the FTG sector, enabling businesses to be flexible in producing the required number of labels at any given time – reducing waste and storage space, as well as saving resources.”

Whether DTM Print approaches clients or the other way round, they initially learn as much as possible about the use case or application which they need labels for, then evaluate requirements – from durability to colour, production speed, volume, etc.

“This helps us find the best product to effectively meet their needs. And depending on the client’s location, we connect them to a local partner. We have a strong distribution network all over the EMEA region. It can not only communicate with clients in their native language but provide additional support or services to complement our offerings. This ensures access to a comprehensive range of resources.

“We also offer to produce test prints, to demonstrate the quality and suitability of our solutions firsthand before making a commitment, helping to build trust. Furthermore, we suggest fitting solutions, taking into consideration factors such as durability, size and production volume. Because of our experience, we know that label substrates are a key element for each solution.

or custom sizes, as well as recyclable and sustainable labels.

“There’s a consultation with clients to ensure the right choice and we offer a vast variety of materials in our Genuine DTM Label Stock for all kinds of applications – including paper, polyester and foils with matte, semigloss and high-gloss finish in standard

“And our products are easy to install and operate. If necessary, we of

course provide any other assistance that may be necessary to ensure a smooth transition. Our goal is to make the process as easy and convenient as possible for clients, ultimately leading to a successful partnership.”

One valuable avenue of connection is the Natural & Organic Products Expo 2024 (NOPEX), which DTM Print attended in April.

“We’ve been going for almost two decades now, initially because it was the perfect platform to meet small- to medium-sized companies in need of ondemand label printing solutions.

Right from the beginning, we were well received by attendees. The eco-friendly and sustainable model of the show certainly

aligns with our values.

For example, the LX610e Colour Label Printer that features ultra-low energy consumption, low weight by using less material, non-toxic ink supplies and 100% recyclable components.

“We recently introduced the DTM EcoTec Label Line, which includes ecofriendly, recycled and natural labels.”

In terms of the future, DTM Print is looking forward to further technical advancement focused on sustainability, reducing CO2 emissions and saving resources.

“There’s a growing emphasis on solutions for personalising products, such as in-shop systems that can print labels with individual messages or names, as well as advanced technologies like our edible ink printer, Eddie – that prints directly onto food like biscuits, marshmallows, chocolate, cupcake toppers, macarons and so much more.

“All you need to do is look around – labels are everywhere. And our printers are used in so many different markets, it’s exciting to work on different projects, while also keeping our environment in mind.”

with labelling solutions by DTM Print

It‘s all about you and your product

We provide label printers and customisable printing solutions to help you produce high-quality, brand-elevating labels that support your corporate vision.

Be flexible

Our adaptable printers offer unparalleled versatility, handling heavy-duty labels, intricate custom shapes, diverse materials and various print formats to meet your unique requirements effortlessly.

Warranty & quality

DTM Print offers a 36-month warranty*, supported by an accessible support team, easy-to-use printers and resources like local partners, a know-how website, video tutorials, online training and on-site visits.

Advantages for food packaging

Our DTM Genuine Label Stock offers water, heat and UV resistant materials, as well as deep-freeze suitable materials, ensuring label longevity in challenging conditions and compatibility with diverse packaging materials.

For more information

Wanting to satisfy a market that is increasingly attentive to the nutritional profile and labels of food products, CSM Ingredients – a global player in food ingredient research, innovation and production – has developed a number of solutions ideal for reducing fats and additives in laminated bakery and pastry products, without compromising performance and taste.

Fats – in recommended doses – are a fundamental part of the human diet. They also offer functional and sensory characteristics necessary to make products appealing and rewarding for consumers. The real challenge, therefore, lies in finding solutions that can improve the nutritional profile of food products without changing their appearance, texture and taste.

“Fats are a segment of interest for the evolution of the entire food industry,” explained Christian Sobolta, CSM Group managing director. “At CSM Ingredients, we have an entire innovation centre in Delmenhorst, Germany, dedicated to the research and development of increasingly innovative and sustainable oils, fats and emulsifiers, to meet the needs of customers and enable consumers to find nutritionally balanced products

that can also satisfy taste buds. SlimBAKE and our E-free margarines represent the results of these efforts and are the demonstration that it is absolutely possible to reconcile the pleasure of food with a wellnessconscious approach.”

SlimBAKE, in particular, is an emulsion that enables up to a 30% reduction in the fat content of finished bakery products, made possible thanks to a combination of functional ingredients and advanced production

"Fats are a segment of interest for the evolution of the entire food industry."

technologies. The use of SlimBAKE has a twofold benefit: on one hand, it allows industrial users to keep both the original recipe and the production processes unchanged while adding

the claim ‘reduced fat content’ on pack in accordance with EU regulations1; on the other, it allows end consumers to combine taste and lightness without having to make compromises on the joy and sensory experience of croissants, Danish pastries and puff pastries.

The new emulsion – for both ambient packed products and frozen baked goods – is available in two variants, butter-based and vegetable-based, thus allowing to meet the diverse demands of today’s consumers, including those who follow a vegan diet.

In addition to SlimBAKE, CSM Ingredients has launched an ‘E-free margarine’, created by combining natural functional ingredients with advanced production technologies. This additive-free margarine meets the desires of those increasingly looking for ‘clean labels’ and is ideal for major lamination applications.

It was possible to start producing this unique, new margarine thanks to technological innovations achieved with the introduction – in September 2023 – of a new production line at the company’s plant in Crema, Italy.

CSM Ingredients is also developing a second variant of the E-free margarine, ideal for incorporation applications, which will soon be available on the market.

1EC legislation no 1924/2006 on nutrition and health claims made on food: a claim stating that the content in one nutrient has been reduced may only be made where the reduction is at least 30% compared to a similar product.

join us on the journey

Did you know that Faerch Group is not only a rigid food packaging manufacturer but also has its own recycling facilities in the Netherlands?

We are proud to say that at Faerch circular recycling of rigid food packaging is not some distant vision, it is a reality already happening today. As the world’s first integrated food tray-to-tray recycler, we are doing circularity on an industrial scale.

Faerch are on a mission to convert waste into valuable resources by pioneering advancements in recycling technology, and this commitment to circularity is demonstrated by the recent expansion of our flagship recycling plant in Duiven, Netherlands.

With nearly 24 billion rigid food containers sold annually, Faerch plays a vital role in preserving food freshness while addressing environmental challenges head-on at the same time.

Learn how we are reshaping the industry landscape by prioritising circular content by ramping up our integrated recycling capacity.

And this is just the beginning… Join us on the journey towards a more sustainable future, where post-consumer waste transforms into new food packaging - over and over again!