INSIDE: MARINE SURVEYOR DIRECTORY

BC SHIPPING NEWS

Volume 2 Issue 10

www.bcshippingnews.com

December 2012/January 2013

Commercial Marine News for Canada’s West Coast.

Naval Architecture

Building a bridge between design and operations with ShipFare software

Marine Salvage

West Coast salvage: A 21st century view

Marine Surveys

Surveyors explain: pleasure craft, deepsea vessels and marine engineer surveys

Industry Insight

DEC/JAN 13 CP PM# 42161530 DEC/JAN 2013

Tim Ellis, Association of Marine Surveyors of B.C.

$4.95

12

0

74470 80667

7

Plus:

Fraser Surrey Docks’ VP excited by the next 50 years

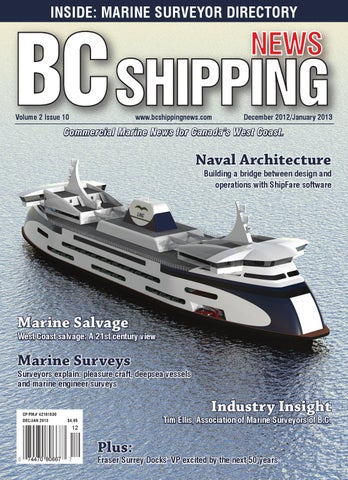

December 2012/January 2013 On the cover: Capilano Maritime Design Ltd.’s LNG ro-ro ferry concept which used ShipFare software to determine the benefits of natural gas over diesel. Rendering courtesy of Coda Marine Design Inc.

Volume 2 Issue 10

Contents Cover Stories 37

Deepsea and underwater surveys On, over and under the sea

craft surveys 30 Pleasure Buyer beware engineer surveys 34 Marine Going beyond inspection

10 Industry insight Young enough to climb Jacob’s ladder, old enough to know better Marine surveyors need to be shipwrights, marine engineers, naval architects and diplomats...all traits inherently found in Ellis.

26 Surveyor directory

Members of the AMSBC This handy reference guide provides the contact information for marine surveyor members of the Association of Marine Surveyors of B.C.

Technology

47

Sludge contamination remedies

Fuel Right President Tim Rivard and colleague Bob Tatnall look at the benefits of filming amines to eradicate sludge that could be fouling up your marine diesel fuel system.

D E P A R T M E N T S

F E A T U R E S

Tim Ellis

6

News briefs / industry traffic

16

History lesson

19

Ports symposium

21

Ports & terminals

24

Marine salvage

39

Legal affairs

41

Marine investigations

44

Trade routes

50

LNG ferries

52

Naval architecture

Letters to the editor and news

Survey of the Alpha — by Lisa Glandt Northern Ports Symposium highlights development opportunities — by Dan Dibbelt Fraser Surrey Docks’ VP excited by the next 50 years — by Ray Dykes West Coast salvage: a 21st century view — by J.Spears and D.Mackenzie Must a ship owner pay for the negligence of an assist tug? — by James Vander Woude Forensics of the sea — by Jeroen De Haas and Han Wensink The Saint Lawrence Seaway — by Captain Stephen Brown The MF Boknafjord: the world’s largest gas ferry — from Rolls-Royce Building a bridge between design and operations — ShipFare software

December 2012/January 2013 BC Shipping News 3

BC SHIPPING NEWS

A great holiday gift idea!

December 2012/January 2013 Volume 2/Issue 10 Publisher McIvor Communications Inc. President & Editor Jane McIvor

Give a gift subscription and we’ll send a greetings and gift card on your behalf. Contact BC Shipping News

T: 604-893-8800 / E: jane@bcshippingnews.com or visit:

www.bcshippingnews.com

Canadian K9 Detection, Security & Investigations Ltd. Explosives l Narcotics l Firearms Canine Detection services by the largest, full service Security and Canine Detection firm in Canada.

Contributing Writers Todd Braconnier Captain Stephen Brown Dan Dibbelt Ray Dykes Tim Ellis Lisa Glandt Jeroen De Haas Captain Andrew Korek Captain Don Mackenzie Philip Oldham Tim Rivard K.Joseph Spears Bob Tatnall James Vander Woude Han Wensink Advertising and Subscriptions Jane McIvor Phone: 604-893-8800 / Email: jane@bcshippingnews.com ANNUAL SUBSCRIPTION Canada Two Years $69.95 Cdn* One Year $37.50 Cdn* USA One Year $60.00 Cdn Other Countries One Year $75.00 Cdn Single copies Outside of Canada *Canadian rates add 12% HST

$4.95 Cdn* $6.00 Cdn

Security Consulting, Security Patrol and Investigations Services.

Subscribe online at www.bcshippingnews.com Contents copyrighted 2012 McIvor Communications Inc. 300 - 1275 West 6th Avenue, Vancouver, British Columbia Canada V6H 1A6 Phone: 604-893-8800/Fax: 604-708-1920 E-mail: contact@bcshippingnews.com

Professional Discreet Certified

www.canadiank9.com

Telephone:(604) 254-3763 - Toll Free:866-540-DOGS (3647) E-mail: admin@canadiank9.com

4 BC Shipping News December 2012/January 2013

International Standard Serial Number ISSN: 1925-4865 Published 10 times per year. The opinions expressed by contributing writers are not necessarily those of the Publisher. No part of this magazine may be reproduced in any form without written permission of the publisher.

EDITOR’S NOTE

Giving credit where credit is due

W

e’ve reached a milestone! BC Shipping News is celebrating the end of its second year in publication. This is an important benchmark because, as any statistician will tell you, if you can make it past two years, your odds of success greatly improve. And based on feedback, we have now become an integral part of your source for information on the marine industry on the West Coast. Without question, a key factor in the success of BC Shipping News has been the support we’ve received from all sectors of the industry and, given this momentous occasion, I think it’s only fair to give credit where credit is due — you! You have written articles, sat for interviews, submitted photos and comments, Member of:

advertised and subscribed. Your support has been overwhelming and I thank you. BC Shipping News has gotten off to a great start on its goal of being a true voice for the industry by the industry. It’s unfortunate that there’s not nearly enough space in this editorial to recognize all of the people who have significantly contributed to our success: • Industry leaders like Stephen Brown, Kaity Arsoniadis-Stein, Zak Farid, Phill Nelson and Donna Spalding — without their positive response to the concept, BC Shipping News would have remained just that, a concept. • Contributing writers like Ray Dykes, Joe Spears, Lisa Glandt, Syd Heal, Darryl Anderson and the entire gang at Bernard & Partners who have

consistently provided articles that are relevant, thoughtful and informative. • Advertisers like Nanaimo Port Authority (and especially Doug Peterson for coming up with the idea of BC Shipping News in the first place), Canadian K9, CMC Electronics and a list that keeps growing who are seeing the results of consistent ad placement. • Subscribers like Neville Hodgson from Sanko Kisen (our first) and Longshoreman James Knight (our most recent) who have made the long hours and tight deadlines all worthwhile. Thanks to each of you. I look forward to our continued collaboration. Merry Christmas and all the best in 2013. — Jane McIvor

Local traffic...

Thanks to Ken Pfister for submitting this photo of the Global Garland sitting just off Jack Point, Nanaimo. The Global Garland is a dry bulk carrier built in 2009 (by Hakodate Dock, Japan) and owned by NYK Global Bulk. The vessel is 176 metres in length with a 30-metre beam and gross tonnage of 19,817. She can reach a speed of 9.8 knots (average: 8.1 knots). (Details from www.marinetraffic.com.)

International Sailor’s Society Canada

Got a great photo? Send it to jane@bcshippingnews.com to be included in our new feature on ships visiting our local waters. December 2012/January 2013 BC Shipping News 5

INDUSTRY traffic BCIT Marine Campus co-ordinator honoured

L

Lieutenant (Navy) Jeff Otto (left) receives the Queen Elizabeth II Diamond Jubilee Medal from Commodore David Craig, Commander Naval Reserves.

TRAVEL WITH THE INDUSTRY’S BEST... Marine and corporate travel experts available 24/7. If you’re looking for a Marine Travel Management Company to manage your marine & shipping travel, we offer the perfect solution. Our multi-national buying power for marine, offshore and corporate travel, together with our local and global expertise, make us a perfect partner to meet your travel needs. ATP Instone agents are worldwide travel experts specializing in the shipping and energy sectors. We understand the complexities of moving a diverse crew around the world and the challenges of finding efficient and effective travel for the marine industry. Contact: Louise Kawaler ACTM, Director Canada Mobile: 604.329.1143 Email: Louise.Kawaler@atpi.com

www.atpi.com 6 BC Shipping News December 2012/January 2013

ieutenant (Navy) Jeff Otto, co-op co-ordinator at the BCIT Marine Campus (BMC), has been awarded the Queen Elizabeth II Diamond Jubilee Medal. Jeff received the honour at an investiture ceremony held at HMCS Discovery on October 16, 2012. In addition to his full-time role at the BMC, Jeff is currently a serving Officer of the Royal Canadian Navy Reserve. The Queen Elizabeth II Diamond Jubilee Medal is a tangible way for Canada to honour Her Majesty for her service to this country. At the same time, it serves to recognize and honour significant contributions and achievements by Canadians like Jeff. Kaity Arsoniadis-Stein and Kyle Washington also received the medal at a separate ceremony as reported last month. In 2010, Jeff took time away from BCIT to prepare and train for deploying as part of Operation Podium within the Port Security Unit and supporting the RCMP during the 2010 Olympic Games. In 2009, he was in Winnipeg as part of the Canadian Forces contingent lending assistance to the Province of Manitoba during the flood season of that year. From January 2012 until this past August he filled the position of Acting Executive Officer (Second in Command) of HMCS Discovery, Vancouver’s Naval Reserve Division: a busy schedule on top of all his great work at the Marine Campus. Congratulations Jeff . Well done and well-deserved!

Letter... Re: Syd Heal’s The passing of the log carrier Hello, I am a Seaspan employee, had the pleasure of working on the King, the Pacer, the Queen, the Doris, the Challenger, the Carrier Princess and the Princess Superior. Thoroughly enjoyed your article. Saved it to show dad and wife. All the best, and thanks, Kevin O’Brien

NEWS BRIEFS

D

avid Brander-Smith, Q.C., is perhaps best known in marine circles for his report on Tanker Safety and Marine Spills Response Capability. While the report was written in 1990 — over 20 years ago — it is still widely recognized as one of the most comprehensive reports on the issue and is still referenced today. Mr. Brander-Smith passed away peacefully in Vancouver on October 17, 2012. He was 86 years old. Predeceased by his wife, June Brander-Smith in 2007, Brander-Smith leaves four daughters — Gail, Nora, Sandra and Cynthia — and nine grandchildren. After serving overseas in the Canadian Navy and Merchant Service, surviving the torpedoing of the Nabob in 1944, he graduated from the University of British Columbia in 1950 and practised law at Bull Housser and Tupper, specializing in international maritime law. In 1989, he served as Chairman of the Public Review Panel on Tanker Safety and Marine Spills Response Capability and then went on to serve as a member of the Fraser River Sockeye Public Review Board. He was active on many professional and community boards including President of the Canadian Maritime Law Association, Chairman of the Directors’ Advisory Board of the Institute of Ocean Sciences and Chairman of the B.C. Arthritis Society.

Colin How joins Edoc as COO

E

doc Systems Group is pleased to announce that Colin How has joined the company as Chief Operations Officer. How will lead Edoc’s operations, organizational growth and scalability as the company expands into overseas markets. “We are thrilled to have someone of Colin’s calibre joining our growing team,” said Ron deBruyne, CEO and Founder of Edoc. “His historical track record of success and his vision for the future of Edoc as we grow internationally is very exciting.” Most recently, How served as COO, then subsequently Interim President/ CEO of Terapeak, a Victoria-based technology company that acted as the exclusive worldwide distributor of eBay’s data. Under How’s leadership Terapeak achieved record revenues, reducing churn by more than half, and signed a groundbreaking data partnership with Yahoo! Japan. Previously, as founder, president and CEO of H2ST, How was selected as a finalist for Red Herrings’ Top 100, a list of North America’s most promising

www.gecomarine.com

Obituary: David Brander-Smith, Q.C.

Colin How, new COO for Edoc. new technology companies. H2ST’s flagship product, PiXPO, was awarded PC Magazine’s Editor’s Choice Award. How has been acknowledged for his entrepreneurial success with his inclusion in the Top 40 under 40 for British Columbia and Vancouver Island, and his nomination as a finalist for Ernst and Young’s emerging entrepreneur of the year.

Fleet technical management and permanent maintenance services. Quality service, access to a huge pool of licensed marine engineers, 24-hour technical support and decent labour rates from a company that can take care of all your vessel’s technical needs. GECO MARINE LTD. Contact: George Coman, Senior Engineer 604-988-4411 / george@gecomarine.com

Brander-Smith was an accomplished sailor, an avid traveller, an automobile aficionado, a well respected lawyer and a devoted family man and friend. Donations in David’s name may be made to the Alzheimer’s Society of Canada or the B.C. Arthritis Society.

December 2012/January 2013 BC Shipping News 7

INDUSTRY TRAFFIC Robert Allan design for the Amazon

A

thousand miles (1,600 km) up the Amazon River, the Port of Manaus has long attracted ocean-going vessels. In the 19th century they came for rubber, today the products are more varied with a dutyfree zone generating additional commerce. Other ports along the Amazon may be for a single commodity such as soyabeans. Recently, the first of a series of Robert Allan Ltd.-designed ship-docking tugs was launched from the Estaleiros Rio Negro Ltda. (ERIN Shipyard). The tug was launched into the waters of the

Rio Negro at Manaus where it merges with the Solimões River to form the Amazon proper. This latest boat is a RAmparts25 with a 25-metre length and 10-metre beam. The hull has a molded depth of 4.19 metres and, with the additional depth of the Z-drives and skeg, a 4.55-metre draft.

Main propulsion for the new tug are a pair of Cummins Tier II, Cummins QSK38-M engines each delivering 1400 hp at 1800 rpm to Rolls-Royce US155 model azimuth drives. The new tug is fitted with a hawser winch and will be employed at the Itacoatiara Port of Hermosa Logistics, about 260 km down river from Manaus. The vessel has tanks for 55,000 litres of fuel and 15,000 litres of water. Accommodation is provided for a crew of up to eight people. Thanks to Alan Haig-Brown for the submission through Cummins Hottips. If you haven’t yet been to Alan’s website (www.haigbrown.com), it’s well worth a visit for the latest on Cummins products, vessel designs and deliveries from around the world.

Letter...

Re: Joe Spears’ The History of the RCMP Marine Services

Photos courtesy of Estaleiros Rio Negro Ltda. (ERIN Shipyard) and Cummins

RAL’s RAmparts25 on the Rio Negro at Manaus. Inset above: One of the tug’s two Cummins QSK38-M main engines.

com m e rci a l a nd m ar itim e law on c an ada's we s t coa s t. W. Gary Wharton Mark W. Hilton Katherine A. Arnold David S. Jarrett

Nevin L. Fishman David K. Jones Catherine A. Hofmann Mark Tinmouth

Peter Swanson Neo J. Tuytel Connie Risi

associate counsel:

Lorna Pawluk

Joan Rush

Thomas S. Hawkins Tom Beasley Paul D. Mooney

Peter G. Bernard, QC (retired) tel: 6 04.681.1700 fax: 6 0 4 .6 8 1.17 8 8 emergency response: 604. 681 . 1 700 address: 1500–570 Granville Street, Vancouver, BC, Canada, V6C 3P1 website: www.bernardpartners.com

8 BC Shipping News December 2012/January 2013

Dear Joe, My name is Jim Haycock, a proud brother to Kenn Haycock. I received a copy of your review on The History of the RCMP Marine Services, from my sister-in-law Jacquie Haycock, Kenn’s widow. On behalf of my family, I would like to extend our sincere gratitude. I will be taking copies of it to share with my mother and siblings, as I’m sure they will be as thrilled to read it as I was. I know how important this book was to Kenn, as were his many other projects. Seeing it published is a great reminder to his family of his many accomplishments and is a true reflection of the passion he had for his work. Although Kenn wrote this book with the sole purpose of documenting the history of the marine unit, he would have been pleased with all of the recognition and support it has received. That has come from people like, Ken Burton, Peter Vassilopoulos, the rest of the RCMP family, and now you. Sincerely, Jim Haycock

news briefs Open house at WCMRC highlights response capabilities

T

he Western Canada Marine Response Corporation (WCMRC) welcomed visitors to their Burnaby facility for an open house in mid-October. With staff on-hand to provide details of the equipment on display and explanations of their use, the event highlighted WCMRC’s oil spill response capabilities on marine waters. Visitors could tour the warehouse to see shelves upon shelves of supplies, including various types of boom, sorbents, personal safety equipment and ancillary equipment; the mobile command and communications centre; the incident command room; and numerous boats and vehicles all prepared to be deployed at a moment’s notice. The Burnaby warehouse stores eight per cent of WCMRC’s inventory of equipment — the remainder can be found at their two other warehouses in Duncan and Prince Rupert as well as caches all along the coast. Demonstrations were conducted on a frequent basis — skimmers, rope mop, anciliary equipment such as portable open-top containers and transfer pumps were all set up in the parking lot with staff available at each display to answer questions. Additonal areas demonstrated best practices for such operations as the decontamination process of clean-up crews and field operations for incident response teams. The open house was a great way to learn about the capabilities of the WCMRC — if you missed it, visit their website (www. wcmrc.com) to learn more about spill preparedness.

Senior Business Analyst Toni Frisby was on hand to welcome visitors to WCMRC’s open house at their Burnaby location.

December 2012/January 2013 BC Shipping News 9

INDUSTRY INSIGHT

Young enough to climb Jacob’s ladder, old enough to know better.

Tim Ellis, Principal, JT Ellis & Associates Secretary, Association of Marine Surveyors of B.C.

I

f you look up the definition of a “marine surveyor” on Wikipedia, you’ll read a quote from the International Association of Classification Societies (IACS): When it comes to defining the qualities and qualifications of a marine surveyor, a memorandum of 1834 has not been bettered: “The utmost care and discrimination have been exercised by the Committee in the selection of men of talent, integrity, and firmness as surveyors, on whom the practical efficacy of the system and the contemplated advantages must so materially depend; the Committee have in their judgment appointed those persons only… who appeared to them to be most competent to discharge the important duties of their situations with fidelity and ability, and to ensure strict and impartial justice to all parties whose property shall come under their supervision.” Taken one step further, Tim Ellis points to a more recent description from colleague Philip Oldham: “A marine surveyor is young and limber enough to scramble through the smallest hatch, strong enough to lift the heaviest hatch cover, yet old enough to have seen it all. He has the eye of an eagle and can write like Boswell. He is expected to be a

shipwright, a naval architect, a marine engineer and perhaps most important of all, a diplomat. He must know the market value of every boat and what it costs for every type of repair. Marine surveyors are the people in the field who put on the coveralls and crawl in and around the bilges and bottoms of boats and report to you on the condition of a boat or the cause and extent of loss. We are the eyes and ears of the insurance underwriter.”

“A marine surveyor is...expected to be a shipwright, a naval architect, a marine engineer and perhaps most important of all, a diplomat. It is with these definitions in mind that we clearly see the inherent traits of a surveyor in Tim Ellis, Principal of JT Ellis & Associates and Secretary of the Association of Marine Surveyors of British Columbia (AMSBC). BCSN: Given the definitions above, could you explain the duties — or perhaps categories is a better word — that a surveyor performs? TE: Sure, the very basic duties of a marine surveyor can be boiled down

10 BC Shipping News December 2012/January 2013

to: inspecting, assessing, measuring, weighing and reporting. As for categories, or more appropriately, reasons to engage a surveyor, there are many: valuation, condition, damage, fitness for purpose, new construction, salvage, underwater, marine accident investigation, compliance, draft surveying, class surveying, the supervision of the loading and unloading of projects and cargoes, sampling, handling, routing, lashing, stability surveys, heavy lifts…just to name but a very few. BCSN: Given the extent of knowledge that is required of a marine surveyor is there any accreditation required, either from a government agency or other organization that a surveyor needs to obtain? TE: There is no federal or provincial government requirement for marine surveyors. In North America, there are several associations of marine surveyors, but most are south of the border and not representative of the national and local conditions we experience here in Canada and here in B.C. — hence, the Association of Marine Surveyors of B.C. (AMSBC). The International Institute of Marine Surveyors, with whom we are affiliated, acts as an umbrella organization for marine

INDUSTRY INSIGHT surveying associations around the world and gives us a window into the trials and tribulations affecting surveyors wherever they are found. Within the AMSBC, we require surveyors to have five years’ worth of work experience, to undergo an interview by their peers, pass an examination and agree to abide by the ethics and standards promulgated by the Association. We would like to see the AMSBC receive a mandate from the provincial government that would ensure that all marine surveyors who hang out a shingle in British Columbia have some form of accreditation and that that accreditation is based on appropriate qualifications, knowledge and experience. We are seeking Chartered Status to achieve this. Up until 25 years ago, the qualifications for a marine surveyor were that he came from the commercial shipping industry and he would be either a master, mate or engineer but in fact, there never was the formal requirement for qualifications — surveyors’ clients just wouldn’t employ people who didn’t have these qualifications. At some point over the last few decades, it became obvious that the requirement to be a master, mate or engineer was impeding progress and the value of knowledge and experience was deemed to be greater than the need for these

difficult-to-get qualifications of master mariners, mates and engineers. So that’s led to a bit of a “rush” — many people loosely affiliated with the sea through pleasure boating or fishing, for example, believe that they can go into marine surveying as an easy option. Someone who retires early and still wants to work thinks they can become a marine surveyor but of course it doesn’t work like that — there is no substitute for experience and expertise.

The AMSBC is quite progressive in the way it has approached issues like education. BCSN: Are there courses available that a person can take to become a marine surveyor? TE: There is an educational course provided by the International Institute of Marine Surveyors (IIMS) who works with Edexcel (an organization in the U.K. that facilitates the program — audits the exam and study material and marks the results). This allows for distance learning and a consistency in application and evaluation of the exam. For surveyors in B.C., the exams are proctored by the AMSBC. The AMSBC is quite progressive in the way it has approached issues like

education. In addition to our educational association with the IIMS, we have resourced numerous questions from our member surveyors — in fact, one of the requirements of membership is that you have to contribute to the Continuing Education Program. BCSN: You mentioned earlier that the AMSBC requires members to abide by standards in ethics — is that a big issue for the Association? Further, how does the Association work to resolve issues? TE: I wouldn’t say we have a litany of these complaints but even four or five over a three-year period are far more than I’d like to see. The good news is that, of those four or five, only one related to a member and that complaint related to an omission rather than commission — i.e., the charge was that his reporting was not adequate, however when we carefully reviewed the client’s instructions, the report achieved what had been asked and, in fact, the surveyor had completed his instructions satisfactorily. The committee that reviews complaints are all very experienced surveyors. To give another example of the types of things we see, we had a case where a surveyor (not a member) had inspected a vessel — and bear in mind that reports are purchased and are the sole property of the person who commissioned the report — and in this

December 2012/January 2013 BC Shipping News 11

INDUSTRY INSIGHT case, the surveyor had communicated the contents of the report to an authority who made a determination based on the findings contained within that report. This was done without the knowledge of the person who had commissioned the report and was to his detriment. The surveyor’s duty is to the person who commissioned the report. BCSN: Surveyors are obviously integral to determine causes of damages in accidents. Could you give some examples of how you would work within the legal processes of cases involving accidents? TE: In general terms, the surveyor’s duty to an employer is to determine the cause, cost and extent of damages, but the actual input depends upon the instructions issued to the surveyor by the client. To give an example: A dry-bulker enters a claimed ‘safe berth’ and during the discharge it’s noted that water is entering the vessel’s foremost hold. The investigation indicates that the mid-stream berth is shallower as a result of rapidly falling water levels and that the vessel may have come into contact with the bottom. An incomplete examination of the damage indicates that the vessel may have pressed a hole through her hull by coming into contact with her own anchor…or the pile securing the forward end of the buoyage system…or by the stevedore’s equipment…or by contact with some heretofore unknown underwater obstruction…or through stress upon the vessel…or perhaps previous and unreported damage. There are several factors that must be taken into account during a survey, including damage to the vessel, damage to

cargo, delays to the discharge, stevedore’s stand-by time, loss of use of the berth, loss of charter hire, removal and disposal of damaged cargo, loss of future use of the vessel (charter hire), dry-docking, repair, loss to the receiver, incomplete out-turn, etc. and lawyers and surveyors representing each of these stakeholders will want to survey every aspect of the incident to determine cause, extent and cost. It is not uncommon to have numerous surveyors onboard a vessel, all at the same time, all jockeying for position and all utterly convinced of the righteousness of their position and their right to preeminence. In this case, after years of legal wrangling, the loss was found to be the responsibility of the berth owner. The surveyor can act as the disponent owner, but this is not so common now, the purpose of such employment is more likely as an independent third party to assess and report to a client. In general, the surveyor’s activities are employed by one of the parties which may be, for example, owner, charterer, sub-charterer, P&I Club, hull insurer, cargo interests, stevedore and /or longshoremen, berth owner, berth operator, ship handler (tugs), pilots, bunkers, and so on. There are many more to list. A typical charter party dispute can arise from something as simple as a vessel’s inability to load a contracted volume of cargo, for example, the wrong kind of wheat, or perhaps due to a stability issue arising from the order of loading, or perhaps she cannot maintain a warranted speed — 12.5 knots instead of 14 knots, or a vessel might be detained in port for a safety infraction causing delay and loss — all of the foregoing will require attendance by a knowledgeable surveyor to determine the cause, extent and cost.

Liability insurance for all professionals in recent years has become an issue. A single claim can put even the most successful surveyor out of business. BCSN: What about the liability of a marine surveyor? TE: Liability insurance for all professionals in recent years has become an issue. A single claim can put even the most successful surveyor out of business. Lawyers pursuing negligence claims often use the shotgun method where all parties involved are named jointly, leaving a judge or arbiter to assign a value to each defendant named. Even when a surveyor is faultless, the costs of defence are considerable. Our litigious world makes us all careful and prudent. Insurance is critical because it’s not just a case of protecting yourself from the possibility of suits but a lack of insurance can inhibit people from doing the best work that they can. Some surveyors, especially those who operate at the small vessel level, probably find it hard to justify the high costs of insurance but, having said that, the AMSBC recently negotiated a very competitive and attractive package on behalf of our members with BFL Canada Insurance Ltd. It took two and a half years to work out an agreement on behalf of our members. BCSN: Let’s focus now on the ships that you survey. What sort of trends have you seen in terms of deficiencies or issues that are continually identified? 12 BC Shipping News December 2012/January 2013

INDUSTRY INSIGHT TE: I’d have to say adequate manning and size of crew is a very big issue today. Modern vessels are larger and more complex than any of their predecessors but crews are smaller than they have ever been. For example, a handy bulker circa 1985 might have 44 crew aboard whereas a Panamax-sized vessel today will have as few as 15. Today’s vessels are efficient but lonely. Time at sea has not been reduced, but time in port has declined to the point that many serving seamen won’t have time to leave their vessels at all during a seven-month contract (and those contracts are often extended to over a year). Modern vessels also rely much more on dock facilities to discharge their cargoes.

Today’s vessels are efficient but lonely...many serving seamen won’t have time to leave their vessels at all during a seven-month contract... The shipping companies try to operate as efficiently as possible by contracting out as much as they possibly can. This especially impacts on operations while in port because it means that, for example, during a loading or unloading, the crew has to be available virtually all the time that they’re in port to open and close hatches, move the vessel up and down the dock — whatever is required — and with only 12, 15 or 17 people onboard, that can be a problem. Crew become tired, stressed and start making mistakes. Some owners are, too often, remote from their ships and their crews whilst maintaining interest in profits, expenses and the business of logistics. Officers are overwhelmed by bureaucracy, harried by owners, and ignored by busy ports. Crews lack basic skills compounded by an inability to communicate with each other due to language barriers, pay is stagnating and responsibilities are increasing. Another issue that, while not as prevalent today as 20 years ago but can still be seen, is in the cleanliness of cargo holds. A vessel that is not clean is not fit for loading. Vessels are much December 2012/January 2013 BC Shipping News 13

INDUSTRY INSIGHT

With a passion for sailing, Tim’s life has revolved around the sea. more multi-purpose than they used to be and are expected to carry any cargo — for example, you could carry sugar on one voyage, salt on another, cement on a third. Sugar chemically reacts with cement so that it’s no longer cement so you can destroy a very large, valuable cargo through inattention. A seed of wheat trapped on a shelf high up on a ship’s hull that falls into cement, for example, will sprout when it gets wet, and it will exert 4,000 p.s.i. within drying cement. A few grains of corn inside a cargo of cement will sprout through the cement; or a handful of oily coal dust in cement can spoil an entire cargo. We run into this from time to time but shipping companies have learned that cleanliness is very important. I wouldn’t hesitate to say that a ship hold that may be 20 metres deep needs to be inspected with your nose against the plate from the very bottom to the very top. You may need a cherry picker in there to accomplish this and you go up and down between every frame in the hull and inspect it to make sure it’s clean. The grain inspections undertaken by Transport Canada and by private surveyors are of a similar nature — they will not accept any loose debris inside a ship’s hull. BCSN: Does a surveyor’s work include inspection of port-side infrastructure? TE: Yes, that’s part of our work as

well. We’ve seen it before where a company builds a dock, say for example in the Arctic, but doesn’t talk to anybody qualified to actually work in the conditions they’re expecting. So the designers go ahead and design wonderful features for a port and they don’t work. They forget that a ship is not discharged statically. The ship will move up and down the dock underneath the handling equipment. If your ship is on a dock that’s not

long enough or there are no dolphins to hold it, it suddenly becomes an impossible task to unload cargo. Surveyors have a very critical job function when it comes to assessing, monitoring or even assisting with the designs (or redesigns) of these kinds of features. Surveyors are also involved with monitoring ships’ gear, port-side gear, containers, container handling or other areas where you’re seeking to gain advantages through efficiencies in handling. BCSN: Does the economy impact on surveying? For example, are you more likely to see less maintenance? TE: There are now few vessels trading that are over 15 years old and although one can find the odd 25-yearold ship, these tend to be in specialist trades or built to a particularly high standard with higher scantlings than we might see today. What this means is that most vessels afloat are now very new, or less than 10 years old. One of the main reasons for scrapping the old fleet was that maintenance had become such a grave issue that it led to excessive risks with leaking hatches, rusting decking, inoperative machinery, breakdowns and so on. New ships, better paint systems, electronic engine monitoring, computerized ballasting

About Tim Ellis

P

rior to establishing JT Ellis & Associates in 1977, Tim Ellis was employed by a European shipping line, working in offices in Vienna, London and Hong Kong. Tim gained valuable experience in commercial marketing, operations, accounting, management and analysis as well as container operations and risk management. Located in Taipei, Taiwan, Tim provided marine surveying and project management services for cargo, project shipping, and ocean-going vessels. He also provided services in the areas of transport management, risk management, yachts and small craft, and insolvency. Since 1993, Tim has been based in Vancouver, B.C. and provides services for cargo, project management, transport consultancy, ocean going vessels, commercial craft including floating and fixed structures, risk management and control, valuations, yachts and small craft. Tim has been married to Esther for 26 years and enjoys sailing, rowing and boatbuilding.

14 BC Shipping News December 2012/January 2013

and stability programs and associated equipment (available for 30 years but only truly functional in this generation of vessels) all help to allow maintenance to be directed where it is most needed rather than everywhere and all the time. Maintenance, or the lack of it, is likely to become an issue as the aging fleet approaches the end of its useful life which is generally considered to be 25 years. BCSN: How does today’s focus on environmental sustainability impact on surveying (for example, new regulations, new technology)? TE: Environmental sustainability, outside of the auditing function, is not something we would come across a lot but mostly we address this in terms of the cleanliness of a ship’s operation — the question of invasive species from ballast water is a useful example. Surveyors are required to board vessels to examine their logs and determine what and how much ballast is taken on, where it’s being discharged, etc. There are instances where surveyors in the engineering department have found quite serious violations — for example, a vessel had fitted false panelling to disguise the fact that they were pumping their sewage and grey water directly overboard and the very fact that they had panelled this in and that the valves were not marked as to function meant that they had conspired to do this. BCSN: Is that something the surveyor would pick up on and is he obligated to report it to authorities? TE: If it’s not part of his instructions for the survey he’s undertaking, then he’s not required to look for it, but if it’s his job to review the engineer’s log books to find out how much and where and how waste was pumped out and handled, and he inspected it and identified serious deficiencies, then yes, he’d certainly report on it. Once it’s written in the surveyor’s report, it would be unwise for the company to ignore it. When you come to any kind of legal process the first thing that will be put on the table is the surveyor’s report. BCSN: How has technology impacted on the surveyor’s job? TE: The obvious advances, such as communications and reporting, are beneficial even if not always welcome. Other technologically advanced tools such as ultrasound, imaging, and similar devices are still beyond many small practices purely due to the expense and training required, but it is now evident that these will become mandatory in time simply because their use limits exposure to risk — for example, using ultrasound to detect whether or not a ship’s hatches leak is far superior to running a hose pipe of water over the hatch coaming. Imaging is another advancement that is becoming viable. It allows you to view a ship’s hull to indicate stress points, fractures, void spaces and all sorts of other, useful information. The entry-level equipment is expensive and it puts it out of sight of most marine surveyors but you can see an evolution taking place with these kinds of technologies. It is difficult to imagine a future without even greater reliance on technological advances than we currently have. I have heard of companies in Vancouver who will not use surveyors who don’t have ultra sound equipment to inspect the hatches of vessels loading grain — and I would consider

that to be very reasonable. Ship owners, disponent owners, cargo owners and receivers absolutely demand that these kinds of surveys do the job they’re supposed to do because the risks associated with improper hatch sealing or simple things like rust holes in the decks are just not acceptable. BCSN: Earlier on in the interview, we discussed training standards and the required qualifications for a marine surveyor. Is the industry maintaining an adequate supply of surveyors currently, and following from that, do you see the upcoming retirement surge as being an issue? Are there any plans within the AMSBC to address this? TE: I think we would like to see more young people enter the profession but I’m not sure many are willing to put themselves at risk in terms of job security, nor are they attracted by the hours that must be worked and the travel involved. The AMSBC has not identified a pool of likely candidates. In the case of small boats, there is the attraction of sailing or yachts that bring people who may or may not be suited to marine surveying but who feel they could be marine surveyors. A willingness or desire to become a marine surveyor has to be backed up by “proofs” and the only way to get that is by exams, tests, etc. For the commercial and deepsea surveying requirements, this is an emerging problem. BCSN

About the AMSBC

T

he Association of Marine Surveyors of British Columbia (AMSBC) was formed in 1969 for the purpose of bringing together general marine surveyors with the object of enhancing and developing the practice while providing a representative body in approaching the maritime industry. Affiliated with the International Institute of Marine Surveying, the AMSBC membership comprises practicing marine surveyors situated throughout the province of British Columbia, particularly at the principal ports of Vancouver, Victoria and Nanaimo, who bring to the Association their particular experience providing a broad and diverse input. The members of this Association have undertaken to perform their respective services in keeping with the Code of Ethics and Constitution of the Association. Surveys provided by the membership range through hulls, machinery, cargo and terminals (port operations) to surveys of special or particular nature embraced in the term “Marine Related Transport”. For the full membership directory of the AMSBC, please see page 26 of this month’s BC Shipping News. For more information about the AMSBC, please visit: www.amsbc.org. December 2012/January 2013 BC Shipping News 15

HISTORY LESSON

Survey of the Alpha By Lisa Glandt

Librarian/Archivist, Vancouver Maritime Museum

In 1962, the museum received a donation that included the registration and survey certificates for the first ship to be officially listed in the Port of Vancouver. Aptly named the Alpha, she was an 81.5-foot-long sidewheel steamer built by Captain Richard E. Gosse in False Creek from the burnt-out hull of the old sternwheeler Richmond. Among the archival records for the vessel is the original certificate of survey completed by a Surveyor of Shipping for the Port of Vancouver on December 27, 1890.

The Alpha was first owned by Imperial Steamships Ltd. (Captain Gosse was the President) and was used to transport farm produce from up the Fraser River down to Vancouver proper. In September 1891, the vessel sold to A.W.E. Thompson — but through misfortune, he only owned her for a week! On September 24, 1891 the Alpha was carrying a cargo of hay and potatoes off False Creek when a spark from the funnel caught the hay on fire. The vessel quickly burned down to the waterline and the wreck was subsequently

16 BC Shipping News December 2012/January 2013

beached at Kitsilano. Not much more is known about the fate of the vessel. The archival records related to the Alpha are a wealth of information about the construction of the sternwheeler and an example of the standardization being undertaken by the Port of Vancouver which had recently been declared a port of registry (prior to this, vessels were either registered at New Westminster or Victoria). The Certificate of Survey includes details about the physical dimensions of the vessel and the hold along with engine

VANCOUVER MARITIME MUSEUM and tonnage specifics. The engine for the sternwheeler was built in 1884 by a Seattle, Washington company and was previously used on the vessel Pearl. A secondary survey certificate contains information as filed by “J.A. Thomson, Inspector of Boilers and Machinery, Department of Marine, Dominion of Canada” and certifies that “…her engine, boiler and machinery are sufficient for a freight boat and may be so used without hazard to life, that the engine of the said Alpha can carry with safety 105 pounds per square inch of steam pressure and no more…”.

...records that do prevail are extremely Publication BC Shipping News useful for researchers, model makers

Issue and shipwreck enthusiasts November

Size These records are unique in themselves(half becausepage they vertical) rarely exist over Island the years to be donated to a museum or archives — indeed, we have few Deadline records5,like this in our holdings! October 2012 However, those records that do prevail Features are extremely useful for researchers, model makers and shipwreck enthusi Industry Insight – Bud construction asts looking to confirm

details and understand the nautical integrity of a vessel. In this case, we do not have any photographs of the vessel (our file only contains a photograph of a drawing that was done), increasing the importance of survey figures and other recorded construction details. First-hand survey and registry documents like those for the Alpha compliment the information that is found in publications such as “Lloyd’s Register of Shipping” that is based on detailed

and strictly controlled vessel surveying techniques. When research from these sources is combined, the true history of a vessel can be revealed. Lisa Glandt has been the Librarian/ Archivist for the Vancouver Maritime Museum since 2007. She started volunteering at the museum in 1999 sharing maritime stories with school children and now she preserves the stories. She can be contacted at archives@vancouvermaritimemuseum. com.

Endurable Designs designs@ral.ca

CCGS Vladykov

Near Shore Fisheries Research Vessel

Streeter, Lloyd's Register Canadian Coast Guard articles: From the office of Michel Vermette (Deputy Commissioner, CCG – Vessel Procurement) – an update on fleet renewal (including activity at Irving for naval vessels); interview with Vija Poruks (Assistant Commissioner, CCG Pacific); Arctic operations with Duke Snider (Assistant to Vija and author of recent book: Polar Operations). Forensics of the Sea – from BMT De Beer – looking at the complexities of marine surveyors (Note: this might end up in the December issue). Interview with R-Adm William Truelove – Commander, Maritime Forces Pacific. Recap of Maritime Security Challenges Conference Recap of CFOA conference Technical section: Consilium products (detection systems, ECDIS) Human Smuggling from Darryl Anderson Navios Group from Syd Heal

Certificate of Survey for the Alpha, circa 1890. December 2012/January 2013 BC Shipping News 17

ports symposium

Northern Ports Symposium highlights development opportunities By Dan Dibbelt, Executive Director, Northwest Corridor Development Corporation

N

ew industry developments proposed in the Prince Rupert / Kitimat region were the focus of the Northern Ports Symposium and Northwest Corridor Development Corporation (NCDC) AGM, in Prince Rupert, October 10 to 12, 2012. Rio Tinto Alcan, Enbridge, CN Rail and the Port of Prince Rupert all highlighted new developments proposed in the port region as well as along the corridor. “Now is an exciting time for the region,” said Pacific Northern Gas, (PNG) and NCDC Vice-Chair Ron Vanderlee. “Kinder Morgan, Spectra Energy, and Shell, as well as Enbridge, all have proposals in the plans for this region,” said Vanderlee. “The economic impact and the opportunity for further development in this region are huge.”

“Going back 100 years to the turn of the last century, there was a group of foresighted individuals who had a plan to realize the north’s potential...” “One of the key goals of the symposium was to highlight the importance of not just industry development proposed for the region, but to also inform those attending, of the importance of the communities and industry along the northwest corridor as part of this important supply chain,” said NCDC Chair, Carolyn Kolebaba. “NCDC members recognize the need to develop the corridor and open up value-added opportunities along the corridor to feed these port developments.” “Going back 100 years to the turn of the last century, there was a group of foresighted individuals who had a plan to realize the north’s potential,” said keynote speaker Graham Kedgley. “Today, we see the development of a container facility here in Prince Rupert, the significantly upgraded rail

lines across the northern provinces, the inland port in Edmonton, the enormously improved and expanded Prince George airport, a power line up the West Coast of B.C., to name but a few,” he added.

Kitimat Clean filed an environmental assessment application on September 21 to build an oil refinery in Kitimat. It would be the first such refinery to be built in Canada since 1984. Kedgley went on to talk about the need to continue developments along the corridor to feed into these important northern ports and in order to take advantage of their proximity to AsiaPacific markets. Kedgley, who was the original executive director of NCDC, was also a key player in the development of the organization and instrumental in the development of a coal terminal in Prince Rupert. The symposium, however, did not limit itself to Prince Rupert, presentations from Rio Tinto Alcan, Enbridge and Kitimat Clean Ltd. focused on the Kitimat region. David Black, President of Kitimat Clean Ltd. and Black Media discussed his proposal to see a refinery built in Kitimat to process bitumen from Alberta’s oilsands. Black spoke to the need to find solutions for environmental concerns about using tankers off the northern ports to ship bitumen. His $13 billion proposed refinery would allow bitumen to be refined and shipped as refined oil, which he said would have reduced environmental concerns if an oil spill occurred. He added that there are many legitimate concerns about the (Enbridge) pipeline and said it should not proceed unless there is confidence that any pipeline leakage would be immaterial.

Kitimat Clean Ltd. filed an environmental assessment application on September 21 to build an oil refinery in Kitimat. It would be the first such refinery to be built in Canada since 1984. Black estimated that construction of the facility would employ 6,000 workers for five years and require approximately 3,000 permanent employees to operate the refinery once it was built. Enbridge’s Senior Manager of Community and Municipal Relations, Michele Perret, spoke to Enbridge’s proposed Northern Gateway Pipeline Project. The pipeline would run 1,177 km from Bruderheim, Alberta to Kitimat, British Columbia and transfer 525,000 barrels of oil per day. The proposed expansion of Fairview Terminals as well as other developments on the Prince Rupert Port was highlighted by Prince Rupert Port Authority President and CEO, Don Krusel. A vital link in the transportation chain in getting product to the port is CN Rail, the only rail line that runs to Prince Rupert.

“CN Rail truly appreciates the importance of the corridor that leads to the Port of Prince Rupert”... “CN Rail truly appreciates the importance of the corridor that leads to the Port of Prince Rupert,” said Mike Cory, CN Senior Vice President, Western Region. “CN has and will continue to invest in rail along this corridor to increase capacity of this line and improve accessibility for the corridor, to the benefit of both imports and exports.” Port Alberta’s CEO, Wendy Cooper, highlighted developments in Alberta, while Cathy Goulet, Executive Director with the Northern Alberta

December 2012/January 2013 BC Shipping News 19

ports symposium Development Council, spoke to the value of the strategic corridor leading to Prince Rupert for Alberta shipments. Other speakers included Tara Bogh with Initiatives Prince George and Evan Van Dyke with Terrace Economic

David Black, President of Kitimat Clean Ltd. and Black Media; and Carolyn Kolebaba, Chair, Northwest Corridor Development Corporation.

Development highlighting the growth sectors in their region. The symposium also offered an opportunity for NCDC to present their latest research document, “Accessing the Corridor”, which highlighted the fact that the mass majority of northern Alberta products do not utilize the northern ports and in fact ship most of their products south. ”This research demonstrates the necessity to increase northern transportation corridors to open up the opportunity for our producers and processors to ship to Asia-Pacific markets effectively and efficiently,” said Kolebaba. “NCDC undertakes this type of research to help educate all stakeholders, including all levels of government, on the need to build northern east/west transportation corridors. The Northern Ports Symposium brought together more than 80 key stakeholders, many from Edmonton and northern Alberta to hear about developments in the region and along the corridor and to network with industry and municipalities. Also on hand was United Kingdom Consul General Rupert Potter, opening the reception with comments on the United Kingdom’s plans for investment and trade opportunities in British Columbia. The United Kingdom is Canada’s second largest trading partner. Dan Dibbelt is the Executive Director for the Northwest Corridor Development Corporation and can be reached at: dandibbelt@nwcorridor.net

Located at Vancouver Waterfront and Roberts Bank

www.flyingangel.ca 20 BC Shipping News December 2012/January 2013

ports & terminals

Fraser Surrey Docks’ VP excited by the next 50 years By Ray Dykes

W

ith 50 years under its belt, Port Metro Vancouver’s largest multi-purpose terminal, Fraser Surrey Docks, is busily planning for an exciting 50 more. There’s talk of the Fraser River becoming a super highway and Fraser Surrey Docks emerging as the premier super port on that evolving highway. And there’s even a prediction that Port Metro Vancouver will become North America’s largest port by volume within a decade or two. From his office overlooking a murky Fraser River on a wet, grey Friday, Fraser Surrey Docks’ Vice President of Sales & Marketing, Bill Wehnert, has polished up his crystal ball and is bringing some enthusiasm to his task. I had asked him to look ahead another 50 years after we’d carefully traced progress over the past five decades now being celebrated by Fraser Surrey Docks (FSD) this year. Wehnert has little doubt about how the Fraser River seven-berth, 154-acre terminal will fare and assures me that FSD is confidently investing in the future. “Fraser Surrey Docks will become a super terminal in Port Metro Vancouver because of our ability to service multiple markets, markets that need support,” he predicts. “I think we will become the flagship of business on the Fraser River and I see the Fraser coming of age as the

next St. Lawrence Seaway or Mississippi River.” After basing its success in the first 50 years on handling import steel, export raw logs, other break bulk, containers, and project cargoes, the terminal has “purposefully” looked at how its future will be and has chosen to base growth on bulk agri-products it ventured into in 2011, and a newcomer, coal.

...FSD announced to its neighbours early in the fall that it wanted to get into the coal export business. In a surprise move, FSD announced to its neighbours early in the fall that it wanted to get into the coal export business. It has applied to Port Metro Vancouver for a project permit to build coal handling facilities within the existing terminal operations. The plan, which it hopes will be underway in 2013, would haul coal in from the rich-seamed Powder River Basin in Wyoming and Montana, load it onto barges by conveyor, and tow the barges to Texada Island in the Strait of Georgia for transshipment and eventual passage to Asian markets such as Japan and China. Texada Island has an established export terminal now serving the domestic shipments and occasional

exports of Vancouver Island miner Quinsam Coal, owned by Swiss-based Vitol Anker International B.V. The trip down the Fraser and north on the strait to Texada is not seen as onerous or a deal breaker for future coal exports. Wehnert and his Fraser Surrey Docks’ boss, Jeff Scott, President & CEO, are not subject to bouts of wishful thinking. Coal is going to be a valuable and vital part of Fraser River traffic if the terminal wins approval from PMV. There are still a lot of details to be determined, but FSD confidently put out a Community Update in mid-September letting all local residents know of its plans. It has assured the residents there will be no permanent stockpiling of coal at the river terminal. But, the proposed coal handling facility would require a significant investment to upgrade existing infrastructure, including: • Additional terminal rail track; • Installation of two railcar unloading pits for bottom dumping cars; • Conveyor to connect the pits to the barges (front end loaders would groom the pits to feed the conveyor); • Upgrades to the electrical system; • Installation of associated dust and fire prevention systems. FSD plans to handle energy coal, something that emerging countries in Asia can’t seem to get enough of to power their growth these days. Just

December 2012/January 2013 BC Shipping News 21

ports & terminals

April 2011: The first rail car to carry agri-products (through a joint venture with Parrish & Heimbecker) enters FSD. look at the six new coal export facilities now being pushed along the Pacific Northwest coast. Not all of them will go ahead even though the U.S. West Coast currently has no indigenous coal export terminal of its own. And into this mix comes Fraser Surrey Docks with an initial annual

capacity of four million tonnes already sold out, according to Wehnert, and there are now plans to go to eight million tonnes a year. Wehnert says he is averaging a phone call a week from interested mining companies and while he won’t disclose FSD’s partners in the proposed new coal export venture, any

EARTH MATTERs A leading environmental and energy services company, Tervita is a key service provider to the marine industry, specializing in: Bilge water & sludge • Waste fuel & oil • Hazardous waste Recycling & disposal of solid waste & garbage Victoria, B.C. (250)-380-0436 24hrs: 1-800-327-7455

22 BC Shipping News December 2012/January 2013

tervita.com

number of Powder River Basin mines could be involved. And why not? The premier coal export of choice for both Canada and the United States is currently Westshore Terminals, which shipped a best ever 8.2 million tonnes of U.S. coal in 2011 on its way to a record 23.7 million tonnes overall and is going great guns in 2012. But, like the other coal export terminals in British Columbia — Neptune Bulk Terminals in PMV and Ridley Terminals in the rapidly expanding Port of Prince Rupert — Westshore is upgrading its equipment and improving its capacity . . . all while turning away business. Despite environmental protests, Wehnert and others in the shipping and mining industry feel energy coal — that’s the thermal coal used to generate electricity in power stations around the world — can do more to power Asian growth than any other fuel. He notes improvements underway in coal-fired power station emission levels and says it would be difficult to convince Asian countries now hungry for coal to find another fuel that is as readily available. With its ample coal supplies and numerous new mines looking to come into production over the next five years, Canada should be taking advantage of its assets, says Wehnert. Regardless, Fraser Surrey Docks intends to be among the action, expanding as it makes economic sense. A buoyant Fraser Surrey Docks and the creation of other terminals on the Fraser River in coming years are part of the reason why Wehnert also predicts Port Metro Vancouver will eventually become the busiest port in all of North America. Meanwhile, the Fraser River’s “superstore of port terminals” — as Fraser Surrey Docks is being billed these days — is all about diversification and coal is just the latest commodity to catch its eye. While overall yearly throughput tonnage figures are difficult to come by for some reason, the terminal expects to dock 221 ships this year at its berths, which currently comfortably handle Handymax-sized vessels, usually regarded as from 40,000 to 60,000 deadweight tonnes. Above that size,

ports & terminals percentages in recent years with the handling of equipment and machinery for oil rigs and natural gas plants, plus the export of old pulp mill equipment, much assisted, says Wehnert, by the on-dock rail capacity.

...the Fraser River’s “superstore of port terminals” — as Fraser Surrey Docks is being billed these days — is all about diversification...

Fraser Surrey Docks: seven berths and 154 acres of waterfront along the Fraser River. the terminal can handle newer Panamax-sized ships (up to 82,500 dwt) if they have the more modern and shallower hull designs, or if they are only partially loaded. Much of the past 50 years of growth, despite relatively frequent ownership changes — the terminal has been owned by Macquarie Infrastructure Partners since 2007 — has been based on imports of steel and that will continue, says Wehnert. In fact, FSD has no intention of quitting steel handling nor is it abandoning its venture into containers, which peaked at about 350,000 TEUs (20-foot equivalent units) in 2005 and has slipped through the global depression and consolidation of shipping lines to around 100,000 TEUs today. And it won’t be turning its back on shipments of raw logs, now largely to China, despite that business not being all that lucrative. Nor is it forsaking its new venture into handling agriproducts such as canola meal, malt or lentils with its new horizontal storage facility built in partnership with Parrish & Heimbecker Ltd. and rail car belly dump system and conveyors and weighing structure. Agri-bulk handling could go as high as 600,000 tonnes a year with current equipment and FSD is prepared to grow the facility to meet demand. Shipments in the first year in 2011 topped 100,000 tonnes and this year will be substantially better than that, according to Wehnert. Part of FSD’s competitive advantage is the 38,000 feet of on-dock rail it boasts and Wehnert muses there’s probably not a terminal in Port Metro Vancouver with more. FSD has a Class II B.C. locomotive licence and switches trains in and out of its facility. Project cargoes, often involving heavy lifts, are also a Fraser Surrey Docks specialty. In the past, the FSD has offloaded huge pieces of a new stacker-reclaimer for Westshore Terminals, which were barged to that Roberts Bank facility for assembly. And project cargo has grown by double-digit

But, there are some darker clouds on the otherwise seemingly rosy horizon. Dredging of the massive silt load that comes down the Fraser River each year is imperative. Maintenance dredging is done every year by PMV and every few years capital dredging, costing much more, is done to preserve the existing 11.5 metre shipping channel. Ideally, the channel should be deepened to 12.5 m or to 13.5 m — break bulk steel shipment vessels, for example, will need 12.5 m and future growth in that business is being threatened. However, one of the biggest impediments to this growth, which would allow larger ships on the river, is the George Massey Tunnel in Ladner. No wonder President & CEO Scott enthusiastically endorsed B.C. Premier Christy Cark’s announcement in September that the provincial government was looking to replace the tunnel — a severe traffic bottleneck at almost any time of the working day. “Sufficient draft in the Fraser River is critical to the port’s ability to service the world’s increasing fleet of larger vessels,” Scott said at the time. If that tunnel river restriction is removed, then the next 50 years should be one exciting voyage for Fraser Surrey Docks. Ray Dykes is a journalist who has worked his way around the world as a writer/photographer. Ray can be reached at prplus@ shaw.ca.

December 2012/January 2013 BC Shipping News 23

marine salvage

West Coast salvage: A 21st century view By K. Joseph Spears and Captain Don Mackenzie

S

alvage is an important component of having a strong and resilient marine response capability on Canada’s West Coast. Recent projects involving the export of energy resources from British Columbia to IndoPacific markets have focused attention on maritime issues. Canada is discovering that it is a maritime nation and the West Coast is central to Canada’s economic future. Salvage, provided by the private sector, is an integral part of the commercial shipping world and it is not well understood by those not in the business. This article will focus on the underpinnings of the concept of salvage and its growing importance in the 21st century as shipping has become more complex and protection of the marine environment from dangerous and hazardous cargoes has increased. Salvage is both the undertaking of the actual work dealing with a marine casualty as well as the maritime law elements of getting paid for the salvage work which can often prove more difficult than the actual work itself. Premier Christy Clark, in a recent policy statement, spoke about the need for a world-class response for marine pollution as a term of B.C.’s support for the Northern Gateway. On Canada’s West Coast, salvage response by private salvors has been world-class for generations. The B.C. coast is unique in that it is a remote coast line with very little infrastructure, strong tidal currents and a high energy environment — oceanographic speak for big storms

and waves. Some of the strongest tidal currents in the world are found in our waters. To give some perspective on the volume of water running through coastal British Columbia, at Turn Point in Haro Strait near Victoria, four times the volume of the Amazon River changes direction twice-daily. These tidal currents, some of which exceed 22 knots, deep-water fjords and pinnacles present special challenges to salvors. This, combined with a heightened environmental awareness, works to create added pressure on salvors to obtain a successful result. Our waters are also among the most pristine in the world.

...none of the recent reports have considered the important role that salvage plays in marine response. As a recent report from the Office of the Auditor General indicated, Canada does not have adequate marine spill capability. But none of the recent reports have considered the important role that salvage plays in marine response. This is a subject that needs to be central in any world-class marine response capability. The good news is that much of this capability and capacity on the coast already exists in the towboat, marine eco-tourism and fishing industries. There is a strong web of local knowledge, suitable vessels, equipment, diving contractors and,

24 BC Shipping News December 2012/January 2013

most importantly, a “can-do” attitude to get the job done that bodes well for the complexities of the 21st century. These assets need to be brought front and centre into the awareness of Canada’s ocean management. It is equally important to bring both First Nations and coastal communities into the fold to increase response capability on British Columbia’s 28,000-kilometre coastline. We need to encourage private sector companies to learn about salvage response and how that can be co-ordinated and integrated into marine response. Increasing Canada’s salvage capability will also increase community resilience as was recently seen with the 7.7 magnitude earthquake off Haida Gwaii. It is crucial and critical that this occur now. In the past, especially in Canada, salvage has been thought of essentially as a private sector response protecting private property interests — namely the vessel and its cargo — and it had a very large marine insurance focus. The International Maritime Organization (IMO), through its work to develop the international Salvage Convention, 1989, has recognized the importance of protecting the marine environment. Article 14, the safety net provision, provides an enhanced award for protection of the environment even if the vessel is not successfully salvaged. Internationally, this is still a very controversial topic. Canada adopted the Salvage Convention, 1989 as a schedule to Canada Shipping Act, 2001. It is part of Canadian maritime law.

Joe Spears/SLC Ocean House Collection

marine salvage

Captain Don Mackenzie, the late Don Carpenter, C.A., and Dave Unsworth of D and E Towing stand outside the Lloyd’s Building in London, circa 2000. Don’s smile reflects the outcome of the Golden Cell LOF. Normally, salvage work is compensated on the basis of success and that is a fundamental underpinning of the Lloyd’s Open Form salvage process — “no cure-no pay” — that has been in place in the commercial shipping industry for generations. Traditionally on the B.C. coast, when towboats were salvaging towboats, the rate was double the daily towing rate. Today, a “double-double” may be good for coffee but not for salvage given the complexities and the need to protect the marine environment and the salvor’s potential liability. It is our view that the Lloyd’s Open Form (LOF) salvage agreement is the preferred route. This allows a prompt mechanism for payment for salvage services. In the case of the successful salvage of the Golden Cell, undertaken by writer Captain Mackenzie in 1999, payment was made within nine months of the completion of salvage. The LOF process uses salvage arbitrators in London who are experienced maritime barristers who have a streamlined, efficient hearing process. The LOF process is administered by the Lloyd’s Salvage branch in London and it is very user-friendly. Getting successfully paid in any salvage case is often the hardest part of salvage work. The key is the development of the salvage brief which often is more painful than the salvage itself. Farley Mowat, the great Canadian writer, who never let the facts get in the way of a good story, summed this up well in his classic marine yarn, Grey Seas Under. Farley wrote: The salvors, meanwhile, have been hard at work preparing an extraordinary document known as a salvage brief. It describes the operation in the most meticulous detail. A really good brief can make you hear the thunder of breakers and yearn for the reassuring feel of a life-belt around your waist...The preparation of the brief is a highly skilled exercise in creative writing. Not fiction, mind you, but subjective fact. Conducting salvage on the B.C. coast in the 21st century is a complex dance involving many parties including the vessel owner, their insurers, surveyors appointed by various groups, regulatory authorities, municipal governments

and the media to just name a few. West Coast mariners have the skills and are up to the challenge to be professional salvors when the call comes, however, we need to have a full and frank discussion about enhancing West Coast salvage capabilities and have more people understand the Lloyd’s salvage arbitration process. The LOF works and can provide a solid foundation for increasing British Columbia’s marine response capability. Private sector salvage has an important role to play in Canada’s pollution salvage capability in the 21st century. A robust and vigorous West Coast salvage capability, led by the private sector and supported by all levels of government, First Nations and local communities is a valuable asset to pollution counter-measures and Canada’s ocean management. This will ensure that British Columbia’s pristine coastline is protected for future generations. Captain Donald McKenzie is a mariner with over 60 years of towboat experience, ship-berthing and a broad range of marine experience and underwater support services on the West Coast. He is the president of Mackenzie Sea Services Limited. He was found to be a professional salvor in the 1999 LOF Golden Cell arbitration. He now sails the coast in his yacht, the Flying Fish 4. Don can be reached at macsea@telus.net. Joe Spears is maritime counsel with Straith Litigation Chambers, a certified mariner and Canadian Coast Guard Rescue Coxswain. He is also the founding principal of Horseshoe Bay Marine Group. He undertook his first salvage off Ketch Harbour at age 11. He is a frequent speaker and commentator on salvage and pollution countermeasures and was legal counsel to Mackenzie Sea Services during the Lloyd’s salvage arbitration involving the M/Y Golden Cell. He can be reached at kjs@oceanlawcanada.com.

FULL SERVICE REPAIR YARD 330 Ton Marine Travelift Welding Electrical Repairs Mechanical Repairs Vessel Refits Painting and Sandblasting Custom Steel and Aluminum Projects CSI Inspection Readiness 24 Hour Emergency Service

11580 Mitchell Road, Richmond 604-323-7402 www.ArrowMarineServices.com

December 2012/January 2013 BC Shipping News 25

SURVEYOR DIRECTORY Association of Marine Surveyors of B.C. membership directory Small Craft

(Yachts, Power Boats, Pleasure Craft)

Tim Amy Inland Marine Surveyors Sidney, Okanagan, Shuswap P: (250) 833-2444/C: (250) 833-2444 E: tim@inlandmarine.ca www.inlandmarine.ca Volodymyr Bondarev IMS Marine Surveyors Ltd. Burnaby P: (604) 298-9968/C: (604) 562-7851 E: admin@ims-van.com www.ims-van.com Todd Braconnier TCB Marine Consulting Service North Vancouver P: (604) 375-0923/C: (604) 375-0923 E: tcbroc@shaw.ca www.tcbmarine.ca J. Timothy Ellis JT Ellis & Associates Burnaby P: (604) 299-8827/C: (604) 716-1240 E: timothy.ellis@mac.com Peter Golden Blue Seas Yacht Surveys Fanny Bay P: (250) 335-9171/C: (250) 218-4021 E: pmgolden@shaw.ca Patrick Haliburton HUB International TOS Limited North Vancouver P: (604) 990-6497/ C: (604) 626-2774 E: haliburton@telus.net www.hubinternational.com

Allan Hart

Donald Kimura Don Kimura Marine Surveyor Port Alberni P: (250) 723-4496 E: dkmsdf@shaw.ca

Donald Rose Capt. Rose Marine Consulting & Surveys Ltd. (Surrey) P: (604) 596-4389/C: (604) 312 4074 E: captainrosemarine@gmail.com

Laurie Langill Coast Claim Services Ltd. Powell River P: (604) 485-4782 E: llangill@coastclaims.com www.coastclaims.com

Peter Strathdee Coast Claim Services Ltd. Campbell River P: (250) 287-2283 E: pstrathdee@coastclaims.com www.coastclaims.com

Edward Lipsett Lipsett Marine Consultants Ltd. Ladysmith P: (250) 924-6565 E: ealipsett@shaw.ca David Logan Pacific Marine Services Pitt Meadows P: (604) 230-1040/C: (604) 329-1094 E: pacificmarine@shaw.ca Jim Moser Propacific Services Corporation Surrey P: (604) 340-9435 E: propacific@telus.net Philip Oldham Philip Oldham Marine Surveyors North Vancouver P: (604) 984-7286 E: philipoldham@shaw.ca Wayne (Pat) Patrick P.R. Marine Surveyors Powell River P: (604) 485-5992 E: patsplace@shaw.ca

Mal Walsh Blue Seas Yacht Surveys Comox P: (250) 890-3293 E: kminc@shaw.ca Allen Waugh Accurate Appraisals & Marine Surveys Cobble Hill P: (250) 715-5589 E: a-swaugh@shaw.ca Brian Whelen Intermar Marine Services Ltd. Nanoose Bay P: (250) 468-9595 E: intermar@telus.net Sarah White Student Member (Vancouver) P: (604) 218-7220/C: (604) 218-7220 E: sarah@specialty-yachts.com www.yachtworld.com/ specialtyyachtsales/

Deepsea

(Hull, Machinery, On/Off-Hire, Hold Inspection)

Coast Claim Services Ltd. Victoria P: (250) 386-3111 E: ahart@coastclaims.com www.coastclaims.com

Bryon Polly Strathcona Marine Surveyors Campbell River P: (250) 923-1855 E: bpolly@telus.net

Alistair Beaton Certispec Services Inc. Port Moody P: (604) 939-7070 E: abeaton@certispec.com www.certispec.com

Jostien Hoddevik IMS Marine Surveyors Ltd. Burnaby P: (604) 298-9968 E: hoddevik@ims-van.com www.ims-van.com

John Roberts All Points Marine Surveyors Vancouver P: (604) 288-0634/C: (604) 288-0634 E: marineboatsurveyor@gmail.com www.marinesurveyor.com/allpoints

Volodymyr Bondarev IMS Marine Surveyors Ltd. Burnaby P: (604) 298-9968/C: (604) 562-7851 E: admin@ims-van.com www.ims-van.com

26 BC Shipping News December 2012/January 2013

SURVEYOR DIRECTORY Todd Braconnier TCB Marine Consulting Service North Vancouver P: (604) 375-0923/C: (604) 375-0923 E: tcbroc@shaw.ca www.tcbmarine.ca Rene Dickinson Greenwich Marine Services Delta P: (604) 940-0922 E: greenwichmarine@dccnet.com

David Logan Pacific Marine Services Pitt Meadows P: (604) 230-1040/C: (604) 329-1094 E: pacificmarine@shaw.ca Laurence Luiz Lorimar Marine Canada Ltd Surrey P: (604) 585-3384 E: lmcanada@telus.net

Ralph D’Rozario Rozario Marine Ltd. Delta P: (604) 543-7432 E: rozariorvd@yahoo.ca

Nelson Ng Safeport Marine Services Ltd. Burnaby P: (604) 420-2308 E: nelson@safeport.ca www.safeport.ca

J. Timothy Ellis JT Ellis & Associates Burnaby P: (604) 299-8827/C: (604) 716-1240 E: timothy.ellis@mac.com

Cecil Noronha Certispec Services Inc. Port Moody P: (604) 469-9180 E: cnoronha@certispec.com www.certispec.com

Mike Fothergill Benline Holdings Ltd. Nanaimo P: (250) 756-2108 E: mariner@shaw.ca www.bcmariner.com

Craig Perry Glencannon Shipping Ltd. Gibsons P: (604) 886-2830 E: glha@telus.net

Allan Hart Coast Claim Services Ltd. Victoria P: (250) 386-3111 E: ahart@coastclaims.com www.coastclaims.com Jostien Hoddevik IMS Marine Surveyors Ltd. Burnaby P: (604) 298-9968 E: hoddevik@ims-van.com www.ims-van.com Donald Kimura Don Kimura Marine Surveyor Port Alberni P: (250) 723-4496 E: dkmsdf@shaw.ca Andrew Korek Phoenix Marine Services Inc. Abbotsford P: (604) 855-7874 E: phoenixmarine@shaw.ca www.phoenixmarine.ca Edward Lipsett Lipsett Marine Consultants Ltd. Ladysmith P: (250) 924-6565 E: ealipsett@shaw.ca

Augustine Rebello Certispec Services Inc. Port Moody P: (604) 469-9180 E: arebello@certispec.com www.certispec.com Roy Sluyter Certispec Services Inc. Port Moody P: (604) 469-9180 E: rsluyter@certispec.com www.certispec.com Richard Smith Certispec Services Inc. Port Moody P: (604) 939-7070 E: jrfsmith@certispec.com www.certispec.com Peter Strathdee Coast Claim Services Ltd. Campbell River P: (250) 287-2283 E: pstrathdee@coastclaims.com www.coastclaims.com

Donald Tranter Trans Marine Consultants Ltd. North Vancouver P: (604) 929-4733 E: donaldtranter@telus.net www.transmarineconsultants.com David Trickett Building Sea Marine Ltd. Vancouver P: (604) 802-8891 E: buildingsea@gmail.com Allen Waugh Accurate Appraisals & Marine Surveys Cobble Hill P: (250) 715-5589 E: a-swaugh@shaw.ca

Coastal Commercial

(Fishing Vessels, Tug Boats, Barges, Passenger Vessels, Work-Boats, Dredges, etc., and their machinery)