EXECUTIVE INSIGHT

Helpingto Eliminate Global Plastic Pollution

Aquapak’s unique invention, an environmentally friendly and functional polymer, gives plastics a whole new meaning.

Aquapak’s unique invention, an environmentally friendly and functional polymer, gives plastics a whole new meaning.

Aquapak’s unique invention, an environmentally friendly and functional polymer, gives plastics a whole new meaning.

Aquapak is a science-led business with over 10 years of research and development in polyvinyl alcohol (PVOH) resin technology. The UK-based company was established with a clear mission - to help businesses shift to a less polluting world by developing planet-friendly material technologies and helping to enable the circular economy.

Let us explore sustainable packaging together at Norner’s advanced technology centre in Norway:

• Film extrusion development centre

• Injection and blow moulding development centre

• Plastics recycling pilot centre

• Compounding pilot centre

• Advanced laboratories for analysis and testing

What we can help you with:

• Mono material, barrier and MDO development

• Alternative materials for barrier functionality

• Testing and validation of recycled material quality

• Application development with materials

• RecyClass certification and protocol testing

• Bioplastics and compostable alternatives

• Food and medical packaging

• Pharmacopeia testing

• Material and package testing

Norner is a global market leader of industrial polymer R&D services based in Norway where we operate an advanced technology centre for development and testing. Our main focus is on innovations and investments which address climate change and plastic circularity.

norner.no | post@norner.no

Norner is a leading industrial polymer Research & Development centre for the polymer and plastics industry with over 40 years of experience. Norner currently has 90 employees from 12 nationalities and is in an exciting development.

Our business vision is to become the market leader in industrial R&D services through the development of innovative and sustainable polymer solutions in close cooperation with leading industry. Norner operates advanced laboratories, polymerisation units and a processing pilot centre relevant to industrial-scale operations. We want to create value for our customers, owners, and society through innovation supporting the UN’s sustainability goals.

We are moving into a new, purpose-designed technology centre in Porsgrunn 2022, where we also in -

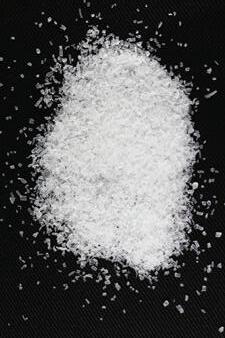

Aquapak’s flagship product marketed under the name of Hydropol™ is an innovative, water soluble, biodegradable polymer for a wide range of applications, designed to eliminate plastic pollution at source. The unique polymer technology offers excellent functionality that is both recyclable and environmentally safe, enabling multiple end-of-life options.

“The new material has been developed to solve some of the existing challenges that the world, and particularly the packaging industry, is facing. However, we don’t believe there is a single silver bullet suitable for all applications so our aim is to collaborate with other materials and other partners in order to enable them to design better products. And they can do it now, with a new tool in their toolbox - Hydropol™,” says company CEO Mark Lapping.

He explains that Hydropol™ is non-toxic and marine-safe and because of its inherent biodegradability in different environmental conditions, it offers a safer alternative to conventional polluting plastics.

“Hydropol™ is a soluble polymer - it dissolves in water, literally leaving no trace, hence it doesn’t produce any toxic micro plastics. It looks like a plastic and behaves like one, but it doesn’t break down like a plastic. It breaks down into CO2 and water and a little bit of biomass, which over time will be completely assimilated and then biodegrade.”

vest in new facilities, for the benefit of our customers and projects.

Norner covers the whole polymer value chain from catalyst and process development for polymerisation, polymer modification, polymer additivation, and industrial applications of polymer to innovative solutions for plastics in a circular economy. We provide R&D and technical services to various industry segments where innovative solutions of plastics and composites are requested. We are owned by SCG Chemicals, one of the largest integrated petrochemicals companies in Thailand and we have more than 700 customers in over 60 countries.

Our efforts are based on expertise, knowledge and a continuous search for new opportunities together with our values;

As such, the product may be the solution to one of today’s key questions, one that has been worrying experts and, increasingly, the general public - what happens to plastics at the end of their product life?

Making a difference

Mark Lapping affirms that there is no question about the role of plastics as such: “Let us remember that plastics are a miracle material. Brought into the world some 70 years ago, they’ve completely revolutionised the way we think of storing and transporting materials, for example food, and, let’s be very clear, they are irreplaceable. The issue is how we use them and what we do with them.”

He explains that as there are so many different polymers, it is hard to split them apart for recycling. For that reason, today only less than 10% of plastic films is recycled, while about 90% is either landfilled or incinerated.

Here Hydropol™ can make a real difference - the polymer can either follow the biodegradation route, or it can be combined with other materials to make them recyclable. For example, in paper mills, Hydropol™ has been proven to wash off in the repulping process, allowing 100% of paper fibres to be recycled with no negative effects to the paper mill.

“As focus on designing circular products is increasing, we can offer a new polymer for the packaging industry to be processed into a film, coated on other materials, injection-

moulded into a product. It is thermo-processable, so can be used to design products with a different end of life; it also acts as a barrier: gas, oxygen, grease, fat, oil, you name it. “

Environmentallyfriendly and functional

Mark Lapping pointed out that the base material that Aquapak uses is polyvinyl alcohol (PVOH), that has been around for a long time in niche uses Aquapak has made it into a more functional product. allowing it to be thermally processed on conventional equipment. “Hydropol can be formulated to dissolve in water at different temperatures from ambient to boiling water only. This property and all the other functional attributes makes it a truly sustainable and Circular Economy material”

To develop a highly functional thermally processable version of polyvinyl alcohol that can be widely used by industry was something that a lot of companies have tried but never succeeded. Aquapak did and patented the new technology.

Mark Lapping, who joined the company 4 years ago, remarked that it was the focus on the environment and the functionality that first attracted him to Aquapak. “With a background in the packaging industry, I

Hydropol™ is

was intrigued to find new tools to be able to create better products for a new sustainable world.”

“And because I came from the packaging world, I was also looking at the functional

benefits needed in order to design great products.

Hydropol™ offers both - it is functional yet fully environmentally friendly, supporting the circular economy.”

The company continues to invest in its capability, affirmed Mr Lapping. “We have great shareholders who can see the benefits of this material and the long-term goals of

the company.”

Aquapak’s modern 4,700 m2 compounding production facility located in Birmingham has 10,000 tonnes capacity, doubled from 5,000 last year, and can be further

a soluble polymer - it dissolves in water, literally leaving no trace, hence it doesn’t produce any toxic micro plastics. It looks like a plastic and behaves like one, but it doesn’t break down like a plastic. It breaks down into CO2 and water and a little bit of biomass, which over time will be completely assimilated and then biodegrade

A Leader in Innovative Polymer Solutions

increased up to 50,000 tonnes. “Our aim is to build up and sell out this plant, and then to set up another.”

Aquapak continues invest in R&D, but has also formed R&D collaborations with a number of major plastics and bio plastics producers to create new materials and innovative combinations of Hydropol™ with wellestablished plastics and paper.

“We also collaborate with nine UK universities, to complement our in-house expertise. We have some incredibly talented people working for

I’m really proud of the diversity of our team - there are 60 of us, and we speak over 20 languages.

our company. Being located in Birmingham is a great help as it is such a cosmopolitan place, and because of the universities, it has attracted a

lot of talented people. I’m really proud of the diversity of our team - there are 60 of us, and we speak over 20 languages.”

As CSR has now become a key part of any company strategy, and ‘reusable, recyclable or compostable’ is the goal everyone aspires to by 2025, Hydropol™ seems to be the right product coming at the right time, with a potential that is almost unlimited, given the number of potential applications.

“Our customer base, as well as our supply chain, is international. We can buy our material anywhere and we can sell our product anywhere. Obviously, we recruit locally but we have also people working for us, in different parts of the world: in the US, in Australia and in Asia.”

“Still, we are proud to be here in Birmingham, taking a UK technology to the world, and then scaling it up here in the UK. We want to grow, we want to get our product out there into the market, use it in mainstream applications. To this end, will continue to expand our capacity and capability both in terms of material and people. The world needs innovative materials to enable the circular economy, and we are going to provide them.”

Our customer base, as well as our supply chain, is international. We can buy our material anywhere and we can sell our product anywhere.