EXECUTIVE INSIGHT

Geothermal energy is the cleanest, cheapest and most efficient baseload green energy available anywhere

Geothermal energy is the cleanest, cheapest and most efficient baseload green energy available anywhere. Geothermal resources are theoretically more than adequate to supply humanity’s energy needs, although only a very small fraction is currently being commercially exploited. UK-based CeraPhi Energy is set to change that, explains the company’s founder and CEO Karl Farrow.

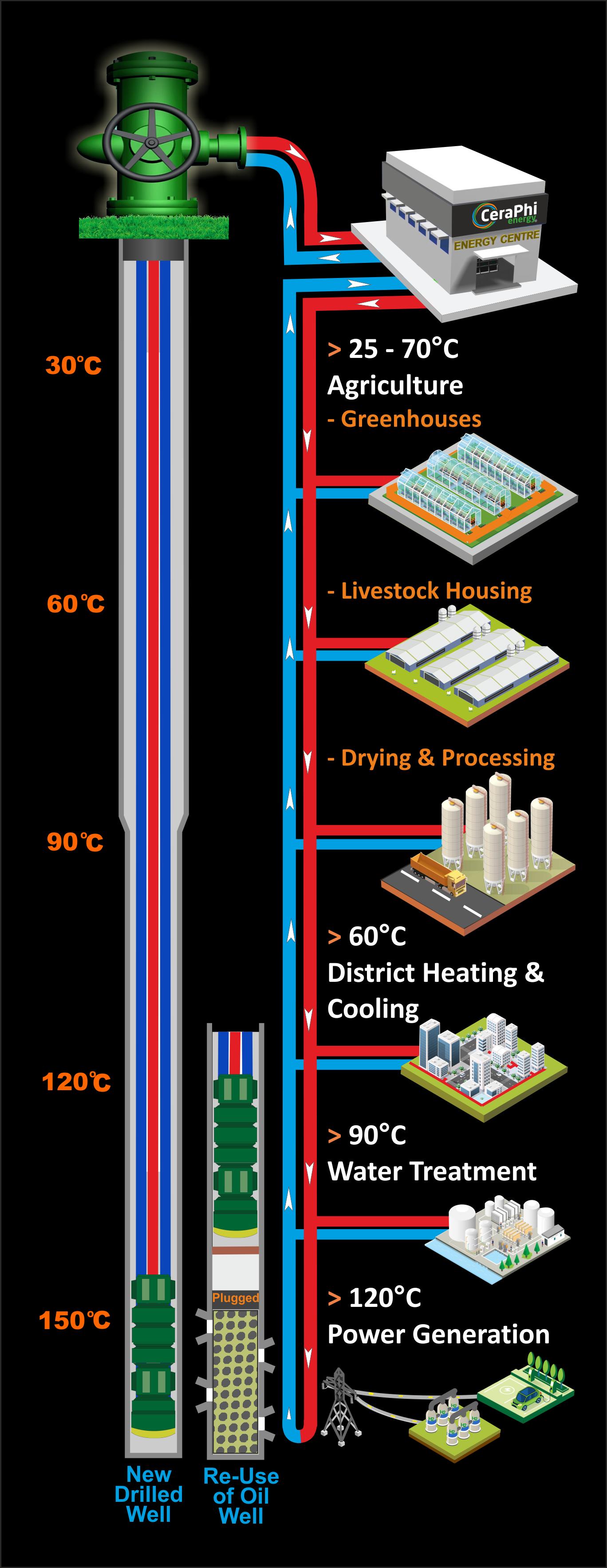

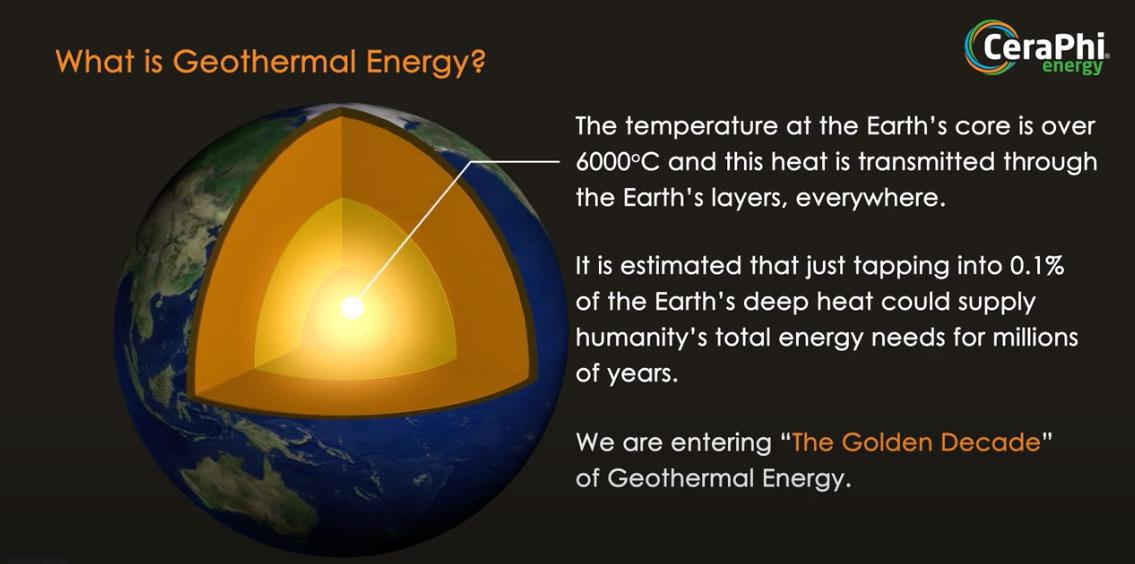

Geothermal is a form of renewable energy taken from heat derived from the earth’s subsurface. It is one of the cleanest forms of energy and can be applied as a direct power source as well as for heating and cooling utilities. CeraPhi Energy’s closed loop solution makes geothermal available everywhere and anywhere.

halliburton.com

Halliburton leads the future of energy.

Geothermal offering:

• 70 + years of experience

• Industry-leading people, products, services, and technology

• Integrated, full cycle solutions for greater efficiencies and profitability

• Successful global execution by leveraging our in-country experience to streamline the field development process

A COMPREHENSIVE APPROACH TO HARNESS

GEOTHERMAL ENERGY

Since the 1950s, Halliburton has pioneered the development of global geothermal resources. We offer a full array of products, technology, and integrated services that lower the resource development costs of low-and high-enthalpy geothermal projects. At Halliburton, we collaborate to identify and develop conventional (hydrothermal), enhanced (stimulated), advanced (closed loop), and direct heating geothermal projects, applying the best solutions to each geothermal project. Our comprehensive approach can manage all four stages of a geothermal well lifecycle: subsurface understanding and testing, well construction, completions, and production.

• Geothermal energy is a cost-effective, reliable, renewable, and environmentally friendly resource that offers an endless supply of power. This energy source can be accessed and harvested anywhere in the world.

• Geothermal energy systems are relatively clean. They adapt to many industrial applications, in addition to heating and cooling residential and commercial buildings.

• Geothermal power plants can produce electricity or heat 24/7, as geothermal systems are not affected by weather. They occupy a much smaller footprint than other power plants.

“We are pleased to build on our decades of global geothermal business to collaborate with CeraPhi to deliver and maximise the value of their geothermal wells. This agreement will allow us to deliver fully integrated solutions to reduce planning time, lower costs and optimise the value chain performance.”

Steve Nowe, Senior Area Manager Halliburton Europe.Subsurface

Software

Formation evaluation

Well Construction

Formation evaluation

Drilling

Drilling fluids

Completion tools

Cementing

Formation evaluation

Completions

Completion tools

Perforating

Well testing

Artificial lift

Chemicals

CONSULTING & PROJECT MANAGEMENT

Production

Well integrity and diagnostics

Surface and well monitoring

Water management

In conventional geothermal wells, bottomhole temperatures can reach 480°F to 600°F (250°C to 316°C). These ultra-high temperatures and thermal expansion can harm equipment, accelerate cement fatigue, and eventually result in casing collapse. Enhanced and advanced geothermal systems require detailed subsurface knowledge so horizontal and vertical wells can optimally target the reservoir for maximum heat exchange. Halliburton designs tools and services specifically for these difficult conditions, which require models of temperatures and pressures in and around the well. Once we determine the proper geothermal system, we can provide the right well construction and completion products to successfully execute field development plans.

In addition, our team can screen, identify play fairway, characterize and verify the reservoir, and prepare field development plans to best harness geothermal resources.

Our software solutions and technical expertise support all geothermal system types, including conventional high temperature, advanced closed loop, and enhanced geothermal systems. We also provide comprehensive heat flow maps, reservoir characterization, and geologic modelling to provide accurate information regarding the formation’s capacity, conductivity, and structure (fault proximity).

Halliburton is an industry leader in key subsurface technologies such as core sampling, borehole imaging while drilling, high-resolution sonic imaging, formation density tools, and formation pressure sampling.

GEOTHERMAL POWER IS CLEAN, CONTINUOUS, AND RENEWABLE, MAKING IT AN ATTRACTIVE ALTERNATIVE TO COAL AND NATURAL GAS AS A BASE ENERGY SOURCE

The hard granite and basalt formations that are targeted for conventional geothermal wells are often highly fractured with unconsolidated formations overlaying these harder formations. Both sets of conditions generally suffer from excessive fluid loss during drilling and cementing operations which can result in decreased rates of penetrations (ROPs), stuck pipe, loss of zonal isolation, and wellbore instability. Halliburton controls these losses with a portfolio of products designed for these severe loss conditions. Advanced closed loop geothermal projects require precise lateral placement and mapping for well interception, implementation of multi-lateral well design, and enhanced stimulated projects require optimal placement in the reservoir for heat transfer.

At Halliburton, we collaborate on well construction to determine the proper drill bits, tool specifications, directional drilling, managed pressure drilling (MPD), drilling fluids, and cementing for each geothermal well. This integrated team tackles such challenges as borehole and bottomhole stability, high temperatures, hard rock formations, well control issues, lost circulation, corrosion, pore pressure, and ROP reliability. In geothermal environments, well placement and directional drilling require a comprehensive approach to drilling operations. Our drilling team provides solutions to avoid risks and minimize problems by implementing tools that provide reliable measurements of well trajectory, borehole temperature and pressure, and drill string vibration. Plus, we can obtain the necessary information in ultra-high temperatures.

Two defining characteristics of conventional geothermal resources are ultra-high temperatures and large, irregular fracture systems. To accurately characterize the resource and production capacity, testing and imaging tools must make reliable and focused measurements in highly variable environments with hostile downhole conditions. Enhanced and advanced geothermal systems require tailored completion solutions to maximize heat exchange with the geothermal reservoir.

Halliburton offers the optimal completion hardware, packers, interval control valves (ICVs), stimulation, and material selections to manage conductivity, flow, and thermal cycling in geothermal wells. Cost-effective down hole tool solutions include bidirectional anchoring devices, sensors that are designed for use in ultra-high-temperature environments, and premium hangers and packers optimized for reliable liner installations.

Production monitoring and logging operations ensure well integrity, create conductivity and flow assurance, mitigate corrosion and scaling, proppant efficacy, and arrange for brine (heavy minerals) disposal. Halliburton offers the latest in production logging tools, including mechanical well integrity measurements, real-time fibre monitoring of injection and production well flow, and integrated sensor diagnostics (ISD). We provide mechanical and chemical scale treatment to maintain economic production rates, and reliable water management in geothermal energy production with electric submersible pumps (ESPs).

How did it all start?

Karl Farrow, with a successful career in the global energy sector and an investor and business entrepreneur himself, could see the potential of geothermal in the challenging and uncertain times of climate change and an increased focus on sustainability and green energy.

In his introductory message he says: “After nearly 30 years in the energy sector I finally realised the reason for my life’s journey, discovering the true potential of the energy beneath

our feet, so I decided to do something about it, bringing together the best minds and experts I could find to develop a scalable solution unleashing geothermal energy from its ubiquitous state to become our first choice of clean baseload energy within the next 30 years, to help meet the 2050 Paris Agreement targets to achieve net zero.”

In just two years, CeraPhi Energy has become a leading project development company delivering global geo-

thermal energy solutions at scale. With its proprietary technology, the company offers solutions through the development of new wells and infrastructure or through reusing and repurposing existing oil and gas wells or deep-water wells including the use of mine water.

“CeraPhi Energy is a part of the energy transition. We all come from an oil and gas background, and we were very interested in trying to apply that knowledge from oil and gas elsewhere, looking at how we could make an positive impact on

the environment.

“Looking at taking heat from the ground, and our focus was actually making that commercial, both for heating, direct use and also for power generation. Applying skills from oil and gas obviously helped us to do that; amongst other things, we were looking at removing the exploration risksre-purposing existing oil and gas wells that are coming to the end of life, and looking at how these can be used for energy production in a green and environmentally safe manner.”

The fact that the existing wells can

be used is one of the biggest advantages of CeraPhi’s approach, and its viability has been verified by the global interest shown in it. While established and headquartered in the UK, CeraPhi has an operational office in Houston, US, and representatives in the Middle East and Brazil. “Our key markets currently are the UK, Europe, North America but the potential is worldwide,” says Karl Farrow.

He points out that the uniqueness of the company is based on

its technology, developed with a different approach to heat commercialisation. Its CeraPhiWell is a closed loop downhole heat exchanger that draws up subsurface heat for different applications for scalable baseload energy.

“We wanted to do something which was effectively doable today, without going into a long, extended R&D programme, but also to take some innovation and technology provisions along that process to enhance what was already available in the market.”

He explains that CeraPhiWell propri-

Greenglove Boreholes are a multi-disciplined nationwide drilling contractor. Using the most up to date drilling and recycling equipment, our fully trained and experienced staff can provide a turnkey solution.

etary patents cover the design and installation of a downhole heat exchanger system utilizing existing technologies in a novel manner. The system has a level of flexibility that allows the recovery of commercially useable heat energy from the subsurface virtually anywhere around the globe.

Additionally, the CeraPhiWell can be considered a fallback/insurance option for those wells that fall short of expectations regarding well output. In this instance CeraPhiWell retrofit architecture can be installed to bring some commercial return instead of having to undertake costly well abandonment.

The company has also developed special software that enables it to manage the process of energy delivery in an investor-friendly manner, calculating suitable projects that can be developed into a commercial business case. CeraPhiPro software basically provides a custom-built energy solution aligned to the end user’s requirements.

The company currently has around about $100 million in total worth of projects ready to roll over with several different clients, says Karl Farrow. In August 2022, CeraPhi Energy has entered into an exclusive drilling and intervention services agreement with Halliburton, with an initial focus of supporting CeraPhi’s

existing opportunities to repurpose end-oflife oil and gas wells in the UK and USA.

“This is a very exciting stage of CeraPhi’s commercialisation and totally in line with our strategic plan to align ourselves with serious execution and delivery partners who believe in the tremendous opportunity for geothermal and have the ability to scale globally.”

“We are moving into our first development site over the coming

months. This will be a turning point for the company, moving us from a technology demonstrator into a commercial stage,” says Karl, adding that CeraPhi has just been awarded funding from the Net Zero Technology Centre in Aberdeen to support that project.

The funding will also enable the company to validate its technology in repurposing oil and gas wells, to establish proof of technology and to

This will be a turning point for the company, moving us from a technology demonstrator into a commercial stage “

move towards becoming commercially operational. Speaking about the award, Karl Farrow said: “With the support of the NZTC this project will be a flagship project not only for CeraPhi Energy, but potentially ground breaking for the UK, providing a step change in energy transition.”

For a small company that was founded only two years ago the

progress is impressive. Karl affirms that the credit goes to a very strong team, dedicated to the mission of impacting on the trajectory of climate change.

“The environmental aspect has attracted a team of people who are not only employees – nearly 90% of our employees are also investors. We have grown a strong stakeholder base from an employee foundation, which I think is also a great achievement.”

The human factor, teamwork and partnerships will continue to be key for the company going forward. “From the very beginning, partnership has been the core pillar of our strategy, we knew we would never do it alone. We have spent a good part of the last two years building up a network of partners, and we’ve signed over 50 different partner agreements.”

“And we continue to do that. We are taking

our partners on a journey which is beneficial for them as we’re opening doors to opportunities that they would never have. These are medium- to long-term opportunities, but they are opportunities that could completely change the global energy landscape,” he says, in concluding.

We manufacture cables and supply electrical components of the very highest quality, to the automotive and marine sectors. Trusted by clients and distribution networks for nearly six decades, we strive to make the ordering, purchasing and distribution of the world class products we manufacture and stock as easy and straightforward as it can be – with solutions and brands that our customers and distributors trust and value; delivered on time, and as expected – as standard. We simply connect.