Mopani Copper Mines (MCM) is looking to cement its position in the

chain says Gershom Tanga, the company’s Supply Chain Manager

Mopani Copper Mines (MCM) is looking to cement its position in the

chain says Gershom Tanga, the company’s Supply Chain Manager

Following a major investment deal, Zambian company Mopani Copper Mines (MCM), one of the largest copper and cobalt producers and exporters in the world, is entering the next stage of its development, looking to cement its position in the global supply chain. The future success of its operations relies, to a great extent, on its own supply chain and its management, says Gershom Tanga, the company’s Supply Chain Manager.

Mopani is one of the most important copper mines in the world and a major driver for Zambia’s economy not only as an important producer of valued natural resource but also as a key source of income for thousands of suppliers. Managing the extensive supplier base has been the responsibility of Mr Gershom Tanga, who has implemented crucial changes to the company’s procurement system. As a result, not only has the overall procurement performance significantly improved but his team has become recognised for its ethical practices, setting the benchmark for the whole of the Central African region.

To this end, new career development plans were drawn up and upskilling was brought to the forefront of our priorities.

Under Tanga’s leadership, Mopani Copper Mines is striving to align its supply-chain employees with the requirements of the CIPS (Chartered Institute of Procurement & Supply), a UK-based global professional body representing the procurement and supply chain profession, to ensure they are benchmarked against the highest international standards.

For its efforts, the company has recently achieved the prestigious CIPS Corporate Ethics Kite Mark, which now sets the standard for Africa’s mining sector. This achievement demonstrates the company’s commitment to investing in ethical practices in its procurement and supply chain activities.

Gershom Tanga, himself a CIPS UK Fellow, was instrumental in Mopani’s achievement. Starting his career over 20 years ago in Konkola Copper Mines, one of Africa’s largest integrated copper producers, he joined Mopani in 2007, moving through various roles in accounting, internal audit, implementation of information systems, risk management and finance before being appointed Supply Chain Manager in 2022.”Throughout my career, I have had the great opportunity not only to learn about different areas of the business but also to refine my leadership and people management skills,” he said.

Our strength lies in having multiple subsidiaries under Bellview Group delivering specialised services to a diverse range of clients.

CONSTRUCTION DIVISION

Construction works with distinctive quality and service delivered on schedule through our excellent Project Management skills and experience.

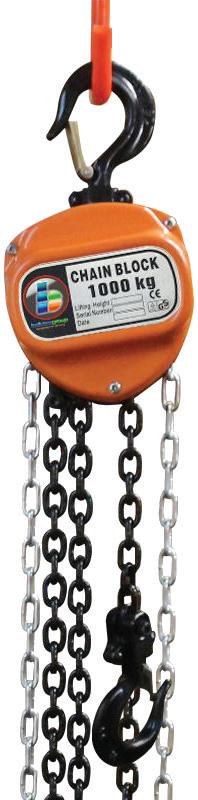

LIFTING DIVISION

Supply, service and inspection of crane, rigging and lifting equipment, load testing, maintenance, consultation and training services.

SUPPLY DIVISION

Design & Develop, Manufacture & Supply, Service & Repair all lifting, Pump and Wear, Underground and Surface Equipment and Assessories in the Mining Industry.

LOGISTICS DIVISION

Bellview Logistics and Transportation

Haulage Limited is a dynamic entity currently offering total transportation, warehousing, accommodation and logistical solutions.

Training Division.

Bellview workforce solutions, After Sale Services, Operators and Maintenance training, rebuilds and labour hire in the mining industry.

BMES HAS DISTRIBUTION AGREEMENTS WITH LEADING INTERNATIONAL MANUFACTURERS FROM THE UNITED STATES, UNITED KINGDOM, CANADA, AUSTRALIA, ASIA, AND SOUTH AFRICA.

Mopani copper mines is implementing a supplier development programme that aims at supporting an enhanced manufacturing sector in Zambia. In, this programme, Mopani has identified a number of companies, one of which is Bellview Mining Equipment & Services Limited to be part of the pilot programme. It is hoped that the programme will contribute to lessons on effective ways to support local manufacturing.

Bellview Group, based in Kitwe, Zambia, has undergone a name change from Bellview Tools Limited (BTL) to Bellview Mining Equipment and Services Limited (BMES). This transformation reflects the company’s evolution into a rapidly expanding medium-sized enterprise that encompasses specialized divisions focused on mining and industrial equipment, after-sales services, and comprehensive training programs. The selected partners during the two-year trial period are pivotal in achieving the platform for attracting off-takers for Bellview’s Kalumbila Industrial Park Foundry and Manufacturing Project.

Bellview OEM Partners

Drillcube

Drillcube is an innovative Australian-owned company transforming underground mining services with over 100 years of combined industry experience. They emphasize transparency and ethical practices throughout their supply chain, offering a comprehensive solution as a “one-stop-shop” for all mining needs. By providing necessary equipment, tools, and consumables in a single monthly order, Drillcube mitigates supply chain constraints, enhances production forecasts, and reduces costs, thereby increasing profitability and net present value (NPV) of mining assets. Drillcube specializes in shaft sinking and face drilling, critical during mining project development. Their partnership with Bellview Group aims to establish a specialized underground service division in Zambia, focusing on Rapid Development Mining Systems, safety practices, and workforce upskilling. This commitment to operational efficiency and safety positions Drillcube as a reliable partner for mining projects worldwide.

Fambition Heavy Machinery Co., Ltd.

Established in 1993, Qingdao Fambition Heavy Machinery Co., Ltd., situated in China, is renowned for its manufacturing of trackless mining equipment. Committed to becoming a technology-leading enterprise, Fambition specializes in the research and development, as well as manufacturing, of underground LHDs, Dump Trucks, and mining Utility Vehicles. Fambition aims to provide safe, efficient, and intelligent trackless equipment for underground mines worldwide, fostering an automated, digital, and intelligent ecosystem for underground mining operations. The company’s objectives include enhancing ore shovel loading efficiency, reducing equipment operating costs, elevating production management levels, and achieving sustainable productivity. Over two decades of practical application have demonstrated the effectiveness of Fambition equipment in large mining operations across Chile, Peru, Mexico, Bolivia, Russia, Kazakhstan, Canada, Turkey, Nigeria, China, the Philippines, Vietnam, and beyond.

ABS Sfere

ABS is the steelmaking division of Danieli Group, the construction leader of steel plants all over the world. Established in 1988, ABS Sfere is the ABS brand specialising in the production and distribution of grinding media. ABS boasts a wide range of steel - producing over 1,000 types of steel grades. This makes us unique in the global steel industry arena, employing over 1,500 people, boasting an annual turnover of over 1.4B Euros. ABS produces steel only using the electric cycle from scrap, which reduces emissions by 65% compared to the blast furnace cycle. ABS products are made using 95% recycled raw materials. ABS Sfere leverages its expertise as a renowned Italian steel producer to cater specifically to the mining sector for diverse grinding applications, integrating advanced knowledge and engineering.

Fratelli Zenzalari S.r.l. is a supplier of spare parts for earth moving equipment with more than fifty years of experience in service the market. Located in northwestern Italy, Zenzalari is already doing business in several African countries, spanning from west to east across the continent. We can provide undercarriage wear parts, track chains, track shoes, complete track groups, rollers, sprockets and idlers for almost all types of crawler machines. Buckets for excavators up to 50 tons operational weig ht and related GET wear parts. Miscellaneous parts for engine, transmission, hydraulic and electrical sy stem. Furthermore, used components for a wide range of hydraulic excavators are available.

Authorised Distributors / Sales Agents for:

• Wanawake Industrial Supplies - Hi-Force, Alkitronic, Ebara Pumps, Gedore, Mobi Jack - www.wanawake-is.co.za

• Turnkey Hydraulics - www.turnkeyhydraulics.co.za

• PRO Hydraulics - www.prohydraulics.co.za

• Thermitec CC - Oxygen Equipment - www.thermitec.co.za

• EICKHOFF SA - www.eickhoff.co.za

As a growing leader in the Zambian engineering space, Surmpy Engineering and Service Limited provides a full and diversified product offering across the engineering and mining industry. Serving Zambia and beyond, Surmpy Engineering and Service Limited combines a commitment to product excellence with a wide range of service capabilities. We have adopted a zero-tolerance approach to corruption, and the feedback we have received from other mines has assured us that we are on the right track

We are Exclusive Distributors for:

• Ernest Lowe Pty Limited - Pneumatic and Hydraulic Automation Solutions www.elco.co.za

• The Hydraulic Centre Pty Limited - Hydraulic Hoses and Fittings www.thc.co.za

sales@surmpy.co.za | starlin.musampi@surmpy.co.za | info@surmpy.co.za Mobile/WhatsApp: +260 967 454343 | www.surmpy.co.za

He became Supply Chain Manager at a highly challenging time for Mopani. “My first task was to focus on the most prized asset –the people, and to lift their spirits, to prepare them for a positive future ahead. To this end, new career development plans were drawn up and upskilling was brought to the forefront of our priorities.”

In addition, other fundamental topics had to be addressed, he noted, such as promoting sustainability, ensuring that Mopani’s procurement processes are aligned with environmental policies; and eliminating corruption, a challenging task. “I’m proud to say that in this respect, we are now being looked at in a very good light,” he affirmed. “We have adopted a zero-tolerance approach to corruption, and the feedback we have received from other mines has assured us that we are on the right track.”

He affirmed that Mopani is dedicated to upholding the highest standards of ethics, integrity and compliance throughout its operations, firmly believing in fostering a transparent and accountable work and business environment. As part of its commitment, the company has established a confidential whistleblowing line.

Having the new practices in place gives everyone an equal and fair opportunity, which is very important and very responsible.

Tanga explained that sophisticated technology has played a key role in raising the company’s ethics profile. For example, Mopani’s procurement processes including RFQ (Request For Quote) are now online and subject to a stringent control mechanism with the server being controlled externally by a third party. Suppliers’ performance, including their capacity, is also monitored via virtual tools, as are warehouse management and environmental compliance, specifically for imported raw materials.

The company currently has over 2.500 vendors in its database, of which some 75% to 80% are local, family-owned businesses, for whom working for Mopani is crucial. But that has to be done according to Mopani’s standards. “Having the new practices in place gives everyone an equal and fair opportunity, which is very important and very responsible.”

“The supply chain is fundamental for our future development and its role cannot be underestimated. We have continuous engagement with the vendors and vendors associations to make sure the partnerships work at their best. It is our role to support local vendors and the community to help alleviate poverty, to help them grow their businesses which in turn has a positive impact on the country’s economy.”

To this end a lot has already been done, and the company’s efforts have not gone unnoticed. Last year, Mopani Copper Mines won two awards at the 4th CSR and Responsible Business Awards 2023 held in Lusaka and organized by Corporate Social Responsibility Network Zambia (CSRNZ).

Mopani Copper Mines was recently achieved the prestigious Chartered Institute of Procurement & Supply (CIPS) Corporate Ethics Kite Mark, which sets the standard for Africa’s mining sector. This achievement demonstrates the company’s commitment to investing in ethical practices in its procurement and supply chain activities

It is quite clear that training and development for individuals is at the forefront of the company’s thinking and crucial for building Mopani’s future as well.

Mopani collected the Best Community Social Impact Award in the Skills Development category and the CSR Excellence Award in Safe Drinking Water in the Water Reticulation category. Mopani’s Agribusiness Community project was voted the best in the Community Social Impact Award.

Within the project, focused on the mining company’s host districts of Kitwe and Mufulira, material and skills training in poultry production, horticulture, and other forms of agriculture training has been offered to 600 direct beneficiaries and 3,600 indirect beneficiaries comprising 12 cooperatives in the initial stage.

Tanga acknowledged that internal staff training has also been an integral part of the changes he has instigated. “It is quite clear that training and development for individuals is at the forefront of the company’s thinking and crucial for building Mopani’s future as well. It is not just the academic aspect that we support, we also engage with our own Mopani Training Centre to enhance practical skills.”

Following the recent $1 billion investment from the Middle East, significant growth at Mopani’s operations is expected and, accordingly, the importance of efficient supply-chain management will further increase.

Tanga affirms that Mopani is ready to embark on a new course. “Adaptability and agility will be crucial. We have to ensure that everybody from the bottom up is familiar with the revised business strategy, and then ensure that everybody appreciates where the supply chain fits in. We are ramping up in terms of our operations, our mine development, our exploration. I want the Mopani supply-chain department to be an enabler, to be adding value, helping the business to be more efficient, effectively progressing towards its targets.”

“Our endeavours at the same time must benefit the local communities, ensuring we develop the capacity and livelihoods of the local people as the ultimate owners of the operation. We will add value in terms of being transparent, being fair, ensuring that those who deserve business with us, will get that business with us. As such, our department will actively support Mopani’s commitment to promote national development.”

Adaptability and agility will be crucial. We have to ensure that everybody from the bottom up is familiar with the revised business strategy, and then ensure that everybody appreciates where the supply chain fits in.