CORE TECHNOLOGIES & EXPERTISE ENABLING THE DATA ERA

KLA develops industry-leading equipment and services that enable innovation throughout the electronics industry. We provide advanced process control and process-enabling solutions for manufacturing wafers and reticles, integrated circuits, leading customers across the globe, our expert teams of physicists, engineers, data scientists and problem solvers design solutions that move the world forward.

Illumination sources: Broadband plasmas, lasers, LEDs, x-rays, electron-beams

Optics:

DUV/UV/Vis/IR light, x-rays and electron-beams

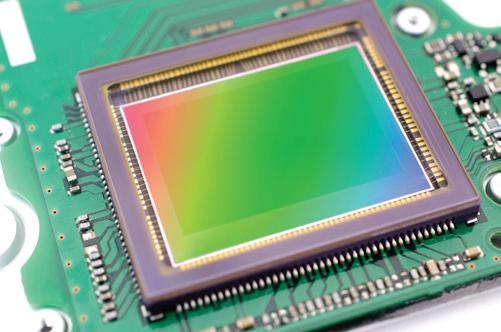

Sensors:

Image sensors, photo multiplier tubes, CMOS sensors, cameras

Mechanics: Precision stages, motion control, robotics

Image and data processing:

High-speed data processing, high-performance computing, AI/ML/DL, algorithms, computational physics

EXPANDING THE BOUNDARIES OF AI, ML & COMPUTE POWER

for optimized decision making

between subtle defect signals and surrounding noise

Super compute hardware and software manage and process micro-machine controls, illumination functions, high-speed image acquisition, data processing, and sample handling

Integrated, user-friendly system software drives all sub-systems of each functional, production-ready product

Problem-solving, solution-enabling applications development and hands-on support provide unique customer value in the global electronics ecosystem

INNOVATIVE OPTICAL, X-RAY & ELECTRON-BEAM

Sub-systems are designed, manufactured and integrated into each KLA system:

Laser sources, illumination, power control

High power, broadband plasma DUV, UV, visible and IR wavelength

illumination systems

High-performance time delay integrated image sensors, CMOS sensors, photo multiplier tubes, cameras

Electron-beam sources, optics, detectors

X-ray sources, optics, detectors

Source, optics and detector hardware integration and management

ROBOTICS & CONTROLLERS FOR MAXIMUM PRODUCTIVITY

Mechatronics engineered micro precision, vibration and temperature-controlled subsystems are designed to deliver precise metrology results

Robotic controllers enable full automation by managing customer samples

Precision air bearing linear and spinning motion stages enable accurate sample placement, positioning and instrument measurement

Environmental controls provide ultra-clean micro-contamination management and sample protection

Machine learning approach is leveraged for predictive tool maintenance and maximum customer utilization

LEGEND

KLA Locations

U.S. Headquarters: R&D Centers in Milpitas, CA, and Ann Arbor, MI

$1.2B