18 minute read

ttz Bremerhaven: Resource scarcity, scope of action and perspectives for bakeries

Resource scarcity: scope of action and perspectives for bakeries

Resource scarcity is affecting nearly all sectors of the economy worldwide, with the baking industry being no exception. The massively increased energy prices are currently the main concern for bakeries, but recurring shortages of raw materials and personnel are making the situation worse. This article aims at describing the current issues of resource scarcity and proposes solutions – mainly in the technical field – to tackle the crisis.

By Dr. Julien Huen, ttz Bremerhaven

+It is very legitimate to expect political solutions from governments, yet companies must also check what they can do to adapt their business models to the new conditions. The current megatrends in consumer demand should not be put out of sight.

The COVID pandemic, the war in Ukraine and climate change are global events with massive consequences on the availability of resources, especially in the agricultural and food sectors. Bakery companies are facing a series of acute challenges that need to be addressed rapidly. Ideally, the adaptations performed should not only consider the short-term situation but rather be part of a strategy that places the companies in a favorable situation for the future.

Energy costs

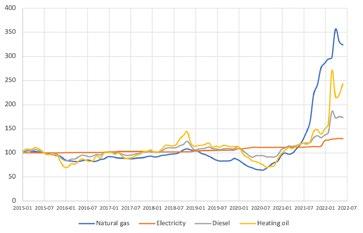

The production of baked goods is a very energy-intensive activity that implies especially mechanical and thermal processing steps. The most common energy sources in the bakery industry are electricity for mechanical processes and cooling, and gas for heating. Both energy sources are currently going through dramatic price increases (figure 1). In addition, shortages of both energy sources are not excluded in the coming winter.

Fig. 1: Energy price indices in Germany

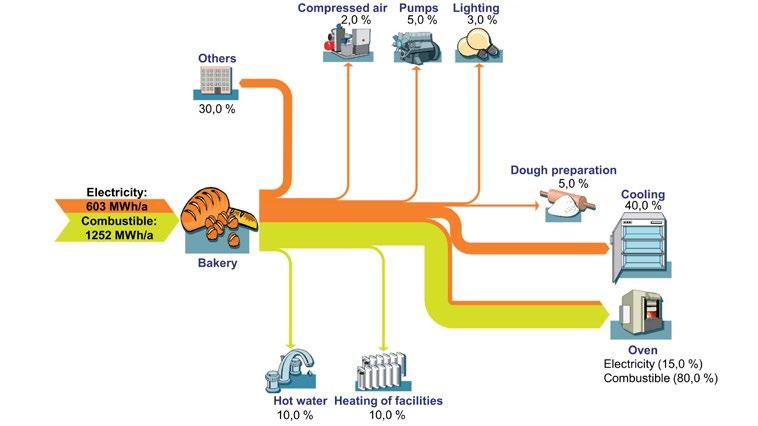

Fig. 2: Energy use in a typical artisan bakery

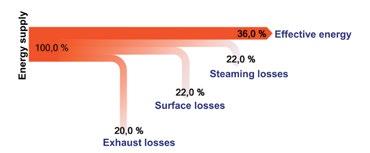

Fig. 3: Energy use in a typical artisan oven

source: ttz study “EnEff Bäckerei”

How high is energy consumption actually in the baking business? It has been estimated that bread-making companies spend between 1,5 and 6 kWh for the transformation of 1 kg of wheat flour (so-called ‘specific energy consumption’), with a strong dependency on the size of the company: production sites processing higher amounts of flour have, on average, much better energy efficiency.

It is interesting to compare these figures with the enthalpy of some basic physical phenomena taking place during bakery processes: the gelatinization of starch contained in 1 kg of wheat flour consumes 0,002 kWh, the denaturation of protein contained in 1 kg of wheat flour consumes 0,00015 kWh, the evaporation of 200 g of water (typical bake loss in relation to 1 kg of flour) 0,12 kWh. Heating 1,65 kg of dough (typical dough quantity obtained from 1 kg of flour) from 25 to 100°C needs 0,1 kWh, and freezing 1,65 kg of bread dough from 25 to -20°C consumes 0,12 kWh. This makes it clear that the main part of energy spent in bakeries does not actually reach the product, but rather is lost in the process or used in the concomitant activities. Figure 2 shows that heating and cooling are the main processes consuming energy. During baking, it is estimated that only 36% of the energy reaches the product (Figure 3). Therefore, addressing energy scarcity will include reflecting on which energy sources are being used, where energy losses can be reduced and whether product/process concepts can be rethought, to minimize energy consumption.

source: ttz study “EnEff Bäckerei”

Raw materials scarcity

The shortage of raw materials may have different causes, including (1) actual reduction of the quantities available on the market (nearly non-existent export of wheat and sunflower from Ukraine, of palm oil from Indonesia; reduced harvests following extreme weather conditions), (2) logistic difficulties in global supply chains, (3) ‘panic buying’ from some market stakeholders (as recently in the case of dry yeast) and (4) competition with non-food applications like biofuel production.

Figure 4 shows the price evolution of foodstuff on the global market: since the beginning of 2020, high volatility with a clear upwards trend is observed with about +50% for cereals and +80% for vegetable oils.

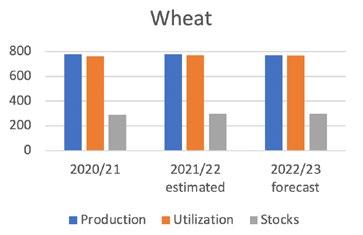

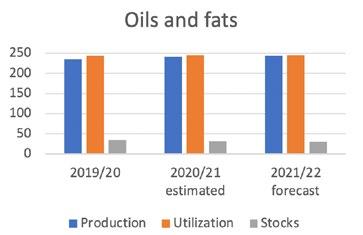

It is to be noted that, from a global point of view, there has been no significant change in the balance between production and consumption since 2020, as FAO data show (figure 5). Local shortages are, therefore, mainly a problem of distribution. Consequently, price increases are mainly related to local shortages, increasing energy costs and speculation.

In the case of wheat, the EU is in a favorable situation with an annual production (approx. 125 million tons) clearly exceeding its consumption (approx. 100 million tons). In contrast, countries that are net importers and with low capita income experience strong difficulties: Lebanon is currently not able to satisfy its domestic market demand and Egypt has decided to increase the amount of bran in refined wheat flour to 6% to compensate for the price increases.

It is difficult to predict the impact of climate change on future global harvest quantities and quality. Studies suggest that, in some places, a warmer climate may lead to higher yields. Alternatively, climate change will also result in more frequent drought episodes and other extreme weather conditions that compromise harvests. In addition, increasing land degradation leads to a decrease in the total amount of cultivable surfaces. It is reasonable to expect at least an increasing variability of the raw material quality due to changing climatic conditions.

Fig. 4: FAO food price indices

source: fao.org, reference period 100 = 2014-2016

Fig. 5: Global quantities of wheat and oils/fats production, utilization and stocks in the last years (in million tons)

source: FAO Staff shortage

While the bakery business has been suffering from difficulties in attracting qualified staff for years, the situation has further worsened since the beginning of the COVID pandemic. Difficult working times, low wages, physically demanding working conditions and an image of backwardness are reasons for employees increasingly turning to other business fields in a tight job market.

Megatrends in consumer demand

While the availability of resources is decreasing, the consumers’ expectations do not stop evolving. Therefore, adaptation strategies should take both the resource and the customer side into account. Current changes in consumer demand target the use of ingredients from local farming and processing, nutritional/health quality, plant-based, clean label and low environmental impact. In addition, in the context of global inflation and decreasing spending capacity, some consumers may look increasingly for products in the low-price segment.

Solutions

Due to such dramatic changes in market conditions, bakery companies can hardly continue running their business in the way they used to: either the resources or the customer demand would be missing. In this context, we would like to propose some approaches for tackling the described challenges (see table 1). Our focus lies on solutions that may be implemented by the companies themselves. Political interventions that aim at regulating energy prices, preventing insolvency of businesses and supporting consumption, are not being considered.

Of course, each business situation is unique. Choosing the appropriate combination of measures is a highly strategic decision and should reflect the genuine identity of the company. Some of the described solutions address specifically one resource, whereas others target improving the overall resource efficiency. Some solutions consider only the resource side, while others also involve the modified consumer demand.

Simplification

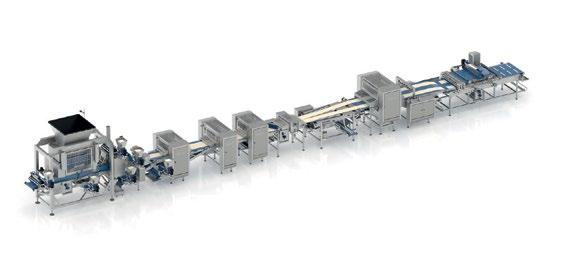

The simplification approach is based on the general assumption that complex processes lead to a decrease in efficiency and a waste of resources. How can this be applied to bakery production? It can easily be conceived that automated

Fig. 6: Symbolic representation of the complexity of process management in a bakery with batch processes. A high number of different products being manufactured simultaneously, each of them with different processing times and parameters on the single equipment lead to suboptimal loading and subsequent waste of energy

source: ttz Bremerhaven

industrial continuous lines on which one single product is running for several days without interruption allow for very high efficiency in terms of personnel, raw material and energy resources. Switching from one product to the next always implies downtimes, material losses and workload. In artisan bakeries, the daily production of a high number of fresh products with batch processes is essentially less efficient (see figure 6). At the same time, this means that artisan bakeries have the highest potential for improvement in resource usage.

Applied to the product range, the simplification approach implies finding out which core products are mainly responsible for the success of the company and represent its identity best. Eliminating products that do not match these criteria will improve overall productivity. If needed, complementary products may be sourced externally.

A further step concerns the recipes, following the trend of clean labels and striving for a reduction of the total number of ingredients and additives in use. This will decrease the dependence upon specific raw materials and lower the resources needed for sourcing and storing the ingredients. Some functionalities may be replaced by the development of process know-how, like the use of sourdough. Removing raw materials with stabilizing functionality may reduce the degree of standardization of the products. It must be evaluated whether consumers are ready to accept this higher variability, which may be the case if the clean label concept is well communicated.

ADVERTISEMENT

www.precisma.com

Customized machines for bakery engineering

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Precisma machinery is the specialist for inividual systems and customized solutions in the field of bakery engineering.

We offer you:

• Baking tray cleaning machines • Release agent applicators • Predusters • Conveyors and handling plants • Combined machines • For small businesses and industries New

KOBRA

Cleaning system

Precisma GmbH, Leombach 10, 4621 Sipbachzell, Austria Tel.: +43 (0) 7240 / 20 919, E-Mail: office@precisma.com

Table 1: Overview of proposed approaches and solutions to improve resource usage while better serving the new consumer demand

Generic solutions for better resource utilization

Approach

Unsold products represent a waste of resources

A high number of products (broad range) lead to losses of efficiency in production and sales

Specific solutions regarding energy consumption

A high number of raw materials implies a high amount of effort for sourcing and storing as well as a higher risk of shortage

Bakery products with poor nutritional value (high fat content, high SAFA content, high salt content, low fiber content) represent a bad utilization of resources in regard of the nutritional benefit

Products from the current range may not fit well with the new resource and market demand situation

Suboptimal loading of machinery leads to a waste of energy

Most of the energy consumed does not reach the product but is lost in the process Energy consumption can only be optimized if it is known which processes consume the highest amount of energy

Product-specific process parameters have seldom been determined with a view to reducing energy consumption

Old machinery has a lower energy efficiency

Some products require a lot of energy due to a succession of cooling and heating steps, as well as a succession of hydrating followed by water evaporation steps

Suboptimal maintenance of equipment (especially burners) lead to energy losses

Dependency on electricity reduces margins in case of price increases and the ability to manufacture in case of shortage

Dependency on one combustible (e.g. gas) reduces margins in case of price increases and ability to manufacture in case of shortage

Solutions

Anticipate the quantities actually needed by customers based on historical (and weather) data Rework unsold products.

Reduce the number of products to a core range that is well aligned with market expectations and company identity If needed buy complementary products from other manufacturers

Reduce the number of raw materials, thereby focusing on ingredients from local farming and processing. Try to eliminate functional additives, develop process know-how instead

Focus on ingredients and recipes with high nutritional value (e.g. products based on whole grain flour) Develop creative recipes to ensure sensory acceptance of the products

Additional benefits & potential drawbacks for consumers

Potentially better prices Risk of reduced availability

Potentially better quality of products Potentially better prices The identity and values of the company is more clearly defined, addressing the wish for “authentic products” Reduced product range, less choice

Addresses the demand for clean label, local production and authentic products Risk of higher variability of product quality

Addresses the demand for healthy products Risk of low sensory acceptance

Develop new products that are well compatible with the new situation, rather than sticking to the old ones Addresses the new customer wishes Acceptance of new products by consumers is not guaranteed

Decomplexify processes and re-schedule Addresses the demand for products with low environmental impact Potentially better prices Ensures ability to supply

Implement an appropriate energy monitoring for determining the energy consumption of the single processes Investigate the energy efficiency of the most critical processes and take single optimization measures (e.g. heat recovery systems)

Check whether cooling/freezing temperatures can be increased, heating temperatures can be decreased; check the effects on product quality, energy consumption and process times

Invest in new machinery

Assess energy consumption of single products Check whether the whole manufacturing process may be redesigned so as to use less energy

Optimize maintenance plans.

Use of photovoltaic panels for own electricity production In future: Use of photovoltaic panels for own hydrogen production

Invest in several types of burners or use hybrid burners to be able to switch between combustibles (this can be best achieved with a thermal oil system) In future: Hydrogen may be one combustible, which can be sourced externally (preferentially from a green source) or produced on own photovoltaic panels

Specific solutions regarding raw materials

Specific solutions regarding personnel

Approach Solutions

Dependency on single suppliers increases the risk of shortage and reduces the ability for price negotiations

Quality variations of raw materials may increase in the future due to the effects of climate change and the instability of supply chains

Difficulty to attract qualified personnel

Repetitive, physically demanding tasks

Night work

Image of backwardness

Lower wages compared to other industries Assess relevant raw material properties (specification) and identify alternative suppliers

Develop process know-how (adaptation of process parameters to the quality of raw materials)

Invest in the qualification of existing personnel

Invest in automation of single processes

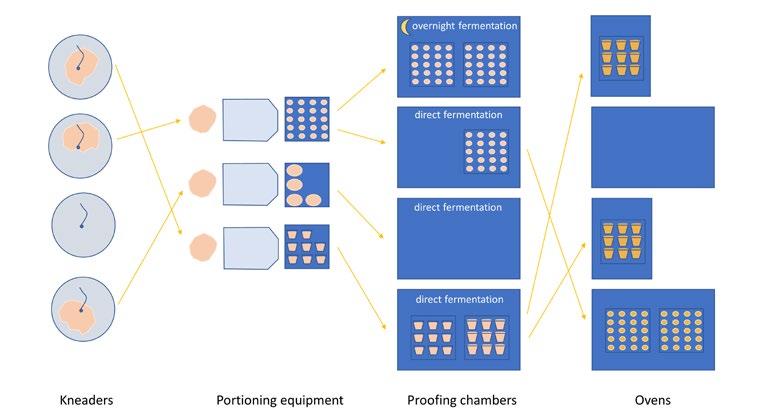

Reduce night work by changing processes (e.g. use of retarded fermentation)

Develop know-how on ingredients, process and nutrition and communicate it appropriately to staff and customers

Increase wages as far as the economic situation allows for it. Increase involvement of personnel by other measures (culture of trust, training, flexible working times, other advantages and compensations)

Additional benefits & potential drawbacks for consumers

Ensures ability to supply Potentially better prices

Process know-how addresses the demand for “authentic” products. Risk of low acceptance of remaining product quality variations by consumers.

A positive image as an employer also improves perception by customers

ADVERTISEMENT

Effective & profitable bread production

Modular concept Wide product variety Excellent dough quality

INNOVATIVE PRODUCTION LINES FOR

Julien Huen, Area Manager – Analytics for Process Optimization, ttz Bremerhaven

As an additional measure, manufacturing can be reorganized to reduce downtimes, the partial load of equipment, raw material waste as well as staff-intensive manufacturing steps.

An important source of resource wasting may lie in unsold product quantities. Reducing them implies better anticipating sales based on historical data (and possibly weather) and producing only the quantity actually needed. The remaining quantity of unsold products may be reworked, i.e. by the use of a bread syrup.

Develop new products

As it may be difficult to further manufacture the current product range under the new resource conditions, and as customers may not want to accept changes to existing products, developing and launching new products can represent a good solution.

Especially the trends of local ingredients, clean label, plant-based (e.g. egg replacement), high nutritional/health quality and low environmental impact should be taken into consideration. In this context, whole grain flour (high nutritional value, no side-stream during milling) and pulse flours like fava bean flour (local farming, functional proteins) may be of particular interest.

Special measures on energy consumption

Dealing with energy shortage may include different strategies. Reducing energy consumption implies first quantifying energy demand, the energy efficiency of the single processes in the company, and then implementing single measures such as waste heat recovery, swath reduction, the use of aerosol technology instead of steam in proofing, maintenance and equipment loading optimization, minimizing downtimes, implementing low-energy lighting, and replacing old equipment with low energy efficiency provided by state-of-the-art machinery. Reducing the dependency on an external electricity supply can be achieved by installing photovoltaic panels for the in-house production of electrical energy or thermal energy. Minimizing the dependency on a single energy source can be achieved by investing in equipment able to deal with different kinds of combustibles. For example, a small combined heat and power plant (CHP) produces electrical energy and thermal energy at the same time, thanks to fuel combustion. In a CHP, both fossil fuels (e.g. natural gas or heating oil) and also renewable raw materials (e.g. biogas, biodiesel and wood pellets) can be used.

Another alternative is the use of hydrogen as an energy carrier, especially green hydrogen, with vast opportunities for a regenerative energy industry. ttz Bremerhaven currently works on a project on the use of hydrogen as a direct combustible in a bakery oven. The study aims to examine its general feasibility by using a demonstration object for the use of hydrogen as an energy carrier in the bakery. It was shown that the direct combustion of hydrogen in the oven is possible, safe and allows for the manufacturing of high-quality baked goods. The vision is the use of ‘green hydrogen’ produced via electrolysis and renewable energy sources such as wind or solar power. Hydrogen serves as an intermediate storage medium of energy and its direct combustion is emission-free and only releases heat and water vapor; both resulting products are directly usable in the baking process. Bakery companies could either source hydrogen from industrial green production, or produce it by themselves using photovoltaic panels in combination with an electrolyzer (a combination of both sources also being possible).

Special measures on raw materials

One consequence of raw material shortage can be the necessity to accept a higher variability of the quality of raw materials: it may be necessary to switch between suppliers, or a given supplier may deliver a varying quality because

of its own sourcing difficulties. Different strategies may be used to cope with this increasing variability: (1) accept an increasing quality variation of the final product (the trend of ‘over-specification’ of food products has been regularly criticized in the last years), (2) use sensors for live quality monitoring in production and implement control loops to adapt the process conditions in real-time; (3) use ingredients and additives with a stabilizing function and adapt their dosage to the actual quality of the raw materials. The latter strategy, however, should be applied with care considering the risk of shortage of those ingredients and additives as well as their acceptance by the customers.

As mentioned above, simplifying recipes and moving to raw materials from local production may help ensure the continuity of supply. Having long-term direct contracts with local farmers increases the safety of supply even more, but also creates a higher dependency on the quality of the local harvest. Conclusion

With the availability of resources decreasing, it becomes vital to make the best possible use of them and to avoid waste wherever possible. This can be best achieved by focusing on a limited number of products made from a limited number of well-chosen raw materials, with production processes that are very well under control under the action of qualified and motivated employees. The concept of the final products must address the actual consumer needs and demands, especially from the nutritional, sensory and environmental point of view.

Having a clear view of what makes a company unique in terms of products and manufacturing, and appropriately communicating this will increase the market value of its products, and increase customer and staff loyalty.

The current global conditions are extremely challenging and require cool-headed management. Bakeries profit from satisfying a fundamental need of human beings, with cereals products representing 50% of the total calories supply (wheat: 20%) and being an essential source of carbohydrates, proteins, fibers and minerals. Companies should capitalize on these fundamental demands and develop business models that address them in the most efficient and transparent way possible. +++

Special personnel measures

Increasing the attractivity of the company as an employer may include decreasing the amount of night work by the use of fermentation interruption techniques or by rationalizing the product portfolio; further developing the internal process and product know-how and disseminating the knowledge on a wide basis via on-the-job training activities; automating repetitive and fastidious tasks; increasing wages, provided that the market success allows for it.

It can also make sense to externalize tasks of low strategic importance and to use external training/consulting services to develop the skills of the existing staff. At the level of professional organizations, improving the image of careers in bakery production would imply integrating more technological and scientific content into the apprentice curricula, especially in the fields of nutrition, biochemistry, biotechnology and process engineering.

ADVERTISEMENT

THE INTERNATIONAL NEWSFEED YOU NEED.

Subscribe to the Bakery Mirror newsletter, delivered to your inbox every other Wednesday.

www.bakingbiscuit.com