CONTRASTING APPROACHES IN LASER ENGRAVING BUSINESSES

TRANSFORMING SCRAP PILES INTO PROFIT

LIGHTBURN CORNER ETSY SPOTLIGHT

SIGNS OF OPPORTUNITY

PACKAGING 101 MASTERING 3D COIN ENGRAVING

CONTRASTING APPROACHES IN LASER ENGRAVING BUSINESSES

TRANSFORMING SCRAP PILES INTO PROFIT

LIGHTBURN CORNER ETSY SPOTLIGHT

SIGNS OF OPPORTUNITY

PACKAGING 101 MASTERING 3D COIN ENGRAVING

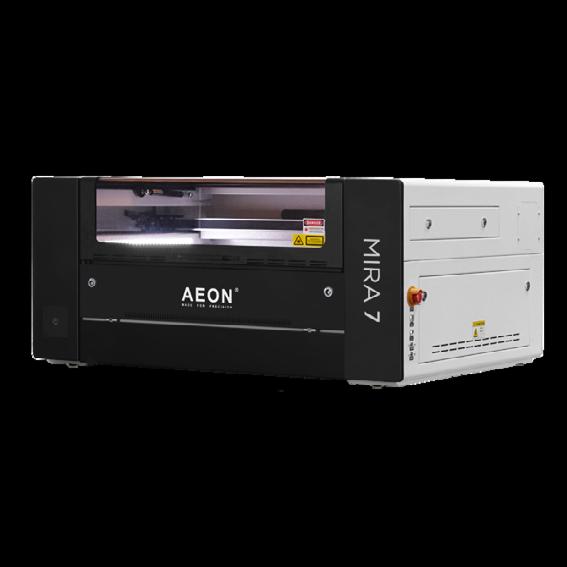

Aeon

GS2 Awards

H & H Creations Tampa

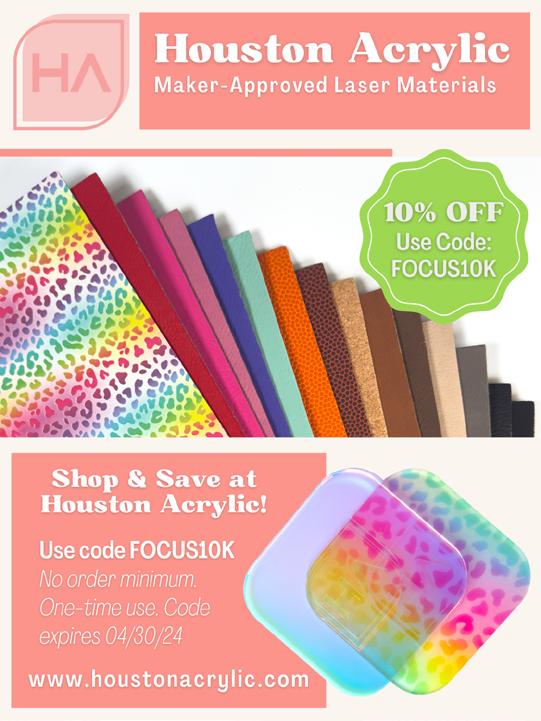

Houston Acrylic

Johnsons Plastics Plus

Laser Craft Fest

Lightburn Rotoboss

The Stainless Depot

Thunder Laser

Welcome to Laser Focused! As we dive into the March-April 2024 issue, I’m thrilled to unveil a fantastic addition that is sure to elevate your laser journey to new heights.

I’m delighted to announce the launch of our highly anticipated File Maker Directory! This directory is a game-changer for our File Maker community, providing a platform for all our talented creators to showcase their company. This directory is a ticket to increased visibility and more opportunities to introduce our subscribed laserpreneurs to new designers – or remind them of the seasoned pros!

But that’s not all – we’re not stopping there! In the coming issues, we’ll be rolling out even more directories to cater to the diverse needs of our community. Keep an eye out for our Membership Directory, perfect for those of you offering memberships to your laser services. We’ll also be introducing a Course Directory for those offering specialized courses to help fellow makers hone their skills. Last but not least, we’ll have a directory dedicated to coaching and consulting services, connecting you with experts who can provide valuable guidance and support as you navigate your laser journey.

In addition to these exciting developments, this issue is packed with invaluable insights and tips to help you succeed in your laser business. You’ll find a range of articles covering different business models and ideas to inspire and empower you on your entrepreneurial journey. From marketing strategies as simple as your packaging elements to new-to-you skills and techniques, we’ve got you covered with practical advice, taking your business to the next level.

I want to take a moment to thank our incredible contributors for sharing their expertise and experiences with us. Your passion and dedication to the laser community are truly inspiring, and we’re grateful to have you on board. Drop them a thanks online when you see them!

Please remember to check out our advertisers. They are the reason Laser Focused is free to you, our readers, so please consider them when making any of your laser-related purchases.

As always, I encourage you to make the most of everything Laser Focused has to offer. Dive into the articles, explore our new directory, and connect with fellow makers who share your passion for laser life. Together, we’ll continue to learn, grow, and inspire each other to reach new heights of creativity and success.

Editor Robin Roberts

Creative Director

Victor Havens

Copyright ©2024

So, let’s keep the momentum going and stay laser-focused on our goals. Remember, your journey is unique, but you’re never alone in it. Together, we’ll continue to shine bright and make waves in the world of lasers.

Laser On!

Become a guest contributor and showcase your expertise with Laser Focused readers. Contact us HERE!

Correction: Our apologies go out to two contributors who were mistakenly left out of the last issue. Lucy Kelly of Bloom by bel monili and Jeff Stockton of Upstate Laser Engraving.

Do you sometimes find, when you share a link on Facebook, that the wrong image shows up as the preview? I have a quick tip that will help you fix it in most instances. Visit https://developers.facebook.com/tools/ debug/ or just google “Facebook Sharing Debugger.” Once there, paste in the link you are trying to share and click debug. It will load with some code and such, but the main thing to look for is the image it is pulling. It will be the inaccurate image you are seeing when you post. Click the “Scrape Again” button next to the top line that mentions “Time Scraped”, this will usually be a date well in the past. Once you click that button, it should pull the new information that you want seen.

- Carol Pyles, My Graphic Fairy

For added depth in your painted projects - I paint each piece, then use Tri-Art Liquid Acrylic Glass Pouring Medium (https://amzn.to/3uB3MZ1)*, applying it to on the pieces. When it dries, it gives it a 3-dimensional look!

- Lori Quillman-Jarrett, Acorn Lane Laser Arts

Great Glitter pens, even ones like these POSCA Pens (https://amzn.to/48BV8HL)*, sometimes stop working. Here’s the secret to unclogging glitter pens: pull out the tip, wash it in water, put it back in (still damp), and prime it. Some of the kits come with spare tips - even handier!

- Caroline Armstrong

Use coffee grounds to darken engraving on wood. After I engraved a wooden jewelry box, I realized the wood/stain made it super hard to see the words. I opened a used coffee pod and rubbed the grounds into the design. Then wiped it away with a damp paper towel. I did repeat this 2-3 times. Worked great.

- Morgan Russell

When building reels on Canva, you are given the size, BUT you want to keep all your important info in between what Instagram(Ig) adds to the screen. I used nail polish to make two dots on the side of my phone case. This helps me arrange stickers, polls, etc, so they stay within the lines. Although IG provides guidelines, people often put important info too high or too low, and then it can not be easily read/seen. This prevents that.

- Nicole Weisman, Creator at Mabel The Whoodle

Have a Tip or Trick you want to share? Let us know! Click Here!

*As an Amazon Associate, Laser Focused earns from qualifying purchases.

“If you’re not having a good time, why have one at all?”

When you first meet Liz Rivers, you’ll instantly notice her sly grin. It’s the kind of grin you might expect from a former police officer with over 24 years of experience and a thing for jokes. “If I pulled you over to give you a ticket, I had a knack of wanting to hear jokes. I’d be like, Okay, you did this, this, this, and this, but if you tell me a good joke, you get to go.” One man wasn’t having it and responded: “Young lady, knock it off - I have shoes older than you!” (Liz wasn’t convinced - he ended up with a ticket.)

By Adam RobertsBorn in San Juan, Puerto Rico, she was 13 years old when her mom brought the family back to Tarrytown, just north of New York City.

Liz still lives just 30 minutes north of Manhattan. She says it’s the best of both worlds: she gets to recharge with her husband by the lakes and the mountains (Liz is a self-professed “nature girl”) but has easy access to NYC and all of the cultural goodies it has to offer. Liz has a passion for the 3 things New York is best at: Broadway shows, food, and - of course - shopping! Take it from Liz: “If you don’t find it in New York, they don’t make it.”

This is the spirit that first drove her to experiment with laser cutting. At the time, the ever-crafty Liz had graduated from cutting out stickers with her Cricut to sublimation printing. She was making and selling primarily tee shirts, cups, and signs. In 2019, she was making door signs by sublimating a print onto a laser-cut sublimation blank. “I didn’t know what it was cut on. I placed my order with this supplier, and they arrived damaged. Tip number one - do not sell what you don’t have!”

Caught between an unresponsive blanks vendor and the prospect of having to refund all of her customers, she did something that only a crafty & creative gal like Liz would do: she decided to cut out the middle man. “I said, you know what? I’m spending four, five hundred dollars a month

with you - I’ll show you! I’m gonna find out how you make these blanks.” A google-session later, and Liz came across Glowforge. After more research, she realized she needed more production capability for the volume she was anticipating. To get more information, “I joined the bigger boys’ groups, and they were talking about stuff that I have no idea what they’re talking about.” Fortunately, Liz met Aaron Cherman, who took the time to explain some of the laser world’s technicalities, but more importantly, he recommended Liz look into Emily Caroline, AKA That Mom With A Laser.

“I remember being in my patrol car and private messaging her... ‘I hear that you have a big laser, can I call you?’ And you could sense her hesitation, but me thinking that everybody knows that I’m a friendly individual, I said to her, ‘Don’t worry, I’m a cop!’ As if that made a difference.”

After the phone call with Emily, Liz decided to pull the trigger, so to speak. And when her brand new Mira 9 arrived in spring 2020, it was time to get to work! At first, she had trouble finding a local community of crafters to turn to for creative and business advice, so she had to practice and learn on her own. “I was crashing my laser head. I didn’t know much about the software, so it was a lot of trial and error.” But through this process, Liz learned a lot about how her laser actually worked. The more she learned, the more she made - and

she started selling to family, friends, her community, and, as she put it, “anybody and everybody who would buy from me.”

This was easier said than done, though. Right as Liz’s business was starting up, all her customers were shut down, stuck at home during the first months of the Covid-19 pandemic. But Liz’s friends were so interested in what she was making that the lockdown was hardly a barrier for them. “I would have Zoom parties with my friends and be like, look what I’m making! That’s how it started.” On top of that, Liz and her coworkers were still going to work every day - so her fellow police officers became some of her first customers.

As the lockdowns began to ease up, Liz started showing her work at local craft markets. “I love the markets, I just hate the setup... three times a year I do markets, mainly in the holiday season.”

Liz’s main products in the early days were tumblers & cutting boards, but now she carries more specialized stock for holiday shows.

Due to her inexperience, during her initial days, Liz found the task of preparing her market inventory to be quite daunting. At her first show, she sold hardly anything. Liz candidly described her display as “really awful.” The experience taught her firsthand the importance of presentation as it directly influences sales.

For the second show, she focused more on her display and prepared accordingly, assuming that a better display would lead to more interested customers. She prepared 20 of each item - and sold out. Next time she made 30 of each item, which seemed to be her sweet spot.

One thing Liz doesn’t do much anymore is year-specific ornaments; if there are any left over at the end of the year, they’re nearly impossible to get rid of. And her biggest seller? You’ll never guess. Go on, try.

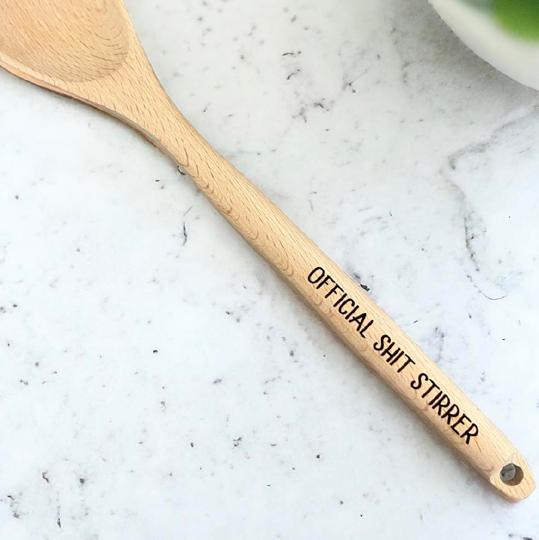

Spoons. Snarky wooden spoons. “I must have sold, at one market, 92 spoons. I didn’t bring enough.” (Did you guess right from the post on our page? Let us know on the Laser Focused Facebook page!)

So Liz seems to have cracked the code on her local markets, but where does she get her business sense from? Based on our conversation, there are two key elements. As cliché as it may sound, her friendliness and passion have each been integral to her success.

As a police officer with a background in social work, Liz didn’t have much formal business education. But one advantage her career gave her was a level of comfort with being social and open to new connections. “I’m not for everyone, I know that.” But many who know Liz comment on what a ray of sunshine she is.

More importantly, though, it was her passion for the work that drove her. From the beginning, Liz loved working with lasers, and that kept her coming back every day to make something new. As her hobby snowballed into more and more sales, her husband pointed out that she needed to formalize the business for tax purposes. Even then,

Liz says that it didn’t truly become a business until she retired from the police force and dedicated her full day to her laser work. “Up until that point, I was doing whatever I wanted... now I actually have a product line. I only do spur-of-the-moment [pieces] to spark my creativity, [for] friends.”

Liz’s current product line includes glass ornaments, spoons, engraved jewelry, tumblers, and wooden greeting cards. She sells online using Shopify, but her main traffic comes from her community.

And what a community! Liz started two Facebook groups that have been an important part of her development as a laser user and an entrepreneur. You may already know The Laser Outpost, a group she started while she was recovering from an injury on duty. “I was bedridden. So I started going into the groups and helping everyone. Liz decided to start the Laser Outpost as a strictly educational group with no sales - a group that currently has about 4900 members. Liz describes it as a place where people can ask for help and get non-judgmental answers. “[People come] to learn. It’s strictly to share to learn; it’s strictly a community.

Over time, she observed a need in the community for jewelry blanks, yet found no one filling this void. So she became a jewelry blanks dealer herself and started another group to help fill in this gap: a group with the oh-so-catchy name “XTool F1 and Fiber Laser and Jewelry Blanks.”

In the XTool F1 Fiber and Laser and Jewelry Blanks group, Liz sells high-quality jewelry blanks to the laser community while also “showing them how I test the pieces and what results they can expect.” While this group does link directly to Liz’s website (so you can purchase the blanks), the purpose of the group, Liz says, “is to provide

The “Not Liz Movement” might be how you first heard of Liz Rivers. But despite what it sounds like, she wasn’t being canceled - she was being celebrated! Liz posted a video demonstrating how to use her new laser. To keep her kids from “borrowing” it, she decided to engrave her own phone charger with the phrase - you guessed it - “Liz’s Charger.”

“Martin from Aeon Laser USA decided to be funny and write ‘Not Liz’s Charger.’ And before I knew it, people were like, ‘Not Liz’s Phone, Not Liz’s Pen...it just became this whole movement. It was really, really funny, and it made my day.”

Laser engraving businesses have gained immense popularity in recent years, offering a unique blend of precision and personalization. However, within this industry, two distinct approaches emerge: those businesses that primarily focus on engraving items brought in by customers and those that center their operations around purchasing blank items, engraving them, and subsequently reselling the finished products.

Over the last 10-plus years, I have found great success in operating my Customer-Centric Laser Engraving Business “Sonoma Laser Engraving.” I like the challenge of engraving different items for my customers, coming up with creative solutions to get the job done, or competing with online product-centric laser engraving business. But that’s not to say that either model is better than the other. So Let’s have a deeper look into the contrasting differences between these two models, exploring the advantages, challenges, and considerations associated with each.

A customer-centric laser engraving business revolves around the customization and personalization of items brought in by clients. Whether it’s jewelry, electronics, sentimental objects, drinkware, cutting boards, you name it! This model thrives on transforming personal possessions into cherished keepsakes. The primary advantage lies in the ability to cater to individual preferences, making each engraved item unique and meaningful.

One distinctive characteristic of a customer-centric approach is the varied and unpredictable workload. The business must be equipped to handle a diverse range of items, sizes, and materials. While this versatility can be rewarding in terms of creative expression, it also requires a flexible workflow and a skilled workforce. Another consideration is that you must have confidence in your engraving skills to ensure the engravings come out exactly as promised. You will often work on “one-off” or special items that customers may bring you, and in the event of a mishap, you must also be prepared to fix or replace the item. Last but not least a wide range of laser engraving equipment types, capable of adapting to different materials and engraving requirements, will be required to work this model.

Interacting with customers directly is a crucial aspect of a customer-centric laser engraving business. Understanding their preferences, providing design rec-

ommendations, and ensuring satisfaction throughout the engraving process is paramount. Building a strong relationship with clients can result in repeat business and positive word-of-mouth referrals, contributing significantly to the business’s success.

Customer-centric businesses often adopt flexible pricing structures based on the intricacy and size of the engraving projects. This flexibility allows them to cater to a broad spectrum of clients, from individuals seeking small, personalized gifts to small to large businesses looking for customized promotional items, and let’s not forget B2B laser engraving contracts with part manufacturers that need precision laser marking. The ability to tailor pricing ensures accessibility for a diverse customer base.

In contrast, a product-centric laser engraving business focuses on efficiency and streamlined production. By purchasing blank items in bulk and engraving them in larger quantities, these businesses can benefit from economies of scale, reducing production costs and increasing overall efficiency. This model is particularly suited for mass production of identical or similar items.

One of the primary challenges faced by product-centric businesses is managing inventory. With a reliance on pre-purchased blank items, there is a need to fore -

Laser engraving has been making waves in the creative maker world, leaving its mark on wood, metal, and acrylic. But have you ever wondered about the untapped potential of leather in this game? We’re here to spill the secrets of why leather is the unsung hero of laser engraving – from its tactile texture to its timeless vibes.

Different Types of Leather: Leather comes in various types, each with distinct characteristics catering to different preferences and applications. Each type of leather serves a specific purpose, and the choice depends on factors such as intended use, desired aesthetics, and budget considerations.

• Full-grain leather, considered top-tier, retains the entire grain, showcasing natural markings and gaining a unique patina over time.

• Top-grain leather, slightly altered by sanding or buffing, maintains durability with a more uniform appearance and is often used in high-end products.

• Split-grain leather, made from lower layers after removing the top grain, offers a softer, more pliable feel and is commonly used in suede production.

• Corrected-grain leather is top-grain leather with corrected imperfections, presenting a uniform look, and is widely used in furniture and accessories.

• Nubuck leather is top-grain leather buffed for a suede-like texture, known for its softness but requires careful maintenance.

• Aniline leather is dyed with soluble dyes without surface covering, preserving the natural texture and markings for a soft, natural appearance.

• Semi-aniline leather, similar to aniline but with a light surface coating, balances a natural look with enhanced durability, often found in upscale furniture.

• Bicast leather involves coating split leather with polyurethane or vinyl for a uniform appearance and increased wear resistance.

• Bonded leather, made from leather scraps combined with a bonding agent, is more affordable but lower quality than genuine leather, commonly used in budget-friendly furniture.

• Exotic leather, derived from animals like snakes or alligators, offers unique patterns and textures, often used in luxury fashion items.

• Leatherette, a synthetic alternative to genuine leather, mimics the look and feel using fabric or paper coated with materials like polyurethane or polyvinyl chloride. It’s a more affordable, cruelty-free option with varying textures and finishes, offering resistance to

stains and ease of cleaning. Widely used in upholstery, fashion accessories, and automobile interiors, leatherette provides a versatile and budget-friendly choice for those who appreciate the aesthetic of leather without the associated cost or ethical concerns.

Leather’s Swagger - Classic meets Cool: Leather isn’t just a material; it’s got a history, a personality, and a vibe that’s hard to beat. The tactile experience of running your fingers over leather and feeling its warmth is unmatched. It’s not just about what you see; it’s about what you feel. And let’s not forget the nostalgia – leather has this uncanny ability to evoke emotions and tell stories, making it a canvas of cultural significance. There is really something cool about seeing a brand or scar on a piece of leather that you are about to make something with. You think about the history of that side or shoulder.

Laser Meets Leather: Let’s talk about the magical chemistry between laser technology and leather. It’s like they were destined to create together. Leather is incredibly versatile, and laser engraving technology adds that extra touch of finesse. From genuine leather to faux leather, different leathers groove with laser engraving, bringing out unique patterns and textures. And guess what? The natural variations in leather only add to its charm, making each piece one-of-a-kind. You can engrave and cut leather on many lasers, from gantry to galvo. I personally use either a gantry RF tube laser or a galvo UV laser when engraving leather. The detail you get with one of these lasers (versus a CO2 glass tube laser) really makes the design pop. With leatherette, you can purchase colors that, when engraved, reveal a gold or silver underneath with many great applications.

Cool Stuff You Can Engrave on Leather: Imagine rocking accessories that are not just yours but uniquely yours – wallets, belts, keychains, you name it. Laser-engraved leather takes personalization to a whole new level. But it’s not just about utility; it’s about turning leather into art. Sculptures, awards, and even corporate swag – the possibilities are as endless as your imagination. One of my most fun projects was taking the logo of LEATHER

By Kacey Beal, Holly and Liz

By Kacey Beal, Holly and Liz

I see that scrap pile in the corner. Yeah, that one over there, the one you just looked at, the one that is stacked up well over the top of your “to throw out” bucket. Do you have plans for that? Let me guess, you were thinking of just throwing it out, but your inner hoarder continues to stop you. There is so much money just sitting there, begging for your attention. Maybe you’re thinking of just burning it, watching all that money go up in flames and smoke. Maybe you’re thinking that you will finally use it for that one small project. Maybe you are thinking you will just hold onto them for a little bit longer, as you are practically a hoarder of supplies these days.

Isn’t this the life we live as laser creators? The materials cost a lot of money, so now what do you do with all the little scrap sheets of wood and acrylic that lay around each day, yelling at us from the corner, begging for our attention? Oh yeah, and don’t forget all the lasering you have to do this week that will only make the pile bigger and bigger. I know you have plans for that pile, or at least you want to make plans for that pile. Think of how much money is in that stack, hundreds or even thousands of dollars. Don’t just look at it with pity, use it! How, you ask? One word, earrings! Don’t roll your eyes. I saw you doing it. You know it is a good thought. Maybe it’s even a thought you have considered recently. One of the greatest things you can do with that scrap material is turn it into earrings.

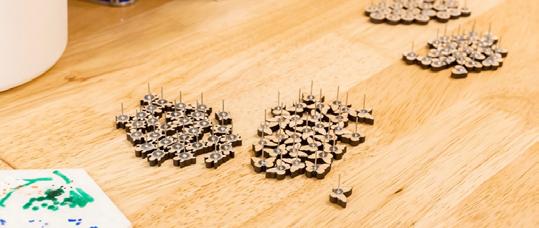

Did you know that many online shoppers are women searching for gifts for family members, girlfriends, neighbors, teachers, coaches, and even themselves? Why not give them something that will fit no matter what size they are? One size fits all in the earring world after all! Just think of all the design possibilities. Animals, sports, holidays, lines, circles, shapes, and all the colors of the rainbow including glitter, mirror, matte, plus clear acrylic. It is never-ending. Whether you have scrap wood or scrap acrylic, I know that you can use up 99% of that sheet to make earrings. You can get about 1000 stud earrings from a single 19x12 inch sheet of wood or acrylic, each pair taking just a few seconds to make.

Here’s the low down on how to make a pair yourself. The best thickness to use is 1/8 inch or 3 mm wood or acrylic. Thicker ¼ inch, 6 mm, is doable but not ideal. If using thinner, think of layering the pieces to get thicker. Earrings can be as small as about half an inch for posts and up to three to four inches for the larger statement drops.

All you need now are some metal posts and glue (I like Starbond medium the best) for stud earrings. Be sure to sand the metal posts a little, a few scuffs with some sandpaper will do. Be sure to let the glue dry for several hours before sending it to your customer. Pliers, jump rings, and metal hooks are all you need for drop earrings. Open the jump ring

with pliers, add your wood or acrylic piece and a metal hook. Close the jump ring, making the ends match together. You did it! You made earrings!

Need some inspiration? Think of all the holidays that women and girls love to wear earrings for. Christmas is huge, of course. Next is Valentine’s Day, Easter, the 4th of July, and Halloween. Then look at the sport mamas out there. They all need a pair to show their support for their kids playing. Don’t forget teachers and the corporate world too. Flowers, plants, patterns, food, and geometric shapes are great as well. One can never have enough earrings!

Are you planning on participating in a craft show or vendor event? Earrings are an easy, lightweight, and affordable item that can attract plenty of buyers. Consumers are always looking for small gifts to give. They are small enough to fit in a purse and cheap enough to buy on a whim. Create even more sales with a buy one, get one deal. Then watch your earrings roll out in multiples all day long.

So, before you toss your scrap pile in the bin, consider the possibilities. With a little creativity and effort, you can turn that pile of waste into a pile of money.

Kacey Beal is the owner of Holly and Liz. To get all your earring questions answered, you can contact her at support@hollyandliz.com or visit www.hollyandliz.com.

You Tube: https://youtu.be/Pj_89Vl_RUQ?si=Gvsves3Z7LBbiXtl Fb: @hollyandliz

IG: @holly.and.liz

TT: @hollyandliz

I engraved a full sheet of 42 keychains in about 50 minutes On my old laser, it would've been 2-3 hours, for sure

Crystal Aguila Riley Black Designs Fort Lauderdale, Florida

It's SOOOO much faster now that I have my Mira. What used to take 40ish minutes now takes me less than 10!

Rachaelle Larsen-Grimsrud Tree City Creations Boise, Idaho

FITS PERFECTLY INSIDE A SPARE BEDROOM OR CRAFT ROOM GREAT FOR STARTING OR EXPANDING A SMALL BUSINESS

ENGRAVES FASTER AND CUTS THICKER MATERIALS THAN A HOBBY-GRADE LASER

ENGRAVE UP TO 6 CUPS AT ONCE WITH THE INDUSTRIES FIRST MULTI-ROLLER ROTARY

high-quality laser jewelry blanks while educating laser users so they can make informed purchases and avoid the kind of catastrophe I experienced early in my time with sublimation blanks.”

Liz now owns a fiber laser and a diode/infrared laser in addition to her CO2. As you might have guessed already, one of Liz’s main lasers right now is a portable XTool laser, which has both a diode and an infrared mode. Using this with a heavy-duty battery pack, she is able to do certain custom orders at shows - even outdoors. “They get to pick a name, and I have pre-chosen phrases... [I] stay away from [detailed] personalizations that take a long time. You don’t make much money out of that.” Liz describes it as a game changer. “People just looking at that light - it immediately attracts [them]. There’s a fascination over things made on the spot.”

Despite purchasing it for its portability, it’s one of the lasers Liz uses the most. “It’s actually sitting in my dining room... I have my little filter, and when we’re all watching TV or whatever we’re doing as a family, I’m involved. I’m not away.” The flexibility of a portable diode laser is helping Liz balance her work and family life much more than if she were

stuck in the garage all day.

Ultimately, if there’s one thing that embodies so much of what Liz has brought to the laser community, it’s this piece of advice she got from somebody in a group: “When you surround yourself with like-minded people who are willing to see you grow and are there to support your growth, you will grow.”

And her parting advice for all our readers? “Do what makes you happy... I was lucky enough to find two jobs that I loved, so they didn’t feel like work. So find something that makes you happy, and try to convert it and make a living at it.”

“You got this. Work hard towards your goals, find like-minded people, find passion in what you’re doing, and you’ll succeed.”

IG - https://www.instagram.com/thelaseroutpost/ TT - https://www.tiktok.com/@thelaseroutpost

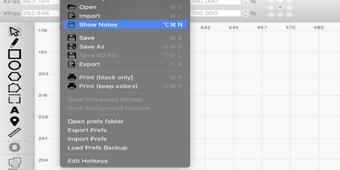

We all need a reminder now and again. Having to relearn special steps you used on past projects is time consuming, and even minor oversights when sending a project to your laser can lead to mistakes that waste material. LightBurn’s Project Notes and Job Checklist features are tools to get you up to speed quickly, and keep you from overlooking any essentials before running your job.

In LightBurn, you can go to “File” > “Show Notes” to create, view, and edit any notes you’d like saved to a specific project. Project Notes can be brief reminders or in-depth instructions, making them a great tool for those times when you’re opening a file you haven’t worked with for quite a while, or are sharing LightBurn files with other users.

You can save notes on materials used and special processes, provide instructions on applying settings based on layer colors, or jot down anything else you think you might need to remember, or someone else who opens the file might need to know.

By toggling on “Show on File Open,” you can make sure that you or anyone else who opens the file gets the memo, and is greeted with the notes you

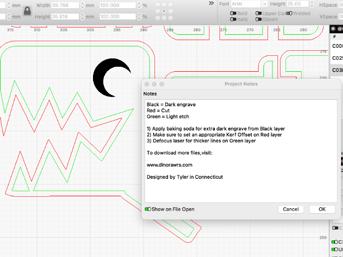

The Job Checklist is your reminder for the other end of the process - you’re just about ready to start your job, but want to make sure you don’t forget any crucial steps. Unlike Project Notes, the Job Checklist is saved to a device profile, and will apply to any project run from that profile.

The Job Checklist is available under “Edit” > “Device Settings.” You’ll see a switch to toggle the

Checklist on, and an “Edit” button to create or modify your checklist. Common checklist items are to make sure you’ve Previewed and Framed your job, put on your safety glasses, checked your laser’s focus, and turned on its chiller and air assist.

When you Start or Send a project with your laser, you’ll be met with your checklist, and will need to click “Yes” to confirm you’ve completed all the tasks and Start the job. If you’ve forgotten one or more items, click “No” to cancel the job and go complete those tasks.

Start using these convenient reminders today, take a few worries off your plate, and commit that newly freed mental energy to thinking up new laser project ideas!

Tyler Raps is a Support Agent, Copywriter, and one-man shipping department at LightBurn Software. For more information on the above tools, and many more, visit our documentation at https://docs.lightburnsoftware.com/ index.html or email us at support@lightburnsoftware.com.

Have you ever wanted more time in your day? We probably all have, right? Well, that’s exactly where I was back in 2016 when I was spending hours working on custom signs. I knew there had to be a way for me to scale my business, but I wasn’t sure how since I was already busy enough with my creative ventures, plus being a mom to 7 young kids!

I’m not just going to tell you my story here but also let you in on a little secret that changed the game for me. It’s not just about making and selling; it’s about teaching and sharing. I learned that I could take the same amount of time as it took me to create a custom sign and teach a class instead! It’s about turning one project into an experience that many can enjoy and learn from, and yes, it also makes better financial sense!

So, whether you’re a laser enthusiast, a curious beginner, or just someone who loves a good entrepreneurial tale, stick around. I’m about to take you on a journey from my rocky beginnings to a thriving business, all

while juggling the chaos of being a mom to seven amazing kids. Join me as I dive into the world of creativity and business and turn the unexpected into success!

In the midst of all the chaos that surrounds a home filled with 9 people, I found myself craving something more - a creative outlet and some much-needed adult interaction. My husband, a hardworking power lineman at the time, was often on the road, leaving me to manage the (joyful) craziness at home. That’s when the idea struck: I needed to do something that not only fueled my creativity but also got me out of the house! (hello, adults!)

What if I could figure out how to make signs from the pallets my husband was bringing home from work? It seemed like the perfect blend of art and entertainment and something that could keep my creative juices flowing. However, I quickly realized that spending three hours on a single custom piece wasn’t the most efficient use of my time, especially with a house full of energetic kids. I needed to find a way to turn that same amount of time into more profit. And that’s when the idea of DIY sign-making classes – or ‘parties,’ as I like to call them – came to life.

In the beginning, I knew next to nothing about making signs, let alone teaching it. There weren’t any groups or coaches I could turn to for guidance, at least none that I was aware of. But I was determined to figure it out. I convinced someone to host my very first sign-making party. Truth be told, I did just about everything wrong that first time. But something magical happened – the ladies attending knew nothing about my struggles and had an absolute blast! The pictures from that party were shared online, and just like that, my business began to take off.

It seemed like a nice little addition to my routine, a way to meet new people and share my love for creativity. But to my surprise, the demand for these parties was overwhelming. It turned out

that there was a real desire for this kind of creative gathering. Within the second month, I was hosting more parties than I had initially aimed for, and I quickly surpassed my own expectations.

Looking back, those early struggles were crucial. They taught me the ropes of both sign makingwhat worked and what didn’t - and conducting a successful class. More importantly, they showed me that even when you start with little knowledge, determination and a willingness to learn can lead you to unexpected successes. It was this journey from uncertainty to triumph that laid the foundation for my business today.

The decision to start hosting DIY sign-making parties was a game-changer for me. What began as a personal need for creativity and social interaction quickly turned into a bustling enterprise. Initially, my goal was modest - a few parties here and there, and ultimately 1 per week. But before I knew it, the concept took off, and I was hosting between 5 and 7 parties every week by myself! The demand was incredible, and I quickly realized I couldn’t do it all alone.

Six months into this venture, I hired my first instructor. This step was crucial in scaling my business. By the end of my first year, the numbers were beyond my wildest dreams: up to 9 parties a week, 6 instructors on my team, and over 200 parties hosted. This rapid expansion was a testament

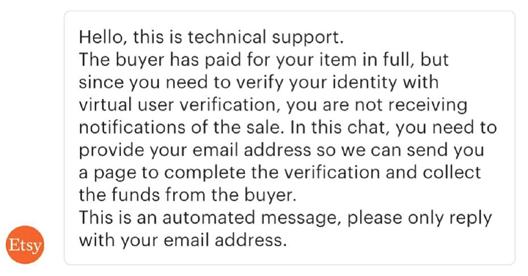

While being an online seller comes with many perks, it also comes with some problems! If you’ve been on Etsy in the past few months, you’ll likely have noticed new strange-looking messages in your Etsy inbox!

If you have read recent posts in the Underachievers Facebook group lately, you are aware that scams seem to be at an all-time high on Etsy. Some target shoppers, some shop owners.

The scams targeting shop owners are happening in the Etsy messaging system.

Here are just a few examples of messages that scammers are sending:

If you have questions about whether a message is legitimate, go to a desktop login and look at the new Etsy messaging system. Etsy messages will ONLY come from the inbox labeled “From Etsy”. Please note that the seller app does not have this view yet.

In general, Etsy will not:

• use emojis

• have typos

• ever ask you for your email address – because Etsy already has it.

• call you “dear seller” – Etsy knows your name already!

• use the word “kindly”

If you receive a message that doesn’t seem right, but you want to know if it’s legit (or not), contact Etsy through their chat support. But never, ever open an attachment or click a link from anyone in your Etsy account.

Jessica Trueblood is an Etsy coach and strategist. She is the owner of Shop Review Crew, founder of the Etsy Underachievers group on Facebook, which provides free resources to Etsy sellers. She teaches using only Etsy best practices to ensure her students get the best information possible! She lives in Colorado with her husband, son and her Glowforge, Maxine. You can connect with her at www.shopreviewcrew.com

Packaging is one of the easiest yet most important parts of your business, especially if you are a small business. It represents care, thought, and attention to detail in the last touch before your customer receives your product, making it vitally important as well as imperative to a good customer experience. When you own a retail shop, you can say ‘Thank you’ or ‘Come again!’ but when shipping your products, you have to make a lasting impression with your shipment packaging. This can be done inexpensively and easily with a few simple resources.

Use of personalized packaging is an easy and eye-catching way to wow your customers. This can be as simple as a handwritten thank-you note, a custom message printed inside the box, and a sticker with your logo. You can purchase a package of note cards inexpensively and a package of Avery labels and print your labels at home with ‘Thank you for your order’ or ‘Thank you for supporting my small business’; you can also print logo labels. Alternatively, you can purchase your labels in bulk, already printed like the ones pictured. These small but impactful touches will leave a lasting impression on your customer when they receive their package and likely want to order from you again. I always include a handwritten thank you on the packaging slip and address my customer by their first name; this makes the impersonal exchange more personal and shows I put time into packing their order.

Another inexpensive way to wow customers is by including a small freebie or sample as a surprise. These could be related products, promotional items, candies, or snacks. It shows appreciation and adds an element of delight. Again, these don’t have to break the bank, but they do need to be professional and show that you put thought into the packaging experience. I recently included 2” engraved magnets with my business tagline and a simple yet elegant line graphic. Not only did my customer receive something they didn’t expect, but they could see another product I offer and potentially give it as a gift.

Attractive and secure wrapping is an often-overlooked packaging strategy that achieves two ob -

jectives. By ensuring items are securely wrapped and cushioned while making the wrapping visually appealing, you go the extra mile to ensure your order arrives in one piece and looks nice. Bubble wrap is fairly inexpensive these days and often provides the level of protection needed, even though it’s not visually appealing. However, using branded or colorful tissue paper, colorful ribbons, or unique stickers, you can level up the unboxing experience.

Lastly, including interactive elements that engage your customer, such as QR codes linking to exclusive content, an unboxing challenge, or a social media contest, encourages them to share their experience and bring the purchase full circle. This may also serve as a way to introduce your customers to your social media profile, thereby giving you one additional touch and opportunity to retain them. QR codes have become a popular and widely used medium that appeals to younger customers and gives you some quantitative data you can use to continue to grow your business.

Don’t forget that all items you use in packaging are expenses and can be used as deductions at tax time. I am no tax expert, but I always keep track of my packaging purchases to send them to my accountant; every little bit helps!

Packaging serves multiple purposes:

• Personalization makes everyone feel valued.

• It showcases products with a small freebie.

• It is protective.

• It is engaging.

Packaging is the last touch opportunity to show your customer that you value their purchase, which can foster a long-term relationship. In a world where we are constantly bombarded with print and digital advertisements, your packaging allows you to stand out from the crowd without being overly salesy or blatant.

Great packaging leads to more sales, increased visibility, and overall business viability, so take a couple of extra minutes to up-level your product packaging.

Sara Mawyer is the owner of Coral and Cove Co. a small laser business based on the Outer Banks of North Carolina. You can reach out to her at hello@coralandcoveco.com or visit her website www.CoralandCoveCo.com.

to the power of shared experiences and having fun while crafting!

What made this approach so effective was the shift in my business model. Instead of spending hours on a few custom signs, I was now facilitating experiences for groups, multiplying the profit potential of those same hours. It wasn’t just about the crafts anymore; it was about the experience, the community, and the joy of creating together.

For anyone with a passion for crafting or those curious about starting their creative journey, I can’t recommend this model enough. Teaching others how to make or paint their own creations isn’t just financially rewarding; it’s also a fantastic way to embed yourself in the community. This involvement can lead to collaborations and support from local businesses, fostering a network that helps everyone grow.

Thinking outside the box is key. There’s so much potential beyond the traditional business models. And for those who are more digitally inclined, this model opens another lucrative avenue: creating and selling online courses to other creatives. It’s a way to share your knowledge and passion with a broader audience, further expanding your business’s reach and impact.

In summary, the shift from crafting individual pieces to hosting creative parties didn’t just transform my business—it redefined it. It allowed for exponential growth, community engagement, and new opportunities in the digital space, all of which contributed to a successful and fulfilling creative enterprise.

Dawn Marie Legatt is a ‘no-fluff’ business coach who helps creative entrepreneurs expand their streams of income with craft parties and course creation so they can turn their passions into profit. She can be reached at dawnmarielegatt@gmail.com and her website www.dawnmarielegatt.com.

GS2 Awards has been a supplier of premium wood and laser materials to the industry and is now honored to have been selected as an Official Distributor for Trotec Lasers. We are so happy to now offer both materials and machines that can help revolutionize our customers’ business. Whether you need materials or machines, GS2 Awards is officially a one-stop solution! GS2Awards.com

Introducing our new line of double-sided tape from Creative Cut Supplies!

With a great hold strength, this tape will help take your projects to the next level!

As we run a laser business that uses a lot of 3M tape, we were on the lookout for a margin-boosting alternative. After testing many samples and working on a solution, we are excited to launch DualTite, a game-changer in the laser industry. https://creativecutsupplies.com/collections/dualtite

LightBurn’s 3D Sliced function is a game-changer for galvo users looking to add dimensionality to their coin engravings. Unlike traditional raster engraving techniques, 3D Sliced operates on a layer-by-layer basis, akin to the slicing process used in 3D printing. By resampling and rasterizing grayscale images with varying cutoff thresholds for each pass, the software transforms flat images into stunning, tactile engravings on coins that boast both visual depth and texture.

To maximize the depth and visual impact of your engravings, it’s crucial to start with a grayscale image in a photo-negative format. This format, resembling a photo negative with a Gaussian blur applied, provides the ideal foundation for achieving lifelike depth maps. In the ‘Adjust Image’ option, select 3D Sliced and then fine-tune key image parameters such as contrast, brightness, gamma, and enhancement to enhance depth perception and detail.

Increasing contrast widens the gap between dark and light areas while decreasing brightness lowers the overall luminosity of the image. Adjusting gamma darkens mid-tones, while enhancement enhances edge contrast, resulting in heightened depth perception. Experiment with these settings to achieve your desired level of depth and detail.

Another critical element is timing. This will affect the crispness of your image. You can follow this link to a video that delves into timing in more detail. https://youtu.be/NdFr70yoRyA?si=TVwAf0x3YwB7SpPd

The software adapts seamlessly to any number of passes, with 256 levels of grayscale providing a versatile base for customization. Adjusting the number of passes allows you to fine-tune the depth and appearance of your engravings to suit your preferences. Although we are just looking at coins here, the 3D Sliced function is compatible with a wide range of materials, offering endless possibilities for creative expression.

Patrick Moore is a part-time pharmacist and full-time laser operator/owner at Light Source Engraving. He runs a YouTube channel providing tutorials and training for diode, CO2 Galvo and Gantry, UV, and Fiber lasers. He also develops and sells laser accessories on his website www.lightsource.pro

IG: instagram.com/lsengraving/ Fb: facebook.com/patrickalanmoore

View the video of 3D Coin Engraving: https://youtu.be/sRcEPEXsrmI

Selecting the right lens is paramount to achieving optimal engraving quality and runtime efficiency. Different lenses produce varying spot sizes, which directly impact engraving resolution and speed. Additionally, adjusting the interval – the line distance between each pass – can significantly alter engraving time and final quality. By correlating the interval with the spot size, you can optimize both engraving speed and output quality for your specific laser and lens configuration.

The ultimate goal of 3D coin engraving is to produce high-quality results with minimal post-processing effort. By meticulously calibrating your settings and conducting thorough testing, you can streamline your workflow and achieve consistent, professional-looking engravings. Whether it’s brass brushing, wet tumbling, light polishing, or sanding, aim for post-processing steps that require minimal time and effort, ensuring a swift and efficient production process.

Using LightBurn’s 3D Sliced function empowers you to push the boundaries of creativity and craftsmanship. By leveraging advanced image processing techniques, optimizing key parameters, and selecting the right materials and lenses, you can unlock the full potential of your laser engraving machine. With dedication, experimentation, and a keen eye for detail, you can achieve stunning results that captivate and inspire. So, what are you waiting for? Dive into the world of 3D coin engraving and unleash your artistic vision today!

BUSINESS Continued from P 11

cast demand accurately and maintain a well-organized inventory system. Overestimating demand can lead to excess stock, while underestimating can result in missed opportunities and disappointed customers.

Unlike customer-centric businesses, product-centric engraving operations often focus on building a brand and market presence. This involves creating a unique identity for the engraved products, which can be crucial in establishing a strong online and offline presence. Developing a cohesive brand image helps attract a dedicated customer base and fosters recognition in craft shows and online retail stores.

Product-centric businesses often adopt fixed pricing strategies for their engraved items. This simplifies the purchasing process for customers and enables the business to market its products with clear, standardized prices. While this approach may lack the flexibility seen in customer-centric models, it provides transparency and consistency, making it easier for customers to make purchasing decisions.

In the world of laser engraving businesses, the choice between a customer-centric and a product-centric

model boils down to the desired focus, goals, and operational preferences of the entrepreneur. A customer-centric approach thrives on personalization, varied workloads, and direct client interactions, while a product-centric approach emphasizes efficiency, inventory management, and brand building.

Ultimately, success in either model requires a deep understanding of the target market, a commitment to quality engraving, and a strategic approach to business operations. As the laser engraving industry continues to evolve, entrepreneurs must carefully evaluate these models to determine which aligns best with their vision and objectives for running a successful and sustainable business.

Michael Mullins has been operating his Customer-Centric Laser engraving business since 2013, and also runs a successful YouTube Channel called “Laser Engraving 911” where he focuses on educating people on laser engraving techniques and laser engraving business practices. www.sonomalaserengraving.com https://www.youtube.com/@laserengraving911 Michael@laserengraving911.com

a famous musician and making leather patches for her guitar strap. We made four lathes with her logo in different colors. Yes, you can add color to leather.

Oops, Challenges! But We Got This: Every journey has its bumps, and laser-engraved leather is no exception. Thickness hiccups, variations in leather – these challenges are part of the game. But fear not! Technology and some nifty tricks are at your disposal to overcome these obstacles. From tweaking settings to choosing the right leather type, there’s a solution for every challenge. What I like about leather is that each hide brings you a new canvas on which to be creative. Each tannery has a different finishing process as well that impacts the workability of a hide. Working with leather presents several challenges, stemming from the variability in the material, the precision required in cutting and stitching, and the necessity for meticulous edge finishing. Achieving consistent dyeing and staining is an art influenced by factors like leather type and application techniques. Durability considerations, including selecting the right leather and reinforcing stress points, contribute to the overall longevity of leather items. Sensitivity to weather conditions necessitates proper care to prevent discoloration or deterioration. Furthermore, the cost of quality

leather is a significant consideration, urging artisans to plan meticulously to minimize material waste. Despite these challenges, mastering leatherworking allows craftsmen to create enduring, high-quality products, making the journey an integral part of the craft’s allure.

Leather Love for the Earth: Let’s shift our focus to sustainability. Eco vibes are in, and leather can be part of the green movement. Sustainable leather options paired with laser engraving technology make for an eco-friendly combo. The precision of lasers also plays a role in minimizing waste, making leather and lasers a dream team for the environmentally conscious creator.

Laser-engraved leather isn’t just a craft; it’s a journey where tradition meets high-tech creativity. The tactile charm of leather, coupled with the precision of lasers, allows you to craft unique, personalized art. As the creative landscape continues to evolve, the marriage of leather and laser engraving promises even more opportunities for crafting timeless, one-of-a-kind coolness. So, what are you waiting for? Let the laser-etched leather adventures begin!

Alisha Pate is a partner, along with her husband, James, in Pate Ranch Creations. You can find them on Facebook and Instagram.

From scoring doodle patterns to pretty floral engravings & single line files-we’ve got you covered.

Creative Designs for Inlay Earrings, Earrings, Tumbler Wraps, Leather Jewelry, & more! Star Seller 15% OFF with THANKSLFMAG

Snark Heart: When you need the best designs to stand out from the crowd. Fun and easy laser files for makers. Click now!

Earring SVG files perfect to use with acrylic! 3D Designs, Hair Clip designs and Fonts.

Wood Inlay Files, sized for 12x19 boards, instructions, SVG, PDF, DXF & EPS.

Materials

MAS Epoxy, Eye Candy Mica powder, stir sticks, 1-3 oz disposable mixing cups, wax paste, table risers, line level, gloves, heat gun, propane torch. MAS epoxy and Eye Candy Mica Powder pigments create high-quality projects. My favorites are Eye Candy Pacific Blue, Okinawa Blue, and Sora-Iro Blue mica, as well as white pigment from MAS epoxy. (I’m an affiliate for both, and my links are available on my link tree!)

Hey, y’all, I’m Shawna Armendariz, owner and creator of Gypsy Finns Texas. I started this journey in 2017, simply as a hobby to keep my mind busy throughout Chemotherapy, fighting stage 4 colon cancer. My business and interests evolved to include resin art, laser projects, and woodworking. We are now a husband-and-wife team, slinging sawdust and glitter, celebrating remission on the Corpus Christi coast. If you can dream it, you can create it. Personalization will further elevate your project, and clients love it.

If you’re interested in following our journey and our soon-to-be-released resin course, please visit Gypsy Finns Tx on all social media and our website at GypsyFinns.com

Safety with resin Protect yourself. Non-negotiables are a full-face respirator, gloves, old clothes, a hair tie, and an apron. Resin is messy! I have found covering the workspace with butcher paper makes for quick and easy cleanup.

Prep your project using 120 grit sandpaper until smooth; this removes any sealer, waxes, and or oil that will prevent proper adhesion to your project.

Ensure you are using a clean surface by utilizing alcohol and a lint free cloth.

In order to prevent the resin from sticking to the back/bottom of your project, cover the back of your board in Paste wax. Position your table risers to elevate the board off the table, it is imperative that you ensure your board is level prior to beginning your design. If you do not have table risers, disposable mixing cups are a great alternative. Grab your mask and gloves, and let’s get started!

1st layer of resin- Using MAS Epoxy, mix equal parts of A and B or follow the manufacturer’s directions for your preferred brand. I have found that 3 minutes is the average time, so I no longer see any striations or foggy streaks throughout the resin. Ensure you are mixing at a slow tempo; too much speed will add air, causing bubbles in your project. Use small cups to separate each of your different Eye Candy pigment colors. In the example of a Coastal Beach theme project, I recommend Pacific Blue, Okinawa Blue, Sora-Iro Blue mica, Ocean Art White Dye, and one cup with no pigment added.

Slowly stir in your Mica powder pigments until you achieve your desired shade. It is important to mix colors thoroughly or risk uneven coloring in your project.

Beginning with your darkest color (Pacific Blue), start at the top of your board, moving downward to the lightest color (Okinawa Blue). Use your gloved finger to encourage the resin down the sides of the board and smooth it out evenly for full coverage. This does not need to be perfect, your focus should be establishing a level base layer. Gently blend your colors to give a gradient effect.

Next, apply a thin line of clear resin to the base of the lightest color; this will help to create and accentuate the beautiful wave shape. Trust the process the gradient may not appear perfect, and that is ok!

Ocean Wave Technique- Pour a thin line of your MAS Ocean Art White Dye resin along the shoreline of your project. Turn your heat gun on high, hold the gun at a 45-degree angle, and blow upward so the white pigment begins to skim across the clear resin. You will continue to blow until the desired effect is achieved. This is all about your own preference; remember, the waves in the ocean do not roll in the same way every time. The most important thing is that you do not leave your heat in one area for too long, as it’s easy to burn your resin. Your pigment will continue to change and develop as the resin sets up. Allow your project to sit for 5 minutes, then use your propane torch to pop any bubbles that have surfaced.

Cure for 10-12 hours - This allows enough time to add another layer.

Repeat the steps above to give your project additional depth and dimension, I find success with 2-5 layers.

Finishing touches -Once your project has cured for 24 hours, it is ready to be cleaned up. Using a heat gun, heat the resin drips on the back side and remove by cutting with a craft knife or simply just picking them off.

Step 11:

Sand the rough areas with 120 – 150 grit sandpaper to achieve that smooth finish without damaging the integrity of your design.

Step 12:

Oil your board with your choice of food safe oil to reveal the beautiful wood grain.

Step 13:

Engraving The addition of a beautiful quote, name, GPS coordinates, etc provides the ability to personalize each and every item.

By joining Laser Focused Patreon, you’ll not only support our mission but also gain access to laserfocused resources, community engagement, and invaluable insights from industry experts.

Become part of an exclusive community that celebrates innovation, creativity, and the laserpowered brilliance that sets us apart. Unleash your potential and make your mark in the laser world. Level up your laser game and unlock a world of exclusive benefits with Laser Focused Patreon.

Let’s light up the laser universe together and unlock limitless possibilities! JOIN TODAY