QUALIFICATIONS AND APPROACH

QUALIFICATIONS AND APPROACH

We believe that sustainability and highperformance are integral to design quality and are core tenets of who we are as a firm. Made up of architects, engineers, urban planners and interior designers, we take an integrated and holistic approach to every design solution.

Kimberly R. Cowman pe, leed ap, hfdi VP, National Director of Engineering

Kimberly R. Cowman pe, leed ap, hfdi VP, National Director of Engineering

As a firm, we are invested in our commitment to identifying, measuring and improving our environmental and social impacts. We work in the spirit of continuous improvement and recognize that meaningful change is an ever-evolving journey. Through setting a series of both short term and long term goals, we aim to focus our efforts on the way that we design the built environment, the way that we conduct ourselves as a company and the way that we contribute to and interact with our communities.

We recognize that there is an industry-wide need to fundamentally rethink how we traditionally approach design. We must move beyond the linear and siloed process that has been our long-standing methodology and into an inclusive, diverse and integrated approach to design. At LEO A DALY, we are committed to a design agenda that encompasses these principles.

LEO A DALY’s overall design agenda is rooted in the performance outcomes of our projects. Achieving truly high performance design outcomes requires an integrative design process including the perspectives of all stakeholders - architectural, engineering, interiors, landscape, construction, owner - into a whole. We recognize the interdependence of these practices and consider each indispensable design collaborators.

To give structure to an integrative performance design agenda, we are committed to adopting the AIA Framework for Design Excellence (FFDE) as the foundation. The FFDE is a well-considered, inclusive structure to set larger objectives and establish priorities for each design discipline in service of the whole. LEO A DALY uses the FFDE as the basis for a common design process and language, holistically integrating sustainability and performance in all aspects.

We embrace the use of analytical metrics to evaluate performance. Data is an essential tool to inform design decisions and measure their effectiveness in a performance-based design agenda. LEO A DALY has implemented three process priorities to elevate the elements of craft, performance, and resonance in our work, with performance being the most important given the environmental crises to which our work must respond.

Process priorities:

1. ESTABLISHING PROJECT PERFORMANCE GOALS TO CREATE ACCOUNTABILITY AND COLLABORATION THROUGHOUT THE PROJECT.

2. CONDUCTING AN INTEGRATION WORKSHOP TO COLLECTIVELY UNCOVER OPPORTUNITIES TO INTEGRATE A PROJECT’S PERFORMANCE GOALS THROUGH DESIGN.

3. COMMITTING TO EARLY PHASE ENERGY MODELING AND PERFORMANCE ANALYSIS TO DESIGN HIGHERPERFORMING BUILDINGS AS PART OF OUR STANDARD DESIGN PROCESS.

ABU DHABI • ATLANTA • DALLAS • OMAHA

LOS ANGELES • MIAMI • MINNEAPOLIS

WASHINGTON DC • WEST PALM BEACH

5 LEED Platinum Projects

5 Net Zero retrofit projects

145 staff with LEED, WELL or FitWel accreditation

182 projects pursuing certification: 170 LEED

10 Green Globes

1 Estidama

5 WELL or FitWel

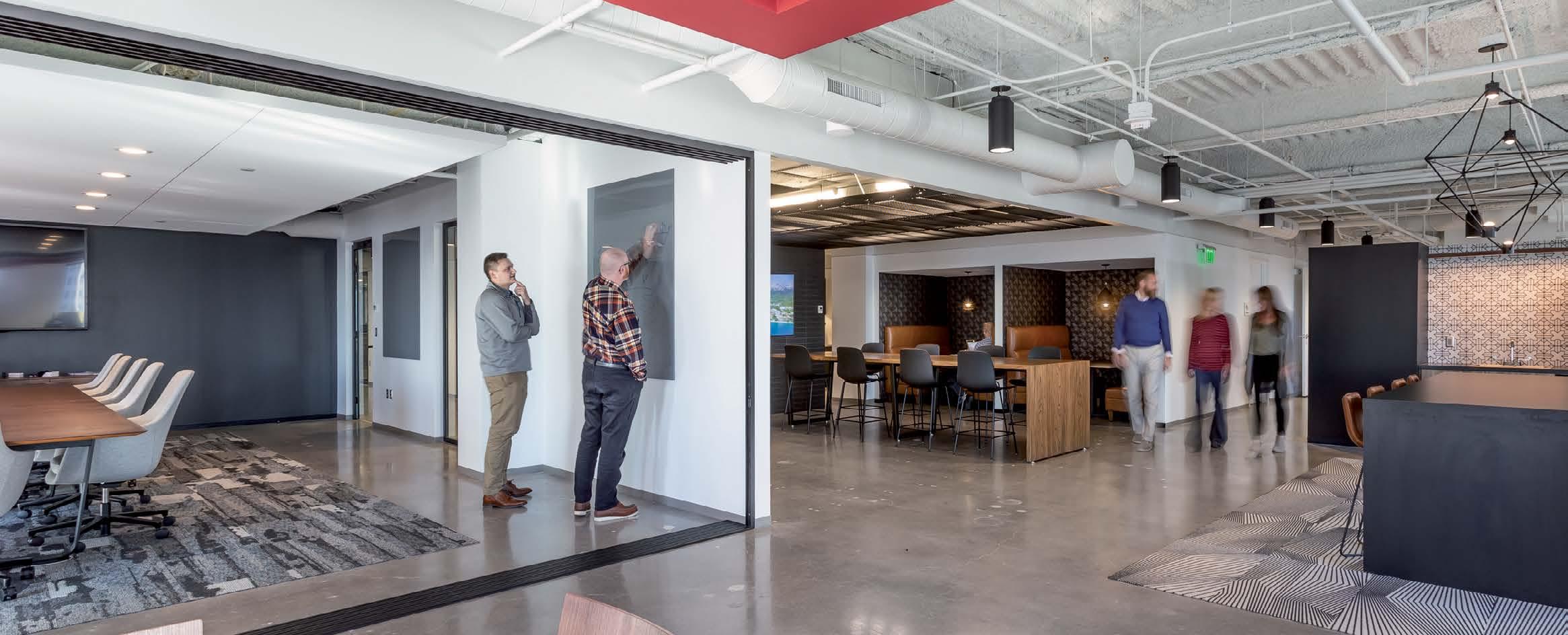

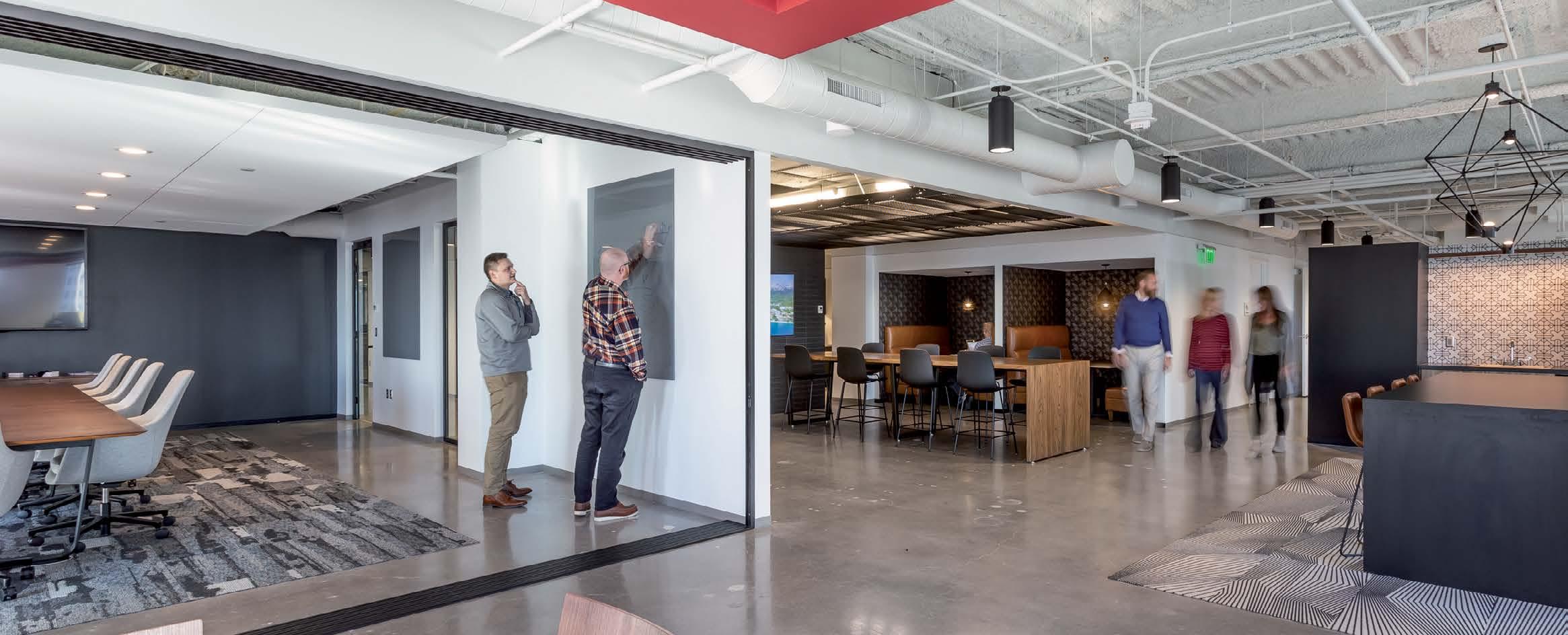

CARSON GROUP HEADQUARTERS

OMAHA, NEBRASKA

CARSON GROUP HEADQUARTERS

OMAHA, NEBRASKA

LEO A DALY is committed to holding ourselves accountable within the industry regarding our sustainable practices and performance. As signatories across various industry leading sustainability commitments, we continue to benchmark ourselves compared to our peers and act as champions of sustainable design practices across our entire portfolio of work.

The 2030 Commitment aims to transform the practice of architecture to respond to the climate crisis in a way that is holistic, firm-wide, project-based, and datadriven. Signatories have committed to transform their practices to deliver carbon neutral buildings by 2030. They demonstrate their progress by reporting the predicted energy performance of their entire body of work in design each to the AIA each year.

In 2009, LEO A DALY became 2030 Commitment signatories and committed to sharing our design portfolio energy performance data.

Our 2022 reporting information for the firm showed:

• REPORTED OVER 6.39 MILLION SQUARE FEET OF BUILDING AREA WITHIN THE AIA REPORTING DATABASE.

• PROVIDED ENERGY MODELING AND REPORTED ON 73% OF OUR APPLICABLE PORTFOLIO PROJECTS.

• LEO A DALY AVERAGE PERCENT REDUCTION OF PREDICTED ENERGY USE INTENSITY WAS 48.8% SAVINGS OVER THE AIA BASELINE BUILDING ENERGY USAGE.

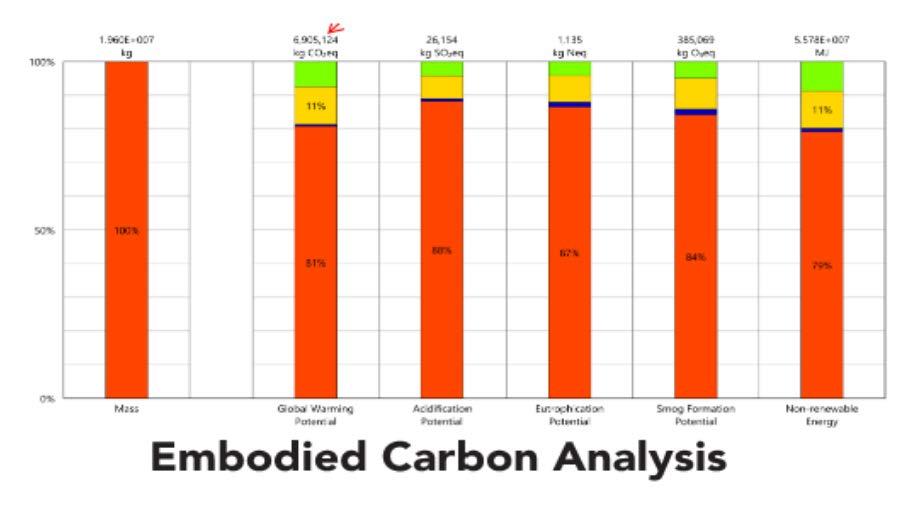

The Structural Engineers 2050 Commitment Program and was developed in response to the SE 2050 Challenge issued in 2019 by the Carbon Leadership Forum (CLF) and the Structural Engineering Institute (SEI). This comprehensive program has been designated to ensure substantiative embodied carbon reductions in the design and construction of structural systems by the collective structural engineering profession all in the name of achieving zero net carbon structures by 2050.

In 2021, LEO A DALY became SE2050 signatories and committed to focusing on educating educating ourselves and clients on the best practices of sustainable structural design, engage in an embodied carbon tracking program within the industry, and reporting on current impacts and trend of structural systems in the name of achieving zero net carbon structures by 2050.

Our 2022 reported structural embodied carbon information showed:

• REPORTED OVER 1.12 MILLION SQUARE FEET OF BUILDING AREA.

• PROVIDED EMBODIED CARBON CALCULATIONS FOR 17.56% OF OUR STRUCTURAL DESIGN PORTFOLIO

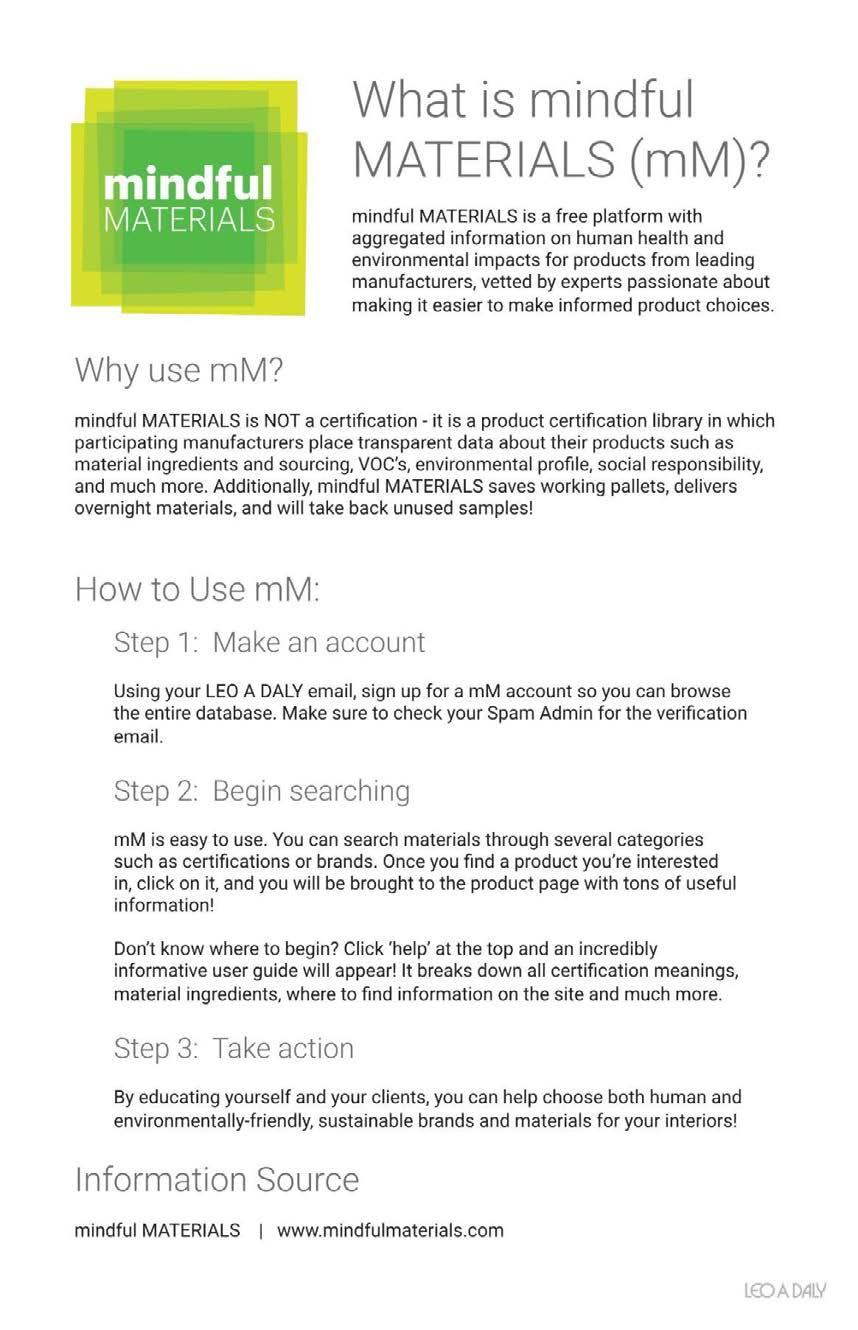

The AIA Materials Pledge intent is to inspire a shift in how the industry evaluates the products and finishes specified on a daily basis. Participants commit to five overarching statements that will lead to more intentional product specifications across their portfolios over time. The five pledge statements address:

• HUMAN HEALTH

• SOCIAL HEALTH & EQUITY

• ECOSYSTEM HEALTH

• CLIMATE HEALTH

• CIRCULAR ECONOMY

In 2021, LEO A DALY signed on the AIA Materials Pledge and formed a Responsible Materials working group composed of architects and interior designers to evaluate and implement changes to our approach in material selections across the firm.

Our commitment actions to date include:

• IMPLEMENTING MODIFICATIONS TO OUR MASTER SPECIFICATIONS ACROSS THE FIRM TO INCORPORATE SUSTAINABLE MATERIALS REQUIREMENTS.

• CREATING RESPONSIBLE MATERIALS VENDOR QUESTIONNAIRES FOR OUR MANUFACTURER PARTNERS TO UNDERSTAND THE SUSTAINABLE ATTRIBUTES OF SPECIFIED PRODUCTS.

• DEVELOPED MINDFULMATERIALS POSTERS FOR EDUCATING INTERNAL STAFFING ON MATERIAL PROPERTIES AND IMPACTS.

• IDENTIFIED INDUSTRY LEADING STAFF TRAINING COURSES FOR ELEVATION INTERNAL SUBJECT MATTER EXPERTISE.

COBALT CREDIT UNION HEADQUARTERS IN PAPILLON, NEBRASKA IS A HIGH-PERFORMANCE BUILDING USING GEOTHERMAL HEAT PUMPS, CHILLED BEAMS, AND MASS TIMBER ELEMENTS.

In our commitment to sustainability, we are focusing on five distinct arenas that allow us to implement a holistic design approach across the firm’s portfolio:

• HIGH PERFORMANCE DESIGN

• EMBODIED CARBON

• RESPONSIBLE MATERIALS

• WELLBEING

• POST-OCCUPANCY VALIDATION

INTERNATIONAL HARVESTER MISSISSIPPI VALLEY CREDIT UNION HEADQUARTERS IN MOLINE, ILLINOIS IS A HIGH-PERFORMANCE BUILDING INCORPORATING PRINCIPLES OF BIOPHILIA. THE BUILDING’S ORIENTATION HIGHLIGHTS VIEWS TO THE RIVER FROM COLLABORATION AREAS AND MAXIMIZES DAYLIGHT CONTROL STRATEGIES.

Data is an

essential tool to inform design decisions and measure their effectiveness in a performance based design agenda.

As we respond to our industry’s responsibility to mitigate climate change by reducing CO2 emissions, the central technology we have to design highperformance buildings on time and within budget is early phase modeling.

Beginning at the earliest stages of design, we now require every project to benchmark its energy performance, align around an energy target that will inform the design process, and complete early phase energy modeling analysis to inform architectural

To effectively incorporate energy performance modeling and analysis during the design process, LEO A DALY has focused on design team training, identifying early phase modeling leads in each of our studio locations, expanded our modeling software options to encompass analysis from concept design to final compliance modeling, and implementing budgeting and planning actions to ensure thoughtful incorporation for every applicable project. Our integrated design practice promotes architectureengineering partnerships to identify design options early for analysis.

EARLY ENERGY MODELING WORKING GROUP. This group of dedicated designers, located in the studios featured above, is responsible for the training and implementation of early phase performance modeling across the firm’s portfolio. The objectives are to expand the early phase modeling group to include one designer or architect per studio, expand software options to include CoveTool and IES-VE, and to promote architect–engineer partnerships.

Nicholas A. Lassek pe, cbcp Associate, Engineer, Mechanical High Performance Design

High Performance Design Subject Matter Expert

Nicholas A. Lassek pe, cbcp Associate, Engineer, Mechanical High Performance Design

High Performance Design Subject Matter Expert

During a period of incredible growth, Cobalt Credit Union (formerly SAC Federal Credit Union) recognized they needed a consolidated home to sustain the next 30 years of operation. Cobalt commissioned LEO A DALY to design a new and efficient headquarters near Omaha, Nebraska. The four-story, 94,000-SF headquarters is designed to office up to 250 employees and operate as a full branch credit union. Anchored by the “communication core” — a glass and aluminumencased central atrium with monumental staircase — the building systems feature multiple strategies to reduce operational carbon and minimize cost.

Keeping cool with less effort

Keeping staff and credit union members comfortable during humid Nebraska summers is a necessity. To cool office spaces throughout the building, an active chilled beam system circulates 57-degree water through suspended cooling coils. Warm air rises from the ambient space, passes over water-cooled coils in the ceiling and is circulated back into the room, minimizing the need for mechanical cooling from fans. The system provides more comfort and uses 44% less energy with lower operating costs than standard mechanical cooling.

Illuminating performance strategies

The lighting design incorporates energy-efficient luminaires and lamp sources, including LEDs and fluorescent lamps. Multi-level switching, dimming controls and occupancy sensors are combined with full-building automated lighting control panels to further reduce energy consumption. Additionally, daylight harvesting and light shelves are incorporated in multiple areas to take full advantage of available natural light.

44% ENERGY SAVED

42% LESS CARBON EMITTED

20,000 DOLLARS SAVED PER YEAR

Within the last few years, the industry has recognized that designing buildings to operate more efficiently is not enough to keep global temperatures under the 1.5-degree threshold that scientists believe will enable us to avoid the most catastrophic consequences of climate change. We must also reduce embodied carbon, defined as the carbon emitted in association with the extraction, manufacturing and transport of building materials.

Embodied carbon is found in a variety of building materials but is most heavily concentrated in steel concrete (specifically cement), aluminum, and glass. Because of this, our short-term goals are focused on structural and envelope design, using life cycle assessments to help us understand the order of magnitude impact and lower impact alternatives, such as wood, bamboo, cork, and cement alternatives.

Our structural engineering practice evaluates options ranging from “low-hanging fruit” strategies, specifications and substitutions, and all the way to assessing opportunities for mass timber structures. In addition, we evaluate options to make changes to our envelope designs as well as influencing interior materials selections through the lens of embodied carbon reduction.

We have invested in life cycle cost analysis tools, such as Tally, to measure design embodied carbon impacts and are educating ourselves and our clients on the value of prioritizing building reuse.

LEFT As energy codes and increased use of energy modeling drive down operational carbon emissions, the relative proportion of emissions associated with materials (embodied carbon) becomes more important and especially so in the early stages of a building’s life.

Jake K. Zach se Senior Engineer, Structural Embodied Carbon Subject Matter Expert

Jake K. Zach se Senior Engineer, Structural Embodied Carbon Subject Matter Expert

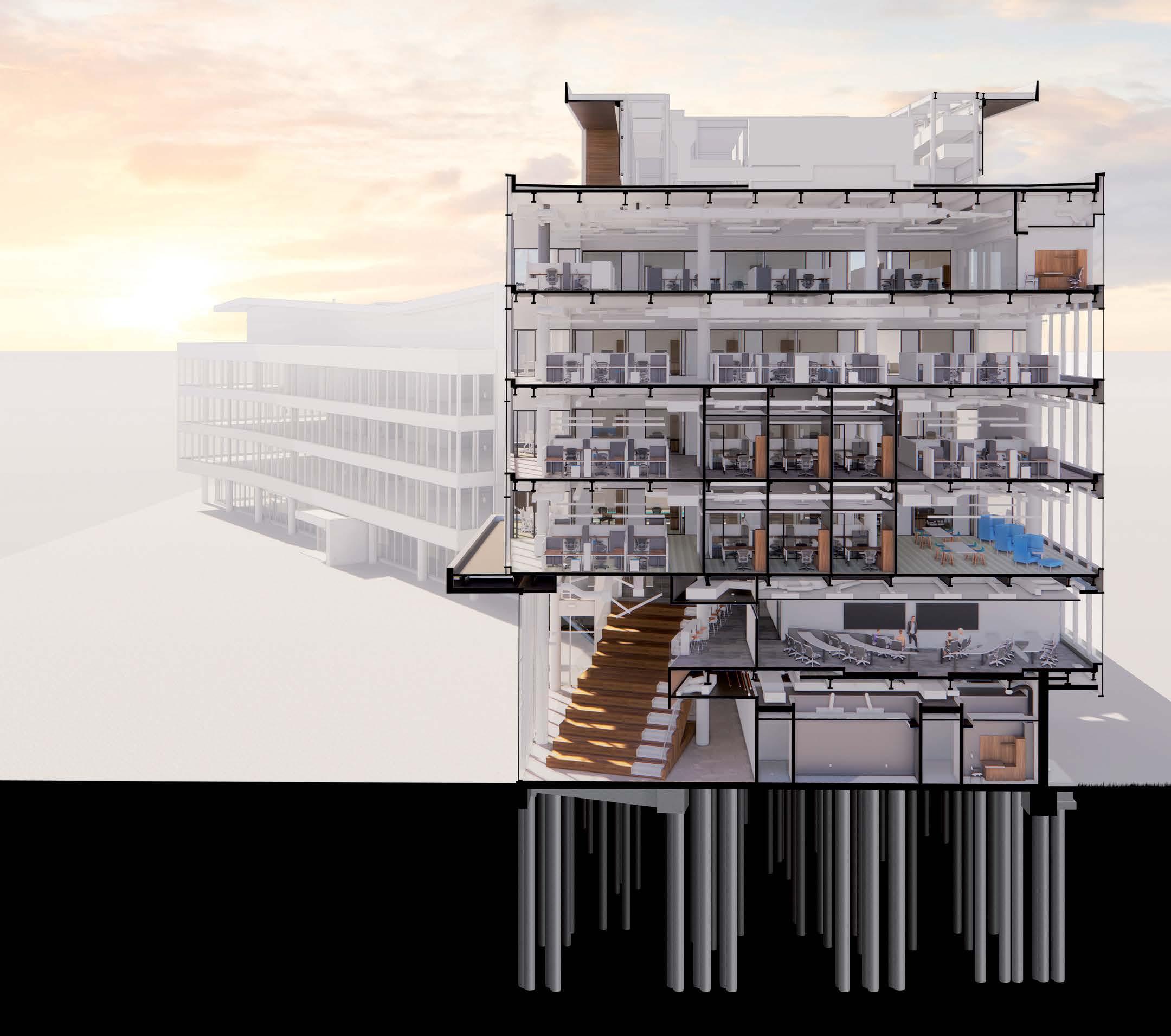

20 Massachusetts Avenue

WASHINGTON, DC

Massachusetts Avenue has been a prominent piece of Washington, DC’s city landscape since the conception of the Nation’s capital urban masterplan. The new development combines ground-floor retail and restaurants to create a vibrant streetscape with an inviting entrance and pedestrian experience, a four-star hotel, and class-A office space with amenities at the penthouse level as well as an extensive green roof.

LEO A DALY’s design for 20 Massachusetts Avenue is exemplary in its commitment to environmental stewardship and occupant health. The LEED Gold and WELL Silver project is aimed at minimizing carbon emissions, maximizing energy efficiency, and safeguarding the physical and mental wellbeing of users.

The existing structural skeleton was preserved, resulting in a significant savings in embodied carbon. Had the building been razed in favor of a new build, the project would have emitted an additional 6,905 metric tons of CO2e. This is the equivalent of removing 1,500 cars from the road for a year. Prefabrication of guestroom elements in the Royal Sonesta reduced construction waste, accelerated construction, and further reduced embodied carbon.

20,800+

RESOURCES SAVED: TONS OF CONCRETE METRIC TONS CO2EQ SAVED TONS OF STEEL

7,000+ = 785+

We are committed to understanding the environmental and human health impacts of our building materials. As such, we are committed to raising awareness and developing resources to help teams select and specify products that are responsibly sourced, transparent in their chemical makeup, and that disclose their life cycle impacts.

We recognize that the chemical makeup of furniture and finishes plays a critical role in the health impacts of the built environment. As such, we are committed to understanding and using product transparency and optimization labels as a lens through which we make material selections. Where possible, we endeavor to give preference to products that freely disclose their chemical makeup and are striving to find more benign alternatives to chemicals thought to have negative health impacts, not only during their installed life, but looking at their impacts from cradle to grave.

Beginning in 2021, LEO A DALY organized a Responsible Materials working group dedicated to advancing our collective awareness of the environmental and human health impacts of building materials. Our two-pronged approach focused on the two most common ways materials make it into buildings–through design selections and specifications.

Affecting design selections made by architects and interior designers directly required that we focus on education. We created a Vendor Questionnaire (right) to be distributed to product reps as they presented their mateirals to our studios, proactively asking that they address the impacts of their product lines and let us know which of their products had labels and certifications. The secondary benefit of this document is that it also allowed the designers themselves to research and understand the various labels and utilize resources such as mindfulMaterials to efficiently search and sort them. The second strategy required us to create a Division 01 specification section to be used for all projects and that set minimum thresholds for selecting products with environmental and human health disclosures.

BELOW Americans spend 90% of their time indoors. As such, understanding the materials properties of the indoor materials and their impact to human health is a first step in selecting more responsible materials for occupants and the greater environment impacted by their production. The below resources are just a couple of examples of the ways in which our team is driving this mission forward across LEO A DALY.

1.

Responsible Materials Subject Matter Expert

MINNEAPOLIS, MINNESOTA

The new Hennepin County Medical Examiner’s (HCME) Facility is one of the Nation’s leading and most advanced medical examiner facilities. With the goal of supporting an expanded service model and attracting the Nation’s top talent in Forensic death investigations, the stat-of-the-art office and lab building makes Hennepin County a regional magnet for forensic death investigations and medico-legal autopsy services.

Among other sustainable achievements, HCME is notable for its reponsible materials selection. Every material used in HCME fullfills a dual purpose: first, to stand up to the rugged wear-and-tear of life in a laboratory and second, to meet the state’s B3 sustainable design program. These criteria motivated the design team to select interiors products that came from ethical sources, contributed positively to the health of occupants, and met the client’s high durability and cleaning standards.

The project was required to use at least 55% salvaged or reused, recycled, recyclable, bio-based, responsibly sourced, or regional materials. The project shattered the 55% benchmark with an environmentally preferable materials ratio of 81%.

For lab spaces, the design predominantly features stainless steel surfaces with high recycled content and Terrazzo with recycled porcelain content to balance the selections of epoxy and solid surfaces. Office spaces use carpet with high recycled content, ceiling tiles with plant-based binders, and reconstituted wood wall covering instead of vinyl. Every material used in the facility is low-VOC–a feature that improves indoor air quality and contributes to the health of occupants.

55% 81%

REUSED, RECYCLED, RECYCLABLE, BIOBASED, RESPONSIBLY SOURCED, OR REGIONAL MATERIAL USAGE REQUIREMENT ACHIEVED

Recognizing that environmental health and human health are two sides of the same coin, our action plan also focuses on wellbeing design across scales–from individual spaces within buildings to buildings themselves, even looking beyond the building scale to the community and neighborhood scale.

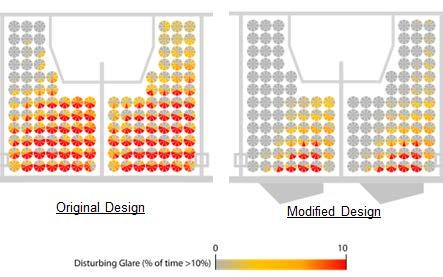

Within buildings, our multidisciplinary approach affords us the ability to look at the quality of the indoor environment more broadly. We are able to assess factors such as increased ventilation, temperature and humidity rates, systems strategies to both filter the air and control how it moves through the space. In addition, we can maximize the amount of useful daylight through both the architectural design and lighting controls, optimizing for variables such as glare, diffuse / indirect light, and color temperature.

Using data and performance modeling to validate metrics associated with human health and comfort are equally as important as evaluating energy performance metrics. Our design experts across disciplines work to evaluate glare analysis modeling results in concert with energy perfromance results to find integrated solutions that result in high performance buildings without sacrificing humancentric design practices. We have invested in various daylighting and glare analysis software as well as thermal comfort analysis tools and trained key users to provide this full level of analysis for project teams.

BELOW Examples of daylighting analyses for an exterior shading device to reduce uncomfortable glare in an inpatient hospital room.

Heather E. Robbins ncidq, iida, leed ap, edac, well ap Senior Associate, Project Manager

Wellbeing Subject Matter Expert

Trevor S. Hollins pe, lc, assoc. iald Associate, Practice Lead–Lighting

Wellbeing Subject Matter Expert

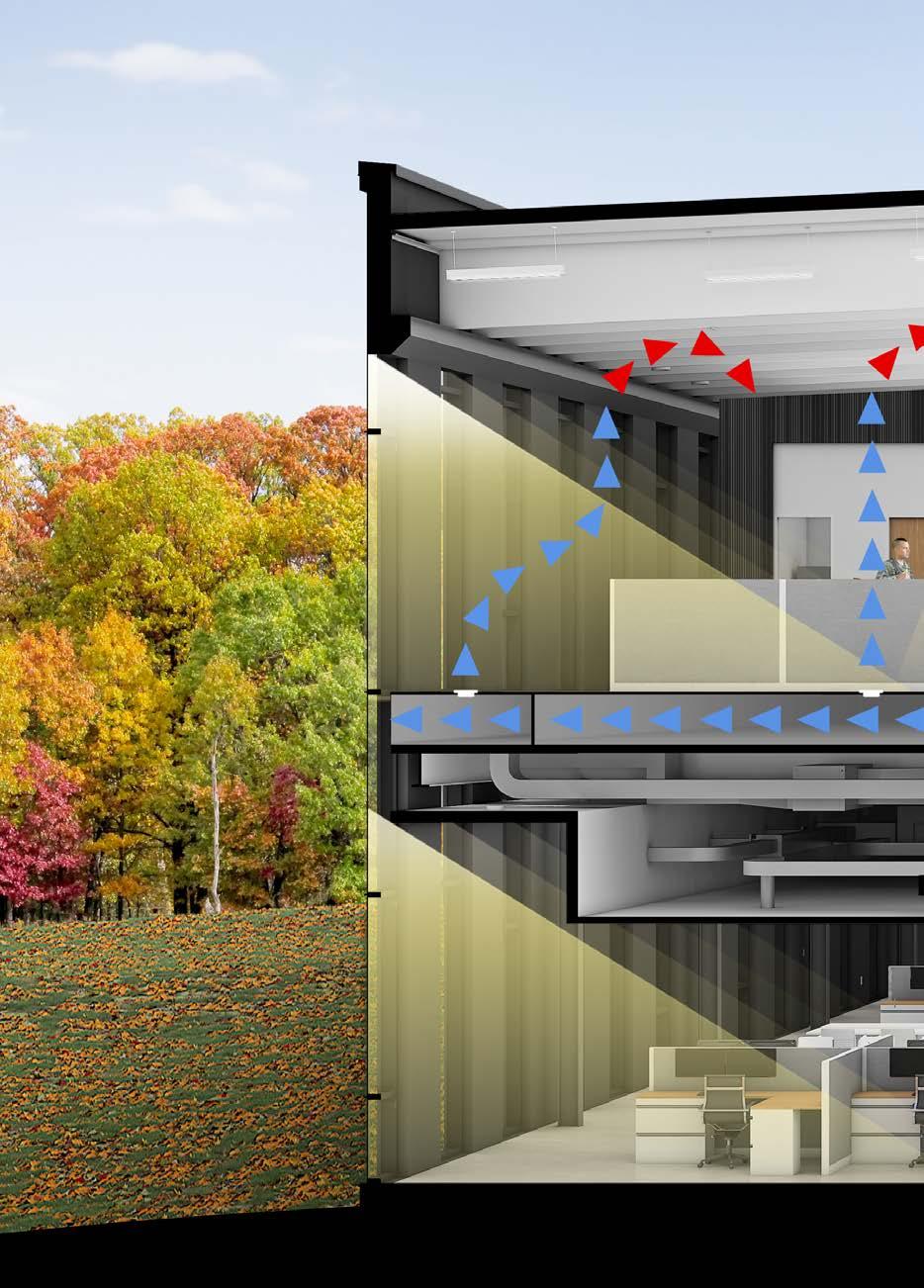

The General John W. Vessey Readiness Center serves as the new home for the 34th Infantry Division (ID) “Red Bulls” of the Minnesota Army National Guard (MNARNG). The design supports the Red Bull mission and provides an ideal functional environment for training, planning, and command of stateside and forward deployed units.

Sustainability goals were initially driven by the U.S. Army and Department of Defense (DoD); however, a fully integrated project design team and careful tracking of construction processes allowed the team to deliver a high-performing, LEED Gold Certified facility to last for generations to come.

The mental and physical wellbeing of citizen-soldiers was paramount to the design. Some of the most critical design elements for supporting the users’ wellbeing are outlined in the diagram at right.

115 solar light tube devices provide ample the center floor plate. Those for enclosed are equipped with light ducts that transfer with an efficiency

ADAPTABLE FLOOR PLATE

Double tees span space providing an column free interior that can adapt to changing requirements of any mission

DAYLIGHT

ample light to enclosed rooms transfer light efficiency of 99%

INDIVIDUAL TEMPERATURE CONTROL

325 floor diffusers supply air at each workspace for individual control of air flow/temperature

ACOUSTIC ISOLATION

Leveraging the below grade spaces for learning centers provides natural acoustic isolation and no daylight per mission requirements

FLOOR the an interior the requirements

RECONFIGURABLE FLOOR SYSTEM

Raised access floors spans the entire Main level Admin Wing providing a chase for cable trays, conduits and HVAC air flow(2,400 SF)

INCREASED VENTILATION EFFICIENCY

Air is only supplied from below near the breathing zone and returned at the roof structure. This increases ventilation effectiveness and decreases the amount of outside air required, saving energy

DAYLIGHT & VIEWS

50% of the exterior envelope has full height glazing to provide daylight and direct views for the entire administrative workspace

EFFICIENT HVAC ZONING

Perimeter glazing is supplied by dedicated heat pump system allowing the main system to shutdown when not occupied

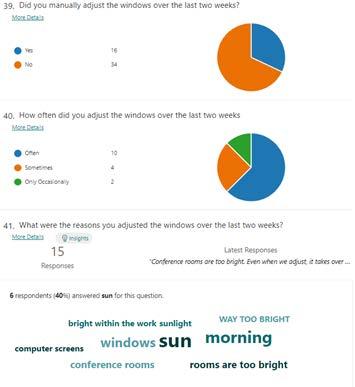

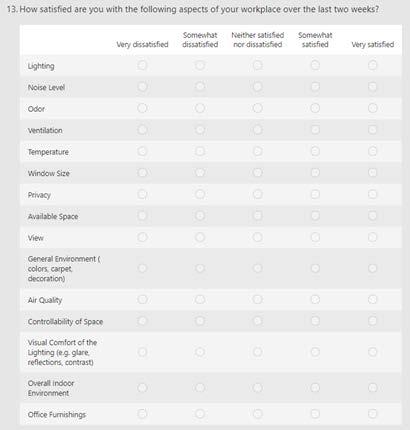

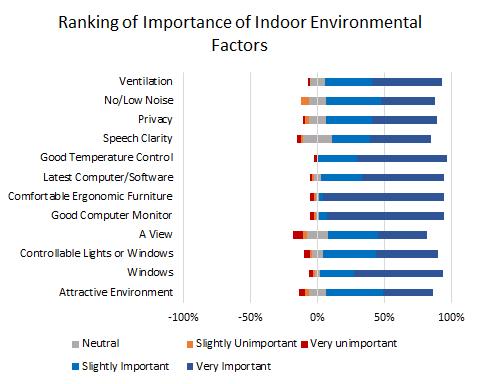

Validating our design decisions and implementation of design solutions through post-occupancy validation is a critical component of the design process that is often overlooked.

LEO A DALY feels obtaining user and occupant feedback is invaluable in understanding how occupants experience their spaces under normal, everyday operating conditions. Soliciting feedback through post-occupancy surveys optimizes our process and provides input that drives innovation in future design decisions. Our concise and user-friendly online surveys focused on the occupants’ experiences within and perceptions of the design facilitate a straightforward post-occupancy data collection process.

In addition to survey-gathering, we have also completed post-occupancy data collection specific to indoor environmental factors, such as temperature measurements, sound measures, lighting and glare measurement, and air particulate measurement to validate specific design solutions and our design performance modeling calculations.

LEFT, BELOW, AND BELOW LEFT

Snapshots of post-occupancy survey data collection surveys, captured results, and data analysis post-collection..

Michael B. Kuhlenengel Engineer-in-Training, Electrical

Michael B. Kuhlenengel Engineer-in-Training, Electrical

Ph.D. Candidate, University of Nebraska–Lincoln, College of Engineering

Post-Occupancy Subject Matter Expert

OMAHA, NEBRASKA

Based on intensive research of Carson’s brand and values,

LEO A DALY designed Carson’s 200,000-SF office campus headquarters to embrace a thriving company. The design supports and anticipates innovations in how people work, enabling flexibility through technology and space planning.

An electrochromic glass envelope tints organically in response to changing concentrations of daylight. With no need for window coverings, every perimeter view is unimpeded. Our energy and lighting models accounted for the reduced heat gain and glare, which led to tailored solutions such as reduced energy HVAC. The transparent skin invites ample interior daylighting to a mix of private and collaborative workspaces, while conveying outwardly Carson’s value of transparency.

LEO A DALY undertook a limited post-occupancy evaluation (POE) to understand the impact of electrochromic glazing on HVAC performance and occupant comfort, especially related to electric lighting, daylighting, glare and thermal comfort. Air quality and noise were also evaluated although not directly impacted by the glazing. Measurements were accomplished using illuminance meters, spectrometers, temperature and relative-humidity meters, sound-level meters, particle counters, and CO2 meters combined with subjective impressions gathered from about 55 occupants. This revealed the actual conditions and subjective human responses to them.

We found that the electrochromic glazing lived up to its claims for both energy performance and occupant comfort. Allowing occupants to control the dimming qualities of the electrochromic glass proved less effective than allowing the envelope to operate automatically. In limited situations and locations, the envelope’s dimming operation as perceived to reduce overall lighting to uncomfortable levels. Ventilation performed very well and reduces CO2 to low levels.

WITH LOWER SOLAR GAIN, SMALLER AIR-HANDLING UNITS SAVE $100,000 UP FRONT AND USE 15% LESS ENERGY.

OVERSIZED DUCTS REDUCE AIR PRESSURE, IMPROVE EFFICIENCY AND ALLOW REPURPOSING OF SPACE.

ELECTROCHROMIC GLASS REDUCES DISTRUBING GLARE BY 74.4%, REDUCES SUMMER COOLING LOADS BY 15%, AND REDUCES WINTER HEAT LOSS BY 20%.

DAYLIGHTING REDUCES ELECTRIC LIGHTING LOADS UP TO 74%, WITH NO NEED FOR WINDOW COVERINGS. OCCUPANTS RETAIN CONNECTIONS TO NATURE.

DESIGN VERIFICATION: MX1104 MULTIMETERS, PLACED AT DESK LEVEL, VERIFIED THERMAL AND VISUAL COMFORT.

DESIGN VERIFICATION: SPECTROMETERS, PLACED AT EYE LEVEL WHEN SEATED, RECORDED BENEFICIAL AMOUNTS OF MELONPIC LUX, WHICH ENHANCES SLEEP CYCLES.

A DEEP FOUNDATION SYSTEM SUES 80FOOT AUGERCAST PILES TO SUPPORT THE BUILDING EFFICIENTLY AND ECONOMICALLY. 1 2 3 4 5 6 7

1

2

3

4

5

6 7

POST-OCCUPANCY

POST-OCCUPANCY EVALUATION