THE ARCHITECTURAL TECHNOLOGISTS BOOK

004 THE DESIGNERS - Design news from around the world 018 NEWS & VIEWS - News and views from the building industry 028 INTERIORS - The latest trends 044 DOORS AND GLAZING - A product and project insight 056 PROJECT NEWS - The latest projects from the building industry

Front cover image courtesy of Schlüter-Systems - www.schluter.co.uk Page 2 image courtesy of CRL - www.crlstone.co.uk

Some of the colour photography used in The Architectural Technologists Book is provided and paid for by contributors. The publishers do not accept liability for errors that may appear in the publication. Dedicated to our friend Mike. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means without the publisher's consent.

Published by L2 Architectural Media Ltd, Park House, Stafford ST17 4AL. Tel: 01785 291442 www.L2am.online

Antonio Citterio Patricia Viel reveals the interiors of the Dongzhimen 8 penthouses in Beijing, as part of the restyling of the more than 30-floor residential building. Combining a rich mix of textures and a selection of highquality materials, the project comprises a total of 21 penthouses on the topmost seven floors of the building, with a unique design for three different residence types. “The penthouses are characterized by a series of exceptionally wide window openings that open the residences to panoramic views of Beijing. The custom designed seating in the windows offers spaces where people can relax, unwind, and explore a new relationship with the city,” says architect Antonio Citterio, Chairman of ACPV ARCHITECTS.

The design of the apartments is accentuated by clear horizontal lines in the wooden wall paneling: the upper and lower edges of the window openings run through the entire apartment to visually elongate the space, and to make residents feel at ease.

“Following ACPV ARCHITECTS’ approach to interiors, the penthouses feature a curated selection of materials, such as marble in the bathrooms and textured clay detailing on the ceilings with nature motifs,” says architect Patricia Viel, CEO of ACPV ARCHITECTS.

The penthouses’ furniture selection comprises worldrenown Italian brands, including pieces designed by Antonio Citterio. The penthouses’ walk-in closet by B&B Italia, and sofas by Maxalto and Flexform add a touch of timeless refinement to the living spaces.

“The focal point of the apartments are the shared spaces that foster interaction among residents and their guests. For example, the kitchen by Arclinea provides generous spaces where people can spend time with their friends and family,” says Chung-Yi Yang, Partner of ACPV ARCHITECTS, in charge of the project for Dongzhimen 8. (cont...)

(cont...) The most compact residence, “FLAT A”, has been conceived as a yacht-like living space that is defined by an openness to its surroundings. Inspired by naval architecture, the design features inlaid parquet, and smooth rounded details. The curved walls between the kitchen and the living areas both separate and connect the two spaces for optimized use. Italian green marble wall cladding, and the use of wood creates a warm and calm atmosphere through natural colors. In contrast, the design of “FLAT B” includes elm wood wall paneling and elegant clear stone flooring, while the prominent use of leather, and its soft texture and warm hues, evoke a pleasant atmosphere.

The living room’s feature wall creates a strong horizontal continuity between the leather shelving and the panoramic window. The design of the four-bedroom “FLAT C” is characterized by teak wall paneling, stone flooring and shelving by Rimadesio that enhances the sophisticated character of the living space. The large living room and dining room of “FLAT C” provide ample spaces where residents can spend time in the company of guests. The 65-sqm master bedroom, complemented by a 20-sqm bathroom and his and her walk-in closets, guarantees maximum privacy by a distanced separation from the living area. www.acpvarchitects.com

International interior design studio Jolie have unveiled the interior design scheme for The Nest, an upscale restaurant concept in Frankfurt, Germany. Positioned between the banking district and the Alte Oper, and situated within the grounds of notable local landmark, BAO, which offers a generous, green outdoor area, the restaurant serves as a temporary development, and is expected to operate for five years.

Constructed above a pre-existing underground car park, The Nest faced unique structural challenges due to weight and loading limitations. To address this, Jolie employed innovative design techniques, opting for lightweight yet robust materials such as lime-wash paints, laminates and plasters to maintain the integrity and bold aesthetic of the space. (cont...)

(cont..) This modular construction not only ensures minimal impact on the existing infrastructure, but also enhances the project’s sustainability. The Nest’s entire structure is designed for future relocation, supporting a life cycle that minimises waste and maximises reuse, embodying Jolie’s commitment to environmental stewardship and adaptable, long-lasting design.

As a sensory-led design studio, Jolie believes in incorporating scientific sensory research to emotionally drive people in their environment. The visual experience at The Nest is a tapestry of soothing and stimulating elements. Cool, calming tones establish a sophisticated foundation, with unexpected pops of vibrant colour enhancing the energy of the space. Sound is a sense often overlooked in interior design, but one that Jolie paid close attention to in their design for The Nest.

The acoustic landscape has been carefully considered to complement its visual aesthetics, with Jolie curating a selection of ambient music, featuring the likes of Malibu Beach and LeChiffre Beats, to play throughout the day, enhancing the atmosphere from the buzz of morning coffee to the relaxed vibes of evening cocktails. The soundtrack helps to create a seamless transition from the lively outdoor terrace to the more

intimate settings of the dining and lounge areas. As with every Jolie interior design scheme, fragrance plays a pivotal role in The Nest’s sensory experience.

The main dining area and bar are infused with the fresh, connecting scents of sandalwood, bergamot and citrus, designed to reduce anxiety and enhance the social atmosphere. The outdoor dining area features the uplifting aroma of fresh green fig, while the restrooms offer a revitalising blend of juniper and cedarwood, ensuring that each moment at The Nest is underscored by a thoughtful olfactory experience.

The tactile elements at The Nest are designed to evoke comfort and luxury. From the plush tactile texture of the banquette seating encouraging open, meaningful conversations to the smooth, cool pink arble of the bar, every surface is selected to appeal to the touch. The outdoor lounge’s use of natural wood and soft textiles invites relaxation and a connection with the natural world, enhancing the overall tactile experience. www. joliestudio.co.uk

Mason Kirby has revitalized a 1987 home in Mill Valley, CA, in 2024. The ‘Trapeze Swinger’ project is a testament to the transmutative power of architecture by reimagining its existing building to enhance functionality and integration with the landscape, underscoring the impact through simplicity of form.

On a tranquil hillside lot, Mason Kirby transformed a home through visionary redesign, moving beyond structural change to demonstrate architecture's role in addressing challenges, harmonising with landscapes, and enhancing human interaction. ‘Trapeze Swinger’ illustrates Mason Kirby's ability to rethink space and structure, proving architecture's power in evolving living environments. “The essence of design lies beyond aesthetic appeal; it dwells in the intricacies of solving complex formal, engaging scales, perspectives, and the profound relationship between a structure and its landscape” explains Mason Kirby. (cont...)

(cont...) “Trapeze Swinger illuminates these facets of architectural invention, serving as an example of how architecture can address and restate the challenges inherent in pre-existing buildings”. The project showcases how architecture can overcome pre-existing building challenges by recognising and unlocking compositional opportunities that more firmly set the structure within its surroundings.

Mason Kirby's renovation involved a detailed analysis of the home's original layout, opting for strategic modifications over complete reconstruction. This respectful dialogue with the site enhanced the home's foundational elements, breathing new vitality into the space through careful refinement. Good architecture involves amplifying a space's inherent qualities to transform it significantly. This project showcases architecture's power to fundamentally reimagine a building's essence, not merely its appearance.

Mason Kirby highlights architectural problem-solving with scale, perspective, and site integration, vital for harmonizing built environments with their natural settings.

Strategic changes, like extending rooflines and adjusting window sizes, go beyond aesthetics to enhance the building's relationship with its site. These modifications emphasize architecture's role in shaping how buildings interact with their surroundings and the experience of their inhabitants. Moreover, spatial connections within the home have shifted space perception. Strategic window placements and layout adjustments have maximised views and natural light, enriching the indoor-outdoor experience and elevating the overall living quality. www.masonkirby.com

Leading UK paint manufacturer Bradite is promoting the benefits of its One Can product when used as a coating over uPVC. Here, Operations Director Ben Mottershead answers some quick-fire questions on its application and suitability.

uPVC is particularly suitable as a substrate for doors and windows as it often requires little maintenance. However, as the material can stain or discolour and fade over time, painting uPVC is the perfect way to provide a quick update. The two most important characteristics for painting on uPVC are adherence and weatherproofing. Not all paint formulations are suitable for use on uPVC because they do not adhere to the surface sufficiently strongly.

Why is One Can particularly suited for painting uPVC in this regard?

“The ambient cross-linking technology in One Can means the coating becomes harder and more durable as the reaction continues. Whilst the paint applies smoothly with a low-odour, water-based finish, it dries to a robust and durable coating. This process occurs extremely quickly – One Can is touch dry in 30 minutes and recoats are possible after just 1 hour.”

HowdoesOneCanmeetthisweatherproofingrequirement?

"The binder used in One Can is based on a high-specification binder, which contains a monomer that is particularly water resistant. It also contains proprietary wet adhesion promotion. Together, this means that One Can gives superb protection against the elements in the long-term, even as a water-based finish that is quick and easy to apply.”

What outside temperature will guarantee the best results? How long will it likely take for the paint to dry?

“For best results, outside temperature should be 8-10 degrees or above, but it should be noted that the surface temperature will be considerably colder if applied at lower temperatures. One Can is surface dry within 30 minutes, and recoatable after just 1 hour – although exact timings will depend on the on-site conditions during application.”

www.bradite .com

Making sure you have the right colour for your decorating job is not always straightforward. There are many factors in play and that has nothing to do with whether or not you are colour blind, a condition that only affects about 4.5 percent of the British population anyway. HMG Paint has researched the subject of colour matching very thoroughly and has issued a detailed guide to help both the user and the decorator to get it right first time.

Shade cards and wall charts can prove misleading so HMG offers some sensible do’s and don’ts. Colours can vary slightly throughout shade cards and that can be as a result of the printing inks used. Cards can ‘yellow’ over time, matching one batch with another can be tricky and observing colours under different sources of illumination can be misleading. HMG ensures that ever colour in its library is standardised in digital format, all are allocated unique library codes and every colour produced is measured against the standard using a spectrophotometer.

The firm’s batch cards are also stored for up to five years in a dark storage area so previous batches can be checked. Simple advice to the end user includes always make sure you use the same batch on the same job and when ordering colours be specific. HMG makes the point that ordering, for example, Ford Gentian Blue is not specific but ordering Ford Gentian

Blue XSC1146 is. Orders should also be placed against standard RAL or library codes and users should bear in mind that colours are a matter of perception. One person’s view of “one shade lighter” can differ from someone else’s view. A physical sample is a better bet.

Meanwhile, distributors are advised always to order sufficient paint to ensure the same batch can be used for a specific job and there are a series of helpful hints for merchants mixing colours. HMG reinforces the point: “has the colour been observed in natural daylight?”

HMG match all its colours under natural daylight. The comprehensive Guide to Achieving the Correct Colour is available via the HMG Paints website, part of the company’s comprehensive Knowledge Base of informative articles covering various aspects of decorating from paint application to problem solving.

www.hmgpaint.com/knowledge/knowledge-base/302/hmgguide-to-achieving-the-correct-colour

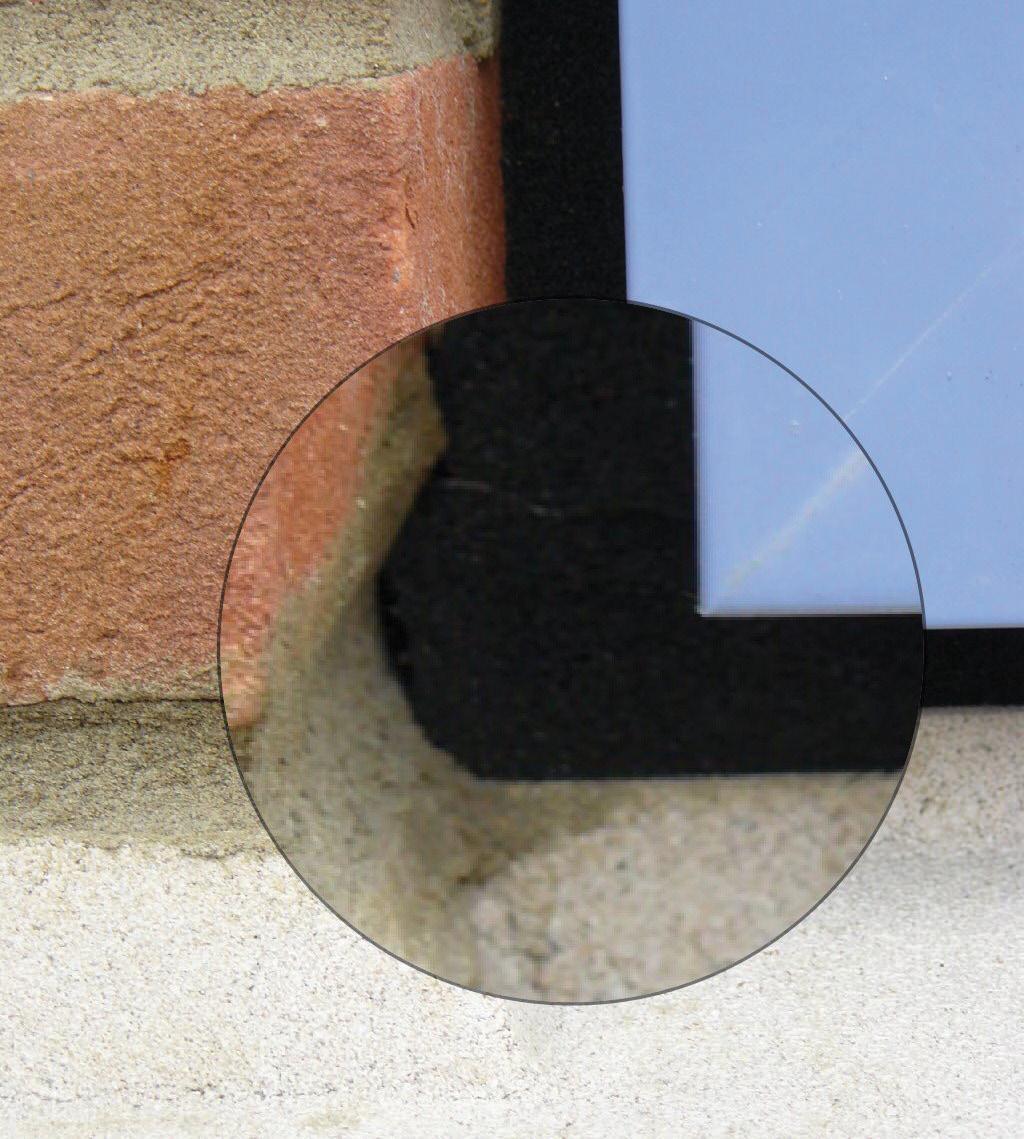

The founder of stone conservation and restoration pioneers Stonehealth has warned specifiers and building owners of the risk of using inferior machinery and unqualified practitioners. Brian Crowe said that since the latest iteration of the iconic Doff III machine launched earlier this year, increasing numbers of reports were coming in of impostor and incorrect machinery being used on sensitive restoration projects. Instances included chemical damage to stonework, excessive pressure blowing out sensitive lime mortar joints and stripping of surface layers of masonry. The company has even discovered a photo showing a competitor machine being used on a project in Scotland while carrying a Doff sticker in an attempt to appear authentic. Such deceitful activity could lead to legal action either from specifiers or from Stonehealth.

“For the past 30 years we have created a reputation as the leaders in our field,” said Mr Crowe. “So while in a way it’s a compliment to have impostors pretending to be us, it’s not one that we welcome. What we are often finding is that our products are specified for projects but then, to save costs, inferior machinery is used by unqualified personnel. Our unique system enables high temperature steam – 150 degrees C at the nozzle end – to be gently applied when cleaning masonry. Any reduction in temperature must be compensated for by increased pressure, which is where damage can occur."

“One of our other products, the Torc, is able to carefully use granulate and a gentle swirling vortex to clean delicate masonry. Inferior products will result in damage to the surface. “While this is a serious issue for our business – we risk suffering damage to our brand – we have a major concern about the impact of our heritage buildings. If damage is done, it’s irreversible. If you remove the surface of stone or break then you can’t get it back. If there are any doubts over the credibility of machinery and operatives, then contact us.”

Mr Crowe, who founded Gloucestershire-based Stonehealth in 1989, said education was key to ensuring that buildings continued to be properly treated. "Our intention is to make architects, surveyors and other specifiers – including conservation officers – aware of people working with something different to what’s been specified or approved. Any queries on whether the contractors and machines are genuine should be directed to us."

"We know where our machines are and the personnel who are trained to use them. We place great emphasis on training the contractors who use our equipment, as well as ensuring that our machines are properly specified. “Our reputation has been earned over decades of innovation and care for our industry and we won’t tolerate abuse of it, or the risk of unsatisfactory results from impostors harming the likelihood of our products being specified again.”

To help ensure that only bona fide contractors are considered and awarded contracts, Stonehealth has set up its Approved Rosette Contractors Scheme. Approved contractors must meet stringent criteria including: full training in use of Stonehealth equipment, reviewed every year; use of only genuine Stonehealth parts and materials; annual inspection and servicing of machinery by Stonehealth; provision of at least two customer testimonials per year to maintain Rosette status. Stonehealth is based in Cam near Dursley in Gloucestershire and supplies systems and products throughout the UK and many countries worldwide. https://stonehealth.com

Leading door and loading solutions manufacturer Hörmann UK has introduced a new online portal to provide architects and specifiers with access to information across its wide range of industrial, commercial, and domestic construction products.

Designed and developed to make life easier, ProductPortal is quick and easy to use and brings together everything required to specify Hörmann products into just one place. The portal has been created with a clear, simple layout offering quick and flexible searches for Hörmann products, with multiple functions and filters which allow for further refinement of product details.

In-depth information is provided which includes a full product description, technical data, tender texts, downloadable CAD drawings and BIM models. All relevant product brochures, datasheets, videos, and certification documentation are also available. As a quick introduction and to illustrate just how easy it is to use the new portal, Hörmann have produced a short, demonstration video which is available on the Hörmann Youtube channel Hörmann Product portal (youtube.com) or by visiting the portal at Hörmann Business Portal (hoermann.com)

With the findings of the Grenfell Inquiry continuing to reshape building practices across the UK, the annual construction show at Olympia is this year doubling in size and being refocused as the London Build Fire & Security Expo (November 20-21st) with insulation specialist Marmox UK Ltd on hand to demonstrate its Fireboard product on Stand L42. The Marmox Stone Wool based product is suitable for both internal and external wall insulation (IWI/EWI) applications.

Externally the A1 non-combustible certified Fireboard can serve as a weatherproof render-backer, or be used internally across walls and ceilings to take a plaster finish, while providing sound absorption properties, along with thermal insulation. With a nominal density of 150 kg/m3 the boards’ core material offers a compressive strength of 90kPa (9 tonnes/m2), while its high insulation performance will help combat thermal-bridging and the formation of surface condensation, as well as having the potential to cut energy bills.

As detailed in its A5 technical brochure which can be downloaded, Marmox Fireboard has been tested to prove compliance with BS EN 1182, EN 1716 and EN13823 (Resistance to fire test) conducted by UKTC, along with other testing completed by the BRE. www.marmox.co.uk

The construction industry is increasingly coming to the view that breather membranes in high-rise and higher-risk buildings should have a minimum Euroclass A fire safety rating in line with the law for cladding, but there is less clarity over the question of whether to use an A1-rated system or an A2-rated system. Matt Thompson, Sales Director at ITP Ltd, explains the differences between the two options.

The Euroclass European classification EN 13501-1:2018 has become the standard reference in relation to fire safety regulations in building. The current minimum Euroclass rating required by law for breather membranes in high-rise buildings is Euroclass B-s3, d0. However, safety specialists and advocates of best practice advise a minimum Euroclass A to match the standards required for cladding and other external wall elements.

When an A-rated option is available, it makes sense to maximise fire safety throughout the building envelope. That approach seems straightforward at first glance, but complexity arises when you consider the detail behind systems manufactured to meet A1 and systems manufactured to meet A2.

Due to differences in their design and composition, A1 membranes are considered the better option for some buildings while A2 membranes are more suitable for others. A1 denotes a non-combustible material and is the highest rating a product can achieve, defined as a material that does not contribute to fire at any stage, including a fully developed fire.

A2 denotes limited-combustible material in England and Wales (somewhat confusingly, it denotes non-combustible material in Scotland). The s1 denotes little or no smoke propagated and the d0 denotes no flaming droplets or particles. These categories are essential references for any building specification, but those responsible for choosing building materials must also consider the classifications in the context of how they might affect other areas of the material’s performance. Breather membranes have two primary functions.

Firstly, they allow the building to ‘breathe’ with the release of excess moisture vapour into the atmosphere, thereby preventing the build-up of condensation in the insulation layer. In many buildings, they perform a second primary function with resistance to the inward passage of water from rain and damp air. A breather membrane’s ability to perform this function is measured by its water tightness, classified in ratings of W1, W2 and W3. W1 is the highest rating, providing the best protection in the most demanding conditions.

Membranes used in safety critical installations comprise a base layer, which gives the resistance to fire, and a coating layer which gives the water protection. Euroclass A1 membranes have been developed for the highest level of fire protection. However, the outer coating layer needs to be as thin as possible to achieve the A1 rating. This results in a W2 rating for water tightness. A Euroclass A2-s1, d0 membrane has a heavier coating, enabling a W1 rating.

These differences mean that A1 is considered the optimum solution for closed facades but A2 is considered the optimum solution for buildings in locations with high exposure to winddriven rain and buildings with open-jointed façade cladding or leaky cladding. As well as understanding the difference between A1 and A2 membranes, it’s also vital to be aware of the testing and certification requirements for Euroclass ratings.

The quality of testing and data within the construction industry is highly variable. Some suppliers and manufacturers will go to the nth degree to demonstrate that their products meet and exceed performance requirements. Others will cut corners, obfuscate and omit. Façade design is an area of construction that illustrates the problems caused by this variation. A product’s classification can be misleading when separated from the context of its durability.

A Declaration of Performance (DOP) should show the tests results before and after ageing as specified in the harmonised standard BS EN 13859-2, but some manufacturers supply a DOP without the results after ageing. It’s impossible to make an informed decision about membrane specification without that data, particularly in relation to open-jointed cladding and permanently open facades which demand higher levels of UV resistance as well as W1 water tightness to prevent degradation in other areas of performance such as fire safety.

Architects and contractors should also be wary of crucial omissions within lab testing methodology. For example, some membrane manufacturers supply fire test data for their textile, but not for the integrated adhesive materials they supply to fix it to the façade or to make overlaps. It is always worth asking manufacturers about the fire safety credentials of any accessories that they supply as standard with their products.

The arrival of the Building Safety Regulator ushered in a new era of more robust regulation and much greater scrutiny of fire safety data. Knowledge of best practice in façade fire safety and related product testing will be a vital resource for all dutyholders involved in the design and construction of high-rise projects. Itpltd.com

As a specialist in all areas of the building envelope, SFS Group Fastening Technology has created a comprehensive selection of CPD seminars which are intended to offer architects and other specifiers valuable insights into relevant industry topics, embracing key issues such as sustainability, safety and structural stability.

The RIBA approved presentations have been compiled to ensure participants gain a better understanding of the topics which range from fall protection systems to the fixing of warm roofs. Each seminar normally runs for 40 minutes with the opportunity for questions afterwards, while RIBA Chartered Architects will qualify for double CPD points. There is also the choice of having seminars delivered by the manufacturer's Specification Team at offices and at the SFS Academy in Leeds or Welwyn Garden City.

Vincent Matthews, the Head of UK Marketing for SFS Group Fastening Technology, commented: "The CPD sessions have been designed to develop the knowledge of architects and other construction industry professionals on topics impacting the industry. The subjects include rainscreen cladding systems, designing the correct roof safety systems, and Evolution to Innovation: the fixing of warm roofs. Each subject is broken down into specific areas" Also, the force behind the Fall Protection Installer Network, SFS continues to innovate and helps shape the future of the industry through its CPD programme while offering a growing library of While Papers along with other training and education support. https://uk.sfs.com

Beauflor® is returning to London Build Expo this November as it continues to develop relationships in the commercial flooring sector. Beauflor® is exhibiting at London Build Expo, 20th21st November, Olympia London. Beauflor will show its product ranges designed to fulfil the needs of housing projects including Blacktex, Smartex and Quintex, as well as innovations in product and manufacturing that have led to a bio-based sheet vinyl floor and digital printing that allows bespoke designs and patterns.

With a textile back that allows Blacktex, Smartex and Quintex to be quickly installed without glue, these floors make refurbishing within properties fast and easy. Installed without glue in rooms up to 36m2, so that it can simply be lifted and replaced with new.

The Belgian manufacturer will also be focusing in on its approach to sustainability, which sees a pathway of sustainable raw materials and production practices, reduced consumption and better end-of-life solutions.

Recent developments as a result of this pathway include Twilight, a bio-based and circular PVC floor with a 40% lower CO2e footprint than conventional heterogeneous cushion vinyl 1. Find Beauflor on Stand E20, London Build Expo, 20th-21st November, Olympia London. www.beauflor.com

Here Katherine Kates, Production Director at Haddonstone, delves into their meticulous production methods, from the initial design phase to the final finishing touches. She uncovers the journey of transforming raw materials into stunning building and construction, and home and garden cast stonework - a process that combines traditional craftsmanship with modern technology, resulting in exceptional durability and aesthetic appeal.

How does Haddonstone craft excellence? - Our teams define project requirements through personalised customer service; at the core of everything we do is a commitment to providing the highest levels of personalised customer service. Whether working with technical drawings or a simple photograph, the team collaborates closely with the client while the architectural solutions cater to a wide range of projects, from private residential new builds and extensions to large-scale commercial developments and renovation projects.

Haddonstone's expertise in both cutting-edge technology and traditional techniques allows us to create cast stonework to almost any specification. The award-winning Building and Construction team is celebrated for exceptional customer service and expertise.

Each person is dedicated to giving the very best individual care and attention and, by maintaining complete control throughout each project, the team guarantees a smooth process and delivers the highest-quality cast stone. We also provide details of trusted independent contractors who offer comprehensive installation services.

What do we do? - Technical advice and product supportcomprehensive packages including quotations, detailed CAD drawings, product schedules, and installation guidelines, all at no extra cost.

• Transparent lead times - honest and accurate timelines for all projects.

• Competitive pricing - clear and fair pricing with no hidden costs.

• Quick, accurate project drawings - the experienced technical team provides drawing assistance and support while a free and user-friendly product drawing package, compatible with AutoCAD software, is offered. This package features a complete library of Haddonstone components in Dynamic Blocks for easy use.

Benefits - the client can:

• Compare different stone component profiles and products

• Identify cost-effective, standard stonework design solutions early to minimise additional bespoke project costs

• Specify from a vast range of high-quality Haddonstone products.

• Seamlessly include rendered 2D images of Haddonstone stonework in your drawings.

Manufacture - Haddonstone's own in-house production facilities, including design studio, extensive mould shop and laboratory, allows us to cater for everything from lightweight retrofit designs to large structural units. Every component is handmade to order and, by crafting all our own models and moulds, and overseeing every step of the process, we ensure that each project specification is met with precision.

The teams specialise in creating bespoke components and, impressively, over 80% of stonework is custommade and remains only marginally more expensive than standard designs. In addition, Haddonstone excels in producing replica stonework for restoration projects utilising the latest in 3D technology alongside traditional techniques.

By taking detailed impressions of the original components onsite, the replicas are crafted with meticulous attention to detail, preserving the integrity and beauty of the original structures.

Integrating structural reinforcement - Cast stone's strength, durability, and impressive compression resistance make it an ideal material for a wide range of commercial and residential architectural solutions. Whether for new construction projects, retrofits, or restoration commissions, Haddonstone's cast stone offers unparalleled versatility.

The in-house manufacturing team can create steel cages and bars needed for additional structural reinforcement in many weight-bearing components in collaboration with a structural engineer, prior to crafting the bespoke cast stone components.

Offering high-quality cast stone material options - At Haddonstone, three premium cast stone material options are offered, each surpasses British manufacturing standards and are the highest-quality, most durable products on the market today.

The materials are produced in-house, combining British limestone sourced from an ethically responsible supplier, as well as other ingredients including water, cement, sand and glass fibre (TecLite). The bespoke colour and material match service also means that we can meet any project's exact specifications.

The Haddonstone (semi-dry cast) material is packed into a mould either by hand or a pneumatic rammer. The TecStone (wet-cast) and TecLite (fibre-reinforced)

are poured and agitated, with the filled moulds then left to cure overnight. As a founding member of the United Kingdom Cast Stone Association, Haddonstone is committed to not only meeting but exceeding industry standards and stringent technical performance requirements.

The rigorous Quality Assurance procedures include computer batch controlling, ensuring consistent mix and colour in every batch; automated tracking systems to monitor the performance of each batch to maintain high standards and regular testing of our materials and products, including evaluations by independent experts, to ensure they surpass industry standards in areas such as water absorption, compressive strength, and fixing pull-out tests.

Perfecting designs with finishing touches - The meticulous production process is completed in a series of steps beginning with demoulding intricate designs from wooden or rubber moulds.

The Haddonstone semi-dry cast limestone designs then undergo chamber curing, a controlled process that enhances their durability and longevity. With TecStone products, acid etching is employed to achieve a smooth, sealed finish which is much more akin to Coade stone. This makes it ideal for larger architectural products and contemporary designs as it does not weather quickly and is usually easier to clean.

Each item is then thoroughly checked and meticulously hand-finished by the skilled team which removes any imperfections. Finally, our dedicated transport fleet and drivers deliver the finished products to clients, ensuring they arrive in perfect condition. www.haddonstone.com

'W Edinburgh’ is located in the lively area of St James Quarter. The hotel itself spans 3 buildings. The Ribbon Building, James Craig Walk and the Quarter House, together combining 199 bedrooms, 45 suites, a Gym, luxury Spa and a variety of Restaurants and Bars. Edinburgh is a historic and culturally rich city. The design of the unique rooms and suites in the hotel reflect the spirit of the city.

The interior design is breathtaking! The design concept from Keppie included unusual circular brass inlays for the beautiful Terrazzo flooring. Terrazzo is a composite material that is poured in situ. It consists of chips of marble, quartz, granite, and glass. The challenge was to integrate our products seamlessly into the

opulent surroundings. The brass inlays supplied by Dural allowed the Terrazzo to be segmented into unusual flowing shapes and areas. Circles were specified and the Dural Z-Flex machine allowed the brass inlays to be shaped on site or prefabricated and delivered.

This allowed for a reduced time schedule for such a complex design. High end materials were used throughout, creating a luxurious feel. The unique geometries that make up the flooring of ‘W Edinburgh’ co-ordinate seamlessly with unique furniture, artwork and lighting. A truly fabulous guest experience.

Dural supplied Durosol 5mm brass Z-Flex profiles. Many of these were fabricated and welded into perfect closed circles for the intricate design. Dural also fabricated sections of the designs at the head office and delivered them to site for installation. The finish floor is an eyecatching, luxurious terrazzo, subtle gold highlights reflect the circular theme that flows throughout.

The Z-Flex profile by Dural is available in many finishes and sizes and is formed to be able to cleverly accommodate shaping. They can be easily rounded and bent either curving inwards or outwards. These tile trims can be shaped and formed to fit archways, circular floors and curved areas The smallest attainable radius depends on the material and the geometry of the profile so that there are no fixed values.

The thinner the shell of the profile, the smaller the radius to which it can be bent. The edging profiles are of course protective in their function but also satisfy a highly demanding decorative brief. Here they make smooth joints and transitions, between the different colours of Terrazzo, creating artistic patterns. To ensure the curve is even, it is recommended that the Z-FLEX CURVER is used for bending the profiles.

This is a tool that makes it possible to bend the profiles more accurately. In addition to our bespoke profile manufacturing capabilities, Dural is now able to offer a broader range of terrazzo profiles than ever before and this range complements the trend to embrace sustainable flooring options. Terrazzo flooring as an option is no longer reserved for commercial projects but is finding its way into high end interior design and stylish homes.

Terrazzo as a floor and Z-Flex inlays allow the designer to create areas of art almost, it comes in a variety of colour combinations that make it super fun to create with. Dural are able to colour match profiles and inlays, to any design choice! www.colouredmovementjoints.co.uk

When it comes to blending classic charm with modern functionality, few materials achieve this as seamlessly as CRL Quartz. That’s why this versatile surface was chosen for the stunning refurbishment of Don Paddy’s, a popular bar and kitchen in the heart of Uppingham, Rutland.

Set in a Grade II listed property on the town’s historic market square, Don Paddy’s has been a local favourite for over 20 years, owned and operated by the same family. In January 2024, the venue embarked on a comprehensive refurbishment, which saw the introduction of CRL Quartz surfaces to add a touch of refinement. The transformation was completed in three months, with Don Paddy’s reopening its doors in April.

The main objective of the refurbishment was to create an even more inviting atmosphere, particularly on the first floor, where owners wanted to encourage more customers to relax and enjoy the upstairs space. It was essential to achieve this while preserving the warm, welcoming ambience Don Paddy’s has always been known for.

Alongside aesthetic upgrades, the building underwent a full electrical rewire, installation of new plumbing, and a heating system to ensure both form and function were of a high quality. CRL Quartz played a crucial role in achieving the desired look.

The owners were keen to introduce a more contemporary feel without losing the traditional charm of the space, and the distinctive appeal of the Cristallo Platino surface met this challenge head on. Its natural stone inspired design, featuring dark grey veins and warm brushstrokes set against a lighter grey backdrop, blended perfectly with the colour palette, adding depth and texture to the bar’s visual identity.

A standout feature in a timeless setting One of the project’s most significant challenges was incorporating modern finishes into a Grade II listed building without compromising its historical features. The Cristallo Platino bar countertop, positioned front and centre, became a key design element.

Rock Revelations, the expert team behind the installation, ensured every detail was meticulously executed despite the tight schedule, completing the job in time for the grand reopening. While the Cristallo Platino surface added industrial flair to the main bar, Verona from the CRL Quartz range was chosen for other parts of the interior, including beneath the log burner and on the second bar.

Its marble-effect finish, with warm brown veins flowing through the material, provided a softer, more refined contrast to the Cristallo Platino, adding warmth and character throughout the space. Both surfaces worked harmoniously with the darker timber accents, making the bar and its surroundings an eye-catching focal point.

CRL Quartz is well-known for its exceptional durability and ease of maintenance, making it an ideal choice for commercial environments like Don Paddy’s. Its hardwearing properties ensure the surface will withstand the rigours of a busy bar and restaurant, while its non-porous nature means it is resistant to stains and easy to care for – key considerations for the team at Don Paddy’s, who wanted materials that would stand the test of time without compromising on style.

The seamless integration of these surfaces into the overall design was aided by the expert vision of Sally Longden Interiors, who spearheaded the project. Sally’s ability to balance modern finishes with the building’s historic features was instrumental in the success of the refurbishment, helping to create a cohesive and inviting space.

By choosing Cristallo Platino and Verona from CRL Quartz, the team at Don Paddy’s has successfully transformed this iconic Uppingham venue, ensuring it remains a cherished local hotspot for years to come, where customers can feel at home. www.crlstone.co.uk

Schlüter-Systems is well known as the expert in enabling the design and installation of long-lasting, creative kitchens and bathrooms with portfolios of intelligent products and systems. The collection of lighting systems, which incorporate advanced control and luminaire technology, offers almost unlimited choice for the most imaginative schemes.

The key is Schlüter-LIPROTEC which creates restful lighting for relaxing spaces, or bright, colourful lighting for a busy family bathroom or kitchen. It can be installed in a choice of direct or indirect lighting effects, enabling the interior designer, architect or property owner to illuminate feature walls, pictures, tiled areas such as shower enclosures or study spaces, kitchen countertops and stairways; in fact, anywhere the creative mind can conceive a plan for.

The collection offers the option of neutral white, warm white or RGB+W LEDs; the latter allowing for coloured and white LEDS on a single strip, to generate coloured light or temperature-controllable white light, which can be selected from 2500 K to 6500 K. The system can be programmed to deliver a choice of 16 million colours via a Bluetooth app and remote control.

Suitable for moisture-prone areas such as kitchens, bathrooms and showers, the LED strips are completely encapsulated and conform to IP67 protection rating.

Schlüter-LIPROTEC-EASY is the company's simple plug-and-play version which comes with matching power supply units up to 100W. The Schlüter-LIPROTEC-PRO series, meanwhile, is geared towards professional installers and offers bespoke lighting solutions. The LED modules are available either with a fixed white-light colour temperature of 3000 K or 4900 K, or with the full RGB+W colour range.

Schlüter-KERDI-BOARD-NLT units are stylish niche sets fabricated from the company's KERDI-BOARD and featuring plug-and-play LIPROTEC-LED technology. They can be used to create illuminated recesses and storage surfaces for all kinds of wall areas, making a great feature for bathrooms and showers, and are enabled with Bluetooth/wireless receivers. The various light colours can also be selected via the supplied remote control or suitable Bluetooth-compatible smartphones and tablets. www.schluter.co.uk

Located in Liverpool's Knowledge Quarter, The Spine is the northern home of the Royal College of Physicians (RCP) and is one of the healthiest buildings in the UK, adhering to the ethos and principles of the WELL Building Standard. Supporting this commitment to health, partitioning expert Style worked with AHR architects, and main contractor, Overbury to install 10 Dorma Huppe semi-automatic Variflex moveable walls over 3 floors, creating adaptable space that encourages collaborative working amongst RCP staff.

Furthermore, Variflex walls hold both a Health Product Declaration, detailing the health effects of all the elements of the system, as well as an Environmental Product Declaration, which provides verified information on the environmental impact of the product across its lifecycle. “We were incredibly proud to have been specified to deliver flexible space in this pioneering new building,” said Andy Gibson, Style’s director for the North.

“We were also delighted to work with AHR architects and Overbury, who gave our team 9.6 out of 10 for our work on site, reporting that the Style team was ‘excellent and really helpful’ and that Overbury’s project team was ‘very happy with Style and would highly recommend us’.”

Offering the option to open up the floor space, or to create individual rooms based upon requirements, the Variflex moveable walls not only offer flexibility but also provide exceptional privacy thanks to their impressive 57dB acoustic integrity.

“The semi-automatic operation option of the Variflex walls ensures that the acoustic seals are applied to exactly the right pressure for optimum acoustic performance, every time,” explains Gibson. “This means meetings and gatherings can take place undisturbed once the walls are in place, with the integrated pass doors allowing ease of movement between rooms.”

The walls were finished in a chic laminate, with those on the 13th floor of the RCP featuring additional graphics to create a highly stylish interior. The Spine has been built as a beacon of excellence, bringing together local communities, improving the wellbeing of its occupants and operating in a sustainable way. The floors belonging to the RCP have recently been WELL Certified™ at the Platinum level, by the International WELL Building Institute. www.style-partitions.co.uk

Prevent everyday wear and tear with Yeoman Shield’s extensive range of easy-clean, wall and door protection.

Our attractive, maintenance free, hygienic products protect healthcare environments from costly impact damage, making repainting and repair a thing of the past.

Blending with decors, and available in primary dementia-friendly colours, our designs can include signage, to promote the well-being of patients and aid wayfinding.

Zentia, the UK’s market leader in complete ceiling solutions, is excited to announce the renaming of its popular Axiom range of canopies to DecoFrame. This change reflects the company’s commitment to modern design and high acoustic performance, offering customers a solution where aesthetics and functionality meet seamlessly. Previously known as Axiom, the newly named DecoFrame line includes several key changes: .

• ∙Axiom C Canopy is now DecoFrame Kit Classic Canopy

• ∙Axiom KE Canopy is now DecoFrame Kit Blade Canopy

• ∙Axiom Curved Canopy is now DecoFrame Kit Curved Canopy

• ∙Axiom Circle Canopy is now DecoFrame Kit Circle Canopy

Zentia’s DecoFrame canopies are designed to deliver on both style and practicality, providing a modern, striking visual appearance while maintaining excellent acoustic performance. Packaged and delivered as a kit, the canopies offer quick and easy installation. With DecoFrame, there’s no need to compromise between aesthetics and functionality. This makes DecoFrame canopies the perfect solution for open-plan environments such as offices, schools, and public buildings, where controlling acoustics and maintaining an appealing design are critical.

Key features of the DecoFrame include:

• ∙Seamless Integration: DecoFrame canopies integrate effortlessly with nearly all of Zentia’s range of ceiling tiles, providing designers with creative flexibility.

• ∙Optimised Acoustics: Each canopy enhances sound control, making it ideal for open-plan spaces such as offices, schools, and public buildings.

• ∙Customisable Design: Available in various shapes, including circle, curved, and rectangular, DecoFrame is customisable to meet the unique needs of any project.

The DecoFrame range offers a variety of standout features designed to enhance both aesthetics and functionality. Its floating canopy design adds dimension and visual appeal to any space, available in customisable shapes like circle, curved, and rectangular forms.

The frame and tile system is compatible with a wide range of ceiling tiles, offering design flexibility for all shapes, while the acoustic performance makes it an ideal choice for open-plan areas like offices and schools. Installation is simple and efficient thanks to the joggled Gridline system, allowing for quick, hassle-free setup.

Built from durable materials, DecoFrame ensures long-lasting performance with minimal maintenance. The canopies are fully compatible with DecoMesh, a range of metal mesh ceiling tiles, offering designers the option to incorporate expanded metal mesh materials for added texture and visual interest. The DecoFrame also pairs perfectly with the Prestige range, a balanced acoustical tile that comes in a wide range of colours.

The DecoFrame’s modular construction allows easy expansion or modification, making it adaptable to evolving project needs, providing a versatile and functional solution for modern spaces. Zentia continues to lead the way in providing innovative ceiling solutions that balance design and performance. The renaming of the Axiom range to DecoFrame reinforces Zentia’s dedication to offering products that not only look great but also deliver exceptional functionality. www.zentia.com

Countertops from Welsh Slate feature at the award-winning 1 Hotel Mayfair. A hotel brand that is leading the way in sustainable hospitality has made sensory use in its interiors of an architectural product from Welsh Slate’s diverse portfolio. Sleek dark countertops produced from Welsh Slate’s honed and dressed Cwt-y-Bugail Dark Blue Grey slate feature on the vanity units and minibar tops in the 181 bedrooms and suites of the European debut of the missiondriven 1 Hotel brand, in glitzy Mayfair, London.

Specified by hotel interior design specialists the GA Group, the Welsh Slate products complement the organic design narrative at the nine-storey flagship building overlooking Green Park. 1 Hotels' commitment to sustainability and biophilic design principles drove every decision when it came to creating this property, starting with the defining decision to reuse and renovate the two pre-existing Mayfair buildings, as opposed to constructing from scratch.

The resulting retention of more than 80% of the existing structures reduced the amount of embodied carbon produced during demolition and construction, mitigated construction waste and debris, and helped the project to meet BREEAM "Excellent" standards. Every 1 Hotel under the umbrella of US-based SH Hotels & Resorts (founded by hospitality virtuoso Barry Sternlicht) has systems in place to reduce its environmental impact by minimising energy usage, harnessing local resources, preserving non-renewable materials, reducing plastic and paper consumption, and reducing landfill waste.

1 Hotel Mayfair has installed combined heat and power systems that produce electricity that will feed back into London's utility grid, saving on electricity while at the same time capturing the waste heat to preheat domestic hot water on the property.

While the 181 bedrooms are distributed across 14 different categories, each features the Welsh Slate vanity units and minibar tops alongside handcrafted sisal coffee tables and smoked timber mirrors. Welsh Slate combines beauty and practicality which is why it is the perfect material for countertops, combining minimal liquid absorption levels with a luxurious warm feel to the hand. The material is supplied as a completed wipe-clean slate worktop to contractors' projects or as unfinished or polished scant to worktop manufacturers.

A variety of edge details are also available, including Bull Nose and Half Bull Nose, along with drainage grooves, sink cut outs and tap holes. At 1 Hotel Mayfair, it was fabricated by GD Stones and installed by County Contractors. Unaffected by normal extremes of temperature, a Welsh Slate countertop can withstand the worst a domestic or commercial bathroom or kitchen can throw at it. It is also non-fading and stain proof and available in Penrhyn Heather in addition to the Cwt-y-Bugail used at the 1 Hotel Mayfair. www.welshslate.com

For many years Stelrad’s Compact radiator range has been the best-selling radiator in the UK and Ireland. The Compact has evolved over the years improving its appearance and its efficiency and is nowadays anything but an ordinary radiator which speaks volumes for its on-going popularity. It’s a sleek, well designed and highly efficient radiator and continues to out-sell all other models.

But many people inside and outside the heating industry have not realised that this excellent radiator has been at the heart of many of the company’s premium panel radiators such as the Silhouette, Deco and Plan models in the popular Vita Series range of radiators – all Compacts, but with stylish fronts that give the radiators that individual designer look once installed in homes and businesses up and down the country. And that goes for the traditional horizontal models and the fast-growing market for vertical radiators. “We offer this one great radiator with a choice of four stylish fronts,” says Chris Harvey, Head of Marketing at the leading radiator company.

“Whether the style of the property they will heat dictates a regular radiator design or a flat fronted or horizontal or vertically lined casing, they all benefit from the heating instincts of the Compact radiator as the heating product behind the front that householders, visitors, business owners or customers see when they enter the room that is heated by the radiator."

"And all our radiators are designed to look good on any wall in any room these days – the old fashioned designs from twenty or more years ago have been largely consigned to the archives. No longer just heating appliances, they are often becoming focal points of the décor in a modern or retro-home.”

And whilst radiators used to be something of an afterthought – a heating system was perhaps just ‘a boiler and eight rads’ - these days more and more homeowners are having a say in the selection of their radiators having seen the insides of many more homes than was the case even a decade ago – with all the property and design programmes on TV, radiators are becoming an aspirational product – not just the fancy towel rail in the bathroom which is where style first crept into heating, but now in virtually every room in the home – especially in the kitchen, the main living room and the master bedroom – designer looking radiators are becoming ‘the norm’ with upgraded radiators bringing a certain style to these rooms that they didn’t used to display.

Even in conservatories, the radiators will be seen by friends and family and are increasingly being upgraded from a simple radiator to one with a little panache. “Whilst the Compact radiator is ‘the go-to option’ for many installers and very few homeowners with a say will object because they are striking radiators with clean, crisp lines, come in a wide variety of sizes and models and have neat rounded edges and corners and attractive grills, many people are willing to pay a little extra to transform their radiators into something a little bit more special,” says Chris Harvey.

“The addition of the front panel makes the radiator look every inch designer, it makes a big difference to many people and whilst they are all a breeze to fit as they have the same piping connections and brackets, the finished look of one of the ‘added extra’ radiators is enough to enthuse many homeowners and developers that are keen to up the ante when it comes to choosing a serious heating system.”

The difference in price is minimal and you could be recommending – or choosing a more fancy radiator that will improve the look of the home and the value of the property. It’s amazing what a new front can do to your heating system! www.stelrad.com

Twin Rundum Original ‘round the corner’ side sliding doors have been manufactured and installed by bespoke garage door specialist Rundum Meir UK as part of the North Quay development in Hayle, Cornwall.

Rundum Meir was approached to explore the potential for twin bespoke doors with radiused corners at their adjacent edge.

This design was perfectly suited to the Rundum Original, which slides along a track as it opens sideways before turning a corner to run along an inner side wall of the garage.

Equally important, however, was the ability to manufacture the garage door in materials that would enable aesthetic goals to be achieved

whilst being suitable for the harsh coastal conditions. Rundum Meir was able to use Accoya for the timber slats that make up each of the doors. Accoya is ideal for conditions of this kind, and for meeting the project’s sustainability aims, given its superior durability and FSC accreditation.

Marine grade stainless steel was used to create the U-channels which guide the Rundum Original as it slides, along with the PPC tracks and binding.

The Rundum Meir garage doors are also automated. A door-mounted motor is activated via a remote control device and it is HomeLink compatible for safe and secure operation from inside a vehicle. www.rundumgaragedoors.co.uk

Striving to be recognised as a modern college that welcomes students from a wide range of backgrounds, Trinity College, in central Oxford, developed the new Levine Building. The building is a benchmark for overall accessibility, with main contractor, Gilbert Ash, specifying TORMAX to automate ten key access points throughout the building. Delivering reliable swing door automation, TORMAX installed their technologically superior iMotion 1301 to the main entrance doors and elsewhere in the building.

For the aesthetically sensitive entrances, TORMAX recommended the iMotion 1401 operator which is neatly housed in a casing beneath floor to create invisible automation. As Trinity College has continued to improve accessibility elsewhere on campus, TORMAX has automated three further swing door entrances. The Levine Building is designed by ADAM Architecture and is a modern classical building that sits harmoniously within a rich built and landscape heritage. Focusing on the College’s ambition to improve diversity of applicants, user groups were drawn from across the whole College community so that specific needs could be addressed.

Providing world-class facilities for teaching, residential accommodation, public outreach, and social activity, the Levine Building has level access to all public areas, teaching rooms at ground floor level and two new lifts.

The TORMAX automated doors help ensure ease of movement throughout the building for all users. “Since being opened by HRH Prince of Wales in 2022, the Levine Building has proved to be a superb asset to the College,” confirms Andy Hooper, Clerk of Works at Trinity. “The careful planning that went into ensuring that all elements of the facility can be accessed by everyone is evident throughout, with lifts, no-step accessible rooms and automated doors.”

Swiss-owned, TORMAX UK Ltd has over 60 years of experience in the design, manufacture, installation and ongoing service of automatic door systems. With a complete range of technologically advanced door drives, for revolving, swing, sliding and folding doors, an automatic entrance is a reality for almost any location. www.tormax.co.uk

By Wojciech Brożyna - MD Aluprof UK

Leading aluminium systems company, Aluprof, well known for providing high performance fire resistant glazed screens, doors, windows and curtain walls, now supply fire resistant glass to complete their systems offer. The new company ‘Glassprof’, whose headquarters are located in Ogrodzona in Poland, specialises in the production of fire-resistant glass and the processing of glazed units that work in harmony with Aluprof’s fire rated aluminium systems.

This is a first for the aluminium systems industry and allows Aluprof UK to offer a single, tested source of supply for fire rated fenestration installation across the UK & Ireland. Fire resistant fenestration systems are used both internally and externally to reduce the risk of the spread of fire whilst offering occupants safe routes of escape. Whilst specified on construction of various building types, who is responsible for maintaining these systems so that they perform correctly on the outbreak of a fire?

According to the Regulatory Reform (Fire Safety) Order 2005 (RRFSO), the landlord or building manager is designated as the 'responsible person' for fire safety. This individual is legally obligated to implement adequate and suitable fire safety measures. Consequently, one of their primary responsibilities is to conduct a fire risk assessment.

The fire risk assessment serves to identify potential fire hazards, provide recommendations for risk reduction, and document the implementation of these recommendations. It is a systematic approach to recognising fire risks and taking proactive measures to lessen their likelihood and potential consequences. This assessment encompasses not only potential ignition sources but also evaluates the adequacy and accessibility of escape routes, fire doors, fire safety equipment, and the effectiveness of compartmentation, which

involves constructing parts of a building to inhibit the spread of fire to other areas or adjacent properties. In the wake of the Grenfell Tower tragedy in 2017, fire safety regulations for multi-occupancy residential buildings have undergone significant review, leading to the enactment of the Fire Safety Act 2021.

This legislation clarifies the responsibilities and procedures related to fire safety in such properties. Additionally, following the Grenfell incident, the PAS 79:2020 was introduced, offering more detailed guidance on fire risk assessments specifically for landlords and building managers.

The new Building Safety Act (BSA) building control framework was fully implemented in April 2024, and the industry is beginning to grasp the practical implications of the new Gateway approval process for high-risk buildings (HRBs).

Launched on October 1, 2023, ‘Gateway 2’ serves as a critical checkpoint in the new building control framework for HighRise Buildings (HRBs) during the transition from design to construction. It mandates the submission of a comprehensive application to the Building Safety Regulator (BSR), which is designated as part of the Health and Safety Executive (HSE) under the Building Safety Act 2022.

This application must detail how the project will adhere to the functional requirements of building regulations, including supplementary information on competence, fire safety, control measures, and mandatory reporting. A multi-disciplinary team, comprising a registered Building Inspector and various specialists, review the application under the BSR.

The Gateway application forms as a definitive halt, prohibiting any onsite work until the necessary approval is obtained. The HSE outlines that the objective of the Gateway 2 process is threefold. Firstly, it aims to ensure that potential design issues are identified and resolved at an early stage rather than being inherently integrated into the design.

Secondly, it seeks to confirm that the design is adequately advanced to instil confidence in moving forward with all aspects of the construction. Lastly, it verifies that the duty holders possess the requisite capability to implement the design effectively. As a prominent systems company in Europe, Aluprof have firmly established themselves as a leader in the field of aluminium framed fire-rated windows, doors, screens and curtain walls. As a building project supplier, this places Aluprof in the enviable position not only of being able to develop and test both framing and glazing together, but to be able to supply complete and fully tested products direct to site.

Thanks to the use of the latest and fully automated production technology, Glassprof offers glazed units that combine various glazing options to include fire protection, thermal insulation, solar control and sound insulation. Aluprof firmly believes that the collaboration with Glassprof will offer comprehensive and hassle-free glazing solutions that will prove advantageous to a wide range of buildings, including libraries, schools, hotels, and student accommodations.

Given the paramount importance of fire safety as a critical design consideration, this partnership strives to provide architects and specifiers with a profound sense of assurance and peace of mind. Together with the new Glassprof products, Aluprof offer a comprehensive range of aluminium fire resistant systems to cater for all building requirements.

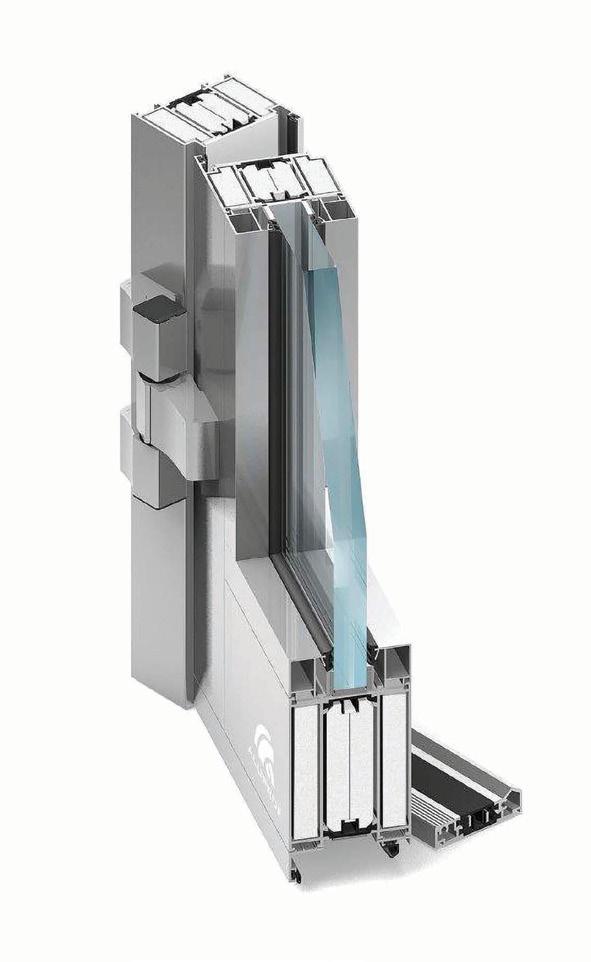

The MB-118 EI is designed to offer internal or external fire rated partitions that can offer resistance up to EI120. The system suites with Aluprof's MB-78EI and carries many of the same fire restart components. With a structural depth of just 118mm the system carries a generous 34mm wide thermal break for thermal insulation.

The MB-78EI door with its own 78mm wide framing system can be made up into screens that offer various fire resistance classes up to EI90 when tested to the standard, PN-EN 135012+A1:2010. The MP-78EI system offers an excellent thermal insulation coefficient Uf due to the adoption of 34 mm wide thermal break. Depending on the required fire resistance class, GKF (fire protection plasterboard) or CI (polymer–ceramic composite) strips are inserted inside the chambers of profiles and within the thermal insulation space between the aluminium profiles.

Fire rated glasses of up to 49mm in width can be accommodated within the system. Complementing the windows, doors and screen systems is the MB-SR50N EI, a stick curtain wall system which can offer various fire resistances up to EI60 when tested to the standards PN-EN 1364-3 and PN-EN 1364-1.

The curtain wall can also be used in glazed roof coverings and offer a fire resistance class of RE30 as per the standard PNEN 1365-2. Along with this 50mm wide capped curtain wall system, a further version of the curtain wall system, the MBSR50N EI EFEKT offers fire resistance of up to EI60 in a cap-less curtain wall system as used at high level on the The Core, a refurbishment project in Manchester which uses the cap-less curtain wall which is unique to Aluprof.

These curtain wall systems are enhanced within the profile to cater for an EI60 fire resistance. Specifiers can use the non-enhanced system for the complete building and only use the fire resistant construction in areas where fire resistance is required, this enables consistency in visible sight lines across the build.

Aluprof UK, part of Aluprof based in Poland have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems.

Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company’s website at aluprof. co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

The energy crisis will continue to fuel demand for window and door foam sealant tapes in 2025, says Andy Swift, sales and operations manager for ISO-Chemie. He predicts the UK market will remain robust in the next 12 months with the need for more effective insulation and sealing solutions of windows and doors remaining a priority in the design, specification, new build housing and wider commercial construction sectors.Building regulations and increasing numbers of planning reviews in the wake of the Labour Government’s raft of changes to national planning policy, including measures to accelerate the delivery of renewable schemes, will all create a strong case for ever more energy efficient products.

Additional new homes in 2025 to meet the chronic shortage will also see extra windows fitted, while anticipated cuts to interest rates will help to stimulate levels of house building activity throughout the year. This will all contribute to healthy interest - and sales - in cost effective, easy-to-use window sealing solutions among specifiers and developers, says Andy Swift.

“The UK window and door sectors along with associated products, will undoubtedly experience continued growth next year. We expect to see many more retrofits of old housing stock and refurbishment of existing housing stock. This will accelerate opportunities for innovative sealing and load bearing bracket support systems such as our Bloco One and WINFRAMER products to deliver better thermally efficient window installations,” he said. “Retrofitting properties with sealant tapes becomes a direct focus for property developers and housing associations and is a cost-effective way to insulate existing properties very quickly. As they say the greenest home is the one already built. It just needs suitable retrofit insulation.”

Andy Swift says as we look towards the coming 12 months, understanding current energy saving trends is crucial for stakeholders within the industry to be able to deliver effective end-user solutions. “House building to higher air and thermal standards remains a priority in the next 12 months - and is a message that we will continue to push to architects and other property specifiers. There are products out there to ensure that airtightness and thermal efficiency within buildings should never be overlooked or ignored - it remains a matter of specifying and designing in these products.” https://www.iso-chemie.eu/en-GB/

The Sash Window Workshop were contacted to upgrade the windows and doors at a property in the Cotswolds. The new joinery needed to improve energy efficiency, while being in keeping with the architectural style of the building. The customer decided to proceed with new sashes in 16 sash windows.

As the property was in a conservation area,and the windows were not being replaced like-for-like, the customer needed to obtain planning permission for the new windows.The sashes were manufactured in the company’s workshop in Berkshire. The sashes were manufactured using Accoya wood, which is a FSC certified timber and comes with a 50-year anti-rot guarantee. The sashes were then fully factory finished in a bespoke semigloss paint.

The customer was very happy with the work, so they decided to place several additional orders for more work. This included three new timber doors, a new casement window, and new double-glazed sashes in ten casement windows. The Sash Window Workshop select the highest quality materials, enabling them to produce windows and doors that provide the best possible performance, combining minimum maintenance with maximum lifespan. The company’s new joinery is designed to be energy efficient and to suit the architectural style of the property. They offer a supply only service for new joinery across Great Britain, with a supply and installation service for properties across London and the South. Where necessary, they can comply with Conservation Area and listed building requirements. www.sashwindow.com

The Automatic Door Suppliers Association has spearheaded safety, standards, and professional excellence in the powered pedestrian door industry since 1985.

We lead the way in compliance, competence and consultancy to ensure that automatic doors and entrances are manufactured, installed and serviced to the highest standards.

With 500+ members and a legacy of industry-shaping milestones, ADSA continues to drive the future of safety and innovation while delivering a host of membership benefits.

ADSA - 40 years of excellence with safety, security and accessibility at the heart of our mission.

Find out more: www.adsa.org.uk 01827 216136

In 2025, the Automatic Door Suppliers Association (ADSA) proudly celebrates its 40th anniversary, acknowledging the key milestone in its journey from aspirational beginnings to becoming the leading authority in the automatic door industry in the UK. With four decades of unwavering dedication to safety, standards, and professional excellence, ADSA has shaped the industry in the UK and beyond. As the association heads into commemorating this momentous occasion, we reflect on its origins, achievements, and its role in advancing innovation and safety in the automatic door sector.

The Birth of ADSA: 1985 - 1985: Margaret Thatcher was PM, the coal miners strike began, Torvill and Dean won gold at the Winter Olympics and Frankie Goes to Hollywood, Wham! and Duran Duran were topping the charts. Meanwhile, representatives from four forward-thinking automatic door manufacturers - Besam, W Langley & Co, Stanley Magic Door and Dor-O-Matic - gathered in London for ADSA’s inaugural meeting. They were driven by a clear vision: to establish a collective body for the development of industrywide standards, safety promotion, and collaboration.

A constitution established, Michael Haddon-Grant was elected as ADSA’s first chair, and secretarial and admin support acquired through a strategic partnership with the National Association of Shopfitters – aligned by automatic door requirements for retail outlets. These founding fathers created a Defined Code of Practice (DCOP) – a framework for industry regulation. ADSA’s early efforts were crucial in bringing structure to an industry which was increasing in size due to legislative requirements for greater building accessibility.

Defining Safety: The BS7036 Standard (1988) and DDA (1992) - Three years later, ADSA made a landmark contribution by influencing the creation of the BS7036 Safety Standard, derived from its DCOP. This pivotal moment established guidelines for the safe use and installation of automatic doors, ensuring better protection for users across various built environments.

ADSA’s role in spearheading inclusivity is also significant. In 1992, the association actively prepared for the introduction of the Disability Discrimination Act (DDA), ensuring all automatic door sets and installations met requirements and helping key buildings to become accessible to all.

Advancements and Innovations: 1996-2000 - During the mid-90s there were continued efforts to revise and refine industry standards. In 1996, the BS7036 Safety Standard underwent revision, taking into account new technology and safety requirements. ADSA also launched its first certificated qualification for technicians, cementing its role in professional development. A key moment came in 1997 when ADSA was incorporated as a limited company, establishing itself as the “voice of the industry”. It moved its operations from London and the South East to the Midlands, establishing a registered office in Lichfield, and later moving to Tamworth.

Around this time, the Health and Safety Executive (HSE) Safety Notice (SN(02)) became another key driver which further emphasised the importance of safety in the operation and maintenance of automatic doors. As the new millennium beckoned, ADSA focused on regulatory compliance, particularly in emergency escape scenarios.

In 2000, ADSA successfully lobbied for Scottish regulations on emergency escape systems, ensuring that automatic doors were not only safe but also effective in emergency situations. Two members were key to this achievement: John Robb, who now works for Record UK, was a member of ADSA’s technical committee and remains so today and Paul Watson, of RTR, a current member ADSA executive team. This period also marked the association’s involvement in CEN standard development, reinforcing its role as an international player in the automatic door sector.

Education and Innovation: 2014 - 2016 - By 2014, ADSA solidified its position as a leader in training and qualifications. The introduction of qualification training programmes provided automatic door technicians with the knowledge and skills necessary to meet evolving safety standards and regulations.

Industry stalwart Dave Hill took on the role of ADSA’s consultant managing director, introducing many initiatives including a Charity Golf Day. This popular sporting and networking event recently marked its 10 th anniversary and has raised more than £64,000 for good causes over the past decade.

In 2016, ADSA helped paved the way for the introduction of BIM4M2, producing Building Information Modelling for powered pedestrian door operators. This initiative was aimed at enhancing digital design and construction processes for mechanical and electrical systems, including automatic doors. ADSA's involvement in BIM ensured that automatic door systems seamlessly integrated into modern building designs, positioning the association at the forefront of technological advancements in the construction industry. Technology, Member Benefits and Working Partnerships:

2017 - 2019 - ADSA’s commitment to education was further enhanced by the creation of the ADSA Academy in 2017, an online e-learning hub to support professional development for all member employees. This was upgraded in 2024, introducing a wider span of educational resources to support continuous professional development.

Darren Hyde became ADSA’s technical and training manager in 2017. He had been a member of the executive team since 2014 while working as technical manager for GEZE UK. The association’s membership steadily grew – by 2018, to deliver the programme and to date, seven cohorts have commenced involving 87 students, with 38 end point assessments having been completed.

it stood at around 250 - a testament to its reputation and influence within the industry. The following year, saw Ken Price, former national sales manager for GEZE UK, take up the post of ADSA’s first full-time managing director. This heralded an era of great change and introduction of innovative member benefits and extended services.

By the end of the 2019, ADSA launched an Apprenticeship and Diploma programme, further bolstering the career paths available to those entering the industry and supporting the development of a future workforce. This was the culmination of seven years work, led by Paul Watson and supported by Darren Hyde.

The concept was scoped, tested and developed into a trailblazer scheme, monitored DoE and Skills Funding Agency prior to launch. The following year, South Staffordshire College was appointed to deliver the programme and to date, seven cohorts have commenced involving 87 students, with 38 end point assessments having been completed.