Where Region Meets Building

Authors:

Darrell Puffer, AIA, LEED AP, WELL AP

Ting Wang, AIA

Authors:

Darrell Puffer, AIA, LEED AP, WELL AP

Ting Wang, AIA

Rooted in Place

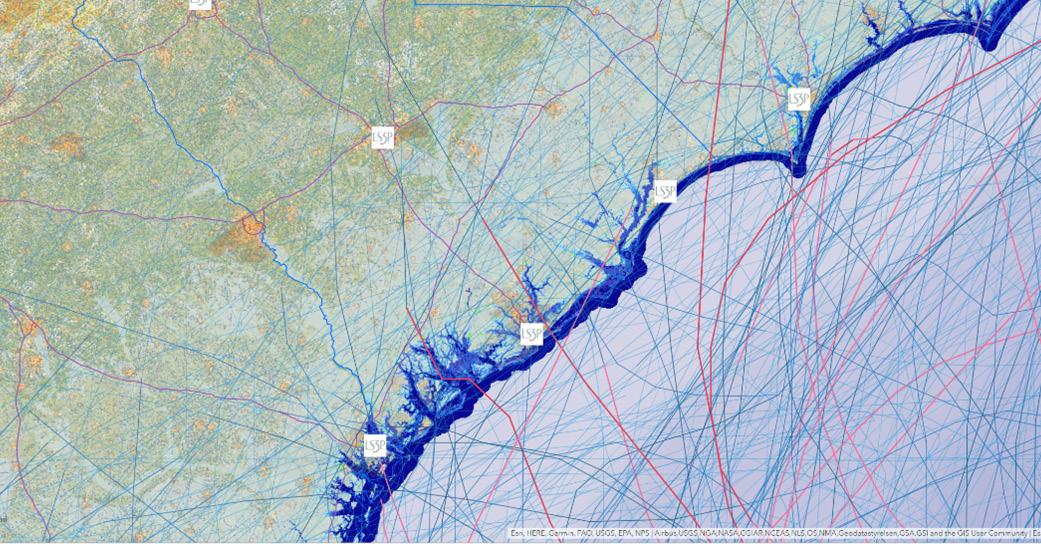

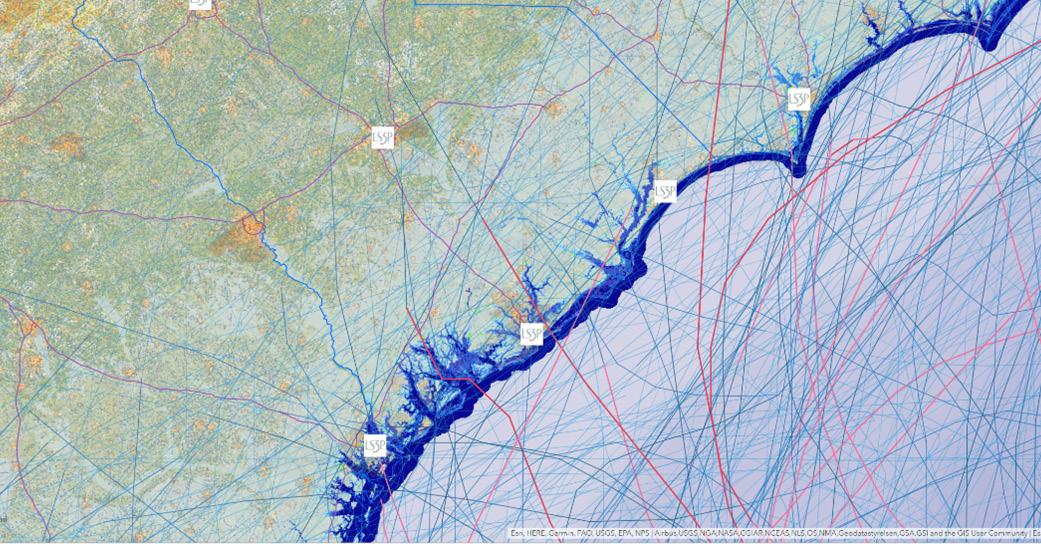

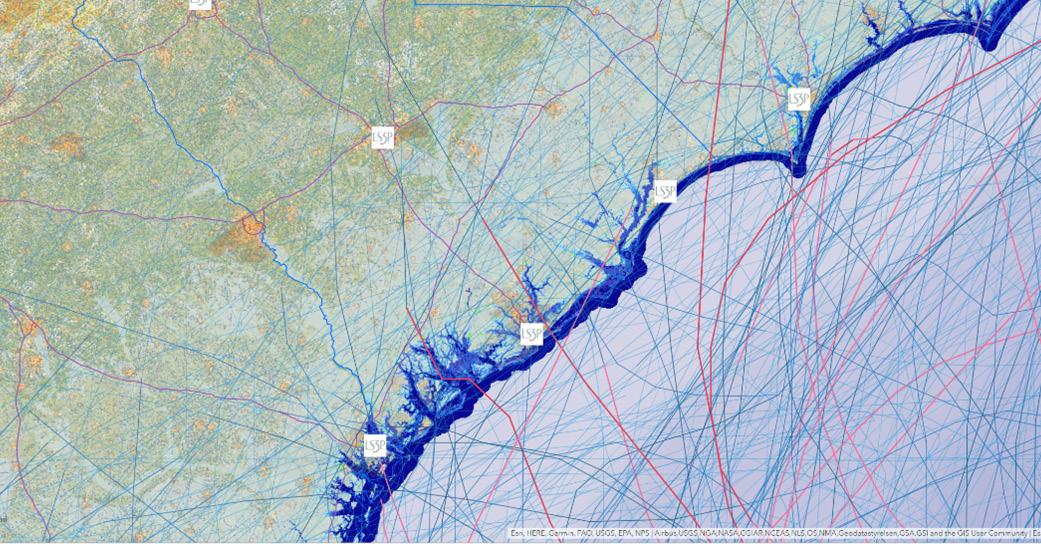

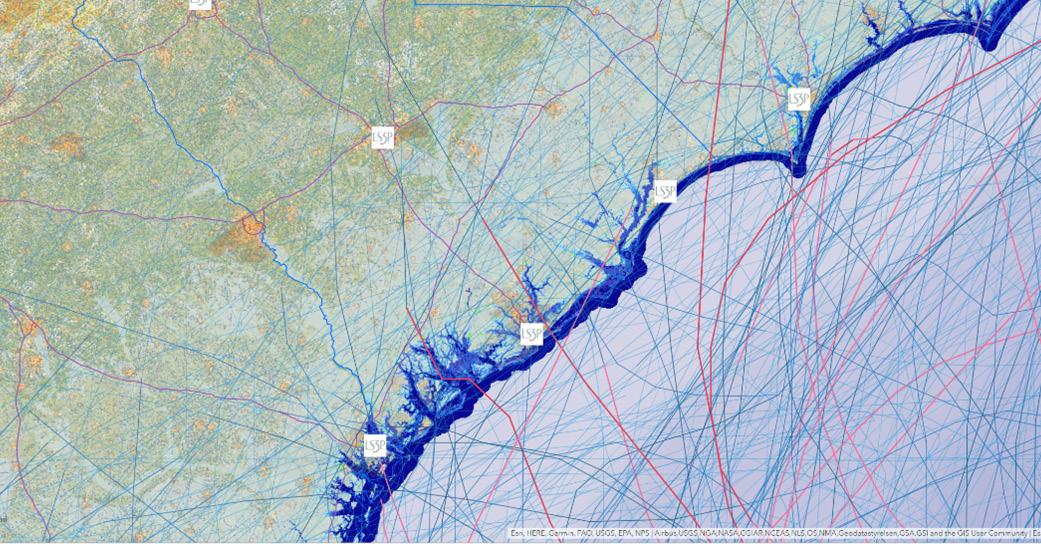

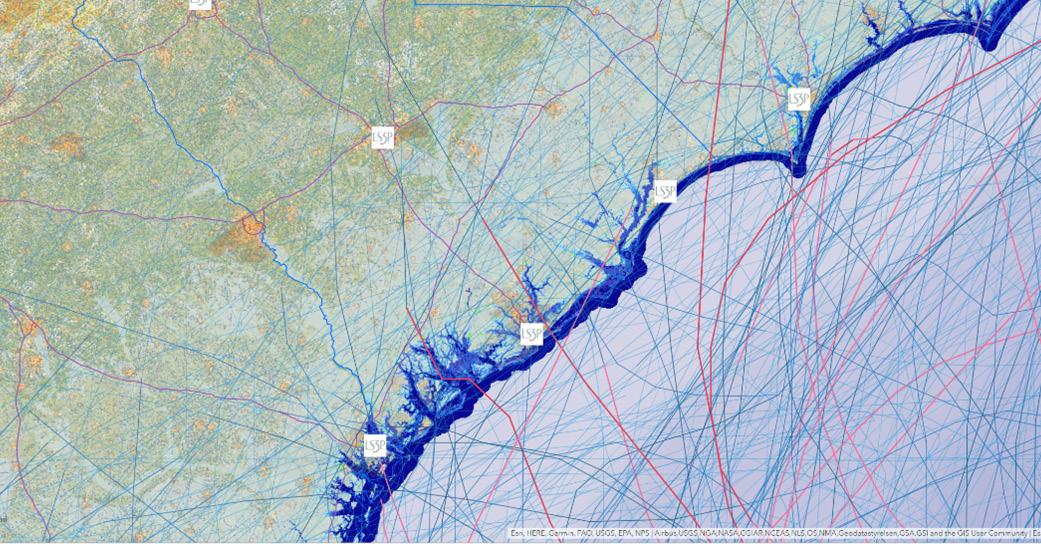

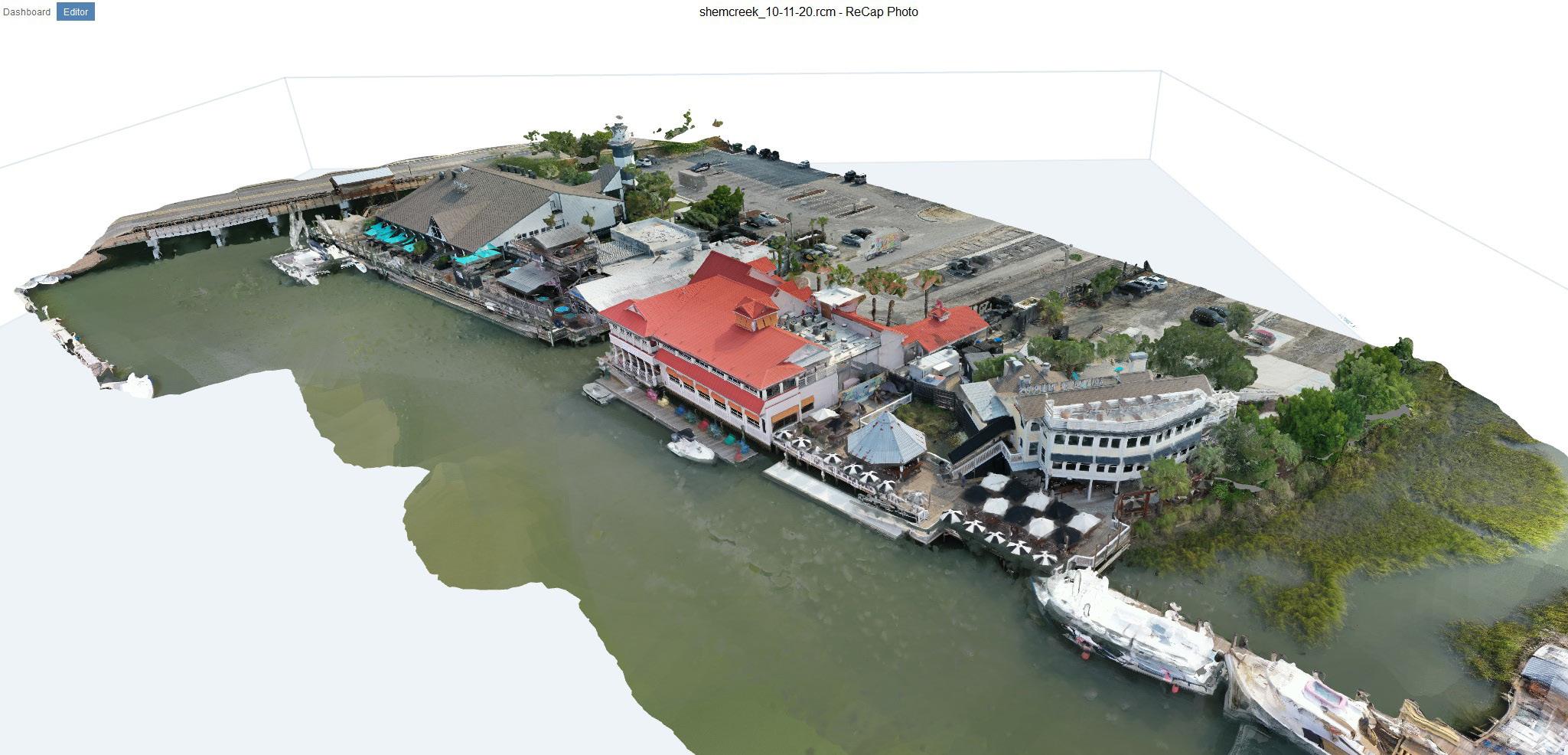

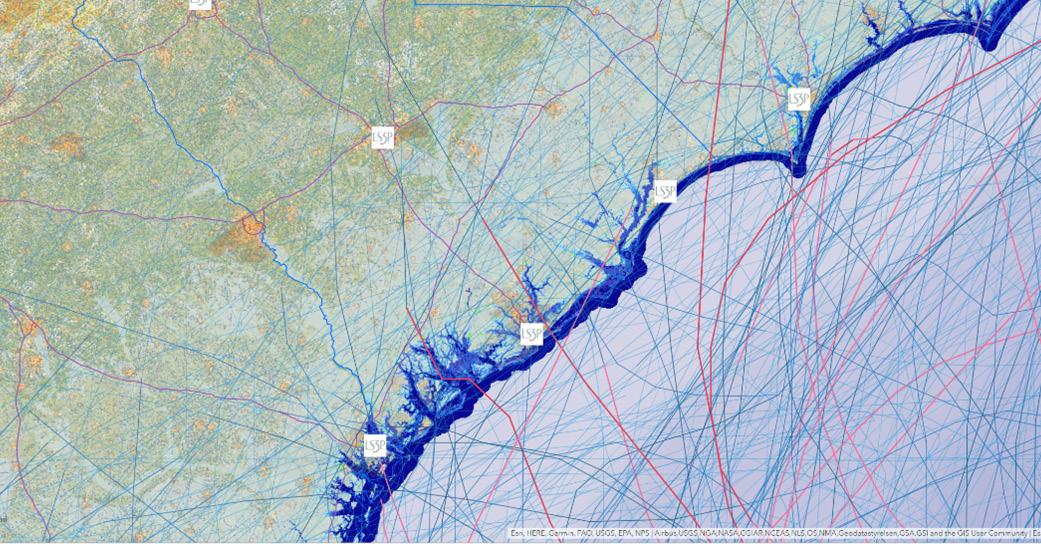

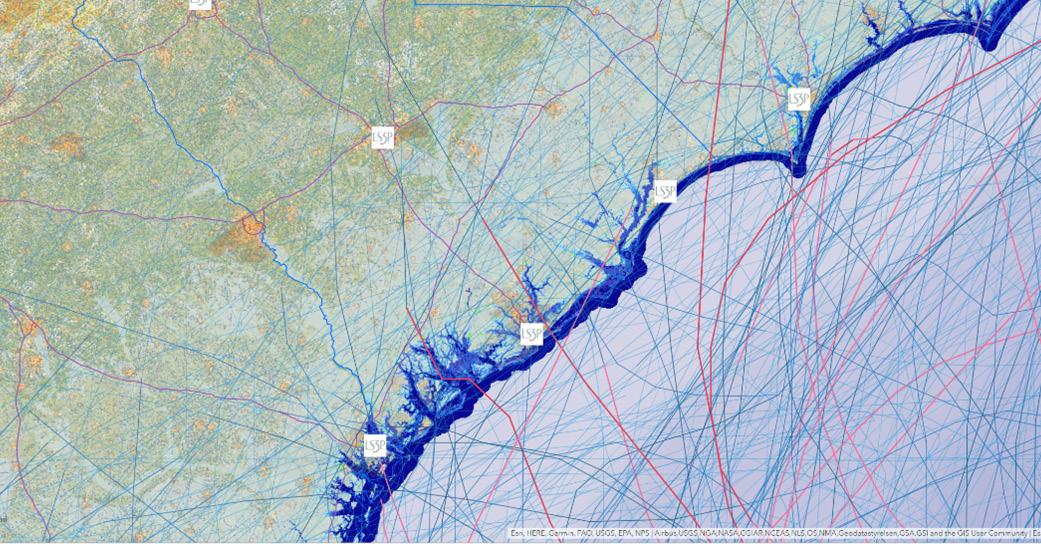

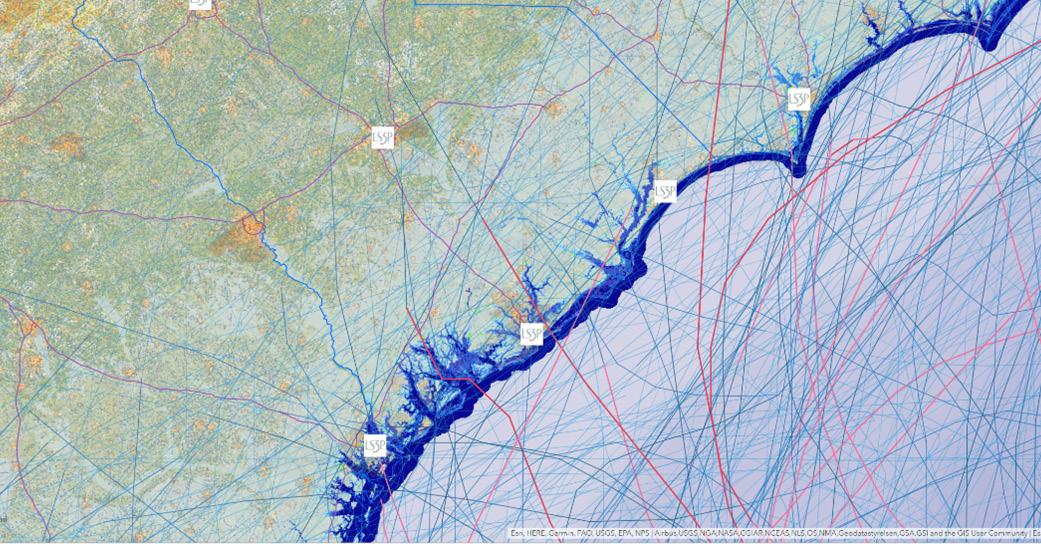

LS3P, an architecture, interiors, and planning firm founded in Charleston in 1963, is a regionally-focused Southeastern firm. With offices in North Carolina, South Carolina, and Georgia, the firm’s work and culture grow out of a strong sense of place and a commitment to serving communities across the region.

At first glance, a region may appear relatively uniform in terms of culture, geography, and climate. Careful mapping of regional data, however, reveals diverse patterns in motion across both regional geography and climate. LS3P’s office locations cover an area that spans the Blue Ridge, the Piedmont, the Sandhills, and the Coastal Plain crossing several climate zones. This area is a transitional zone between the continental, subtropical, and tropical climates. In addition to seasonal shifts and climate variations from office to office, the firm works in a climate which can experience significant temperature swings over the course of a single day. It is not uncommon to start the day with temperatures in the 40s and rising to the 70s by afternoon; this change in temperature (ΔT), conspiring with wind-driven water, humidity, and heat, define the challenges that can influence the built environment and the performance of the exterior wall. In addition, the seasonal threat of named tropical storms and hurricanes that come onshore presents significant weather events every year.

Regional concerns can be summarized in a few words: heat and moisture transport.

The building envelope is a physical separation between the natural environment and the conditioned built environment. This continuous constructed barrier controls the indoor temperature, humidity, and air quality necessary for human comfort and building longevity. The control function of a building enclosure is at the core of good building performance and resilience.

As an architectural practice, LS3P develops professional standards and guides to distribute proficiency in workflow and maintain consistent high-quality documentation. The firm leverages digital content to build standard libraries within the BIM workflow. Two-dimensional drafting views can be referenced to three-dimensional wall and roof elements with integrated specifications, thermal performance criteria, and visualization maps. The digital environment is rich with information that is curated and reviewed with an internal Quality Control team called “ADVANCE.” The “ADVANCE” team consists of a representative group of LS3P architects with a vast amount of accrued knowledge and experience in the field. This assembled group authors and validates content and methodologies for the practice, serving a key role in standard-setting organization.

LS3P’s Ting Wang serves as Practice Technology Manager. Her focus on building enclosure details and performance drives the process of standard-setting development. Her unique role in applying technology to improve the design and performance of the built environment led to a foundational study for the firm bridging three important issues: standards, performative design, and critical regionalism.

The team set out to research and evaluate exterior wall systems and build a trustworthy digital library of architectural standards. This investigation started with the gathering and formatting of LS3P’s exterior wall system details commonly in use. Collected from active projects, the selected wall designs represent a large percentage of those specified in built work. The team created a BIM Content Management Library and developed a standardsetting methodology for the review process and then identified an approach for third-party performance analysis and validation.

LS3P partnered with Chicago-based engineer Manfred Kehrer, WJE, an expert in harnessing the power of WUFI software, to quantify the impacts of moisture on materials. WUFI, a German acronym for “Warme Und Feutchte Instationar” or “heat and moisture transiency,” simulates the dynamic coupled heat and moisture transport through envelope assembly under real climate conditions and enables full reporting, including a mold growth index, that serves as the crucial criteria to assess the hygrothermal performance per AHRAE Standard 160. This method offers a more holistic approach to wall hygrothermal analysis than traditional methods, and incorporates leading-edge software to study weathering conditions in very specific locations over time. WUFI technology is commonly used in cold climates to address the threat of thermal problems related to cold and freezing; however, its use in the southeastern region is innovative and unusual.

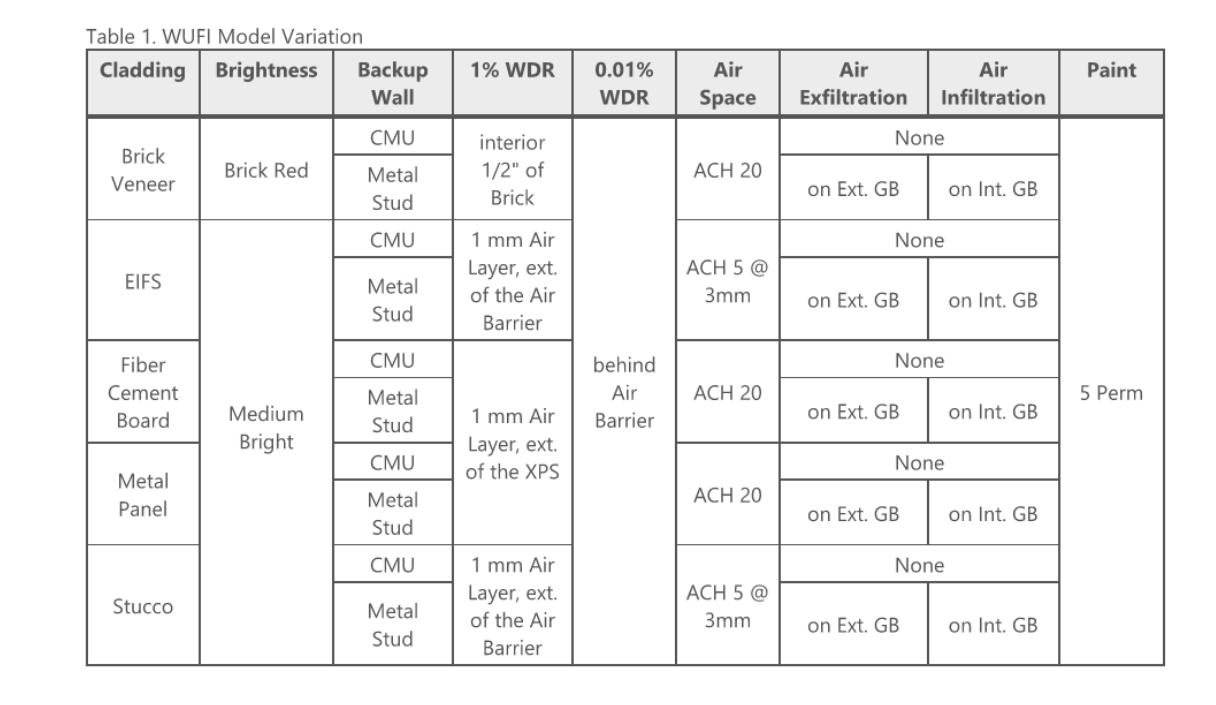

Ting and Manfred worked closely together to determine a basic simulation setup for each typical assembly and its variations with

known factors and plausible assumptions. This collaborative study focused on five different cladding systems on two different back-up walls – concrete masonry unit and metal stud framing. The CMU back-up was simulated as a grouted and a non-grouted system, assuming 8 PCF for the initial water content of the grout. The team simulated these wall assemblies in four cities located in North Carolina, South Carolina, and Georgia, representing the four climate zones per IECC. Additionally, the team performed simulations for a north orientation to cover severe conditions for lack of solar radiation and for a south-oriented wall to investigate potential solar-driven moisture. For each location, the north or the south orientation also includes high wind-driven rain exposure. The combinations of five claddings on three backup wall structures at four locations with two orientations led to a total of 120 simulations.

The analysis assumed a one percent wind-driven rain source penetrating the exterior cladding of the wall assemblies in general accordance with ASHRAE Standard 160. Furthermore, to reflect construction imperfections, a 0.01 percent wind-driven rain source was placed behind the 0.1 perm air and water resistive barrier. (See Table 1). Additionally, the layers in the cladding system were assumed to be vented to the outside using an air exchange rate defined in Table 1.

Moisture accumulation at the exterior gypsum board due to air exfiltration, based on an IECC code compliant airtightness, was applied according to the model built in WUFI for the metal stud framing. Moisture accumulation at the interior gypsum board due

to air infiltration based on IECC code compliant airtightness was also applied for these assemblies.

Material properties were taken from the WUFI database and coordinated with LS3P specifications. The purpose of the WUFI assessment was to determine the hygrothermal performance of the standard wall assemblies per ASHRAE Standard 160 Criteria for Moisture-Control Design Analysis in Buildings. WUFI Pro 6.3 was used by WJE to perform the simulations effectively analyzing the coupled heat and moisture transport in building enclosure systems such as these walls and roofs. This process currently represents the state of the art for this type of analysis. By running the simulation analysis for multiple years, the program model can identify trends in the moisture content of a structure’s wall and roofing assemblies during historic climate conditions.

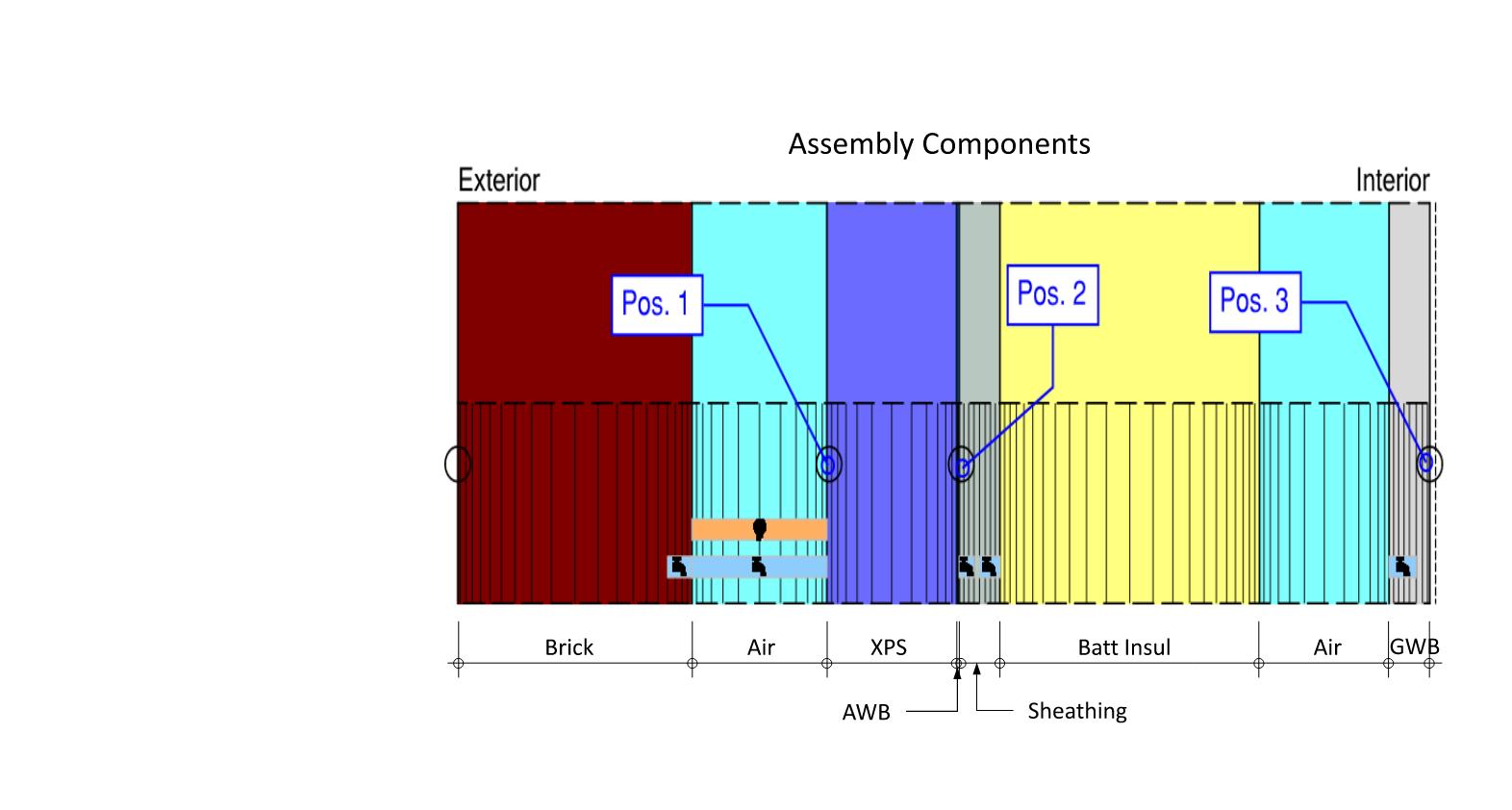

Assembly components and 3 monitored positions for mold growth evaluation

Monitored Positions:

Pos.1 - Exterior face of XPS

Pos.2 - Exterior face of sheathing

Pos.3 - Interior face of GWB

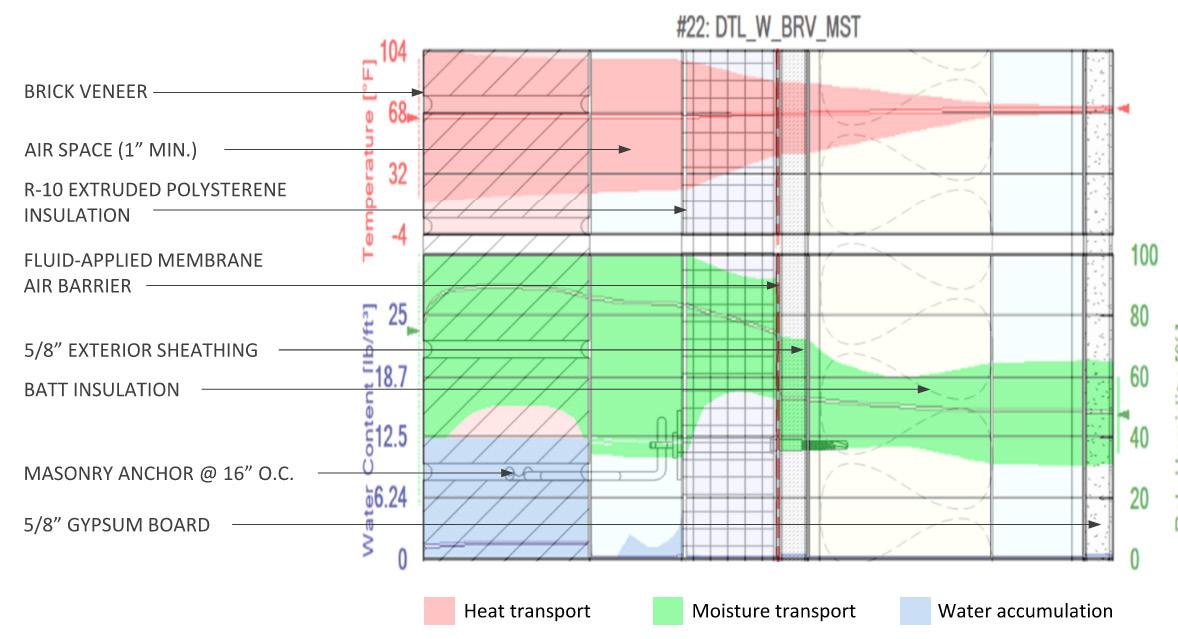

Case #22 Annual hygrothermal average value and range through the assembly

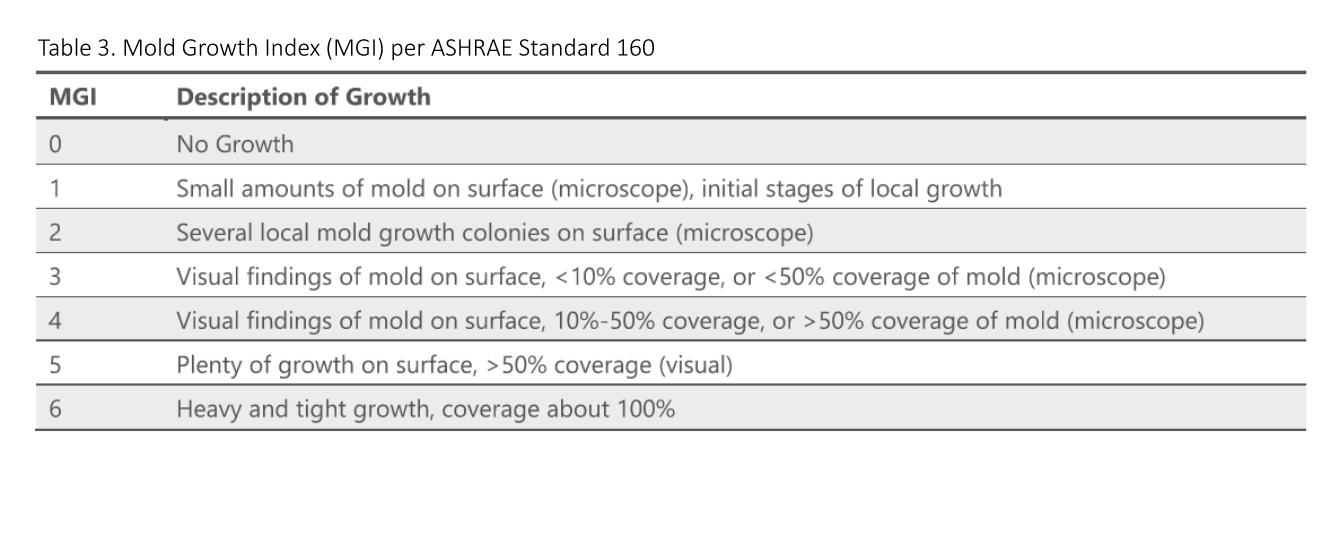

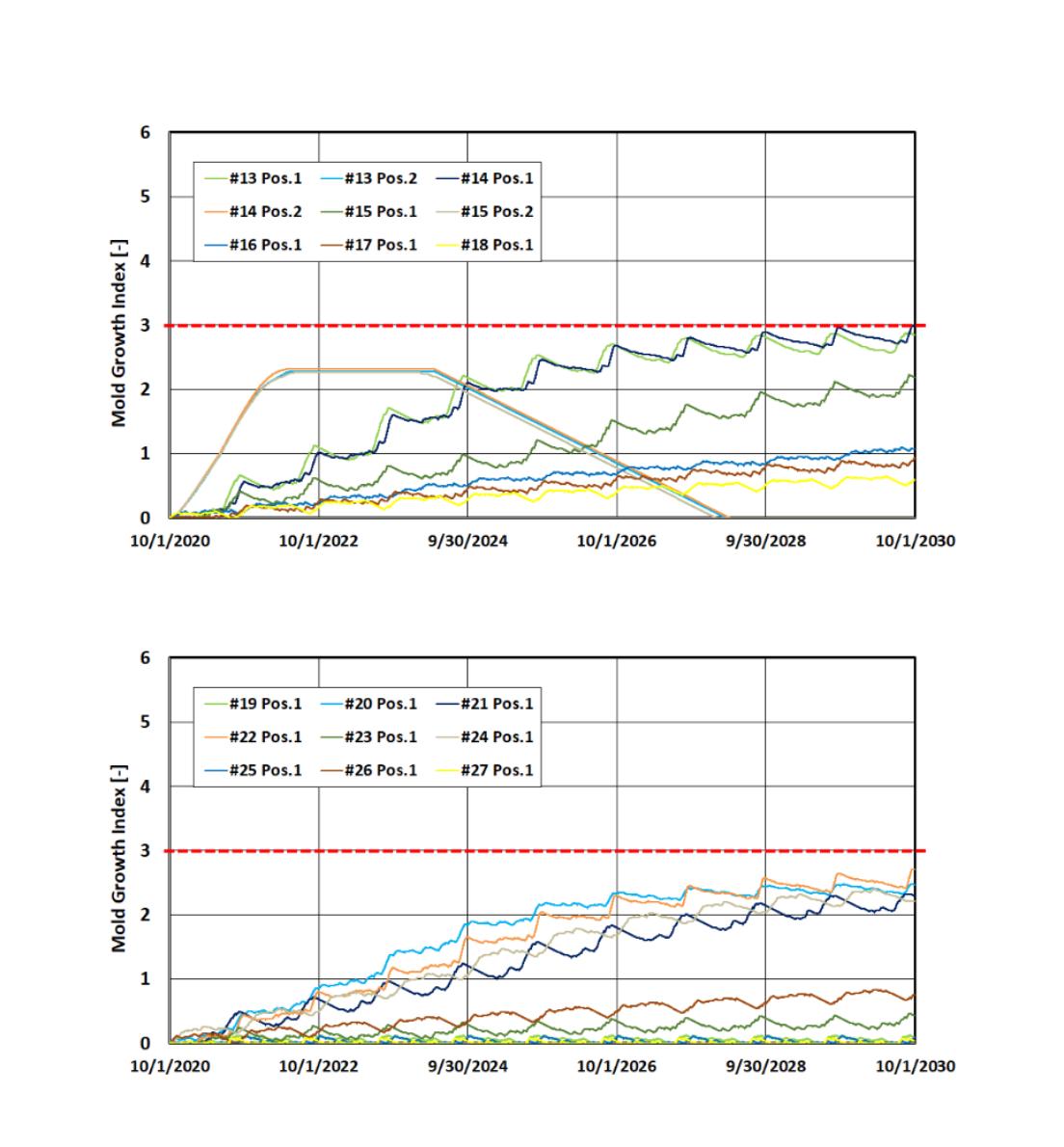

Note: MGI at monitored positions shall not exceed a value of 3

Note: MGI trends over 10-year simulation period are below critical value of 3 for all cases

The geography of the southeast region serves to transport water, as wet conditions drive water to move from wet to dry places as heat moves to find cold air. Thermal and moisture control within a wall is crucial to the health and durability of the built environment. Yet, compared to all the other aspects of building envelope’s control function, this control is less understood by most design professionals due to its complex physical mechanism.

Understanding how to calculate dew point analysis has been critical to the design of new buildings as well as the assessment of existing buildings; however, the definition of the dew point alone does not provide us with a full view of performance. The dew point method has a significant limitation: it lacks precision and accuracy, because this method looks at just a snapshot in time rather than considering time-changing boundary conditions. Furthermore, the method does not take moisture storage of building materials into account, nor the impact of rain or solar radiation. This is especially true in a geographically complex region with mixed climate zones such as the southeastern US. Moisture interacts with construction materials differently under various conditions, and therefore it makes sense that wall analysis should consider fluctuations and weather events over time to determine whether a wall is slowly being decomposed. Misinterpretation can result in either overdesign increasing construction costs, or inadequate design which may accelerate building material deterioration over time.

One significant step beyond dew point analysis, WUFI provides a useful tool for the relative comparison of various enclosures; however, WUFI is limited in that it only analyzes a one-dimensional “cut” through an assembly without additional considerations such as thermal bridging or airtightness. Even advanced wall analysis does not account for imperfections in the building materials or other construction quality issues that affect performance of the constructed assembly. In spite the limits of current technology, the case for more performative analysis of common construction systems is critical. The southeastern region needs tools for more achievable distributed resilience with regards to residential construction.

The challenges facing the architecture and construction industry are well known and the opportunities to reshape the industry exist at a global and regional level. The route to productivity is rooted in technology and innovation. Architects should strive to work with methods that can scale to address the intractable

problems facing the industry, the environment, and communities across the region.

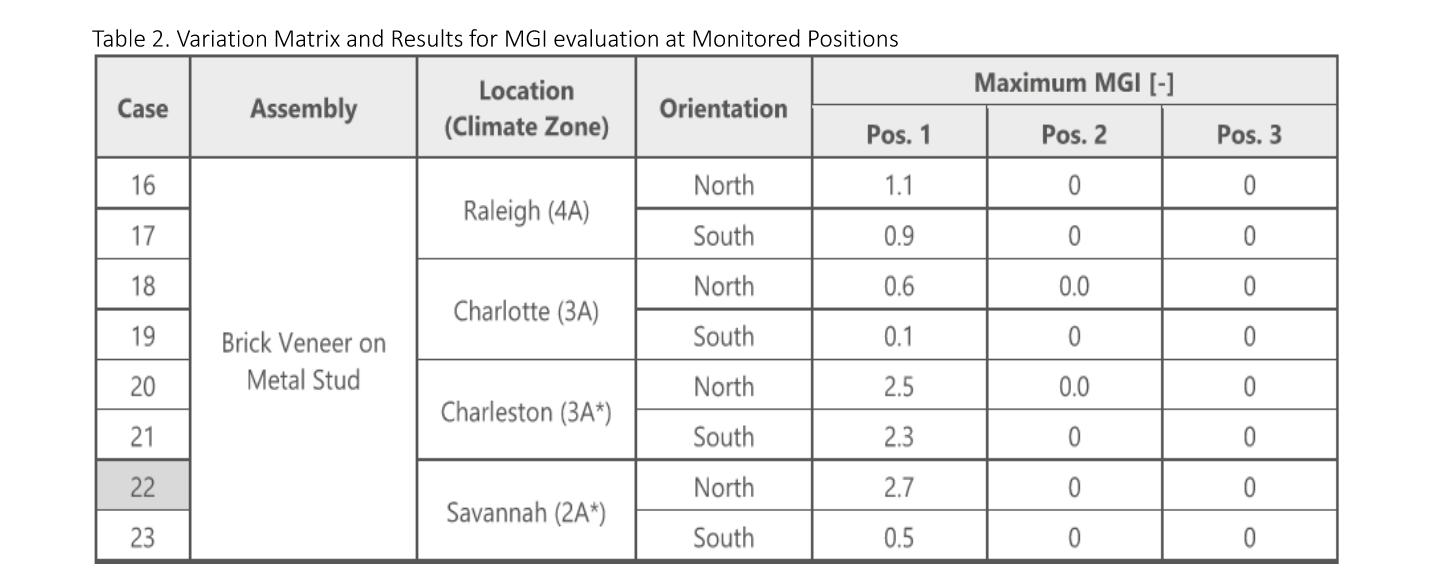

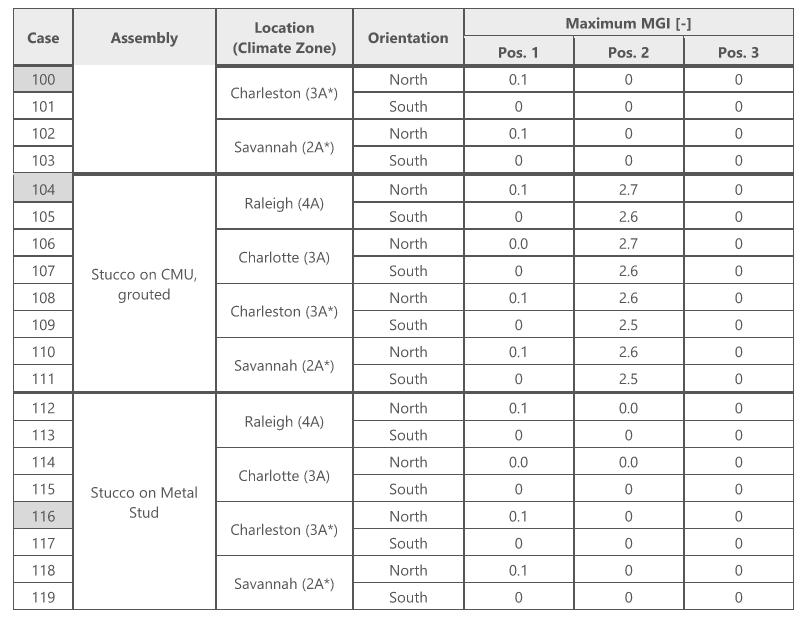

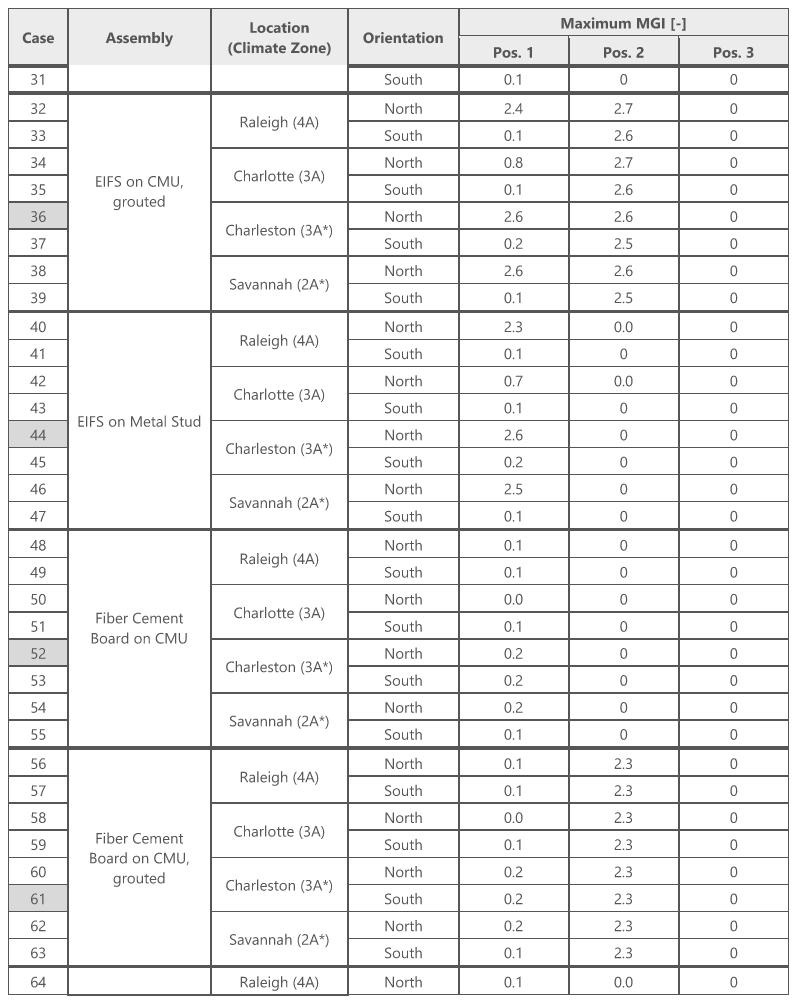

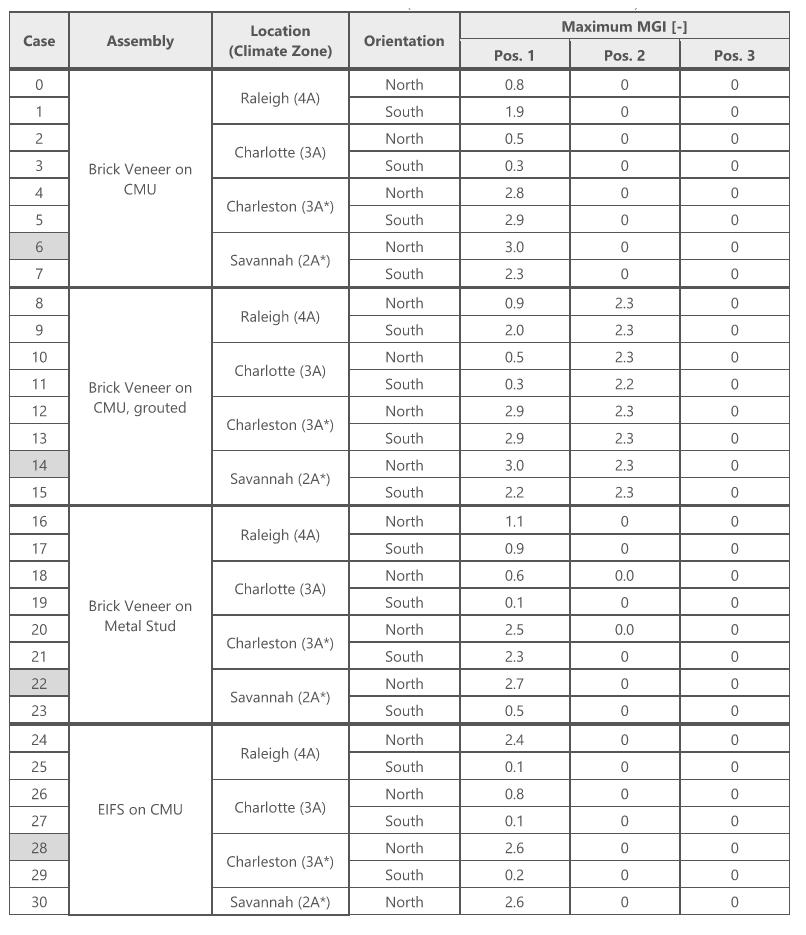

Tables on the right summarize all 120 simulation variations and results for the maximum Mold Growth Index (MGI) evaluation at positions 1 through 3. In general, the MGI values do not reach above 3.0. All simulations show an MGI of zero at the interior surface (Pos. 3). Cases with a brick veneer cladding show elevated MGI values up to 3.0 behind the cladding and visual mold growth may occur (Pos. 1); however, no negative impact to the structure or the living space is expected.

Grouted CMU systems show maximum MGI values between 2.3 and 2.7 within the first years at the exterior CMU shell (Pos. 2) until the grout has been dried out and then drop to zero.

The assemblies with EIFS and stucco cladding show good performance at all positions.

BIM content library of vetted exterior wall details set as standard for hygrothermal evaluation.