We produce Digital Content for Digital People across 20+ Global Brands, reaching over 15M Executives

Digital Magazines

Websites

Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

Work with us

In this issue of Manufacturing Digital, we hear about synthetic diamonds and smart technology designed to save time & reduce emissions, as well as Microsoft’s use of digital twins for factories

Welcome to the latest issue of Manufacturing Digital! In this month’s magazine, Colin Lloyd from Element Six discusses synthetic diamonds and tungsten carbide advanced material manufacturing, while Augury CEO Saar Yoskovtiz explores how AI and smart technology help manufacturers save time, effort, and emissions. Finally, we catch up with Indranil Sircar, Chief Technology Officer for manufacturing and mobility at Microsoft, who tells us more about the company’s core platform capabilities. “We continue to look at what is next on the horizon, like creating digital twins for factories or facilitating simulations,” he tells us. Keep looking up,

HELEN ADAMSHelen.Adams@bizclikmedia.com

We continue to look at what is next on the horizon, like creating digital twins for factories or facilitating simulations ”

Innovators are paving the way for a more resilient, sustainable and efficient future. The rules have changed. It’s time for DISRUPTION.

Tech LIVE Virtual returns to highlight the innovators changing the industry through expert keynote speakers, interactive fireside and panel discussions. This exclusive 1-day virtual event will bring together the greatest voices in the industry for an essential deep dive into the future of Technology, AI and Cyber.

Brought to you by BizClik, Technology, AI and Cyber Magazines, the event will shine a light on essential topics such as the AI revolution, quantum computing, the virtual workplace, technology’s place in sustainability and much more.

It’s time for DISRUPTION.

Position your business as a pioneer in Technology and showcase your values, products and services at Tech LIVE Virtual.

This is your chance to share your innovations with the technology community by making an impact in front of fellow decision-makers and influencers as well as accessing potential partners via an active and engaged audience.

See you on the 8th June 2023.

12 BIG PICTURE

Earthquake in Turkey

14 THE BRIEF

The Digitisation of Diamond Manufacturing

16 TIMELINE

Tesla timeline – from Silicon Valley to falconwing doors: a brief overview of the company

18 TRAILBLAZER

Ursula Burns

20 FIVE MINS WITH Jerry Huang

Join the must-see virtual event disrupting procurement and supply chain on the 28th of June 2023.

This year, we are bringing you a solely virtual event, Procurement & SupplyChain LIVE Virtual will highlight the innovators changing the industry. Brought to you by BizClik, Procurement & SupplyChain LIVE Virtual will be held on 28th June 2023, streaming remotely to virtual audiences around the world.

The unmissable event will feature expert keynote speakers, interactive fireside and panel discussions, and more. Do not miss this 1-day deep dive into the disruption and the future of procurement, supply chain and logistics.

Sponsorship Opportunities

Do you want to position your brand in front of thousands of innovators, decision-makers and influencers?

Sponsor Procurement & SupplyChain LIVE to unlock the future of your business, access thousands of potential partners and influence businesses at the highest level.

Both global giants and innovative start-ups alike can discover the ideal platform with easy access to an engaged and active audience.

Contact a member of our team today to discuss sponsorship opportunities.

See you on 28th June 2023.

It’s time for DISRUPTION. GET YOUR PASS SPONSORSHIP

Innovators are paving the way for a more resilient, sustainable, and efficient future. The rules have changed. It’s time for disruption.▶ Watch our showreel from PROCUREMENT & SUPPLY CHAIN LIVE London 2022

The earthquake that hit Turkey in February reached a magnitude of 7.8 and killed 50,000 people. This caused supply chain disruption due to Turkey’s damaged ports, bridges, roads, and factories. Risk management company Resilinc says it will take up to eight months for production to resume.

In the recent IoT Signals for Manufacturing report, Microsoft found that 7 2 %

READ MORE

of customers are able to scale their connected factory from proof of concepts into various stages of implementation.

Indranil Sircar, Chief Technology Officer for manufacturing and mobility at Microsoft, discusses the company’s core platform capabilities.

READ MORE

READ MORE

Saar Yoskovtiz is the CEO of Augury, a software company that uses AI and smart technology to help manufacturers save time, money, and emissions.

READ MORE

Valiot’s Federico Crespo & TXI’s Jason Hehman discuss sustainable supply chains & how the Titanium Economy is adopting sustainable manufacturing methods.

READ MORE

READ MORE

“Augury technology has customers that include some of the world’s largest manufacturers, from Hershey’s to ColgatePalmolive”

Saar Yoskovtiz CEO of Augury

“We recognise that, even as a worldleading company, we cannot stand still”

Colin Lloyd Head of Business Excellence, Element Six

“IIoT is the foundation on which we connect to the factory”

Indranil Sircar Chief Technology Officer for manufacturing and mobility, Microsoft

Reshoring – or the relocation of production to the country of company origin – is growing. A Deloitte report this year on freight points to 350,000 jobs being reshored to the US, a 25% increase on 2021.

Element Six – a company harnessing the unique properties of synthetic diamond and tungsten carbide to engineer advanced material solutions that improve the efficiency, performance, and reliability of industrial tools and technology – was founded in 1946.

Colin Lloyd joined the company in 2010 and became Head of Business Excellence in 2021.

“Element Six has a rich history in synthetic diamonds, spanning over 70 years. We played a pioneering role in the development of the material and its growth methods, which include HPHT (High Pressure, High Temperature) and CVD (Chemical Vapour Deposition). Innovation has played a crucial part in that success,” said Lloyd.

“However, we recognise that, even as a world-leading company, we cannot stand still. Throughout the decades, we held a fundamental, long-standing principle of ‘doing something better today than yesterday’, and this still holds true, all these years later.”

The health and safety of manufacturers is a key topic currently appearing in manufacturing discussions. Johann Cilliers, Group Marketing Director at Welding Alloys, argues that technology has improved Health & Safety in the industry.

A factor weighing on the manufacturing industry has been the sharp increase in natural gas costs, which pushed up inflation and costs for manufacturers. Electricity wholesale prices have also risen steeply.

The global semiconductor shortage has hugely impacted the manufacturing industry, says Browne Jacobson lawyer Paul Kirkpatrick.

An American manufacturer of electric vehicles, solar panels, car batteries, and home power storage, boasting 127,855 employees in addition to factories from Nevada to Shanghai to Berlin, Tesla practically runs the world. We give a rundown of some of the key moments in its history and an idea of what’s still to come.

Tesla Motors is founded Tesla was founded by engineers Martin Eberhard and Marc Tarpenning, who named their company after physicist Nikola Tesla. Together, they believed that electrical automation could change the world – and reduce oil consumption. “Tesla is a car manufacturer that’s also a technology company,” said Eberhard.

In 2002, Elon Musk’s PayPal was bought by eBay, earning him US$180mn. Musk used the money to found SpaceX the same year, but later found himself drawn to Tesla.

In 2004, Musk led the company's Series A funding round, contributing US$6.5mn and becoming chairman. Musk became CEO in 2008.

It might seem that supply chain delays are unique to a post-pandemic world, but Tesla’s much-anticipated Model X SUV was pushed back by two years due to problems in production. It was the vehicle's unique features –such as its falcon-wing doors – that were a challenge for manufacturers.

In 2016, Musk stated his belief in automation being the key to the future of the company. He said he saw a lot of sense in ‘building the machine that makes the machine’. Tesla then brought Grohmann Engineering. Founded in 1963, the company is focused on manufacturing automation.

Mexico’s President Lopez Obrador has long-hoped to make Mexico a global manufacturing hub. In a US$5bn deal with Tesla, a new factory is to be built in Monterrey. In addition, Tesla has announced that it plans to reduce overall assembly costs of its cars by up to one half in future models.

For many working mothers, there’s still the pressure of trying to ‘have it all’: a Facebook-perfect marriage, happy children, a tidy home and Insta-worthy garden, a wide circle of friends, being a regular presence at the gym, and hitting career milestones.

But Ursula Burns, the first Black female CEO of a Fortune 500 company, never understood the pressure.

“I was not a believer that you had to go to all your kids’ games. I just don’t understand what that’s all about,” she flatly told CNBC. “It takes a village, and we had the village.”

As Burns began to rise up in the business world, her husband, the late Lloyd Bean, retired to be a full-time dad to their two children, Melissa and Malcolm. The family was supported by wider family members, too, allowing Burns to lead Xerox from 2009 to 2016.

Born and raised on Manhattan’s Lower East Side, Burns and her siblings were raised by their Mother, who took on various jobs to earn enough money to pay for their education. At Cathedral High, a Roman Catholic preparatory school, Burns enjoyed maths –something recognised by her teachers.

She then went on to study at the Polytechnic Institute of New York University in Brooklyn and earned a bachelor’s degree in Mechanical Engineering in 1980. At Columbia University, she completed a master’s degree in Mechanical Engineering and then joined Xerox as a summer intern for mechanicalengineering. This also paid part of her educational costs.

Burns is the first African American female CEO of a Fortune 500 company

Founded in 1906, Rochester, New York, Xerox began as a printing service and has since grown to become a leader in digital document products and services. Scientists and engineers at Xerox use augmented reality, robotic process automation, additive manufacturing, Industrial Internet of Things, and cleantech in their work.

Once her master’s degree was completed, Burns started working at Xerox full time, beginning in product development. By 2000, she was Senior Vice President of corporate strategic services, where she was able to learn more about global research and product development. In 2007, Burns became President of Xerox, and CEO in 2009. That year, then-President Barack Obama appointed Burns to guide the White House National STEM programme, an initiative that

encourages the youth in STEM careers. Burns was appointed Xerox’s Chairman of the Board in 2010.

Supporting employees in the workplace Burns left Xerox in 2016, but the company continues to move in a sustainable direction.

It was recently named as one of Corporate Knights’ Global 100 Most Sustainable Corporations in the World.

The Age Friendly Institute has recognised Xerox as a Certified Age Friendly Employer™ (CAFE) – the USA’s only certification programme that identifies businesses welcoming and supporting those aged 50+.

The title of Burns’ 2021 memoir, ‘Where You Are Is Not Who You Are’, is based on a quote from her Mother.

“I had to always remember during my rise to the top, that those circumstances were only a portion of who I was. People around me, even if they didn’t have as much as I had – or had more – were worthy of attention. It was my Mother’s way of saying ‘Don’t get too big for your breeches’, make sure that you understand that humans are humans. They deserve respect and being cared for.”

“People around me, even if they didn’t have as much as I had – or had more – were worthy of attention”Photo-Illustration: by The Cut; Photo: Getty Images

Manufacturing Digital caught up with Jerry Huang just after Chinese New Year to discuss why Taiwan is so well suited to manufacturing & how Profet AI helps manufacturers build prediction models

Q. Hi Jerry, please introduce yourself.

» “I’m Jerry Huang, Co-founder & CEO of Profet AI. Previously, I worked in global software companies such as IBM, SAP, and PTC and other companies in the manufacturing industry for 20 years before starting my own company, Profet AI.”

» “Taiwan's manufacturing industry is vital to the global supply chain and is a leader in areas like EMS, PCB, IC design and manufacturing, and optical lens modules. Taiwan has an unmatchable global implementation environment for AI in the manufacturing industry.

“However, in 2019, as manufacturers began really looking at AI, we discovered that many of the software solutions provided by global companies didn't cater to the specific needs of Taiwanese manufacturing customers, forcing them to spend extra on customisation services. To address this, we aim to create products that meet the manufacturing industry's needs.

“We are really blessed to be based in Taiwan, with all the manufacturing resources and best practices here. We also have extensive industrial experience and domain know-how, as well as a highlyqualified workforce. This means we have the advantage of being able to closely understand the pain points of our customers and customise the most suitable solutions for them to solve problems, which is something we are 100% committed to.

“We know that many companies understand the importance of digital transformation but struggle to implement it effectively. This is often because senior executives from different departments have varying views on which problems AI should solve, plus there's a shortage of data science and AI talent.

“That's where our AutoML virtual data scientist platform comes in. It's a no-code AI platform that's easy to learn and use, and key employees can quickly master it within two hours. Compared to traditional AI projects, Profet AI can help customers complete POC within a week, and more than 80% of non-IT industry experts can use it with its ‘plug-andplay’ feature. It’s this 80% that would have previously struggled with implementing AI.”

»“Last year, Profet AI completed its Series A fundraising and has raised over US$6.4mn in total. Profet AI is a manufacturing auto machine learning software company that provides an end-to-end no-code AutoML platform with an on-demand AI application knowledge base. This enables industry sectors, domain users, or IT professionals to quickly build high-quality predictive models and rapidly deploy AI applications to solve daily production and digitisation challenges.

“As things stand, we can count more than 100 medium- and large-sized manufacturing companies across 12 major industries as our customers, of which more than 70% are industry leaders and listed companies, such as AUO, Qisda, Everest Textile, WUS Printed Circuit, Eternal Materials, and Cheng Shin Rubber.”

“Taiwan has an unmatchable global implementation environment for AI in the manufacturing industry”

Q. Tell us about your industrial AI software.

» “Currently, our product portfolio includes:

• AutoML virtual data scientist platform: as mentioned above, Profet AI AutoML product is a no-code AI platform that is easy to learn, easy to use, and can be quickly mastered by key employees within two hours. Compared to the monthslong process of implementing a typical AI project, Profet AI can be completed within a week, allowing 80% of non-IT industry experts (production line employees, R&D, Facilities, HR, marketers, IT) to use AI, which help further democratise AI implementations.

• Ready-to-Go App on-demand AI application knowledge base: with 12 major industry categories and over 100 application databases, this inspires customers' AI usage ideas.

• Profet AI Inside: a cross-industry collaboration ecosystem that uses Profet AI’s core capabilities to add value to customer products. Currently, there are multiple partners, including Nexcom IPC+AI, Harbortech IOT+AI, and Asia Giant, the chemical equipment manufacturer, collaborating to make their equipment diagnosis intelligent. We are open to collaboration opportunities to create win-win situations with our partners from other industries.”

Q. How does Profet AI help manufacturers build prediction models?

» “We focus on applications in the manufacturing industry and have accumulated 50 commonly-used algorithms in the manufacturing industry over the past few years.

“Our no-code software platform, powered by our AutoML engine, empowers everyone within the enterprise to rapidly design and develop Enterprise AI applications for their everyday processes. Operators, domain experts, and data scientists can also come together to collaborate on Enterprise digitalisation at every level.

“Taiwan's manufacturing industry is vital to the global supply chain”

“We provide a large library of tried-andtested ‘Plug & Play’ AI applications that are industry and application-specific. Built upon our Enterprise AI platform, these applications are ready to be deployed and hyper-scaled at the get-go, in any public cloud or on-premise environment.”

Q. You've worked for many companies, such as IBM and SAP – what did you learn while working there?

» “Global perspective: IBM and SAP are global companies with a wide range of businesses and customer bases. We learned how to collaborate with people of different cultural backgrounds and how to do business

globally, which helped us handle customers and partners from different regions and cultures in our entrepreneurship.”

Q. What does the next year hold for you and Profet AI?

» “Increasing supply chain resilience as a countermeasure to a difficult global geopolitical situation that is hampering business; predicting demand from emerging areas to pursue business growth (such as auto car, green energy, food, and agriculture); and addressing issues of netzero carbon emissions and labour shortages (e.g. with the retirement of the baby boomer generation).”

SAP is a global software provider and a leader for enterprise business process software, including solutions to manage supply chains. SAP provides technologies, supports the cloud and cloud platform environments, as well as artificial intelligence/machine learning (AI/ML) libraries, robotic process automation (RPA) and in-memory technology for high-end computers. SAP’s solutions for manufacturing execution and insights are part of a portfolio of products for supply chain management and leverages these technologies.

“We're an enterprise business software and a technologies company,” says Sam Castro Senior Director, Solution Management, LoB Digital Manufacturing.

Castro is a Senior Director at SAP and a part of the line of business manufacturing solution management team. The line of business covers the 27 manufacturing industries for which SAP provides software solutions.

“All of those industrial companies have needs around operations visibility, control and reporting,” Castro explains. “The different industries have different targets that they're after. Some are heavier on the asset side, some of them are heavier on product quality and yields, others are all about logistics and moving products around on-time through the supply chain.”

SAP is met with a diverse set of requirements and needs from its customers. Solution management takes these industry needs and applies them to market direction and invests them in the portfolio.

“We provide guidance on where to focus and the emphasis for development, and that strategy big picture where we want to take the products,” Castro explains.

In college, Castro completed a Bachelor's in computer engineering and a Master's in computer science at the Rochester Institute of Technology (RIT).

“I came from the hardware bridge to the software bridge very naturally after graduating,” says Castro. “I was dropped into the manufacturing floor because that is exactly where the hardware automation side bridges over into the software.”

He was faced with a great deal of information and digital signals from the automation layer and was tasked to turn it into information — how does SAP make that translation?

“I started at the very lowest level and moved my way through Lighthammer Software, which was acquired by SAP back in July 2005,” says Castro. “I worked my way through SAP into the role that I'm in today.”

“Being a sustainable enterprise means that you're an efficient enterprise”

SAM CASTRO SENIOR DIRECTOR, SOLUTION MANAGEMENT, LOB DIGITAL MANUFACTURING, SAP

Sam Castro is Senior Director of Solution

Management, LoB Digital Manufacturing at SAP

Sam Castro is Senior Director of Solution

Management, LoB Digital Manufacturing at SAP

Today’s supply chain comes with constant uncertainty. So how are you preparing for whatever comes next?

Discover how Deloitte can help you enable a built-to-evolve digital supply chain that allows you to pivot quickly no matter what surprises the future brings.

Learn more about our Kinetic Supply Chain offerings for embedding flexible capabilities, intelligent insights, and sustainability from end to end.

Contact SAP@deloitte.com to get the conversation started.

Digitally driven business is an imperative in today’s uncertain landscape, but to thrive organizations will need digital supply chains that can anticipate disruption and evolve in lockstep with change all while prioritizing sustainability and responsible practices.

At Deloitte, such capabilities are part of our vision for the Kinetic Supply Chain a built-to-evolve supply chain enabled by a clean-core ERP, intelligent technologies, responsive cloud solutions, and an inclusive ecosystem of capabilities. Kinetic Supply Chain capabilities can allow you to see issues and opportunities before they arise and to take action sooner.

Ultimately, it’s about flexibility which can be elusive for many organizations. While optimizing supply chains over the years, some companies may have gained efficiencies without gaining the flexibility that they need in today’s environment. For example, they may have gotten down to one or two key suppliers instead of 20,

but they may not have the ability to sense the need for new suppliers, in the event of a regional fuel or material shortage, for example. They also may lack the ability to seamlessly and quickly integrate any new suppliers into their digital ecosystem. And at the same time, they may lack visibility into what those suppliers will mean for their carbon footprint, their sustainability goals, and their impact on the planet.

With a Kinetic Supply Chain covering planning, procurement, distribution, and operations you can proactively address many of those challenges and become “disruption ready.” More than a vision, the Kinetic Supply Chain is real, and you can see it in action at The Smart Factory @ Wichita At this full-fledged manufacturing facility, housed in a net-zero-impact building, Deloitte, SAP, and others are collaborating to solve real business needs and understand what it takes to build and scale flexible digital supply chains. Contact SAP@deloitte.com to schedule a visit or to get more insights on enabling a built-to-evolve digital supply chain.

When you talk about risk resilience at SAP, it’s about how to handle the real world, not setting up a plan and adhering to it day in and day out.

“You would like it to be like clockwork, for sure,” says Castro. “Where everything always aligns and meshes the way that it's supposed to all the time, every second. But we know that's not always the case.”

Weather events, pandemics, labour shortages or large sporting events can cause supply chain issues. For Castro, resiliency is the byproduct of having to have to handle these off-topic or out-of-sync scenarios and the ability to detect that you're out of sync

“Here are the enablers of AI and ML type algorithms that you can use and put together how you see fit”

SAM CASTRO SENIOR DIRECTOR, SOLUTION MANAGEMENT, LOB DIGITAL MANUFACTURING, SAP

with the original plan and react to it in a coordinated manner.

“The faster you can do that, the faster you can correct that problem,” says Castro. “Then you’re able to identify how often those deviations occur — that frequency of occurrence, that is your opportunity.”

Being able to quantify that opportunity and understand what those little deviations actually add up to, and how that impacts the business financially, is one of the key topics around what customers will hear about resiliency from SAP, says Castro.

“Sustainability is an overlay to that, sustainability is a byproduct of efficiency,” says Castro. “Being a sustainable enterprise means that you're an efficient enterprise.

TITLE: GLOBAL VICE PRESIDENT, CENTRE OF EXCELLENCE

INDUSTRY: MANUFACTURING

LOCATION: PENNSYLVANIA, US

Sam Castro joined SAP in July of 2005 with the acquisition of a small company called Lighthammer. He was responsible for implementation consulting, field enablement, custom development, and training for the core products (Illuminator, Xacute, UDS, CMS). These products have since evolved into the core SAP Connected Manufacturing products (Mfg. Integration & Intelligence or MII and Plant connectivity or PCo) that you see today.

Sam is now part of SAP LoB Manufacturing Solution Management group, which is directly responsible for strategy, direction, and customer adoption of all of the manufacturing products at SAP. He is specifically responsible for Industrial Analytics, that is SAP MII, Digital Manufacturing for insights, and Digital Manufacturing for execution, and he is the solution owner for Process MES products. In this role, he is actively working on mid- and long-term features and deliverables and how they are positioned with the broader SAP portfolio; he also provides guidance for product development investment.

If things are running effectively, things are running safely, and in a very energy-friendly manner as well.”

Castro views the impact of the cloud on manufacturing as a positive one.

“There are benefits for the IT team from a maintenance perspective and a continuous update and management of that software package,” he explains.

Cloud users are not dealing out of sync or outdated documentation, they’re not dealing with security issues that creep into the environment over time. Updates and patches are handled in real-time by the cloud hosting and software provider, that SaaS provider in the cloud environment. Castro views offloading that burden from the manufacturing layer and the IT teams that support them centrally and locally as a big deal for organisations and businesses.

“It keeps that barrier to entry for managing efficient production and tracking off of those teams, and it puts it firmly on the shoulders of the software provider. What does that mean for the business? It means that the end users aren't working with stale software. You're not working with software that has a UI from 15 years ago. You're not working with an ad-hoc analytical environment that used to be cool but now uses plug-ins and stuff that your browser doesn't support and ultimately causes it to have problems,” Castro explains.

As businesses are not dealing with these issues from the end user perspective, they're able to take advantage of a very modern, easy to consume and use software experience and focus on their core business functions.

“Despite not directly interacting with it, the work around you is what's driving that environment for you,” says Castro. “You're not putting that burden of three or four extra clicks on somebody, this is just software that's being driven from digital signals; from

integration, automation, and the tasks that the operator is performing.”

This newer approach to software design is how SAP leverages the industry investment companies have made and it is what's ultimately reducing the impact that end users have on that environment themselves.

There are different pillars within organisations, which have their own priorities. CEOs, CIOs, CTOs and CFOs are all working together and have overlapping needs that drive different business cases. But they need to have the right information at the top layer to make the right decision for the lowest layers within the organisation. This doesn't happen unless there is a framework in place for the distribution

and analysis of the data that is generated, from the very edges of the manufacturing and supply chain processes to the shop floor.

“If you don't have a way for that information to work its way up to the top, organisations

really struggle to understand where the priority needs to be,” says Castro.

For manufacturers to focus on business value versus technology, Castro believes that they need to intelligently manage profitability and investments. As a result of that additional profitability, they also need to protect that inflow of money and profitable behaviour for the company.

“Is that a CapEx investment? Is it an OPEX investment? Is it better granularity on product quality and an emphasis on quality for certain products or certain areas within a process that are very tricky and cumbersome?” asks Castro. “Maybe it's a new product that you're introducing and as a result, that process isn't fully stable yet. What is the emphasis in how

“Sustainability is an overlay to that, sustainability is a byproduct of efficiency”

SAM CASTRO SENIOR DIRECTOR, SOLUTION MANAGEMENT, LOB DIGITAL MANUFACTURING, SAP

much we put into that project to stabilise it? Those are the goals that are very coveted from the C-suite down, but they really are reliant from all edges of the supply chain and having that information roll all the way up.”

Enterprise-led manufacturing follows in tune with this exactly.

“The enterprise has to provide guidance to the manufacturing and supply chain teams as a whole,” says Castro. Where they want to see improvements and how much they're willing to invest in those improvements, what's it worth? How do you build that community up?”

To understand the role that manufacturing plays in an organisation’s reinvestment strategy, you must first understand where it matches up with other locales in the manufacturing environment.

112.6K+ employees worldwide (Sept. 30, 2022)

160 number of countries

22K+ partner companies

245mn+ Subscribers in SAP’s cloud-based user base

“Manufacturing isn't just a single-faceted environment. It's often made up of plants that have been around for a long time, some that were built up by your own organisation, some that came into the organisation through acquisition,” says Castro. “So you see different heritages and mentalities. They have this communal approach for how the plant manager wants to lead that group in the business forward.”

At SAP, being able to take advantage of AI standardisation in a universal way is important.

“You can take and apply these very technical algorithms in order to get information off them. Here's the technology, here are the enablers of data, here are the enablers of AI- and ML-type algorithms that you can use and put together how you see fit,” says Castro. “Then that carries over into

the application side, which says, we know we have these technologies, we know that this data is being generated from our transacting processes, so we have our own structured analytics pieces and now we can use these structures to drive our own models to influence our execution process.”

SAP has global partners, as well as local partners, who rely on its technology. When Castro talks about partnerships, he does not put one partner over another.

“We try to keep the community as open as possible,” he says. “We try not to promote one partner over another, because they're all very important to us.”

The openness of SAP and the openness of its software is for its customers to take advantage of, but also for their partners to put their own industry expertise behind.

“It is what gives SAP the power that we have to leverage in our own technologies to leverage partner-led innovation using those technologies to intelligently power our applications.”

“ You want it to be like clockwork, where everything always aligns. But we know that that's not always the case”

SAM CASTRO SENIOR DIRECTOR, SOLUTION MANAGEMENT, LOB DIGITAL MANUFACTURING, SAP

Colin Lloyd is Head of Business Excellence at Element Six, a global leader in synthetic diamond and tungsten carbide advanced material manufacturing

WRITTEN BY: CHARLIE KINGThe benefits of digitisation of diamond manufacturing can be seen across the world: as companies develop digital processes, they remove necessity and risk in mining.

At the forefront of global supermaterial manufacturing is Element Six, a company that harnesses the unique properties of synthetic diamond and tungsten carbide to engineer advanced material solutions that improve the efficiency, performance, and reliability of industrial tools and technology.

The heart of Element Six: continuous improvement in manufacturing tech Colin Lloyd joined the company in 2010 and became Head of Business Excellence in 2021. With a background in automotive manufacturing, Lloyd started his journey at Loughborough University in 1991, where he studied Manufacturing Engineering before quickly working his way up the ranks of global manufacturing leaders.

“Element Six has a rich history in synthetic diamonds, spanning over 70 years. We played a pioneering role in the development

of the material and its growth methods, which include HPHT (High Pressure, High Temperature) and CVD (Chemical Vapour Deposition). Innovation has played a crucial part in that success,” said Lloyd.

“However, we recognise that, even as a world-leading company, we cannot stand still. Throughout the decades, we held a fundamental, long-standing principle of ‘doing something better today than yesterday’, and this still holds true, all these years later.”

Lloyd is proud to be at the heart of Element Six’s emphasis on continually

learning, developing and improving every part of the business. As Head of Business Excellence, his remit has grown in comparison to his previous role as Head of Quality.

“I now have more of a businesswide focus as we strive for continuous improvement and transformation. At Element Six, we seek to develop and empower our people to tackle both the technical and business challenges we’ll face in the future and utilise the opportunities that will come our way.”

Wipro’s products on AWS such as condition-based monitoring, smart track and trace, and production monitoring and process automation provide smart monitoring technologies, data collection and analysis, product development, supply chain modernization, and maintenance recommendations that revolutionize manufacturing efforts.

Read more about Wipro Industry Solutions on AWS

manufacturers achieve digital transformation quickly and seamlessly.

To ensure consistent top quality, Element Six utilises an end-to-end process with focused controls at every point.

“Our system helps us to build-in quality at each and every stage,” says Lloyd. “With a deep-rooted understanding of the enduser application, we ensure that, during our development phase, the product meets the required performance needs of the customer.”

The company is embracing digitisation of manufacturing processes.

“Harnessing the data that this technology provides allows us to diagnose problems and troubleshoot at stages throughout the process, ultimately improving the finished product,” says Lloyd. “Being truly end-toend means immersing yourself in your customers’ challenges, using your technical insights and materials knowledge to create solutions for an end-user application.”

Lloyd’s previous experiences in quality and supplier development roles have led him to recognise that, to improve a business, you need to work with its people. This is a quality that attracted him to Element Six back in 2010, along with their ethos of continuous development and improvement.

“TO IMPROVE A BUSINESS, YOU NEED TO WORK WITH ITS PEOPLE – AND ALLOW THEM TO GROW AND CONTRIBUTE”

COLIN LLOYD HEAD OF BUSINESS EXCELLENCE, ELEMENT SIX

“Some people say ‘business is business’; I truly believe that ‘business is people’.”

“I recall, as a young quality engineer, always being in awe of the Directors at the car plant where I worked,” Lloyd says. “One in particular was the Managing Director –Sir Alan Jones, who sadly passed away in 2022. I remember once taking Sir Alan to look at a problem on a car. He was genuinely interested – not just in the problem, but also in what I was doing. All the interactions I had with him over the years left me feeling positive; taking his comments and feedback on board allowed me to gain a better understanding of what I was doing and how to continue to improve.

“When he retired, he walked around the entire factory and shook hands with all the staff. He was a genuine leader and so passionate about giving people the opportunity to be the best they could be. This has certainly influenced my attitude, and a willingness to collaborate was shaped at this young age. This collaborative approach is how we’re looking to improve the way we operate at Element Six: it’s important we’re all on the same page”.

Lloyd now works with three junior members of staff at Element Six as part of their extensive mentoring programme,

FASTER, AND FOR LONGER”

COLIN LLOYD HEAD OF BUSINESS EXCELLENCE, ELEMENT SIX

encouraging development and connection between different levels within the business.

During his time at University, Lloyd took part in two industry placements that made up his first experiences within manufacturing and that, teamed with his developmental relationships with managers throughout his career, gave him insight of how important programmes like Element Six’s mentoring are.

Alongside development, key to the teams within Element Six are communication and respect.

“When people feel they are nurtured and listened to, they start to bring new ideas and suggestions to the table, and then take the appropriate actions to implement them,” says Lloyd, referring to both internal teams and customers. He prioritises listening to where to focus business development and working to be open to ideas that allow the business to be influenced by global leaders in manufacturing.

“Our materials and solutions cannot be delivered alone. It’s through the ‘voice of the customer’ that we can both understand and build their requirements into the materials and solutions we sell.”

Through listening to voices both in-house and external, Element Six are moving towards a more digitised process.

AND IS PRIMARILY BASED IN THE UK, IRELAND, GERMANY, SOUTH AFRICA, AND THE USA WHERE IT EMPLOYS OVER 1,900 PEOPLE.

“There is a wave of excitement about the possibilities of digital at all levels in the company,” says Lloyd. “We have developed a long-term digital roadmap that aligns all the sites and business functions, incorporating insights from all levels of the business, from shopfloor staff and administrators to engineers, specialists and senior leaders”.

He sees the increase in technology within the sector as an exciting opportunity to digitise previously manual processes, allowing the team to use the increasing data to improve customer experience, increase product quality, and to continue the company shift to solutions-based manufacturing and client relationships.

“Our expertise lies in the ability to help our customers and partners do things better, faster and for longer,” said Lloyd. “Historically, we’ve been viewed as materials specialists, but it’s exciting to see how our company is changing.”

Element Six is now much more of a solutions-oriented business, working with partners to identify their pain points and develop solutions to support them, with materials expertise and patented technology underpinning the work.

“By re-skilling and upskilling our staff, as an organisation, we hold true to the mantra: ‘We never stop learning!’.”

“WE RECOGNISE THAT, EVEN AS A WORLDLEADING COMPANY, WE CANNOT STAND STILL”

COLIN LLOYD HEAD OF BUSINESS EXCELLENCE, ELEMENT SIX

WRITTEN BY: TOM SWALLOW

PRODUCED BY: THOMAS LIVERMORE

WRITTEN BY: TOM SWALLOW

PRODUCED BY: THOMAS LIVERMORE

Since the mid-20th century, automotive has evolved around the chief component powering mobility—the engine. As the internal combustion engine (ICE) came to fruition, more and more car manufacturers centred their efforts around it to improve performance, increase fuel efficiency, and even to refine their engine sounds, appealing to the fast-driving, thrillseeking car buyers out there.

When it comes to car design, the general trend—particularly among high-end, supercar builders—is the elongated front end to house ever-growing engines, alongside other petrol and diesel components.

In an electrified world, this sort of frontelongated chassis won’t be necessary; EV infrastructure presents a unique opportunity to alter the way cars are designed and built.

Enter AEHRA, which took 2022 by storm when it introduced an SUV to the world that caters for many of the issues we see today in the automotive sector: emissions, unsustainable products, wasteful manufacturing processes, and globalised supply chains, the latter including ties to other organisations’ emissions reduction efforts.

‘A bold new image that challenges the principles of car design’ is probably the best way to describe the AEHRA SUV in a nutshell. The car is both a display of automotive prestige and a model of the future.

Currently, AEHRA rates the car as achieving a near-800km range once operational, which is supported by its incredibly low drag coefficient of 0.21.

The car is designed with a monocoque body, requiring a “highly outrageous” approach to create what Felippo Perini describes as its ‘elegant design’.

Not only does the car defy what is classed as ‘normal’, but it also evolves its supercar heritage by taking the sharp, rigid stance of a high-end supercar and turning it into a singular flowing line that runs the length of its body.

“With the SUV, we have created a vehicle that goes far beyond the conventional standards set by the automotive industry for an SUV, in addition to setting new benchmarks for style and comfort” -

Filippo Perini, Chief Design Officer at AEHRA.Co-Founded by the company’s CEO, Hazim Nada, AEHRA enters into unchartered territory. The company leverages the electrical revolution to produce an ultra-premium EV with sustainable, localised credentials. The SUV was unveiled in the company’s home city of Milan, Italy, where the team astonished the crowd with the sheer stance and scale of the vehicle, which portrays the essence of Italian automotive innovation in a new generation of mobility.

Year founded 16+

Number of employees

difficult to

back to a traditional design

production”

HAZIM NADA CO-FOUNDER & CEO, AEHRA

“It will be

go

once this is in

There are many lessons to be learned from AEHRA’s story around the importance of passion within a team, commitment to sustainability, and innovative steps to be made in manufacturing sustainably— in particular, ensuring cars are infinitely recyclable—and doing so to meet the demands of high-end customers.

How it all began: AEHRA’s Italian automotive heritage Nada himself is a well-educated man who chose to leave his previous role as an oil merchant and instead flip his career on its head. Despite this, it is the vision for AEHRA that caught the attention of some leading members of the Italian car community.

“The first challenge was convincing the engineering partners: many engineering firms have large-scale customers, so for them to entertain a small reality was the beginning. I then had to attract the right type of talent, getting people like Filippo Perini and all the other designers that we now have on board,” says Nada.

Having met with Perini trackside to discuss the idea, it’s safe to say that he took some initial convincing to consider

“The challenge was convincing the engineering partners; many engineering firms have largescale customers”

HAZIM NADA CO-FOUNDER & CEO, AEHRA

the idea that Nada was proposing—a car with a shorter ‘nose’ that defies the conventional trend in the automotive sector. While the idea was still in its infancy at the time, Perini was the first critical stakeholder to challenge the proposal in order to encourage a more provocative approach to the aesthetics of the EV. This resulted in AEHRA not only redefining the car, but pioneering design.

Describing this stage of building the team means understanding the idea that Nada presented to his now colleague.

“It’s the first product that we’ve unveiled, but what I can say is that we’re committed to bringing out vehicles that are developed around the electric powertrain. If we go back in time to the 1920s and 30s,

we’ll see that the automotive industry was experimenting with a lot of shapes, aerodynamics and whatnot.

“All these trials have given way to what we see today with three-body architecture, because it’s the best architecture when it comes to accommodating the thermal and volumetric needs of internal combustion engines.

“This isn’t the same for electric vehicles. We see no reason to continue to utilise the shapes of the 70s, 80s, and 90s.”

AEHRA is, by definition, changing the game by leveraging more sustainable design principles that also accommodate EV architecture in the most intuitive way— giving way to the long nose of an ICE car and shortening the front end of its vehicles.

“The key element that we’ve done away with is the long hood—we’ve shortened the overhangs and developed this monobody architecture. This is the key element; AEHRA is redefining the shape of electric vehicles,” says Nada.

“By doing so, we’ve given a lot of character to the AEHRA SUV that you wouldn’t otherwise see in an electric vehicle. We’re also expanding the cabin space within the same volume of car, changing the customer experience.”

The three-metre-long stance of the SUV is one of its trademark attributes and, when combined with a significantly shorter front end, provides a substantial increase in space inside the car—enough space to comfortably fit four NBA players.

The luxury car with a sustainable conscience

Procurement is an important focal point of AEHRA’s efforts, as the company looks to reduce the number of bespoke components in the car— and even the car body itself.

The sustainable breakthrough can be seen in the monobody formation of the vehicle, which is made using sheet mould carbon (a carbon fibre process that is essential to the company’s production plans). From a material perspective, this is one of the highlights of the car. Using composite material means that the AEHRA SUV is not only made of recycled carbon fibre materials, but is also recyclable at the end of life.

“When it comes to the materials that we’re using, we will be the very first to conduct mass production of a vehicle of this size, these dimensions, utilising sheet mould carbon,” says Nada.

“The resulting structure that is produced within our process will be reutilised for at least five cycles after end of its life, resulting in weight savings by using such materials, which then translates into a direct energy saving that’s also enhancing sustainability.”

When it comes to sourcing the battery and other electrical components of the SUV, Nada assures us that negotiations are taking place to encourage a sustainable supply of equipment for the car. Having put such a strong emphasis on procurement allows the company to localise most of its supplier network and encourage production efforts closer to home.

“So far, we’re able to procure pretty much all of the components within the continent. Using composite materials means we have to stay as close as possible to Italy, because it’s the only country that contains the know-how and production capacity for such materials,” Nada explains.

The team taking on these challenges is one of Italian heritage. Nada himself reached out to some of the key innovators in the automotive world to tap into their expertise thus far. As of now, the production segment of the business will be led by its new Chief Engineering Officer. Plucked from the very heart of the automotive industry, Franco Cimatti is the latest to join the team in hopes that he will encourage the same disruptive ethos of its Founder.

“With over three decades in charge of engineering at Ferrari, and also about five years at Lotus, he’s a particularly important person, because he comes from the core of the vehicle dynamics experience—the

“We will ramp up the demonstration of the two vehicles together, around the world”

HAZIM NADA CO-FOUNDER & CEO, AEHRA

top end of the internal combustion engine experience,” says Nada.

“He has also been in charge of fully electric platform developments at key houses like that of Lotus, so he’s a very important Italian figure and is able to marry all the key elements that we require.”

Nada believes that Cimatti’s presence will not only enhance the company’s ability to produce the car, but also influence the right talent that share the AEHRA ethos—and bring with them the Italian touch.

Technology-driven experience equals luxury

The firm recognises the growing trend for digital capabilities. One of the key benefits of the monobody architecture adopted by AEHRA is its capacity for a revolutionary cockpit experience.

As infotainment is a critical part of any high-end vehicle, the team is focusing on how it can make the SUV more intuitive, as well as make full use of the electrified platform and extra space inside the car.

One of the main drivers of the humanmachine interface (HMI) design is consumers themselves. According to Nada, customers are less likely to want rear passenger screens due to nausea and discomfort—as well as the fact they probably already have one on their person.

The AEHRA will do the impossible and provide passengers a connected experience that allows the car to collaborate with other devices in the digital ecosystem.

“For the rear passengers, we are focusing on these types of experiences: personalised media solutions for each seat that can interact with such solutions. We’re not aiming to have screens in the back,” says Nada.

“The front row will be dominated by this particular screen solution, because it’s very unique and allows a level of productivity and entertainment that is impossible today.”

But the most important feature is the range— 800km per charge—and that will be supported by the battery solutions. The battery pack itself will be somewhere “between 115 to 120kWh”. Though Nada states that “it will be closer to 120 with the solution that we’re currently developing and make use of NCM prismatic cells”.

The AEHRA story is one of technological, engineering and sustainable triumph packed into an EV that will likely evolve as time goes on and trends become evermore digital.

Since the SUV made it into the media, the company has grown more determined than ever by the responses received across various platforms. The design

of the vehicle itself is its main selling point, both to potential customers and the industry itself—in terms of being a feasible, thriving concept, the company has been praised for its exceptional work on the production-ready product. The time is now for AEHRA to secure the heart and soul of the daring automobile.

AEHRA’s aim for the near future is to finalise its negotiations with partners and suppliers to get them on board for the ride—a ride that will soon be split between two vehicles when AEHRA kicks its Sedan prototype development into gear.

“In April, we will ramp up the demonstration of the two vehicles together around the world. As soon as the saloon version is unveiled, we will begin our tour to market both vehicles,” says Nada. “Within the next six months, we need to identify a location to potentially internalise the final assembly. These locations will need to be affordable and workable.”

“When you place our sedan or the SUV close to a traditional vehicle, both really stand out; they’re very different. I think it will be difficult to go back to a traditional design once this is in production.”

“We’ve

AEHRA

Indranil Sircar, Chief Technology Officer for manufacturing and mobility at Microsoft, discusses the company’s core platform capabilities

WRITTEN BY: HELEN ADAMS

The industrial internet of things (IIoT) is an environment of sensors and applications which analyses data from across industrial operations and is used to make sure production runs effectively. The term was first developed in 1999 and is now used across the manufacturing sector.

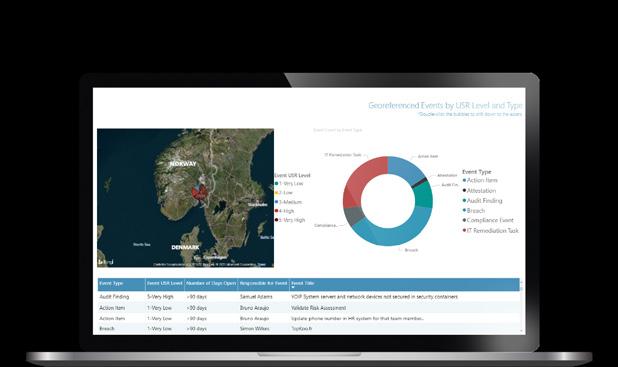

As Chief Technology Officer (CTO) for manufacturing and mobility at Microsoft, Indranil Sircar’s work involves the use of IIoT. He is focused on incorporating the industry and manufacturing vision in business outcomes for customers utilising Microsoft’s core platform capabilities. From a business context, he’s working with the partner ecosystem and Microsoft’s customers to help them realise the value of its core technology.

“I’ve been with Microsoft for a little over 10 years, and my time here has always focused on the manufacturing industry,” says Sircar.

Prior to Microsoft, he was at HP, primarily focused on manufacturing and supply chain as well. Now, from an industrial IoT perspective, Microsoft’s vision is to empower customers to build more agile factories and leverage data to incorporate more automation.

“This is the key focus of our work, but we continue to look at what is next on the horizon, like creating digital twins for factories, facilitating simulations, and becoming more predictive,” explains Sircar. “By using these digital tools, we shift focus to transforming the workforce, allowing manufacturing and supply chain workers to use the data generated to enhance outcomes and performance. IIoT is the foundation on which we connect to the factory.”

This allows companies to gather the right data and then translate it into more

predictions, more insights, more actions and drive automation. This is what Sircar believes will ultimately transform the factory.

“As CTO for manufacturing and mobility, I am focused on shaping Microsoft’s industry solutions strategy, by driving the full value of product innovation and advanced capabilities including IIoT to accelerate digital transformation and value to customers and partners.”

“IIoT is the foundation on which we connect to the factory”

INDRANIL SIRCAR CHIEF TECHNOLOGY OFFICER FOR MANUFACTURING AND MOBILITY, MICROSOFT

Due to the supply chain challenges over the past two years, Microsoft's use of IIoT has changed.

“Recently, we’ve seen that the value chain has become critical to the success of any industry, including automotive, aerospace, defence and retail,” says Sircar. “Manufacturing organisations need to constantly be aware of potential disruptors and plan for a shift in production. For

example, if there are chip shortages, factory closures due to COVID-19 outbreaks or other complications, manufacturers must decipher what is most important to produce and when.”

At Microsoft, the company is constantly building out core capabilities that will enable its customers to achieve their end-to-end results in an integrated fashion. Recently, Microsoft announced the Microsoft Supply Chain Center, which will allow for visibility

A modern network must be able to respond easily, quickly and flexibly to the growing needs of today’s digital business. Must provide visibility & control of applications, users and devices on and off the network and Intelligently direct traffic across the WAN. Be scalable and automate the process to provide new innovative services. Support IoT devices and utilize state-of-the-art technologies such as real-time analytics, ML and AI. And all these must be provided with maximum security and minimum cost.

This is the power that brings the integration of two cloud managed platforms, Cisco Meraki and Cisco Umbrella. This integration is binding together the best of breed in cloud-managed networking and Security. cisco.com

into inventory, material movement, inbound and outbound supply chain and any critical manufacturing functions where raw materials, components and parts are received.

Additionally, customers will be able to better combat disruptions by making informed decisions to plan and prioritise products to manufacture, while remaining transparent with customers.

“It is a little-known fact that we are a manufacturer ourselves,” says Sircar. “Not only does Microsoft understand supply chains, but

we have modernised our own. For example, within our Xbox and Surface supply chain, we manufacture 45,000 SKU’s, ship close to 100m units to 1.3m locations in 120 countries.”

As Microsoft’s data was siloed, sitting in disparate systems and Excel spreadsheets, the team brought all data into a single data lake and created a digital twin of the entire global operation, which provided Microsoft with visibility and signals across factories, parts, logistics providers, destinations, inventory, orders and more — all within minutes.

“We’ll see how customers start to build on the foundation that they’re establishing with IIoT and create the industrial metaverse”

In the recent IoT Signals for Manufacturing report, the company found that 72% of customers are able to scale their connected factory from proof of concepts into various stages of implementation.

“A digital twin allows us to do modelling and simulate possible disruption,” says Sircar. “We are ensuring everyone is acting on one version of data truth. This allows us to push information to the right person at the right time for streamlined decision-making through our control tower. We are able to track our carbon footprint across materials, contract manufacturers, logistics providers, usage and more.”

The benefits are outstanding. Automation has increased by 70% and planning time has gone from five days to taking less than a single day.

“We have scaled the business with 100% more SKUs. We have achieved 100% real-time

tracking through manufacturing and logistics. We have increased customer loyalty with 60% growth in orders and the list goes on...”

Customers are starting to see what IIoT will deliver.

“The report also highlights that customers recognise scalability challenges, such as security (43%), new application development (49%) and skill shortages (45%). We will see customers evolve and address many of these core areas of interest for industrialgrade implementation in their own environment.”

Additionally, customers are leveraging next-generation industrial automation, driven by the adoption of digital technology. Customers are beginning to create more connected products to deliver better services, prediction, and overall equipment effectiveness (OEE). For example, one manufacturing customer added value-based features to help customers extend product lifetimes. Using a connectivity layer on the bearings, the company created a dashboard to monitor the lubrication of machines with little human interaction. It identified four distinct features that create customer value: active information about the current grease level, active information about alarms, remote adjustment of lubrication and a dashboard with additional insights.

“In the long term, we will see how customers start to build on the foundation that they are establishing with IIoT and create the industrial metaverse, which gives companies the ability to simulate, predict and automate virtually any operation,” says Sircar. “This is done using real-time data to create digital representations of systems, automating key business processes, and using machine learning to move from reactive to proactive.”

Lastly, as the next generation of IIoT and digital twins, Sircar believes that the industrial metaverse has the potential to solve some of the world’s most difficult challenges across supply chain resiliency, business efficiency, and global sustainability.

“All of this is happening on the Microsoft Cloud with leading edge companies taking advantage of digital twins, mixed reality, AI, IoT, and the power of the intelligent cloud and the intelligent edge,” he says. “We will start seeing more industrial metaverse investments and implementations coming to life in 2023 and beyond.”

“We continue to look at what is next on the horizon, like creating digital twins for factories or facilitating simulations”

INDRANIL SIRCAR CHIEF TECHNOLOGY OFFICER FOR MANUFACTURING AND MOBILITY, MICROSOFT

The expectations manufacturers face are increasing – customers want their products delivered faster and competition is driving them to be cheaper. Employees want reassurance that their jobs are secure and working environments are safe, while stakeholders want to see emissions are being lowered and waste reduced. AI technology can transform the way manufacturers work in meeting these goals.

Saar Yoskovtiz is the Co-Founder and CEO of Augury, a software development company based in New York that uses AI technology to give customers insights into how their machines are working and which are not working as productively as possible.

“I founded Augury with my Co-Founder, and now CPTO, Gal Shaul in 2011,” says Yoskovtiz. “Since founding the company, my role has evolved from developing the software behind our AI to leading the company’s growth and expansion.”

Yoskovtiz now works with the Augury team on integrating technology from their latest acquisition, Seebo, and expanding its offering of real-time insights to their clients and partners. Augury provides IoT and AI technology to the world’s biggest manufacturers.

“In a nutshell, our sensors monitor machines, and our AI-driven insights predict and prevent machine failures, improving their performance,” explains Yoskovtiz.

“Our Machine Health platform shares realtime diagnostics with maintenance and reliability teams so they can see what to fix and how to fix it, at the earliest sign of any developing issue.”

At the most basic level, Augury helps manufacturers make their production lines more reliable, more productive, and more sustainable, so they can make and deliver the products and services society counts on.

Saar Yoskovtiz is the CEO of Augury, a software company that uses AI and smart technology to help manufacturers save time, money, and emissions

Manufacturing is a lucrative target for cybercrime. As a large industry with valuable data and a growing IoT attack surface, your data is of direct value to hackers.

The idea for Augury came 11 years ago, when Yoskovtiz and his friend, Shaul, discussed the possibilities of using machine learning (ML) to analyse sound.

“Gal was working at a medical device start-up and getting frustrated making service calls for software problems when he could immediately tell by the sound of the device that there were other problems. He started to think about how much time and energy could be saved if we could hear machines ‘talk’.”

The two were set on a path of looking at diagnosing machines based on ML, so started listening to machines. “We spoke to mentors and consultants across different markets, including commercial buildings, factories, car fleets, overseas shipping – even doctors.”

Together, Yoskovtiz and Shaul spent two and a half years building their company,

dedicating time to customer discovery and building the first prototype themselves.

“Today, Augury technology is installed on thousands of machines, with customers that include some of the world’s largest manufacturers, from Hershey’s to ColgatePalmolive,” says Yoskovtiz. “We never stop innovating though. For example, we recently acquired process-health AI specialist Seebo because we believe process and operational performance is the next frontier beyond Machine Health.”

Both believe that smart technology has a lot to offer manufacturers, such as using smart technology to cut waste.

“By tapping into the data manufacturers already have from manufacturing machines and their production lines, manufacturers can learn how to maximise output,” says Yoskovtiz. “Machines are producing thousands of signals daily that can be turned into insights.

“Augury technology has customers that include some of the world’s largest manufacturers, from Hershey’s to Colgate-Palmolive”

SAAR YOSKOVTIZ CEO OF AUGURY

“Updating your technology infrastructure with Machine Health AI-driven insights and continuous sensing means you can harness the mountains of data your plant produces and identify problems with almost 100% accuracy. Even better, you can detect problems before they occur, avoiding unnecessary downtime altogether.”

If manufacturers can improve the performance of their machines, this can impact their energy usage and avoid the

waste of products and raw materials created when equipment fails or doesn’t run optimally.

“Augury uses AI technology in its sensors, which listen to machines and manufacturing equipment for warning signs they are breaking down or not running at full efficiency,” explains Yoskovtiz. “Smart machine health technology captures vibration, temperature and magnetic data from rotating machinery via IoT connectivity. It combines this information

with advanced AI diagnostics and input from human-reliability experts, alerting users when a machine is going to fail, what to fix, and how to fix it.”

The technology continually builds ‘knowledge’, improving at the same time as it monitors the manufacturing equipment.

“Customers everyone will have heard of include the likes of Colgate-Palmolive and Hershey’s, partners like Grundfos and Baker Hughes, just to name a few,” says Yoskovtiz.

One reason for this is because Augury is working hard to lower the emissions that they produce and are able to save money at the same time.

“Healthier running machines use less energy,” says Yoskovtiz. “I’ve seen companies reduce their total energy consumption by as much as 20%, just by getting ahead of problems and eliminating downtime.”

For example, since 2020 Osem Nestlé has been using Machine Health technology to avoid unexpected downtime.

“Recently, one alert on their Sabra hummus production line allowed teams to make an early repair, saving thousands of dollars and preventing a shutdown of their entire factory. In the words of Gofna LIss-Rubin their Open Innovation Manager: ‘Whenever we prevent a failure, we, of course, prevent everything that comes from that. We reduce the amount of labour time, machine time; we reduce all the inputs that are used in our operating machines — including energy, water, and gas emissions’.”

Any improvement Augury has in operation and the reduction of the inputs is helping the company meet their sustainability goals.

“By tapping into the data manufacturers have from machines and production lines, manufacturers can learn how to maximise output”

SAAR YOSKOVTIZ CEO OF AUGURY

Augury works with manufacturers across many sectors – from food, beverages and consumer packaged goods to building materials, forest products and pharmaceuticals.

Valiot’s Federico Crespo & TXI’s Jason Hehman discuss sustainable supply chains & how the Titanium Economy is adopting sustainable manufacturing methods

WRITTEN BY: HELEN ADAMSFor the modern manufacturing sector, ‘sustainability’ has to become more than a buzzword and the supply chain less remote. Stakeholders and customers alike are united in their desire for transparent information on a business’s sustainability credentials. What ESG initiatives are in place? Is there an emission-offsetting programme? A net-zero deadline? Clearer details on supply chain structure and practices should then also follow – how far do items travel? What do Scope 3 emissions look like? What has the business done to keep forced labour out of its supply chain?

Here, two manufacturers tell us about sustainable manufacturing methods and supply chains.

Federico Crespo is the CEO of Valiot, a company that builds innovative manufacturing automation solutions for businesses such as Heineken, John Dere, Metalsa, and Coca Cola. Here he discusses with us the ways a sustainable supply chain can be generated.

“Valiot provides integrated AI solutions that help improve factory efficiency and optimise the value chain,” explains Crespo. “Its products, FactoryOS and ValueChainOS, enable manufacturers to anticipate and identify production bottlenecks and mitigate pain points in the production process before they become a major concern, actually making the operation smarter.”

One way in which AI is used at Valiot, is to strengthen the supply chain.

“Our ValueChainOS product oversees the operation of one or multiple factories to optimise the entire value chain. Everything is connected to the same data lake, allowing key processes – like the ever-

6 - 7 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

changing demand forecast and inventory management – to be in the same space,” explains Crespo.

AI algorithms then run thousands of scenarios to provide the most optimal production sequencing. Continuous information analysis predicts factory behaviours and guarantees the production sequence remains optimal. If it’s not, it autonomously reschedules and provides the ideal plan.

“This optimises service and inventory levels, significantly reducing production cycle times and maximising productivity and throughput,” says Crespo, who is also excited about the future of factory automation and its potential to revolutionise the manufacturing industry.

“I also expect to see a greater emphasis on sustainability, digital logistics and more sophisticated tracking systems”

FEDERICO CRESPO CEO, VALIOT

“For years, factories have been relying on outdated and inefficient manual labour to produce goods, which has led to higher costs, slower production, and a decrease in quality and output.

“Factory automation has the potential to drastically reduce these inefficiencies, resulting in improved production, lower costs, and better quality goods. Automation also allows factories to focus on core processes, such as design and product development, while the automation system handles the tedious and time-consuming tasks associated with production.”

Ultimately, Crespo believes that factory automation is the future of manufacturing and he’s excited to be a part of it. “With the right tools, training, and support, I am confident that our clients will be able to see the benefits of automation for their businesses,” he says.

In 2023, Crespo expects the global supply chain to become increasingly digitised and automated, with advanced technologies such as blockchain and predictive analytics being more widely utilised.

“I’m expecting to see an increase in the use of 3D printing and other new technologies. These could allow companies to quickly and easily produce customised products with minimal materials and waste,” he says. “I also expect to see a greater emphasis on sustainability, with more companies understanding the importance of creating a more sustainable supply chain, with a greater emphasis on digital logistics and more sophisticated tracking systems that allow companies to better monitor their supply chains.”

Crespo hopes to see the global supply chain become more interconnected, with more companies collaborating and sharing

“More companies need to understand the importance of creating a more sustainable supply chain”

FEDERICO CRESPO CEO, VALIOT

data on a global scale: “This could lead to greater efficiency and cost savings for businesses, as well as a more transparent and secure supply chain.”

Jason Hehman is Client Partner at TXI, a product innovation consultancy that builds engaging digital products to transform businesses.

“I help our clients tackle their most interesting and difficult business challenges by establishing trust among product teams

and customers, breaking down internal silos, and developing resilient, innovative cultures,” explains Hehman. “We provide pragmatic advice that helps guide leaders through the product innovation process — from new product discovery to delivery and beyond.

“We’re unique in our space because of our commitment to engineering excellence, continuous discovery, and research-driven design thinking. We work with clients in healthcare, life sciences, digital health, biopharma, retail, education, and manufacturing.”

Stakeholders and customers alike are united in their desire for transparent information on a business’s sustainability credentials.

“Consumer and investor pressures for sustainability create opportunities for manufacturing companies to differentiate themselves”

JASON HEHMAN

CLIENT PARTNER, TXI

TXI works to understand digital product user behaviours and needs, then build platforms and applications that help meet them. For manufacturers, this can involve engaging with their customers in new ways, understanding shifts in their ordering and purchasing processes, and developing new, innovative tools and product offerings that serve an evolving industrial market. The result is great process flexibility, increased productivity and revenue, and higherquality production.

Hehman himself is fascinated by what’s dubbed ‘the Titanium Economy’ and its evolving role in manufacturing. Coined by

McKinsey consultants in a book with the same name, the titanium economy refers to a group of over 4,000 small-to-midsize industrial firms that have transformed their business with technology over the last decade.

“The average consumer doesn’t know their name, but they develop the parts and materials (think: truck parts, plastic lumber, and colour enamels) for things we use every day. Further, their business performance has rivalled that of flashier tech companies over the last decade,” explains Hehman. “These under-appreciated firms are developing a digital-first culture of innovation and using it to transform their operations with technology. As they shifted from traditional manufacturers to industrial technology companies, they didn’t just revamp old processes with automated equipment — they’re adopting new ways of thinking that lead to new product applications, custom offerings, and sustainable manufacturing methods.”

Naturally forward-thinking, titanium economy companies are leaders in decarbonising operations and accelerating green initiatives.

“Consumer and investor pressures for sustainability create opportunities for manufacturing companies to differentiate themselves by providing green alternatives to traditional materials and energy sources,” explains Hehman. “Companies that are vocal about their sustainability progress also find it easier to align talent and supplier relationships with their values.”

The manufacturing sector – from the Titanium Economy to newly-founded companies – is clearly moving in a sustainable direction not because it’s a popular choice, but because it gets results.

In the early hours of 6th February, 2023, the border of Turkey and Syria was struck by a 7.8 earthquake, affecting both countries. The fiercest for 100 years, up to 50,000 people have lost their lives so far.

Just a week or so later, a smaller earthquake – measuring 6.3 on the Richter Scale – struck in a similar spot, followed by a slew of powerful aftershocks that compounded the destruction.

The sheer scale of devastation will cause conflicting and ongoing supply chain disruptions to pile atop one another due to damaged ports, bridges, and roads across Turkey, with manufacturing companies similarly impacted. Supplies such as food, water, and other aid have already been difficult to deliver to areas in both Turkey and Syria, with debris blocking roads and many other buildings on the cusp of collapse.

Turkey’s manufacturing sector includes that of vehicles, responsible for 15.2% of Turkey’s total exports and totalling US$23.9bn of the country’s revenue. So here, we’re taking a look at the Top 10 manufacturing companies in Turkey –and wishing them a quick recovery.

Istanbul

50 employees

Co-Founder: Ergin Aydin

Leading apparel manufacturer Blok Moda creates and exports ladies knitwear, providing customers with their technical expertise and top quality products, using their own collections to put together on-trend pieces. The company has invested in high-standard technology and has a minimum production capacity of 200k pieces each month.

Regularly seen at fashion and fabric fairs around the world, Blok Moda’s creative team reviews domestic and international fabrics, patterns, and accessories to help them create the trendiest design for loyal customers.

Most recently, the company has been looking for ways to make sure their garments have the highest sustainability standards.

Izmir

50 employees

Assistant General Manager: Sedat Coşkun

Medical products manufacturer