Manufacturing magazine is an established and trusted voice with an engaged and highly targeted audience of 2,000,000 global executives

Digital Magazine

Website Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

WORK WITH US

In this issue, we look at the Top 10 sustainable manufacturers, Factories of the Future, and why the manufacturing sector is so well-suited to veterans once they return from service

Welcome back to Manufacturing Digital! In this issue, China Performance Group’s Coral Li & Aurora Zhai explore Factories of the Future and supply chains while Ralf Schedel, who leads market development at Giesecke+Devrient’s automotive business, shares his thoughts on the new expectations for car manufacturers.

Meanwhile, Laura Capper, Head of Manufacturing & Construction at NatWest, discusses how she helps manufacturers minimise energy costs and advance their sustainability credentials.

Finally, QAD Redzone’s Lance Olmstead talks about his journey back to civilian life after years of service and how the manufacturing sector can support veterans. We also take a look at the Top 10 most sustainable manufacturers – as we’re certainly going to need them. Keep looking up,

Helen.Adams@bizclikmedia.com

QAD Redzone’s Lance Olmstead talks about his journey back to civilian life after years of service and how the manufacturing sector can support veterans ”

Innovators are paving the way for a more resilient, sustainable and efficient future. The rules have changed. It’s time for DISRUPTION.

Tech LIVE Virtual returns to highlight the innovators changing the industry through expert keynote speakers, interactive fireside and panel discussions. This exclusive 1-day virtual event will bring together the greatest voices in the industry for an essential deep dive into the future of Technology, AI and Cyber.

Brought to you by BizClik, Technology, AI and Cyber Magazines, the event will shine a light on essential topics such as the AI revolution, quantum computing, the virtual workplace, technology’s place in sustainability and much more.

It’s time for DISRUPTION.

Position your business as a pioneer in Technology and showcase your values, products and services at Tech LIVE Virtual.

This is your chance to share your innovations with the technology community by making an impact in front of fellow decision-makers and influencers as well as accessing potential partners via an active and engaged audience.

See you on the 8th June 2023.

014 BIG PICTURE Manufacturers head for decarbonisation

016 FIVE MINS WITH Kanti Prabha is the President of contract lifecycle management company Sirion

020 LIFE TIME ACHIEVEMENT

Mary Barra is CEO of General Motors, a role she started in 2016, after beginning work at GM in 1980

078 THE ROYAL MINT

Inside the tech-led reinvention of Britain’s coin maker

096 SUSTAINABILITY

Helping manufacturers reach their sustainability goals

104 MICROSOFT

Mike J. Walker at Microsoft empowers pharma supply chain innovations

120 TECHNOLOGY AND AI

Why veterans make an excellent fit in manufacturing

128 CAPGEMINI INVENT

Capgemini Invent helps companies hit their sustainable goals

146 TOP 10 Sustainable manufacturers

158 MICROSOFT

Microsoft empowering manufacturing firms to accelerate supply chain innovation

172 BIZERBA

Why Bizerba prides itself on being 'stronger together'

188 EVIDEN

The €5bn startup helping clients accelerate digital transformation

204 FARADAY FUTURE

The leader in luxury electric vehicles

096 078

104

Join the must-see virtual event disrupting procurement and supply chain on the 28th of June 2023.

This year, we are bringing you a solely virtual event, Procurement & SupplyChain LIVE Virtual will highlight the innovators changing the industry. Brought to you by BizClik, Procurement & SupplyChain LIVE Virtual will be held on 28th June 2023, streaming remotely to virtual audiences around the world.

The unmissable event will feature expert keynote speakers, interactive fireside and panel discussions, and more. Do not miss this 1-day deep dive into the disruption and the future of procurement, supply chain and logistics.

Do you want to position your brand in front of thousands of innovators, decision-makers and influencers?

Sponsor Procurement & SupplyChain LIVE to unlock the future of your business, access thousands of potential partners and influence businesses at the highest level.

Both global giants and innovative start-ups alike can discover the ideal platform with easy access to an engaged and active audience.

Contact a member of our team today to discuss sponsorship opportunities.

See you on 28th June 2023.

Innovators are paving the way for a more resilient, sustainable, and efficient future. The rules have changed. It’s time for disruption.▶ Watch our showreel from PROCUREMENT & SUPPLY CHAIN LIVE London 2022

83% of manufacturing businesses would like to decarbonise their vehicles and switch to EVs.

Cost, fears around efficiency, and a lack of infrastructure are delaying the EV evolution, yet many businesses have firm 2030 targets and sustainability goals.

Kanti Prabha is the President of contract lifecycle management company Sirion.

Sirion’s goal is to simplify how legal, procurement, finance and sales teams can author, negotiate and sign compliant contracts with embedded risk control, while being guided by AI-led contract intelligence.

TITLE: SAAS SPECIALIST COMPANY: SIRIONLABS

INDUSTRY: SOFTWARE DEVELOPMENT

LOCATION: CANADA

“I’m the Co-Founder and President of Sirion, a pioneering contract lifecycle management (CLM) company that fuses large language models – used by the likes of ChatGPT and best-in-class legal AI – to revolutionise how contracts are created, negotiated, and managed. As a founding member on the executive team, I’m deeply involved in guiding the product’s evolution, leading research and development around legal AI, and exploring its many applications and use cases within the CLM domain.”

» “After graduating with a degree in chemistry, I was leading a team of patent reviewers and working on developing techno-legal solutions for large enterprises at UnitedLex. That’s where I met Ajay Agrawal, and, after working with him for a few years, he invited me to join him in launching Sirion. Our first customer was HewlettPackard (HP). They reached out to us after a large acquisition, asking us to find a technological solution that would enable HP to centrally store thousands of contracts. We rose to the occasion by developing our own platform; and as we did, we realised that a repository was just one piece of the contract management puzzle that so many large

enterprises were struggling to solve. This idea inspired us to create Sirion, a true full-stack enterprise class CLM solution that not only enables businesses to store their contracts, but also create, negotiate, and manage the outcomes and value enshrined in them.

“Today, Sirion is used by more than 250 of the world’s most valuable companies in 70+ countries, to manage 5m+ contracts worth upwards of USD$450bn with a common goal: to build risk-free, valuedriven, highly-efficient contracts.”

»

“Manufacturing operations today aren’t as simple as they used to be

“Manufacturing operations today aren’t as simple as they used to be even 25 years ago”

even 25 years ago. Supply chains have been stretching further and further in search of cost efficiency, fragmenting it into a delicately interconnected web of suppliers, subcontractors, and contract manufacturers. If we simply take the example of Apple’s iPhones, for instance, suppliers in 43 countries and six continents work together to build them. And that’s just the production side of it. When we add distribution to the mix, it grows even more complex with businesses having to manage multicountry, multi-region deals, rebate structures, and more.

“Now, think of this on a global scale. Decentralised buy- and sellside processes involving such a set of interdependent parts can lead to major discrepancies and several maverick operational silos within a single manufacturing value chain. The result: significant financial repercussions.

“This is the issue that Sirion CLM strives to solve. By creating a centralised, unified contracting process. CLM can standardise global processes, be it procurement or sales, both within the enterprise as well as across third-party partners. So, a manufacturer located in France can rest assured that their sourcing plant in Shenzhen or their distribution hub in Johannesburg are controlled by a centrally-enforced contracting process and risk playbook whenever they have to create, negotiate, sign or even renew an agreement.

“In addition, with a CLM in place, there’s visibility across their sourcing and distribution chains to ensure that everything is in compliance with local and global regulatory policies.”

» “When it comes to procurement, Sirion offers front-line, self-service contracting capabilities that allow enterprises to rapidly draft contracts, act on supplier information, surface and remediate risks hidden in contracts, and significantly shorten the legal review cycle. But this is only where it begins.

“Sirion is uniquely designed to not just simplify the pre-signature stage of a contract but to expand the scope of post-signature manageability of contracts. By mapping raw performance data extracted from the enterprise IT ecosystem, it allows procurement to defend revenue and realise hard savings to the tune of 6-12% at the invoice level.

“On the other hand, Sirion supports sales teams by cutting quote-to-contract time by as much as 80% and reducing the complexities of cross-functional

“Decentralised buy- and sellside processes can lead to discrepancies and several maverick operational silos within a single manufacturing value chain”

dependencies through self-service contract creation. Its AI-guided legal review capabilities help get the job done 90% faster, further saving enterprises’ time and effort. It also captures post-signature performance data, which can be used to lead account growth conversations.

“Moreover, Sirion helps vendors outline clear deliverables and gain full visibility for all parties involved throughout the course of the contract lifecycle, subsequently enabling better delivery performance and stronger relationships.”

» “We’ve just finished setting up our UX Center of Excellence in France –which is expected to have a significant impact on Sirion’s useability – and we’re

currently working on building out our AI R&D Center of Excellence in North America. The idea is to bring together the expertise and niche cognitive capabilities of Legal AI and the natural language processing power of the recently hyped large language models (LLMs), such as ChatGPT.

“At Sirion we believe that the future of contracting involves the combined power of these two distinct applications of AI. Although LLMs have the cognition to understand and generate natural language, Legal AI can enrich this capability with legal expertise and contextual understanding of contract language. Bringing these together will pave the way towards the future of autonomous, fully-computable contracting. This is what Sirion is working towards building.”

Mary Barra is CEO of General Motors, a role she started in 2016, after beginning work at GM in 1980

Mary Barra is Chair and Chief Executive Officer of General Motors. She aims to advance the customer experience and embolden GM’s core vehicle and services business, in addition to leading the mobility evolution through advanced technologies such as electrification and autonomous driving.

GM founder William Durant set the company up in Flint, Michigan, US. He had a lot of drive and a great deal of ambition: in 1886, he bought a horse cart company and, after some successful marketing at a local fair, received orders for more than 600 carts. 15 years later, the DurantDort Carriage Company had grown from a $2,000 investment to a USD$2m establishment and the largest vehicle manufacturer in the country. Durant became a millionaire by the age of 40 and was named the "King of Carriage Makers", before going on to found GM in 1908.

One century later, GM is leading the automotive industry in a world with ‘Zero Crashes, Zero Emissions and Zero Congestion’ – and CEO Mary Barra is at the helm.

From a co-op student to CEO at GM Barra started her career at GM back in 1980 as a General Motors Institute (Kettering University) co-op student at the Pontiac Motor Division. In 1985, Barra graduated with a Bachelor of Science degree in electrical engineering and she completed a Master of Business Administration from the Stanford Graduate School of Business later in 1990.

Barra took on several roles at GM on her way up to CEO. In 2011, she became Senior Vice President, Global Product Development. In 2013, Barra

was promoted to GM’s Executive Vice President, Global Product Development, Purchasing and Supply Chain.

Barra is Chair of the Business Roundtable and an association of chief executive officers of America’s leading companies, as well as serving on the Board of Directors of the Walt Disney Company, the Duke University Board of Trustees and the Detroit Economic Club.

Barra once said GM needed to “stop making crappy cars”, so that’s what GM did. During its third quarter, GM delivered strong results – including record third-quarter revenue despite supply chain challenges.

MARY BARRA

TITLE: CEO

COMPANY: GENERAL MOTORS

INDUSTRY: MANUFACTURING

LOCATION: DETROIT

Mary Barra is the Chair and Chief Executive Officer of General Motors. She arrived at the company in 1985 while studying at Kettering University. She became Vice President of 2008 and, in 2016, earned the role of CEO.

Barra is responsible for leading the Board of Directors, establishing General Motors' strategic direction and managing the company’s dayto-day global operations, which stretch across 125 countries.

Barra is dedicated to leading GM ‘towards a future of zero crashes, zero emissions and zero congestion’.

These results will keep GM on the right track: this is the company’s third consecutive year of full-size pickup leadership and its 22nd year as the fullsize SUV leader.

GM earned more than 8% of the US electric vehicle market in this quarter due to extraordinary sales of the Chevrolet Bolt EV and Bolt EUV.

“The GM team continues to deliver incredible results, and our Q3 earnings report is evidence of that,” said Barra.

General Motors’ automotive vision is to build a world with no crashes, emissions or congestion, and it is also dedicated to zero exclusion. As an inclusive company, GM is proud of the welcoming environment it has made over the past decades, where ‘everyone feels welcomed and valued for who they are’. The 167,000 GM employees are encouraged to bring wide-ranging perspectives and experiences to solve supply chain and sustainability challenges.

“Diversity is all about the pipeline,” Barra said. “It’s not just about gender, but about all forms of diversity. At GM, when we search for executive candidates, we require a diverse slate. If we find that a position has no diverse candidate, I ask the question, ‘What are we doing so that three years from now there will be a diverse candidate to consider?’”

GM is proud to be leading equal representation from an executive level and will welcome the day when female leadership is the norm. Barra is a founding member of GM’s Inclusion Advisory Board, on which she serves as the Chair.

“The success of every company is about its people,” Barra told Michigan Daily. “I make sure I understand key parts of the business and, having worked in an assembly plant, having been a plant manager, having been responsible for product development, having understood HR – all of those things really round out to give me a lot of the skills that I need as CEO.”

“Diversity is all about the pipeline. And it’s not just about gender, but about all forms of diversity”

WRITTEN BY: HELEN ADAMS

PRODUCED BY: MIKE SADR

WRITTEN BY: HELEN ADAMS

PRODUCED BY: MIKE SADR

Kevin Nelson is the Chief Procurement Officer at BD (Becton, Dickinson and Company), a medical technology company based in Franklin Lakes, New Jersey. His responsibilities include overseeing all third-party spend, including direct and indirect.

“I’ve been in the procurement profession for a number of years, starting my career in the high-tech industry and evolving into roles within the biotechnology arena before leading strategic sourcing at C. R. Bard, a medical device company that BD acquired about six years ago,” he says.

BD is one of the world’s largest medical technology companies. Its purpose is ‘advancing the world of health’ by improving medical discovery, diagnostics and the delivery of care.

“Roughly 90% of patients coming into a clinical setting in the United States are going to use a BD product,” says Nelson.

Products vary from well-known medical devices such as needles, syringes and blood collection tubes to sophisticated electromechanical devices, diagnostic instruments and reagents.

COVID-19 changed the world foreverhybrid working is the new normal, face masks are as common as earrings and you never leave your house without your keys,

how his team mitigates supply chain risks and delivers innovative solutions in an ethical way

Gainfront’s AI driven technology platform is designed to increase procurement efficiency while solving the unique procurement process challenges that arise from today’s remote and hybrid work environments and increased focus on corporate social responsibility around supplier diversity, ethical compliance, and reducing green house gas emissions

Gainfront’s highly customisable, modular, procure-to-pay powerhouse platform for Diversity, ESG, and collaboration

Gainfront is a platform that meets the procurement needs of today’s business landscape, focusing on mandates related to diversity, supplier diversity, workforce diversity, as well as ESG tracking. Led by Hetal Mehta, CEO of Gainfront, the company provides organisations with an innovative way to achieve compliance to preferred buying while offering powerful workflow automation, which is essential in today’s hybrid work environment.

Gainfront enables customers to easily configure their workflows, whether in sourcing, finance, or HR, granting them full control over the process through team collaboration and audit trails. As a complete Procure-to-Pay platform, Gainfront fully embraces diversity, ESG, and workflow automation requirements, providing a comprehensive solution for procurement professionals.

Gainfront recognises the pressing need for finding new, diverse, and environmentally conscious suppliers on a global scale. With current supply chain challenges, customers often struggle to identify and source from new suppliers. Gainfront addresses this issue by offering their customers access to a strong and robust global Discovery database. Mehta highlights the importance of this database, stating that it resolves the problem of customers being unable to replace suppliers due to a lack of viable alternatives.

In the context of today’s hybrid work environment, there is a growing need to find qualified suppliers while managing risk profiles. Gainfront introduces the RFX Concierge service, which allows customers to source suppliers easily by providing preliminary criteria. By leveraging this service, Gainfront identifies qualified suppliers and connects them, significantly reducing customers’ search time by almost 60%.

“Gainfront recognises the importance of collaboration in today’s hybrid work environment,” says Mehta. “The company’s horizontal approach to workflow automation provides customers with team collaboration capabilities, allowing for efficient communication and tracking of audit trails. By gathering all decision-making processes in a team-collaboration environment, individuals are held accountable, mitigating the risk of miscommunication or lost information.”

Gainfront’s Partnership with Becton Dickinson (BD) Becton Dickinson (BD) has been a customer of Gainfront for the past three years. Mehta and her team have been instrumental in helping BD manage supplier diversity, spend management, and tracking, thereby assisting them in achieving their BDR goals. Through Gainfront’s database, BD gains access to new suppliers, enabling them to meet their sourcing and diversity goals successfully.

wallet, phone and hand sanitiser. The postpandemic planet changed the procurement process too, especially for those dealing with medical equipment.

“The world has changed and our supply chains need to adapt,” said Nelson. “When we look at the environment, or the world around us right now, we are continuing to see more disruptions every year. We’ve been tracking this, not only within BD, but also within the healthcare and the life sciences industry.”

More frequent disruptions in the supply chain are happening year over year, which include plant shutdowns, supplier shutdowns, supplier insolvency, port strikes, geopolitical tensions and more.

“BD has taken this ‘moment’ to lead a ‘movement’ to create the supply chain of the future, and that all starts with enhanced procurement visibility and agility”

KEVIN NELSON SENIOR VP & CPO, BD

TITLE: SENIOR VP & CPO

COMPANY: BD

INDUSTRY: MANUFACTURING

LOCATION: NEW JERSEY, US

Kevin Nelson has served as BD’s SVP and Chief Procurement Officer for the past five years focused on applying advanced Procurement strategies to help BD navigate supply chain disruptions and inflationary challenges during the pandemic. Kevin created BD’s Responsible Sourcing Program which strives to develop an ethical, agile supply chain capable of sustaining external pressures.

Prior to B, Kevin was VP of Global Strategic Sourcing C.R. Bard where he introduced an advanced sourcing methodology that delivered solid yearover-year savings as well as additional value through innovative supplier relationship management, revenue generation, reduced backorder and a supplier risk management program.

“All these things result in some sort of disruption to the supply chain,” says Nelson. “We have continued to see that and experience it. That has led us to asking, what do we need to do differently? Because we’re probably not going to get back to this ‘normal’ that everyone’s been waiting for. BD has taken this ‘moment’ to lead a ‘movement’ to create the supply chain of the future, and that all starts with enhanced supply chain visibility and agility.”

This “movement” at BD has resulted in multiple initiatives to evolve procurement strategies to be more resilient, agile and socially responsible.

Kevin received his B.A. from the University of North Dakota and MBA from Boston University. Kevin is a member of the Healthcare Transparency Institute, Strategic Marketplace Initiative, National Minority Supplier Development Committee, Institute for Supply Management and sits on multiple advisory boards in the medical device industry.

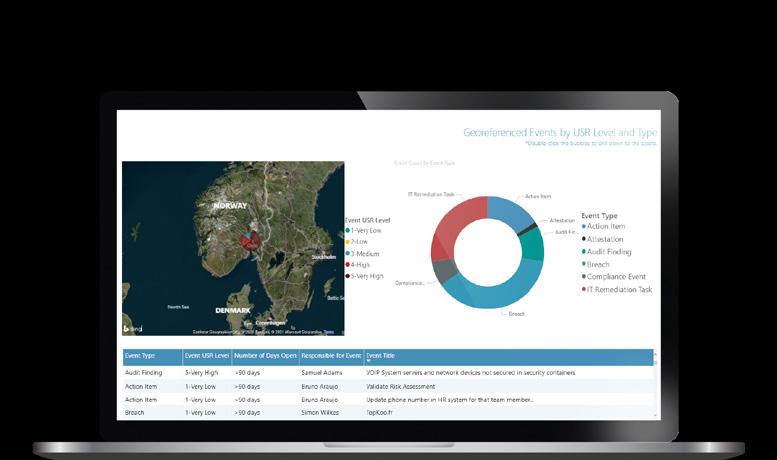

Enhanced visibility via AI & ML

“To start building our supply chain of the future, we mapped our product lines to identify which ones are considered critical to healthcare,” Nelson explains. “These are products that the healthcare industry has

deemed essential to care for the patients, and if they aren’t on the market, there’ll be a problem around meeting basic or routine healthcare needs.”

BD identified over a hundred different product lines that are critical to healthcare. Nelson and his team conducted an assessment on every product line, looking at every item in the bills of materials and ensured remediation is in place for the critical high-risk materials.

“A product line may have a few items in the bill of materials, or it may have a few hundred items. We do an assessment on every item in that bill of materials and on every supplier, to see where potential risks are.”

BD creates a composite score that allows them to plot product lines to see which ones are in a high-risk quadrant.

“We’re looking at how we can help a community where our customers are living”

BD: Ensuring a resilient, responsible and agile supply chain

KEVIN NELSON SENIOR VP & CPO, BD

“We can take that back to our business units and work with them to create mitigation plans to dual source, adjust inventory levels, and/or regionally source some of the material or components.”

90%

As part of the work to de-risk high-priority products, BD uses discovery technology that employs AI and machine learning ML to map subtier supply chains for critical products and leveraged that visibility to uncover hidden risks in its suppliers’ extended supply chains.

“During COVID-19, 80% of BD’s supply chain disruptions didn’t come from our direct suppliers,” Nelson adds. “They came from our suppliers’ suppliers or even three or four levels down the chain. Unless you have mapped your entire supply chain and employ

very sophisticated technology, it is very hard to know how a disruption at a third or fourth-tier supplier will impact your product.”

An example of the payoff of this work was a recent paper strike in Finland. Because BD mapped the supply chain, the procurement team knew that pulp from Finland was used in medical grade labels the company uses and that there were very few alternate suppliers. BD received early warning signals from the risk intelligence partner along with the visibility to understand the issue early on, work with its partners to find alternate sources and secure inventory of labels well in advance of other companies or industries that would be vying for the same label stock.

Roughly 90% of patients coming into a clinical setting in the United States are going to use a BD product

The life sciences industry continues to experience unparalleled innovation as investment and talent flow into the sector and breakthrough discoveries happen at a rapid pace.

Named the 2021 BD Sustainability Supplier of the Year, JLL helps life sciences companies create compelling real estate and facilities strategies that improve efficiency, mitigate risk and deliver a sustainable workplace. Lay the groundwork for rapid growth →

Creating a socially & environmentally responsible supply chain BD knows its customers want them to provide high-quality products at a fair price and that they expect more than the basics. Improved resiliency, visibility and agility are adding value, but the company is also focusing on sustainable business practices that are environmentally, ethically and socially responsible.

“At BD, we stay true to our values, including doing what is right. We set up the Responsible Sourcing Program to ensure we embed supplier responsibility and sustainability in every purchasing decision we make,” Nelson explains.

This includes partnering with ethical and diverse suppliers, helping protect human rights and working to ensure environmental stewardship.

“Our customers want to understand the bigger picture, too,” Nelson explains. “Are they buying a product from us that is sourced from an ethical and responsible supplier paying fair wages to its workers?”

BD ensures compliance in these areas through ongoing assessments, desktop and face-to-face audits and close partnerships across its supply base. This is all to ensure that suppliers understand exactly what BD

“Unless you have mapped your entire supply chain and employ very sophisticated technology, it is very hard to know how a disruption at a fifth-level supplier will impact your product”

expects when doing business with them, while also making sure risks are anticipated and managed effectively.

Like most companies, Nelson and his team have certainly found some areas of concern in their network that need to improve.

“Instead of moving away from that supplier and letting it be someone else’s problem, we’ve tried to see how we can work with them to identify an area they need to improve in. If they’re able to, that’s great. If not, then we’d have to move away. So far, we’ve been successful in mitigating issues. We’re working to help improve human rights around the world while ensuring important medical products get to those who need them.”

Another focus area of BD’s Responsible Sourcing Program is supplier sustainability. This examines where suppliers are driving reductions in greenhouse gases, diverting waste away from landfills and understanding how much renewable energy they use. The Responsible Sourcing team is also working internally with product stewardship and category management to develop and implement strategies to eliminate materials of concern where possible.

“The partnership is that three-legged stool: our customer, our internal stakeholders and our suppliers”

KEVIN NELSON SENIOR VP & CPO, BD

How well do you know your suppliers?

Or even your suppliers’ supplier?

Get clear visibility and unmatched intelligence to make faster, smarter supply chain decisions. Everstream reveals supplier, material, and revenue risk before anyone else. With the world’s most accurate and reliable data, network graphing, and human analysis, Everstream empowers supply chain leaders to build strong, agile, and sustainable supply chains.

Take control of your supply chain with Everstream everstream.ai

everstream.ai/demo

KEVIN NELSON SENIOR VP & CPO, BDsustainable sterilisation technologies, and addressing materials of concern (MOC).

The third area of focus of the Responsible Sourcing Program is supplier diversity, which has gained a lot of momentum in the US.

“We pivoted our supplier diversity focus from one that historically assessed our spend with small businesses and diverse suppliers, which was more of a reactive approach. Today, we are looking at economic impact in terms of how we’re helping different regions and local economies by using diverse and small businesses that are truly making an impact. We’re looking at how we can help a community where our customers are living,” explains Nelson.

“The Supplier Sustainability pillar includes working alongside our R&D team and business units to identify products, materials and components that are ‘greener’ in nature while also making products that are more effective, efficient and economical,” Nelson explains. “This might be a packaging component that uses less energy to make or is recyclable.”

In 2022, BD launched the Sustainable Medical Technology Institute, a model of practice within the organisation that brings together BD researchers and engineers, as well as quality, regulatory, policy, sourcing and operational expertise, to focus on reducing the environmental impact of the company’s product portfolio in three areas: adopting sustainable product design strategies, developing and deploying

Finally, there’s end-to-end transparency, which is connecting back to the customer and providing enhanced visibility to them. “The key is providing this information proactively and transparently to the customers, to the patients, before it’s a problem, so they have the ability to do something in advance.”

As with any medical manufacturer, BD’s partner ecosystem is vast.

“Partnering with our customers upfront is a key priority for BD. We aim to identify the customer requirements and expectations and build those into our long term strategies and initiatives,” he explains.

From day one, BD’s style has been to collaborate and work with its partners, which was essential during the pandemic.

“We came in working together, wanting to figure out a solution with our supplier partners, as opposed to demanding, ‘Shift this or I’m going to move away from you’.

“Instead of moving away from that supplier, we’ve tried to see how we can work with them to identify how they can improve”

“The partnership is a three-legged stool: our customer, our suppliers and our internal stakeholders that includes business units, Quality and Regulatory, among others.”

This work is further strengthened through strategic collaboration and public-private partnerships with government agencies, including the FDA, HHS, POTUS/White House – and industry collaboratives like Advamed – to address supply chain and sourcing issues that plague the broader healthcare industry.

Being able to incorporate those areas into BD’s strategy has allowed what Nelson sees as a resilient end-to-end supply chain.

The momentum of BD’s procurement supply chain team has been exciting for Nelson and his team.

“We’ve experienced very little turnover in our function, and I think a big reason for that is that people see the movement we are driving and understand we have become extremely vital to BD, our customers and the patients they serve. We are on the frontlines; we are helping shape strategy as we go forward here.”

Nelson views this as an entirely different kind of mindset and even acumen, from a team perspective.

“I think it’s been refreshing for the team to pivot away from historical firefighting or cost-reduction to facing the bigger opportunity we’re trying to address.”

“We have more engineers on the team now doing more,” says Nelson. “Our engineers look at an existing product line and see what we can do to redesign elements that can meet the needs of our customer and patients, reduce our overall risk exposure and benefit BD as well.”

China Performance Group’s Coral Li & Aurora Zhai discuss digital twins, ‘Factories

28.7%

of the world’s manufacturing output takes place in China. The north-eastern coastal city of Shanghai is its biggest hub, with over 2,000 container ships leaving the port each month delivering cars, electronics, and clothes to the world. Megacity Beijing is home to 21mn people and thousands of businesses – including China Performance Group.

Coral Li is the Sourcing Manager at CPG’s Beijing office, where she manages the work of CPG’s Sourcing and Quality Assurance teams to ensure clients’ short- and longterm China-sourcing goals are achieved in a cost-efficient way, both in terms of time and money.

“China Performance Group (CPG) provides support to importers who seek excellence from their China supply chain management. We use a transparent, fee-based approach, ‘The China Sourcing Solution’, which enables

global companies to manage complicated business transactions from afar and enjoy all the benefits of their own professional China office without any of the burdens,” Li explains. “Our approach provides companies with a dedicated sourcing team and branch office in China, tailored to their specific needs and objectives. The CPG team manages all the company's sourcing processes to deliver predictable, repeatable results.”

At CPG, Factories of the Future will play a big role.

“The ‘future factory’ will have digitalisation at its core, running with the aid of digital twins, artificial intelligence, big data, and constantly evolving production that requires innovative information technology. Through the digitalisation of R&D, production, manufacturing, marketing, and management, enterprises will run based

Wipro’s products on AWS such as condition-based monitoring, smart track and trace, and production monitoring and process automation provide smart monitoring technologies, data collection and analysis, product development, supply chain modernization, and maintenance recommendations that revolutionize manufacturing efforts.

Read more about Wipro Industry Solutions on AWS

manufacturers achieve digital transformation quickly and seamlessly.

on the calibration of data and subsequent predictions,” says Li.

Aurora Zhai is a Sourcing Specialist at China Performance Group, where she manages and executes clients’ projects on the China side.

“At China Performance Group, we help importers source goods from China safely, responsibly, and effectively. We enable international buyers to obtain the maximum benefits of doing business with China – while significantly reducing their risk.

“My primary job responsibilities include sourcing, helping clients find the most suitable suppliers in China for existing products and new product development, as well as price benchmarking, order management, shipping management and logistics,” explains Zhai.

CPG supports manufacturers in a variety of ways, from helping to build positive relationships to guiding suppliers through a supply chain crisis.

“We connect them with serious buyers, facilitate communication and help to forge a professional, close, transparent client-buyer relationship,” says Zhai.

Zhai’s support for her clients also helps manufacturers by enabling them to perform

“The ‘future factory’ will have digitalisation at its core, and run with digital twins, artificial intelligence and big data”

LI SOURCING MANAGER, CHINA PERFORMANCE GROUP

better and in close accordance with the buyer’s wishes.

“We do this by providing timely feedback to suppliers on client’s requirements, goals, responses, and this strengthens the relationship,” says Zhai. “We collect information on industry segments and market trends for our clients and provide suppliers with the latest foreign market and product trends that the buyers want.”

Over the past few years, Zhai has learned a lot about supply chain management.

“One of the easiest, most fundamental ways CPG helps clients navigate the

supply chain crisis is by finding back-up and alternative suppliers in advance. By doing this, we gain leverage; we can calmly address any problem and still meet clients' requirements on pricing, quality, and delivery should issues arise,” says Zhai.

To build successful supply chain management, Zhai claims that transparency and information sharing helps build trustbut more is needed.

“Continued rapport building and cooperation between supply chain stakeholders is also essential,” says Zhai. “As well as ongoing training and

learning to facilitate innovation and continuous improvement.”

Every business on the planet has learned lessons from the supply chain crisis. At CPG, its careful coordination between clients and suppliers has solved problems and made partnerships stronger.

“Without identifying the root cause of a problem, how can one manage or resolve it effectively?” asks Li. Here, she shares her supply chain survival tips:

Act quickly to prevent a crisis

“Preventing or resolving a supply chain crisis

“Through digitalisation of R&D, production, manufacturing and management, enterprises will run based on the calibration of data and subsequent predictions”

SOURCING MANAGER, CHINA PERFORMANCE GROUP

requires immediate and effective solutions. CPG can provide clients with numerous approaches to choose from that can significantly mitigate their risk based on our years of experience working on the frontlines and dealing with thousands of mainland suppliers, coupled with our inherent understanding of the client’s vision and the local culture.”

“While many issues occur suddenly, many also provide warning signs that can alert you to a potential crisis before it happens. For example, if you know a supplier well enough, every abnormal or atypical reaction to a client request can betray the possibility that something might be amiss.

“Furthermore, market signals and changes to government policies are always good indicators to buyers that they might need to make preemptive adjustments to their sourcing programmes. The better you know

your supplier and the market, the earlier you can anticipate and prevent any potential risk.”

Over the next year, CPG will launch the following initiatives to ensure they maintain the highest standards of service for clients.

The ongoing training of employees will include repeat training and assessment of valued sourcing procedures, alongside training on new technologies and data analysis platforms. Team members will also participate in industry seminars.

“CPG participates in seminars related to our client’s industries, gathers and analyses market data, and writes quarterly market reports that are shared internally, and with our clients as requested,” explains Li. “This enables both CPG and our clients to understand the pulse of their industry and its trends, so we can adjust our sourcing goals and work accordingly.

Buy Direct From China“CPG will also hold weekly client management meetings to ensure client project missions are clarified, executed, and completed in the most satisfactory and efficient manner. Issues are solved quickly and thoroughly through teamwork and brainstorming,” says Li.

For Zhai, the next year will involve identifying new opportunities for clients that may not be readily apparent to them based on CPG’s continued vision and interaction with the China manufacturing sector.

“We connect manufacturers with serious buyers, facilitate communication and help to forge a close, professional and transparent clientbuyer relationship”

AURORA ZHAI SOURCING SPECIALIST, CHINA PERFORMANCE GROUP

United Urology Group (UUG) is a US-based national network of 1,500 urology healthcarefocused employees. It has affiliate practices in Arizona, Colorado, Delaware, Maryland, and Tennessee.

Founded in 2016 and with its HQ in Maryland, it supports 220 providers in 95 locations across five states, making it one of the largest urology networks in the US.

At heart, UUG is a management services organisation (MSO), providing administrative and support services to urology practices across the United States. This support includes revenue cycle management, financial management, human resources, marketing, and strategic planning.

David Forbes is VP of Supply Chain Management for UUG and is responsible for its source-to-pay programme, strategic sourcing, procurement, and accounts payable. He also provides consulting services in inventory management for UUG clinics.

The support Forbes and his team provide includes everything from human resources and sourcing services to IT.

He says: “I source contracts for my practices. I aggregate everybody's spend and negotiate the best possible agreements with the right trading partners at the right level.”

Why supply chain is a point of difference for US-based healthcare management services organisation, United Urology Group

Forbes also offers procurement support, or “day-to-day blocking and tackling” as he describes it. Accounts payable is another of his areas, and his team also ‘owns’ the company’s source-to-pay solution that serves its physician practices.

UUG’s network of practices are known for their integrated urologic care programs, a patient-first approach, clinical excellence, and innovative treatments for

a wide range of urologic conditions, from the most common to the most complex cases.

“We aim to support our affiliated practices in providing high-quality, patient-centred care,” he says, “and to support our affiliated practices in delivering care in an efficient and effective manner.”

UUG’s supply chain organisation is vital to this goal, says Forbes, who explains that it helps the

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

“We aim to provide high-quality, patientcentred care”

company deliver on its Quadruple Aim strategy, comprising:

• Clinical efficacy

• Patient experience

• Clinician experience

• Cost takeout

“These are four metrics our practices look to base decisions on, whether small or major,” says Forbes.

He adds: “Clinical efficacy is about whether or not a decision made by our affiliated practices improve patient outcomes. Clinician experience refers to the experience

TITLE: VP SUPPLY CHAIN MANAGEMENT

COMPANY: UNITED UROLOGY GROUP

INDUSTRY: HEALTHCARE

David Forbes is a seasoned supply chain professional with almost two decades of experience. Currently serving as the VP of Supply Chain Management for United Urology Group, his team is responsible for providing end-toend source-to-pay support to over 220 urologists and advanced practice practitioners. David's extensive experience includes working with the Healthcare Industry Distributors Association to develop healthcare trading partner data communication standards, building value analysis and sourcing departments for a hospital-based system, and serving as a strategic sourcing consultant with The Advisory Board Company. He holds a B.S. in Business from Miami University and an MBA from Loyola University Maryland.

“Shortages and back orders are the toughest part of the job. In the healthcare industry, we've never seen it as bad as it is right now”

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

of physicians, nurses, and medical assistants when using the product or service.”

Patient experience, he explains, concerns factors such as patient comfort and recovery each of which “are key considerations in cost takeout”.

Forbes cites as an example the purchase of a simple piece of urological equipment, such as a catheter.

“Cost takeout is about what we can do to prune unnecessary costs from healthcare, but it is not always about monetary cost. I might be able to negotiate a fantastic deal on the latest foley catheter, say, but if this product is going to cause urinary tract infections, or if it’s difficult to insert or remove, then it doesn't make sense to do it.”

Supply chain, he says, helps UUG deliver on its Quadruple Aim metrics.

“The obvious one is cost takeout, and the rest are impacted through the clinical integration of my department with our physician practices.”

220

Number of providers UUG has for its urology practices

95

Number of locations

5

Number of US states covered

Specialty Networks and United Urology Group have partnered over the past decade to better practices across the group and improve patient care. The common focus on improvement in every area, along with clinical integration throughout, promotes consistent advancement at a clinical level.

Specialty Networks, partnered with United Urology Group since 2013, enhancing practice performance through data, events, and group purchasing support.

Specialty Networks is the parent organisation of companies including group purchasing organisation UroGPO, of which United Urology Group is a member.

Specialty Networks has presence in multiple specialties

As a multi-specialist organisation, Specialty Networks has deployed GPOs in urology, gastroenterology, and rheumatology, alongside a robust data analytics platform (PPS Analytics) and also a research arm. The latter supports members like United Urology in conducting research inside their practices, with a data analytics arm to support practices while addressing gaps in care.

“The GPO establishes best-in-class purchasing agreements with manufacturers in areas including pharmaceuticals, services, and medical devices,”

Darren Dieleman, Senior Vice President at Specialty Networks, says. “We’re aggregating not just United Urology Group, but also the other 720 urology practices across the country into one buying group, then negotiating value-added programs with manufacturers to support the individual members.”

The partnership with United Urology Group

“What’s unique about the relationship between United Urology Group and Specialty Networks

via UroGPO is the fact that we share the common customer of our physician practices,” explains David Forbes, the Vice President of Supply Chain Management for United Urology Group. Alongside the benefits of the GPO, United Urology Group also utilises PPS Analytics – the data analytics arm of Specialty Networks – to streamline and identify potential gaps in patient care.

“We also run customised educational events at their individual pods and a series of live events across the country,” Dieleman explains. “We’re running a summit for United Urology in May to allow their practices, many acquired during the pandemic, to come together to establish longterm goals and objectives, network, and attend educational podium sessions.”

What’s next for the partnership?

“Live events, purchasing, reporting – there’s a much larger strategy ahead of us to help United Urology Group achieve in aggregate what they wanted to achieve individually as independent practices,” says Dieleman.

Specialty Networks and United Urology are moving forward with a hands-on approach to continually bettering themselves, the practices, and, therefore, patient care.

He adds: “This is why it's really important that as a supply chain organisation we’re closely aligned with the clinicians, so that we can be sure to execute on our collective goals.”

UUG is plugged into a large ecosystem of businesses who help it deliver on its goals.

These include:

• Specialty Networks

A niche group-purchasing organisation that negotiates agreements for specialty products, most prominently branded oncology pharmaceuticals.

• Medline

Medical-surgical distributor Medline is a key supplier. “We recently partnered with Medline because they are designed to scale with us,” says Forbes.

• Neotract

Manufactures a proprietary treatment called Urolift, of which our Chesapeake practice was an early adopter.

• Karl Storz

A key player in scopes and video equipment, crucial instruments that help urology practices meet patients’ clinical needs.

Such partnerships help Forbes meet his defining goal: the care of patients, whose health, often delicate, he and his team hold in their hands.

Along with just about every other supply chain executive on the planet, Forbes has been faced with a difficult market over the past few years.

Being able to juggle everything and keep things moving in the right direction in the face of adversity “comes down to people and systems”, says Forbes. “It’s all about making sure that you have the right infrastructure in place.”

He adds: I'll give you an example. When I first joined, only one other person other than me provided procurement support. When you're spread across the country like we are you can't expect somebody to be available at 7:30am Eastern Time and 6.00pm Western Time.

“So we made the decision to have somebody support our western markets, in Colorado and Arizona. Not only did this improve employee satisfaction, obviously, but it also made us more responsive to our market needs.”

Technology is another area UUG sees as a means to give it a competitive edge.

“We put a really heavy focus on the right technology in supply chain,” says Forbes. “Our prime strategy around resource management is leveraging technology. In my own department, we're evaluating AI tools to assist us not only with invoice processing, but also with strategic sourcing and contracts lifecycle management.”

Technology, says Forbes, helps UUG serve its customers, who are the practices in the field, for which assist them to focus on the communities they serve.

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

“We're evaluating AI tools to assist us not only with invoice processing, but also with strategic sourcing and contracts lifecycle management”

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

But as with any sizable change project, there are hurdles to clear and barriers to break down.

“You’ve got to be sure that you choose the right solutions in the first place,” he says. “But you also need to ensure you're then using these solutions correctly.”

Data is a massive issue, as it is with so many digital transformations.

“Organising data around category management is a massive issue in supply chain in general,” says Forbes, who reveals that he and his team procure more than 200 categories of products and services.

He adds: “We have to make sure that our data is structured in a way that allows us to mine it, so that we can have efficient

request-for-proposals, without which we cannot manage our contracts.

UUG’s new procurement programme “is fully built out” says Forbes, who adds that it has made a huge difference to the company’s procurement and sourcing processes.

“When I first started, it was taking us upwards of eight days to reconcile inventory at the end of the month, but this past month, we did it all in a single day. All counted, all reconciled.”

He says that, although the procurement transformation was tough at first, it has been “a caveman-discovering-fire moment”.

“We are now able to intelligently manage inventory levels, and drive a formulary of products. We used to get complaints from vendors about not being paid, but now we now have steadfast processes in place that ensure prompt payment. We’ve gone from taking 57 days to process an invoice to about 10 days.”

“Over time we acquired additional practices and when you grow you need to scale-up your staff”

Forbes says the rapid pace of the transformation was driven by the fact UUG was going through a period of rapid growth.

In 2016, UUG included only a single practice, Chesapeake Urology, and operated only in the mid-Atlantic region.

“Over time we acquired additional practices,” Forbes says, “and when you grow you need to scale-up your staff.”

He joined the company in 2020 “when UUG was starting to get our legs back from the initial COVID push”.

That growth is continuing apace, says Forbes, who reveals the coming 18 months will see the group focus on integrating with its ambulatory surgery centre (ASC) jointventure partners.

These partners help operate the largest ambulatory platform in the US, comprising

“Running a supply chain is like ‘being a conductor at the front of an orchestra’”

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

ASCs are modern healthcare facilities focused on providing same-day surgical care, including diagnostic and preventive procedures.

They have transformed the outpatient experience for millions of Americans, by providing a convenient alternative to hospitalbased outpatient procedures. They also have a strong track record of quality care and positive patient outcomes.

In June 2022, UUG formed a joint venture partnership in 22 ASCs. At the time, UUG CEO Sanford Siegel said of the deal that “we have an exciting runway with USPI as our partner,

and we look forward to bringing our patientfocused cultures together” – a sentiment Forbes echoes.

“It’s an exciting time for us,” he says. “An exciting future.”

Customer satisfaction is everything and in supply chain that means being able to respond to needs in the field – “such as being able to procure items on shortage, or back order.”

Forbes says running a supply chain is like “being a conductor at the front of an orchestra”.

“I might need to set up a regional hub-andspoke in our Maryland market to manage a shortage, else we're going to run out of products to certain clinics.”

Forbes’ voice tails off, as he lets the implications of that sink in: compromised care for patients, some of whom will be seriously ill.

“It might be that we have to consolidate our inventory, and then I’m the conductor on that,” he adds, waving an imaginary baton.

Ralf Schedel leads market development in Giesecke+Devrient’s automotive business.

Here, he discusses new expectations for car manufacturers

WRITTEN BY: HELEN ADAMSiesecke+Devrient engineers customise security technologies with passion and precision in four major fields: payment, connectivity, identities and digital infrastructures. As such, they’ve been the trusted partner of the most demanding institutions since 1852 and have been part of the global SIM success story for the last 50 years. As pioneers in the field, G&D delivered the world’s first commercial SIM and the first eSIM management solution. Today, the company is a market leader in eSIM management and continues to offer connectivity and security solutions for the consumer, enterprise and industrial IoT.

“My task is to tailor G+D’s smart connectivity management solutions and offerings to the specific needs and use cases of the automotive industry players, car OEMs and their Tier-1 suppliers,” explains Ralf Schedel, who’s in charge of the market development of G+D’s automotive business.

Prior to this position, Schedel held several sales, product, and programme manager positions within G+D. One of these roles included a period at semiconductor manufacturing company Infineon Technologies, where he ran several innovation projects for leading OEMs in the field of information and communication security. A notable innovation project was the first integration of an embedded Secure Element in a smartphone back in 2012, followed by the showcase of an eSIM in a wearable device at MWC in 2016.

“What brought me to the automotive industry from semiconductors was the momentum that was triggered by the European eCall legislation, which made the automotive sector a forerunner and pioneer in the adoption of eSIM technology for its telematic units,” says Schedel.

A modern network must be able to respond easily, quickly and flexibly to the growing needs of today’s digital business. Must provide visibility & control of applications, users and devices on and off the network and Intelligently direct traffic across the WAN. Be scalable and automate the process to provide new innovative services. Support IoT devices and utilize state-of-the-art technologies such as real-time analytics, ML and AI. And all these must be provided with maximum security and minimum cost.

This is the power that brings the integration of two cloud managed platforms, Cisco Meraki and Cisco Umbrella. This integration is binding together the best of breed in cloud-managed networking and Security. cisco.com

“I crossed industries and brought G+D’s expertise in the emerging eSIM technology to car makers and Tier-1 suppliers, which meant I became more involved, pulled into automotive projects and the wider automotive world. To be a part of such a disruptive market is exciting from day to day, with Electrification, Digital Cockpit, and

continuous SW-Updates to the Connected Car and Car-to-Cloud solutions all revolutionising the industry as we know it.” New expectations for car manufacturers Schedel knows that cars are no longer just about transporting people from A to B; they’re now an integral part of everyday life.

“Not that long ago, high-end in-car entertainment and technologies were seen as optional extras in high-end vehicles,” he says. “Today, drivers increasingly expect personalised digital experiences and flexible connectivity options as a must-have in every price category. Instant in-car connectivity is essentially the new horsepower and a new key selling point for attracting new customers.”

Car makers are also being faced more and more with local, country-specific regulations

“What brought me to the automotive industry from semiconductors was the momentum that made it a forerunner in eSIM technology”

To give their customers the experience of instant connectivity, G+D – in conjunction with its partner, BMW – developed a new technology, known as Dual-SIM Dual-Active, or DSDA. With this technology, vehicles are equipped with two eSIM modules that act independently of each other.

in the area of telecommunications, data privacy, and eCall.

“Such regulations and laws limit permanent roaming options and enforce local breakouts with in-country operational setups,” says Schedel. “Therefore, to comply with these regulations, they need eSIM management and connectivity management solutions that can integrate the respective local mobile network operators.”

To give their customers the experience of instant connectivity, G+D – in conjunction with its partner, BMW – developed a new technology, known as Dual-SIM Dual-

Active, or DSDA. With this technology, vehicles are equipped with two eSIM modules that act independently of each other.

“One eSIM is used to enable the vehicle manufacturer’s telematics services and eCall,” says Schedel. “The second eSIM, called Personal eSIM, allows the driver to access infotainment and entertainment services. The telematics’ eSIM is linked to the mobile operator the car manufacturer brings in, and the personal eSIM is linked to the operator where the car driver holds their private mobile phone contract.”

“Today, drivers increasingly expect personalised digital experiences and flexible connectivity options”

RALF SCHEDEL DIRECTOR DOMAIN AUTOMOTIVE , G&D

G+D is working with its OEM and MNO partners to offer customers the opportunity to extend their data plans to the ‘car’ as another ‘device’ in the future – similar to existing Multi-SIM offerings for wearables and tablets.

“This way the data consumption for private infotainment services in the car is covered by the driver’s connectivity contract. Drivers can benefit from highly-connected, user-centric services and bring their digital ecosystem into their car, including their private mobile phone number.”

DSDA enables cars to act as an extension of the driver’s smartphone, which, for example, allows them to seamlessly continue a call with the hands-free system. Listening to music is also instantaneous, and removes the need for clumsy Bluetooth connections to the vehicle’s infotainment system.

“In terms of safety, dual cellular links by network separation provides the assurance of a robust car-to-cloud connection,” said Schedel. “Regulatory requirements in a number of countries can be more easily met, where different telecommunication and data privacy laws apply for consumerorientated ISP services versus M2M and telematics services.”

G+D’s DSDA solution and AirOn360® eSIM management platform is in operation with the BMW iX and BMW i4, and will also be available in other models in the future.

“Private digital services in the car can be utilised by passengers in tandem with carto-cloud communication for BMW Group telematics services. Registration for the Personal eSIM service in the car can be achieved via the MNO or BMW app as an entry point. Once registered, the personal eSIM profile will be downloaded and can be instantly used. Family members can also load their eSIM profiles. Via the infotainment

screen the driver can activate/deactivate the desired profile. To make this approach and service a new standard, we worked together with BMW at GSMA.”

In coming years, Schedel expects more and more vendors will offer a similar service. But for G&D, the next 12 months will involve working with partners on the rollout of further innovations, such as use of 5G private network environments during car manufacturing at the plant for testing and on-plant MNO profile provisioning.

“This way, car manufacturers can source a generic eSIM and define at the end of the production line which operator profile shall be loaded, dependent on the country the car is exported to,” says Schedel. “We will continue to grow our worldwide coverage of local, in-country setups to meet regulations and expand our connectivity management platform, enabling the rapid onboarding of new Car OEM customers and new MNO partners, ready-made for advanced 5G Car Connectivity services.”

“Instant in-car connectivity is essentially the new horsepower and a new key selling point for attracting new customers”

RALF SCHEDEL DIRECTOR DOMAIN AUTOMOTIVE , G&D

WRITTEN BY: TOM CHAPMAN

PRODUCED BY: KRISTOFER PALMER

WRITTEN BY: TOM CHAPMAN

PRODUCED BY: KRISTOFER PALMER

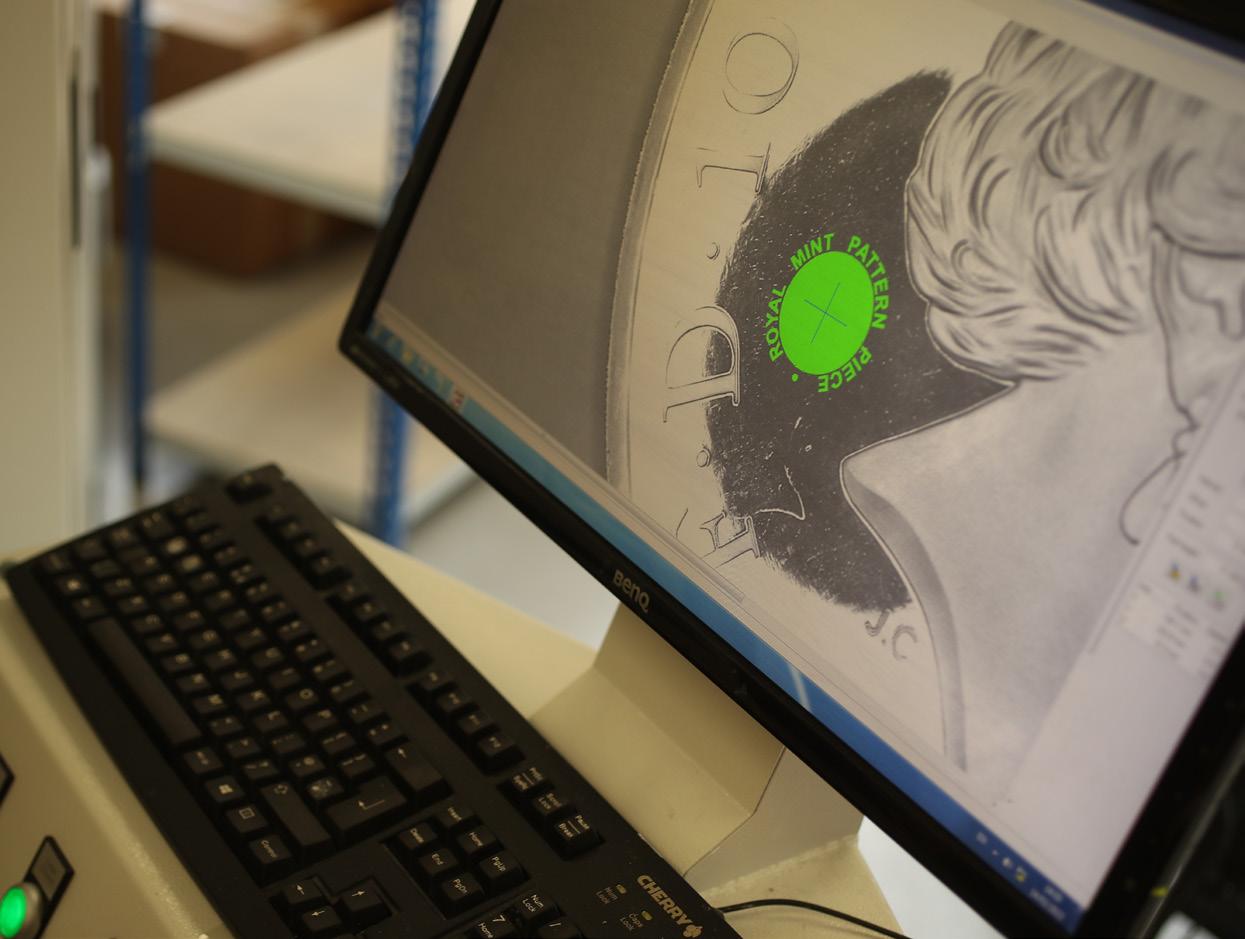

The Royal Mint is a company that needs little introduction, at least not to the majority of the Great British public, coin collectors, or those interested in the Royal Family.

Founded more than 1,100 years ago in around 886 AD, the Mint – as it’s colloquially known – is one of the UK’s oldest brands and remains the official maker of British coins. It’s also billed as the home of precious metals (think gold bullion bars) and recently launched a luxury jewellery collection called 886 by The Royal Mint.

That’s without mentioning the illustrious commemorative coins side of the business, which continues to thrive, and the iconic Olympic medals it created for London 2012. It will come as no surprise, however, that The Royal Mint has had to digitally adapt to rapidly-evolving societal norms and technological advances.

Much of that responsibility has fallen to Richard Hobbs, Group IT Director of The Royal Mint, who joined just before the pandemic in early 2020. Hobbs has been spearheading The Royal Mint’s technology transformation and implementing a five-year strategy that supports the organisation as it diversifies –which, he believes, is on the right track.

“We’re transforming from a traditional manufacturer into a modern, digital-oriented organisation,” says Hobbs. “And over the last five years or so, we’ve been very successful in our commercial diversification but also in introducing new technology into the business.”

Like all forward-thinking manufacturing businesses, The Royal Mint has come to recognise the undeniable importance of sustainability and, with that, is factoring sustainable practices into its everyday operations.

Later this year, The Royal Mint is opening a plant to recover precious metals from electronic waste. Once up and running, the precious metals’ recovery site is expected to process 90 tonnes of UK-sourced e-waste every week.

Clearly, then, The Royal Mint requires a powerful ERP system in the form of

“We’ve been really successful in our diversification, but also in introducing new technology to help the organisation”

RICHARD HOBBS GROUP IT DIRECTOR, THE ROYAL MINT

Gwillimdesign process

Microsoft Dynamics 365 for Finance and Operations to support this groundbreaking journey. The aim, Hobbs explains, was for this technology to support that entire manufacturing process – from the minute the e-waste is sourced, all the way through to products reaching the consumer.

That includes being able to track e-waste loads as they come in, manage the process of removing component parts, identify them, and then move them into The Royal Mint’s business. Building an effective ERP system was therefore “critical”, but also served as a huge opportunity for the tech team.

“There aren’t many opportunities to implement a greenfield ERP in an existing

TITLE: GROUP IT DIRECTOR

COMPANY: THE ROYAL MINT

INDUSTRY: CONSUMER GOODS

LOCATION: CARDIFF

Rich joined The Royal Mint in January 2020, bringing 20 years’ experience from financial services, where he worked for Barclays Bank, Barclaycard, Lloyds Banking Group and Admiral Insurance. During his time, Rich has led his team to implement the technology strategy at The Royal Mint, driving forward its digital transformation, modernising cybersecurity and growing the IT function as The Royal Mint diversifies and expands its business. Working closely with the executive board, Rich has led in driving a culture of technological innovation, enabling the delivery of The Royal Mint’s

Hitachi Solutions is a global Digital, Data and Technology consultancy specialising in end-to-end transformation using Microsoft Cloud Services, Dynamics 365 Business Applications, Power Platform and Azure, including Application Modernisation and Data & Analytics. Our highly skilled teams drive improvements, create efficiencies and enable growth to revolutionise the Public Sector.

Jamie Watson, Client Director at Hitachi Solutions Europe, explains why his firm was well-equipped to assist The Royal Mint in its ambitious transformation

Embarking on its world-first Sustainable Precious Metals (SPM) programme, The Royal Mint (TRM) needed a partner that could seamlessly establish a new ERP system. The Mint joined forces with global consultancy firm Hitachi Solutions, which specialises in people-first business transformation using Microsoft technologies.

Jamie Watson, Client Director at Hitachi Solutions Europe, explains: “From a tech perspective, this involves the full suite of Dynamics 365 (D365) Business Applications: the Power Platform, Azure, and the data and AI platforms. “From a people perspective, it’s centred around change management and digital innovation.”

Detailing Hitachi Solutions’ engagement with TRM, Watson adds: “We worked very closely with The Royal Mint team to deliver a people and business-led engagement that initially focused on understanding their needs and goals. “We prioritised those needs and worked out what enabling technology was required within the Microsoft technology stack to turn those needs

into real-life outcomes. “Since then, we’ve continued our relationship, successfully tendered the SPM ERP transformation programme, and we’ve gone live with the D365 Finance and Supply Chain Management solution.”

The design and build of TRM’s new ERP solution means it will prove to be extremely sustainable in the long term. “As a collective team,” Watson continues, “we had less than six months to design, configure, test and deploy a production-ready ERP solution, which, for anyone familiar with these types of programmes, is almost unheard of.”

Watson said the project had provided “huge opportunity” for transformation across TRM’s organisation. He adds: “We can focus less on keeping the lights on and focus more on continually adding new functionality like the Power Platform, robotic process automation, and even brand-new technologies that are hitting us across AI and machine learning. “That will certainly become relevant to The Royal Mint and could, in itself, provide significant long-term benefits.”

business, so we were very quick to recognise it as an opportunity to test drive some of our assumptions and processes,” says Hobbs.

“It’s been a great learning curve for us to start on our ERP journey and, in fact, we delivered the MVP ERP within 15 weeks of inception. That was done by January and we’re already at the end of phase two, which is implementing a second phase of change.

“It’s been a really successful programme that’s had a big impact on the business.”

The pronounced importance of cloud computing to modern living, technology and the manufacturing industry is well documented. The Royal Mint’s IT transformation from on-premise to the cloud allowed for greater technological flexibility.

“Our new ERP sits on the cloud, giving us the ability to be really quick and nimble, keep it updated, and take on technology,”

“Sustainability is now at the heart of The Royal Mint – and technology plays a crucial role in this journey”

RICHARD HOBBS GROUP IT DIRECTOR, THE ROYAL MINT

says Hobbs. “But it also enables integrations to be fast and effective, allowing us to scale up the product during busy periods and to be elastic without even thinking about it.”

Moreover, cloud computing has allowed The Royal Mint to enhance its data management and cybersecurity, both of which lie at the heart of the aforementioned technology strategy. A data management function has been created to appropriately surface information to the business, which is self-serving and maintains an organised, controlled, and secure data team.

Moving to the cloud and the implementation of modern ERP across the Mint has even helped change internal perceptions of the technology department, with Hobbs adding: “We’re now seen as much more of an enabling function than a

cost function. When the business is moving fast, trying new things, and diversifying quickly, it needs the technology to do it.”

The Royal Mint has been able to count on a whole host of partners to help carry out its recent technological transformation and activities.

Its primary partner within the ERP space has been Hitachi Solutions, which worked closely with The Royal Mint’s tech team to implement the Dynamics 365 system managing the precious metals recovery site.

“We’re essentially a public sector organisation, so we have to go through a procurement process,” explains Hobbs. “When we spoke to Hitachi, from quite early on we recognised there was a really strong cultural fit.

886AD

Founded in 886 AD during the time of Alfred the Great, The Royal Mint is one of the oldest brands in Great Britain

800

The Royal Mint employs more than 800 people across functions including manufacturing and technology

Away from producing currency for the UK and other countries, The Royal Mint has successful businesses across commemorative coins and investments as well as its new luxury jewellery range

“Knowing an ERP project is potentially two or three years long, we wanted to make sure we could work together. The technology itself is quite prescribed but, on the softer side of things, Hitachi were able to engage with us and support us in our decision making.”

Also key was Hitachi Solutions’ experience in working with similar organisations and its success rate in implementing Dynamics 365. This meant that, rather than simply responding to The Royal Mint’s questions, project team members were able to add some colour to the conversations around what they’d seen before.

“We were so lucky,” Hobbs continues. “Hitachi brought in a great project team who we kept for the whole duration; they engaged with The Royal Mint side of things really effectively. It felt like they were part of our own team.

“Hitachi Solutions has been a great partner of ours for about two years now, helping to shape our story and the build we’ve just completed.”

Using Dynamics 365 and sitting within a Microsoft Azure cloud means the Mint has, of course, worked closely with Microsoft, while Optimizely provides its website platform. The emphasis from The Royal Mint’s point of view is on gathering a small but focused group of partners that help the company push through its strategy.

“We recognise that we don’t know the answers to everything,” says Hobbs. “Picking

On a mission to expand on its digital e-commerce operation, with the customer at the forefront, The Royal Mint leveraged Expleo’s domain expertise and best-in-class proprietary methods for testing and assuring technology rollouts.

Find out how Expleo can help your organisation embrace a culture of hyperautomation. LEARN MORE

As the country’s oldest company and holder of the exclusive contract to produce the nation’s coinage, The Royal Mint is an icon of British business. Expleo was offered a rare opportunity to partner with one of the country’s greatest establishments in its digital transformation.

In 2020, Richard Hobbs, Group IT Director of The Royal Mint recognised the significance of innovation within the technology function and formulated a plan to bring new technologies into the business, while accelerating time to market with new product offerings. This coupled with heightened customer expectations around seamless online experiences provided the impetus for the Royal Mint to replace legacy systems and digitalise manual processes that were tying up resources and time. The Royal Mint issued a tender for a project to digitalise its IT infrastructure, selecting Expleo to automate the testing of its e-commerce digital platforms and oversee the testing process for its switch to a new payment provider. Hobbs, architect of the

Royal Mint’s digital agenda, envisioned an ‘automation-first’ approach to IT refurbishment, geared towards expanding the company’s product suite and client base.

Top of the list of deliverables was a highperformance website – RoyalMint.com. Expleo quickly implemented a robust testing framework to identify defects within the existing IT infrastructure and put in place a quality assurance tool that has allowed The Royal Mint to develop new functionality for a smoother customer journey. This intervention dramatically reduced the number of hours required to execute a core regression test pack by 80%.

Expleo’s

Mint’s website helped the company to unlock new revenue streams across its products. Additionally, the improved testing and bug detection capabilities decreased the risk of lost sales due to system downtime, while bolstering the security of The Royal Mint’s website, and mitigating the risk of cyber-attacks.

our partners based on shared synergies and the ability to work well together is the driving factor for me.”

Another important partner for The Royal Mint is Expleo, which has grown to become a force in the fields of engineering, technology and consulting.

“Expleo has supported the expansion of our commercial horizons,” Hobbs says. “Their team’s technical know-how enabled us to improve our development processes and increase efficiencies across the board.

“Expleo facilitated a re-platforming of our website and oversaw the testing process for our switch to a new payments provider. Through this engagement with Expleo, we’ve been able to expedite time-

Royal Mint Pattern

Royal Mint Pattern

to-market with a new product line, unlock viable new revenue streams and become more commercially agile.

“Overall, this phase of automation has allowed us to focus resources on more strategic initiatives, increase productivity, improve customer satisfaction and boost revenue growth.”

The Royal Mint is focused on working towards a sustainable future for its business and the environment, and this includes developing talent within the technology team.

Hobbs says: “Our technology function is robust and we want to ensure we’re sustaining as well as attracting talent to the business.”

The Group IT Director and his team have forged partnerships with the University of South Wales and the National Cyber Security Academy. They collaborate in a number of ways, including supporting students with projects and dissertations, attending speaking opportunities and sharing insights to provide students with case studies to aid their assessments.

“Hitachi Solutions has been a great partner of ours for about two years now, helping to shape our story and the build we’ve just completed”

RICHARD HOBBS GROUP IT DIRECTOR, THE ROYAL MINT