4 minute read

C-Job Naval Architects can reduce superyacht engineering by four-and-a-half months

Superyacht engineering reduced by four-and-a-half months

C-JOB NAVAL ARCHITECTS HAS PUBLISHED NEW RESEARCH THAT SHOWS THE TIME-TO-MARKET OF SUPERYACHTS CAN BE REDUCED BY UP TO FOUR-AND-A-HALF MONTHS.

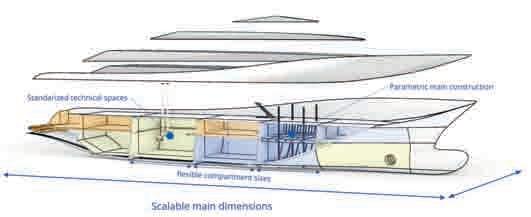

The ship design and engineering company C-Job Naval Architects believes it can achieve a superyacht engineering time reduction by engineering superyachts with what they call the ‘Dynamic Platform’. This allows owners to still fully customise their vessel, while reducing engineering time. The man behind this research is Stefan van der Harst, Junior Naval Architect at C-Job. He proposes disconnecting the engineering the vessel’s lower part from the upper part, looking at the trending superyacht size that lies between 50m and 80m. The upper part of the vessel is unique to each owner, whereas the lower part, the non-owner spaces, show great commonality. Mr van der Harst explains, “The lower part of the vessel houses ample technical and crew areas. Space claiming is exerted per area to get the right space reservation in the final design. However, a great portion of early design phases is consumed by iterating the design to solve all clashes and grid mismatches.” The dynamic platform is a tool that is based on scale-to-order philosophy. The platform translates the owner’s wishes into a finished basic design global model of the lower part of the ship. It does this in three stages, each stage more detailed than the previous one. A default model is chosen in the first stage. The second stage introduces modularity to cope with variations in arrangement. The final stage scales the model to the desired dimensions. Mr van der Harst continues, “By eliminating the space claim clashes and grid mismatches via the dynamic platform in an early stage of the design, a significant design time reduction of up to four-and-a-half months can be realised. This is half of the average time it currently takes to engineer the concept and basic design. More research is needed to make the dynamic platform a reality, yet the first insights are promising. And not just for concept and basic

C-Job Naval Architects Dynamic Yacht Platform visualization.

design phases, as detail engineering could also benefit yachts out of the 50 - 80m range.”

Key findings Twelve yachts ranging from 50m to 81m were selected for analysing the general arrangements. The motorised displacement yachts were selected from varying shipyards to show that they all have similar ideas about arrangements. Eight reference vessels ranging between 40m and 109m were used for the construction principles. Typical construction layouts of the studied vessels reveal great commonality. Commonalities are found where the number and position of watertight bulkheads is consistent, the ducts and pipes are routed under and not through the girders, and the secondary stiffeners are longitudinally oriented. Great commonality is furthermore found in the longitudinal frame spacing, which allows for the distinction of two frame spacings that match the two arrangement layouts. The HVAC principles are mainly common on arrangement level, where the air-conditioning systems are split over different areas in the vessel. The same applies for the grey/black water systems, which also demonstrate commonality in their system layout. For HVAC, the system layout strongly varies between central heating or using fan-coils. The dynamic platform as a part of the whole ship imposes constraints to the way in which the superstructure is designed. These constraints are on a global level maximum dimensions, a maximum power consumption, a fixed total weight, and a fixed centre of gravity.

Image courtesy of C-Job Naval Architects.

On a local topological level, the superstructure has to match the items penetrating the main deck. Some items such as AC units also need to be located around or near a specific position. A lead time reduction of three months can be achieved if the superstructure is assumed unaffected by the strategy. This is possible as the production of the superstructure usually takes three months less than the production of the hull. If the lead time of the superstructure’s design phase can also be reduced, then an engineering lead time reduction of four-and-ahalf months can be expected. Engineering lead time reduction in the design phase of superyachts can be supported by three tasks in the non-owner spaces below the main deck. First execute a standard base topology with standard construction, HVAC, and piping and cable principles. Secondly, make modular variations to the parts known to have more than one common function assignment. Other functional variations will have to be engineered-to-order, but to make the dynamic platform effective these new solutions should match the grid of the adjacent spaces so that the rest of the platform remains intact. The final task includes sizing the (standard) systems, including the construction, ducting, and piping using a parametric model with the overall ship length as main input. This parametric sizing also serves as a check for space claim, stability, water tightness and fire integrity, structural strength, and compliance of power plant between fuel supply and exhaust.