ARINE OG M L www.marinelog.com

R E P O R T I N G O N M A R I N E B U S I N E S S & T E C H N O L O G Y S I N C E 18 78

September 2021

W H Y G R E AT L A K E S YA R D S

AREN'T SLOWING DOWN

BIGGEST BULKER CHARTERERS Demand Greener Tonnage

FISHING VESSEL ACCIDENTS Get NTSB Attention

Q&A WITH REV LNG CEO David Kailbourne

CONTENTS

12 DEPARTMENTS 2 EDITOR’S LETTER Recovery Efforts Underway Along Ida’s Trail 4 INLAND WATERWAYS NTSB Issues Report on Fatal Double Towboat Collision 6 INDUSTRY INSIGHTS 8 WELLNESS Trust and Wellness: The Connection 10 VESSEL OF THE MONTH HST Ella: First Hybrid Chartwell 24 CTV 11 REGULATIONS Cybersecurity: Moving from Ideas to Action 12 UPDATES • Crowley and Shell to Build and Charter Jones Act LNG Bunker Barge • Maersk Makes Major Move on Methanol 16 INSIDE WASHINGTON MARAD Makes New Marine Highway Designations 30 NEWSMAKERS White House Taps Porcari for Supply Chain Task Force Role 31 TECH NEWS Mitsubishi and TotalEnergies Partner on Liquefied CO2 Carrier

24 FEATURES

20 22 24

GREAT LAKES SHIPYARDS’ Shipyards in the Great Lakes are Bustling The need for vessels, maintenance and retrofits has led to a hike in activity for some shipbuilders BULK CARRIERS Major Charterers Push for Greener Tonnage Most newbuilding activity in the sector is backed by long-term charters from producers concerned with reducing the carbon footprint FISHING VESSEL ACCIDENTS Fatigue a Leading Cause of Incidents The NTSB has released its “Safer Seas Digest 2020,” where five disturbing commercial fishing boat accidents were reported on

26

Q&A: LNG BUNKERING & GREAT LAKES REV LNG CEO David Kailbourne on New LNG Strategy Kailbourne updates us on the latest in LNG bunkering on the Great Lakes and where it’s heading

28

TECH SPOTLIGHT: NAVIGATION COMMUNICATIONS Inmarsat Doubles Down As connectivity becomes more essential for shipowners, mobile satellite communications giant Inmarsat is rolling out new services

Cover Photo Credit: Donjon Shipbuilding & Repair

36 SAFETY Risks Associated with ESS are Preventable

September 2021 // Marine Log 1

EDITOR’S COLUMN

MARINELOG SEPTEMBER 2021 VOL. 126, NO. 9 ISSN 08970491 USPS 576-910 SUBSCRIPTIONS: +1 (402) 346-4740 Fax: +1 (847) 291-4816 Email: marinelog@omeda.com PRESIDENT Arthur J. McGinnis, Jr. amcginnis@sbpub.com PUBLISHER Gary Lynch glynch@sbpub.com Photo Credit: Shutterstock/ Yaska

Recovery Efforts Underway Along Ida’s Trail

J

ust before noon on August 29, Hurricane Ida crashed ashore at Port Fourchon, La. Its 150 mph winds made it the fifth-strongest storm to hit the U.S. on record—and after causing devastation across Louisiana and Mississippi, it went on to cause lethal flooding in the Northeast. At the time of this writing, recovery efforts were still underway and it appears that poststorm disruptions may be prolonged. Many marine industry operations have been impacted—including Gulf of Mexico offshore oil and gas operations, shipyards, ports, and the inland waterways industry. In one incident related to the storm was a 22-barge breakaway. There was also an earlier report of a ferry breaking away from its moorings. Those incidents were ones that made the news, however, there were other vessels that wound up in different places after the storm than they were when it began. This isn’t the first time a hurricane has caused a barge breakaway. Several barges broke loose during Hurricane Gustav in 2008. They ran aground causing millions of dollars in damage. Currently, transit delays along the waterways in the path of Hurricane Ida are to be expected well into this month as boats, fleets, terminals and shipyards recover from the hurricane. As parts of the eastern U.S. were still dealing with the lingering but still damaging

effects of the remnants of Ida, recovery efforts in the Gulf Coast area continue. Many maritime operations in the region report that they are currently in the recovery mode, including Edison Chouest Offshore, Bollinger Shipyards and ports in the region. There are still many waterway restrictions in place, including a Captain of the Port order that implements a temporary safety zone on the Lower Mississippi River between miles 105 and 108 above Head of Passes in effect through September 30. The Coast Guard said it would continue to work with port partners on the identification and mitigation of grounded and submerged vessels along banks of the Lower Mississippi River. With storms like this estimated to become more frequent and intense due to climate change, infrastructure has to be hardened to withstand them. In the not so long-term, we have to realize that decarbonization is not just a word—it’s a necessary public policy priority.

SENIOR EDITORIAL CONSULTANT Nicholas Blenkey nblenkey@sbpub.com ART DIRECTOR Nicole D’Antona ndantona@sbpub.com GRAPHIC DESIGNER Hillary Coleman hcoleman@sbpub.com MARKETING DIRECTOR Erica Hayes ehayes@sbpub.com PRODUCTION DIRECTOR Mary Conyers mconyers@sbpub.com SALES MANAGER David Harkey dharkey@sbpub.com SALES REPRESENTATIVE KOREA & CHINA Young-Seoh Chinn corres1@jesmedia.com CLASSIFIED SALES Jennifer Izzo jizzo@mediapeople.com CIRCULATION DIRECTOR Maureen Cooney mcooney@sbpub.com CONFERENCE DIRECTOR Michelle M. Zolkos mzolkos@sbpub.com CONFERENCE ASSISTANT Stephanie Rodriguez srodriguez@sbpub.com CONTRIBUTORS Emily Reiblein Crowley Maritime Corporation Tracy Zea Waterways Council Inc. SIMMONS-BOARDMAN PUBLISHING CORP. 88 Pine Street, 23rd Floor, New York, NY 10005 Tel: (212) 620-7200 Fax: (212) 633-1165 Website: www.marinelog.com E-mail: marinelog@sbpub.com

HEATHER ERVIN Editor-in-Chief hervin@sbpub.com

Marine Log Magazine (Print ISSN 0897-0491, Digital ISSN 2166-210X), (USPS#576-910), (Canada Post Cust. #7204564; Agreement #40612608; IMEX Po Box 25542, London, ON N6C 6B2, Canada) is published monthly by Simmons-Boardman Publ. Corp, 88 Pine St. 23rd Floor, New York, NY 10005. Printed in the U.S.A. Periodicals postage paid at New York, NY and Additional mailing offices. PRICING: Qualified individuals in the marine industry may request a free subscription. For non-qualified subscriptions: Print version, Digital version, Both Print & Digital versions: 1 year, US $98.00; foreign $213.00; foreign, air mail $313.00. 2 years, US $156.00; foreign $270.00; foreign, air mail $470.00. Single Copies are $29.00 each. Subscriptions must be paid in U.S. dollars only. COPYRIGHT © Simmons-Boardman Publishing Corporation 2021. All rights reserved. Contents may not be reproduced without permission. For reprint information contact: PARS International Corp., 102 W 38th St., 6th Floor, New York, N.Y. 10018 Phone (212) 221-9595 Fax (212) 221-9195. For Subscriptions, & address changes, Please call (US, Canada & International) +1 (402) 346-4740, Fax +1 (847) 291-4816, e-mail marinelog@omeda.com or write to: Marine Log Magazine, Simmons-Boardman Publ. Corp, PO Box 239, Lincolnshire IL 60069-0239 USA. POSTMASTER: Send address changes to Marine Log Magazine, PO Box 239, Lincolnshire IL 60069-0239 USA.

2 Marine Log // September 2021

EDITOR-IN-CHIEF Heather Ervin hervin@sbpub.com

Workboat crews want better communication. In fact, they’re screaming for it.

David Clark Marine Headset Systems High winds, roaring engines, pounding through rough water, salt and spray - it’s no wonder workboat crews often have to yell repeatedly to be heard. And the margin for miscommunication runs high.

Series 9100 Digital Communication System Scalability • Versatility • Simplicity

David Clark Marine Headset Systems offer clear communication and rugged reliability in the harshest marine environments, while enhancing the safety and situational awareness of crew members on board patrol boats, offshore service vessels, fire/rescue craft, tug and tow boats and other workboat vessels. Call 800-900-3434 (508-751-5800 Outside the USA) to arrange a system demo or visit www.davidclark.com for more information.

© 2021 David Clark Company Incorporated ® Green headset domes are a David Clark registered trademark.

230-38802 Screaming 8X1075ML.indd 1

W W W. D AV I D C L A R K . C O M

An Employee Owned American Company

8/17/21 4:19 PM

INLAND WATERWAYS

NTSB Issues Report on Fatal Double Towboat Collision

T

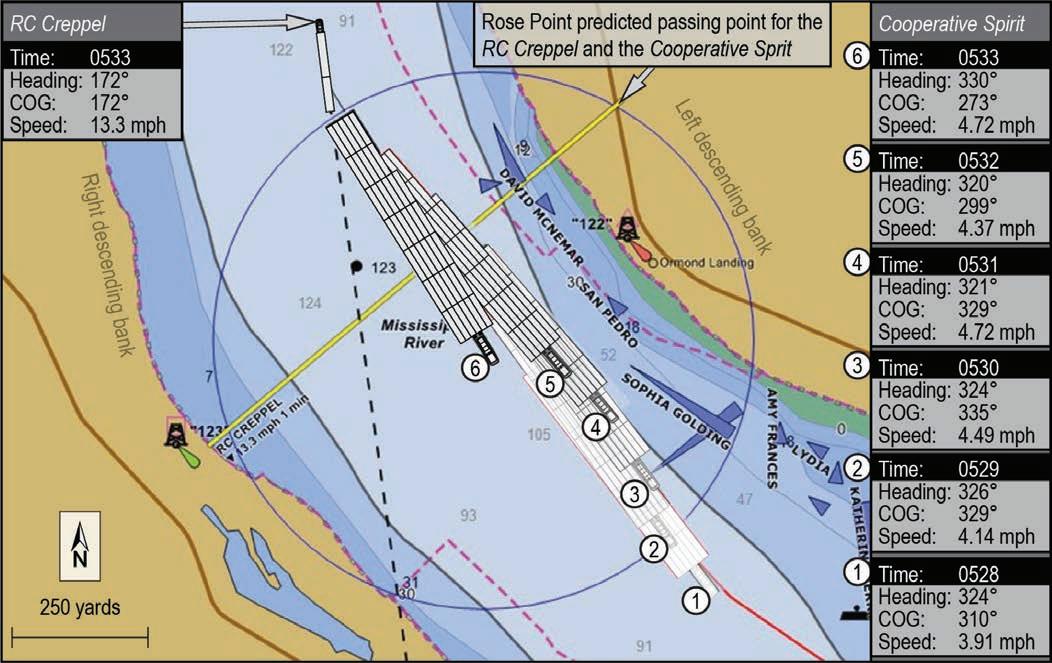

he lack of accurate tow size information and two pilots’ insufficient radio communication are the probably cause of a fatal collision between two towboats on the Lower Mississippi River near Destrehan, La., according to a National Transportation Safety Board Marine Accident Brief released Thursday. The accident brief details the NTSB’s investigation of the January 26, 2020, collision of the towing vessels Cooperative Spirit and RC Creppel. The RC Creppel, which capsized in the accident, had four crewmembers aboard— one was rescued and three others were never found. The accident resulted in a breakaway of a combined 42 barges from both tows, the discharge of approximately 8,000 gallons of diesel fuel into the river and the release of sulfuric acid vapors into the atmosphere. The collision resulted in an estimated $3 million in property damage to three vessels and 11 barges. The RC Creppel was not recovered. The Cooperative Spirit was towing 40 barges upriver, and the RC Creppel was towing two barges downriver. The Cooperative Spirit pilot and the RC Creppel pilot agreed to a port-to-port meeting. The RC Creppel pilot communicated the size of his tow; the 4 Marine Log // September 2021

Cooperative Spirit pilot did not. The barges of the towing vessels collided around Mile 26. As a result of the impact, the RC Creppel capsized and sank. An upbound dry-bulk carrier, the Glory First, collided with the starboard side of the Cooperative Spirit’s tow.

Probable Cause The NTSB determined the probable cause of the collision of the Cooperative Spirit and RC Creppel was the two pilots’ insufficient radio communication before meeting in a bend and not broadcasting accurate Automatic Identification System (AIS) information regarding tow size. In its report, the NTSB said a radio call to the other vessel would have helped both pilots identify each other’s expectations, but neither pilot made a radio call after their initial call to arrange a meeting. The absence of a radio call or “danger” signal indicates that neither pilot was aware of the impending collision. “When meeting or overtaking a vessel in a bend, especially where high-water conditions can increase the risk of a collision, early and effective communication is critical to ensuring a successful meeting,” the report said. “The use of very high frequency radio can help to dispel

assumptions and provide bridge teams and towing vessel operators with the information needed to better assess each vessel’s intentions.” Neither the RC Creppel nor the Cooperative Spirit broadcast the total overall length of the vessels and their tows to other AIS users. The RC Creppel’s AIS broadcast showed its length at 69 feet rather than its actual overall length of 514 feet. The Cooperative Spirit’s AIS broadcast showed the length at 200 feet rather than its actual overall length of 1,600 feet. The vessels would have had an improved picture nearing each other if either’s AIS included the accurate size of the tows. The NTSB has previously noted the importance of ensuring that vessels engaged in towing operations broadcast accurate AIS information regarding tow size. “The overall dimensions of a vessel and its tow may change significantly with each transit,” the report said. “For vessels towing ahead or alongside, the dimensions in AIS should reflect the overall rectangular area of the vessel and its tow. Consistently entering the complete dimensions of a tow configuration into AIS for each transit helps to alleviate possible misinterpretation and thus enhances the situational awareness of all waterway users.”

Photo Credit: American River Transportation Company LLC, annotated by Christy Spangler, NTSB

Screenshot from the Rose Point electronic charting system display showing the Cooperative Spirit’s positions starting at 5:28 a.m. CST.

ISO 9001:2015 Certified

INTRODUCING THE NEXT GENERATION HARDENED SEAT TRIPLE OFFSET VANESSA VALVE! The Result of 3 Years of Development & Navy Shipboard Testing.

Only Available through JA Moody! y Inconel hardening of Nickel y Nickle Aluminum Bronze body with integral seat upgraded without welding y Perfect valve to use in harsh environments like corrosive seawater y Longer life cycle y Metal Seat y Zero Leakage ANSI Class VI soft seat standards

Cold spray technology takes small solid-state particles of INCONEL 624 and accelerates them to over 3,000 feet per second which creates a coating on the base material. As a result of the cold spray, this Vanessa variant has a ½ millimeter thickness of material which provides a substantial increase in hardness and is more than a 2,000% improvement in resistance to erosion/ corrosion. The cold spray seat facing contributes to extending the valve life while preserving its key features.

For additional information about this cutting-edge valve please contact sales@jamoody.com

JAMOODY.COM

An American Veteran Owned Company

INDUSTRY INSIGHTS

THE GREAT LAKES-ST. LAWRENCE SEAWAY SYSTEM STRONG SUPPLY CHAIN FOR WIND ENERGY WELCOME TO Industry Insights, Marine Log’s quick snapshot of current trends in the global marine marketplace. This month, we stick with the theme of the issue and take a look at shipping on the Great lakes. The Great Lakes Seaway Partnership reported last month that American and Canadian ports in the Great Lakes-St. Lawrence Seaway System saw 1,733 total transits from the

opening of the St. Lawrence Seaway on March 22, 2021, through July 31, 2021, a 6.19% increase compared to transits through July last year. Commodities seeing an increase include iron ore, containers, steel, and wind energy cargo. Through July, all cargo shipped through the St. Lawrence Seaway reached 16,669,000 metric tons, up 4.64% compared to shipments during the same time in 2020.

2021 GREAT LAKES-ST LAWRENCE SEAWAY KEY PERFORMANCE INDICATORS** 2020

2021

Change (+/-)

Total Transits*

1,632

1,733

+6.19%

Total Cargo*

15,930,000 mt

16,669,000 mt

+4.64%

*Combined U.S. and Canadian Traffic ** All data is compared year-over-year (2020: Shipments from April 1 to July 31, 2020) (2021: Shipments from March 22 to July 31, 2021

2020

2021

Change (+/-)

Iron Ore*

2,881,000 mt

3,531,000 mt

+22.51%

Coke*

342,000 mt

662,000 mt

+ 93.37%

*Combined U.S. and Canadian Traffic ** All data is compared year-over-year (2020: Shipments from April 1 to July 31, 2020) (2021: Shipments from March 22 to July 31, 2021

Source: Great Lakes Seaway Partnership

6 Marine Log // September 2021

WELLNESS COLUMN

Trust and Wellness: The Connection

8 Marine Log // September 2021

of the basic elements that make up integrity, benevolence, competence and predictability that are all identified by Adam Waytz at the Kellogg School of Management as being the foundations of trust. A lack of oxytocin in human beings has been shown to cause depression and anxiety. They tend to withdraw, mistrust, and feel the effects of mental deterioration. The trust factor can also be influenced through lifestyle choices. Oxytocin is known to release during times we have physical contact with others—between a mother and child, a husband and wife, and even when hugging a friend. Oxytocin levels in mariners or seafarers, who may stand alone on a bridge for days on end, can suffer due to reduced contact. For all of us, COVID-19 has hit this hormone hard as well. Remote work removes contact, and with it, the ability to use Oxytocin to build trusting relationships. Here are a few considerations that may help to boost oxytocin in times of physical separation. 1. Be Seen and Listen Joyously: New digital opportunities leave the doorway open for oxytocin to be a part of the chemical mix. When meeting, turn on your computer or tablet camera and be seen. Make sure the camera works well enough and is placed in such a position that eye contact can be established. Linda Jackson, a “Positive Psychology” lecturer, presented a review of research on oxytocin and eye contact. In it, she said that maintaining eye contact for 30 to 60 seconds triggers the

Nothing in this article constitutes medical advice. All medical advice should be sought from a medical professional.

EMILY REIBLEIN

Director-Health, Safety, Security and Environment (HSSE) Crowley Logistics

Photo Credit: Shutterstock/ Yuriy Seleznev

T

rust is critical in any relationship. It provides a measure of psychological safety that creates a difference in how we feel about colleagues, friends and family. Research now shows that trust is initiated in a cascade of internal chemical reactions that come together and open the doorway to unsurpassed teamwork, strong relationships and a boost in mental health. Over the past few years, trust in the workplace has become a focus of endless research. Paul J. Zak (Neuroscience of Trust, January-February 2017) says that “employees in high-trust organizations are more productive, have more energy at work, collaborate better with their colleagues, and stay with their employers longer than people working at low-trust companies. They also suffer less chronic stress and are happier with their lives, and these factors fuel stronger performance.” Zak’ s research further pointed toward the trust mechanism in the brain revolving around the hormone oxytocin. Oxytocin is a hormone produced by the body that acts as a messenger. It is the result of a cascade of chemicals we mentioned, starting with the releases of dopamine in the brain (the pleasure hormone). Dopamine then turns into the hormone serotonin (known to stabilize mood and immune system booster), which in turn signals for oxytocin to be produced in tissues throughout the body. Oxytocin generally amplifies our positive feelings toward others with noted increases in feelings generosity, forgiveness, trustworthiness, joy and security. Oxytocin drives an individual toward some

release of oxytocin. Researchers have also found that even among strangers who were asked to make eye contact for two minutes there was a reported increase in connectedness, a function of oxytocin. Further, these conversations can and should involve laughter, which produces oxytocin. Additionally, listening to a funny podcast or movie can help revive this hormone during solitary periods. 2. Meditation: Meditation is also a solitary pursuit that has been shown to produce higher levels of oxytocin. Chronic stress has left many in a situation where high levels of the hormone cortisol are released. Cortisol is the hormone that pushes our fight-orflight stress response. In a chronic stress situation cortisol remains high even when there may be no immediate danger. This chronic level of stress causes weight gain, blood sugar abnormalities, inflammation, and mental health issues. Cortisol and oxytocin are like two fighters in a ring because when cortisol is high, oxytocin is held down and can’t increase. In 2013, researchers at UC Davis discovered that cortisol reduces dramatically in just a few short weeks of mindfulness meditation. Later research marked the decrease at over 50%. Embarking on a meditative journey can help increase your feelings of trust, too. 3. Pick-Up The Phone: Research has demonstrated that a conversation over the phone with someone you trust yields oxytocin, which yields more trust. This effect can far outlast the phone conversation and carry on to whomever you are chatting with next. Reach out (on the phone) and touch someone! In a world of remote work and solitary endeavors, trust is even more important though harder to come by. Oxytocin can help set us up to make trust a part of our picture and ultimately support our resilient mental health.

VESSEL OF THE MONTH

The vessel’s innovative hybrid propulsion system includes Caterpillar main engines.

.K. headquartered HST Marine has taken delivery of the HST Ella, the first hybrid version of the successful Chartwell 24 offshore wind crew transfer vessel (CTV) design from Southampton, U.K., naval architect firm Chartwell Marine. The Chartwell 24 CTV series includes a Jones Act version, the first of which, Atlantic Endeavor, was delivered to Quonset Point, R.I.-based Atlantic Wind Transfers (AWT) earlier this year by Blount Boats, Warren, R.I. The HST Ella, just delivered by Isle of Wight shipbuilder Diverse Marine, is an aluminum-hulled catamaran with dimensions of 25.1 meters LOA by 8.63 meters beam. Its innovative hybrid propulsion system has the following main components: • Main engines 2 x Caterpillar C32 Acert • Installed power 2,162 kW • Gearboxes 2 x Servogear HD295PTIL • Propellers 2 x Servogear 1,200mm diameter • E-motors 2 x Danfoss Editron 200 kW • Battery strings 4 x Corvus 46.4kWh 10 Marine Log // September 2021

In a market first for a newbuild CTV, the diesels use hydrotreated vegetable oil (HVO30) as fuel. “Modern crew transfer operations in offshore energy increasingly require proven vessels with a powerful presence on the water,” says HST CEO Tom Nevin. “At the same time, a future-proof f leet consists of vessels with strong green credentials as the goal of emissions reduction continues to move up the agenda. Rapidly maturing hybrid technology means that environmental consciousness can sit hand in hand with operational excellence, and in the HST Ella, we have a vessel that delivers both, following a consultative design process with Chartwell Marine, and a high-quality build at Diverse Marine.” The HST Ella has a transit speed of 10 knots on electric propulsion and 30 knots on diesel, while during port operations, the vessel’s electric operation mode allows for quiet and zero-emission, low-speed maneuverability. Advanced CTVs such as the HST Ella are

increasingly expected to perform a range of auxiliary duties alongside personnel transport. The vessel is able to carry 24 industrial personnel alongside a maximum payload of 15 tonnes, ensuring maximum versatility when supporting offshore wind operations. Following its launch, the HST Ella is set to begin its maiden contract at the East Anglia 1 (EA1) wind farm. “Whether designing a diesel-powered CTV with an innovative hydrofoil system propelled by waterjets, or, as in this case, a large hybridelectric CTV using HVO fuel with controllable pitch propellers, we always look to ensure that the proven characteristics of the Chartwell 24 platform are built in,” said Andy Page, Managing Director, Chartwell Marine. “Designing for hybrid operations brings specific challenges, but our central philosophy is that we design with the vessel’s eventual operational profile front and center, and we have been proud to work with Diverse Marine and HST to incorporate lessons learnt from best practice CTV operation into this vessel.”

Photo Credit: Chartwell Marine

U

HST Ella:

First Hybrid Chartwell 24 CTV

REGULATIONS

Cybersecurity: Moving from Ideas to Action By C.F. St. Clair

Photo Credit: Shutterstock/ Shutterstock/forestgraphic

O

n August 3, the Coast Guard released its updated “Cyber Strategic Outlook” to address rising threats of cyberattacks against U.S. maritime systems. The Coast Guard writes that cyberattacks are “one of the most significant threats to (U.S.) economic and military power since World War II” and that cyber threats outpace physical threats. The outlook is an update to a 2015 cyber strategy report. The outlook is not a regulatory document per se, but operators will want to acquaint themselves with the Coast Guard’s prime areas of concern and be on the lookout for new Coast Guard directives to prevent and counter cyber hacking. Partnerships are central to this cyber defense. The outlook repeatedly references that Coast Guard Captains of the Port (COTP) will reach out “to (defense) partners, allies, international regulatory and standards organizations, and the private sector to identify and manage risks to the global maritime transportation system.” COTPs are charged with establishing an Area Maritime Security Committee and maintaining an Area Maritime Security Plan. The critical nature of cyber defense comes across in the Coast Guard’s observation that, when facing a military threat, the actual, physical ability to surge forces from domestic seaports is largely uncontested. However, that capability depends on routine, everyday commercial technology networks. If those systems are compromised, or fail, the consequences are dire: “We can no longer assume that our surge

capability and sea lines of communication will be uncontested during times of crisis,” the Coast Guard writes. To expand its cyber operations, the Coast Guard will work from risk-based and risk management strategies focusing on three broad areas, referred to as “lines of effort:” • • Defend and operate the Enterprise Mission Platform—this is the Coast Guard’s portion of the Department of Defense Information Network; • Protect the Marine Transportation System (MTS)—this is the effort most likely to involve personnel from the private sector and public ports; and • Operations in and through cyberspace—this will advance the Coast Guard’s cyberspace capabilities to complement traditional duties pertaining to defense, maritime safety and the environment. The Coast Guard notes that interconnected technologies are foundational for maritime transportation. The flip side, however, is that saboteurs use the same tech. New tech developments and applications are constant, of course; more accurately, they are constantly compounding. For example, the Coast Guard cites autonomous shipping, offshore platforms and cargo vessels as some of the future developments adding to “the attack vectors” that could be used by hackers. The outlook comments “as helpful as these new technologies are for business and supply chain operations, the advantages and complexity also increase the

target surface for cyber incidents.” The outlook is clear about what the Coast Guard needs to do to actuate its new lines of effort. What’s less clear, though, is timing: when will this work start? For example, the Coast Guard lists 10 priority tasks for protecting the MTS, ranging from reporting requirements to deploying cyber protection teams to coordinating with interagency partners. When asked about a timetable, though, despite the urgency, a Coast Guard spokesperson said that an internal team “will develop an implementation plan” but “at this point there are no defined starts, deadlines, or resource needs identified.” Ditto for any new COTP outreach to maritime officials. Area Maritime Security Committees will be tapped for increased cybersecurity “across the industry by promoting cyber risk management, accountability, and unified response plans.” Again, though, no start time yet. Cybersecurity is a priority within many groups, of course. One port security expert, commenting on background because his internal team is still reviewing the Coast Guard’s new document, said that, in general, there are many good ideas in the Strategic Outlook. He said many ports are now working to add a cyber component to overall port security plans. There are concerns, however, about exactly what should be included; still, people are proceeding with the goal of at least completing a plan even though it might be judged incomplete. He said guidance now is important to avoid “a disconnect” if cyber plans need formal approval but are then found wanting. The American Bureau of Shipping (ABS) has extensive resources on cybersecurity. A good starting document is the ABS summary “A Primer on IMO Cyber Risk Management Guidelines.” ABS notes that maritime cybersecurity has been a topic of confusion and debate for the past 20 years. Recently, though, new guidance has been forthcoming. IMO recommends placing cyber planning within safety management systems (SMS) development, familiar to most maritime professionals. The ABS Primer references conceptual approaches similar to the Coast Guard’s, i.e., developing systems built on identification, protection, detection, response and recovery. September 2021 // Marine Log 11

UPDATE

CROWLEY AND SHELL CROWLEY MARITIME CORPORATION

has signed a long-term time charter with Shell NA LNG LLC, providing for the building and operation of a new U.S.built, LNG bunker barge. With a capacity of 12,000 cubic meters, it will be the largest Jones Act-compliant vessel of its kind. It will be built at Fincantieri Bay Shipbuilding in Sturgeon Bay, Wis., and will be the second LNG bunkering barge to be built at the shipyard, which is currently constructing a 5,400-cubic-meter unit for Polaris New Energy that is set for delivery later this year. “This additional LNG barge will serve as another demonstration of our commitment to building and servicing sustainable maritime endeavors, both in the United States and globally,” said Dario Deste, president and CEO of Fincantieri Marine Group. “The new bunker barge will extend Crowley’s commitment to deliver cleaner, 12 Marine Log // September 2021

innovative solutions to help the shipping industry continue on the path to decarbonization,” said Tucker Gilliam, vice president, Crowley Shipping. “Orders for ships fueled by liquefied natural gas continue to rise, and the vessel will provide Shell an innovative and reliable service to meet demands for more sustainable energy sources.” The 416 foot long barge will feature advanced technologies in cargo handling capabilities and increased transfer rates, including a state-of-the-art solution from Shell and Crowley Engineering Services to flexibly deliver LNG to various types of LNG containment systems. The design will offer capacity for 12,000 m3 (3.17 million gallons) and product supply equipment to fully serve ocean carriers. The vessel becomes the second Jones Act-compliant bunker barge Shell has under long-ter m char ter in the U.S. It is expected to be deployed to serve

LNG-fueled ships that call on ports on the U.S. East Coast starting in 2024. “Shell is dedicated to g row ing our LNG bunkering network across key trade routes, and this barge supports our commitment to helping provide our customers with the energy solution they are looking for,” said Tahir Faruqui, general manager, Global DLNG for Shell. “The shipping sector is making progress toward decarbonization, and LNG offers immediate emissions reduction with the potential to become a net zero emission marine fuel given the possible roles of bio-LNG and synthetic LNG.” Crowley says that, aligned with actions by its New Energy division in support of the company’s sustainability commitment, the expansion of LNG capacity will allow Crowley and its customers to realize more immediate emissions reductions and fasttrack the transition to new energy sources that reduce greenhouse gas emissions.

Photo Credit: Crowley Maritime

TO BUILD AND CHARTER JONES ACT LNG BUNKER BARGE

UPDATE

Maersk Makes Major Move on Methanol

A.P. MOLLER – Maersk says that in the

Photo Credit: MAN Energy Solutions

first quarter of 2024 it will introduce the first in a series of up to 12 large oceangoing containerships capable of being operated on carbon neutral methanol. Hyundai Heavy Industries will build the 16,000 TEU vessels and the initial agreement with the shipbuilder for eight ships includes an option for an additional four vessels in 2025. The vessels will have dual fuel engines and Maersk says the additional capital expenditure (CAPEX) for the dual fuel capability, which enables operation on methanol as well as conventional low sulfur fuel, will be in the range of 10-15% of the total price. The ships’ methanol propulsion configuration has been developed in collaboration

Dry Docks Work Boats Barges JMS-Designed

Modular Dry Dock 200’ expandable to 420’ 3,800 to 7,500t Lift Capacity Designed by JMS for Group Ocean New Brunswick

with MAN Energy Solutions, Hyundai (Himsen) and Alfa Laval and represents a significant scale-up of the technology from the previous size limit of around 2,000 TEU, so it is no surprise to learn that they will be powered by the largest, methanol fueled engines ever built. Hy u n d a i ’s S h i p b u i l d i n g D iv i s i o n , HHI-SBD, has ordered eight MAN B&W 8G95ME-LGIM (Liquid Gas Injection Methanol) engines for the initial eight ships. The “95” in the designation indicates the cylinder bore in centimeters, And at 95 centimeters it is a significant upgrade on the existing 50 centimeter bore ME-LGIM engines in the MAN Energy Solutions portfolio. Hyundai Engine & Machinery Division, HHI-EMD, will build the engines. The order

contains an option for a further four engines with the first of the confirmed vessels due to enter service in first quarter 2024. The vessels will be classed by ABS and sail under Danish flags. More than half of Maersk’s 200 largest customers have set—or are in the process of setting—ambitious science-based or zero carbon targets for their supply chains. As part of Maersk’s ongoing collaboration with customers, corporate sustainability leaders including Amazon, Disney, H&M Group, HP Inc., Levi Strauss & Co., Microsoft, Novo Nordisk, Procter and Gamble, Puma, Schneider Electric, Signify, Syngenta and Unilever have committed to actively use and scale zero-carbon solutions for their ocean transport, with many more expected to follow. “The time to act is now, if we are to solve shipping’s climate challenge,” says A.P. Moller – Maersk CEO Søren Skou. “This order proves that carbon neutral solutions are available today across container vessel segments and that Maersk stands committed to the growing number of our customers who look to decarbonize their supply chains. Further, this is a firm signal to fuel producers that sizable market demand for the green fuels of the future is emerging at speed.” Maersk says it will operate the vessels on carbon neutral e-methanol or sustainable bio-methanol “as soon as possible.” However, it adds that “sourcing an adequate amount of carbon-neutral methanol from day one in service will be challenging, as it requires a significant production ramp up of proper carbon neutral methanol production, for which Maersk continues to engage in partnerships and collaborations with relevant players.

Let’s make plans. Naval Architecture Marine Engineering www.JMSnet.com 860.536.0009

September 2021 // Marine Log 13

UPDATE

OHT Heavy Lift Ship Completes Tricky Balancing Act

NORWEGIAN SPECIALIST transportation

OHT was chartered by Promaritime International to transport the dry dock, ADBS-1, from Abu Dhabi, around the Cape of Good Hope, to Brest, France. The project got underway at the end of April in Abu Dhabi, where the dry-dock

Photo Credit: OHT

and installation contractor OHT has released details of a challenging contract earlier this year that saw its semi-submersible heavy lift ship M/V Hawk doing a 40-day balancing act with a 180 meter long floating dry dock.

measuring 180 meters long by 37 meters wide, was loaded and diagonally stowed on the Hawk’s deck. The overhang of the dock, measuring approximately 32 meters long on each side of the Hawk, in combination with the vessel’s beam of 55.5 meters resulted in an overall transport width of close to 120 meters. OHT reports that thanks to the exceptional experience of its captain and crew, the Hawk was able to safely nav igate around the Cape of Good Hope with only minimal delays due to adverse weather and without stopping in any safe haven, such as Port Elizabeth. The Hawk arrived in Brest on June 8, 2021, where the floating dry dock was smoothly and seamlessly discharged the following day, with professional support from Promaritime in the coordination of the marine operations. According to Promaritime, ADBS-1 was next towed to Damen Shiprepair Brest for two months of painting and repairs prior to be towed to the port of Rouen to get ready for operations.

14 Marine Log // September 2021

UPDATE

AAM Launches America’s First Hydrogen Fuel Cell Ferry

ALL AMERICAN MARINE INC. (AAM),

Bellingham, Wash., and vessel owner SWITCH Maritime report that the 70-foot, 75-passenger hydrogen fuel cell powered ferry Sea Change has been launched and has started operational trials. The vessel will operate in California’s Bay Area and has been developed and constructed to demonstrate a pathway to commercialization for zero-emission hydrogen fuel cell marine

technologies. Its launch marks both a U.S. and a world first. While still working on permitting of hydrogen fuel systems for maritime vessels with the U.S. Coast Guard, the completed ferry will exhibit the viability of this zero-carbon ship propulsion technology for the commercial and regulatory communities. The project is funded by private capital

from SWITCH, an impact investment platform that is building the first fleet of exclusively zero-carbon maritime vessels to accelerate the decarbonization and energy transition of the U.S. maritime sector. SWITCH acquired the vessel, then named the Water–Go–Round, from project initiator Golden Gate Zero Emission Marine (GGZEM), now named Zero Emissions Industries, in June 2019. The vessel is equipped with a hydrogen fuel cell power package provided by Zero Emissions Industries, comprised of 360 kW of Cummins fuel cells and Hexagon hydrogen storage tanks with a capacity of 246 kg. This system is integrated with 100 kWh of lithium-ion battery provided by XALT and a 2 x 300 kW electric propulsion system provided by BAE Systems. The hydrogen fuel cell power train system delivers the same operational flexibility as diesel with zero emissions and less maintenance. The vessel design originates from Incat Crowther, and the construction supervision and management is led by Hornblower Group.

Prepare for Paperless Transit as NOAA sunsets paper charts by 2025 Rose Point ECS software combined with HATTTELAND® Series X Gen2 panel computers will meet the specification for paperless carriage requirements set forth in USCG NVIC 01-16.

Photo Credit: All American Marine

Don’t get caught behind this momentous change! Choose a complete system from Rose Point Navigation Systems that combines the best ECS on the market with a 19” or 24” all-in-one system from HATTTELAND® – the best solution for your fleet to maintain compliance! For more information, please contact us at: joe@rosepoint.com

425-605-0985

September 2021 // Marine Log 15

INSIDE WASHINGTON

MARAD Makes New Marine Highway Designations

T

he U.S. Maritime Administration has designated six new Marine Highway Projects as part of the America’s Marine Highway Program (AMHP), which encourages the use of navigable waterways for the movement of freight and people as an alternative to land-based transportation. In May, the department announced the availability of nearly $11 million in grant funding that will be awarded to advance marine highway projects.

Project Designations M-5 Coastal Connector (California/ Oregon/Washington): This designation will support a service transporting goods on barges between Bellingham, Wash.; Southern Oregon; and San Diego, Calif. This project would provide regional cargo interests with additional modal options, reducing truck traffic along Interstate 5. Guam Marine

16 Marine Log // September 2021

Transportation Enhancement Initiative (Guam): This designation will expand and promote inbound and outbound cargo within the islands. Service providers transporting freight utilize U.S. ports in Hawaii and the West Coast before making their way through Guam and the Commonwealth of the Northern Mariana Islands (CNMI). CNMI Freight Improvement Project: The designation of the CNMI project will support the movement of containers between the Port of Guam and Commonwealth Port Authority ports of Saipan, Tinian, and Rota. The CNMI is exploring the expansion of its maritime capacities for the shipping of inter-island cargo and commodities to increase frequency and reduce shipping costs. Missouri River Container-on-Barge Project: This designation will expand options for the transportation of goods on inland waterways, including agricultural commodities in containers

originating within Central Missouri from ports and terminals to ocean ports along the Gulf on the M-10. Port Raritan Terminal Facility (New Jersey): This designation will support service from the Raritan Port located in New Jersey to various locations in New York City, accommodating RO/RO barges carrying wheeled containers, ferries capable of carrying trucks, LO/LO barges that can be used to support offshore windenergy turbines and other services. M-90 Transbay Freight Service Project (Wisconsin): This project will be the first to divert the transportation of large vessel modules and materialhandling equipment from the highways to the waterways among Marinette/ Menominee, Sturgeon Bay, and Green Bay. It will help ensure the long-term sustainability and growth of the service and the provision of cost-effective shipping service for that region to sustain and create jobs.

#LISW21

REGISTERED FOR THE FREE LISW21 PORTAL YET?

You will need to register if you want to access all the week’s in-person and virtual events

Scan QR code to register

(https://www.eventbrite.co.uk/e/london-international-shipping-week-2021-tickets-158897062391) For sponsorship opportunities please contact Karen Martin by emailing kmartin@elabor8.co.uk or sales@shippinginnovation.com

www.londoninternationalshippingweek.com Diamond Sponsor

Gold Sponsors

Gala Reception Sponsor

Platinum Sponsors

Silver Sponsors

LISW21 WiFi Sponsor

App Sponsor

Lanyard Sponsor

Portal Sponsor

Notepads and Pencils

In Partnership With

Early Bird

REGISTER BY OCT. 15

th

The Ferry Industry is Poised to Rebound in 2022. Are You Ready? Nov. 9–10, 2021

Hyatt Regency Jersey City on the Hudson

REGISTER NOW

www.marinelog.com/ferries

SPONSORSHIPS: dharkey@sbpub.com | QUESTIONS: conferences@sbpub.com

SPEAKERS INCLUDE

Hank Berg Seamus Murphy Cameron Clark WETA Hornblower Group Casco Bay Island Transit District

Morgan Fanberg Matthew Lankowski John Motlow Zero Emission Glosten Glosten Industries

Nigel Cabral Pace Ralli Edmund B. Welch Tideline Marine SWITCH Maritime Passenger Vessel Group LLC Association

Bruce Strupp ABB Marine & Ports

James Moran BMT

5 REASONS TO ATTEND FERRIES 2021 1

Prepare for the anticipated boom in ferry ridership at the first ferry event in 18 months for the Marine Log community

2

Be ready for changing industry regulations and compliance targets under the new administration

3

Take home lessons learned from ferry owners and operators, including moving to safer, more energy-efficient vessels

4

Discover new ways to meet economic and environmental targets through technology, innovative operational strategies, and vessel design

5

Find out how smaller operations can benefit from emerging technologies and diversify their business

SUPPORTING ORGANIZATIONS

Platinum Sponsor

Tour Sponsor

Gold Sponsor

Gold Sponsor

Gold Sponsor

Gold Sponsor

Silver Sponsor

Silver Sponsor

Silver Sponsor

Silver Sponsor

Silver Sponsor

Silver Sponsor

Silver Sponsor

Bronze Sponsor

Bronze Sponsor

Bronze Sponsor

Bronze Sponsor

Bronze Sponsor

Bronze Sponsor

Bronze Sponsor

Silver Sponsor

GREAT GREATLAKES LAKESSHIPYARD SHIPYARD

Aerial view of Donjon Shipbuilding & Repair’s yard in Erie, Pa.

GREAT LAKES SHIPYARDS ARE BUSTLING

A

round the Great Lakes region, shipyards are busy. The need for vessels, maintenance and retrofits, and necessary infrastructure improvements, have led to a hike in activity for some shipbuilders. But disparities in activity between shipbuilders in the region are not the difference between very little business in the sector and lots of it. Some shipyards in the region stayed busy with work throughout the pandemic and its sometimes cumbersome restrictions, others less so. Now, industry pros say, things are picking up. Rick Hammer, general manager for Erie, Pa.based Donjon Shipbuilding & Repair, said he’s seen a noticeable increase in business recently. “We have noticed an uptick,” Hammer said. “I don’t know if I’d link it to the lifting of the pandemic restrictions, but this year we have certainly got more RFQs.” Still, is it possible that the pandemic and the needs it created has in some ways helped to lift 20 Marine Log // September 2021

all boats, so to speak, in shipbuilding? Maybe, in part. Supply chain logistics, capabilities, and ownership are more relevant than ever, because of the pandemic-wrought travel restrictions that made shipping even more important. Now, there’s a new urgency to successfully deliver goods—almost like a wartime situation. That mindset doesn’t seem likely to change anytime soon; governments and the public have been mobilized against the perceived threat of COVID and expectations for delivering goods are changing. It’s possible that it means steady business, long-term, for shipbuilding.

Pandemic Progress Donjon Shipbuilding & Repair’s employees expected a rather brackish business pace when the COVID pandemic hit, but were surprised by how well things worked out. “We were anticipating a rather slow year,

but we had a very successful year,” Hammer said. “Most of the work done during the start of the pandemic was based on plans and budgets from the previous year. I think the fact that commerce must continue and is needed to keep America running factored into the activity.” The trains, trucks and ships still have to deliver on time during war or pandemic, no doubt. Still, it’s not as if shipyards were immune to suffering some ill effects of the pandemic. The lockdowns did create problems resulting in delays in materials and labor, but it didn’t truly impede business, according to Hammer. “Throughout the whole process we were able to remain open and operating, because as part of the marine transport industry, the shipyard was deemed to be critical infrastructure with essential workers,” he said. The unprecedented restrictions of the pandemic were especially damaging to industries that depend upon foot traffic, and many

Photo Credit: Donjon Shipbuilding & Repair

By Jonathan Barnes, Marine Log Contributor

GREAT LAKES SHIPYARD

Photo Credit: Top (Left) Fincantieri Bay Shipbuilding; Top (Right) Donjon Shipbuilding & Repair

The Mark Barker in a graving dock at Fincantieri. didn’t survive. Things are very different from that scenario in shipbuilding. It could be too soon to tell, but the overall effect of the pandemic on shipbuilding might be to have buoyed the sector, adding new projects and new relevance. Certainly, shipping is more prominent these days. Fincantieri Bay Shipbuilding kept on task during the pandemic. The company was able to keep its entire workforce employed during the past 18 months, said Todd Thayse, vice-president and general manager for Fincantieri Bay Shipbuilding. “In addition to our continued and uninterrupted support of the Great Lakes fleet, we delivered two new construction vessels in 2020, [and] are on schedule to deliver a 5,400-cubicmeter LNG bunker barge in 2021,” Thayse said. “In 2022, Fincantieri Bay Shipbuilding will be delivering the Mark Barker, the first U.S.flagged self-unloading vessel for Great Lakes service built since the 1980s.” The new ship being built specifically for the Great Lakes is part of a company legacy of shipbuilding in the region. Fincantieri Bay Shipbuilding has been upgrading and building ships for the Great Lakes for generations. “The Michigan Trader, as well as the Mark Barker, represent a significant lineage of our company. We built many of the Great Lakes bulk carriers in the 1970s and ‘80s, and have been maintaining these vessels since. We delivered the car ferry Madonna to Washington Island Ferry Line last summer, which is the largest ferry in their fleet,” Thayse said. With Fincantieri Marine Group member Marinette Marine Corporation recently awarded a $38 million contract for design and construction of a Constellation-class frigate, the shipbuilder is improving its infrastructure

Shipyard employee at work in the Donjon repair yard.

to meet the challenge of the project. Fincantieri currently is investing $300 million in its Wisconsin shipyards. “Fincantieri Bay Shipbuilding is expanding by adding new buildings for steel storage, to house our new blast and prime line operations, for additional plate and structural shape processing, as well as a new module construct building,” Thayse said. “All of these new facilities will be operational in 2021.” U.S.-flagged Great Lakes fleet operators helped push some of the activity in the past year, investing $87 million over the 2020-2021 winter season in their vessels in shipyards and facilities across the region. In the past year, Fincantieri Bay shipbuilding also has seen some other growing lines of business. “We have seen a significant increase in opportunities this year, across multiple market segments including LNG Bunkering, wind farm support vessels, dredges, ferries and various government programs,” Thayse said.

Offshore Wind Projected growth in offshore wind development has figured into some shipbuilders’ business, but not all. The growth in offshore wind projects is not fueling a lot of activity in the region’s shipyards, some say. “Offshore wind has been discussed on the lakes for many years,” Hammer adds. “It seems to ebb and flow with the politics at the time. We personally have yet to see it come to fruition.” Fincantieri Bay Shipbuilding, being a larger group, may be in a better spot to snag some of the shipbuilding work in offshore wind. Part of the current demand for vessels in the nascent U.S. offshore wind industry is for barges used in feedering systems, and for purpose-built ships such as crew transfer vessels.

The large company finds the growing new market to be a promising one. “We have worked on several projects that will become purpose-built ships and barges to support the offshore wind market,” Thayse said. “We have been working in this market for several years now, supporting our customers in the development of vessels to work in this new market, and we are expecting this market to remain viable for the near future.”

Government Funding Other government-backed business could bode well for the sector, too. President Biden has proposed spending $17 billion on inland waterways, coastal ports, ferries, and land ports of entry. But so far, Great Lakes shipyards aren’t seeing much of a boost from the announcement. “We have yet to see opportunities as a direct result of the infrastructure bill,” Thayse said. “However, we have already seen an increase in opportunities for ferry vessels. We are expecting to see continued opportunities in these market areas as these projects are funded.” The U.S. Department of Transportation’s Maritime Administration has released a report, which states that collectively, U.S. private shipyards amount to $42 billion in gross domestic product. It’s a fact that gives a better sense of the sector’s wide economic impact. “We were unaware of the magnitude of the impact, but have been well aware of the importance of the U.S. shipbuilding industry both to our local communities and the overall economy,” Thayse said. “We see firsthand the impact shipbuilding brings to our local community as we are the largest local employer in a town that has been building and maintaining ships for over 100 years.” September 2021 // Marine Log 21

BULK GREENCARRIIERS PORTS TECHNOLOGY

Bulk Carriers:

MAJOR CHARTERERS PUSH FOR GREENER TONNAGE

22 Marine Log // September 2021

seaborne trade equating to over 5 billion tons per year or 70,000 voyages per year. The major bulk commodities are coal (24%), grain (9%) and iron ore (27%). Looking away from the ups and downs of the Baltic Dry Index, most newbuilding activity in the sector is being backed by longterm charters from producers or end users of these commodities who are increasingly concerned with reducing the carbon footprint of their supply chains. One example of how this is translating into newbuilding designs is a landmark award made to Singapore’s Eastern Pacific Shipping last year by Australian mining giant BHP. The world’s first LNG

dual fuel Newcastlemax bulk carrier contract, it will see five LNG-fueled 209,000 dwt vessels delivered next year to carrying iron ore between Western Australia and China.

Ammonia, Bubbles and Rotors Another mining giant looking to cut its greenhouse gas (GHG) emissions is Brazil’s Vale. In June, it became one of 23 companies signing on for a joint industry on the potential of ammonia as a marine fuel. Meantime, the company recently took delivery of the world’s first ore carrier to be equipped with an air bubble hull lubrication. The Sea Victoria, a 325,000 dwt Guaibamax, has been equipped

Photo Credit: Vale

R

ecently, the Baltic Dry Freight Index, the main measure of bulk carrier market health, has been hovering around 11-year highs. Demand has been sustained by fundamentals, such as an increase in Chinese demand and tightness in supply of tonnage and how long the good times will keep rolling is a matter of debate. Meantime, let’s remind ourselves of some bulker fundamentals. According to Stamford, Conn., headquartered Eagle Bulk Shipping, which owns one of the world’s largest fleets of mid-size buyers, carriage of dry bulk commodities accounts for around 54% of world

BULK GREEN CARRIIERS PORTS Mining giant Vale has chartered in the first ore carrier to be fitted with Norsepower rotor sails.

with a system developed by U.K.-based Silverstream Technologies. Ten compressors installed on the ship’s deck send air to 20 devices positioned under the ship to produce a carpet of bubbles that reduce the friction between the hull and the water, reducing fuel consumption and, consequently, emissions. Vale’s navigation team estimates that, if the test is successful, the technology could be replicated on the remainder of the contracted fleet dedicated to transporting the company’s ore. “Conservative estimates point to a fuel reduction of around 5 to 8%, with a potential reduction of 4.4% in annual emissions from Vale´s maritime transport of iron ore,”

explains Vale’s technical manager for navigation, Rodrigo Bermelho. In another fuel savings development, Vale recently took delivery of the world’s first ore carrier equipped with rotor sails. Another Guaibamax, the Sea Zhoushan has five Norsepower sails distributed along the vessel that, according to Vale, allow an efficiency gain of up to 8% and a consequent reduction of up to 3.4 thousand tons of CO2 equivalent per ship per year. If the pilot project proves to be efficient, it is estimated that at least 40% of the fleet will be able to use the technology, which would result in a reduction of almost 1.5% in annual emissions from Vale’s maritime transport of iron ore. The rotor sails are cylindrical rotors, four meters in diameter and 24 meters high—equivalent to the height of a seven-story building. In a significant development in rotor sails technology, they can tilt so as not to interfere with cargo operations. Rotor sails are not the only type of sail under consideration by major dry bulk commodity shippers seeking to decarbonize their overall supply chains. Last year agribusiness giant Cargill, one of the world’s top charterers of bulkers, announced that it has partnered with BAR Technologies of the U.K. and Finnish naval architect firm Deltamarin to bring cutting edge wind propulsion technology derived from America’s Cup yacht racing to commercial shipping. The project will see BAR Technologies’’ WindWings—large, solid wing sails that measure up to 45 meters in height—fitted to the deck of bulk cargo ships to harness the power of the wind and reduce CO2 emissions by as much as 30%. The number of wing sails can be tailored to the size of the vessel and the route it will take. Its future moves on this will be to start a tendering process for constructing WindWings assisted vessels; bring customers onboard to join the WindWings consortium. This initiative is just a small part of what Cargill is doing on the emissions-reduction front. In its most recent sustainability report for 2020, it says that it has continually reduced the carbon intensity across all vessel sizes over the last four years by selecting more efficient vessels, by using digital tools to optimize vessel operations and by retrofitting energy saving devices to reduce CO2 emissions. India’s Tata Steel is another charterer looking to adopt wind assistance to lower emissions. It has recently signed a memorandum of understanding with MOL Drybulk, a subsidiary of Japan’s Mitsui O.S.K. Lines

Ltd. (MOL) to develop and deploy an environment friendly bulk carrier. Peeyush Gupta, vice president-supply chain for Tata Steel, said that the various technologies considered will include the Wind Challenger, a telescoping hard sail, which would reduce emissions by harnessing wind energy. MOL has been jointly study ing the technolog y w ith crossindustrial partners and the first vessel to be equipped with the Wind Challenger is slated to start operation in 2022. That ship is a 99,000-dwt coal carrier under construction at Oshima Shipbuilding Co. Ltd. It is set to enter service in 2022 and will be operated by MOL under a charter with Tohoku Electric Power Co. Inc. It is expected to reduce emissions of GHGs by about 5% on the Japan-Australia route or about 8% on the Japan-North America West Coast route, in comparison with a conventional vessel of the same class. Tohoku Electric Power is also involved in another cutting edge Japanese emissions reduction plan. K Line has been conducting a joint project with Mitsubishi Shipbuilding Co. and ClassNK to install a carbon capture plant onboard a vessel as part of a long-term plan aimed at cutting vessel GHG emissions by 50% (compared with the baseline year of 2008) by 2050. A first, small scale, CO2 capture plant was installed last month on the Corona Utility, a coal carrier operated by K-Line for Tohoku Electric Power.

The Conversation Changes Whether a rotor sail or a hard sail is the better way to harness wind power as an auxiliary mode of propulsion is a matter likely to arouse impassioned debate in some circles. No clear answers will emerge until some meaningful numbers of ships have been at sea with the two technologies. Meantime, the debate around green fuels also continues to intensify, with some presently available candidates looking less green than supposed. What’s worth noticing, though, is that nobody is talking much now about the pay back time needed to repay the investments in these technologies out of fuel savings. Now the conversation is simply about the extent which they will reduce GHG emissions. The take away is that leading charterers are increasingly willing to pay a premium for greener tonnage. All of this, of course, is a world away from the short term situation in which spot market operators have pushed up the price of existing, not that green, bulkers on the S&P market as they bet on the Baltic Dry Index sailing even higher. September 2021 // Marine Log 23

FEATURE VESSELS FISHING American Eagle

FISHING VESSEL ACCIDENTS NTSB Identifies Fatigue as a Major Factor

24 Marine Log // September 2021

ensure a culture of safety at sea.” “With every investigation, we learn new safety lessons to prevent or mitigate futures losses, but only when marine stakeholders at all levels of the industry apply these lessons is marine safety improved,” said Homendy. “I hope that the Safer Seas Digest 2020 provides the marine industry with essential information to better understand the safety issues confronting it, and the pathway to making maritime transportation safer.” While the report examines all maritime accidents—from inland towing to cargo ships—this article will focus on five notable fishing vessel incidents that occurred in 2019. As noted, a significant contributing causal factor in the five fishing vessel accidents is crew fatigue. The NTSB noted in the digest that an effective way to prevent fatigue among crewmembers is for owners/operators to have measures in place to ensure that crewmembers receive enough rest to adequately perform navigational and lookout duties.

Misty Blue On December 4, 2017, the uninspected fishing vessel Misty Blue was harvesting clams 9 miles southeast of Nantucket, Mass., when the port clam tank began flooding and the vessel subsequently capsized and sank. Two

crewmembers were trapped on board and perished when the vessel sank; the other two crewmembers managed to escape and were rescued by a nearby fishing vessel. Oil sheens were observed. According to the digest, the probable cause of the capsizing and sinking of the 69-foot Misty Blue was flooding of the port clam tank from an undetermined point of ingress, which led to a decreased freeboard and a list allowing boarding seas to be trapped on deck, thereby decreasing the vessel’s stability. Contributing to the sinking was the relatively small freeing port area of the vessel, which likely increased water accumulation on deck.

American Eagle and Koorale The commercial fishing vessels American Eagle and Koorale were fishing in the eastern Pacific Ocean, approximately 1,475 miles northeast of American Samoa on June 17, 2019. While pursuing the same school of tuna, the two vessels collided. Both vessels sustained damages but were able to return to port. No pollution or injuries to the 33 crewmembers aboard the 258.4-foot American Eagle or the 19 aboard the 182.1-foot Koorale were reported. Damage to the vessels was estimated at $8.3 million.

Photo Credit: American Eagle Fishing LLC

F

ishing vessel incidents feature all too prominently in the “Safer S e a s D i g e s t 2 0 2 0 ” f ro m t h e National Transportatiion Safety Board, with accidents involving five vessels being analyzed—and fatigue seen as significant in each of them. For the eighth year, the National Transportation Safety Board (NTSB) has released its “Safer Seas Digest 2020,” a compendium of the NTSB’s maritime accident investigations involving loss of life, injuries and significant property damage completed in 2020. The digest details lessons learned from those accidents involving contact with fixed objects, sinkings, collisions, fires, explosions, flooding, groundings, and capsizings. Among the investigations included in the 112-page report is the fire aboard the dive boat Conception, where 34 lives were lost, and the collision that took 11 lives aboard the USS Fitzgerald. “These tragedies remind us that whether we are serving in the nation’s armed forces, scuba diving for recreation, fishing on a trawler, or sustaining maritime commerce, we are all reliant on safety measures that must be in place before we step aboard,” said NTSB Chair Jennifer Homendy. “Mariners can use the lessons learned in the Safer Seas Digest to prevent future accidents and owners and operators can use it to help

FISHING VESSELS The probable cause of the collision between the fishing vessels American Eagle and Koorale was both vessels’ captains and fishmasters not following international collision regulations or communicating to make arrangements while pursuing the same school of fish, according to the NTSB.

Ariel The 50-foot Ariel was transiting Sheep Bay, Prince William Sound, Alaska, on August 26, 2019, when a fire broke out in the vessel’s engineroom. The four crewmembers aboard the Ariel attempted to fight the fire, but they were unsuccessful and abandoned ship into the vessel’s skiff. According to the digest, the Ariel continued to burn and subsequently sank. The crew was rescued by nearby vessels and returned to port uninjured. About 500 gallons of diesel fuel was aboard the vessel when it sank. The Ariel, valued at an estimated $600,000, was a total loss. The digest states that the probable cause of the fire aboard the fishing vessel Ariel was the ignition of fuel leaking from the generator fuel supply line in the engineroom. Contributing to the severity of the fire and the eventual loss of the vessel were the

fixed-open inlets for the engineroom ventilation, which allowed fire-extinguishing agent to escape and air to enter the space.

Pacific 1 On February 15, 2019, the 57.8-foot Pacific 1 was engaged in cod fishing in the Bering Sea near Kashega Bay, Unalaska Island, Alaska, when the vessel began to take on water at the stern. The five crewmembers abandoned the vessel and were rescued by the nearby vessel Kona Kai. No crewmembers were injured in the accident, and an oil sheen was reported. The vessel sank and was considered a total constructive loss, valued at an estimated $720,000. The probable cause of the sinking of the fishing vessel Pacific 1 was the captain’s decision to remain at sea with continuous flooding in the lazarette from an undetermined source, which accelerated and eventually led to progressive flooding.

stranded on the rocks. The NTSB stated in the digest that the vessel’s four crewmembers abandoned the boat and swam to a nearby vessel. The vessel was considered a total loss, with damage estimates at $550,000. There were no reports of injuries or pollution. The probable cause of the grounding of the fishing vessel Freyja was the failure of the deckhand on watch to monitor the vessel’s track as a result of falling asleep due to an accumulated sleep deficit and the vessel owner’s lack of countermeasures to mitigate crewmember fatigue.

Freya The 58-foot Freyja was longline fishing in the Bering Sea near Point Tebenkof, Unalaska Island, Alaska, on March 9, 2019, when the vessel grounded and remained

Misty Blue

AS THE SEAS REOPEN

Photo Credit: Enoch MacDonough

while meeting the 0.1% or the 0.5% challenges

CROE_MarineLog_halfPgAd.indd 1

9/1/21 4:07 PM

September 2021 // Marine Log 25

Q&A

LNG being used for the landmark December 10, 2020, bunkering of the M/V Damia Desgagnés in the Port of Hamilton, Ontario, by REV LNG.

ast month, the launch of Pivotal LNG’s newest liquefied natural gas (LNG) facility, Towanda LNG, marked the company’s first expansion into the Northeast and Mid-Atlantic market. Entering service in January 2021, Towanda LNG has already produced more than 1 million gallons of LNG and has supported a wide range of customers across Pennsylvania and the broader region. Located in the heart of the Marcellus 26 Marine Log // September 2021

ON THE GREAT LAKES

shale gas production region, in Wyalusing, Pa., Towanda LNG has a production capacity of 50,000 gallons per a day and approximately 180,000 gallons of onsite storage. REV LNG, with its extensive history of supplying LNG and virtual pipeline services in the Northeastern United States, is supporting the transportation and marketing services for the Towanda LNG facility. “The REV team is proud to team up with BHE GT&S and Pivotal LNG in bringing

the Towanda LNG facility to market,” said David Kailbourne, CEO of REV LNG. “With the proximity of the facility to the growing Northeast and Mid-Atlantic markets, we look forward to providing new customers access to a lower cost and cleaner fuel supply.” Even before the Towanda LNG facility’s official start-up, LNG from the plant was used for the landmark December 10, 2020, bunkering of the M/V Damia Desgagnés in the Port of Hamilton, Ontario, by REV LNG,

Photo Credit: REV LNG

Q&A: L

LNG BUNKERING IS A REALITY

Q&A LNG and its world-class LNG assets, which are part of BHE GT&S, a Berkshire Hathaway Energy company. ML: What can you tell us about the LNG bunkering efforts going on in the Great Lakes between REV LNG and HOPA? D K : In December 2020 on Lake Ontario, the marine vessel M/V Damia Desgagnés was refueled with LNG at the Port of Hamilton as part of a new partnership between HOPA and REV LNG. This was the first time LNG bunkering had ever been done on the Great Lakes. The port authority has been a critical partner from the initial conception of this project through today’s ongoing operations. Its team of professionals has emphasized collaboration and attentiveness to safety and has done great work optimizing logistics for our LNG customers. As of August 2021, REV LNG has transferred more than 800,000 gallons of LNG via Truck to Ship (T TS) operations at HOPA, with plans to scale up these bunkering operations in 2021 and beyond. The port plans to be carbon neutral by 2025, and we are proud to continue our partnership and help however we can toward its achievement of that goal. ML: This is a milestone for green shipping in the Great Lakes. In what other ways are you helping shipping customers reduce their carbon footprint?

a first on the Great Lakes. While Kailbourne told Marine Log that the company would keep the public updated on its progress on the Great Lakes, we wanted to get more background on the project and where it’s going. Marine Log (ML): First, can you tell us about REV LNG and how it’s affiliated with Pivotal LNG? David Kailbourne (DK): REV is a NYbased company and full-service provider of mobile gas solutions. We specialize in the production, supply, and transportation of liquefied natural gas (LNG), compressed natural gas (CNG) and renewable natural gas (RNG) for a range of industries. REV owns a 10% minority interest in Pivotal

customer needs for their bunkering. In the case of the Great Lakes, where a typical bunkering event requires approximately 100,000 gallons of LNG or 400 m3, it takes roughly two days of liquefaction to support the bunkering. The Pivotal-owned Towanda LNG facility in Wyalusing, PA, produces approximately 50,000 gallons of LNG per day and has 180,000 gallons of on-site storage. ML: Where do you see the future of LNG bunkering going in the next five to 10 years in the Great Lakes and elsewhere? D K : We foresee increased demand brought on by expanded environmental, social and governance (ESG) goals of vessel operators and the Canadian and United States Governments. As long as ship owners are committed to a lower carbon future, LNG suppliers like REV and Pivotal—and partners like HOPA—will have the opportunity to provide reliable fuel service. We believe LNG offers an ideal balance of economic and environmentally responsible benefits to ship owners, which allows them to make financial and operational decisions toward investments like building new LNG-fueled ships. There are other locations REV has identified with strategic partners including Pivotal to expand access to LNG in the lakes, as well. Paired with options for LNG from renewable sources, we are confident in the future of this exciting market.

DK: As a solutions provider, REV is always focused on providing our customers with innovative pathways to reduce emissions. Our initial goal was to forge an accessible and safe method to provide LNG to vessels trading on the Great Lakes. Since late 2020, we have successfully done that. Now, with regular operations there, we are in the advanced stages of reviewing ways to supply the shipping market with LNG derived from renewable feedstock. This exciting development will create a new path for shipping companies to significantly reduce carbon emissions through existing supply chains while maintaining competitive pricing. We will keep the market updated on our progress. ML: How long have do you have to run the plant in order to produce enough LNG to bunker a ship? DK: The amount of time may var y, dep ending on t he amount of L NG a

David Kailbourne, CEO of REV LNG September 2021 // Marine Log 27

FEATURE TECH SPOTLIGHT ORCHESTRA combines the American Eagle distinct qualities of GEO, LEO and 5G into a single network.

DOUBLING

DOWN

A

s co n n e c t iv i t y b e co m e s e ve r m o re e s s e n t i a l f o r shipowners aiming to stay head of the game, mobile satellite communications giant Inmarsat made two big announcements within the space of two weeks. First it announced that, over the next five years, it will invest $100 million into what it says will be the largest ever transformation of its services, creating “the communications network of the future.” Called ORCHESTRA, the new network will bring together existing geosynchronous (GEO) satellites with low ear th or bit sate l lites (LEO) and terrestrial 5G into an integrated, highperformance solution. That announcement was followed by the unveiling of Inmarsat ELERA, a global narrowband network aimed at serving the rapidly evolving world of the Internet of Things (IoT) and global mobility customers, including maritime, aviation, governments and key enterprises. 28 Marine Log // September 2021

Let’s look at ORCHESTRA first. Why that name? “An orchestra brings different instruments together, each suppor ting the other and playing its role in the mast e r p i e c e ,” s a i d R a j e e v S u r i , C E O o f Inmarsat. “We’re building ORCHESTRA on the same concept.” By combining the distinct qualities of GEO, LEO and 5G into a single network, said Suri, “we will deliver a service that is far greater than the sum of its parts. Our customers will benefit from dramatically expanded hig h throug hput services around the world. This is the future of connectivity and Inmarsat is perfectly positioned to bring it to the world with its proven technology expertise, right base of customers and partners, and financial strength.” Inmarsat says the new network will open new and previously unattainable possibilities that include close-shore n av i g a t i o n f o r a u to n o m o u s ve s s e l s , next-generation emergency safety

services for maritime crews, secure and tactical private networks for governments and direct-to-cloud connections for airlines. New segments set to benef it include en erg y r ig s an d d r il ling platfor ms, mid-mar ket business aircraft, coastal vessels, smart passenger ships and urban air mobility. According to Inmarsat, LEO, GEO a n d te r re s t r i a l n e t wo r k s h ave n e ve r been combined at scale before to create a unified connectivity ser vice for mobility customers. The result, says Inmarsat, is a “d y n a m i c m e s h n e t w o r k ” t h a t w i l l deliver high-performance connectivit y ever ywhere. By bringing together the lowest average latency and fastest average speeds with unique resilience, ORCHESTRA is designed to eliminate the indust r y-w ide chal lenge of congested network “hot spots.” Inmarsat’s existing GEO satellites—both GX and L-band—will continue to provide global coverage, high performance,

Photo Credit: Inmarsat

Inmarsat Announces Two Major New Services

TECH SPOTLIGHT security and resilience. Terrestrial 5G adds ultra-high capacity in busy “hot spots,” such as ports, airports, and sea canals. A small constellation of LEO satellites will layer additional high capacity over fur ther high-demand areas such as oceanic flight corridors. As a result, says Inmarsat, the network w ill offer the highest capacity for mobility users worldwide, and at hot spots. The network’s dynamic mesh technology will allow individual customer terminals to direct traffic to and from other customer terminals. This means that a ship within reach of a 5G ground station can receive ample capacit y for its ow n needs as well as route capacity onwards to other vessels beyond terrestrial reach. This effectively creates a mobile web of terminals that extend the network’s reach and improve its performance and resilience. The new approach means that Inmarsat can easily boost capacity in hig h-densit y areas such as por ts and airports, ensuring customer needs cont i nu e to b e m e t we l l i n to t h e f u t u re with capacity scaled directly to match their requirements.

Meeting IoT Needs So, what does ELERA bring to the party? “ELERA is perfectly suited to the needs of the connected IoT world,” said Suri. “Global reach, extraordinary resilience,

faster speeds, smaller and lower cost terminals are all part of ensuring that we remain ahead of others in meeting the needs of our customers.” ELERA builds on Inmarsat’s leading position in mobile satellite services and aims to be a springboard for innovation, unlocking, accelerating and scaling a range of pioneering uses. Its foundation is Inmarsat’s L-band network and it incorporates new innovations ranging from higher speeds to smaller, low cost terminals and the new Inmarsat-6 satellites, the first of which (I-6 F1) is scheduled to launch before the end of the year. I n m a r s a t s a y s t h a t E L E R A i n c o rporates new spectrum management capabilities that will deliver the fastest speeds globally available to L-band customers, far outstripping the capabilities of any other worldwide L-band network. Live customer trials in commercial aviation are scheduled to start during the course of 2022 and this technology will be rolled out across a range of sector specific applications for Inmarsat’s mobility, government and IoT customers over the coming few years. ELERA will also see the creation of the smallest footprint, low cost terminal for L-band users, delivering the an ideal framework for satcom IoT at scale, with supporting cloud-based management, for vertical sectors such as maritime and

aviation, infrastructure, rail, logistics, mining, agriculture and government. Inmarsat is launching two new satellites to enhance the ELERA network. The I-6 satellites, the first of which is scheduled to launch at the end of 2021, are the largest and most sophisticated commercial communications satellites ever built. The L-band capacity on each I-6 satellite will be substantially greater than Inmarsat’s fourth generation spacecraft, delivering 50% more capacity per beam; meaning that much more data can be carried over the same geographical area, in addition to unlimited beam routing flexibility. ELERA will also deliver a major ex ten s i on to In m a rs a t’s p or t fo l i o of voice-enabled de v ices, br ing ing new capabilities and innovations to hundreds of thousands of customers. Inmarsat is a world leader in global, mobile satellite communications. It owns and operates the world’s most diverse global portfolio of mobile telecommunications satellite networks, and holds a multi-layered, global spectrum portfolio, covering L-band, Ka-band and S-band, enabling unparalleled breadth and diversity in the solutions it provides. Inmarsat’s long-established g lobal distribution network includes not only the world’s leading channel par tners b u t a l s o i t s ow n s t ro n g d i re c t re t a i l capabilities, enabling end to end customer service assurance.