For Jason, Ferrari’s famous Formula One international-circuit workshop is the pinnacle of how to operate.

He models Ferrari’s attention to detail, precision engineering and lots of thinking, at the massive new Red Stag Cross Laminated Timber plant at Rotorua.

Red Stag uses cutting edge technology on premium pine timber to craft huge Cross Laminated Timber panels, up to 19 tonnes each, to specifications within a millimetre.

Red Stag supplies throughout New Zealand and is about to build another production line to keep up with growing demand for commercial buildings which are safer, quicker to build and store carbon in the wood.

But Jason still observes the human attraction for timber as a natural material. Everyone who visits the plant, he says, will stroke the timber in appreciation the first chance they get.

www.woodourlowcarbonfuture.nz

JASON CORDES Red Stag | Rotorua6: Risk management for residential building projects

In this issue of Builders & Contractors we kick off with some home truths, looking at risk management in residential building projects. With a nod to the current uncertain economic climate, we look at the relationship between land prices and infrastructure development, how to drive your company down the path to success, and five cashflow strategies you need to know.

There are pieces on the significant changes to a leading construction contract, building smarter to cut carbon emissions, how to get your head around goal setting, the Master Electricians Apprentice Challenge and the 2023 Concrete Industry Apprentice of the Year.

As always, we thank all our columnists for their expertise, along with the views, opinions and predictions of all those who contributed, to help you manage the risks you face each and every day.

8: Five cashflow strategies you need to know

10: How to quell the tyranny of urgency

12: Big changes to leading construction contract

14: Getting your head around goal setting

15: Land prices and infrastructure development

16: Driving your company down the path to success

19: Holcim New Zealand’s low-carbon initiative

20: Building smarter to cut carbon emissions

22: Building Code changes for plumbing, drainage and fire protection

27: Master Electricians Apprentice Challenge

30: HERA recognises leading metal minds

Page: 76

34: Getting to grips with steel corrosion

36: The advantages of steel framed housing

37: Patton’s engineering and design solutions

40: The benefits of hiring an accounting company

44: A resilient, low-carbon, concrete way forward

46: The Concrete Industry Apprentice of the Year search begins

50: Improving slurry management on building sites

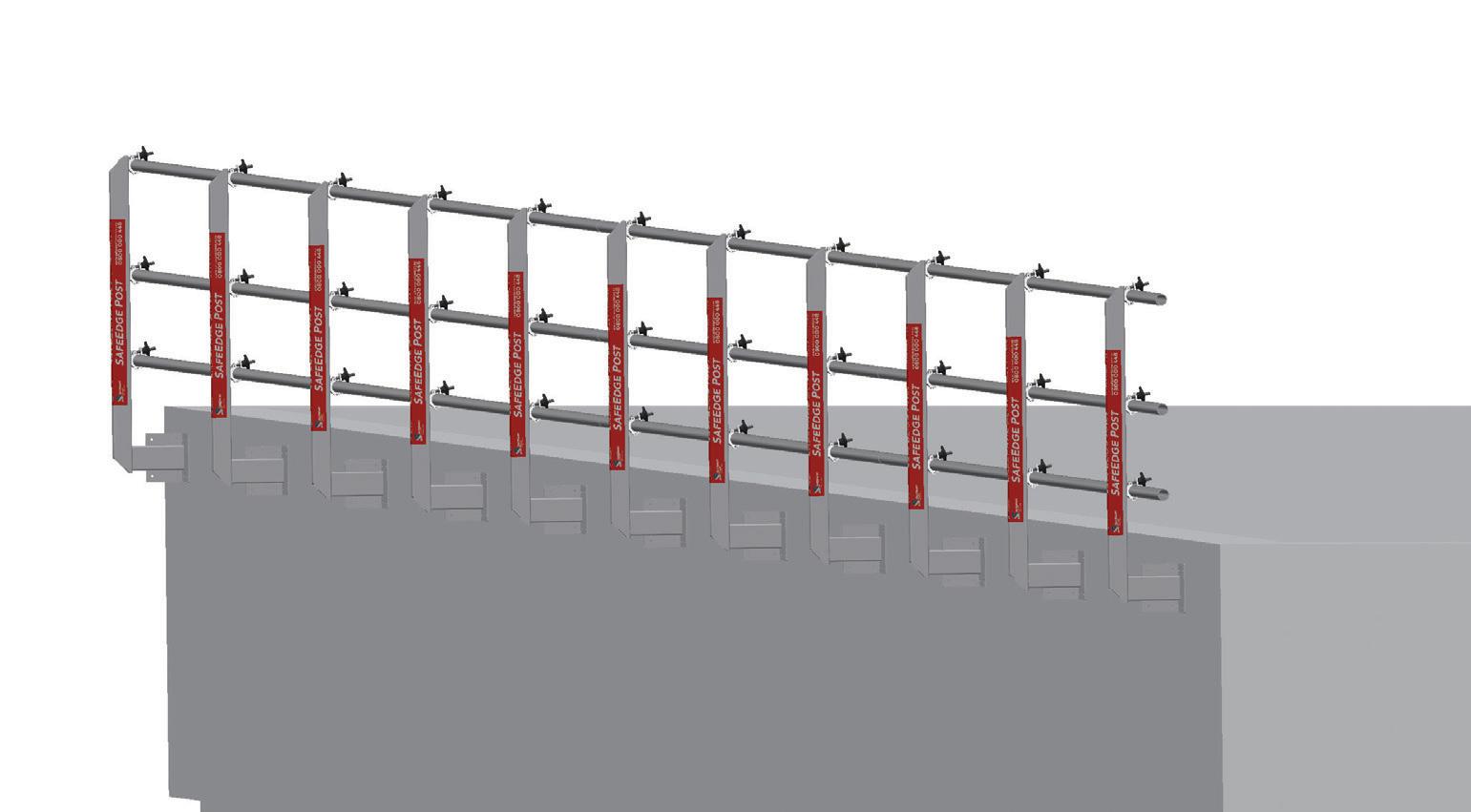

56: Working safely at heights

64: The right tools for serious jobs

66: Developing vehicle technology and its impact on safety

68: Looking out for your mates

72: The ever present danger of asbestos

76: Upgrading midtown Auckland

Editor

Head Office Auckland Office

38 Lowe Street

Addington

Christchurch 8011

Phone: (03) 961 5050

Email: admin@academygroup.co.nz

Web: www.academygroup.co.nz

Readers: Construction/building industry leaders and decision makers: government & trade organisations, site safe members, business owners and professionals in the industry.

Nationwide Distribution: Mailed directly to a carefully maintained list of decision makers and subscribers for 25 years.

Builders and Contractors, a national trade newspaper targeted directly at New Zealand's building and construction industry. For some time we were aware that, although the building and related trades were generally covered individually by some trade journals, there was no amalgamated news link for trades as a whole, especially on a nationwide basis.

This void has been successfully filled by Builders & Contractors. Distribution is by way of various outlets: PlaceMakers, Mitre 10, Builders Hardware, I.T.M., Carters, Site Safe Members, Home Ideas Centre, timber companies, hire companies, together with our database direct mail drop to architects, draughting professionals, consulting engineers, building consultants, designers and local Councils. By these means we aim to reach one of the most powerful buying groups in the industry.

80: Oamaru harbour upgrade forges ahead

Does your company have any exciting projects or products you would like to feature in an upcoming edition of Builders & Contractors?

Please contact us to discuss:

Editorial: Jonathon Taylor Phone: (03) 961 5098 editor@academygroup.co.nz

PO Box 1879, Christchurch, 8140

reproduced without written permission.

Production:

Jarred Shakespeare Phone: (03) 961 5088 jarred@academygroup.co.nz

Sales Manager: Monice Kruger Phone: (03) 961 5083 sales@academygroup.co.nz

www.buildersandcontractors.co.nz

I have previously written about risk management in the commercial setting. This article focuses on the typical array of risks that arise in residential projects, which differ from commercial projects in many respects.

For a start, it is probably the most expensive, protracted and stressful undertaking that most homeowners will encounter in their lives. Therefore, unless they are seasoned investors or developers, they will have more emotion invested in the project than commercial property owners do.

They will also have relatively little experience in managing such a project, and almost invariably they, will be doing it without an engineer to the contract or some other form of project manager. Furthermore, they will be operating on a very tight budget with very little capacity to accommodate price escalations or complex disputeresolution processes.

But, on the flip side, the final differentiating factor is that compared to commercial property owners, they have an abundance of rights and remedies they can use to hold the residential builder accountable –ranging from the law of contract, the tort of negligence, the implied service guarantees in the Consumer Guarantees Act 1993, the implied warranties in the Building Act 2004, and the 12-month defects remedy in the Building Act.

The latter three can’t be contracted out of.

In addition to that, because most residential building work is required to be carried out or supervised by a variety of licensed building practitioners (“LBPs”), an aggrieved homeowner can file a complaint about the LBPs involved in the project, with the Building Practitioners Board (the “BPB”).

However, the ironic thing is that because most residential builders supply materials and perform building work in advance, and then hope to get paid for them afterwards, homeowners have a far more powerful selfhelp remedy available, which does not even require them to establish the merits of their case – and that is to not pay the builder’s latest invoice.

That is frequently regarded by the homeowners as a perfectly satisfactory outcome to the dispute, and it forces the builder (who has already paid up to 80 percent of the invoiced amount

to the building materials suppliers and subcontractors), to initiate expensive and time-consuming disputeresolution procedures.

Because of that, any examination of risk management in residential building projects needs to focus as much on the residential builder’s risk as it does on the homeowner’s risk.

Leaving aside the residential building divisions of the large construction companies, residential builders are typically small firms who don’t have specialist personnel on the payroll to thoroughly document payment claims, variation claims and extension of time claims, and to comply with the strict formalities and deadlines that are characteristic of the commercial construction contracts.

Those contracts are simply unrealistic in a residential setting, unless the contract price is in the seven figures and the building company is better resourced than most.

To put it in perspective, the owneroperators of residential building firms are in many instances less wealthy and less educated than their clients. They might earn something like $150,000-$200,000 per year, out of, say, four major building projects, and they struggle to make ends meet.

Residential builders can’t absorb the cash flow impact of retentions or liquidated damages and they can’t raise performance bonds.

The bulk of whatever they invoice is payable to subcontractors and building materials suppliers, and the latter don’t take kindly to late payment. The prospect of them taking an unpaid $100,000 invoice in their stride is just fanciful.

The two suites of residential building contracts in most common use in New Zealand – those issued by the New Zealand Certified Builders Association and the Registered Master Builders Association – attempt to strike a balance between the competing interests of homeowners and residential builders by incorporating a comprehensive range of warranties in favour of the homeowners, some costeffective and rapid methods for resolving disputes, and some protections for the builder against the self-help remedy referred to above.

In addition, builder members of those two organisations are able to offer their customers a third party guarantee which lasts for 10 years after practical completion.

Having said that, there are some rogue residential building companies out there just as there are some rogue homeowners. So, homeowners need protection against their three most common exposures – defective work or materials, excessive delays, and unjustified overcharging.

The first risk is covered by a combination of the five different laws mentioned above, the BPB complaint process, the third party guarantees, and ideally by an experienced project manager if the homeowners can afford it.

Auckland commercial lawyerand no less, and they can reduce the scope of it if the cost gets out of hand.

With a fixed price contract, the builder is much more at risk and can only manage that risk in one of two ways. First, by adding into the price a substantial contingency in the hope that it will cover any unforeseen difficulties and cost escalations the builder can’t avoid.

That approach involves both parties gambling that the homeowner won’t end up paying too much or too little. The second way is to allow for the fixed price to be adjusted by provisional sums and cost increases, which converts the contract into a hybrid fixed price/cost reimbursement model.

The banks don’t like anything but a true fixed price contract, but in that respect, I think they are being extraordinarily naïve. For a start, every homeowner should have the right to direct variations to be undertaken, within reason, and they always result in a price adjustment.

Secondly, if the builder is counting on earning a certain amount of profit out of the project, it makes no sense to erode that profit by requiring the builder to absorb unforeseen cost escalations that the builder can’t avoid. Leaving aside the fairness of it, a financially distressed or disenchanted builder is no recipe for a successful building project. It is in neither party’s interests to construct a win-lose residential construction contract, because that is just going to sour the relationship from day one.

Delays are best dealt with by obliging the residential builder to work diligently and conscientiously until completion, because builders cannot accurately predict every obstacle that is going to be encountered, nor can they afford to pay penalties for failure to achieve an arbitrary completion date. The unjustified overcharging risk is the hardest one to manage. On a costreimbursement project a rogue builder might charge for more hours than were actually expended, or might do unnecessary work or add an excessive mark-up to the subcontractor or building materials costs.

On a fixed price project, a rogue builder might attempt to claim for variations that were in fact part of the original scope of work. Unless the homeowners have particular expertise in this area, there is no substitute for a qualified quantity surveyor and/or an experienced project manager. Cost-reimbursement contracts seem to me to be fairer, because then the homeowners are paying the true cost of the project, no more

Therefore, when reviewing a building contract prepared by a builder, I urge the homeowner’s advisers to make changes sparingly, and with the spirit and intent of the relevant clauses in mind.

Draconian contract clauses are only there to protect against scurrilous behaviour. The secret to a harmonious residential building project is continuous disclosure and total transparency, so both parties should record their expectations at the outset – and monitor their fulfilment.

Geoff Hardy has 47 years’ experience as a commercial lawyer and is a partner in the Auckland firm Martelli McKegg. He guarantees personal attention to new clients at competitive rates. His phone number is (09) 379 0700, fax (09) 309 4112, and e-mail Geoff.Hardy@martellimckegg.co.nz. This article is not intended to be relied upon as legal advice.

When reviewing a building contract prepared by a builder, I urge the homeowner’s advisers to make changes sparingly, and with the spirit and intent of the relevant clauses in mind.

WORK SMARTER TRAIN AN APPRENTICE ALREADY HAVE THE EXPERIENCE?

GROW YOUR BUSINESS THROUGH TRAINING

CALL BCITO TODAY 0800 4 BCITO (422 486)

BCITO.ORG.NZ

HAVE YOUR TEAM WORK SMARTER, LEARN UP-TO-DATE SKILLS

HELP THEM LEARN THE SKILLS AND BECOME QUALIFIED

GET SKILLS RECOGNISED WITH A FORMAL QUALIFICATION

TRAINING AN APPRENTICE IS AN INVESTMENT IN YOUR BUSINESS AND THE INDUSTRY

2. Ensure your rhythm supports your cash flow

In music, the rhythm is defined as “the underlying structure that all the other elements of music are held together by”. In your business, you also have a rhythm for cashflow. But is it one that supports or hinders your business?

Now that you have the numbers, identify your location and where you want to go. A map will show the way.

Studies from ANZ Bank showed that 82 percent of SMEs fail due to cashflow issues; 69 percent of these businesses were profitable.

In other words, 69 percent of those businesses failed not because they were making losses, but because they ran out of money to pay suppliers, wages, and other expenses to keep going. With better cashflow, many of those businesses likely would have survived.

Doctors know that without oxygen, water and food you cannot survive. Without oxygen, you will last around three minutes, without water for three days and without food, three weeks. It doesn’t matter how fit or healthy you are now - without these three essentials you will not survive.

Cash is the oxygen that keeps your business going. Not convinced? How many days will your business last without cash in the bank? Here are five proven cashflow strategies all tradies need to keep your bank account full and stress levels low.

1. Watch the canary in your coal mine

Coal mine workers would always take a canary in a cage into the mine to see if it was safe. This was their early warning sign. If there was a lack of oxygen and/or dangerous gases, the canary was the first one to be affected. If the canary died or looked unwell, they would drop tools and act immediately while there was still time.

With cashflow in your business there are also early warning signs. The canary for you might be that you seem to be always behind with bills every single week, too many overdue accounts, or that warning letter from the IRD. These are all signs that need immediate attention. It might be making an arrangement with the IRD, chasing overdue invoices, or getting more work. But don’t leave it; act now before cash flow gets out of control. Look for the warning signs early. With our clients, we always equip them with our tradie dashboard which gives a snapshot of each important part of the business and identifies the early warning signs where cashflow will be affected and needs attention.

Are you always scrambling to pay wages every month, chasing the next dollar to stay ahead for another month? Waking up at 3am in the morning realising that you forgot the GST is due tomorrow?

Or, is it a symphony where your business is predictable with a steady flow of cash to pay all the bills and then some?

Where large jobs have payment terms structured with cash flow in mind, invoices are always sent out on time, a team member regularly follows up payments, and there is a healthy cash buffer in both your cheque and tax accounts.

With the right systems in place, key team members taking responsibility and regular check-in points, you can have a predictable rhythm with much less stress and a healthy cash buffer.

3. The numbers are your guide

The numbers will show you how much cash you have available and what is required in the future.

You should be watching your cash position (if you collect all the money owed and paid everyone, what’s left), cashflow forecast (tells you what your bank account is going to look like over the next few weeks/ months), overdues, profit and loss (are you making money or digging a hole?).

Be careful to make sure your numbers are accurate. I often see a lot of builders who have profit figures that look great one month and then terrible the next. This can be a timing issue when deposits are taken or invoicing stages on larger projects, which can really skew your figures big time. We usually have a work in progress calculation added to the profit and loss to allow for this.

One of the first things I always do when working with clients is check if their numbers are correct and show them which ones are most important. Over 50 percent of the time, their numbers are wrong. Wrong information leads to bad decisions. You don’t want to be buying that new ute with cash and then discovering there is not enough to pay the taxes due next month.

If you are travelling from Auckland to Dunedin by car, and you only have a map of Canada that’s not going to help. Many tradies are using the wrong map or no map at all for their cash flow.

putting off all month, but decide to stay on the tools this afternoon instead. Get home and argue with your partner (who pays the bills), about why there is no money in the account and then feel guilty for the rest of the night that you still haven’t done the invoicing.

Procrastination kills momentum, splits your focus, and creates emotional thinking rather than being strategic.

The bank account doesn’t care how you feel or how hard you work. Ultimately it’s just a reflection of the choices (good and bad), you have made in the past, the systems you have put in place for collection, the clients you decided to work with, the overdraft facility you arranged, or the types of jobs you took on.

When you replace emotion with strategy, cashflow gets much simpler and less stressful. You make time in your week for the important things like invoicing, following up overdues, getting your team in sync and cash flow forecasting. Now you have laser focus on what needs to be done and when and who is responsible for completion.

Master this game and your business and bank account will improve significantly.

One of my clients had plenty of work on but was worried about increasing the team even though the work was profitable. The problem is, they were using the old map from last time, which was ‘grab anyone who is available and hope it works out’. It didn’t. This time is different; they have the right map now, a system for attracting and identifying the right team members and a cashflow forecast (so there are no surprises when payroll comes around), have identified the best and most profitable jobs, and built a cash buffer for the first few weeks while the new team members get up to speed. All geared to optimize cash flow. The right map will guide you on the direct path, without all the wrong detours in between.

5. Don’t let your emotions tank your bank account

Do you go into a tailspin every morning when you check the bank account and get crazy frustrated at having to follow up with the late payers yet again? That voice in your head starts playing again, “It’s just not fair…we work so hard… why us?”

Or, maybe you know you need to get into the office and do that invoicing you have been

These strategies work best when you use them consistently and are even more important as you grow your business.

But also, be aware that as your business and the economy changes, you will need to keep adjusting. Many things can disrupt short-term cashflow as the last couple of years have proven with shifting schedules, material shortages, losing or adding key team members, holidays, lockdowns, sick leave, or maybe you are in a growth phase. These all affect cashflow.

With the current uncertain environment, it’s essential to have plans in place to handle cash flow.

Cashflow is the oxygen of your business, make sure you get it right and your business will thrive.

Want better cashflow and a better business?

Book a session with me at:

www.nextleveltradie.co.nz/nextstep.

If you are travelling from Auckland to Dunedin by car, and you only have a map of Canada that’s not going to help. Many tradies are using the wrong map or no map at all for their cash flow.

If you have a team of one or thousands, cashflow is an essential key to having a successful business. It’s also an area a lot of tradies struggle with.Business coach at Next Level Tradie

Do you ever feel like a hamster on a wheel, frantically running, but getting nowhere; barely managing to keep up with the day to day demands and urgent business, let alone getting time to think about the bigger picture and what might be next?

Hopefully, this is more of an occasional situation rather than a continual state, and intentionally taking time to reflect on successes and challenges is a routine practice.

The past informs the future

Wherever you are on your leadership journey, spending time in regular selfreflection; thinking about your leadership style - and how you could improve - is an important factor in your effectiveness.

For many of us, self-reflection is something we often talk about doing, but all too often, neglect to actually make it happen until something forces our hand. This might be client feedback, changes in the business environment or an unexpected event.

The problem with this is that you tend to react rather than proactively respond; you are in effect being driven by the ‘tyranny of the urgent’.

Avoiding the tyranny of the urgent

Using a process that gets you (and keeps you) into the habit of self-reflection helps you avoid being driven by ‘the urgent’, by routinely prompting you to take a step back and consider the bigger picture of where you are headed and why you want to get there.

Stephen Covey, author of The 7 Habits of Highly Effective People, believed that we must increase the amount of time we spend on activities that build our leadership capacity and relationships.

To do this, we need to find ways to minimise the time we spend on urgent tasks that demand our attention and energy, and achieve increased balance and perspective. Ongoing reflection on our performance, goals and purpose is just that sort of activity.

So how might you go about doing this?

Given that clients, team members and everyday business can fill up your calendar really quickly, it’s crucial to create routine and structure for yourself.

As simple as it seems, blocking out time in your diary, and following a process can make all the difference.

Covey also believed that the most powerful way to increase personal effectiveness is to establish a ritual of weekly planning.

This gives you both perspective on bigger picture goals, while providing a manageable enough time span to focus on what’s in front of you.

In essence, it provides a balance between long term perspective and short-term execution, which supports your everyday wellbeing and future goals.

The first thing to do is to reconnect with what you want to achieve in the short or long term - whatever fits your big picture.

Then do what Covey calls ‘sharpening your saw’, and decide when in the coming week you will spend time attending to your wellbeing (this may be physical exercise, spending time with loved ones or friends, or learning something new).

Once you’ve locked these important activities into your calendar, block out times in the week for your personal reflection.

It’s important you ensure this happens by not letting distractions get in the way.

Enlist the support of others by making sure they know when you are unavailable and not to be interrupted.

Obviously circumstances will be different for everyone, so if that’s not an option for you, consider going off site to a place where you can do your best thinking.

A six-step process to turn reflection into action

It’s all very well spending time reflecting on your effectiveness and performance, but it is pointless unless it results in action and improvement.

It’s best to keep it simple. These six steps will help your reflective process become a habit:

1. Identify opportunities and/or areas for improvement.

2. Link these to your wider goals.

3. Share these ideas with others, when and if applicable.

4. Identify what you can do and make plans to put this into action.

5. Stop thinking about it and get on with it!

6. Rinse and repeat.

Making habits stick

Ongoing self-reflection is a cycle of continuous improvement, and has the greatest impact when you can make it stick.

A great way to support this is to record your reflections. You might use a list or a journal, write on post-its or a whiteboard, or even use audio snippets on your phone.

Whichever suits you, find a way to capture your ideas so you can revisit and implement the ones that will make the greatest difference.

Sometimes, you will need to share relevant aspects of your reflections with others to help them become a reality.

Habitually recording your reflections helps them become a reality through ongoing action by:

• Helping you clarify your ideas

• Giving you and others opportunities to identify areas for improvement and innovation

• Inviting others to support you

• Creating self-accountability for your results. This way, not only will you be more balanced, feel better about what you are achieving, and have a better perspective, you’ll be focused on what’s important.

So, if you do find yourself feeling like that hamster on a wheel, and know that you need to quell the tyranny of the urgentwhip out your diary, plan for next week and get reflecting.

Your future self will thank you for it!

Wherever you are on your leadership journey, spending time in regular self-reflection; thinking about your leadership style - and how you could improve - is an important factor in your effectiveness.

Even though we live in a society highly dependent on a “card”, like Eftpos or credit/debit cards, it is a constant battle on-site to get a MEWP operator to show his/her competent operator card.

Most of the time, they either can’t find it, lost it or were never given one by their training company.

Silvercard™ Elevated Work Platform (EWP) training – run and managed by the Hire Industry Association of NZ (HIANZ) – issues over 6,000 Silvercard™ Competent Operator cards every year.

We have some 30,000 competent operators currently registered. The card is the size and shape of a bankcard and has all the required information to verify the operator has been trained and assessed as competent.

Still, it seems, they are harder to keep safe than the card that they can buy goods with.

In an effort to make it easier for the operator to retain and produce their competency training records easily, Silvercard™ has launched an app.

The Silvercard™ Competent Operator App will display all the operator’s competencies for both EWPs and forklifts in one easy place for them to find – on their smartphone.

The app allows the operator to have the most up-to-date record of their training and assessment sitting neatly on their phone, available to whomever asks at a moment’s notice, HIANZ Chief Executive Rodney Grant says.

The app is usable both on and offline and will display a QR code. Using the app to scan this QR code will take the verifier to the Silvercard™ Database to verify the information on the screen is accurate.

New training and assessment are automatically and almost instantaneously displayed on the operator’s app,

giving confidence to supervisors, site managers, employers and PCBU’s of an operator’s competency.

The Silvercard™ Competent Operator app is only available for Silvercard™ trained and assessed operators.

Training and assessment by non-accredited providers will not be displayed. Ensure you are using a Silvercard™ accredited trainer/ assessor for all your operator training. See silvercard.co.nz to find a trainer near you.

The app will remind operators of when they are due for refresher training, says Rodney, and provides information on other relative training available to them.

Safe operating instructions and the Using EWPs Safely training support booklet are available for quick and easy support to operators. This includes an FAQ on safe operation.

“This is the next big step in creating the safest environment when working at heights,” Rodney says.

“EWPs are a control for reducing risk when working at heights. The app supports the competent operator to ensure that they are working safely and giving confidence on-site to others that working at height is low-risk when an EWP is involved and operated by a verified Silvercard™ Competent Operator.”

comprehensive courses combine theory and practical training with valuable one on one time to ensure a successful outcome.

The NZS 3910 is the contract most commonly used in New Zealand’s construction industry. However, recent industry and government reports have pointed to significant issues with the contract’s use that may erode relationships between clients and contractors.

Such relationships play a critical role in driving construction sector productivity, as well as value-for-money in public sector infrastructure spending (around $10 billion each year).

Construction Sector Accord co-chair, Tracey Ryan, says there’s been an overwhelming consensus from the construction sector that the contract needed a comprehensive update.

“The proliferation of special conditions of contract that are often added to address shortcomings in the standard contract was a big focus.

“The fairness of some special conditions and the continual fiddling with the standard contract has caused big problems for the construction industry.”

In response, the New Zealand Infrastructure Commission, Te Waihanga and the Construction Sector Accord, jointly commissioned a comprehensive revision of the contract with support from many within the sector.

Standards New Zealand was appointed in late 2021 to lead and manage the revision process, which was done by a committee of representatives from across the construction sector.

This review of 3910 is the biggest revision the contract’s had since 1987, and the draft version of the revised NZS 3910 is now out for consultation.

“This revised contract aims to bring NZS 3910 in line with the current legislative environment and market conditions,” says Accord co-chair, Andrew Crisp.

“The goal is a balanced contract that is fair and reasonable for all parties. This is expected to reduce some need for parties to insert their own lengthy and complex special conditions and help ensure that the contract is fit for the industry in 2023 and beyond.”

The revised contract is only a tool, however, and its use must be accompanied by a major culture shift, says Ross Copland, chief executive of the New Zealand Infrastructure Commission, Te Waihanga.

“While these updates to NZS 3910 are an important enabler of better construction relationships, I want to emphasise the importance of a cultural shift in our industry from a mindset of contractual ‘winners and losers’, to one where public and private client-side leaders champion fair risk allocation and strive to eliminate, manage or accept some risk, rather than just transferring it.

“In order to rebuild a strong domestic construction industry and attract the talent we desperately need, the sector needs to be profitable, fair and sustainable.

“Over the past decade we have seen far too many leading New Zealand construction

firms fail and clients are most certainly worse off as a result.

“Client behaviour will make the biggest difference, so I’m asking our construction industry leaders to take this opportunity to think about their contract and procurement processes and become champions for better contracting practice.”

The consultation document with the proposed revised standard form contract is now available on Standards NZ website and consultation on it closes on 30 June 2023.

All feedback needs to be submitted through the Standards NZ consultation tool.

Why are the Construction Sector Accord and Te Waihanga involved?

A 2018 report by consultancy Entwine identified significant issues with public sector procurement and contracting of major infrastructure projects which impacted the construction sector.

Following this, the Government and industry signed a Construction Sector Accord in April 2019, acknowledging the challenges

facing the sector and signalling a shared commitment to transform it.

This included a commitment to a more visible pipeline of work and procurement practices that are fair, efficient and predictable. A guiding principle for the Accord is the building of trusting relationships.

In February 2019, the Government announced it would establish the New Zealand Infrastructure Commission, Te Waihanga to help improve how New Zealand co-ordinates and plans its infrastructure, makes the most of the infrastructure it already has, and ensures that investment in infrastructure delivers what New Zealand needs.

The Accord and Te Waihanga are working to improve how government and the private sector work together to build public infrastructure. Their joint commissioning of the NZS 3910 revision is one example of this work.

What is the NZS 3910 review working to address?

Some key things raised in the Entwine report that this review is aiming to address include: Large numbers of special contract conditions effectively make contracts bespoke and these are often not reasonable or well understood by both the public sector and industry. These modifications, along with the use of unfamiliar contract terms, can lead to misunderstanding, confusion, and ultimately, litigation.

Specific concerns regarding special conditions that are becoming more common in public sector construction contracts relate to the use of time bars, the lack of liability caps, and

The fairness of some special conditions and the continual fiddling with the standard contract has caused big problems for the construction industry.

the impartiality of the role of the Engineer to the Contract.

Risk should sit with the party best placed to manage it. The common aggressive approach to risk transfer often means that all risk sits with the contractor. Contractors may also face ‘risk transfer by stealth’ where risk is transferred through appended contract documents such as design specifications. This is not sustainable.

In 2019, the construction sector contributed seven percent to New Zealand’s GDP and employed 10 percent of the national workforce. A thriving sector is vital to New Zealand’s social and economic wellbeing. Additionally, the public sector is a major client of the construction sector, spending around $10 billion a year on procuring infrastructure - an amount that could increase significantly in coming years, as we work to address the infrastructure gap identified in Rautaki Hanganga o Aotearoa New Zealand Infrastructure Strategy. Given such investment, it’s vital that New Zealanders get the best value from this public spending.

Timeline for Conditions of Contract for Building and Civil Engineering Construction (NZS 3910):

1987 - contract first published following a major revision of its predecessor NZS 623.

2003 - contract updated to align with Construction Contracts Act 2002.

2013 - contract underwent a limited scope review.

2018 - report by Infrastructure New Zealand identified significant issues with public sector procurement and contracting of major infrastructure projects. Creating Value Through Procurement: A Report into Public Sector Procurement of Major Infrastructure Projects (Entwine, 2018)

2019 - report by Treasury Infrastructure Transaction Unit found a ‘culture of mistrust’ between public sector (clients) and private sector (contractors). And, that this results in lots of special conditions that modify standard construction contracts and lead to misunderstanding, confusion and, ultimately, litigation. It also found a number of related issues.

An examination of issues associated with the use of NZS Conditions of Contract (Treasury Infrastructure Transactions Unit, August 2019).

2021 - Te Waihanga and the Construction Sector Accord jointly commission the revision of NZS 3910 as part of addressing issues raised in the 2019 report. The revision is carried out by a committee appointed by Standards New Zealand and that represents the range of industry and client interests.

9 May 2023 - revised NZS 3910 contract out for consultation.

30 June 2023 - consultation closes.

October 2023 - Standards New Zealand aims to release the final NZS 3910:2023 contract.

We are a privately owned small business that is passionate about all things in the building industry that involve a trowel. We carry an extremely broad variety of tools, compounds, trims, additives, sealers, paint, repair systems and so much more!

We can also back this up with expert knowledge and service, here at Trowel Trades nothing is a problem....

Setting goals is all about starting and heading into another year on the right track.

Yes, when you reached the end of 2022, you could look back and be proud of all you accomplished. This moment of proud reflection however, needs to be just that – a moment – before turning your attention to the year ahead.

According to Health Navigator New Zealand, having a goal helps motivate you and gives you direction in general everyday life.

“You may have one goal or several and they may be short or long-term. Whatever you’re aiming to achieve, it’s never too late to start.”

They also suggest research shows setting goals and working towards them can contribute to your overall happiness.

There are many different strategies to set goals. Start with deciding what your goals are by doing a self-journaling session or creating a vision board.

Writing down your goals and developing a plan on how you will achieve them is an important part of the goal setting process.

Health Navigator New Zealand says, “Writing your goals down helps clarify what you want to achieve and increases your chances of sticking to them”.

They also suggest that, “You may encounter setbacks on your journey towards achieving your goals. The key is to not give up.

“If you hit a roadblock or something isn’t working, you can always try a different approach or re-adjust some of the steps [if needed] in order to achieve your goal.”

SMART goals

Breaking down your goals into measurable stages will help you feel as if you can achieve them in a timely manner. Using the acronym SMART is one way to help stay on track. Goals which are achievable and realistic means you are more-likely to be selfmotivated to strive for achievement throughout the year.

SMART goals are:

Specific

Make sure your goals are specific enough so you know exactly what you are working towards. Breaking this down can also help with feeling overwhelmed when wanting to set your mind to a task.

Measurable

Ensuring you have a plan on how you can measure your goals is important. Facing the dreaded feeling of not moving forward can be disheartening. Measuring your goals in steps means the outcome will feel possible.

Achievable

This is not to say you can’t ‘reach for the stars’ with your goals, but ask yourself if they are achievable within your current circumstances. What changes do you need to implement in your day-to-day life to ensure you stay on track?

Realistic

Similar to Achievable here! You should travel but how much do you need to save? Want to

You

Be realistic with yourself about how you will work towards them and you’ll be one step closer to them coming true before you know it.

Self-determination theory

Health Navigator New Zealand says, “Setting goals that draw on personal motivations produces greater confidence in our ability to change and greater sense of ownership over the process”.

Personalising your goals to suit your personal motivations is one way to ensure you pick the right goals and they ‘stick’.

eat healthier? You might need to buy less dinners out. Be realistic with yourself and know goals require consistent and realistic effort.

Timely

Putting a timeframe on your goals can help motivate you. If goals are set too far in the future, they may feel impossible to complete. Or, if you don’t allow yourself enough time you may feel unaccomplished. Finding the right balance with time and goal setting is key here.

Reviewing goals periodically means you keep revisiting and reflecting on your progress. Keep on track with your goals by being honest with yourself about what stage you’re at throughout the year.

All of the SMART goal strategies work together to ensure you’re well on your way to accomplishing your goals and dreams.

“The importance of ownership for personal motivation is captured nicely in what is known as the self-determination theory of motivation.

“This place a high level of importance on doing what we find to be intrinsically motivating or working from what is inherently rewarding.”

Selecting goals which come from a place of personal value over external validation will also mean achieving your goal will feel that much more satisfying.

Throughout the year make sure to look after all aspects of your hauora wellbeing including mental and physical health.

Goal setting should be a positive experience where you can take time to understand what you envision your year to look like.

Setting goals in the New Year can be daunting and exciting. Looking ahead into the future can feel impossible but with small, consistent steps, you will be able to see change in your life.

may have one goal or several and they may be short or long-term. Whatever you’re aiming to achieve, it’s never too late to start.

need, from neighbourhood schools to major public transport routes.

“Our current ‘wait and see’ approach often means that valuable infrastructure doesn’t get built at all. By the time we need a new school or a better transport route, the right sites for that infrastructure are gone - they’ve got houses built on them.

“Planning ahead and protecting sites in advance can break that vicious cycle,” he says.

Te Waihanga general manager strategy, Geoff Cooper, says land prices are, in part, an infrastructure issue.

“On one hand, a shortage of infrastructure can limit development opportunities in cities, contributing to higher prices. On the other hand, high land prices can make it costly and difficult to build infrastructure where and when it is needed.”

The first report, Urban land prices - a progress report, examines trends in urban land values between 2010/11 and 2020/21. Between 2010 and 2021, the difference between urban and rural land prices roughly doubled in nearly every large New Zealand city: Auckland, Hamilton, Tauranga, Wellington and Queenstown.

The report finds that infrastructure and planning costs are factors in these increases. The exception is Christchurch, where land has remained more affordable which may possibly be due to changes to housing development and infrastructure following the 2011 Canterbury earthquake.

“In recent years, New Zealand has made significant progress towards addressing challenges with housing supply and urban development, but urban land prices remain high,” Geoff says.

“In some places, infrastructure may now be the main constraint to homebuilding. We know that the sector faces funding, financing, and workforce capacity challenges. And, costs to subdivide and service residential land are rising.”

The second report, Protecting land for infrastructure: How to make good decisions when we aren’t certain about the future, examines how we can manage the impact of rising land prices on infrastructure project delivery.

It finds that designation or acquiring land for infrastructure in advance can make it cheaper and easier to build the infrastructure we

Protecting land needed for future infrastructure keeps our options open and can be easily reversed - we can sell the land if it is ultimately not needed.

“Developing infrastructure is a big investment and once built it will last for decades. Our findings suggest there are ways we can make better long-term infrastructure decisions - no matter what the future holds.”

Key points from Urban land prices - a progress report

• Between 2010/11 and 2020/21, nearly every large New Zealand city, with the exception of Christchurch, experienced significant increases in the value of urban land relative to nearby rural land. For instance, in 2010, Auckland’s urban land values were 2.1 times higher than the value of adjacent rural land. By 2021, this ratio had risen to 4.4.

• In dollar terms, this has been a significant increase. In Auckland, urban-zoned land was valued at a premium of nearly $1,300 per square metre relative to nearby rural-zoned land in 2020/21. This is up from a premium of less than $200 per square metre in 2010/11. Tauranga has a difference of $1,100 per square metre, while Wellington, Hamilton, and Queenstown have differences in the range of $400 to $500 per square metre.

• Christchurch is the only city to experience declining rural-urban land value differences. In 2020/21 Christchurch had the lowest price premium for urban land - around $200 per square metre. While the reasons for this weren’t examined specifically, this is likely due to the impacts of the Canterbury earthquakes and subsequent rebuilding.

• These findings do not reflect the impact of the 2020 National Policy Statement on Urban Development and the 2021 Medium Density Residential Standards, which are expected to reduce pressure on land prices but which were not fully implemented by councils until after the end of our analysis period.

Key point from Protecting land for infrastructure: How to make good decisions when we aren’t certain about the future

• This paper identifies and tests methods that can potentially be used to determine when advance site protection is warranted in New Zealand.

• It models different scenarios using case studies of advance site protection for a small project - a school for a growing suburb - and a large project - a major rail line extension. In each case study, we considered three broad options for acquiring land to build the project: advance purchase, obtaining an option to purchase, and wait and see.

These case studies show that:

• Advance site protection can be beneficial even when it is uncertain when, or if, a project will be built

•In some cases, advance site protection may need to occur decades before projects are built

• A ‘wait and see’ approach to land acquisition often means that needed infrastructure doesn’t get built

• Analysing uncertainty is a powerful tool to decision-makers, but more guidance would be needed to put this into practice.

The link between land prices and infrastructure, and the need to earmark land for future infrastructure, has been highlighted in two new research papers from Te Waihanga, the New Zealand Infrastructure Commission.

Developing infrastructure is a big investment and once built it will last for decades. Our findings suggest there are ways we can make better long-term infrastructure decisions - no matter what the future holds.

“However, a long-term strategy means you can reference back to see if you are meeting objectives and if you’re ‘failing’ what you’re ‘failing’ against and what needs to change.”

Having a business plan to reference and change directions means you can reflect on where you’re at in terms of business success.

“Social media is a way of expressing your brand’s values. For example, ownership in a dynamic TikTok retailer space can engage audiences in a cost-effective way.”

modern work environment such as flexibility or remote working are valued.

Blank Space Strategy (BSS) is an expert boutique digital marketing consultancy. Different from a typical marketing agency, BSS is focussed on supporting small business start-ups looking to grow.

Founder of BSS, Fraser Reeves, suggests some tips for businesses looking to move forward on their entrepreneurial quest and improve business success.

“At BSS we integrate ourselves with partners, founders and leaders. We provide services particularly in the digital marketing setting and digital strategy aspect,” he says.

“For example, market analysis research, geographical research or suggesting marketing strategy aligned personally with individual businesses and much more.”

Fraser says a common tip for effective ideas to improve the success of your business includes creating a long-term business strategy plan.

“I think businesses can often implement short-term actions and keep ‘moving the needle’ which can work for the short-term and might give momentum.

He says there may be businesses who continue to work hard for many years, however, are not led by strategy and rather implement ideas without considering this affect business on an evolving scale.

“Invest in organic brand strategy content. This means investing in a long-term piece of the puzzle.”

He says that sometimes businesses spend ‘too much money’ on digital marketing to fast-track sales or customer engagement.

“Depending on what industry you’re in, you want to consider who your organic customers are. Once this is clear you provide them with information, the solution and value of your product.”

Building and delivering a plan is key to reviewing progress within online digital advertising space. Fraser says self-made content is one of the biggest opportunities businesses have to make an impact in online marketing.

For some brands or businesses, outsourcing to readily available social media platforms such as TikTok can be a successful strategy for improving the success of your business.

Being prepared to evolve in business is important. Despite social media platforms such as TikTok having the possibility of not existing ‘forever’, Fraser says these platforms are still a good chance to invest in.

“Utilise all spaces on social media and don’t just stick to one. Try out different avenues and see what works for your business.”

When speaking about workplace culture and the importance of a successful work environment, Fraser says this is more important than ever before for a successful business to operate.

“Workplace culture could be considered more sophisticated than even five or ten years ago. Fostering a positive workplace culture is valued and important.

“I believe aspects such as allowing emotions in the workplace and having mechanisms where people can express themselves is important.

“External anonymous channels of communication may work for some workplaces or six-monthly structured reviews give employees the opportunity to have conversations.”

He says retaining talent can be a challenge for some workplaces now, as aspects in a

“Exploring options which work for both the employer and employee is important to the success of a positive work environment.

“Especially for younger people these days, I think there is an expectation of an adaptable workplace environment.”

Whether it’s online branding, believing in your brand, being passionate about your values or workplace culture, all impact the success of your business. Ensuring customers are confident in your solution means sales and engagement will rise in no time.

Fraser is looking to connect with any startups or businesses wanting to scale up in operations, particularly in the technology or agri-tech industry.

“There’s a lot of promise in the Canterbury region. I am interested in working with founders and leaders in this space and understanding different market places of this region.”

Fraser says he is excited to see what BSS can do for your brand and develop your business to improve the success overall.

For more information you can get in contact with Fraser through his website, blankspacestrategy.co.nz, and start your next business consultancy with him now.

Finding new ways to improve your business is essential to success. Having a clear plan for your business direction is important for drawing customer attraction to your brand.

safety as well as ‘fan on demand’ which runs only when the machine reaches its maximum heating point, thus reducing noise and the amount of dust that gets into the machine.

Additionally, it features digital meters for precise adjustment as well as an IP23S environmental safety rating which is a requirement for some mine sites.

Unique to the Weldarc 185 is its power factor correction feature, which makes it tolerant to unconditioned power when used with generators or on long extension leads. Like all WIA machines, the Weldarc 185 comes with a three-year warranty for the power source and sets the standard for machines in this category.

The Weldarc 200 AC/DC Stick and TIG welder has been enhanced with new features. Designed for repair and maintenance, aluminium boat fabrication and motorsports fabrication, the Weldarc 200 AC/DC offers precise AC TIG welding of aluminium and comes with power factor correction, ‘fan on demand’ and an LCD screen.

The 2023 range of WIA Stick, MIG and TIG welders, along with a new plasma cutter, incorporate new operating platforms that provide full digital control over the welding process for greater efficiency and precision.

The next generation of WIA welders have been introduced to New Zealand for 2023. Every model has been redesigned from the component level and feature digital technology for enhanced welding performance thanks to more precise arc waveforms and more stable arc control.

The new platform also allows easier software upgrades to be made in the future.

WIA product manager, Aleksandr Koshelyev, says “It’s exciting where we could take these

machines. Simple upgrades can be developed and implemented to meet market demands quickly and easily.”

The redeveloped models provide enhanced control over the process enabling more precise settings. Major components like the IGBT modules, bus bars, reactors, capacitors, diodes, and insulation have been either reinforced or replaced with more robust versions, increasing the reliability of the range.

Selected models of WIA’s new welders now feature an LCD interface which enables an intuitive setup process. This new functionality is achieved through the implementation of the new digital platform, giving operators a new way to interact with the machine.

For beginners, the pre-set functionality simplifies the machine setup process by interactively guiding them through the necessary steps.

WIA has also added two models – a portable Weldarc 135 stick welder as well as a Weldmatic 180 multi-process machine with a 10A plug for beginner to intermediate welders.

Also new to the line-up is the Weldmatic 200+ multi-process model which incorporates an LCD screen interface that allows easy access to pre-set parameters for quick adjustment.

The Weldarc 185 Stick / TIG welder has been redesigned with new features to suit light fabrication, repair, maintenance, farming, and building and construction projects.

The machine has a higher duty cycle than previous models enabling it to run for a longer period at 185A. This model comes with a voltage reduction device for enhanced

WIA’s new Weldmatic multi-process range is supplied with an improved MIG gun featuring a flexible goose neck for better positioning and an upgraded ball cable joint for more flexibility.

The smaller machines in the range have a built-in wire feeder making them portable. The Weldmatic 180 weighs 11kg and the 200 tips the scale at 17kg, making both models easy to transport.

For fabrication workshops, WIA offers the 3 Phase Weldmatic 350 and 500 multi-process machines and 356, 395 and Fabricator MIG welders. All come with a separate wire feeder for flexibility and manoeuvrability.

Both Weldmatic 200+ and 250 incorporate an LCD screen and offer pre-set parameter adjustment. These machines along with the Weldmatic 180, 200, 350, 500, 395 and Fabricator are suitable for both the workshop and outdoor applications and can take gas shielded and gasless wires.

The redesigned Cutmatic 45 has an improved duty cycle, power factor correction and an upgraded air filter. The machine is suitable for precise cutting required for fabrication, on-site maintenance and automotive repair. The cutter features water and oil removal filters to increase consumable life and its 11kg weight makes it portable.

WIA also prides itself in being able to support its products for a very long time in an environment where some suppliers discontinue this after a year.

“We still supply spare parts to many of our models which were discontinued more than 10 years ago,” Aleksandr says.

“When it comes to commercial welding machines, this new WIA range is very comprehensive with each machine built to meet the specific requirements of welders.”

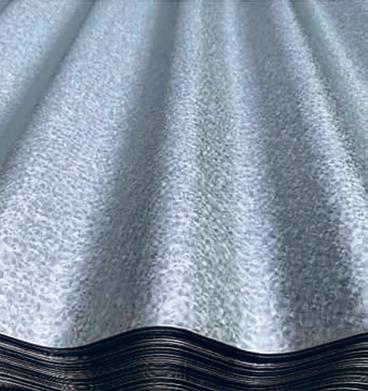

Holcim New Zealand have recently launched new low-carbon initiatives and a new brand identity to match. They’ve officially opened a new low-carbon cement replacement facility at the Ports of Auckland which will reduce the embodied carbon in construction projects.

Holcim executive general manager, Kevin Larcombe, says the company is focused on leading the decarbonisation of the construction industry in Aotearoa New Zealand.

“We recognise that, as a cement company, we have a significant role to play for decarbonisation,” Kevin says. “We have gone from being a global leader in building materials to being a global leader in innovative and sustainable building materials.”

The two biggest contributors to carbon emissions within infrastructure are concrete and steel. Carbon emissions arise during the making of cement. Carbon dioxide is emitted as a by-product of clinker production which is an intermediate product in cement manufacturing.

Kevin says Holcim want to minimise the amount of carbon dioxide given off when manufacturing clinker. They also want to reduce the amount of traditional cement, which relies on clinker, in concrete.

“We are trying to bring as many low carbon cement replacements into New Zealand as possible,” Kevin says. “The great thing about these cement replacements is that they’re

low in carbon, and improve the performance of concrete.

“As we look at what the construction industry needs in the future, we need to ensure that infrastructure can adapt to things like a growing population and climate change.”

He says concrete is the most used building material in the world due to its versatility and capability so Holcim want to enable the construction industry to have access to it without the carbon legacy.

Alongside this, Holcim have had a brand change, one that reflects the focus the company has on sustainable outcomes.

“We’ve not only refreshed the brand to reflect the new focus on sustainability but we have also launched new products, ECOPlanet and ENVIROCore – low carbon alternatives to traditional cements. We’ve also launched the new low carbon facility in Auckland,” Kevin says.

ECOPlanet can reduce embodied carbon by more than 30 percent compared to general purpose cement in New Zealand. Kevin says each year, over 1.5 million tonnes of traditional cement is used in

New Zealand which generates 1.3 million tonnes of carbon dioxide.

The products Holcim have recently launched will enable the country to substantially reduce this.

“We want to make sure we are ready for the needs of the construction industry going forward,” explains Kevin. “Particularly with the lessons from covid in the front of our minds. We need to have a resilient supply chain and make sure that New Zealand has access to low carbon cements.”

Kevin says Holcim is only going to continue to grow. “After Holcim retired its Westport

manufacturing facility, it continued to grow its offering in Aotearoa New Zealand, leveraging off its global supply chain capabilities and innovation hubs.

“We recently made an acquisition into the quarry space, subject to regulatory approvals, and we continue to look at other expansion opportunities.

“We have more announcements to come this year as we continue to deliver on our promise to lead decarbonisation in the construction industry.”

For more information, visit: www.holcim.co.nz

process, we can assess the energy flexibility and efficiency of this technique in different climates.”

Currently, the New Zealand building sector accounts for nine percent of our total carbon emissions and the government has committed to achieving net-zero greenhouse gas emissions by 2050.

University of Canterbury Department of Civil and Natural Resources Engineering, senior lecturer Dr Wentao Wu, is leading the international research which aims to reduce carbon emissions by improving energy efficiency in large buildings.

He has received Royal Society Te Apārangi Catalyst funding to find out how the building sector could use renewable energy sources such as natural ventilation and solar energy to boost the energy performance of thermal mass – the heat absorbing potential of interior furnishings and concrete floorscreating “low-carbon buildings”.

“Global warming has urged us to search for carbon neutral solutions,” Dr Wu says. “One such solution is to transform static building structures into dynamic thermal batteries that store and use energy later on.

“This not only increases energy efficiency, but also increases energy flexibility. By developing an analytical model of this

Dr Wu is leading the project in collaboration with researchers at six universities from five countries, including Harvard University in the United States, Cardiff University in the United Kingdom, and China’s Chonqing University.

Dr Wu says one solution towards designing low-emission buildings is to use cooler outside air at night to ventilate spaces inside a building.

The low-temperature outdoor night-time air cools down materials inside the building, such as concrete slab floors, so they can act as a heat sink, absorbing heat the following day and reducing the need for air conditioning systems to be used. In winter, he believes solar-heated water pipes placed inside concrete floors could be used instead of traditional electric heating systems.

“A combination of night-time ventilation in summer and passive heating in winter transforms thermal mass into a kind of thermal battery that is fuelled for a short

time by renewable energy sources including natural ventilation and sunlight,” he says. He hopes to develop a design and retrofit guideline that will help policy makers, architects and builders create buildings that are more energy efficient, reducing carbon emissions in the sector.

“Better building design can reduce energy costs by using thermal mass to reduce energy demand, especially at peak times.

“It also helps reduce carbon emissions related to buildings which is better for our environment.

“Even small steps such as opening windows at night for ventilation and making sure

curtains are open during the day can make a difference and help harness natural, lowcost cooling and heating.”

Dr Wu recently carried out research in the United States, funded by the US National Science Foundation, which demonstrated the effectiveness of using night-time ventilation systems to cool down the interiors of buildings so they can act as a heat sink the following day.

The technique was shown to achieve annual energy savings of over 600KWh for a 100 sqm building – similar to an average New Zealand home’s monthly energy usage.

A new study aims to explore how public buildings, including schools, could be designed to use sustainable cooling and heating technology and help New Zealand achieve its net-zero 2050 goal.

Buying or selling a business in the construction industry can be a challenging process. But when you engage the services of a professional business broker like Rick Johnson who knows the sector inside and out, it isn’t so complicated.

Internationally renowned as one of the most trusted companies in its field, LINK is a New Zealand owned business brokerage with branches across the country and licenced offices in Australia, the USA & the Philippines. A distinctive & tailored approach to doing business has seen LINK earn the top spot as the largest brokerage in the country, both by broker numbers and market share of successful sales.

LINK boasts copious expert brokers who are grouped into their own specialised divisions, covering a wide range of specialities from large franchises to rural businesses and everything in between.

All LINK brokers have thorough experience in their divisions, including business ownership within

these fields, offering unique & personalised insider knowledge into the sector to help clients achieve impressive results. “We are engaged by the business owner to value, prepare and market the business for sale and manage the entire process through to settlement,” explains Rick.

Based in the Hamilton/Waikato office and servicing the wider region, Rick Johnson’s area of expertise sits within building and construction, manufacturing, engineering, export, trade and service-related businesses. Rick has proven his knowledge and capabilities countless times in the arena of small to medium business brokering, with a particular focus on businesses within the $500,000 to $10 million value range.

Rick’s recent accolades reflect his dedication to brokering and successful outcomes. Last financial year, he was ranked as the #1 LINK broker in Waikato, achieving recognition for “Deal of the Year” as well as “Top Business Marketer”.

Additionally, he is regarded as one of the top 5% of LINK brokers worldwide.

Known for excellent communication, transparency & professionalism, Rick has facilitated an extensive amount of successful business sales and has mastered the craft of connecting buyers with their ideal business, while ensuring vendors get the best possible return on their investment.

As a proud Waikato local, Rick values his community and eagerly contributes to its growth. He is fiercely focused & informed on the emerging opportunities throughout the region. He remains committed to assisting small to medium-sized business owners in increasing the value of their business during exit and helping to identify the next generation of successful shareholder-owners who can continue the legacy of these businesses.

Whether you’re interested in buying or selling, contact Rick Johnson today for a free & confidential discussion to ensure an effortless transition.

“Submissions generally supported the intent to increase the level of life safety from fire in our homes but there was no clear consensus on what the technical details of the change should be.

“We have listened to the feedback we received, made some modifications to the original proposals, and recognise that further consideration is required for the protection from fire for residential homes and will continue to conduct further engagement on this.

“The changes are updates of existing documents used to comply with the Building Code. They aim to improve the quality and reliability of plumbing and drainage services and to protect people from fire in their homes,” says Dr Dave Gittings, manager of Building Performance and Engineering.

“The changes to the plumbing documents include the adoption of the latest version of the AS/NZS 3500 plumbing and drainage standards. These new versions include New Zealand specific requirements that replace several previous modifications to the standards,” he says.

“Children and the elderly are especially at risk for tap water scalds; 65 percent of severe tap water scalds have been found to occur in infants and young children under four years old.

“The changes to water supplies aim to increase protection of those who are most

vulnerable to hot water scalding from taps and baths, and better protect drinking water from backflow contamination.

“We are proceeding with changes to cite the latest industry standards for fire sprinkler, fire alarm and smoke control systems, including the requirement for interconnected smoke alarms as the minimum fire safety system in new homes.

“By adopting the latest industry standards and aligning with similar requirements in other countries, we aim to improve the safety of our communities.

“In response to mixed feedback received in the submissions, we are withdrawing portions of the fire proposal regarding protection of other property from fire spread in townhouses and low-rise multi-unit dwellings.

“By announcing these decisions prior to the publication of the revised Building Code documents, our aim is to provide certainty and direction to the sector, to give manufacturers, suppliers and installers time to comply with the new requirements, and to prepare information and education to support the sector and public with the changes.

“We are committed to continuous improvements to ensure the compliance pathways for the Building Code are fit for purpose and up-to-date and support the delivery of safe, healthy and durable homes and buildings in Aotearoa New Zealand.” The revised acceptable solutions and verification methods documents will be published in November 2023 to allow a 12-month transition period.

At the end of this transition period, the previous versions of the documents can no longer be used.

The Ministry of Business, Innovation and Employment (MBIE) is amending acceptable solutions and verification methods to ensure the safety and wellbeing of New Zealanders when it comes to plumbing, drainage, and protection from fire.

Surveyors | Planners | Engineers | Landscapers

SERVICES:

• Subdivisions

• Construction Monitoring

• Land Development

• Property Layout

• Planning

• Civil Engineering

NEW PLYMOUTH 60 Hurlstone Drive P: 06-759 0904

WHANGANUI

32 Ridgway Street

P: 006 345 0333

www.juffermans.co.nz

We offer safe and effective traffic management services for roading, construction, civil works, essential services, infrastructure, special events and filming.

• Vehicle Crossings

• Tree Felling

• Events

• Cyclist management

• Road Maintenance Or Repairs

• Pedestrian Management

STRATFORD Prospero Place

P: 06-765 4122

HĀWERA

P: 06-278 4135

JSL has a team of experienced surveyors, planners, and engineers who cover all aspects of development engineering, resource management, construction setout and monitoring, and simple back-yard subdivisions. Your

www.trafficmanagementsolutions.co.nz

Are you an upcoming, inspiring, and current apprentice as an electrician?

The annual Master Electricians Apprentice Challenge in New Zealand may interest you.

Master Electricians is a professional trade organisation representing, supporting, and advocating over 1,200 businesses in the electrical industry in New Zealand.

Most of their work is close with Members of Parliament, government officials, and industry stakeholders.

The main sponsor for the Master Electricians Challenge is Schneider Electric, alongside Etco (the electrical training experts), Mechanical Support Systems, Ideal Electrical Suppliers, and many more.

Schneider Electric believes access to energy and digital is a fundamental human right. They provide energy and automation digital solutions for efficiency and sustainability, combining world-leading technologies for designing homes, buildings, and more.

Jared Dinneen, GM of Sales, Home & Distribution for Schneider Electric, says, “We know tradespeople play a critical role as key points of contact for customers.

“We want to help expand electricians’ toolkits so they are versed in changing demand as smart home adoption accelerates.

“Sponsoring the Master Electricians Challenge is a great way for us to champion this valuable sector, and we are excited to see and reward some of the young and emerging talent in the industry.”

This year’s challenge will have a completely new design, focusing on PDL Wiser, a way to interact with your smart home from your phone easily. This includes lowering your blinds and setting your preferred temperatures and light control.

Using PDL Wiser as the new module will create opportunities for apprentices to learn and upskill within smart homes and home automation solutions.

Apprentices throughout the country will battle in two divisions for the titles of:

• New Zealand’s Top Electrical ApprenticeIndustrial Section

• New Zealand’s Top Electrical ApprenticeCommercial & Domestic Section.

A third award will be given - the Initiative Award - to evaluate how well each finalist presented. The evaluation will include how they apply health and safety and how they conduct themselves within a competition setting.

Each competitor will be given a guideline by Master Electricians, which will be an overview of what they will be tested on. This ensures that apprentices can understand that the competition is an educational experience. Sometimes this allows each participant to learn a new skill and gain knowledge from their employer.

There are 13 locations around New Zealand where the competition will hold its regional preliminary rounds, which will kick off in June, with finals in late August, in Auckland.

The top five national competitors for each division will be able to go forward into the competition to the finals; this is an allexpenses-paid trip.

In addition, there will be spot prizes and prizes for the top competitors in the preliminary regional events.

To be eligible for the big challenge, any participant must have a current training agreement.

However, an apprentice who qualifies after 10 August 2023 can compete in the regionals but will not be eligible to participate in the finals.

The Master Electricians Challenge, sponsored by Schneider Electric, is an excellent opportunity for all aged apprentices to test out their skills and gain more knowledge as they compete further into the competition.

Apprentices can visit:

www.meapprenticechallenge.co.nz, for more information and registration.

Sponsoring the Master Electricians Challenge is a great way for us to champion this valuable sector, and we are excited to see and reward some of the young and emerging talent in the industry.

- Jared Dinneen, GM of Sales, Home & Distribution for Schneider Electric

At Southern Institute of Technology – Business Division of Te Pūkenga, women are achieving notable results in trades training across a diverse range of subjects, in the construction and engineering fields.

A consistent trend in recent years has been the prevalence of women on stage at the end-of-year awards ceremonies receiving awards for excellence. The trend looks set to continue, as more women pursue desirable trades careers after graduating.

At the 2022 Invercargill Awards Ceremony, 25 women scooped 29 Trades and Technology awards across nine different subjects, including Architectural Technology, Beauty Therapy, Carpentry Pre-trade, Hairdressing, Joinery, Mechanical Engineering, Diploma and Bachelor-level Engineering, Veterinary Nursing and Animal Care.

Luke Mason, Head of School – Engineering, says much of the breaking down of barriers for women entering into a trades career has already happened.

“We’ve moved past that (initial) getting females into trades, the biggest issue is not whether there are females in the class, the bar is set higher now, and the focus is on getting them into the full range of trade careers.”

He used as an example, heavy automotive engineering. “ ... there are no barriers in those roles which traditionally were dominated by males, (which often came from the physical or heavy nature of the work).” Developments in technology have changed work environments to such an extent that those types of issues are no longer relevant, Mr Mason explained.

He added trades careers are well remunerated, with long-term options for further career growth, making them valuable and highly desirable.

“It is fantastic to be able to re-engage with our former full-time students when they return for apprentice training and find out how their careers are evolving and the positive effects it has had on their lives.”

In 2022, more than half of the students –10 out of 18 - in SIT’s Joinery class were women. Philip Johnstone, SIT Joinery Tutor, says there are two qualities they consistently see in female students which help them to succeed on the course: “they are good at attention to detail, they also listen to and follow instructions.”

Joinery can lead to diverse job outcomes, Joinery Tutor, Lee Park adds. They’ve had graduates go onto upholstery, glazing, furniture making, and aluminium joinery. “The core of the course teaches Health and Safety in the commercial workshop environment and you learn the manufacturing process, which lends itself well to a number of career options.”