What you need to know about the product information requirements

Making price cuts pay

When the banter goes too far

The driving forces behind construction costs

Shedding light on our infrastructure workforce and the drivers of construction costs

ISSUE NO.148 - 2024 WWW.BUILDERSANDCONTRACTORS.CO.NZ ONLINE

FROM

The case for increased housing density

THE GROUND UP Full disclosure

Discounting - a strategic move or a mistake?

The next steps after onsite bullying and harassement Game on Tracking Te Kaha Stadium's progress

WORK SMARTER

Have your team work smarter, learn up-to-date skills.

TRAIN AN APPRENTICE

ALREADY HAVE THE EXPERIENCE?

GROW YOUR BUSINESS THROUGH TRAINING

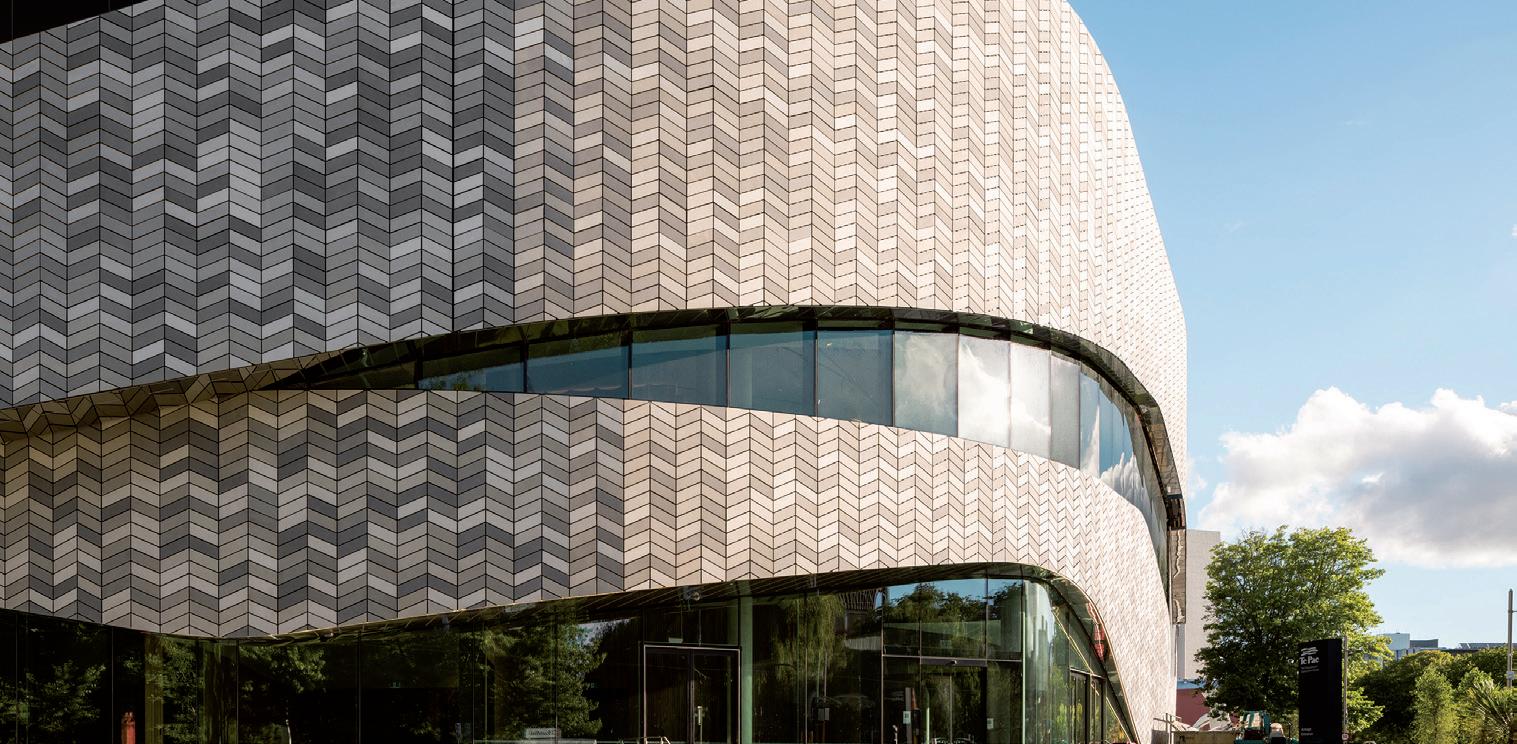

Help them learn the skills and become qualified.

Get skills recognised with a formal qualification.

Training an apprentice is an investment in your business and the industry.

ARCHITECTURAL ALUMINIUM JOINERY

BRICK & BLOCK LAYING

CARPENTRY

CONCRETE

EXTERIOR PLASTERING

FLOORING

FRAME & TRUSS

GLASS & GLAZING

INTERIOR SYSTEMS

JOINERY

KITCHEN & BATHROOM

PAINTING & DECORATING

RESIN FLOORING

STONEMASONRY

SUPERVISOR

TILING

CALL BCITO TODAY 0800 4 BCITO (422 486)

QUALIFICATIONS THAT FIT WHAT YOU DO

DESIGN

BCM-02-24-2106

Contents

Contents

Welcome - Editor’s note

This issue of Builders & Contractors features a discussion with Guy Marriage talking about the case for increased housing density in Aotearoa.

We tell you all you need to know about the new product information requirements and look at the driving forces behind construction costs as new research sheds light on New Zealand’s infrastructure workforce.

There’s also information about pricing, looking at whether discounting is a solid strategic move or a mistake, we track Christchurch’s Te Kaha Stadium build progress, and a look at Kainga Ora’s major nationwide renewal.

When the workplace banter goes too far, there’s information about the steps regarding onsite bullying and harassment and we offer six last-minute tips for the end of the March 31 financial year.

As always, we thank all our columnists for their expertise, along with the views, opinions and predictions of all those who contributed, to help you manage the risks you face each and every day.

9: Six last-minute tips for the end of the financial year

10: Discounting – a strategic move or a mistake?

12: The driving forces behind construction costs

16: Tracking Te Kaha Stadium’s progress

22: Motueka sawmill boosts Nelson’s timber industry

22: The next steps after onsite bullying and harassment

23: Minimising landslide slip-ups

23: Kāinga Ora undertakes major nationwide renewal

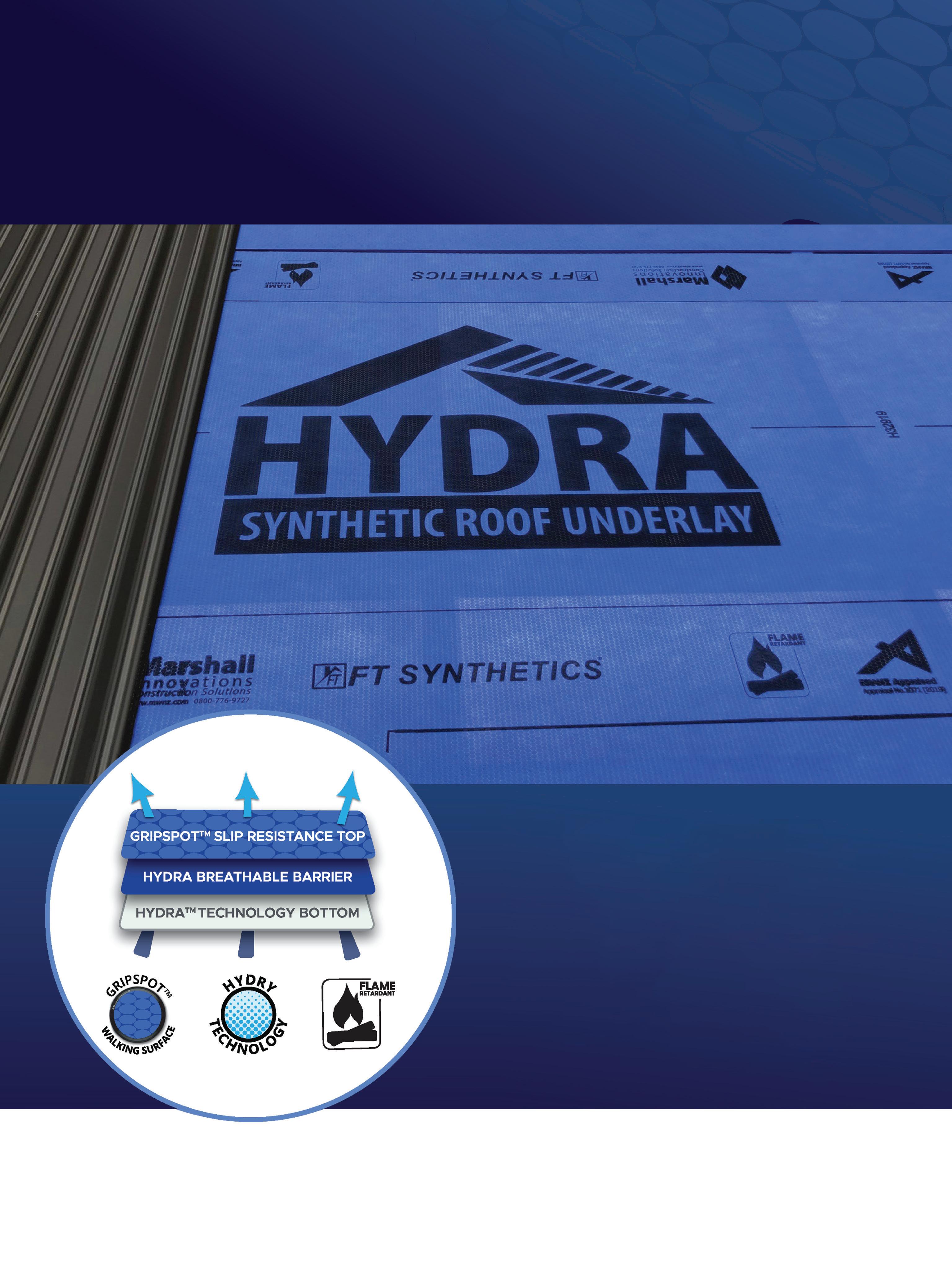

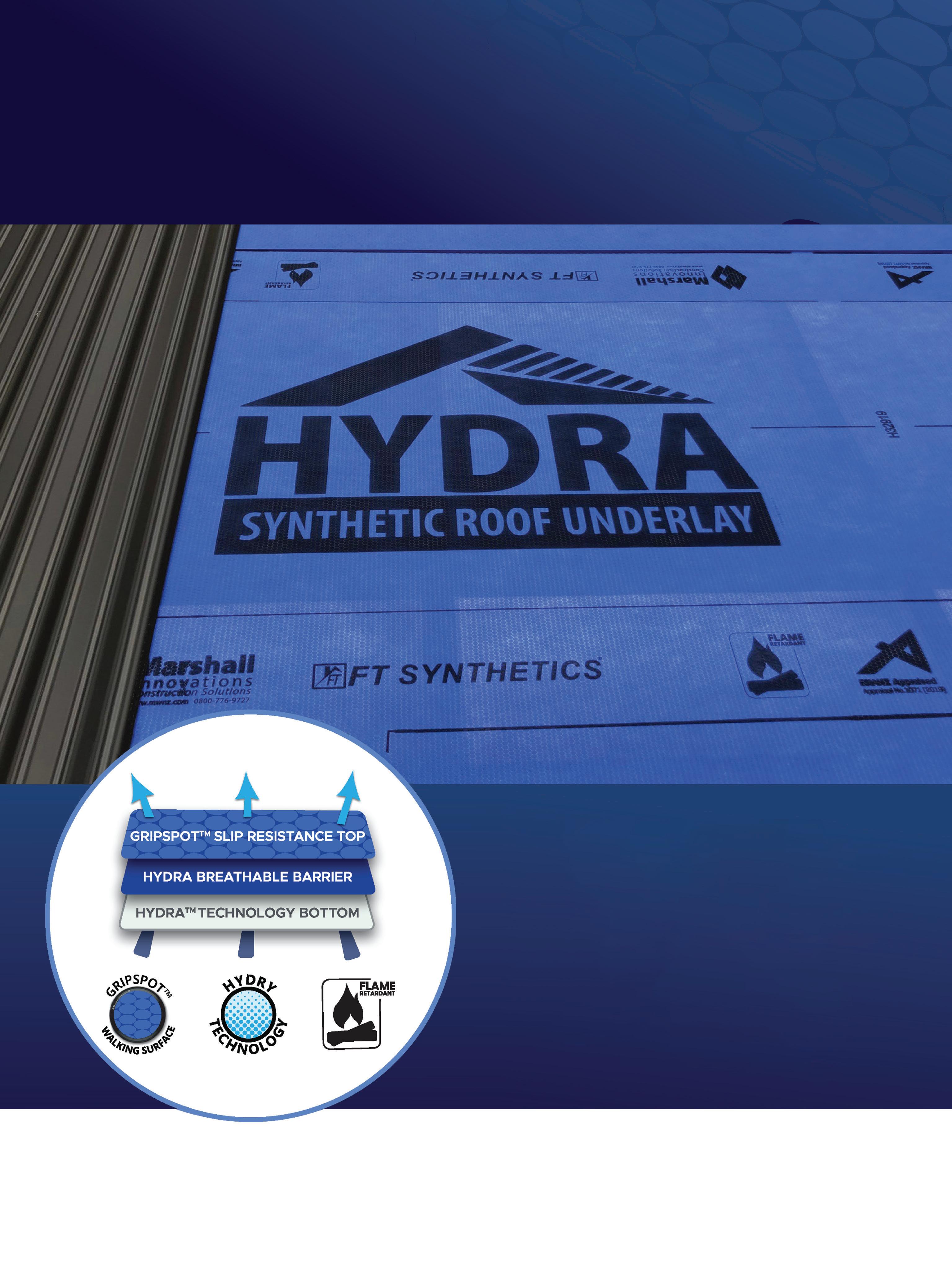

28: Roofing excellence

32: NZ Ceilings & Interiors’ fit-out fitness

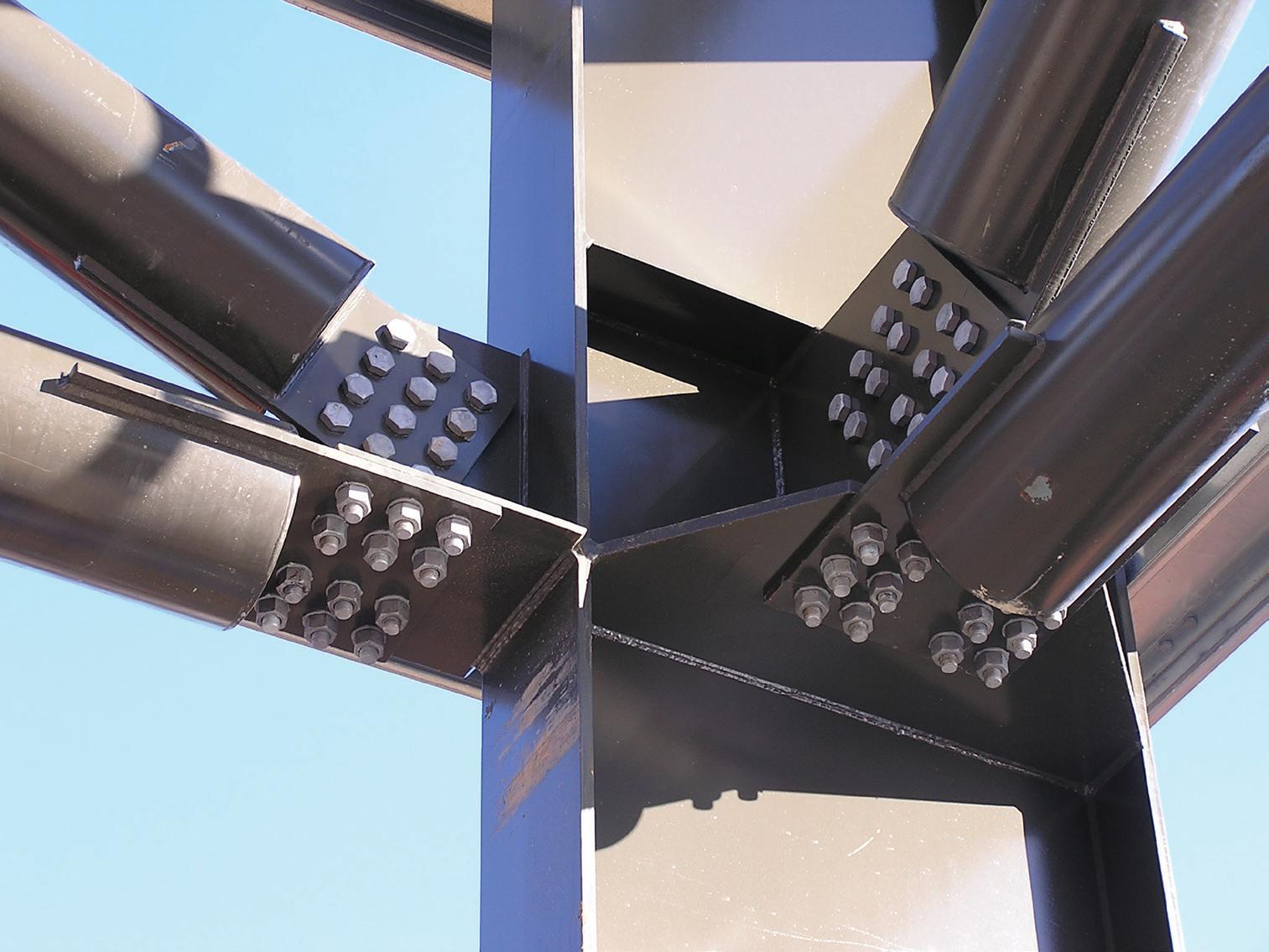

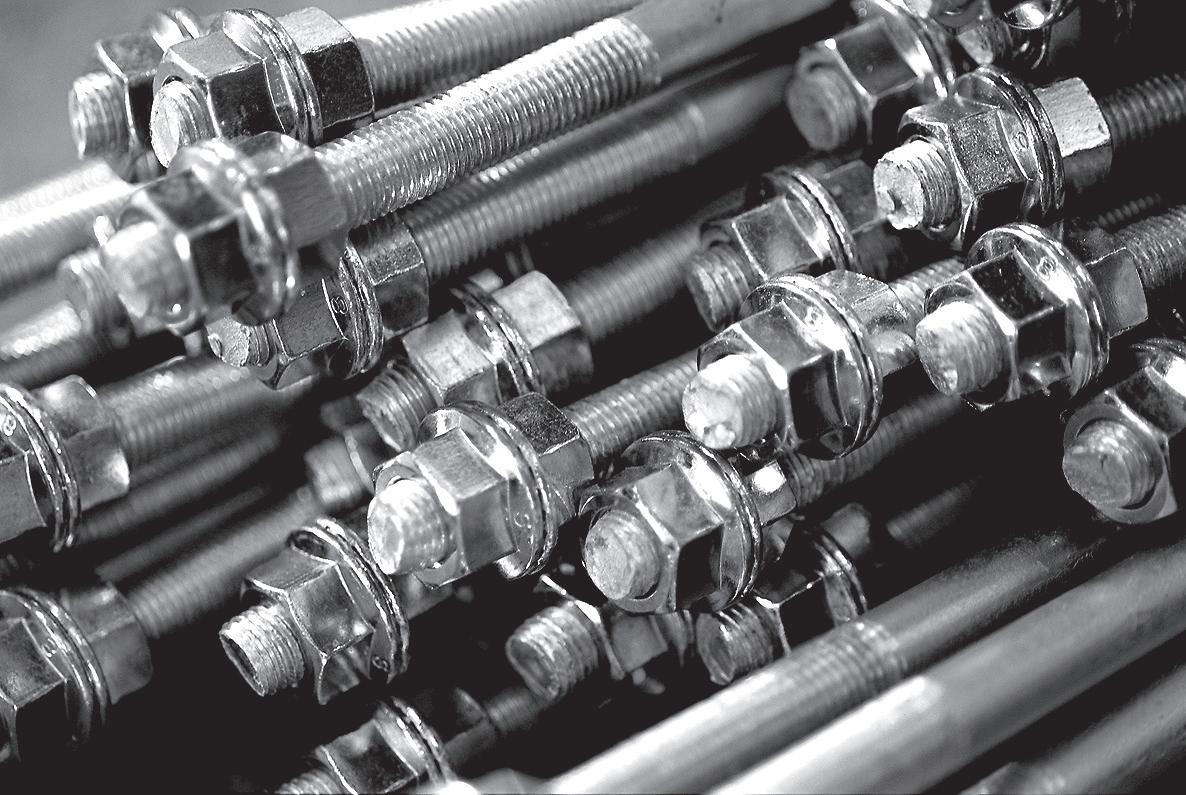

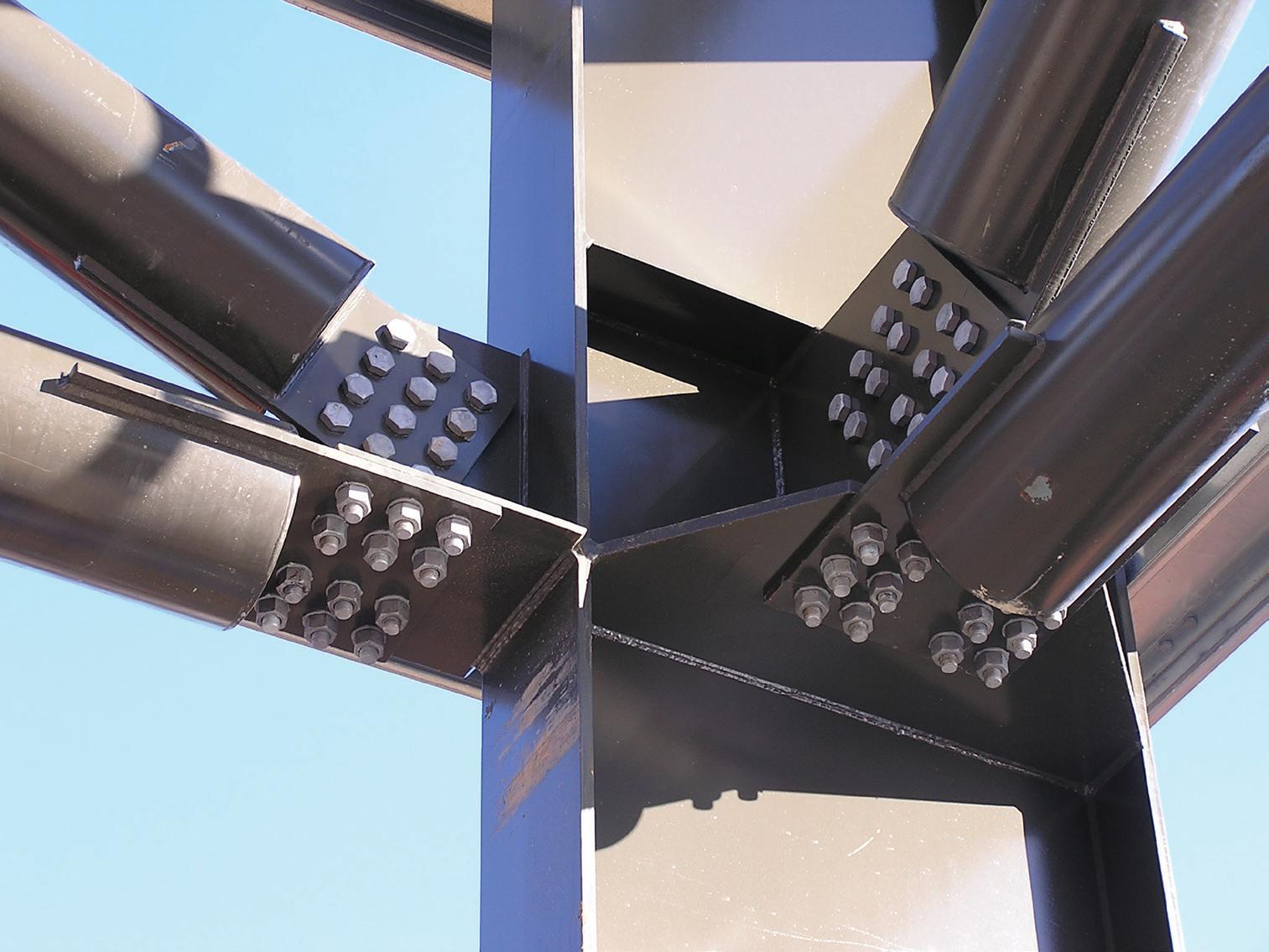

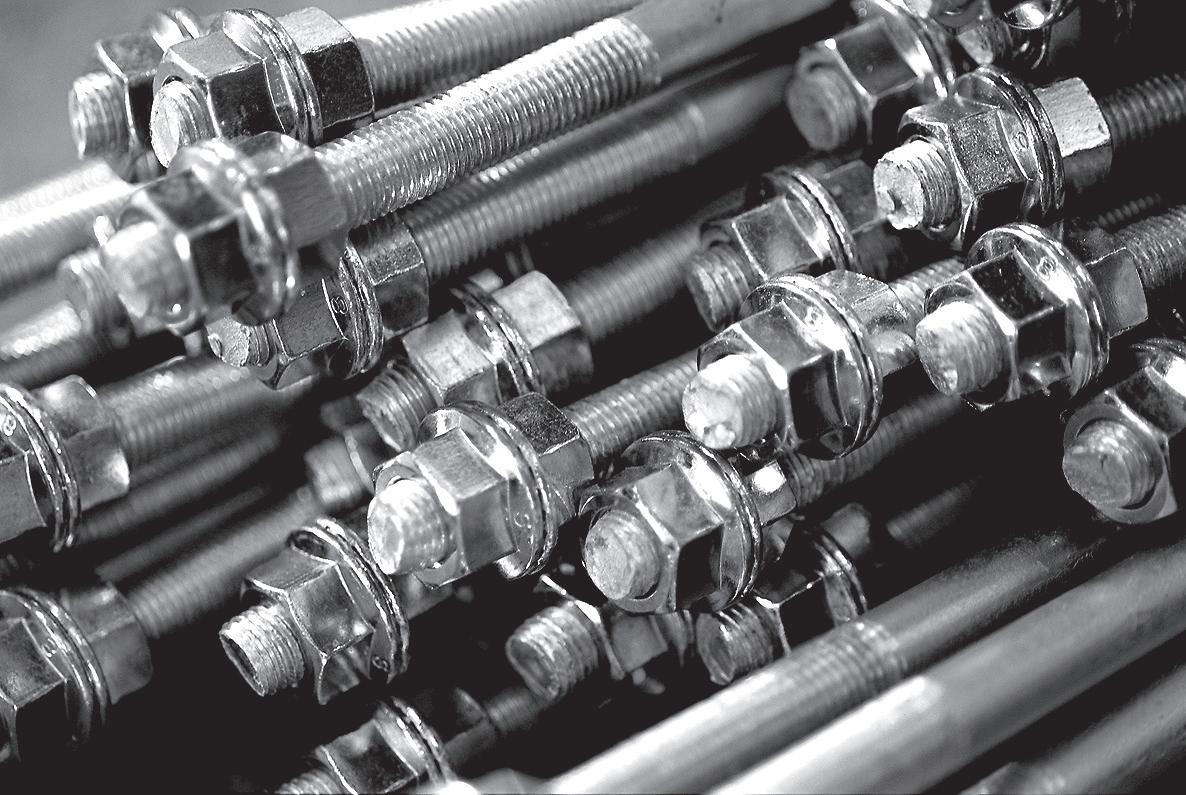

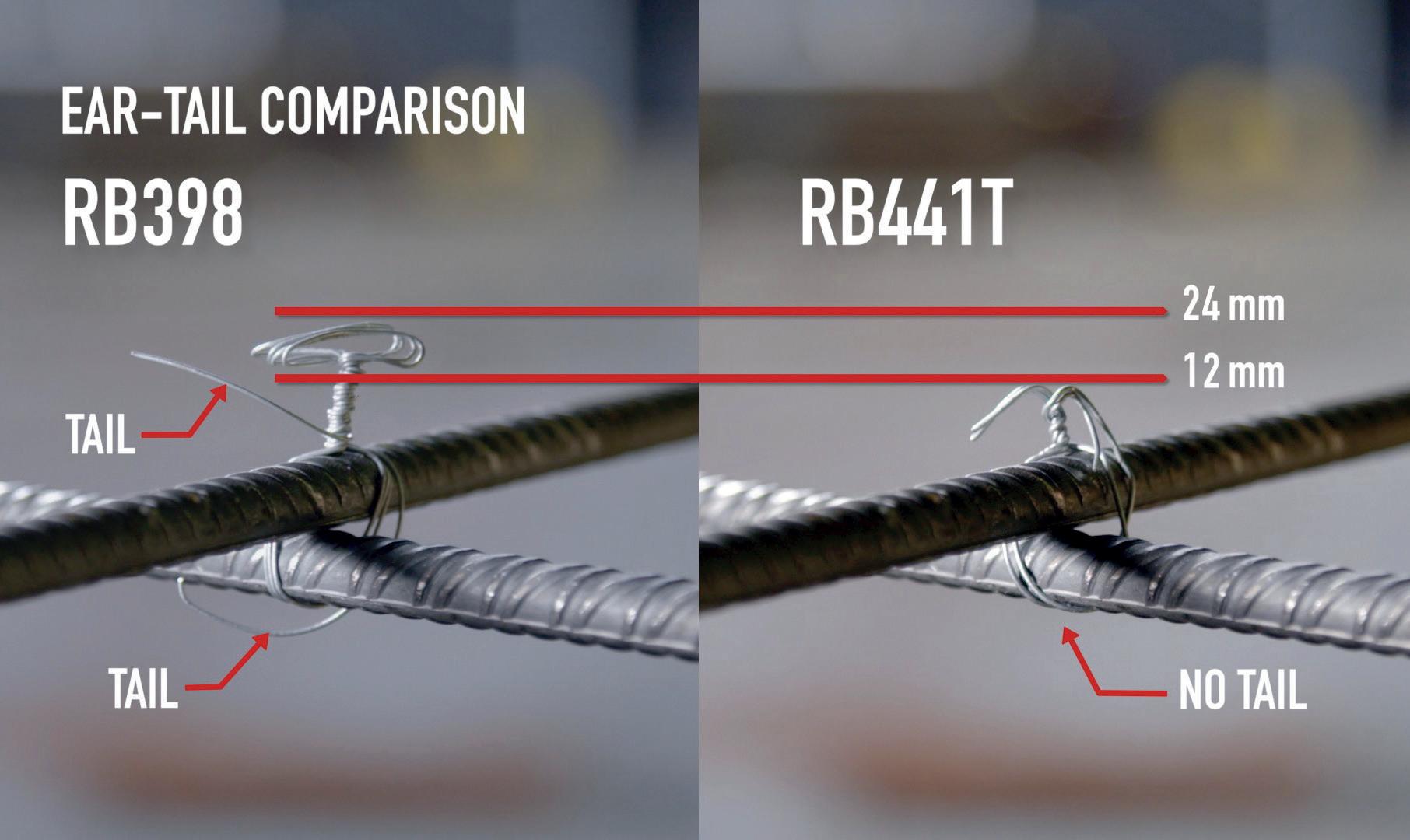

34: The Bolt Import Charter

Page: 16

42: Te Pae Convention Centre to host fib 2024 Symposium

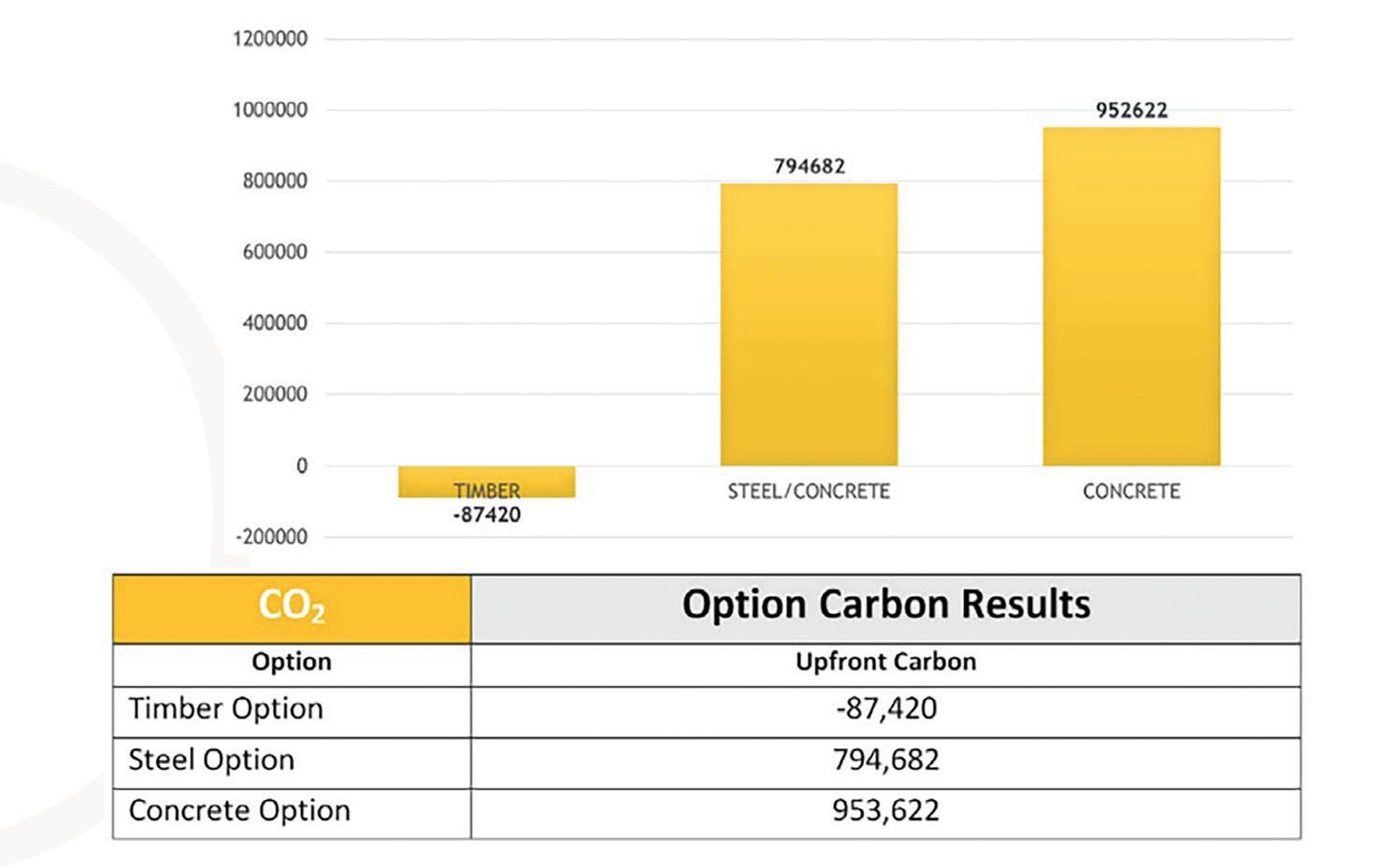

48: Transforming commercial building: the unrivalled advantage of wood

56: A better building framework with the FTMA

60: Industry reaction to H1 updates

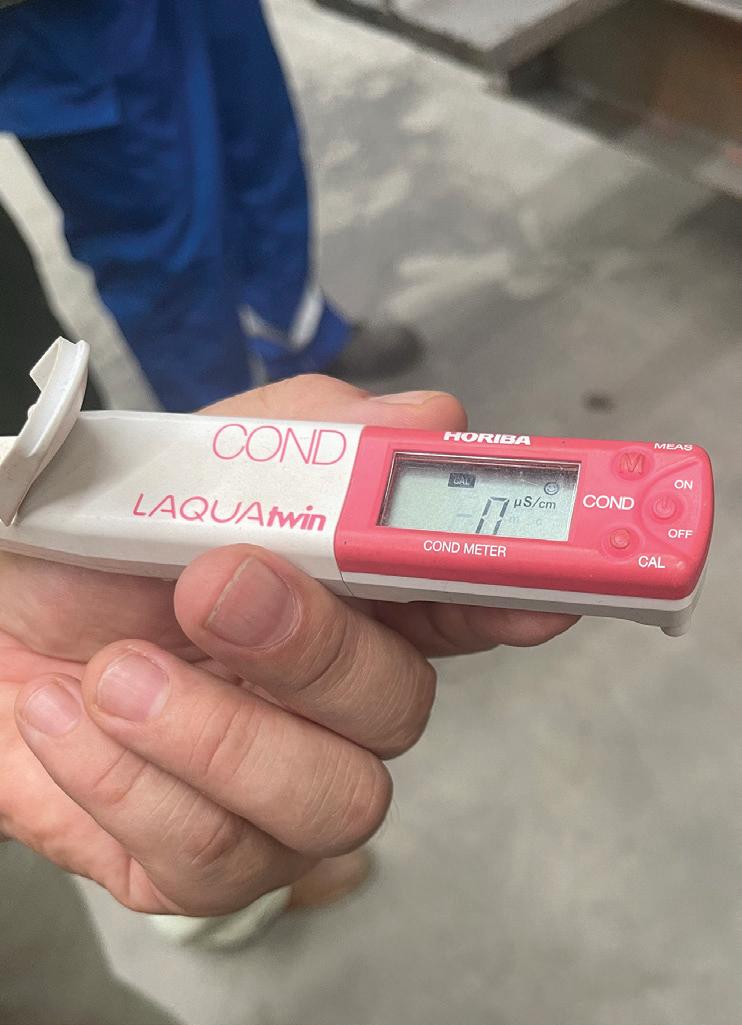

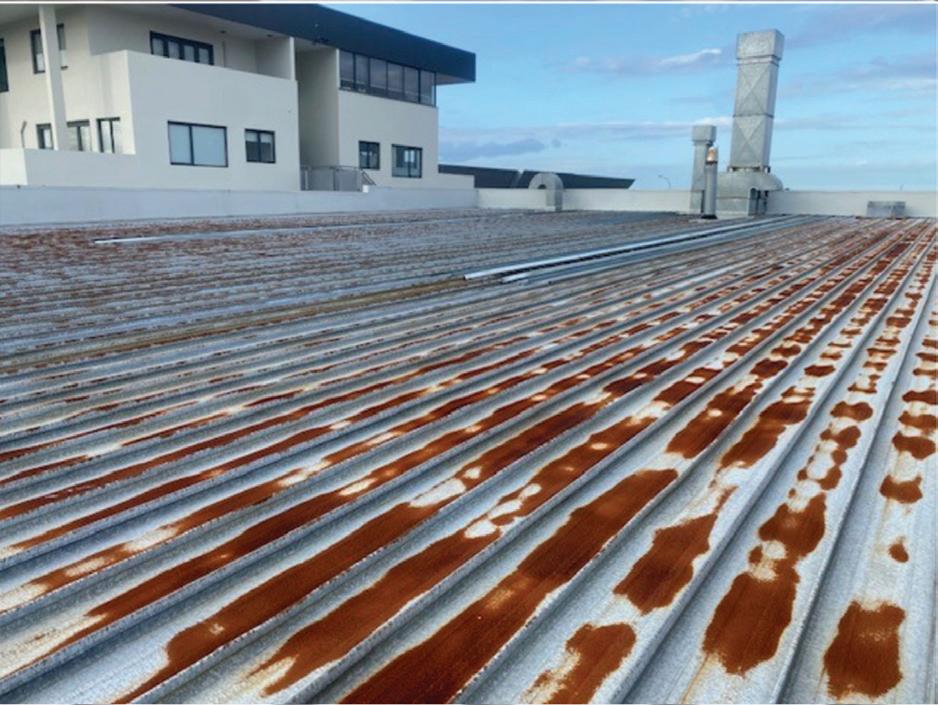

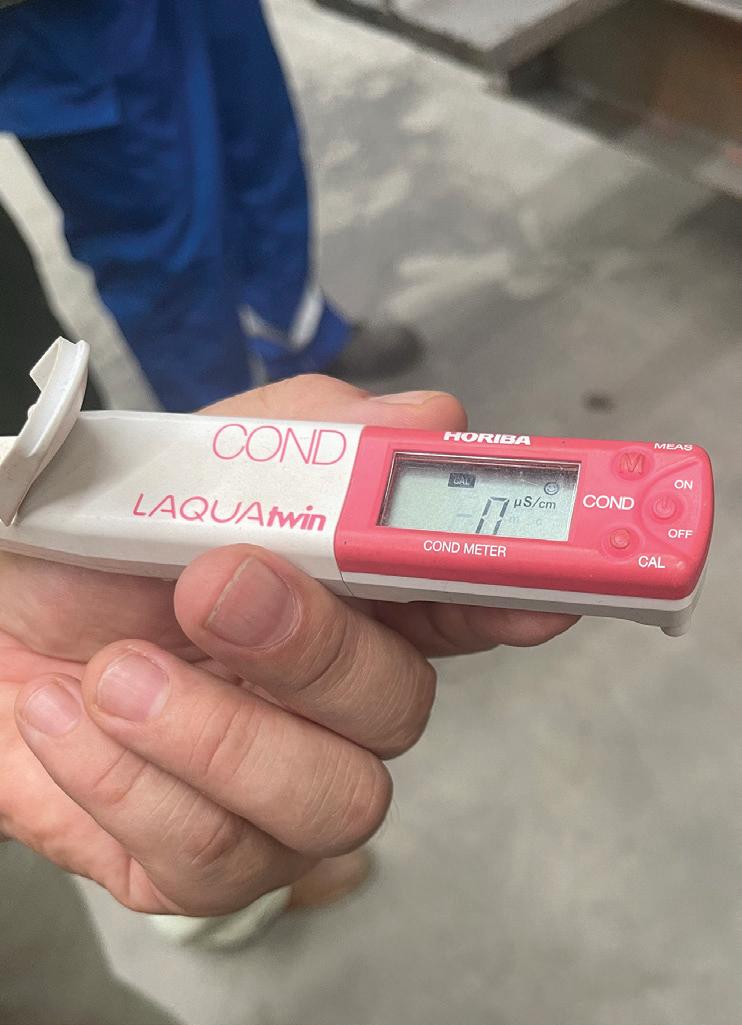

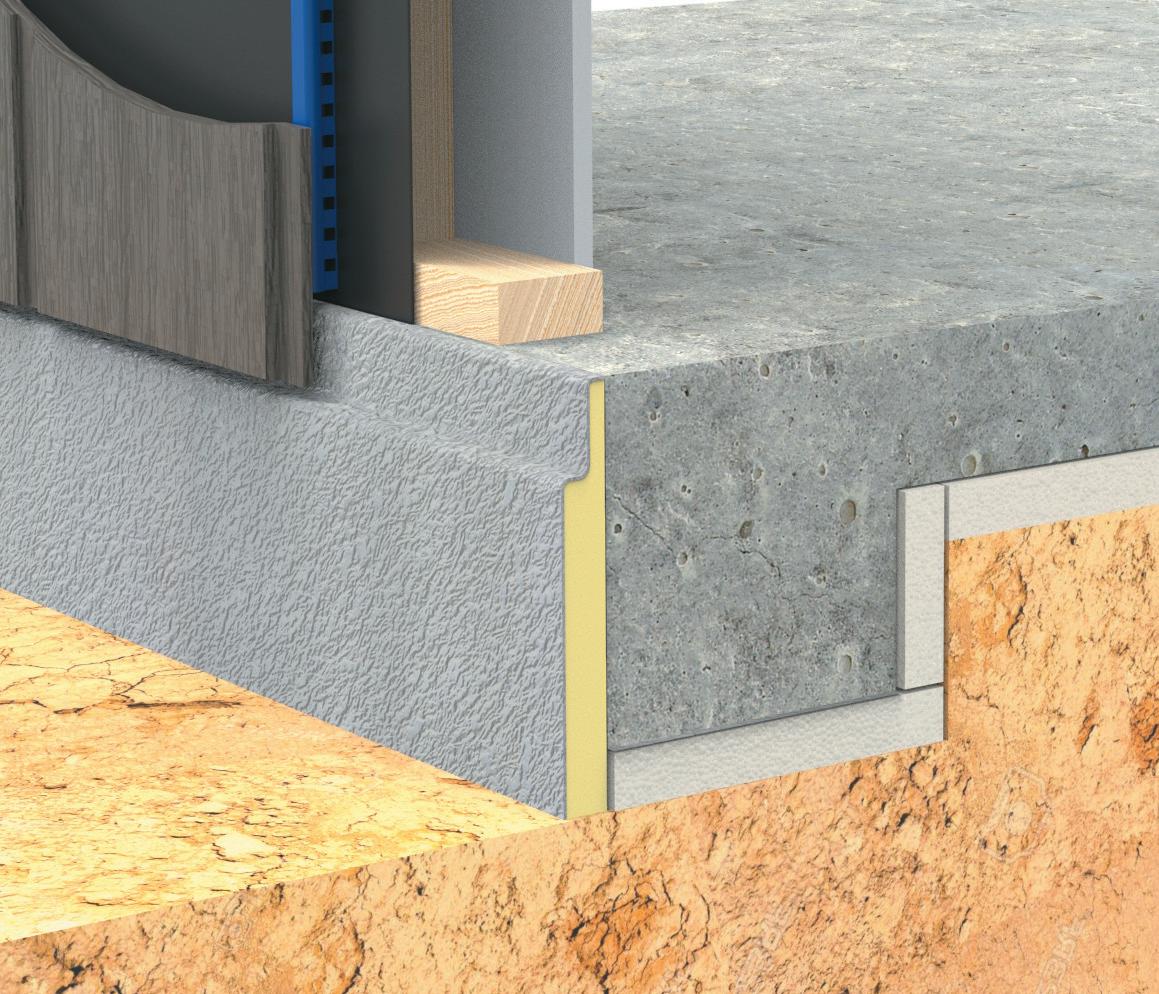

64: Being weathertightness wary

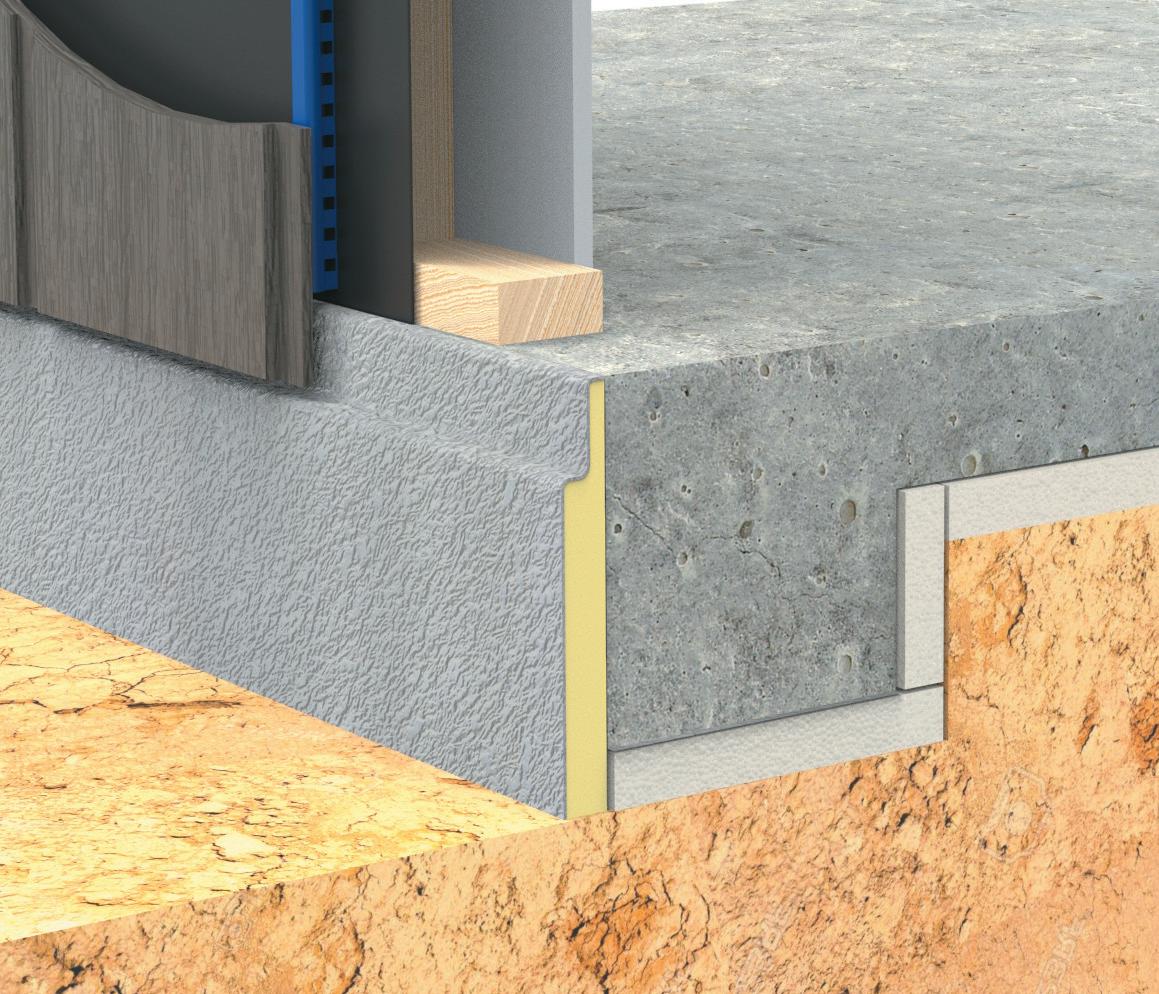

66: Keeping things watertight

70: Ensuring drainage is up to standard

74: The fundamentals of workplace injury prevention

77: Setting EWP safety standards

80: Reducing height safety risks

82: Case studies in green building

84: The passive house paradigm

87: Central Otago’s blossoming building sector

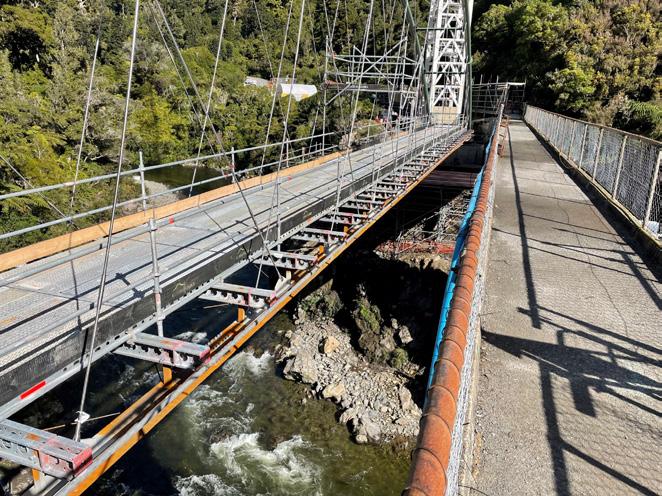

89: The Homer Tunnel’s $29 million safety upgrade

92: Compact construction equipment

94: What to consider before beginning demolition work

Head Office Auckland Office

38 Lowe Street

Addington

Christchurch 8011

Level 3/5

1010

Phone: (03) 961 5050

Email: admin@academygroup.co.nz

Readers: Construction/building industry leaders and decision makers: government & trade organisations, site safe members, business owners and professionals in the industry.

Nationwide Distribution: Mailed directly to a carefully maintained list of decision makers and subscribers for 25 years.

Disclaimer This

Builders and Contractors, a national trade newspaper targeted directly at New Zealand's building and construction industry. For some time we were aware that, although the building and related trades were generally covered individually by some trade journals, there was no amalgamated news link for trades as a whole, especially on a nationwide basis.

This void has been successfully filled by Builders & Contractors. Distribution is by way of various outlets: PlaceMakers, Mitre

10, Builders Hardware, I.T.M., Carters, Site Safe Members, Home Ideas Centre, timber companies, hire companies, together with our database direct mail drop to architects, draughting professionals, consulting engineers, building consultants, designers and local Councils. By these means we aim to reach one of the most powerful buying groups in the industry.

Are there

Please contact us to discuss

Director

Collins

GM of Operations

Kylie Palermo

Art Director

Jarred Shakespeare Phone: (03) 961

PO Box 1879, Christchurch, 8140

Sales Manager

Angela Elley

Phone: (03) 961 5184 sales@academygroup.co.nz

Product Co-ordinator Manager

Amber Mundy

Phone: (03) 961 5075 amber@academygroup.co.nz

Editorial

Jonathon Taylor

Phone: (03) 961 5098 editor@academygroup.co.nz

Administration

Louise Keates

Phone: (03) 961 5050 louisek@academygroup.co.nz

www.buildersandcontractors.co.nz

4 | B&C

Editor

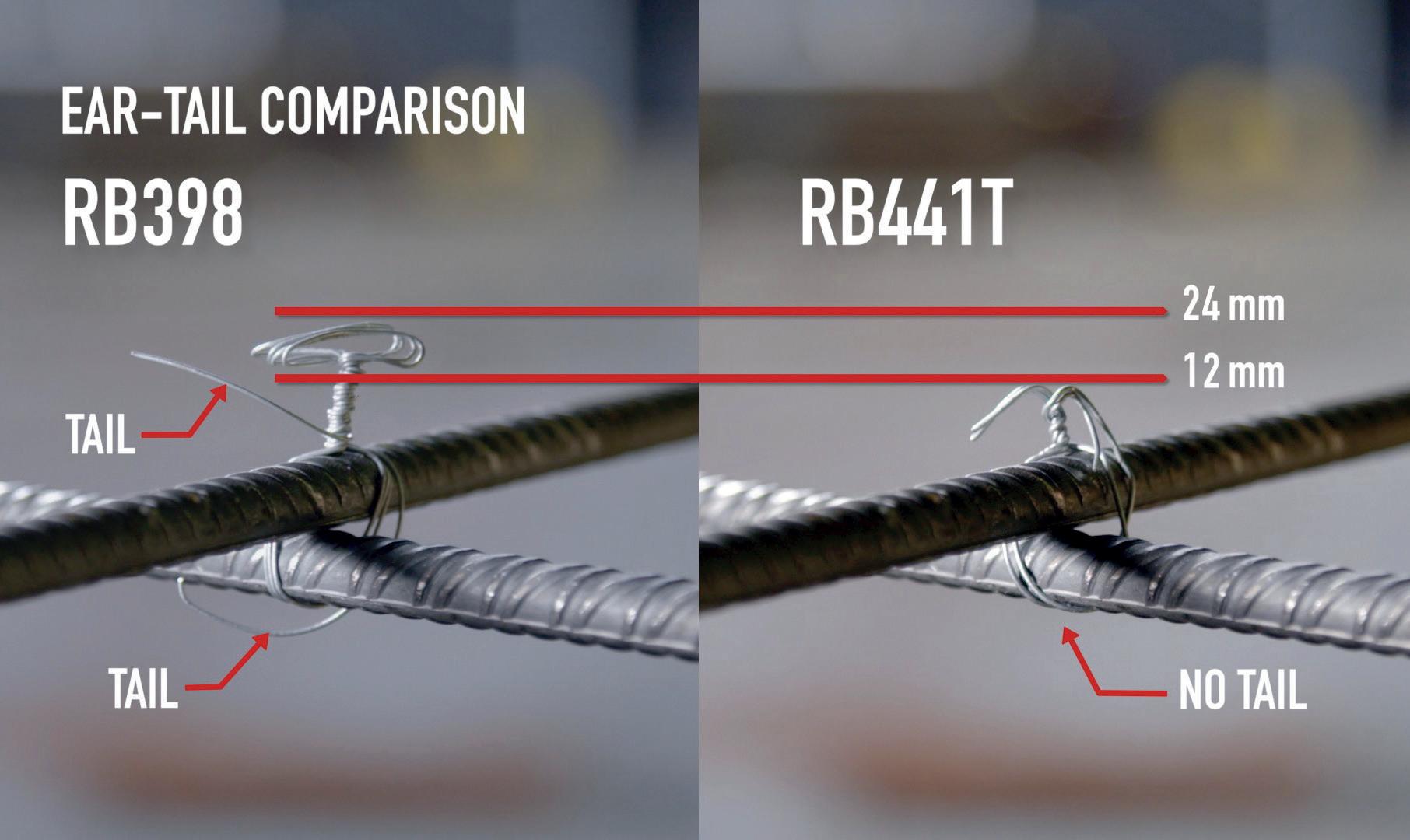

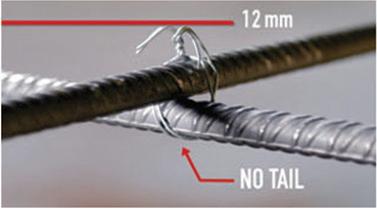

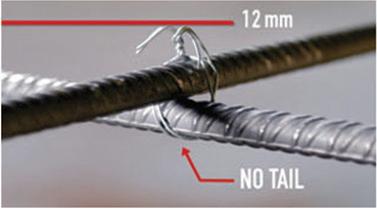

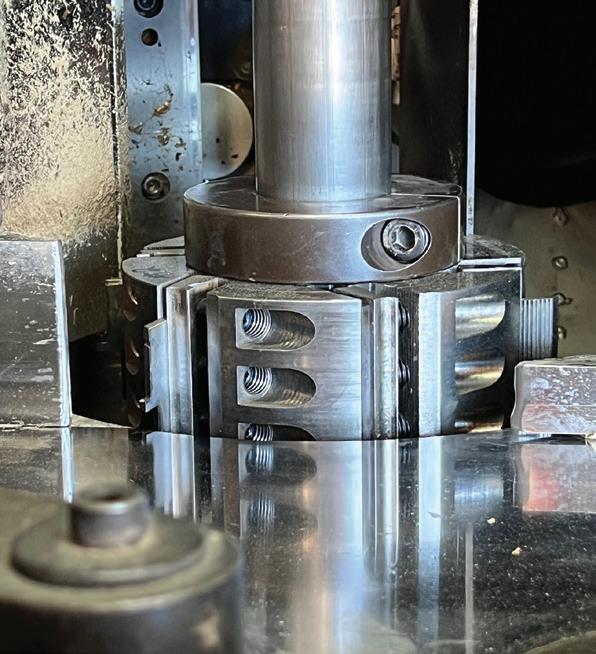

Page: 77 Page:

Page:

34

12

publication is provided on the basis that AMark Publishing NZ Ltd is not responsible for the results of any actions taken on the basis of information in these articles, nor for any error or omission from these articles and that the firm is not hereby engaged in rendering advice or services. AMark Publishing NZ Ltd expressly disclaim all and any liability and responsibility to any person in respect of anything and of the consequences of anything done, or omitted to be done, by any such a person in reliance, whether wholly or partially upon the whole or any part of the contents of this publication. Advertising feature articles are classified as advertising content and as such, information contained in them is subject to the Advertising Standards Authority Codes of Practice. Contents Copyright 2017 by AMark Publishing NZ Ltd. All rights reserved. No article or advertisement may be reproduced without written permission. You can read the full list of terms and conditions on: www.academygroup.co.nz/terms-conditions | www.academygroup.co.nz/competition-terms/

5088 jarred@academygroup.co.nz Managing

Gary

Web: www.buildersandcontractors.co.nz Nelson Street Auckland CBD Auckland

6: What you need to know about the new product information requirements

any captivating projects or products within

company that

like to showcase in the upcoming edition of Builders & Contractors?

18: The case for increased housing density with expert Guy Marriage

your

you'd

The AHL Series offers an attractive louver system that provides both ventilation and sound attenuation. Based on Holyoake’s proven louver technology, the AHL Series has been designed to efficiently allow air to pass through the facade of a building while educing radiated noise.

B&C | 5 AUCKLAND auckland@holyoake.com +64 9 274-4144 WELLINGTON wellington@holyoake.com +64 4 232-2722 CHRISTCHURCH christchurch@holyoake.com +64 3 366-6545 Learn more about AHL Ser ies today!

is plea sed to introduce

Holyoake

it s new A HL Series Acoustic Louver

5 YEAR WARRANTY

Full disclosure

What you need to know about the new product information requirements

By Ben Mitchell, a solicitor from Auckland law firm Martelli McKegg

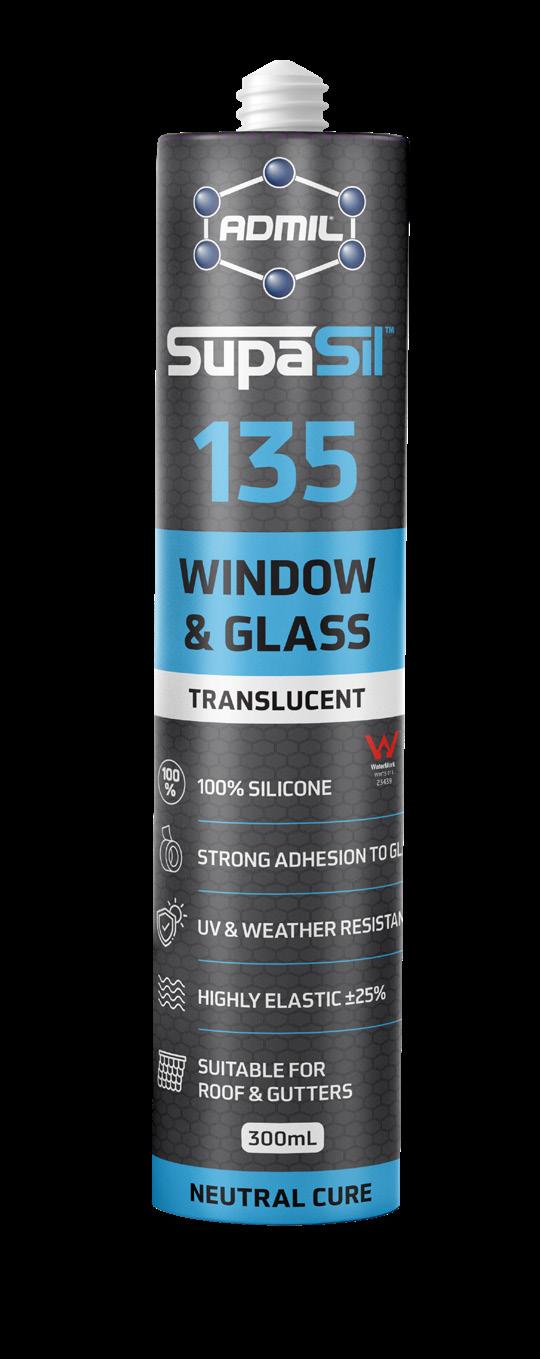

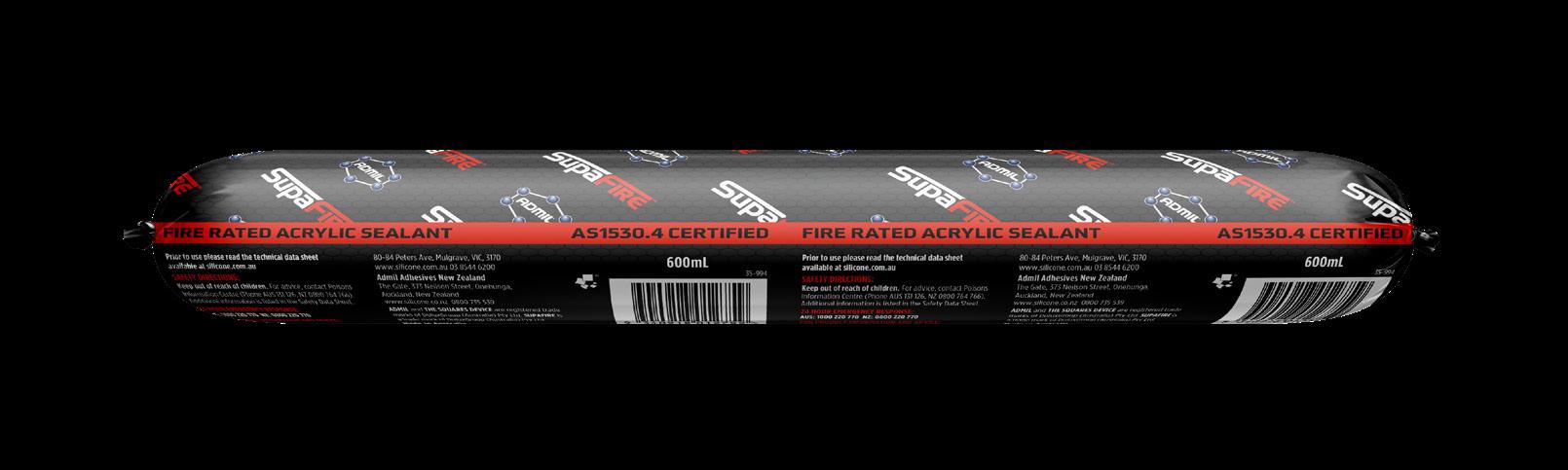

If you manufacture, import, advertise, or sell products in New Zealand that are used in construction, you will need to make sure to comply with the new product information disclosure requirements imposed by the Building (Building Product Information Requirements) Regulations 2022 (Regulations).

What products do the disclosure requirements apply to?

The disclosure requirements imposed by the Regulations apply to “designated building products” of which there are two classes.

The first category (Class 1) is a building product that:

• Is mass produced or is produced in batches to a general specification; and

• Is available for wholesale or retail purchase; and

• Is new (and not used); and

• When used in building work, may affect whether the building work complies with the building code; and

• Is not a product of a kind described in regulation 7.

The second category (Class 2) is a building product that:

• Is based on a line of products where each unit is customised to the specification of the client; and

• Is new (and not used); and

• When used in building work, may affect whether the building work complies with

the building code; and

• Is not a product of the kind described in regulation 7.

Although the Regulations establish two classes of captured products, the first and essential question to be asked is, if used in building work is, how likely will the product affect how the building work complies with the building code?

If the answer is that the product “may” affect how the building work complies with the building code, it is very likely the disclosure requirements of the Regulations will apply.

Unfortunately, the Regulations do not define “building work”. However, it is likely this will be interpreted to be consistent with the expansive definition under the Building Act 2004.

The type of information that you will need to disclose depends on whether the product falls into Class 1 or Class 2.

Ben Mitchell, Martelli McKegg Law Firm

The use of the word “may” is of crucial importance. It suggests that the threshold is low and if there is a chance, it is very likely the product will be captured.

The Regulations do helpfully provide some examples of captured products. However, it does need to be noted these are just examples.

In terms of Class 1:

• Cladding products

• Mechanical fixings

• Insulation products

• Internal lining products

• Roofing products

• Structural wood-based products

• Structural steel and reinforcing products

• Sanitary plumbing and drainage products, including tapware.

For Class 2, just one example has been provided. This being “external window joinery and doors that have been customised to the specifications of individual clients”.

Undoubtedly, there will be some products that will clearly be captured, such as

6 | B&C News

the above examples. However, for other products, it is less clear.

For example, while some paint could be said to be purely aesthetic, other types of paint provide important waterproofing qualities that certainly affect how building work will comply with the building code.

If you believe your product may be captured, the next question to ask is whether the product is excluded under regulation 7 of the Regulations. These excluded products are:

• A building product which has a product certificate registered under s 272A of the Building Act 2004

• A temporary building product that does not form part of the building when construction is complete.

The example given is a barrier used during demolition or construction

• A building product that is:

- A gas appliance or fitting (within the meaning of s 2(1) of the Gas Act 1992).

- An electrical appliance or fitting (within the meaning of s 2(1) of the Electricity Act 1992).

While it might be appealing to look into obtaining a product certificate under s 272A of the Building Act 2004, this does come with significant administrative hurdles and cost. Whether it is worthwhile to obtain a product certificate would need to be a separate article.

However, it could certainly be the case that if the product justifies it, a product certificate could be an option.

Unfortunately, the Regulations do not define “building work”. However, it is likely this will be interpreted to be consistent with the expansive definition under the Building Act 2004.

When do the disclosure requirements apply?

The disclosure requirements imposed by the Regulations apply to “designated building products manufactured in, or imported into, New Zealand,” from (including) 11 December 2023.

While this suggests there is still some time for people who merely sell building products that were manufactured or imported into New Zealand before this date, those products will soon be sold and replaced with captured products.

If you manufacture or import into New Zealand a captured product, the disclosure requirements already apply.

Who is responsible for what in relation to a captured product?

The requirements imposed on you depend on which category of “responsible person” you fall into. Again, there are two categories.

The first category (Category 1) is a person living, or incorporated, in New Zealand, that is the manufacturer or importer of the captured product. This category is responsible to:

These requirements need to be complied with before the captured product is ordered for supply by a wholesaler, retailer, or other distributer of the captured product. These requirements need to be complied with before the captured product is ordered by a client.

Regardless of whether you may fall into Category 1 or Category 2, there are going to be significant practicality difficulties in complying with the above obligations.

What information needs to be disclosed?

As noted above, if you fall into Category 1, you are required to “collate and produce the required product information.” However, even if you fall into Category 2, the type of information that needs to be collated and produced may be of concern to you and your business.

The type of information that you will need to disclose depends on whether the product falls into Class 1 or Class 2. Unfortunately, the lists are too long to repeat in full but they both relevantly include:

• A description of the captured product (including the name of the product and its intended use).

• Whether overseas or in New Zealand, the legal and trading name of the manufacturer or manufacturers, including its address/ addresses, its internet site (if any), its public email (if any), its NZBN (if any).

• Likewise, if the captured product is imported, the information immediately above is required for the importer.

• A statement specifying the clauses of the building code that are relevant, with a statement of the captured product’s intended scope and use.

• How the captured product is expected to contribute to the relevant clauses of the building code.

• Information on the limitations of the captured product.

• Installation requirements

• Maintenance requirements.

Although this is not a comprehensive summary of both lists, it should give a good idea of the extent of the information that will need to be disclosed.

The consequences of non-compliance

There are consequences for non-compliance. Under s 362VB of the Building Act 2004, if you, “in trade”, supply, offer to supply, advertise the supply of, or import into New Zealand for the purpose of supply, a captured product under the Regulations, you can be convicted of an offence and liable, in the case of an individual, to a fine not exceeding $10,000, and in the case of a body corporate, to a fine not exceeding $30,000.00.

B&C | 7

News HAWKEN CONCRETE SERVICES QUALITY CONCRETE AT COMPETITIVE RATES 022 315 2137 | jhawkenconcrete@gmail.com Hawken concrete services L.T.D

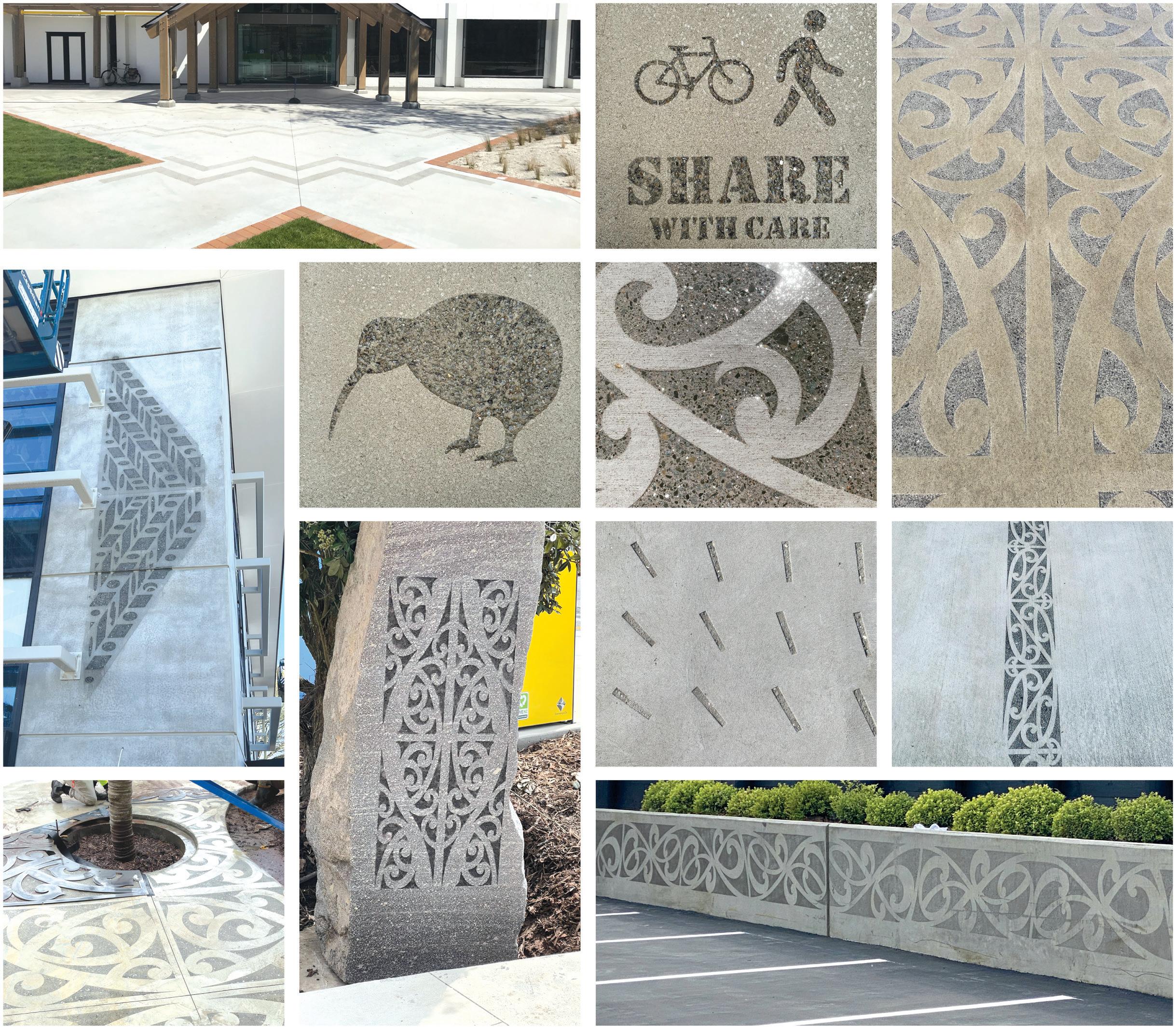

Your one-stop shop for sustainable timber

In today's environmentally conscious world, there is a growing demand for sustainable building materials. Interlink Timber Solutions is a New Zealandbased company that specialises in supplying reclaimed, recycled, and bespoke timbers.

Interlink Timber Solutions offers a wide variety of timber products for both interior, exterior, landscaping, and urban design use.

Interior Linings - Discover Interlink's range of interior wall linings crafted to your home, office, and beautiful spaces. Adding a touch of rustic charm to the indoors, their reclaimed interior timbers are shaped from railway timber, barns, warehouses, and other unique structures. Whatever your choice, their interior wall linings tell their story through the grain designs and character marks on their skin, reflecting the beauty of your design from the inside out.

Interior and Exterior Beams - Adding depth and texture to your interior and exterior areas, exposed timber beams can take an ordinary space and transform it into something truly unique. Whether they take

their place as large entry beams, lintels, exposed trusses or sidings. Wooden beams add cosiness and a touch of rustic charm, while providing grandeur and authenticity to a build.

Landscape - Sourced from New Zealand and beyond, Interlink's railway sleepers, beams and hardwoods have stood the test of time and will continue to do so for years to come. Each cut has a unique tale to tell, bringing character, timelessness, and natural style to your landscape.

Interlink’s urban range of repurposed railway sleepers and beams stand as interesting, impressive features in every design, adding a touch of nature, character and history back into the build.

Urban Design - With unique textures and finishes, Interlink’s urban range of repurposed railway sleepers and beams stand as interesting, impressive features in every design, adding a touch of nature, character and history back into the build. Coupled with their durability and reliability, these rustic timbers are perfect for a wide range of urban designs – whether general landscaping, pergolas, bollards, vertical features, bench seats and tables or anything in between.

The Process - Interlink Timber Solutions is your one-stop shop for sustainable, highquality timber products. They source timber from all over New Zealand, ensuring their products have minimal carbon emission and are of the highest quality.

While providing excellent customer service and a wide variety of options.

"Great service, awesome communication. Delivery on the nail, when and where specified. Happy with the product, worked perfectly for rebuild of steps. Will definitely use again, recommend to all for landscaping products. Clients very happy. hardwood sleepers great to rip for tread fronts, look great." - Paul

If you are looking for sustainable, high-quality timber products, then contact Interlink Timber Solutions today. They can help you find the specific product for your project and provide you with the expert advice needed. Contact them on 0508 468 375 or visit them online at www.interlinkltd.com.

8 | B&C Specialists in supplying authentic reclaimed hardwood timbers for interior and exterior building projects www.interlinkltd.com info@interlinkltd.com 0508 468 375

Six tips for the end of the financial year

The financial year for New Zealand businesses finishes on the 31st of March and can be a stressful time for many business owners.

Research has shown that many owners will be pulling all-nighters and missing out on time with friends and family in order to complete their compliance obligations.

Chartered accountant Scott Gardiner says it is easy for small business owners to leave their end of financial year obligations to the last minute.

“Often SMEs become so focussed on day-today operations of running a business that some of the less exciting aspects, such as bookkeeping, can get pushed aside – creating more pressure in the reporting season,” he says.

“While early preparation is best, it is still not too late for business owners to get their accounts in order. There’s a few things that all businesses can do to make sure they’ve got everything in order and are ready to start the new financial year on the front foot.”

1. Discuss taking advantage of deductions, write-offs and rebates with your accountant and review your assets register to write off worthless stock, plant and equipment.

2. Give your accountant or bookkeeper a complete copy of all your financial files – or give them access to your cloud files to they can do the work for you.

3. Give your payroll reports a final onceover. Although you don’t need to provide a summary to your employees, it’s a good idea to give them Earning Certificates as these can be used to check information provided by the Inland Revenue.

4. Finalise end of year adjustments with your accountant or bookkeeper and once changes have been updated, lock all accounts relating to that year so that data remains accurate. This will help ensure an easy transition into the new financial year.

5. Create a separate copy of your accounts and back it up – it’s better to be safe than sorry. It’s also always a good idea to print

key reports like P&L, Balance sheet and general ledger listing for the financial year and store them securely.

6. Finally, reflect on your business plan and make sure you’re on the right path. It’s a good chance to consider how your business can benefit from cloud accounting solutions that will make the next end of financial year easier to manage.

End of financial year help

With the end of the financial year now approaching for many businesses, PwC has a tax planning checklist to assist with preparations for the year end, as at March 31.

PwC says it’s a good time for businesses to consider their year-end tax positions and all options available to them, as well as their provisional tax obligations.

“Planning for year-end can be a daunting task for business owners so we’ve aimed to simplify the process and provide them with all the elements they should be considering, current taxation rates and information on provisional tax obligations for easy reference.”

Some items of particular importance for businesses are:

• Identifying accrued and/or prepaid expenditure that may not be deductible for tax purposes in the current year

• Ensuring you are maximising the depreciation available on your fixed assets, and making sure your tax fixed asset register is accurate and, where relevant, writing off assets that have been disposed of

• Consideration of whether debts have gone bad and writing these off prior to year-end

• Consideration of intercompany loan balances and whether appropriate interest has been charged

• Monitoring shareholder accounts to ensure they are not overdrawn at year-end

• Considering whether losses can be carried forward from past years or offset between group entities.

B&C | 9 News

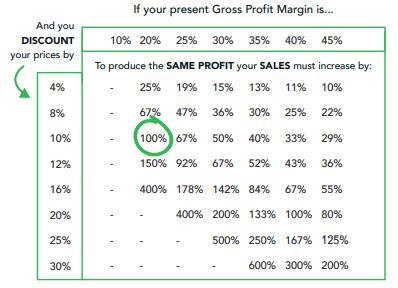

Making price cuts pay

Discounting - a strategic move or mistake?

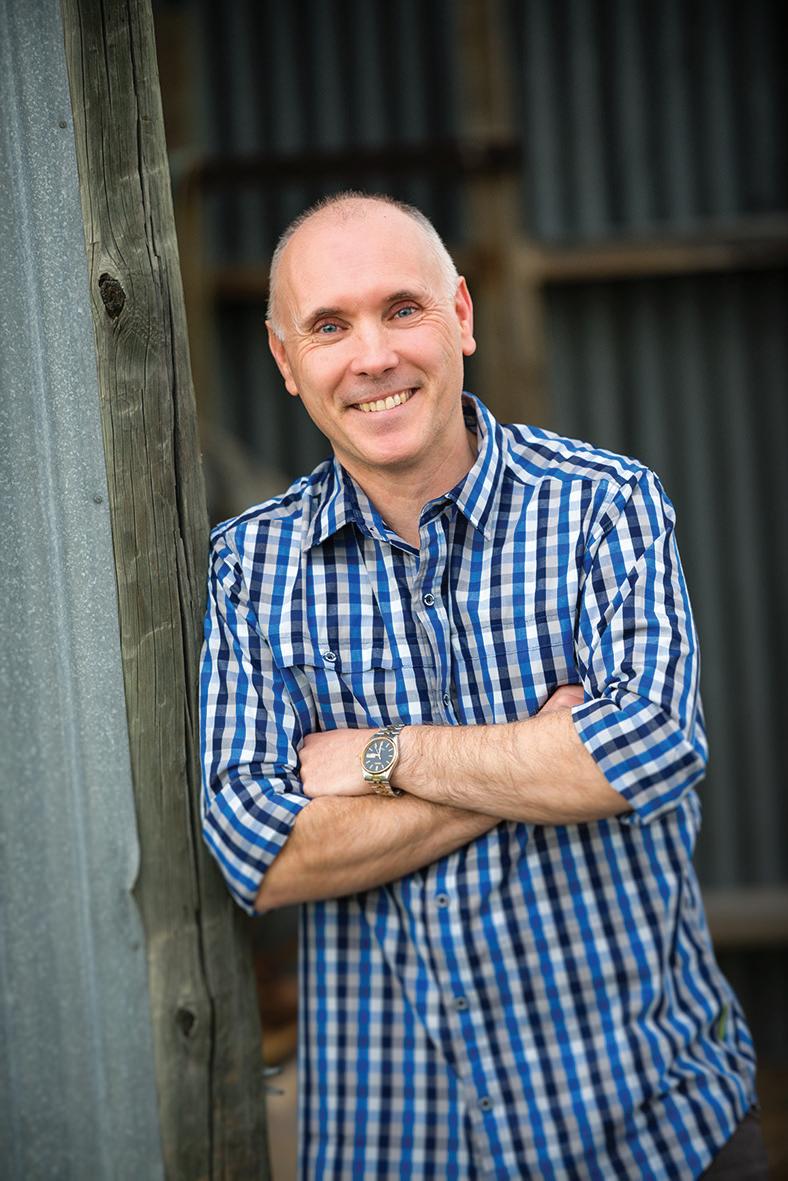

By Daniel Fitzpatrick from Next Level Tradie

Are you finding yourself struggling to secure enough work for your team? Or maybe you’ve noticed that the amount of confirmed work booked ahead is shrinking?

When work starts to dry up, it affects the bottom line. Do you start discounting to get the work or wait it out till things get better?

It’s a situation some tradies are facing right now, and it’s not easy. But before you start slashing prices here are a few things to consider.

Disappearing profit

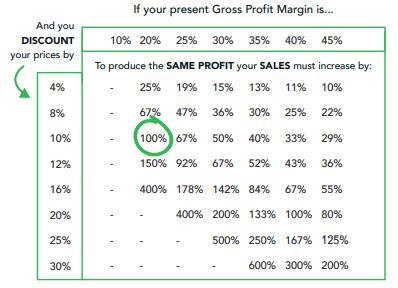

Profits and margins can disappear alarmingly fast once you start cutting your prices, and here’s why.

Let’s say your gross profit margin is around 20 percent. If you reduce your prices on a job by 10 percent, the volume of work you need to complete just to maintain the same dollar profit increases significantly.

For example, if your break-even point is $100,000 per month at a gross profit margin of 20 percent, and you reduce your prices by 10 percent you now need $200,000 of work to reach break-even. That’s twice the work, time, and effort, for the same result you were previously getting.

It’s a stark reminder that while reducing prices might seem like a viable strategy to attract more jobs, the impact on your bottom line can be significant.

Not only does it increase your workload, but it also puts a strain on you and your team, sometimes compromising quality. Too many

rushed jobs that go wrong can also affect your reputation.

So, before you consider cutting your rates, crunch the numbers and understand the real impact on your business’s profitability.

What’s your target gross margin?

Understanding your target gross margin is crucial in determining which jobs are worth your effort.

Your target gross margin is the percentage of profit you aim to make on each job after all direct costs, including wages, are subtracted. This margin should be high enough to cover your business’s overheads plus a healthy profit.

Target Gross Margin could be anywhere between 20 to 60 percent, depending on the trade and your position in the market. High or low end. I don’t like to see anything under 20 percent minimum in any trade; less than 20 percent is too difficult to make a profit.

If you want some help to work out your target gross margin and where you should be for your business, then check out the “Pricing Strategy Session” at the end of this article.

Having a clear target gross margin is like having a compass in the wilderness. Once you know where you want to head you can see clearly if you are going in the right direction and adjust. No more wasted money, time, and energy taking jobs that lose you money.

Sticking to your guns

Your large client wants a better price, what now? Don’t just take this at face value. Test, question, negotiate. Why do they think the price is too dear? What are they comparing their quote to, apples with apples or apples with bananas? Is there more in their budget or can you adjust the brief to fit?

Show them that your price is good value and see what happens next. Some will get it and some won’t, that’s ok. The ones that don’t, fine just move on to the next opportunity.

Eddie, a mentor of mine, would tell me “15 percent of customers will always go for the cheapest option no matter what”.

If another option is one dollar cheaper, they will take it even if the job is half as good. The clients you want are the other 85 percent who care about getting a quality job done right, hassle-free and are prepared to pay for it.

Remember, pricing isn’t just about numbers; it’s a mind game. The right way you present your pricing and value can make all the

Show them that your price is good value and see what happens next. Some will get it and some won’t, that’s ok. The ones that don’t, fine just move on to the next opportunity.

difference in attracting the right kind of clients and getting the work.

When my clients start telling me they are sticking to their rates, margins are increasing, and they now have plenty of good work lined up. That they don’t need every job that comes their way. I know they are on track.

Are you fishing in the right river?

Fishing is about being in the right place at the right time. The right bait at high tide will catch way more fish than at low tide when the fish aren’t around.

It’s the same with your business, are you marketing in the right places? Are you seen as the specialist or a generalist who does a bit of everything? The specialist attracts better clients and can charge more. That’s less work and more profit for you.

Being the cheapest is dangerous.

If your business is based on being the cheapest, that’s a problem. Firstly, you won’t be getting the margins you need and there will eventually be someone else out there who will do it even cheaper.

A builder client Celeb of The Decking Guys, was in the same predicament. He was working 80 hours per week making no money with one part-time worker and struggling to find work. His clients kept asking him for lower rates. I told him to put his rates up and start specialising.

Within 12 months he had a team of 11 and plenty of work. Check out his story on our testimonial page at: www.nextleveltradie. co.nz/real-results

More options, better odds

If you are relying on getting one quote or you can’t pay the bills, you need the job so the pressure is on you. You are in a weak position and are more likely to cave on price to get the work.

A much stronger position would be if you have five other quotes you are following up in the same week with three to six months of work already confirmed. Now you are calling the shots.

If a new client is relying on a small number of quotes and doesn’t have enough work. The first thing we do is help them get their pricing right and find better jobs. This takes the pressure off and puts them back in control of their business.

Don’t waste a good opportunity!

If things are on the quiet side and you’re still not getting the work you want, then this could be the opportunity to consolidate and scale back a little.

Move any bad eggs on and rebuild stronger. Better to have a bit less work for a while rather than working your tail off and going backwards.

If you still want to reduce your rates to get a job short term to pay the bills then ok. But make sure that this is a short-term strategy and use it as motivation to position the business better so that you’re not caught out next time.

Sometimes in a downturn, there will be less work for a while. The key here is to keep the business solid and profitable while looking for better opportunities which, in long term, is not cutting prices.

Are you worried that your pricing isn’t right compared to others in your industry or that you need to get more profitable work? Book our free 45 minute “Pricing Strategy Session” at: www.nextleveltradie.co.nz/nextstep.

10 | B&C

News

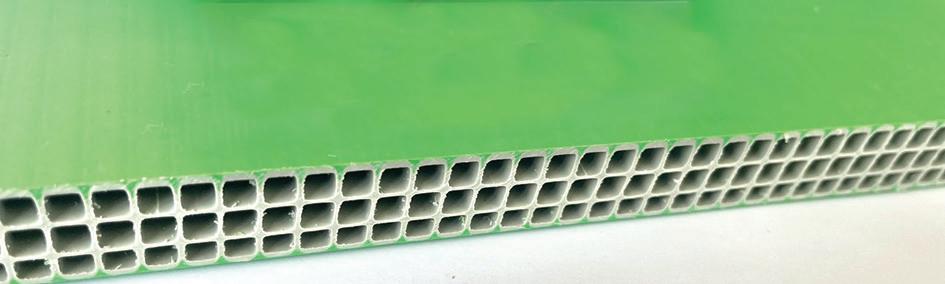

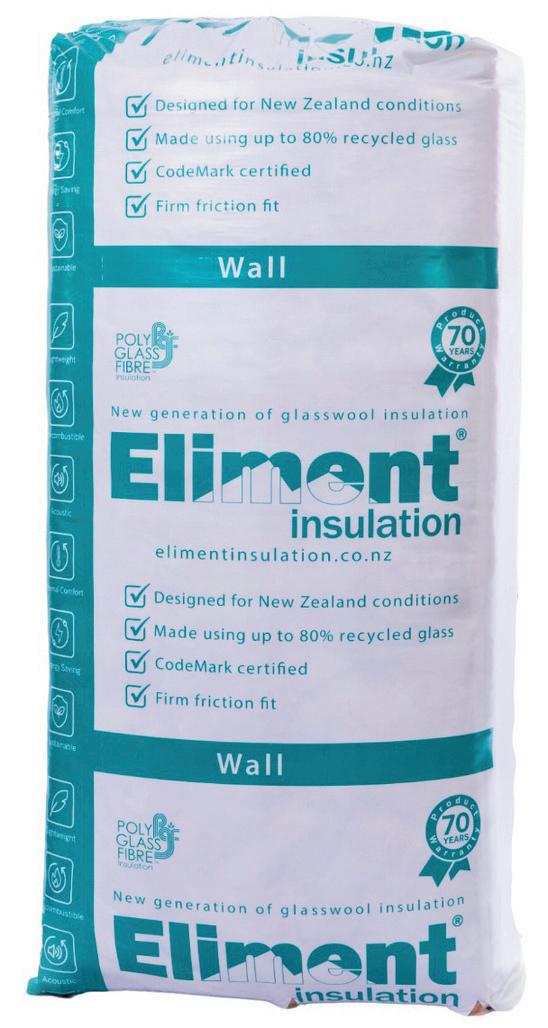

New generation of dual thermal & acoustic glasswool insulation at highly competitive rates

CodeMark certified

Designed for New Zealand conditions

Made using up to 80% recycled glass

70 year product Warranty

Available to order nationwide from ITM, Placemakers and other selected building merchants and installers

Proudly

visit elimentinsulation.co.nz

B&C | 11

more

For

information

distributed

Taupo Central North Island • Pre COF Checks • Pre WOF Checks • A, B And C Small And Large Vehicle Servicing • Mobile Servicing • Vehicle Repairs In Taupo Diesel Truck Mechanical Repairs & Maintenance We offer comprehensive vehicle servicing and repairs on all makes and models. S.I.R, situated in Rakaunui Rd operates a dedicated and fully enclosed workshop for all mechanical repairs, especially suited for trucks, motor homes and horse trucks. Using the very latest automotive technology and employ a team of highly experienced and qualified mechanics. The team will have you and your vehicle back on the road in no time. CALL US! 027 272 2912 www.truckservicing.co.nz

by

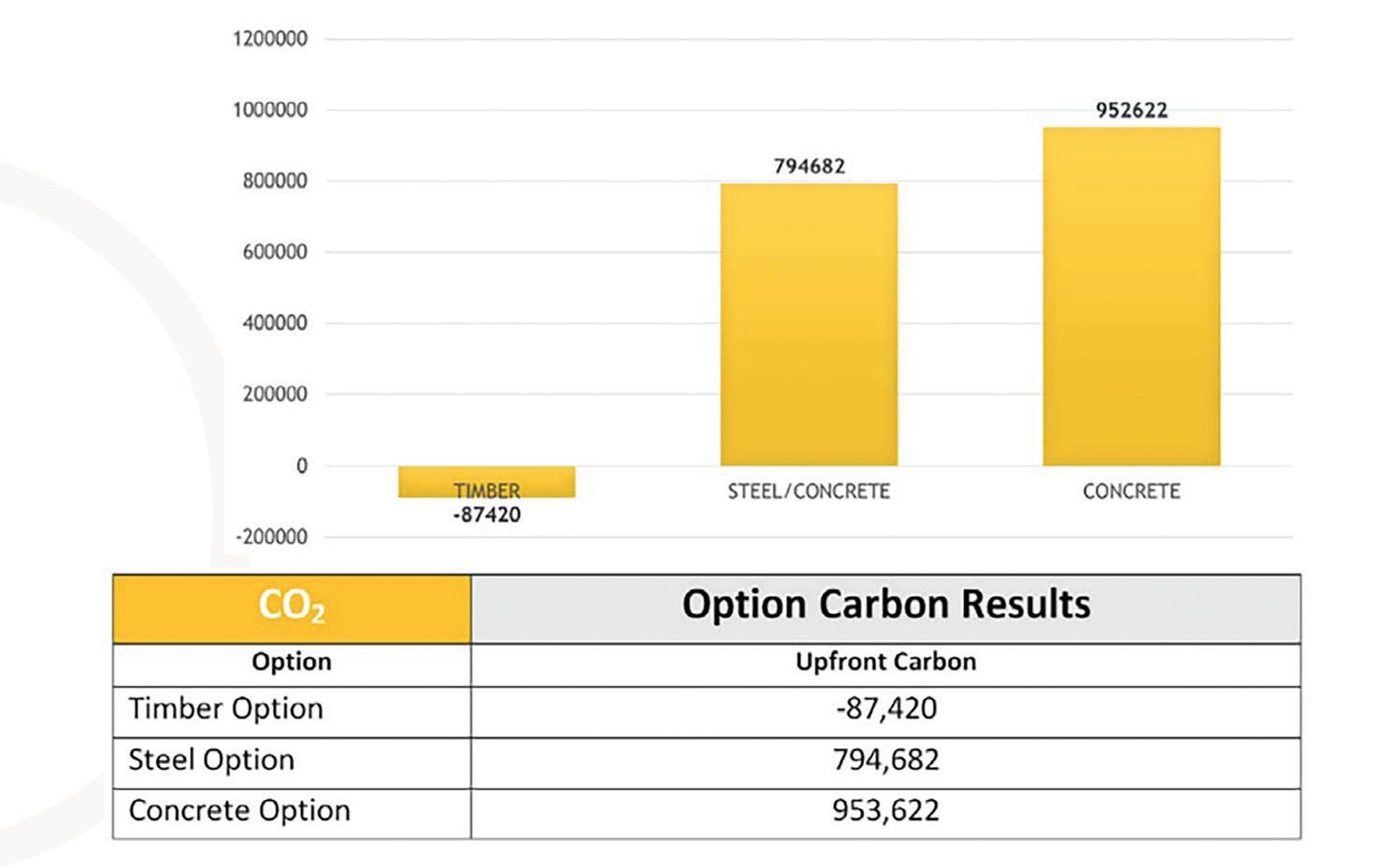

The driving forces behind construction costs

New research sheds light on New Zealand’s infrastructure workforce and drivers of construction costs

Two new research papers from the New Zealand Infrastructure Commission, Te Waihanga, provide baseline information on New Zealand’s infrastructure workforce and show how global and local factors impact on labour and material costs in infrastructure construction.

Who’s working in infrastructure?

A baseline report

This report provides the first comprehensive baseline analysis of New Zealand’s infrastructure workforce.

“You can’t plan for the future if you don’t have a sense of the size and make-up of your current workforce,” says Te Waihanga director of Economics Peter Nunns.

“We wanted to know how many people work in the infrastructure sector and what sort of work they’re doing. We also wanted to understand who’s working in infrastructure, so we looked at factors like age, ethnicity, gender, training, and migration.

“We found that the infrastructure workforce is large and complex, with over 100,000 full-time equivalent workers spread across more than 100 distinct occupations. That’s around 4.7 percent of the total New Zealand workforce,” Peter says.

“We often think about infrastructure work as mainly about new builds, but this actually accounts for less than half of the workforce.

“We estimate that around 14 percent of infrastructure workers are engaged in planning and design, 46% are constructing

new assets, and a further 40 percent of infrastructure workers are engaged in asset management and maintenance. These roles are essential - you can’t build something without planning and designing it first, and once it’s built you have to maintain it.”

The findings also shed light on who is working in infrastructure and the pathways that they follow into the workforce.

Ethnic diversity within the infrastructure workforce is similar to the overall New Zealand population, but the ethnic mix is uneven across occupational categories.

For instance, labourer occupations have a higher-than-average share of Māori and Pacific workers, while professional occupations have a higher-than-average share of European and Asian workers.

Women account for only 11 percent of the total infrastructure workforce compared to around 47 percent of the overall New Zealand workforce. Moreover, younger age cohorts have a similar share of women as older age cohorts, suggesting that gender balance won’t change as older workers retire.

“This data will help us identify where we will face capacity pressures and how we can respond to them by sequencing work better and training and recruiting new workers. It also highlights increasing gender and ethnic diversity as a key opportunity for lifting our capacity to build infrastructure,” Peter says.

Why do construction input costs change?

The role of global and local factors

A second paper published by Te Waihanga looks at past changes in construction wages and prices for five key infrastructure construction materials, shining a light on projects often cost more than expected.

“We analysed several decades of price data for construction inputs to understand how

Understanding what drives infrastructure costs allows us to better plan and mitigate risks and get more infrastructure for the money we spend.

they are affected by both global and local factors,” Peter says.

“We found that infrastructure providers have limited control over their input prices. Price changes mostly reflect the impact of things that are happening outside of the New Zealand construction sector.

“For labour costs, we found that construction wages closely track wages elsewhere in the New Zealand economy. In the short term, high demand for construction workers can push wages a bit above this trend, but construction wages tend to return to trend within two years,” he says.

“Global factors are the primary driver of material prices, especially for traded commodities like structural steel, timber and diesel fuel. Changes in global prices flow through to New Zealand very quickly. Even when we produce or source some materials here, prices are still based on global markets,” he adds.

“The exception is materials like concrete and aggregates that are too heavy to ship long distances. Regional factors, like limits on setting up new quarries near major projects, are likely to play a stronger role for those materials.”

12 | B&C News

Train a BCITO carpentry apprentice today

BCITO has been dedicated to the industry for close to 30 years and is committed to supporting employers and apprentices all around Aotearoa.

BCITO Apprentices are trained and supported to come up to speed and add value to your business from the outset.

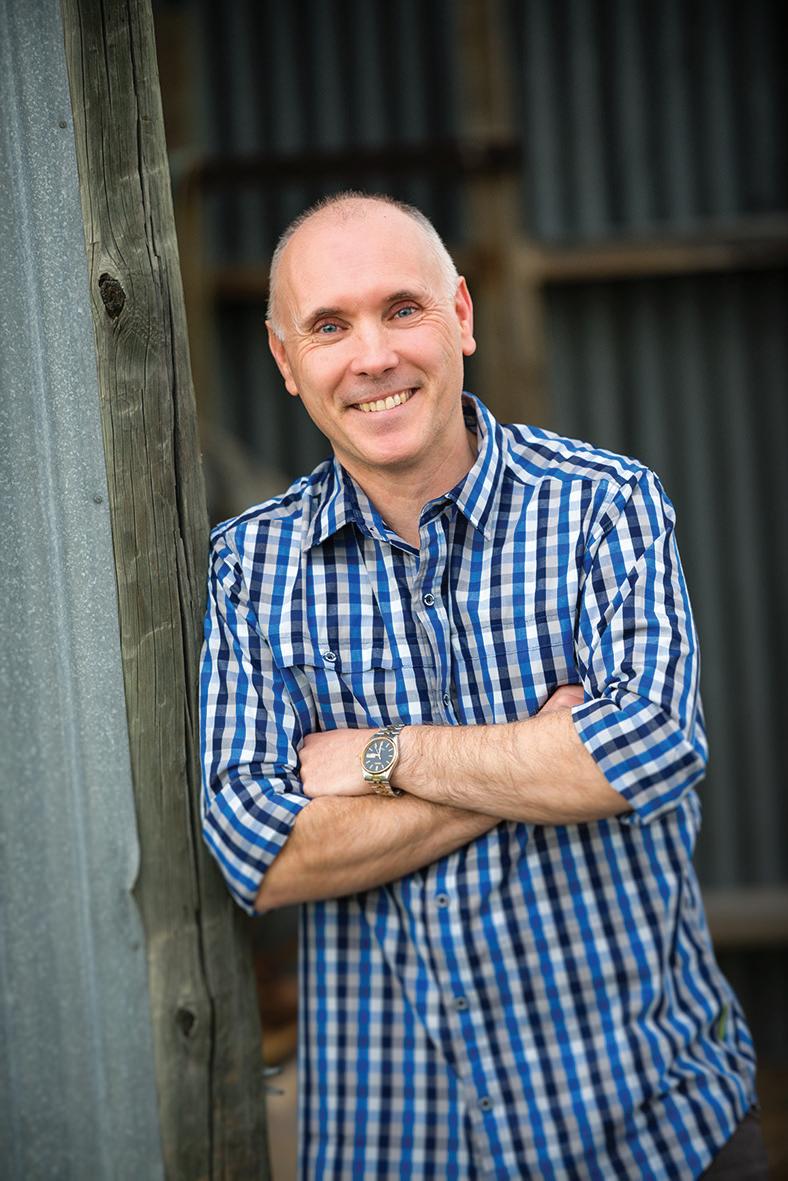

Luke MacGibbon, founder of 90 Degrees Construction is a testament to the positive impact investing in an apprentice has on a business.

“I’ve trained ten BCITO apprentices, and it is a genuine privilege to pass on one’s knowledge and skill set to the next generation. BCITO provides great support for employers and the apprentices, they manage the bookwork, while we manage the apprentices training on the tools”.

Our sector needs more skilled and willing employers to help shape the next generation of qualified professionals. Will you be the next BCITO employer?

B&C | 13 News

CALL BCITO TODAY 0800 4 BCITO (422 486)

The findings of this report build upon earlier research by Te Waihanga that looks at infrastructure construction productivity and infrastructure delivery cost benchmarking.

“Understanding what drives infrastructure costs allows us to better plan and mitigate risks and get more infrastructure for the money we spend.

“While labour and material costs are hard to control, there are some levers we can pull. Infrastructure providers and decisionmakers can focus on driving productivity in construction and optimising projects’ scope and design to ensure that we get the most bang for our buck.”

Key findings from the reports

Who’s working in infrastructure?

A baseline report

• In 2018, the infrastructure workforce included an estimated 108,000 fulltime equivalent workers. This is around 4.7 percent of the overall New Zealand workforce. These workers are split evenly between ‘horizontal’ infrastructure like roads, water pipes, and electricity transmission, and ‘vertical’ infrastructure like schools and hospitals

• Constructing new projects accounts for less than half of the workforce. We estimate that around 14 percent of infrastructure workers are engaged in planning and design, 46 percent are constructing new assets, and a further 40 percent of infrastructure workers are engaged in asset management and maintenance

• Mobility from other sectors is more important for ‘blue collar’ roles and

migration is more important for ‘white collar’ roles. Professional and technical occupations include a higher share of migrants. These occupations are more likely to have university qualifications. Machinery operators and drivers and labourers are less likely to be migrants, and more likely to have moved between industries in recent years

• The infrastructure workforce is ethnically diverse, but women make up a small share of the workforce. The overall infrastructure workforce has a similar ethnic makeup to the New Zealand population, but ethnic mix is uneven across occupational categories. Only 11 percent of infrastructure workers are women. Female participation is only marginally higher among younger age cohorts, meaning that this pattern is unlikely to change as the workforce ages.

Why do construction input costs change?

The role of global and local factors

• New Zealand economy-wide factors are important for understanding labour cost fluctuations but not material costs. Wages in construction track wages elsewhere in the economy. For material prices, we find little evidence that increased investment or strong economic conditions in New Zealand drive higher prices

• Global factors play a significant role in material price fluctuations but not labour costs. Key material prices are correlated across countries, particularly for tradeable materials. Global commodity prices are highly predictive of our material prices, especially for structural steel, timber,

While labour and material costs are hard to control, there are some levers we can pull. Infrastructure providers and decision-makers can focus on driving productivity in construction and optimising projects’ scope and design to ensure that we get the most bang for our buck.

and diesel fuel. Conversely, construction wages in New Zealand do not appear to be affected by Australian construction or economy-wide wages

• Prices for both materials and labour adjust quickly. When construction wage growth is faster or slower than economy-wide wage growth, the gap is closed within a couple of years, rather than decades. For materials, changes in global prices are reflected in New Zealand prices almost instantly.

• Industry-specific factors play a modest role for labour costs and a possible role in material prices. An especially tight labour market for construction workers may drive modestly higher construction wages temporarily, but not in the long run, as higher wages draw in more workers. For materials, local or industry-specific costs like transport costs or regional demand could put pressure on prices.

14 | B&C

News

The Ditch Witch FX20 Vaccum Excavator - The smart choice for productivity and versatility

The Ditch Witch Vacuum Excavator line is the most versatile and productive in the industry. Designed for an extensive range of clean-up and soft excavation tasks they are engineered from the ground up as a trailer vac system that ensure superior functionality.

The FX20 25hp (20.1-kW) Vacuum Excavator is perfect for a wide range of projects and multiple short runs per day. It’s Kohler® engine is renowned for its reliability and ease of maintenance, and it is ideal for a variety of projects such as valve box cleanouts, commercial and residential debris cleanup and landscaping, exposing utility lines, posthole digging, and many other tasks.

“The Ditch Witch FX20 is the ideal machine for a range of excavation tasks. With the agility to conquer any terrain and the power to tackle a diverse range of challenges the FX20 is extremely versatile and comes with a range of options to make them customisable to suit the application”, said CEA NZ General Manager John Grant.

The FX20 can be supplied on a skid frame, or a New Zealand designed and built 2500kg trailer suitable for towing behind ute’s and light trucks. An onboard hose reel and tray provide additional storage while the belt-driven blower is reliable and easy to maintain ensuring its ready to go when you are.

“Because it’s using locally sourced trailers as part of the build Ditch Witch CEA can ensure its not only fit for purpose but built to handle local conditions”, said John.

All Ditch Witch vacuum excavators are built to construction-grade and feature heavyduty components that can withstand the demands of many types of jobsites and applications. They can also be customised with your choice of tank sizes and numerous other options such as reverse flow, water heaters, and wireless hydraulic booms. Designed for a range of tasks including the clean-up of non-hazardous, non-flammable fluids and spills in and around jobsites, storm drains, conduit ad pipe, trenches, sewage lines plus many other locations the FX20 is extremely versatile. Its soft excavation capabilities include digging postholes, potholing, slot trenching, street repairs and keyholing to name a few.

Other uses for the FX20 include nonhazardous wastewater clean-up, salt and sand removal, industrial machine cleaning

If you’re looking for a machine that’s built to last, can tackle a range of jobs with ease and is supported by a highly trained team of technical experts get in touch with us today to find out how we can help maximise your operation.

CLASS LEADING

FROM INDUSTRY LEADING INNOVATORS.

and post emergency restoration, mulch, and gravel removal.

“The team at Ditch Witch CEA not only understands the industry, but the value of uptime. If you’re looking for a machine that’s built to last, can tackle a range of jobs with ease and is supported by a highly trained team of technical experts get in touch with us today to find out how we can help maximise your operation”, said John.

Like to know more about the Ditch Witch FX20? Speak to the team at Ditch Witch CEA today.

Ph: 0800 435 269 W: www.cea.net.nz

Utilising the cutting power of high-pressure water along with a powerful vacuum, the CEA range of vacuum excavators can remove almost any kind of surface without damaging existing infrastructures. Whether its utility locating, micro trenching, general construction site cleanup, potholing, keyholing or utility micro surgery the experienced team at CEA have the equipment and knowledge to ensure you have the machine you need, backed by staff who understand it.

Offering vacuum trailers through to units mounted on skids suitable for truck mounted configurations the range is packed with industry leading features and the best components in hydro excavation. The versatility of the Ring-O-Matic and Ditch WItch ranges ensure you can have the best configuration possible for your specific application

To find out more contact the team at CEA today.

P: 0800 435 269

W: cea.net.nz

B&C | 15

EXCAVATORS

VACUUM

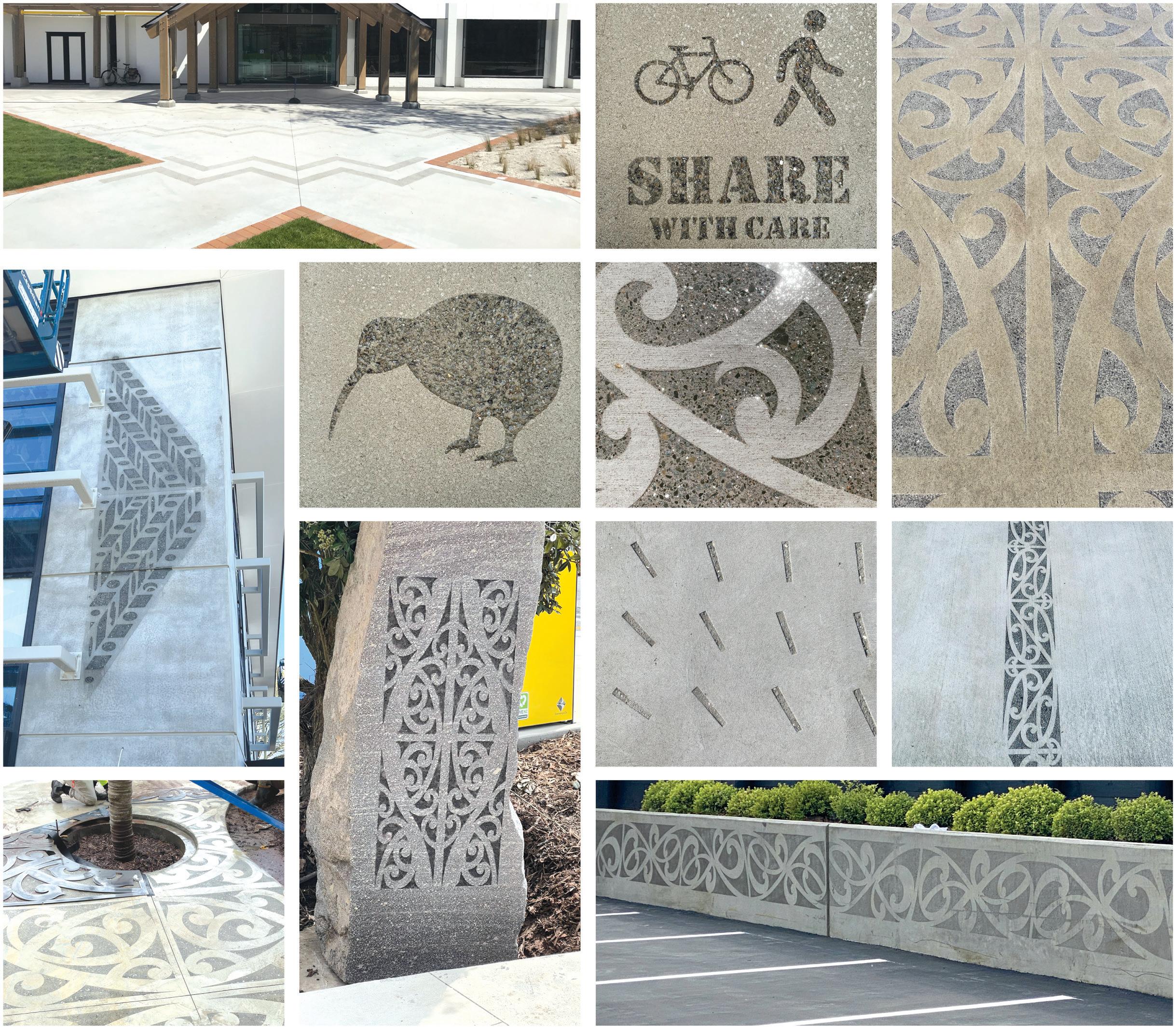

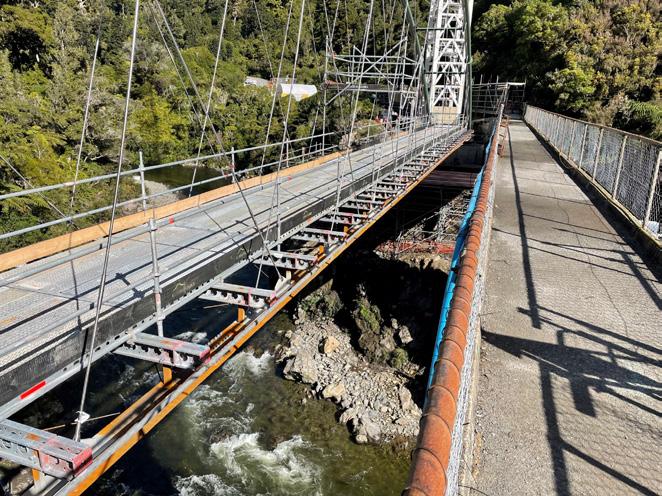

Game on Tracking Te Kaha Stadium’s progress

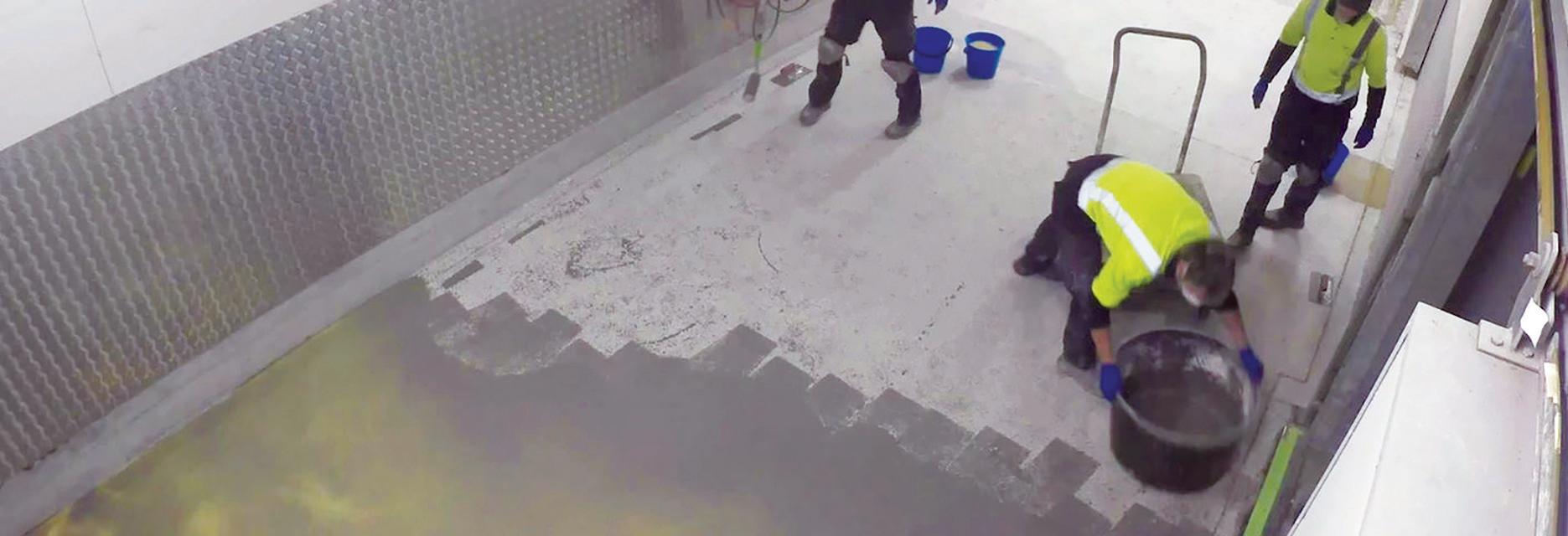

By June Pfister

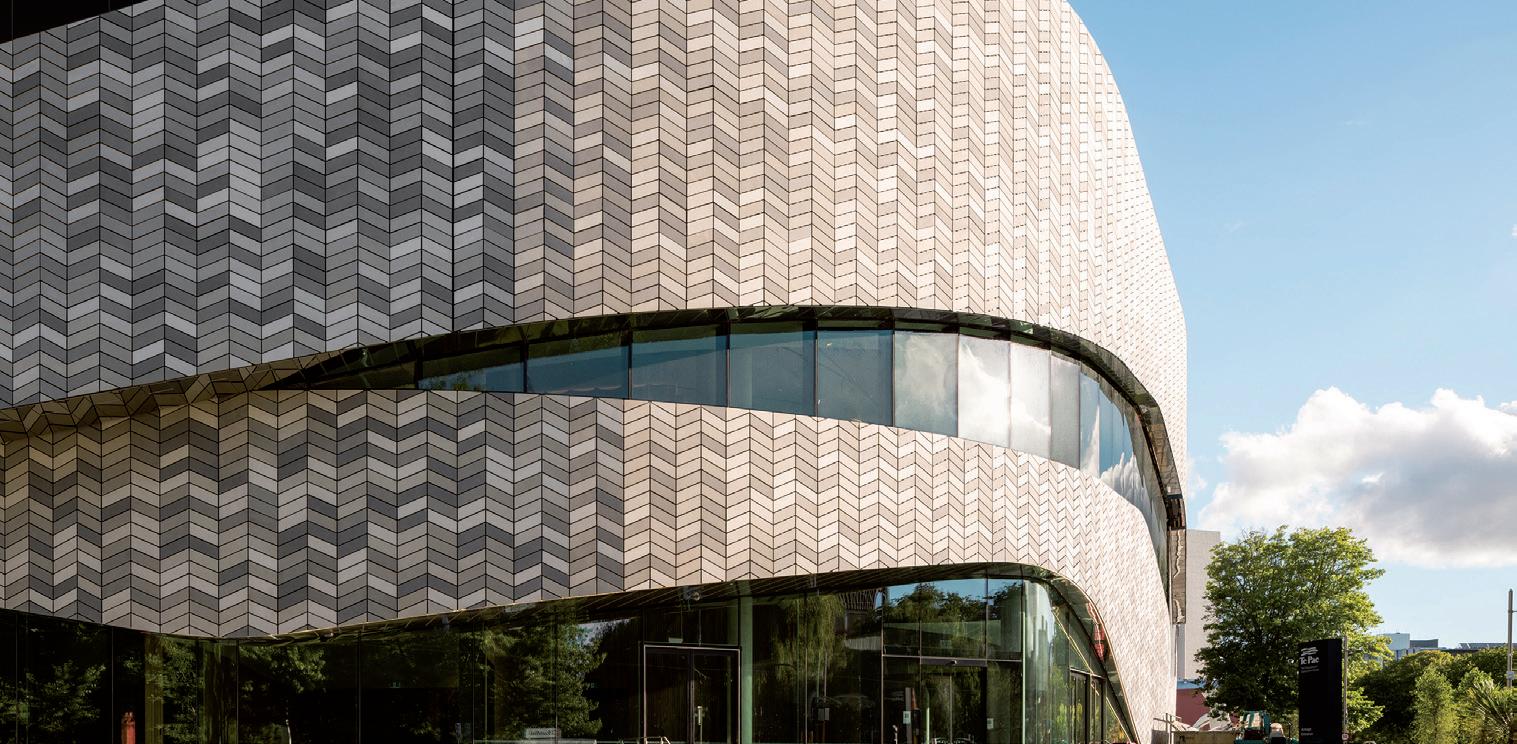

Christchurch, a city with a storied history of resilience after the devastating earthquakes of 2010-2011, is now on the brink of welcoming a monumental addition to its landscape - the Te Kaha Stadium.

This state-of-the-art multi-use stadium promises to be a modern marvel that will host sports events and serve as a venue for large-scale music events.

Being constructed in central Christchurch between Madras, Barbadoes, Hereford, and Tuam streets, Te Kaha Stadium aims to redefine entertainment and sporting experiences.

The city council’s ambitious project outlines a structure with a seating capacity of 30,000 for sports and a minimum of 36,000 for music events. Equipped with a retractable roof, the stadium will operate year-round, shielding events from inclement weather while offering impeccable acoustics for an unparalleled audio experience.

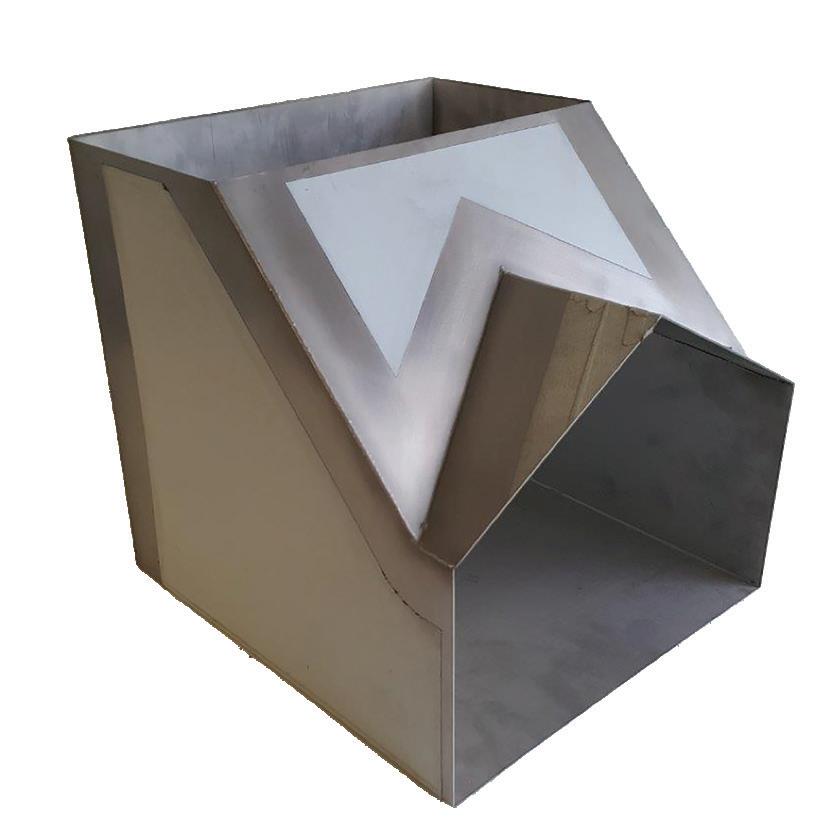

Led by the Kōtui Consortium, comprising Australian-based stadium construction

experts BESIX Watpac, Christchurchbased construction companies Southbase Construction and Fulton Hogan, seismic engineering specialist Lewis Bradford, architects Warren and Mahoney, and global design experts Populous and Mott MacDonald, this collaborative effort signals a fusion of local expertise and global innovation.

The journey towards Te Kaha’s realisation began with extensive geotechnical investigations starting in 2018, ensuring a solid foundation for the ambitious structure. The preliminary design and the bestowed name, “Te Kaha,” was approved by the Council in January 2022, which marked a significant milestone, setting the stage for the project’s design phase.

However, this grand undertaking has been full of financial challenges. Rising insurance, interest, and inflation costs have posed significant hurdles for the Christchurch City Council (CCC), impacting budgetary allocations. According to an article in The Press, the council’s rates have increased 13.3 percent for the 2024-25 financial year, with a cumulative rise of 31.5 percent anticipated by 2026-27. Mayor Phil Mauger’s endeavour to keep rate increases below inflation faces challenges as annual inflation hovers around 5.6 percent.

The Te Kaha Stadium accounts for a notable portion of this increase, constituting 3.5 percent of the rise for the upcoming financial year. Councillors, aware of community concerns about escalating rates, acknowledged the associated angst but pointed to the overwhelming public support garnered during consultations. According to an article written by BusinessDesk, Councilor Sara Templeton said that the Council were clear and upfront with city residents, “We were super clear with people that it would mean rates would increase, and we said how much they would be. People around the table at the time said it would not mean other cuts.”

Templeton’s proposition to isolate Te Kaha’s financial impact received unexpected support from Councillor Aaron Keown, highlighting the acknowledgment of the stadium’s unique position in the budgetary discourse. Some councillors even humorously suggested a giant sign atop the stadium, signifying its 3.5 percent contribution to the rates increase.

2010-2011 - Christchurch earthquakes significantly damage Lancaster Park.

2012 - Land was designated by the Minister for Canterbury Earthquake Recovery for the Multi-Use stadium.

2013 - A cost-share agreement was adopted between the Crown and the Council.

2015 - Council Long Term Plan allocates $253 million to the project.

2018 - Geotechnical investigations began.

2020 - On-site enabling works began in April.

2021 - Kōtui Consortium was announced as the successful tenderer for the design and construction and updated a design direction with 30,000 seats approved by the Council in August.

2022 - Preliminary design and gifted name ‘Te Kaha’ approved by the Council in January.

2023 - First of the steel for the vertical construction is lifted into place in June 2023.

2026 - Construction of the stadium is estimated to be completed by mid-2026.

Yet, amidst the anticipation and public backing, serious concerns have emerged regarding governance, budgeting, and systems. A former project director’s recent report raised critical issues, including budgetary concerns at the project’s tendering stage.

The budget for Te Kaha initially stood at $473 million, with an additional $90 million allocated in August 2022, totalling $533 million. The cost is expected to be $683 million at the completion of construction.

Despite these challenges, the Te Kaha Stadium represents not just a physical structure but a symbol of Christchurch’s unwavering spirit and commitment to regeneration. As construction moves forward, maintaining transparency in governance and financial management will be crucial.

For a more in-depth timeline and information on the Te Kaha project, visit the Christchurch City Council’s website at: www.ccc.govt.nz

Imagery courtesy of the Christchurch City Council.

16 | B&C News

Brief Timeline of the Construction of Te Kaha - from the CCC

Te Kaha Stadium: An artist’s impression of finished design.

Looking at the steel rakers in the southern stand.

Progress update on the 13th of December 2023.

View from the southwest corner, showing the level one concourse progress.

What are the actual risks?

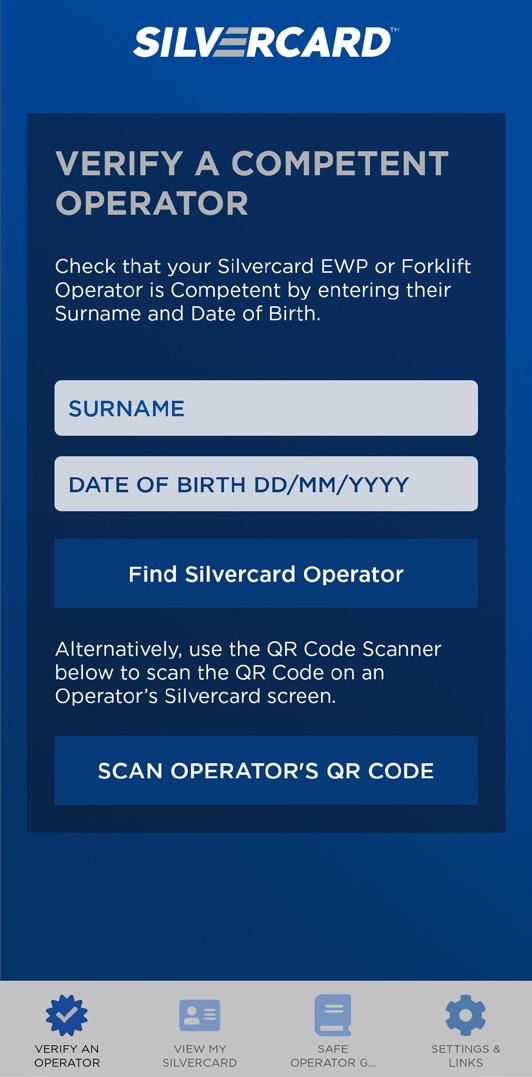

Silvercard™ MEWP

Competent Operator training provides you as an operator of a MEWP, the required knowledge, skills, and experience to ensure your operation of the MEWP is safe.

Further it provides assurance to your employer, workmates, and clients that you know what you are doing and won’t hurt them. Here are a few tips to help you be a competent Operator:

1. Seek professional advice on the right machine for the job. Remember, saving costs will not defend you in a court case!

2. Train yourself and your team to be a competent operator and selecting the right machine. It’s a requirement of the BPG.

3. Refresh your training at a minimum every 3 years or more often if you are not a regular user of a type of MEWP. It’s a requirement of the BPG.

4. Seek verification of competency of the operator on site. Untrained operators put everyone on site at heightened risk.

5. All information, warning and safety signage and instructions are in English on all MEWPs in New Zealand. You must be able to read and comprehend this information to be a competent operator. A translator will more than likely not always be available or translate correctly.

6. Do a Job risk assessment/ task analysis prior to performing your work. Communicate to all around you of your planned activities and controls measures you have in place.

7. Never trust a previous operators’ actions even if they are a good mate. Always pre-operational check a machine before first use of the day or when using it after someone else during the day.

8. Always, and I mean always check and use the logbook. It is a requirement of the BPG.

9. Do not use a machine that has a safety fault. You are gambling your health and more importantly your life if you do. For who and what gain? Don’t gamble with yours or others health and safety.

10. Handrails on the platform of the MEWP are your primary fall protection.

11. Don’t lean over or reach out over the handrails, you can’t fall out of a stationary boom or scissor lift. If you feel you have to reach, you have the wrong machine for your task.

12. A harness and lanyard may restrict a rescue operation if you have fallen out of the machine, and you are hanging in the stack of a scissor lift as it can’t be lowered. Think of it as though you are put into a garlic press!

13. The side force of you swinging in a harness and lanyard maybe enough to pull a scissor lift over if you fell out of it. Some scissor lifts have a side force limit of 400n (40kg with gravity acting on it)

14. Ensure any work carried out from it that requires a force to be enacted is done from the ends of the scissor lift, not the side.

15. The catapult action of the boom lift from movement should be the only reason to have you harnessed into the boom basket.

16. You should always look up and around when operating the MEWP. Crush only comes from not identifying what’s around you.

We want to help you, call us for help or see your local MEWP hire company.

17

Silvercard APP is now live. Download the APP from the Google or Apple store & get all your EWP & Forklift competent operator details on your phone. It's easy for managers to verify a Silvercard operator on site. Download the APP to your own iPhone or Android & then scan the operator’s QR code available in their own APP. Silvercard™ EWP and Forklift Operator courses are delivered by Professional Trainers across New Zealand. Find a Trainer near you: silvercard.co.nz/trainers/

The

The case for increased housing density with Guy Marriage From the ground up

By Ben O’Connell

New Zealand has an affordable housing shortage, yet developing higher-density housing is opposed by many Kiwis. For architect, author, and lecturer Guy Marriage, the case for denser urban living is evident.

When the National Party withdrew its support from the bipartisan housing density agreement with Labour last May, many urban centres entered planning purgatory. National then proposed its policy allowing councils to opt out of Medium Density Residential Standards (MDRS) and instead zone greenfield land for 30 years of development. The Greens said National’s plan promotes urban sprawl, damaging the environment.

Cut to December, when the Christchurch City Council took advantage of the change in government by considering a pause in housing intensification plans.

Public hearings on the Housing and Business Choice Plan Change – also known as Plan Change 14 – are currently postponed to allow more time for clarity from the Government.

The move injected uncertainty into the planning processes of city councils nationwide, uncertainty that only delays housing crisis solutions. As housing density is tracked locally by councils, data is tricky to come by.

Still, political moves signal an increasing trend in medium and high-density housing, as does the nationwide increase in residential building consents. Accepting housing density measures is inevitable, but what’s the best way to do it?

“Build more densely, build off-site, build more intelligently, build for the long-term,” says Guy Marriage.

“As an architect and co-founder of the awardwinning First Light Studio, a senior lecturer

at the Wellington School of Architecture, and the author of three internationally acclaimed books, his advice is priceless.

“Prefabricate whole sections or parts of buildings, doing all the tricky work safely at ground level and then hoisting the completed object into space.”

According to a recent Forbes article, prefab builds are more common in countries like Japan, Sweden, and Germany than here. They account for around 84 percent of Swedish homes, compared to 10 percent in New Zealand.

“Our long-term model of one builder, one ute, one house at a time is rubbish, outdated and needs to stop.

“We build these suburban houses stick by stick, out of kiln-dried timber, and then let it all get wet in some inevitable storms, and then we nail on plasterboard, which really just wants to act as blotting paper, and then slap on a tiny thin cladding layer and wonder why it all starts going sour.”

It undeniably costs more to build better, but Guy says cheap housing inevitably turns nasty.

He envisions factories producing houses that roll off their production line and are taken to site, a New Zealand where we are not afraid to pay the full cost for the best possible builds. It’s about building for the long term, not for short-term financial gain.

“The problem is that we are getting cramped, low-density rather than spacious highdensity,” he says.

“Filling up a section with townhouses, carparks, and nothing else just makes everyone miserable in the long term. Instead of building townhouses on the outskirts of every town, we would be far better to rebuild our central cities, building housing of a sensible height near the middle.”

Innovative building solutions are the future, but it takes time for big ideas to be accepted. Guy wants to do a medium-density housing project with cross-laminated timber (CLT) on a large urban scale. “But New Zealand is still a bit too timid for that. It’ll come. I’ll wait.”

Ultimately, housing density decisions all come down to the price of land. Cheap land means suburban sprawl and maximising expensive land means denser housing.

“It is no coincidence that the best, most inventive housing in the world comes from the places where land is constrained,

rather than just from places where sprawl is unlimited. Hong Kong, for instance, is far more interesting than Houston.”

Many factors contribute to the current housing density issues our country faces. New Zealand has one of the lowest population densities yet is one of the world’s most urbanised nations; around 85 percent of Kiwis call a city home.

Increased density lowers the cost of each unit and the need for infrastructure. Suburban sprawl also means more time wasted in traffic.

Despite being long and thin, Aotearoa has the eighth most cars per capita, on par with the United States, Canada, and Australia.

“It is just that they all live spread out in endless, boring suburbs,” Guy says. “We have these massively wasteful cities, spread out for miles, and the infrastructure of pipes and roads and wires all costs millions.

“There is, unbelievably, still a mentality amongst some people that you have to live in the suburbs to raise your children. Not so. Children raised in urban areas turn out just as well, if not better.”

Warmth, humidity, mould, sound, and fire safety are a few characteristics of housing density that can be just as good—if not better—in an apartment as in a suburban home.

Guy says we need to build, design, and live in our homes better: opening windows to air out spaces as one example.

Guy advocates for multi-generational buildings higher than two storeys tall, with better quality, higher-density designs, and people-friendly common outdoor spaces.

The Coronavirus pandemic showed architects

18 | B&C Cover Story

how vital access to outdoor space for all is, with balcony access at a minimum.

Some people argue against increased housing density because of the loss of green spaces, but Guy says building denser actually saves the outdoors from despoliation.

“One of my favourite examples is Sienna, Italy. It was at war with Florence and other city-states for hundreds of years, and so they lived within the city wall in intense urban conditions, just as they have done for the last 500 years.”

“Meanwhile, you can look out over the edge of the city wall and down below, there is a vineyard growing grapes that feed the city. “There’s no suburbia. It is either urban or rural, and nothing in between.” Italians today are as passionate about their lives within the city walls as their ancestors were centuries ago.

Helping people lead passionate lives is precisely why social housing is important. Without great design and an affordable price, families cannot plan their lives for the long term. People need to feel invested in their accommodation to envision future opportunities, let alone realise them.

Particularly impactful, Guy commends Kainga Ora redevelopment projects in Auckland. Funding from the Government and Wellington City Council for a complete overhaul of city housing blocks is also

promising. Only time tells how successful social housing initiatives are though.

And yet Christchurch notably lags. Guy describes the recent suburban townhouse sprawl in Ōtautahi as horrible, cramped, and scattered around the city like litter. The domino effect from the 2011 earthquakes and subsequent rebuild continues.

A side effect of housing people quickly postquake is suburbs devoid of community and personality. Intensifying density would stop the “dull wave of boring housing sweeping the city,” Guy says.

“Christchurch has been rightly scared off medium density because of the terrible housing that “those” developers have created. You know who I mean.

“They only have one plan, and they rubber stamp it en masse all over town, and it is a mess. Everything is two storeys tall, everything is the same, and only the paint colour changes.

And not everyone lives in a nuclear family.

“But build taller: three, four or five floors, get a mix of household sizes in, so you have single people, grandparents, whole families, students, workers, retirees, children. We need the whole mix of people to get a community going.”

Guy remains hopeful about the future of housing density intensification in New

“We need far better thinking around the places that we say are okay to live in. Don’t build housing on your best horticultural soil!”

As for Guy’s advice to builders and architects, don’t try to reinvent the wheel. “Don’t swamp a city with bland two-storey housing: hire the best architects and design housing that addresses the land first.

“Plan the open spaces first, and then plan the housing to surround those open spaces. Think about the world’s best cities and then think about their parks.”

Guy’s three books demonstrate growing interest and development in the housing density space. Now a seminal textbook

Filling up a section with townhouses, carparks, and nothing else just makes everyone miserable in the long term. Instead of building townhouses on the outskirts of every town, we would be far better to rebuild our central cities, building housing of a sensible height near the middle.

for students worldwide, TALL - the Design and Construction of High-Rise Architecture (Routledge, 2019) covers the rationale behind tall office building design.

His second book, Modern Apartment Design (Routledge, 2022), is focused on the growing interest in constructing tall timber buildings for residential living. Guy says that when done well, apartments are superior above all. Done poorly, and they become hell. Think noisy, loud neighbours and cramped, poorlydesigned spaces.

His latest research project – Medium (EBOSS, 2022), explores creative solutions for living denser and better. Think courtyard houses like the Romans had 2000 years ago, but updated for today.

“Do you know they had apartment buildings back then?” he asks. “The Romans called them insulae, meaning islands, because they rose out of the humdrum dross of the city of Rome. There is nothing new under the sun, really.

“So, let’s repeat it, only do it better this time. Make it more earthquake-resistant, for starters!”

B&C | 19 Cover Story

Zealand. He thinks Christchurch could be the perfect cycling city with the proper infrastructure, like Hastings, which sprawls across some of the best orchard land in the country.

20 | B&C Aden Motel is nestled beside one of New Zealand’s largest lakes and surrounded by magnificent scenery. Whether you have come to enjoy the spectacular Milford or Doubtful Sounds or partake in some of the many activities offered in and around Te Anau like glow worm caves, horse trekking, jet-boating and more, we know you will leave with fond memories. Your hosts Irene Benfell & David Herron welcome you and with their local knowledge, are happy to help plan your daytrips. 03 2497748 | info@adenmotel.co.nz | www.adenmotel.co.nz Phone direct for any discounts FOR SALE 0800 827 329 | enquiries@tasmandaysurgery.co.nz | 341 Lower Queen Street, Richmond, Tasman 7020 www.tasmandaysurgery.co.nz Welcome to Tasman Day Surgery! We are a team of caring health professionals who are dedicated to supporting your health journey in every way we can. Located in Nelson, NZ, our hospital is run by doctors who believe in the simple philosophy of providing high-quality, patient-centred care to their community. As a leading purpose-built private hospital in Nelson, Tasman Day Surgery will be sure to prioritise your safety and comfort every step of the way. The facility and our specialists can provide a wide range of medical and surgical services including: • Endoscopy - Colonoscopy and Gastroscopy • General Surgery • Gynaecology • Skin Surgery • Ear Nose and Throat Surgery • Infusion Service • Orthopaedics THE NEWEST PRIVATE HOSPITAL FOR NELSON AND TASMAN Ask your GP for a referral or call us direct.

Universal Cranes New Zealand offer a diverse fleet ranging from 2.5T to 450T

Formerly known as Auckland Cranes and now proudly operating as Universal Cranes, we’ve emerged as a trusted, leading brand in the industry, drawing on our legacy since 1970. Our track record speaks for itself, with a strong reputation for providing secure and highly efficient solutions for all your lifting and shifting needs.

With locations in Auckland and Hamilton, we offer comprehensive mobile crane rental services, serving diverse industries and businesses. Our commitment to delivering precision lifts remains unwavering, no matter how complex the task.

In collaboration with Smithbridge Group and Universal Cranes Australia, our trans-Tasman partnership enhances our service offerings across Australia and New Zealand. This cross-border collaboration leverages our expertise, resources, and knowledge, offering seamless solutions for clients in both locations.

Exciting times lie ahead as the next generation leads us into a new era. Contact us today to discover our extensive national and international fleet and dependable crane rental services.

B&C | 21

• CIVIL CONSTRUCTION & INFRASTRUCTURE • GENERAL CONSTRUCTION • MANUFACTURING & INDUSTRIAL • RENEWABLE ENERGY WHAT WE DO www.universalcranes.co.nz AUCKLAND Ph: 09 277 2227 Address: 12 Langley Rd, Wiri, Auckland Email: enquiries@universalcranes.co.nz ANY LIFT, ANYWHERE, ANY TIME AUCKLAND| WAIKATO WAIKATO Ph: 07 849 3846 Address: 86 Sunshine Ave, Te Rapa, Hamilton Email: enquiries@universalcranes.co.nz • CRANE AND TRANSPORT • HIRE PROJECTS & HEAVY LIFT • LIFT PLANNING & ENGNEERING • TILT UP PANELS AND PRECAST ERECTION OUR CAPABILITIES

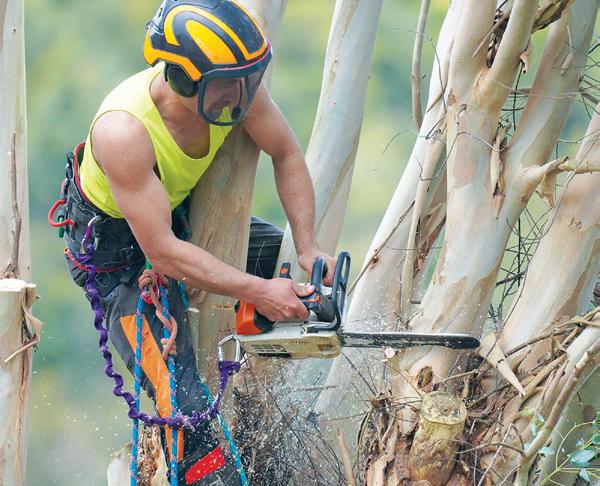

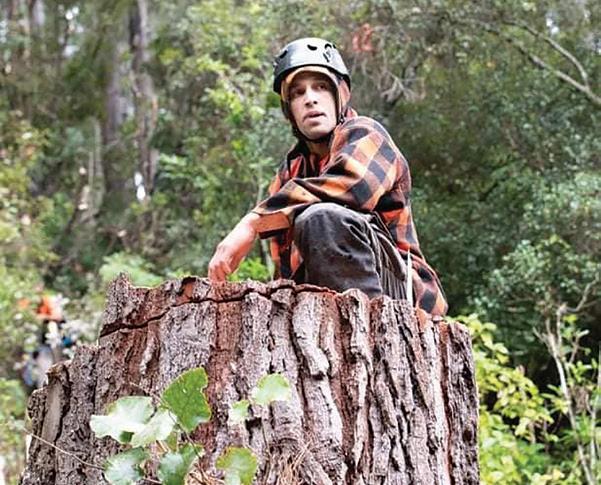

The next steps after onsite bullying and harassment When the banter goes too far

By Ben O’Connell

Working in trades isn’t for the faint of heart. Banter is typical and part of the job. But what happens when it goes too far?

In some workplaces, jokes are a way for people to communicate and have fun. Kiwis often bond with sarcasm.

But all tradespeople should be treated with dignity on the job. Everyone has the right to a safe and respectful work environment.

And it can go both ways. It should go without saying that workers must be respectful to clients.

Recently, a plasterer admitted he went too far after calling his client a con man and child molester because the client wouldn’t pay $16,000 for the work completed.

Written contracts are crucial in settling any dispute, and ensuring licences are up to date is also key.

But for those subject to abuse, there are steps to take when things get out of hand.

Firstly, record every instance where an insult or inappropriate behaviour occurs. This includes the date, time, who was involved, what was said or done, and any witnesses.

Construction sites naturally come with banter.

This documentation can serve as evidence if a formal complaint needs to be made.

It can be easier said than done, but a direct conversation might be the best action if the person making the insults is a colleague. Calmly and professionally explain how their behaviour affects you and ask them to stop.

Prolam re-opens Motueka sawmill boosting Nelson’s timber industry

The first logs in more than five years have been milled at a restored sawmill on Little Sydney Road, Motueka marking a new chapter for the region’s timber industry.

Closed in 2017, Nelson family-owned business Prolam has been working to reinstate the 80-year-old mill to support the production of its innovative structural timber solutions.

Prolam is one of New Zealand’s leading manufacturers of glue-laminated timber building products, and the mill will play a pivotal role in the company’s ability to meet the building industry’s demand for more sustainable, locally-made building materials.

Prolam managing director, John Woodman, said the opportunity to make a positive contribution to the timber processing industry and the local economy was front and

centre in his decision to purchase the site in 2017 and get the mill back up and running.

“We have seen seven or eight mills close across New Zealand in the last 10 years, and when we started planning to reinstate the mill in 2021, structural grade timber was in short supply,” John said.

“We source and use select quality New Zealand plantation-grown radiata pine in our glue-laminated timber beams, posts and portals and while supply is no longer an issue, our ability to mill a proportion of our own timber will have significant benefits for our customers and us.”

Mr Woodman said Prolam has carved a reputation as an industry leader in the supply of premium quality engineered timber solutions in fast lead times and at a competitive price.

“The commencement of production at the mill represents a step change in our production capability and secures our control

If the insults continue or escalate, reporting the incident is essential. Supervisors should be able to guide how to handle the situation and may be able to intervene to stop the behaviour.

Don’t hesitate to contact your support network for advice and emotional support.

There can be a real harden-up mentality when faced with abuse, but times are changing. It doesn’t have to be this way.

This could be a union representative, a trusted colleague, a mental health professional, Employment New Zealand, and so on.

If the insults are severe or frequent, and the employer fails to take action, it may be necessary to seek legal advice. A lawyer can guide whether there are grounds for a complaint or legal action.

There can be a real harden-up mentality when faced with abuse, but times are changing. It doesn’t have to be this way.

Don’t suffer in silence if you’re facing insults or inappropriate behaviour at work. Take action to protect your well-being and dignity.

across key elements of the manufacturing process,” he said.

“It also supports our commitment to the long-term sustainability of the New Zealand timber industry and optimising the use of timber as a renewable resource in the design and construction of residential and commercial buildings.”

Prolam employed experienced Sawmill Manager Damon Taggart to run the reinstatement program and the mill once it was operational, and engaged New Zealand-based companies, Pacific Sawmill Engineering and Tui Technology, to assist in

the planning, design and oversight of the mill’s refurbishment.

“We have invested in new and proven milling technology to create a vertically integrated glue laminated production facility that will enable us to debark logs, mill, kiln dry and treat the timber ready for the lamination process.”

The Prolam range of glue laminated timber products are available from timber merchants and wholesalers nationwide. The Prolam PLX20 Beam was a finalist in the 2023 New Zealand Timber Design Awards.

22 | B&C

News

Minimising landslide slip-ups

By Ben O’Connell

New guidance and mapping measures improve resilience

In January, GNS Science released new land-use planning guidance to manage and reduce the risks of landslides. Considering the dangers of land use early in the planning and decision-making processes avoids costly and potentially dangerous new developments that could pose risks to people, property, and the planet down the line.

Guidance co-author and GNS Engineering

Geologist Dr Saskia de Vilder said that, on average, landslides cost Aotearoa New Zealand $250 million yearly and have resulted in more fatalities than earthquakes, volcanoes and tsunamis combined.

Landslide Planning Guidance: Reducing Landslide Risk through Land-Use Planning has been developed to support a risk-based approach to land-use planning that considers changing weather patterns as well as current risk assessment, management and mitigation practices.

At a minimum, the Guidance recommends councils develop a landslide susceptibility map to better inform important decisions that determine where and how we live.

The Landslide Planning Guidance updates previous guidance released more than

15 years ago. It emphasises the need to consider climate-change scenarios likely to exacerbate landslide hazards due to changing weather patterns.

Speaking of mapping, this new landslide guidance coincides with recent research on landslides from the University of Canterbury. Canterbury researchers and students mapped 140,000 landslides triggered by Cyclone Gabrielle to create models for future weather events.

New Zealand now boasts one of the largest single-event inventories of landslides globally. Senior Lecturer and lead researcher Dr Tom Robinson was surprised at the sheer number of landslides they found, “in the Esk Valley alone, in just one 12km square area, you’ve got over 2000 landslides.”

Mapping and guidance measures both lead to improved future resilience.

“Landslides are difficult to forecast and predict; the only way you can do it is by looking at where they’ve occurred in the past,” Dr Robinson says.

“Mapping tells us the conditions that triggered them in the past: the type of slopes, what is on the land, has rainfall caused it and if so, how intense was the rainfall, was it an earthquake, how much shaking was there – all critical information telling us how landslides occur.

“So, when we have a future event, particularly rainfall, we could say this is

where we think a landslide is most likely to occur, the predicted trajectory, what’s in its path, and therefore do we need to shut roads, do we need to evacuate people?” says Dr Robinson.

The team uses aerial imagery with up to 30cm high resolution, imagery so powerful you could spot a laptop on the ground for mapping.

“We’ve mapped over 140,000 landsides, the smallest roughly the size of a car, from 20 percent of the area affected by Cyclone Gabrielle. We can’t possibly map them all, but we believe there are about 750-850,000 in total.”

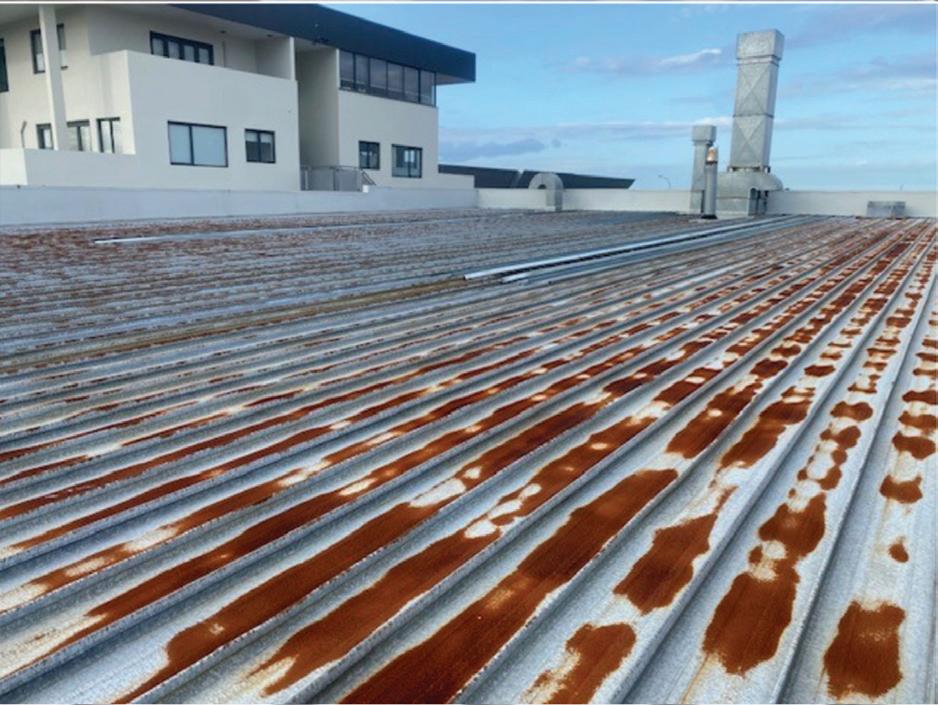

Kainga Ora undertakes major nationwide renewal Record number of public housing renovations

By Ben O’Connell

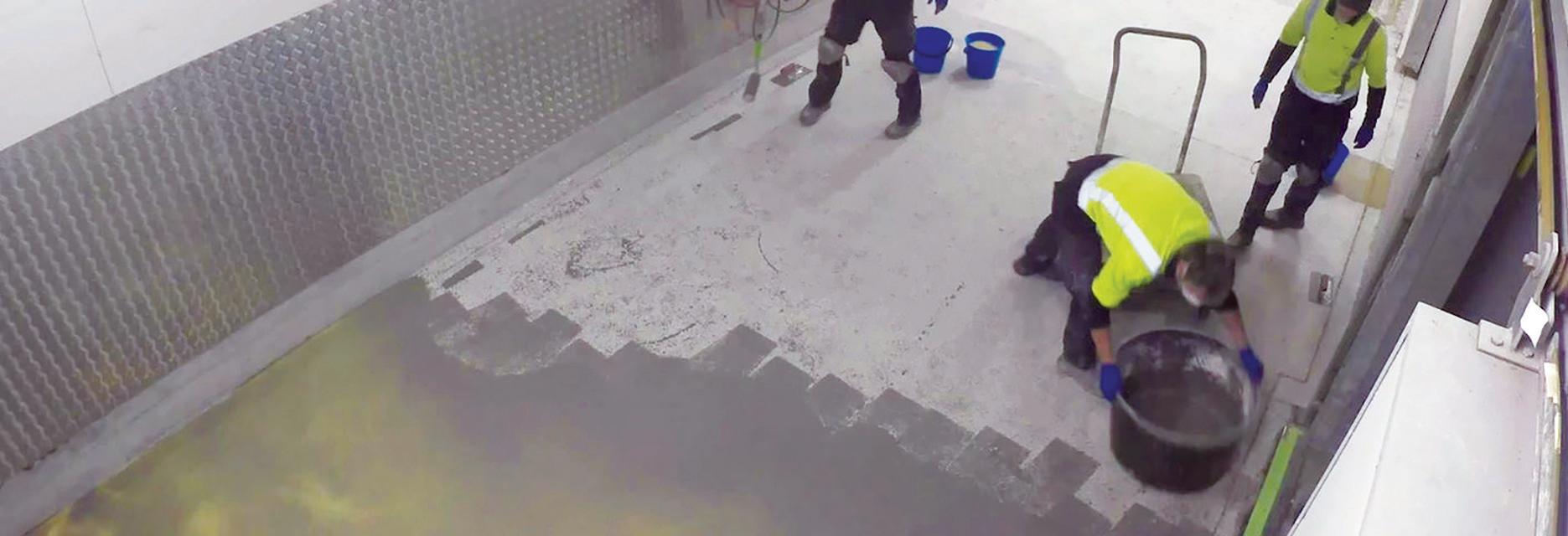

As part of one of the largest housing regeneration initiatives in New Zealand ever, Kāinga Ora is renovating old public homes.

For $251 million, 747 public homes were significantly modified over the past financial year. A further 820 homes will be renovated this year for $323 million.

The renovations are part of a public housing renewal programme that was first piloted in 2019 when 69 old homes were renovated, says Kāinga Ora General Manager Construction and Innovation, Patrick Dougherty.

The initiative has expanded yearly as Kāinga Ora continues to invest in the country’s legacy of providing public houses to those in need.

As for the scale of the initiative, last year’s renovations took nearly 85,000 litres of paint, over 100,000 new double-glazed windows, just over 46,000 square metres of new carpet, and nearly 200,000 square metres of insulation.

In the last financial year to June 2023, Kāinga Ora’s maintenance programme has added 1,878,656 square metres of insulation to homes, which is enough to cover the Wellington Airport runway 21 times.

They have also installed 335,998 square metres of new roofing, enough to cover the roof of Auckland’s Eden Park Stadium 21 times, and fitted more than 20,000 new heat pumps and more than 9700 electric ovens.

About twelve tradespeople work on each home, which creates employment and training opportunities. There’s a raft of positive ripple effects for local builders, suppliers and communities nationwide.

Patrick says Kāinga Ora homes are cared for by a network of around 11,000 tradespeople across the country, who complete more than half a million maintenance jobs a year. It equals roughly one every minute, 24/7.

The renovation work is on top of the regular maintenance work Kāinga Ora does on all its homes. Patrick says that when the renovations are done it’s like stepping into a new build.

Kainga Ora is the country’s public housing landlord, with more than 72,000 properties providing homes to about 185,000 New Zealanders.

Early public housing was designed for a different way of living, and Patrick says they are starting to show their age. Renovating homes with new kitchens, bathrooms, insulation, and double glazing, for example, brings them up to modern standards.

Kāinga Ora is the country’s public housing landlord, with more than 72,000 properties providing homes to about 185,000 New Zealanders.

It is also leading the New Zealand Government’s state house building programme with more than 4,200 new public homes in construction for delivery by the end of June 2024. Its renovation and maintenance programmes are in addition to this building programme.

B&C | 23

Redcliffs 2011 earthquake damage.

News

Interior glam