Botswana

The irrigation answer for Botswana’s farmers

Namibia Zimbabwe

Zimbabwe agri workers’ wage woes

FAW Trucks SA

unveils the JK6 FD/FT variant p 5 Zambia

Revolutionise your farming:

Total control with Zimmatic/FieldNET technology

The irrigation answer for Botswana’s farmers

Zimbabwe agri workers’ wage woes

FAW Trucks SA

unveils the JK6 FD/FT variant p 5 Zambia

Revolutionise your farming:

Total control with Zimmatic/FieldNET technology

We recently had the honour of visiting a few farmers and attending the annual AgriTech Expo in the northern region of Zambia. As we delved into the heart of Africa's agricultural landscape, we uncovered stories of resilience, innovation, and growth that inspire and uplift.

It is evident that more and more farmers are adjusting their way of farming because of the climate change challenges faced throughout Africa. Climate change is here to stay, and it is of utmost importance that farmers and suppliers make the mind shift to adapt and implement new technologies to overcome the new challenges.

Agriculture is central to fostering economic growth, reducing poverty, and improving food security in the Southern African region.

The president of Zambia, Hakainde Hichilema, addressed farmers and the media at a farmers day at the Zambia Agriculture Research Institute (ZARI) at Mount Makulu in Chilanga outside Lusaka, where he once again highlighted the importance and diversity of agriculture: “In Africa, the greater majority of people work in or around agriculture. As research is being done, it should be shared with our farmers to benefit not only our farming operations but the whole value chain. It is important that we implement measures aimed at making African countries food secure by developing adaptive seed

varieties for the staple food,” he said.

UPL and Advanta Seeds have inaugurated a series of successful pilot projects for drought-tolerant seed varieties on which we shall focus in the next edition of ProAgri Africa.

In this issue, we explore the latest advancements in sustainable farming techniques, share success stories of smallholder farmers, and highlight the transformative impact of technology on agriculture.

In our cover story we take a look at Namibian farmer, Emile Mouton’s journey with Zimmatic Irrigation and how Zimmatic and FieldNET technology can revolutionise your entire farming operation. We also take a closer look at the challenges facing the agricultural sector, from climate change to food security, and discuss innovative solutions that are driving positive change and fostering growth.

Join us as we journey through the vibrant world of African agriculture, where passion meets purpose, and together, we cultivate a brighter future for generations to come.

Be sure to keep an eye open for our next edition, where we shall cover all the latest news and trends displayed at AgriTech 2024.

Happy reading, Bianca Henning bianca@proagri.co.za

Zimmatic centre pivots have proven vital in driving the success of farms. A decent irrigation system can benefit the farmer through ease of use and better water management. Read more on page 3 about Namibian farmer, Emile Mouton’s journey with Zimmatic Irrigation.

Bianca Henning >

benine@proagri.co.za +27 82-261-9177

maryna@proagri.co.za

Natasha Pretorius

Ashleigh Schubert

+27 71-585-9422

natasha@proagri.co.za

+27 71-585-9422

ashleigh@proagri.co.za

Annemarie Bremner > Senior Production Manager

+27 82-320-3642

annemarie@proagri.co.za

Zainab Pandor >

+26 (0)97-769-9786

zainab@proagri.co.za

Client Relations Manager

Carin Swartz >

Marketing Manager

+27 82-735-4996

carin@proagri.co.za

Zimmatic/FieldNET technology revolutionises your entire operation

FAW Trucks SA unveils the JK6 FD/FT variant, reinforcing its position as an industry pioneer John Deere’s SMART solution for Africa!

Effects of litter on your broiler production

Erosion control: Old tyres to the rescue

UNECA: Agricultural innovation needed to aid food production in Africa

Hydroponics part 2: Passive and active hydroponics

Technews: The latest in agricultural technology from around the world

Banana production in Africa part 4: Controlling weeds and pest control

Senter 360: The irrigation answer for Botswana’s farmers

Managing water sources is key to water security

Zimbabwe agri workers’ wage woes

Research to drive agricultural sustainability in Zimbabwe

Diane Grobler > Marketing

Xander Pieterse >

Johan Swartz

+27 82-555-6866

diane@proagri.co.za

+27 62-391-6507

xander@proagri.co.za

+27 71-599-9417

johan@proagri.co.za

+27 82-698-3353

tiny@proagri.co.za

+27 74-694-4422

lynette@proagri.co.za

+27 71-891-4441

evette@proagri.co.za

+27 84-416-1780

michelle@proagri.co.za

Jamie-Lee Tromp

+27 73-663-1234

engela@proagri.co.za

+27 79-515-8708

nita@proagri.co.za

+27 84-088-0123

accounts@proagri.co.za

Termination - Akheri spray is an e ective new age chemical with little resistance that will kill o most pests

" The epitome of safe pest termination" Epitome - highest quality

Plot. No 396A/67/D/1 Makeni P.O.Box 34902, Lusaka, Zambia

Safe - Akheri is odourless and has one of the lowest mammalian toxicity of known pest control chemicals

Contact: +260 779 188008 | office: +260 966 500096 | +260 966 500032 |

E-mail:farmersafrica04@gmail.com |farmersafrica01@gmail.com

Termination - Akheri spray is an e ective new age chemical with little resistance that will kill o most pests

www.farmersafricazambia.com

Plot. No 396A/67/D/1 Makeni P.O.Box 34902, Lusaka, Zambia

Contact: +260 779 188008 | office: +260 966 500096 | +260 966 500032 |

www.farmersafricazambia.com

E-mail:farmersafrica04@gmail.com |farmersafrica01@gmail.com

In the heart of Namibia's agricultural landscape, Emile Mouton, a dedicated farmer at Namibia Dairies in Mariental, is spearheading a new era of irrigation practices with Zimmatic technology. With a focus on sustainable water management and improved crop yields, Emile shares insights into the farm's evolution and the pivotal role of irrigation in their success.

He reflects on Namibia Dairies' journey, highlighting its establishment in 2009 under the Ohlthaver & List Group, a pioneering force in the agricultural sector since 1919. Nestled along the Fish River within the Hardap Irrigation Scheme, the farm spans 251 hectares of irrigated land, supporting a diverse range of crops including summer maize, winter wheat, and lucerne.

"The challenges we face," Emile explains, "revolve around optimising water usage to meet demand." This challenge prompted a shift towards pivot irrigation systems, allowing for more precise control over water application, and enhanced efficiency.

partnership with Aqualand Irrigation and Agriculture, one of the Zimmatic dealers in Namibia, renowned for its exemplary support and technical expertise. Emile credits Aqualand for providing crucial monitoring reports, rapid access to spare parts, and invaluable technical assistance.

Emile Mouton from Mariental, Namibia, says Zimmatic pivots are his top choice for irrigation solutions.

In discussing irrigation practices, Emile emphasises the impact of Zimmatic equipment, particularly the control panel and FieldNET remote control which are employed across the farm's three pivot points. These technologies have revolutionised their approach to farming, boosting yields and reducing labourintensive tasks.

"We have seen a significant increase in yields," Emile notes, "averaging between 2 to 2,2 tonnes per hectare on crops irrigated with pivot systems, and the use of FieldNET Pivot Control. This improvement underscores the tangible benefits of investing in modern irrigation solutions.

Looking ahead, Namibia Dairies plans to expand its Zimmatic pivot infrastructure, aiming to add five additional pivot points by 2029 while phasing out flood irrigation methods. This strategic shift aligns with broader efforts to enhance water management and maximize agricultural productivity.

Central to this transformation is the

When asked about his recommendation for fellow farmers, Emile is resolute. "As an agricultural manager focused on financial impacts and crop optimisation," he asserts, "Zimmatic pivots are my top choice for irrigation solutions."

Through innovative technology and strategic partnerships, farmers like Emile Mouton are not only adapting to changing environmental conditions, but are also pioneering sustainable practices that ensure the future resilience of Namibia's agricultural sector. With Zimmatic at the helm, the outlook for Namibia's farming community is one of promise and progress.

Get the best in irrigation and irrigation control. Visit our website to locate your nearest Zimmatic dealer for a quotation: www.lindsay.com or call +27 21986 -8900

F AW Trucks SA, a force in global commercial vehicle manufacturing, proudly announces the introduction launch of the new generation JK6 FD/ FT variant.

This strategic introduction underscores the company's steadfast commitment to advancing technology and performance in the commercial transport sector.

neered to tackle the unique challenges posed by African terrains, demonstrating the company's commitment to providing solutions that perform optimally across varied landscapes.

2. Localised customisation: FAW Trucks understands the diverse requirements of African businesses, providing localised customisation

options for the JK6 FD/FT variant. This allows the truck to be configured to suit the specific needs of industries prevalent in the region, including logistics, construction, and agriculture. Additionally, the chassis offers versatility in applications — it can be utilised as a truck tractor or tipper, adapting to both haulage and transport duties.

3. Eco-friendly performance: Aligning with FAW Trucks’ commitment to sustainability, the JK6 FD/FT variant incorporates features for reduced environmental impact and improved fuel efficiency. This supports businesses in meeting both operational and eco-conscious goals.

With a rich history dating back to its establishment in South Africa in 1994, FAW Trucks has become a leading player in the industry, leveraging its state-of-the-art manufacturing plant in Coega, Eastern Cape.

Establishing a solid foundation in South Africa, FAW Trucks SA invested R600 million in the construction of its innovative manufacturing plant in Coega. This facility serves as the epicentre for the production of high-quality trucks, embodying the company's dedication to precision engineering and technological innovation.

1. Adaptability to African terrain: The JK6 FD/FT variant, presented by FAW Trucks, is meticulously engi-

About FAW Vehicle Manufacturers SA (Pty) Ltd: FAW Vehicle Manufacturers SA (Pty) Ltd, established in 1994, is a leading global player in commercial vehicle manufacturing, committed to delivering cutting-edge solutions. With more than 70 years of experience and one of the only OEMs to have such a diverse and extensive range from small to extra heavy vehicles, FAW Trucks SA continues to be a trusted partner for businesses worldwide.

To explore FAW’s commercial offerings and remain updated on the latest developments, visit www.faw.co.za.

Introducing a groundbreaking initiative! Just over a year ago, John Deere, in collaboration with our innovative SMART model, embarked on a pioneering financing program to empower farmers with access to mechanisation previously unattainable through traditional banking channels. This trailblasing endeavor saw the strategic partnership of John Deere, Senwes, Innovent, and UFD, a dynamic mentorship group led by young agricultural graduates, predominantly comprised of remarkable female leaders.

Venturing into uncharted territory, this program was designed to break barriers and revolutionise the agricultural landscape. Through rigorous planning and unwavering commitment, we successfully launched a first-of-its-kind financing model tailored to support the evolving needs of modern farmers without the hassle of land title deeds. As we navigated challenges and blazed a trail with no established blueprint, the collaborative efforts of John Deere, Senwes, and UFD proved instrumental in achieving remarkable outcomes.

Initially envisioned to support 15 farmers, our expedition encountered hurdles along the journey, leading to the financing of 10 farmers with a fleet of 13 tractors. Striving for comprehensive support, we curated complete packages encompassing tractors and essential implements, ensuring maximum operational efficiency.

Extensive training sessions were conducted to equip farmers with the knowledge and skills needed for optimal equipment utilisation, planting techniques, and maintenance practices. We have demonstrated that the SMART model is the solution that farmers require in the current landscape.

Witnessing the exceptional success and transformative impact of this program, we are thrilled to announce our plans to extend this initiative beyond borders. Our goal is to extend this program to other regions of the continent, empowering farmers across the area to unlock their full potential and make substantial contributions to the agricultural industry. This program heralds a new era of agricultural financing, promising a brighter future for farmers across Africa and fostering a more prosperous and food-secure continent. Join us on this exhilarating journey as we revolutionise farming practices and empower agricultural communities across Africa!

The perfect choice for farmers seeking a modern, versatile tractor that can handle any task. With its robust 75 HP engine and advanced features, the TAFE 7515 4WD Tractor is the

Litter in poultry management refers to the bedding put on the floor to give comfort to the birds and enable absorption of the manure.

There are a number of options when choosing the litter material to use. The options include white pine shavings, coarse pine sawdust, hardwood shavings, pine or hardwood chips, rice hulls, peanut hulls, sand, crushed corn cobs, and chopped straw or hay.

Why good litter is important

In broiler production litter material serves a number of important functions. Thus, it cannot be overemphasised how important it is for the farmer to understand that the condition of the litter in the poultry house could make or break a poultry enterprise.

Some functions of litter include:

• it absorbs excess moisture from the droppings and drinkers, and promotes drying by increasing the surface area of the house floor;

• it dilutes fecal material, thus reducing contact between birds and manure;

• it insulates chicks from the cooling effects of the ground, and provides a protective cushion between the birds and the floor. An effective litter material must be absorbent, lightweight, inexpensive and non-toxic. Ideal materials will have high moisture absorption and release qualities to minimise litter caking. In

addition, litter material must be com patible as a fertiliser or soil amendment after it has served its purpose in the broiler house. Most importantly, litter must not be consumed by birds. The effectiveness of litter will widely depend on the material used and how this material is managed.

Effects of poor litter on your birds

When litter begins to retain moisture, it tends to clump together and become caked. Caked litter will bring about cases of hock and footpad burns, and breast blisters hence reducing the carcass quality of the birds.

An increase in moisture content together with a rise in house temperatures leads to increased fermentation processes in the litter. Fermentation of wet litter contributes to an increase in ammonia emission from the bedding material. Ammonia content is higher in in wet litter.

Ammonia levels, if left too high, reduce the performance of broilers by reducing feed intake, cause irritation to mucus membranes, kerato-conjunctivitis (inflammation of the eyes involving the cornea and the conjunctiva), and air sac lesions. Poultry are most susceptible to elevated ammonia levels at one to twenty-one days of age, which is the early brooding period.

Wet litter may also cause an increase in pathogen loads and consequently, chances of a disease outbreak that may devastate the flock.

Tiger Animal Feeds Technical Team encourages customers to have good litter management practices which ensure a conducive environment for the birds to reach their potential growth. A proper balance between temperature and ventilation will allow litter to remain dry and free of disease and harmful emissions. Poor health and poor growth rate are direct consequences of poorly managed litter.

Moisture can build up because the ventilation rate within the house is inadequate over a prolonged period. To prevent caking, ammonia buildup and all other issues brought about by wet litter, remove excess moisture within the litter by providing adequate ventilation.

Litter quality and performance

Keeping litter dry is a critical part of overall management on every poultry farm. Litter conditions influence bird performance, which in turn affects profits of growers and integrators. Dry litter helps control ammonia levels and provides a healthy flock environment. Good litter and air quality can be maintained with proper ventilation, but it has to start when the previous flock goes out and continue throughout the stay of new flock. The trick is to stay one step ahead while being as efficient as possible.

Maintain good ventilation to promote good performance, health and welfare in your broilers.

In conclusion, it is important to note that, in order to ensure healthy and profitable broilers, on top of acquiring a good bedding material, the farmer should also make sure to manage the litter quality. Always keep litter dry and loose in order to prevent ammonia and pathogen buildup and the negative consequences associated with this buildup throughout the flock.

Old rubber vehicle tyres are super useful for controlling soil erosion in natural rangelands.

Nobody likes the look of old vehicle tyres on a landfill or dumped somewhere in a backyard, but Ken Coetzee of Conservation Management Services in George in the Southern Cape makes use of old tyres to successfully contain soil erosion.

Old tyres are cheap to obtain (if not totally free), are basically indestructible, sturdy, and easy to work with. They are especially useful where natural materials such as brush and stones are not plentiful enough to build a barrier against soil erosion. The rubber takes ages to degrade and will not contaminate the environment, so the risk of chemical contamination is very low.

Unfortunately, old tyres are not very pretty to look at, especially in a natural landscape. But that problem can be overcome by camouflaging them with jute geofabric or by simply filling them with gravel, stones, soil, and mulch and planting seeds or seedlings of native vegetation in them.

“The use of discarded rubber tyres for soil erosion control represents the innovative repurposing of a problematic waste material,” says Ken. They can be very useful as barriers in the effort to contain severe soil erosion

in wide gulleys where water flow is fast and destructive during a rainstorm.

“The secret to success in the use of tyres is that the construction must be consolidated and robust enough to prevent the tyres from being washed down the gulley during the first rainstorm after construction,” says Ken.

The tyres are stacked over iron fencing standards that ha d been driven deeply into the gully floor an d each tyre must be firmly tied to the iron standards.

Tyres are stacked in layers. As the tyres are stacked on top of one another each must be wired to the ones underneath it and to the standard.

Care must be taken to key the construction into the gulley sides at at least a tyre width.

Each t yre must be filled with gravel or stones from the gulley walls and floor before the next layer of tyres is added.

The top tyres in the mid-gulley part of the structure must be at least 200 mm lower than the sides of the gulley walls to ensure the water run-off takes place down the centre of the gulley.

Rubber tyres can also be useful in the control of water flow across sheeteroded areas.

Place the tyres flat in lines across the eroded area. Wire it securely into place to a line of iron standards driven into the ground. (See Figure 1).

The tyre barrier will slow the flow of the water and increase penetration. In addition, sand and organic material will be held in place behind the tyres, helping to improve soil conditions.

The barrier will also check windblown sand, plant debris and seeds.

To create protected sites for seed germination, each tyre can be filled with fine mulch. Loosen the soil in the tyres and plant seeds into them before applying mulch.

High quality feed is critical for your piglets growth and health

Tyres can be used to stabilise the head cut at the nick point of erosion gullies. The nick point can be widened so that a single tyre will fit into it. Secure the tyre to steel or wooden pegs driven into the earth. Fill the tyre with compacted gravel or earth. Plant pioneer vegetation into the tyres and cover with mulch. Use compacted mulch, fine brush, or gravel to fill the cracks between the outer tyre wall and the soil surface.

Tyres can also be used very effectively to combat severe soil erosion, as well as for the construction of large check dams in wide gullies, to stabilise head cuts in deeper gullies (see Figure 2), or to stabilise collapsing stream banks.

To check soil erosion in a deep gulley, create a stepped barrier consisting of layers of tyres filled with soil or gravel. The lower level of tyres can be filled with stones if there are any available, otherwise all tyres can be filled with soil and gravel that is well compacted.

Establish native wetland plants in the tyres, which will further anchor the tyres with their roots once they start growing.

Gravel and soil must also be firmly compacted in place behind each layer of tyres, from the bottom to the top, starting with the widest layer at the bottom and working up to a single tyre layer at the top.

The use of tyres to stabilise a riverbank depends on the manner in which the tyres are secured to stay in position.

Firmly secure the tyres to anchor poles (either wooden stakes or iron standards) that are deeply driven into the sides and floor of the gulley. Wire the tyres to the stakes and the tyres below them and next to them (horizontally and vertically).

This will ensure that the barrier is a rigid and tightly united structure that will not easily be damaged or lost to flooding water (see Figure 3).

When used in gulley erosion control, the tyre structures must provide a

notch for overflow in the middle of the structure.

Lining the tyre structure with geotextile will hold back waterborne silt, organic material, and seeds, which will step up establishment of vegetation that will hold the soil together behind the structure.

FIGURE 3: Details for the construction of the scrap-tyre retaining structure. The original vertical slope is altered to less than 45 degrees. The first layer of tyres is buried in the streambed and all the tyres are filled with soil and gravel and then planted with a variety of robust local wetland plants.

Tyres are also widely used for permaculture gardening, as they hold composted and mulched soil in place, keep the moisture in the soil, and provide some protection from the elements, such as wind and water erosion.

Using discarded tyres to rehabilitate soil erosion is a much better option than burning the vast resource of used tyres which will only contribute to air pollution.

“The effective use of used tyres for soil erosion control is thus a largely unexplored option that has tremendous potential in the rehabilitation of degraded landscapes,” concludes Ken.

For more information contact Ken Coetzee on (+27)76-227-5056 or send an e-mail to consken@ mweb.co.za.

Agriculture innovation and science in Africa are seen as the final frontiers if the continent is to be able to feed itself at a time of the worsening impact of climate change.

This emerged from a recent meeting of African finance ministers held in Victoria Falls, Zimbabwe under the auspices of the United Nations Economic Commission for Africa (UNECA) which noted that the continent needs to upscale its green financing mechanisms. African countries have struggled to attract green financing amid slow inflows of climate finance promised by richer countries.

Experts say this, in turn, has exposed poor African countries to a cycle of missed food production targets, with analysts noting that governments must look for innovative ways to at-

tract investment into sectors such as smart agriculture and drought resilient crop varieties.

This is despite years of numerous conferences to address these challenges, with Veronica Jakarasi, the Chief Director in Zimbabwe's Climate and Meteorological Services, noting that: “To attract green financing, Africa needs to have policy and regulatory frameworks with set targets in line with ambitious development.”

This highlighted the continent's ongoing difficulty to address what has become one of the most pressing issues of the global food production ecosystem with African countries routinely being fed by richer countries, the major drivers of climate change.

Countries such as Zimbabwe have continued to import food despite

The Ministry of Agriculture announced in March this year that government had given a green light on the importation of genetically modified maize.

African countries import food commodities such as wheat, maize, rice, and soya beans valued at USD4 billion annually.

years of evidence that the country needs to upscale its agricultural science and research to address what has become cyclical food deficits.

According to AGRA, African countries import food commodities such as maize, rice, soya beans and wheat valued at USD4 billion annually.

Experts say this is unacceptable when the continent has the potential to feed itself, if only governments could escalate science and innovation in addressing the effects of climate change on food production.

Over the years, countries such as Zimbabwe have continued to lag in both accounts-science and innovation-because of what critics say are policy inconsistencies.

For years government has failed to adequately fund the agriculture ministry, with national budget allocation favouring the security sector.

However, while advocates have noted that GMO research could help address some of these challenges, Zimbabwe has been inconsistent in the growing and importation of genetically modified maize, the country's staple food.

Faced with a debilitating drought, the Ministry of Agriculture announced in March this year that government had given a green light on the importation of genetically modified maize.

Local commercial farmers are on record appealing to government to allow them to grow drought-resilient genetically modified maize, but authorities have remained steadfast in refusing to grant that request. “In the Food Security Outlook April 2024 to March 2025 this is what we deliberated

on, and we said that (the) private sector must continue to import and they will continue to import maize for human consumption … and we also said that if they wished to import genetically modified maize, they can do so," Agriculture Minister Anxious Masuka told state media. The government has previously made the same policy changes after being faced with drought, importing yellow maize from Kenya.

Despite such challenges, there remains no firm policy on where the government stands regarding the science of GMOs. While GMOs remain contested in some African countries, African finance ministers agree that green climate financing will help explore ways to address the continent's food resilience conundrum.

“Green climate finance is key for sustainable development by continental and regional organisations in their quest to capacitate and facilitate low-carbon and climate-resilient development in Africa,” said Linus Mofor, Senior Environmental Expert from the Economic Commission for Africa (ECA), in a UNECA media brief. “Green transition requires financing for sustainable investment and access to real- time climate-related data. We need to have national and regional programmes aimed at galvanising green finance for enhanced economic development and regional collaboration,” Linus said.

UNECA estimates that African countries require USD3 trillion towards the implementation of its climate financing obligation which is expected to anchor the continent's food production drive. The agency says: "The public international financial flows are nowhere near sufficient to address adaptation, loss and damage, or to support the low-carbon development needs of developing countries."

With some countries lagging in innovation to attract climate finance, research into food resilience has also suffered. The failure to invest in science research, as well as policy inconsistencies, have left millions hungry.

“(African) countries should now focus on addressing issues of sustainability and finance to move forward and mitigate climate change effects,” Linus added.

Local commercial farmers are on record appealing to government to allow them to grow drought-resilient genetically modified maize, but authorities have remained steadfast in refusing to grant that request.

Hydroponics is becoming a major role player in farming these days, because you can grow fresh and healthy plants year-round with the right nutrients, lighting, and equipment.

Hydroponics is a method whereby you grow plants without soil. The plants are rooted in a nutrient-rich solution and supported by an inert substance like gravel, sponge, coco coir or anything similar. The nutrient rich solution provides the nutrients the plant needs to grow.

This allows the grower to control the nutrients according to the plant, which can result in faster growth and higher yields. These systems also use less water than traditional planting methods and can be placed virtually anywhere.

Once you have decided to use hydroponics as a planting method there are a few things to consider. The first being what type of hydroponics you want to use.

Hydroponic systems can be divided into two categories, a passive hydroponic system, and an active hydroponic system.

Passive hydroponic systems rely on gravity or evaporation to circulate the nutrient solution. In this type of system, the roots are suspended in the solution which is circulated using gravity.

The wick system is one such an example. The plants roots are suspended in a container with substrate, a reservoir of nutrient solution is placed beneath the container. A wick connects the reservoir to the growing medium

and transports the nutrients to the plant’s roots

This method requires no circulation system and the water and nutrients are only provided from beneath. The reservoir at the bottom needs to be filled up from time to time.

The Kratky syste m is another passive system and requires no pump or timer. In this method the plants roots are suspended directly into the nutrient solution and the container is covered with plastic wrap or a lid. Through this controlled evaporation the residual moisture feeds the plant.

• These systems are relatively simple and easy to set up

• They are less likely to fail

• They are cheaper than other, more complicated systems

• Because they rely on gravity and evaporation there are no pumps or other moving parts necessary

• They are not a s efficient as active systems

• They require more maintenance

Active hydroponic systems rely on pumps to circulate the nutr ient solution. In this system the root of the plant is suspended in a growing container and a pump circulates the nutrient solution through the root s.

The drip system is one such active hydroponic system. In a drip system the nutrient solution is pumped from the reservoir to the grow bed where it drips onto the plants’ roots. The excess solution then drains back into the reservoir.

Another well-known active system is the NFT (Nutrient Film Technique) system. With an NFT system t he nutrient solution is pump ed form the reservoir to the grow bed. It then flows through a channel that runs along the length of the bed. The plants’ roots are suspended in the channel and constantly exposed to the flowing nutrient solution.

• They are m ore efficient than a passive system

• They require less frequent maintenance

• With the use of a pump you have better control over the nutrient supply which allows you more precise timing of the nutrient delivery.

• These systems are more complex and difficult to set up

• They are more expensive to start up. They depend on electricity.

With all this in mind you now must choose the system that will work best for you. Some of the things to consider are:

Gardening takes patience and if you are a novice the learning curve may take some time. Hydroponic systems typically need more expertise than traditional gardening. You must understand all factors, such as the nutritional needs of your plants, the water needs, when it is time to switch containers or when the pH is too high or too low, among other things.

As your experience grows you can try more complicated systems like ebb and flow systems. But if you are new you can stick to wick systems or even drip irrigation.

How much time do you have?

A successful hydroponic system takes time and effort.

If you do not have enough time to focus on the maintenance and monitoring of your system, then the wick system or non-recovery drip irrigation system is the choice for you.

What do you want to grow?

Some plants grow better with certain methods of hydroponics, so you must consider what you want to grow. Matching the system with the type of plant you want to grow can save you time and money and keep you from having to change to a different system or modify your existing system in the future.

Set out your budget before purchasing your hydroponic system, do your research and decide what you need and what the budget would be. There are many different types of hydroponic systems.

How much space do you have?

The type of system you choose will also depend on the space you have available. Hydroponic systems come in all shapes and sizes. Because hydroponic systems typically take up less space than traditional planting methods you will find something that suits your space. Keep in mind that you need to be able to reach all the plants in your hydroponic system.

Different types of hydroponic systems include:

• NFT (Nutrient Film Technique)

• DWC (Deep Water Culture)

• Wick systems

• Ebb and flow/ Flood and drain system

• Drip hydroponics

• Aeroponics

• Kratky method

Wicking

The principle of a wicking bed is that the water is “wicked” from the bottom of a trough into the root zone of the plants, just like the wick in an oil lamp draws the oil up to the flame. In the case of the wicking bed the heat from the sun and the roots of the plants wick the water up into the root zone where the plants can use it.

The top of the soil may seem dry, but it is moist where the roots need moisture.

• Build a trough or use a container, it can be anything that can hold water; plastic, tarpaulin, fibreglass, even an old bath.

• Lay a pipe at the bottom, diagonally across the trough.

• At the bottom of the pipe drill holes in for the water to run out.

• The pipe must have a 90˚ bend (fitting) with an upright pipe connected to it at each end. The tops of the vertical pipes must stick out about 10 cm above the rim of the container.

• Fill the bottom of the trough up to 10 cm with gravel. Put shade cloth over the gravel and up the sides of the trough. (80% shadecloth works well – the water must be able to go through it)

• Make a hole in the side of the trough or container just above the shadecloth for overflow in case of overwatering or rain.

• Get your soil and compost mix ready and put it on top of the shadecloth. This planting area should be about 30 cm deep.

• Plant your seedlings in the compost mix and put water into the gravel through the ends of the pipe sticking up. The water will run out of the bottom of the pipe into the gravel. Only fill until you see the water running out of the overflow hole.

• Normally you only need to check this water level once a week.

• In this wick system the nutrients are supplied by the compost, which makes it an organic system – if you do not use strong chemical pesticides.

• After every harvest cycle you can top up the compost mix.

This link will take you to a short video on how to build a basic wicking bed.

•

•

•

•

•

•

•

•

Landini, historic tractor brand of the Argo Tractors group in Italy, is celebrating its 140th anniversary this year with the release of the recently developed REX4 Full Hybrid tractor. The REX4 is a hybrid tractor with a diesel engine combined with an electric motor.

The key innovations of the Electra–Evolving Hybrid system are its electric front wheel drive with independent wheels, electronically controlled cab suspension and semi-automatic transmission, which lend the Rex 4 even better handling, greater comfort, and ease of use.

The most significant new feature is the fully electric front wheel drive with suspended axle, sporting two independent electric motors and associated sensors, electronic controls, generator, and battery dedicated to energy recovery under braking and deceleration.

The entire system is controlled by the PMS (Power Management System), which supervises the operation of all devices, including the battery and controls motor and generator via their respective inverters.

With the Hybrid tractor Landini promises the following advantages:

• Enjoy a 10% fuel saving on your tractor.

• Benefit from 15% better steering angle for improved manoeuvrability and easier operations.

• Experience greater stability during transport thanks to full integration with the current electric steering system.

• Choose the ratio between the front and rear wheels to suit your needs.

• Enjoy the new electronically controlled cab suspension featuring a semi-active system similar to that already available on high-end open-field tractors. Suspended on

four points, the cab is equipped with two passive front suspension systems, while two anti-damping hydraulic shock absorbers governed by an electronic signal reduce vibration at the rear.

• Shifting gears is even easier thanks to the introduction of the semi-automatic transmission that features a joystick instead of a conventional mechanical lever (drive by wire). The joystick sends its inputs to the electronic control unit (ECU) that operates the actuators that move the transmission control. In addition to fully automated shifting, this solution offers the added benefit of lower noise and pollutant emissions.

It was 1884 when Giovanni Landini founded Officine Landini, a wine-making machinery factory in Fabbrico, Italy where Argo Tractors’ headquarters are still based today. In 1910 the first fixed hot-bulb engine was produced, whereas it was in 1925 that the first tractor went into production: the Landini 25/30 HP.

This year also marks the 30th

anniversary of Landini’s acquisition by the Morra family, which, together with the subsequent addition of McCormick, would lead to the founding of Argo Tractors in 2007.

In 2021 Argo Tractors joined Motor Valley, an association that represents a strip of land in northern Italy that has become world-famous for mechatronic production and is home to famous automotive brands, among which Ferrari and Maserati.

“Passion and innovation are the key drivers that have guided us over the years,” commented Valerio Morra, President of Argo Tractors. “This makes us ambassadors of ‘Made in Italy,’ proudly represented abroad, where we have expanded our presence with the creation of new branches and consolidated our network. 140 years is a historic milestone that places us among the world’s oldest manufacturers, and is also a reason to move proudly on.”

Landini is participating in many major events this year displaying their new slogan: Feel the change.

Applying AI-technology in practical solutions may hold the key to the future success of agricultural companies. One such company clinching the deal is Ecorobotix, based in Switzerland, whose intelligent ARA sprayer has led to multi-million-dollar sales in a very short time.

In the Netherlands alone the company has to deliver 90 new machines this spring.

This machine offers a combination of speed and accuracy which results in savings on time and chemicals. The company

promises on its website: “With respect to conventional spraying methods, ARA enables you to reduce the use of crop protection products by up to 95%!”

The 6-metre wide sprayer can be towed by a standard medium size tractor and has its own control screen mounted in the cabin. It can be used in most of the main crops such as vegetables, other row crops and even pastures.

Cameras monitor the crops at a working speed of 7 km/h and algorithms are applied through artificial intelligence to detect wanted and unwanted plants. Each of the 156 nozzles is equipped with a solenoid valve that can open and close in a fraction of a second to spray directly onto the target with a precision of 6 x 6 cm.

ARA can treat four hectares an hour, and it can work day and night.

All data is recorded and analysed in real time, and will allow the farmer to study the development of his fields by comparing the data collected with previous results.

“With our system, there is a spectacular decrease in the usage of plant protection product, since ARA only sprays what needs to be sprayed – and nothing else,” says Loïc, Wüthrich, Technical Sales Engineer at Ecorobotix.

The company is refining the algorithms for maize, but initial results are impressive:

• Decrease in plant protection product usage: 70 to 80%

• Detection rate: 95%

• Treatment rate: 95%

Follow this link to watch a video describing the ARA: https://www.youtube.com/ watch?v=TkyL0j1PyZU&t=152s

The innovative technology will not only be available to vegetable farmers like many other similar developments. Grain farmers can also take note.

Homemade straw chopper/ spreader from down-under

If standard machinery does not do what you want it to do, then you make your own plan. That is exactly what the Wandel family from MR & HL Wandel Farms in Australia did.

They have found that the chopped straw was not distributed widely and evenly enough behind their combine harvester, especially when working at high speed. To improve this, the farm built an impressive 18-m trailed chopper/spreader.

Located at Scaddan in Western Australia, Neil and Mary Wandel and sons Scott and Mark, grow cereals and beans on more than 10 000 ha. The farm has operated a strict Controlled Traffic Farming policy since 2004 with all vehicles on a 3 m track width and 18 m tramlines.

However, in less-than-ideal conditions they found that there was too much chopped straw directly behind the combine and less on the outer metres. In the end, the family decided to chop

and spread straw in a separate operation and Mark set to work to design and make the dedicated trailed machine.

The robust chopper-spreader is towed behind a John Deere 8R 340. The twin-axle 18-m unit uses a pickup to collect swathed straw. Elevated to the shredder, it is transported via conveyor belts to six rotating straw spreaders.

The massive straw chopper/spreader was built on a family farm in Australia. Everything on this farm has to adhere to their strict Controlled Traffic Farming (CTF) policy.

Controlling weeds and pests in banana production is essential to ensure healthy growth and maximise yields.

Here are some methods for weed and pest control:

1. Manual weeding: Hand-pulling weeds is effective but labourintensive.

2. Mulching: Applying organic mulch helps suppress weed growth.

3. Herbicides: Selective herbicides can be used to control specific weed species without harming the banana plants.

1. Biological control: Introduce natural predators or parasites to control pest populations.

2. Insecticides: Use insecticides that are specific to the pests affecting banana plants.

3. Cultural practices: Crop rotation and maintaining field hygiene can reduce pest infestations

Integrated Pest Management (IPM) is a holistic approach that combines various control methods to manage weeds and pests effectively while minimizing environmental impact. Regular moni-

toring of the field is crucial to identify and address issues promptly.

Control weeds by using:

(A) chemical method or (B) hand method or (C) both methods

A. Chemical sprays are used to kill the weeds and this is called herbicides. Use only recommended chemicals and apply these strictly according to the instructions on the label. Examples of chemical sprays is like roundup.

Do not spray:

- Too much

- The banana plants

- When it is windy

When using chemical control, such as glyphosphate or paraquat, protect all parts of the banana plant from spray drift.

B. Weeds are also killed by using a hoe or by hand, especially in the area near the plant to avoid chemical spray contact with the plants. This method is easy for any farmer.

C. Both methods can be used at the same time to kill weeds.

Remember to give your banana plants support by propping the bunches with a rope and sticks.

Control pests and diseases. Different pests and diseases require different treatments.

Thrips

Use chlorpyrifos pesticide once a month to kill thrips if they are present. Thrips are tiny, almost microscopic, insects with thin, feathery wings and rasping mouthparts. Most thrips feed on plants but a few species are beneficial predators that feed on other insects and mites.

Nematode worms are among the most ubiquitous organisms on earth. They include free-living forms as well as parasites of plants, insects, humans and other animals. Recently, there has been an explosion of interest in nematode biology, including the area of nematode ultrastructure.

If they are present, kill them with Nemacur using 45 kg per hectare (20 g per plant). Compost, kraal manure

and chicken manure applied in ample quantities will also suppress nematodes. Tissue culture plants are free of nematodes.

Sigatoka

Spray with Dithane plus mineral oil

Post-harvest decay relates to decay developing after the fruit have been harvested or during the handling and storage phase. Although decay development occurs after harvest, the process may manifest prior to harvest, while only emerging during storage.

Spray with Dithane plus mineral oil. Dip the banana hands into Benlate solution (5 g Benlate per 10 water) to prevent post-harvest decay.

This article is published with acknowledgement to the ARCInstitute for the use of their manuals. For more information on banana production, visit the ARC’s website at www.arc. agric.za.

An optimized drive concept of the latest generation enables precise, fast, and efficient work. The electronically controlled hydraulic pump permanently adapts the required hydraulic power to the available power of the diesel engine.

“One of the biggest challenges for us in Botswana is the availability of spare parts for our farming equipment, and that is the reason why you have to choose your equipment and brand wisely in order to farm profitably,” he explains.

Fresh

Frederick says: “I visited several farmers before I made an informed decision regarding the irrigation system that I wanted to use on our farm, and Senter 360 stood out above most of all the pivots that I saw. In 2015 we installed our first Senter 360 pivot.”

Altogether they have 200 ha under irrigation, 174 ha irrigated with centre pivots. They have ten Senter 360 pivots in total; nine 16 ha pivots and they recently installed a 30 ha pivot as well. “We plan to acquire two more 30 ha Senter 360 pivots in the near future,” he elaborates.

The main goal for irrigation is to provide plants with the proper quantity of water at the best time. “Our Senter 360 centre pivots enable us to water our crops during the times when it is needed most. They also enable us to supply our vegetables at the right time and right season to our end users,” Frederick explains.

“The one thing that stands out the most to me about Senter 360’s centre pivots is the way they are manufactured and built. They are built to last in Africa conditions. The pivots are sturdy, robust and wind resistant.

“A Senter 360 has a balanced pipe structure and in my opinion the pivots

One of the most important investments a farmer will ever make is a centre pivot irrigation system. Despite the initial outlay, the cost-benefit ratio is extremely favourable in the long term, particularly in areas like Botswana where natural precipitation can be irregular or scarce.

The truth of this statement is aptly proven by a dedicated mother and her son’s farming operation in Botswana.

Born, bred and raised in an agricultural family, Cynthia van der Merwe and her son Frederick farm together in

Botswana outside a small village called Machaneng, close to the South African border. Their farming venture is known as Request Tuli Fresh.

Frederick explains: “We acquired the land in 2012, and a lot of work had to be done to get the farm where it is today. We had to de-bush the whole farm to enable us to grow vegetables. We mainly produce potatoes and butternuts for some of the big supermarkets and smaller shops in Botswana.”

He adds: “Farming is not for the faint-hearted and without perseverance you will never get anywhere. Despite all the challenges, there is nothing I would rather do than farming.

carry their weight much better than other competitors. The quality of their galvanising is also a plus point to me,” he states.

“On the very first pivot that we installed in 2015, nothing has ever been replaced since then; the pivot is still exactly the way it was, and it has many hours on the clock. The maintenance on the pivots is minimal.

Another important benefit is the fact that Senter 360 pivots have their own unique patented, specialised pivot tyres. We do not struggle with flat or perished tyres over time,” Frederick says.

He adds: “The return on investment with the pivots on the farm is absolutely worth it.”

As vital as the mechanised system itself is the need for the right sprinklers for your centre pivot.

“The Senter 360 pivots that I have, are equipped with Komet twister sprinklers, which makes a huge difference in terms of the consistency of droplet size and reduced soil compaction which ensures maximum uniformity of water application,” Frederick explains.

He adds: “The design of the Komet sprinklers is not only beneficial for irrigation purposes, but also for the application of fertiliser, where the fertiliser is applied consistently on all the crops.”

Ideally, therefore, a centre pivot sprinkler should emit droplets that are large enough to withstand wind drift, misting and evaporation, but small enough to avoid surface sealing, compaction and erosion on tighter soils. This is exactly what Komet sprinklers achieve.

Frederick highlights: “Senter 360 pivots come standard with variable rate irrigation for different sectors and precipitation adjustment, which means that you can manage and monitor your water rate and application from your control panel. It also enables you to calculate how long it will take for the pivot to irrigate a 180- or 360-degree circle.”

“It is easy to use, and it is a feature of the pivot that I really like!” he adds.

“Senter 360 is not only cost-effective with parts readily available, but whenever I pick up the phone to contact them regarding any problems or questions, they are always available to help and assist, and you immediately get your answers from them.

“I will definitely recommend Senter 360’s pivots to other African farmers. Not only is their service exceptional, but their pivots are also built to last, especially here in African conditions. We can farm and irrigate our crops with ease of mind, knowing that our pivots won’t let us down,” he concludes.

E verything needs water. You do not need to be a farmer to know this. Small-scale to mega farmers, emerging farmers to seasoned growers, everyone understands that crops need water to grow, and livestock need water to drink. But the threatening reality of climate change is bringing water concerns with it.

In Africa, there are already a multitude of challenges regarding water security. Drought seems to be ever present and since climate change is no longer looming, but a part of our everyday lives, a shift needs to be made away from simply irrigating crops, towards actively managing water sources.

What are the other factors that impact water scarcity in Africa and why is climate change so dangerous? Well, that is not an easy answer. Often, climate change is only seen as rising global temperatures, and not the erratic weather patterns the world is actually experiencing. These weather extremes can cause floods but also prolonged droughts in areas that are accustomed to decent rainfall replenishing natural supplies like rivers and lakes. Extreme heat causes water to evaporate from these systems.

Another factor playing into water scarcity is the imbalance between supply and demand.

Africa’s annual population growth is approximately 2,4%, which sounds small on paper, but for a population of over 1,4 billion, it means roughly thirty million new people each year with no sign of slowing down. Additionally, collapsing infrastructure or the lack of infrastructure means that not enough water is stored safely. There is simply not enough water to go around.

Other factors such as pollution and contamination exacerbate the situation. Africa’s water bodies are filled with pollution to varying degrees and agricultural run-off from fields is contributing to the problem.

Is groundwater the solution?

Other forms of water sources are available on the continent. Wells and boreholes are dug to supply communities and farmers alike for household and irrigation purposes.

This appears to be the most reliable alternative when rivers dry up because the continent has approximately a hundred times more water available underground than in surface water. Aquifers store nearly 660 trillion m3 of water.

With less than 1% of groundwater used for agriculture, and less than 5% of Africa’s agricultural land under irrigation, the solution seems simple: Improve irrigation and use groundwater. But this poses its own challenges. The groundwater available in Africa’s aquifers can be difficult to extract due to complex subterranean structures.

The reality is that farmers in Africa need to shift their focus from irrigation to water management.

How can farmers improve their water management?

It may be important to note that a lot of the changes needed to make a difference in the water scarcity that exists within

the various countries of the continent, can only happen if governments step in to work towards real change. But farmers cannot wait around for the day that governments step up; they need to grow food for their communities and make a living for their families.

So, what can be done in the meantime to ensure farming families survive? There are a few steps they can take to understand and improve their water management.

Step 1: Understand water management

Water management in agriculture is

With

(Source: Pixabay)

Farmers

the efficient use of water to irrigate crops at crucial growth stages and provide animals with water for survival. For irrigation it is necessary to look at soil health which impacts water retention, as well as irrigating crops at the right time.

You can conserve water by irrigating crops early in the morning and late in the afternoon to nighttime. This ensures that most of the water you use is absorbed by

A sprinkler system is just one of the ways to effectively irrigate your crops.

plant roots and there is less evaporation. Use an irrigation method that is most water efficient. Techniques such as flood irrigation uses a lot of water. Instead, turn to options that reduce wastage like drip irrigation, microsprinklers, and precision irrigation. With the latest technology, some systems also can be switched on or off remotely, or give you insight into how much water you are using.

Step 2: Improve water retention

By improving the soil’s water retention means that you can work more efficiently with your water. When the soil is healthy with loads of organic matter in it, it can hold water much better. Techniques that improve soil’s water

holding characteristics are conservation tillage, mixing compost into the soil, and adding a layer of mulch on top of the soil.

Step 3: Choose the right crop

Drought-tolerant crop varieties can improve water efficiency on your farm. They can withstand strain from less water better than other varieties. By practicing crop rotation with these crops, farmers can improve their resilience to water scarcity.

Step 4: Protect your water source

Whether you obtain water from a borehole, well, river or even harvest rainwater, you need to protect the source. Work together with all who share the source to ensure the well or river remains free of pollutants and garbage. Take care not to over-use the source either.

There are technological tools that can assist you in monitoring your water levels and ensuring you always know how much water is available. Gallagher Animal Management has a product that helps you stay on top of your water levels. Their water monitoring system is a wireless system that monitors water levels throughout the day.

Bensen, D. (2023) What is causing water scarcity in Africa? Healing waters, Healing Waters International. Available at: https://healingwaters. org/what-is-causing-water-scarcityin-africa/.

Mahed, G. (2024) Africa’s aquifers hold more than 20 times the water stored in the continent’s lakes, but they aren’t the answer to water scarcity, The Conversation. Available at: https://theconversation. com/africas-aquifers-hold-morethan-20-times-the-water-storedin-the-continents-lakes-but-theyarent-the-answer-to-water-scarcity-201704#:~:text=The%20volume%20of%20groundwater%20 that’s,freshwater%20stored%20 in%20Africa’s%20lakes.

Steyn, M. (2022) Klimaatsver-andering: Boere regoor Afrika ly, ProAgri. Available at: https://proagri.co.za/ klimaatsverandering-boere-regoorafrika-ly/.

Villholth, KG. and Altchenko, Y. (2015) Mapping irrigation potential from renewable groundwater in Africa – a quantitative hydrological approach, Copernicus Publications. Available at: https://hess.copernicus. org/articles/19/1055/2015/hess-191055-2015.pdf.

To find out more about a system that could work for you, you can visit the Holland Greentech website (www.hollandgreentech.com)

Find out more on Gallaghers website at https://gallaghersa.co.za/pages/ water-monitoring-system

How can Biocult® Seed Application help your crop perform with 30% less water?

• Mycorrhizae in Biocult® act as a secondary root system by enlarging the roots’ absorption surface area.

• Biocult® stimulates root development which increases the capabilities to absorb larger quantities of water.

• Mycorrhizae in Biocult® reach into micropores where plant roots can’t access water.

• Mycorrhizae improve soil structure for better water infiltration and water retention.

• Mycorrhizae assist the plant in developing osmolytes which protect cells during time of stress.

KimtraPro 20

A ready-mixed phosphate-salt-trace mineral and protein supplement for ruminants.

• The phosphate source of KimtraPro 20 is Yara Animal Nutrition’s Kynofos 21, a high-quality MDCP.

• Enriched with the most important trace minerals.

• Contains protein to stimulate growth and production of rumen microbes for optimal digestion of grass.

• Contains highly bioavailable magnesium in the form of Magnesium Phosphate.

• Contains molasses by-product to promote palatability and intake.

• Convenient granulated form to minimise dustiness.

• Suitable for cattle, sheep, goats, and ruminant game species.

• Available in 50 kg and 25 kg bags.

Trust KimtraPro 20 for optimal health, production and reproduction.

www.yara.co.za/animal-nutrition/ animal.nutrition.sa@yara.com | Tel: +27 (0)31 910-5100

Yara Animal Nutrition South Africa (Pty) Ltd. Reg. No. 2001/025850/07

KimtraPro 20 - Reg. No. V32853. (All products are registered under Act 36 of 1947.)

Unlock the power of the sun for your irrigation needs with Future Pump. Delivering a maximum flow of 1 LITRE PER SECOND, equivalent to an impressive 3600 LITRES PER HOUR, Future Pump ensures efficient water distribution for your crops. Versatile for flood and drip irrigation methods.

Zimbabwe's agriculture sector workers' demands for a living wage remain elusive amid an escalating cost of living.

As the country makes efforts to grow the sector into a multi-billiondollar industry, farm workers could well find themselves left behind regarding remuneration.

Over the past two decades, the country's economy has tanked, with economists blaming, among other things, the violent farm takeovers for interrupting agriculture production.

Since independence in 1980, Zimbabwe's GDP has been driven by agriculture, and disruptions in the sector have shrunk what was once one of the region's economic hopes.

Salaries have also shrunk, with unskilled workers such as farm hands feeling the pinch.

At the height of the country's agriculture production, hordes of families worked on thriving commercial farms.

After the controversial land reform programme, however, the regular complaints that emerged were that the new farm owners had stiff arms, not too eager to pay workers a living wage.

Now, as the country struggles with inflation, faltering agriculture production, and a host of economic challenges, farm workers have not been spared.

Last February, the National Employment Council for the Agricultural Industry in Zimbabwe announced new wages for agriculture workers, citing the need to keep up with inflation.

Measured against the local currency, the highest paid farm worker would earn USD212, while the lowest would get USD107.

The last increase the National Employment Council for the Agricultural Industry in Zimbabwe had accepted had been in 2020 where farm worker salary was pegged at between ZWD550 and ZWD1 100.

That year, the government pegged

the local dollar at USD1:ZWD25.

This effectively meant the lowest paid farm worker earned USD22 per month, while the highest went home with USD44.

Yet as the Zimbabwean currency continues its free fall against the greenback, this has meant farm workers’ salaries have also been affected.

The sector is one of many in the country where labour unions exist in name only.

Regarding farm worker salaries, the irony is that civil servants earn around USD200, meaning that according to the government and using the official exchange rate, the highest paid farm worker earns more than a teacher and other low level civil servants.

However, that still remains in theory as farm owners are not ready or willing to pay their workers that much.

Thirty-six year-old Simba Chambati knows this only too well.

He has worked on a farm the past three years, got injured while on duty but says he never got compensation from his employer.

As the country struggles with inflation, faltering agriculture production, and a host of economic challenges, farm workers are feeling the impact.

"I have seen first-hand the suffering farm workers go through. The money is just too little and we also do not get paid in time," Simba said.

Because farm workers live within their workplaces, employers view such arrangements as reason not to fully honour official salary requirements such as housing allowances.

Simba’s farm is a mix of cattle ranching and crop production, and he says his duties overlap between the two.

"When I first started, I was told I would look after the crops of maize, cabbages, tomatoes and more. But in the past three years, crop production has suffered and I find myself looking after the cows, and for the same salary I was getting three years ago," he said.

It is a familiar story.

Farm occupational hazards are a regular occurrence in Zimbabwe, but health insurance for farm workers is virtually unheard of, Simba says.

"There are no jobs in the country, and if you have one you make sure to keep it. You cannot demand your dues or else you are told to find work elsewhere," he added.

The Food and Agriculture Organisation notes that “although smallholder farmers play a critical role in food and nutrition security in Zimbabwe, with their production accounting for the bulk of the country’s food, they themselves often struggle with poverty”.

By some estimates there were around more than three hundred thousand farm workers at peak, but that figure is disputed against low agriculture production over the years as workers quit to look for opportunities elsewhere.

In 2009, the General Agricultural and Plantation Workers Union of Zimbabwe reported that up to sixty percent of farm workers said they were the most abused as a direct result of farm takeovers.

By Simba’s own account, not much has changed. If anything, the troubled economy has made things worse.

to maximise its agriculture pro duction, agencies are calling for more research to assist farmers to adopt sustainable practices.

In a recent update, the Food and Agriculture Organisation (FAO) said sustainable farming practices will help promote agricultural biodiversity.

In a press briefing, FAO said research conducted across the country looked at the emergence of new plant pests, poor agronomic practices, toxification of pollinators and the death of livestock due to what the agency says are highly hazardous pesticides.

It is common practice among farmers in Zimbabwe to use pesticides in crops in areas where livestock is also kept resulting in the loss of valuable cattle and other animals.

Pesticides have been used near open water sources, further exposing hu mans to harm.

FAO says these practices severely limit efforts by farmers to reach agricultural production targets for the country to achieve sustainable development goals.

Zimbabwe has routinely struggled to meet its grain production targets despite pouring millions of dollars into the sector.

The authorities have been criticised for not understanding smallholder needs and challenges, resulting in the implementation of policies without proper research.

The research commissioned by the Food and Agriculture Organisation between 2021 and 2023 sought

Zimbabwe has in recent years received fertilisers, machinery, grain and other agro-products from countries such as Russia and Belarus.

to "generate empirical evidence for creating and implementing agricultural policies and practices that integrate ecosystem-based agriculture and sound management of pesticides".

It is part of a broader project on capacity building covering African, Caribbean and Pacific Countries (ACP-MEAs 3) "that seeks to promote agricultural practices and activities that enhance the sustainability and resilience of agrobiodiversity and its associated agroecosystems", FAO says.

The research targeted smallholder farmers, the impact of pesticides on livestock, and the barriers for the adoption of bio pesticides, bio fertilisers and other bio agents vital for environmental sustainability.

However, the FAO research also noted that to implement the outcomes, Zimbabwe's agriculture colleges must model their curricula to cover sustainable agriculture, and that includes drafting courses that will include climatesmart, agroecological, and organic farming practices.

Zimbabwe has scores of agricultural tertiary institutions which however have struggled to move the needle in the country’s agriculture production ambitions.

“Zimbabwe, like many other countries, has committed itself to various multilateral environmental agreements. To fulfil these obligations, the country needs to revise the curricula and teaching methods of higher agricultural education institutions,” said Obert Maminimini, FAO National Project Coordinator.

“The aim is to incorporate contem

It is common practice among farmers in Zimbabwe to use pesticides in crops in areas where livestock is also kept, resulting in the loss of valuable cattle and other animals. (source: Pexels)

porary developments in sustainable agriculture, agroecology, climatesmart agriculture, and organic agriculture,” Obert said at the launch of the report last month.

In recent years, “smart agriculture” has become a buzzword in Zimbabwe's agriculture ministry, but there has been little to show improved self-sustainability as the country continues to struggle to feed itself.

While the country has invested in agriculture extension officers as foot soldiers in the agricultural revolution information drive, concerns remain that smallholders still hold on to old ways that are detrimental to their crops, livestock and the environment.

"The findings of these studies will be useful in mainstreaming biodiversity and sustainable ecosystem-based agriculture practices and policies in Zimbabwe," said Dumisani Kutywayo, Chief Director in the Department of Agricultural Research, Innovation and Development.

"These findings are aligned with and provide the necessary impetus to the National Biodiversity Strategy

and Action Plan

2015-2020 as well as the Agricultural Policy Framework, and the Zimbabwe Food Systems and Rural Transformation Pathways,” Dumisani said at the launch in the capital city Harare last month.

Zimbabwe has in recent years received fertilisers, machinery, grain and other agro-products from countries such as Russia and Belarus.

However, research has shown that despite such largesse, other areas of agricultural research have been neglected, resulting in a cycle of challenges that remain unresolved.

In recent years, “smart agriculture” has become a buzzword in Zimbabwe's agriculture ministry, but there has been little to show improved selfsustainability as the country continues to struggle to feed itself.

Zimbabwe has scores of agricultural tertiary institutions which however have struggled to move the needle in the country’s agriculture production ambitions.

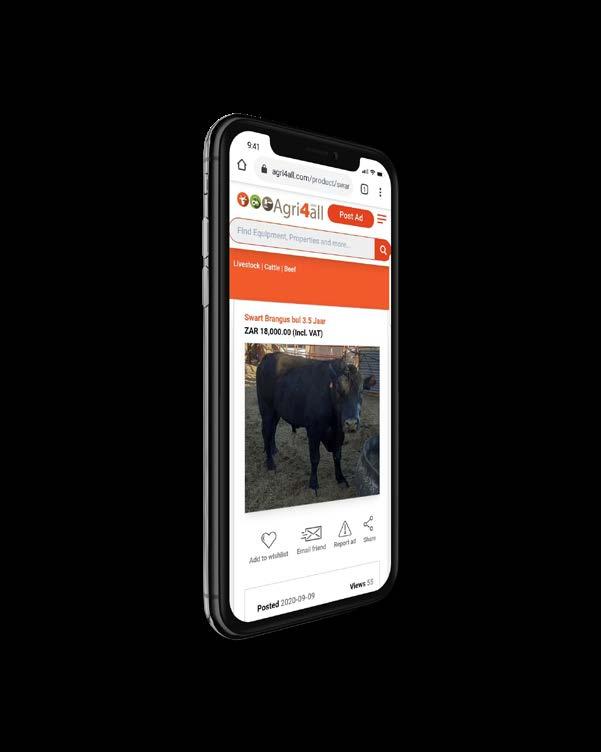

Equipment, implements, livestock, property, transport, services and much more.

Join the largest online trading platform for the agricultural industry in Africa, without paying a cent!

Search and advertise any agricultural product in 27 countries: South Africa, Zambia, Nambia, Botswana, Zimbabwe, Lesotho, Kenya, Malawi, Mozambique, Tanzania, Angola, Algeria, Cameroon, Congo, Egypt, Ethiopia, Guinea, Ghana, Liberia, Libya, Morocco, Nigeria, Rwanda, Senegal, Sudan, Tunisia and Uganda.

Diane Grobler: +27 (0)82 555 6866 | diane@proagri.co.za

ROTOTANK Material Approved By the Food and Drug Administration for Drinking Water

Hereby confirms that all base polymers are sourced from Sasol Polymers. These grades all conform to Food and Drug Administration (FDA section 177.1520-31a).

All ROTOTANK rotational moulding grades conform to FDA regulations and International potable water and food contact regulations. We confirm that no recycled polymers are used in the production of these grades.

Available in various colours.