www.agri4all.com www.proagri.co.za Free ProAgri Zambia No 83 technology for the farmer Engineering ingenuity with Carl Hamm and STÜWA Raise chicks the Novatek way Syngenta announces relocation of offices

Durable. Certified. In stock.

The full range of top-quality PVC-U and PVC-M pipe.

We understand what you are looking for in a pipe. With over 30 years of experience, our engineering team has the knowledge to supply the correct type of pipe, in the diameter and pressure class you need.

We carry extensive stock, ready for delivery. We stock the full range of PVC-U and PVC-M pipe in all standard diameters (from 20 mm up to 630 mm) and pressure classes (fromclass 4 up to class 20).

And, we also understand that the optimal solution has to be a cost-effective one. That is why we offer reliable yet affordable pipe and fittings in industry standard colour, giving you the perfect connection, every time.

IsoFlo, our PVC-U range. Economical, durable, corrosion free and easy to install. SANS 966-1 approved.

IsoTuff, our PVC-M range. Tough, shock resistant and cost-efficient. SANS 966-2 approved.

IsoDrain, our sewage & drain pipe range. Lightweight and ideal for non-pressure applications. SANS 791 approved.

www.agrico.co.za | +27 21 950 4111 | info@agrico.co.za

Review of 2022 … and a look at the future

This time of the year, we often hear people say they can't believe it is December already, and they wonder where the time flew. Only yesterday 2022 was still a dream; now the year has almost reached its end. Which made me think again: What is time?

Time is the single biggest factor affecting everybody's life. Everything is measured by time.

Life is sometimes shorter than we expect, and I realise it is a gift, a very precious gift and a privilege, and we have the choice to embrace each day and live it with integrity, passion and love.

When I look back at the year and all we wrote about, there were a lot of highlights and special events. Most of the agricultural shows took place again after two years of anticipation. Farmers and other role players in agriculture could reunite, and strengthen the ties of friendship in the interest of agriculture.

At certain times of the year, we had to take out candles, lamps and generators as Eskom's load shedding left us in the dark.

Nevertheless, we have made it, and here we are at the end of yet another busy year.

During this time, we wish to acknowledge all the farmers – especially for their persistence in the responsibility to produce food sustainably.

To my ProAgri colleagues, I also thank you for your courage, passion and perseverance. Come what may, we make it work.

Let us not forget the lessons learnt this year when we relax during the big days; let us reflect on what we have learned, and how we can use this beneficially in the new year.

To all our farmers and the other role players in the industry, my sincere thanks to you for all your support this year. I wish you a blessed Christmas. Do not let opportunities pass, live with integrity, plan and work purposefully!

Our dreams and visions are the hope for a better future. May 2023 be the best year ever!

No. 10 Tito Road Rhodespark, Lusaka +26 (0)97-769-9786 www.proagri.co.za

Copyright © 2022. All rights reserved. No material, text or photographs may be reproduced, copied or in any other way transmitted without the written consent of the publisher. Opinions expressed are not necessarily those of the publisher or of the editor. We recognise all trademarks and logos as the sole property of their respective owners. ProAgri shall not be liable for any errors or for any actions in reliance thereon.

xander@proagri.co.za +27 71-599-9417

johan@proagri.co.za +27 82-698-3353 tiny@proagri.co.za +27 74-694-4422 lynette@proagri.co.za +27 72-419-3990 christiaan@proagri.co.za

+27 12-803-0782 engela@proagri.co.za +27 79-515-8708 nita@proagri.co.za +27 12-803-0782 accounts@proagri.co.za

Content 3 7 13 15 20 33 Cover Carl

on superior quality

equipment.

the

strength material that they use

their products, they design their products with safety, durability and longevity

Editor Bianca Henning > Reporters Benine Ackermann > Maryna Steyn > Natasha Kruger > Specialist Writer Annemarie Bremner > Senior Production Manager Zainab Pandor > Client Relations Manager Carin Swartz > Marketing Manager Diane Grobler > Marketing Xander Pieterse > Johan Swartz > Tiny Smith > Lynette van Tonder > Creative Director Christiaan Joubert > Design Michelle Kruger Enquiries Engela Botha > Distribution and subscription Nita Volmer-van Zyl > Accounts Ronel Schluter > Business Manager George Grobler

Hamm pride themselves

borehole

Apart from

high-

in

in mind.

+27 82-326-2572 bianca@proagri.co.za +27 73-105-6938 benine@proagri.co.za +27 82-261-9177 maryna@proagri.co.za +27 81-736-4236 natasha@proagri.co.za +27 82-320-3642 annemarie@proagri.co.za +26 (0)97-769-9786 zainab@proagri.co.za +27 84-233-0123 carin@proagri.co.za +27 82-555-6866 diane@proagri.co.za +27 79-524-0934

ProAgri Zambia 83 1

ProAgri Zambia

ProAgri greetings Bianca Henning bianca@proagri.co.za

Engineering ingenuity with Carl Hamm and STÜWA Implements with your needs in mind from Ripper Tillage Tips from Novatek: Raising baby chicks Syngenta Zambia “cements” its commitment to Zambian farmers Prolick: An excellent source of non-protein nitrogen for ruminant animals Technews: Latest farming and agriculture news from around the world Pig farming Part 4: Health management in your piggery Beekeeping Part 5: Challenges that beekeepers face Processing of condiments Part 24: Sweet potato sugar syrup Preventing early IBV variant 2 infections in pullets Sheep breeds part 1: Sheep raised for mutton Ancient African food Part 5.5: Yam bean and horned melon De Haasenjagt Boerdery: Chicken farming done right 3. 5. 7. 9. 13. 15. 18. 20. 24. 26. 29. 33. 37.

ProAgri ProAgri technology for the farmer Zambia

aggrowth.com CONTACT US AT africasales@aggrowth.com

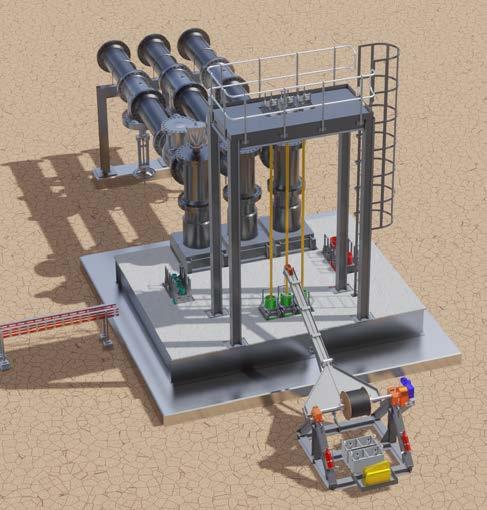

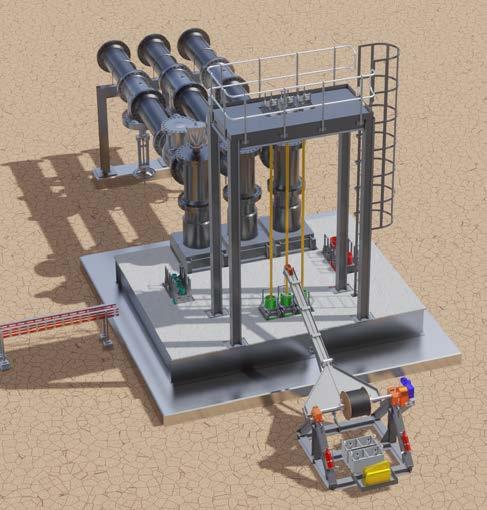

Engineering ingenuity with Carl Hamm and STÜWA

Article supplied

Boreholes

are vital for deep soil water extraction. Much like everything else on your farm, taking care of your borehole will ensure that it takes care of you. That is why you need quality parts that are both effective and durable.

Carl Hamm PPS, supplier of specialised pumps and pipes for the agricultural and mining industries, together with their German partner and manufacturer, STÜWA, is geared to ensure your borehole is well managed and will continue to deliver pure water through superior equipment.

Two products specifically produce proven effective results:

The slotted bridge well screen

A well screen is a part of the casing at the bottom of a well or borehole that stabilises the structure of the hole while also preventing debris such as rocks and dirt from the surrounding borehole wall from entering the water supply system.

What makes this product effective is the shape of the holes in the screen. The holes appear to have bridge-like structures over them, ensuring that water can still pass through the holes, but preventing any rocks and sand from doing the same. The slotted bridge well screen is produced according to internal STÜWA standards.

“STÜWA bridge slotted screens and casings are at the cutting edge when it comes to stability and material quality,” says Chris Munnick, CEO of Carl Hamm PPS. By using a well screen, it stabilises the aquafer strata and helps water flow into the borehole at a consistent rate, therefore protecting the

area around it.

Depending on wall thickness of each well screen, slot widths are approximately 0,5 mm or more. The wall itself can be up to a thickness of 12 mm. Screens are available in plastic and stainless steel, making them rust resistant and durable.

The ZSM riser connection

A wide range of connections are available, but the ultimate decision rests on the technical requirements of your borehole or well. Depending on the circumstances in which these connections will be used, the following factors need to be considered:

• tensile strength,

• collapse resistance,

• outer diameter, and

• installation guidelines

“What makes this coupling strong and unique is that, unlike a screw-in pipe, it doesn’t need to be exactly straight to prevent a leak, and it is connected in seconds,” Chris explains. “The fact that there are no screws that can damage the pipe is also a plus.”

A ZSM connection has a restraining pin that slides into the slot to form a perfect seal. This pin acts as a hook that holds the opposite part of the connection perfectly in place. Since there are no grooves, as with screw connections, the seal is tight and prevents sand from making its way into the thread. Furthermore, water cannot escape past this type of connection’s seal ring.

The ZSM connection is quick and easy to install and can handle a lot of pressure — up to 40 bar! The pipes can fit into wells of up to 300 m deep and 250 mm in diameter.

This slim, thin connection is the ideal choice for any project where there is little wiggle room. The couplings are made from stainless steel, meaning that they are durable and rust-

SICcasts combine silicone carbide and epoxy resin to make corrosion resistant, moulded parts.

need to replace tarnished connections because they last exceptionally long.

German engineering that offers durability and longevity

Carl Hamm and STÜWA share a similar beginning. Both are family businesses that are currently being managed by the fourth generation of their respective families. Together they strive to deliver customers with products of proven efficacy and durability. All products are developed in-house in Germany and shipped straight from the factory.

Hard as a diamond

Carl Hamm PPS is a proud distributor of SICcast.

SICcast produces the complete range of MC pumps and coats parts affected by strong erosion, abrasion and/or corrosion in liquid media based on patented silicon carbide materials.

This is an artificially produced industrial material with a diamond-like hardness. Silicon carbide (SiC) is a special mixture of epoxy resin cast into precision moulds and formed under a vacuum.

It started with the casting of several pump parts for the MC series and afterwards for the MCC series of affiliated company DÜCHTING pumps.

The important key feature of the material is the simultaneous resistance against corrosion and abrasion.

Based on the hardness of silicon carbide (9,7 on the Mohs' scale and close to the hardness of diamond), and the high filling grade of the components, it has very good results in casting new pump parts and in coating worn spare parts. The benefits of the SICcast-technology are longer service lives and lower costs compared to new parts.

-

For more information on the products and services that Carl Hamm provides, contact Chris Munnick on +27(0)10-900-2005 or send an e-mail to chris@carl-hamm. co.za. Visit their website at www. carl-hamm.co.za

ProAgri Zambia 83 3

The working platform with the pipes already connected.

The riser pipe con

nection has a pin that slides into the slot to seal the connection.

4 ProAgri Zambia 83 Happy Holidays Thank you for your loyal support Tradebor Mo & Final K Convenient pack size For the small scale farmer Litre container 1 planthealth.ltd@gmail.com | www.planthealthagri.com | +26 0977 505 031 info@planthealthagri.com | planthealthagriltd | planthealthagriltd Plot No. 7314 Chibengele Road, Off Kachidza Road, Light Industrial Area, Lusaka. Steward Moonga planthealth.ltd@gmail.com info@planthealthagri.com +260 977 505 031 Pllant Heealth Agri Ltd is a wholly owned Zambian Company that is specialised in agrochemicals distribution. We work with both small scale and commercial farmers customising crop protection solutions. We pride ourselves as leaders in nanotechnology pesticides. We help farmers reduce environmental impact. PL ANT HEALTH AGRI LTD PL ANT HEALTH AGRI LTD PL ANT HEALTH AGRI LTD WE SEEK COST-EFFECTIVE CROP NUTRITION SOLUTIONS HIGH QUALITY SOY BEANS HIGH YIELDING SOY BEANS We help farmers produce in f

R

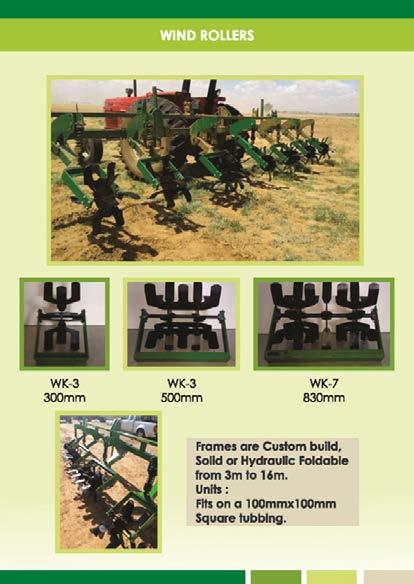

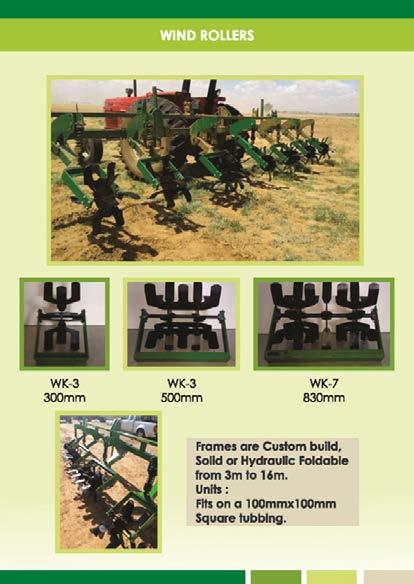

Implements with your needs in mind from Ripper Tillage Equipment

ipper Tillage Equipment offers more than robust and efficient implements; they start every customer journey with the question: What are your requirements? This includes the needs of your business according to the scale of your farming operation, the soil type, structure, and the crops you plan on planting.

By asking this question, Ripper Tillage Equipment is able to offer you, the farmer, the solution that fits your unique requirements. “We consider how the soil needs to be prepared for the type of crop the farmer wants to plant,” Christine Bouwer, Director and Technical Marketer of Ripper Tillage Equipment, explains.

This manufacturer designs and builds implements for every part of seedbed preparation and planting needs: before planting, during planting and after. This includes rip-till and strip-till equipment, rotary hoes and planting equipment.

“We specialise in rip-on the row. This means that instead of ripping and tilling the entire seedbed, the tine ensures that soil is only cultivated in the rows where the seed will be planted,” Christine elaborates.

Rip-Till equipment means the same seedbed, but different result Rip-till seedbed preparation means deeper tillage (deeper than 300 mm) that loosens the undersoil to ensure an even seedbed just like strip-till.

With conservation farming becoming more and more popular, conservation tillage is also increasingly popular. Rip-till implements from Ripper Tillage Equipment are ideal for this task, and what is more, their rip-on-the-row equipment delivers tillage that keeps soil moisture locked in.

On-the-row rip means you only till the soil in the row where your planter will carefully place the seeds. When, for example, using a 0,9 m (3 ft) 8-row planter, you will also use a 0,9 m 8-row ripper instead of ploughing the entire area of your field.

This process involves: • cutting of residue with a cutting coulter

• row cleaning

• rip and optional fertilize placements

• closing of furrow and compressing with a roller

Because there is less soil tilled over a large area, the machinery – tractor included – has less wear. What is more, you also use less fuel and require less labour.

“Our rotary hoe (rolegtand) is very popular for after-planting seedbed care when it comes to crumbling soil after heavy rain,” she adds.”

Tillage is more than implements, it is caring for the soil Ripper Tillage Equipment employees are skilled in identifying soil requirements. “We come to your farm, do a soil analysis with a demonstration, and determine the type of implement that will give you the best results,” Christine explains.

“We consider the type of soil on your farm as well as the last crop you planted – for example residue management. When we look at the soil condition, we understand how to help the farmer plant his next crop in the best possible way. We can suggest the implement

by

by

with the right tines or closing coulters to get the job done.”

This is the added benefit of custommade implements: Guidance and expertise in what is best for your soil. Because soil conditions and crop needs differ from area to area, investing in exactly the right tools that give you the maximum results help you succeed. “We do not only make products and sell them,” she adds. “We determine your exact needs, and provide tillage equipment that will give you the results you need. You won’t find a ready-made “one-sizefits-all” implement on a show floor.

“Maintenance is also fairly easy and inexpensive, because most parts are available locally,” she adds.

For more information on customised equipment for your seedbed preparation, contact Ripper Tillage Equipment on +27(0)82-773-9297 or send an e-mail to cpbothariptill@ gmail.com. Check out their visit website at: www.rippertillage. co.za or find them on Facebook: www.facebook.com/RipperTillage.

Left is an unclosed seedbed, and right with closing units.

Planter closing wheels.

ProAgri Zambia 83 5

Maryna Steyn

Tips from Novatek: Raising baby chicks

Chickens are relatively easy animals to maintain once they are adults, but mortality rates can be high while the baby chicks are still growing. It, therefore, becomes cardinal that measures are put into place to minimize mortalities and improve the growth rate of the chicks at this stage.

Arrival of chicks

At least a week before the chicks arrive, it is important to ensure that the brooding house is cleaned and disinfected. The waterers and feeders must be full even before the chicks arrive. Fill the waterers with fresh clean water and all feeders with starter feeds.

Brooding

A newly hatched chick does not fully develop the thermoregulatory mechanism, and takes about two weeks to develop this mechanism and homeostasis. Therefore, they cannot maintain the body temperature for the first few weeks of life and may be subjected to chilling if not properly taken care of.

This is where brooding comes into play. Brooding is the provision of artificial heat to help the chicks with temperature

regulation. The heat can be provided by electricity, gas, or charcoal stoves.

The brooder area must be comfortable, warm, well-ventilated and have dry bedding. The area must be ready at least 24 hours before the chicks arrive. Once the chicks arrive, place them in the brooding area so that they are kept warm.

Feed efficiency is affected by brooding temperatures. When temperatures get low, the feed efficiency is also reduced as the chicks use the feed to generate heat instead of growth, hence the importance of brooding in the early stages of life of the chicks.

Feeding

The chicks need to feed immediately when they arrive from the hatchery to minimize the hours of fasting. Prolonged fasting has a negative effect on growth. Early development of the digestive function in the newly hatched chick will enable it to better utilize nutrients and grow efficiently. Digestive tract growth and function in the newly hatched chick improves when the chick has early access to feed and water. Delaying access to feed and water decreases performance and results in loss of body weight.

by Nelia Mbewe

Studies have shown that early access to feed enhances body weight and development of the intestine. Skeletal muscle growth is stimulated and this results in a good carcass yield at the end of the cycle. It is therefore imperative that the day-old chick is fed on diets that are highly digestible owing to the fact that its digestive system is still immature and undergoing development.

The day-old chick will be fed on a starter crumble that is high in protein. The Novatek Broiler Pre-Starter and Starter diets contain high-quality nutrients for healthy growth of the chicks. Ensure that the chick is given enough high-quality feed, especially during the early phase of life for its development.

For more information on raising chicks, contact our nutritionists or sales technical team for assistance.

Send an e-mail to Robert Kanyembo, National Sales Manager, on salesmanager@novatek.co.zm, or contact him on +26-097-1 252-522 . Visit the website at www.novatekfeeds.com

ProAgri Zambia 83 7

8 ProAgri Zambia 83

Syngenta Zambia “cements” its commitment to Zambian farmers

Article supplied

Syngenta Zambia has “cemented” its commitment to Zambian farmers and crop protection with their new corporate office in Lusaka’s Rhodes Park area.

Syngenta Zambia held a launch event in Lusaka to officially unveil the company’s new location in Rhodespark. Farmers, government representatives and an audience of key players in the agricultural business community attended the event to celebrate the unveiling of the office which is a significant step in symbolising the company’s dedication to the Zambian market.

Speaking at the event, Syngenta’s Head of Crop Protection in Africa and Middle East, Jerome Barbaron, and Given Mudende, Head of Southern Africa Business and Managing Director of Syngenta in Zambia, highlighted that the move to a new office is a major step in improving their customer service delivery especially to corporate clientele and also fuelling their long-term commitment to Zambian farmers.

Mr Mudenda spoke about their “Good Growth Plan” – a plant protection strategy that is aimed at the overall improvement and sustainability of agriculture in Syngenta’s operations.

He said: “Climate change is a huge challenge to the sustainability of the agricultural ecosystem. Our Good Growth Plan aims to take on these challenges by making agriculture more resilient and sustainable and driving a better, greener, recovery. We must help farmers address it with new technologies and services, both to mitigate and adapt to the effects of climate change.”

Syngenta remains committed to the agri-sector in Zambia and other Southern African countries, and fully dedicated to its customers and their growth in the industry. In affirmation of this commitment, Mr Barbaron further stated that crop and seed protection is a firm promise of their global operations.

“From the moment a seed is planted through to harvest, crops need to be protected from weeds, insects, and diseases, as well as droughts and floods, heat and cold. As a world market leader in crop protection, we help farmers to counter these threats and ensure enough safe, nutritious, affordable food for all – while minimizing the use of land and other agricultural inputs.”

Syngenta Zambia has upheld another industry promise to empower the agricultural sector with impactful collaborations and professional solutions.

“To create successful collaborations, we need diversity of ideas and expertise. We do not work alone but have many partners, such as universities, research institutes, and sustainable agriculture experts.”

The new Syngenta Zambia office will play a significant role in their mission to offer environmentally sustainable methods to enhance the productivity and value of agricultural businesses in Zambia.

• Syngenta has been a provider of agricultural services and products in Zambia for over fifteen years with proven recognition as an industry leader in Zambia and surrounding countries.

• With a solution-driven approach to agriculture, Syngenta Zambia has continued to provide best-inclass products aimed at promoting sustainable agriculture and bringing plant potential to life.

• Syngenta Zambia farmers and customers have benefited from the various product offerings by the world’s largest crop chemical producer which is amongst the global champions in seed and biotechnology.

• With the on-going threat of climate change, crop protection has become a vital mission in the operations of Syngenta as a global and continental participant in agriculture.

• As part of its Good Growth Plan, Syngenta has accelerated its innovation to provide solutions for farmers. Syngenta is a world market leader in crop protection products, offering farmers an extensive toolbox of solutions through herbicides, insecticides, fungicides, and seed treatment products that promote strong and healthy growth.

• As a sign of Syngenta’s long-term commitment to Zambian growers and Southern African countries, Syngenta has launched a new corporate office in Lusaka, Zambia as the Southern Africa Headquarters.

The new Syngenta corporate office will aid the company in offering improved service delivery to the booming corporate clientele in the agricultural industry.

Syngenta is one of the world’s leading agriculture companies, comprised of Syngenta Crop Protection and Syngenta Seeds. Our ambition is to help safely feed the world while taking care of the planet. We aim to improve the sustainability, quality, and safety of agriculture with world class science and innovative crop solutions. Our technologies enable millions of farmers around the world to make better use of limited agricultural resources. Syngenta Crop Protection and Syngenta Seeds are part of Syngenta Group. In more than 100 countries we are working to transform how crops are grown. Through partnerships, collaboration, and The Good Growth Plan we are committed to accelerating innovation for farmers and nature, striving for regenerative agriculture, helping people stay safe and healthy, and partnering for impact.

Visit Syngenta’s website on www.syngenta.com.zm and www.goodgrowthplan.com

Follow Syngenta on Twitter at www.twitter.com/Syngenta, www.twitter.com/SyngentaUS and on LinkedIn at www.linkedin. com/company/syngenta

For more information contact Syngenta, Zambia, on +26-096-762-4634 or send an e-mail to sales.zambia@syngenta.com.

ProAgri Zambia 83 9

Given Mudenda, Managing Director of Syngenta Zambia, and Jerome Barbaron, Head of Crop Protection in Africa and Middle East.

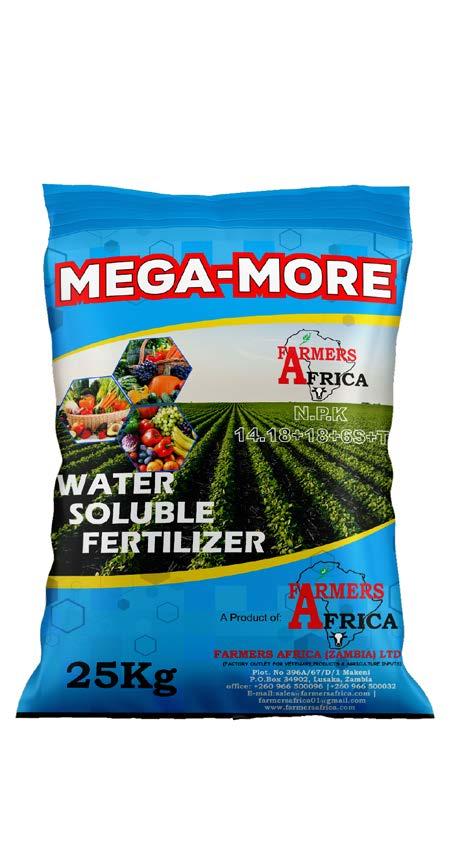

ProAgri Zambia 83 (FACTORY OUTLET FOR VETENARY PRODUCTS & AGRICULTURE INPUTS) Plot. No 396A/67/D/1 Makeni P.O.Box 34902, Lusaka, Zambia Contact: +260 978 463921 Office: +260 966 500096 | +260 966 500032 farmersafrica04@gmail.com farmersafrica01@gmail.com www.farmersafrica.com FARMERS AFRICA (ZAMBIA) LTD More powerful fertiliser with added advantage of Sulphur for all types of crops and for different applications !! MEGA-MORE N.P.K 14.18+18+6S+TE WATER SOLUBLE FERTILIZER

Prolick: An excellent source of non-protein nitrogen for ruminant animals

by Barbara Mulonda Simbaya, Technical Advisor at Tiger Animal Feeds

minerals, and vitamins. It is not possible to meet all the nutritional requirements of the animals by basically allowing them to feed off the veld. The grasses normally contain less than two percent digestible crude protein in dry season, which means that supplementation must be provided just to maintain the weight of the animals throughout the dry periods of the year. Prolick as a source of non-protein nitrogen can help Zambian farmers by ensuring that they meet the protein needs of their livestock at the worst time of the year when pastures are low in quality as well as quantity.

• The cattle lick should be kept out of rain because if the cattle drink the water with the dissolved urea, they will die of urea poisoning.

Expected feed intake

The expected feed intake is 400 to 600 g per animal, per day, when there is no fodder available and approximately 250 g per animal, per day when there is some fodder or grazing available.

Non-protein nitrogen (NPN) is a term used in animal nutrition to refer collectively to components such as urea, biuret, and ammonia, which are not proteins but can be converted into proteins by microbes in the ruminant animal’s stomach. In cattle, ruminal microbes can utilise NPN to synthesise proteins that can replace a portion of their total dietary protein requirements.

NPN can be very beneficial to the farmer by providing a cheaper but effective source of dietary protein. NPN is ideal, especially during the dry season when the pastures are poor and low in protein content. This means that despite the highly fibrous and poor-quality grasses available during the dry season, the animals can continue gaining weight and remain productive.

Sources of non-protein nitrogen and how they work Prolick, a cattle lick block produced by Tiger Animal Feeds, is an excellent source of non-protein nitrogen because of the urea it contains.

When Prolick lick block is consumed, it provides the much-desired urea in the rumen for bacterial urease to dissolve and hydrolyse into ammonia. Then, further metabolism combines ammonia with carbon chains to form amino acids. Finally, the rumen micro-organisms metabolise and incorporate the amino acids into rumen microbial protein. These bacteria are later broken down and their microbial protein and vitamins absorbed by the animal in the intestines. Cattle can utilise NPNs to synthesise proteins that can replace a portion of their total dietary protein requirements.

Why should cattle farmers in Zambia consider Prolick as a source of protein?

Most pasture range in Zambia is not improved, hence it is of very poor quality, particularly in the dry season. It is low in the quantity of digestible protein, energy,

Benefits of Prolick to cattle

• The urea in Prolick will keep up activity by ensuring that rumen bacteria multiply, and hence more microbial crude protein is made available to the animal.

• The rumen bacteria are not only important in protein synthesis through the use of NPN, but will also help the animals to extract energy from the highly fibrous grasses that they must consume.

• Feed supplementation with Prolick will improve the survival rate and increase the roughage intake of cattle. It is also found to reduce body weight loss, improve birth weight of calves, reduce neonatal mortality, and lead to higher milk yields and calf growth rate. The urea in Prolick will enable the animals to survive during droughts.

• Prolick is a cost-effective way of ensuring that the animals can meet their protein requirements.

The safe use of non-protein nitrogen (urea)

Urea can be deadly if not used correctly! Ammonia poisoning will result from excessive consumption of sources of NPN or urea. Ammonia poisoning is acute and often rapidly fatal, with clinical signs including muscle tremors, abdominal pain, incoordination, respiratory distress, and recumbency followed by death. In order to use urea or any other NPN safely, there are several precautions the farmer needs to take note off:

• Tiger Animal feeds ensures the safe and effective use of urea by incorporating it into a cattle block lick. Prolick, a mineral block lick, should be used when grass is dry. It supplies all the nutrients the animal needs. However, because of the urea present in the lick block, it should only be fed to cattle and not to horses and game.

• If you are using urea that has not been incorporated into a lick block, be sure that only one-third (1/3) of the total protein provided in the diet of the animal is the urea. The maximum quantity of urea that should be allowed to maintain growth in cattle during the dry season on the veld is 25 g per 100 kg live weight per day.

• In concentrate rations, the maximum allowance should be 3% of the complete mixture. But lower quantities are usually sufficient for production or fattening rations. The best utilisation of urea is achieved when there is a true source of protein in the mixture.

• Urea needs careful and thorough mixing when it is incorporated with other feed ingredients. This is because it is hygroscopic and absorbs water from the atmosphere. It then forms hard lumps which may be sufficiently large to kill an animal if consumed at once.

Please note: Do not use urea in a concentrate mixture containing soya beans because soya beans contain enzymes urease which may speed up the breakdown of urea to ammonia and thus increase the chances of poisoning.

For more information on Prolick and the wide range of products and stock Tiger Feeds has, contact Barbara Mulonda Simbaya on (+26)096-920-2207, or send an e-mail to barbara.mulonda@ tigerfeeds.com.zm.

ProAgri Zambia 83 13

Cattle grazing on poor-quality pastures during dry season.

Tiger Animal Feeds cattle block lick.

THE TRUSTED COMPANY THAT’S A BREED APART.

The TOPIGS Tempo boar is ideally adapted for African environmental conditions, this proven by our client list, their production results and profitability. Many top farmers in Africa have invested in the breed with huge success. The excellent health status of our genetics is considered a major competitive advantage. Many producers choose to repopulate with Topigs Norsvin genetics to reap the benefits of this advantage.

The TN70

• The TN70 is a cross between the Topigs Large White and the Norsvin Landrace.

Characteristics

• Highly prolific, easy in use sow

• Amazing weaning ability

• Top contribution to finishing pig quality

• Produces large litters of strong, uniform

TN70 & TN Tempo: The ultimate combination

• Tn Tempo brings robustness, uniformity and fast growth potential

• The TN70 is and excellent mother which strengthens these qualities by contributing the best feed efficiency to the finisher compared to any other sow in the world

• Together, the TN Tempo and TN70 offer you the potential to produce the most output against the lowest cost, combination unrivaled.

Zambian Pig Genetics is the distributor of Topigs Norsvin genetics in Central Africa. Built on our global research, innovation and absolute commitment to integrity and biosecurity, our close partnership approach means your farm benefits directly from our experience, energy and passion.

14

Technews: Latest farming and agriculture news from around the world

by Annemarie Bremner

Robotic vineyard tractor gets a business boost

Same Deutz-Fahr has taken a majority stake in vineyard robotics start-up VitiBot. Based in Reims, in the heart of the Champagne region, the French company makes a 100% electric and autonomous straddle tractor called the Bakus. Described by SDF as an innovation accelerator, the move will allow VitiBot to accelerate its commercial development in vineyard equipment, and the two companies plan to develop a new range of precision farming solutions for a market that is expected to grow in the future.

SDF already owns the grape harvester and sprayer manufacturer, Grégoire. VitiBot will operate like this French subsidiary in that it will remain independent within the SDF Group.

SDF top man Lodovico Bussolati said that after a thorough search of available technologies, the company realised that VitiBot was the best solution for vineyards. “It allows us to enrich our tractor offer with self-driving and zero-emission electric vehicles,” he comments.

VitiBot was founded in 2016 by French wine grower Dominique Bache and his son Cedric, a robotics engineer. It took them five years to develop the roughly 2,4 t Bakus tool carrier, which is available as the S-model, for straddling 1,75 m high x 60 cm wide vines, and the L-version for 2,20 m high x 80 cm wide crops.

The Bakus can be equipped with a range of electric and non-electric

tools, including mowers, sprayers and mechanical weeders. More than 50 of these machines are already working in vineyards around the world. (Source: SDF)

make inroads, but most Dutch growers continue to cut cabbages and cauliflowers by hand, placing them on conveyors and a packing platform carried behind a tractor. Covering just 130 m/h, the tractor drives in the slowest creep speed. Most growers have long used a cable behind the tractor to operate it remotely. Van der Werf has gone a stage further and ditched the cable for a dedicated remote control unit.

Shown on a Case IH Maxxum 115 at the Bejo Zaden Machinery Show at Warmenhuizen (north of Amsterdam), the Dutch dealer has offered the conversion for some years now and has sold more than 100 systems, mainly to cauliflower growers. “It is a normal job for us,” comments Sander Klabbers of Van der Werf.

Activating the system is easy in three steps; start the tractor, engage the creeper and then turn on the remote unit (receiver connects to it). Engine speed is always set in idle for this type of work. The remote could be programmed to start the tractor and reverse it, but most growers opt for the six functions of stop, forward, gear change (up/down) and steering (left/ right). The tractor is always turned manually at the headland. The remote is only used when crossing a field.

The Maxxum is the most popular tractor for conversion, but the dealer has also installed the kit on a number of New Holland and Steyr tractors. The Dutch dealer reckons it is difficult to convert a CVT to remote control. The

Remote controlled Case IH Maxxum

Dutch Case IH and Steyr dealer Van der Werf Mechanisatie have developed a remote control unit that allows cabbages and cauliflowers to be harvested without a driver in the tractor cab.

Mechanical harvesters continue to

easiest is a mechanical transmission. It depends on the tractor and required functions, but the cost of the conversion is usually around €4 000. (Source: profi)

ProAgri Zambia 83 15

Fendt is back with new powerful Katana

Fendt has returned to the 588 kW (800 hp+) self-propelled forage harvester market with the Katana 850. The new model is available to order now for the 2023 season in Europe.

Main features of the new machine include the redesigned CropFlow 2.0 system to maximise throughput and chop quality. Claimed as the largest on the market, the 720 mm diameter of the chopping cylinder with its high flywheel mass is said to ensure very smooth running and increased operator comfort. Optional chopping cylinders with 20, 28 or 40 knives are available to cover chop lengths from 2,6 to 41,4 mm.

The Katana 850 can be matched to the Kemper 490 Plus 12-row header to fully utilise the power of the 18-litre six-cylinder 623 kW (847 hp) Liebherr engine. The Liebherr block meets Stage V emissions with SCR, but there is no diesel particulate filter or exhaust gas recirculation. If the full power of the engine is not required, it can be operated in eco mode, which maintains the speed of the chopping cylinder, but then at reduced engine rpm.

Metal and stone detectors on the first of the six pre-compression rollers of the feed intake prevent damage to the chopping cylinder, and crop volume data recorded by a sensor in the rear area of the feed intake is available for yield monitoring and documentation.

Three different 300 mm diameter roller crackers are available. The standard R cracker with sawtooth profile is suitable

for chop lengths of up to 20 mm. The optional RS cracker with V-spiral groove has been developed for longer chop lengths. The speed difference of 30 or optionally 40 percent ensures thorough processing of the crop.

The loading height of the revised discharge chute is extended to 6,2 m. The Fill Control filling assistance option automatically controls the discharge flap if the discharge chute swivels, to

ensure trailers are filled more evenly. A camera is positioned next to the discharge flap.

Other options include a fully integrated silage additive system with 215-litre tank, the intelligent all-wheel drive BalancedGrip system, and an interface for an NIR sensor. This allows the dry matter content of the crop to be measured. An ISObus interface enables the use of different sensors. (Source: AGCO)

Lightweight plough completes Juwel range

16 ProAgri Zambia 83

6 ranges. Suitable for tractors from 51 to 95 kW, the new low-draught model will be available early next year.

With a 110 mm box section frame and an underframe clearance of 80 cm, the Juwel 6 is available in versions with three to five furrows. The M version provides four mechanically adjusted working widths per body, while the 6MV provides infinitely variable hydraulic working width adjustment (hydraulic frame swivelling is optional). LEMKEN says that when combined with the iQblue Connect electronics kit, the implement can easily be transformed into a smart plough with ISObus control.

All LEMKEN mounted ploughs are equipped with the new pendulum wheel, the height of which can be adjusted without tools via a series of holes. For material protection and greater working comfort, hydraulic suspension is also fitted to the depth wheel. A simple conversion kit is available to upgrade to a Uni wheel for road transport.

Standard equipment on the Juwel 6 includes the tried-and-tested Dural bodies (DuraMaxx optional). Mechanical non-stop overload protection is recommended for stony soils, and as with all the company’s mounted reversible ploughs, the Juwel 6 comes with the Optiquick adjustment system for side draught-free work. (Source: www.world-agritech.com)

ProAgri Zambia 83 17

Slotting in below the LEMKEN Juwel 7, 8 and 10 mounted reversible ploughs, the new Juwel 6 replaces the longstanding EurOpal and VariOpal 5 and

We are commited to quality & service sarozambia.com | (+260) (211) 2414 77 / 387 001/9 | saroagri.co.zm Plot No. 5284 Buyantanshi Road, Lusaka, Zambia Thank you for your business this year Happy Holidays To all our hardworking customers

Pig farming Part 4: Health management in your piggery

P iggery production systems are kept at peak performance by the upholding of a variety of parameters. One of these is health management. Efficient and effective health management safeguards good reproductive performance, consistent pig numbers at all stages of production, and consistent growth factors, which then contribute to a steady, high income for the piggery enterprise.

One of the first steps towards creating a health management system is the use of production records. Various records are utilised to assess performance and identify areas of concern. Record-keeping ensures an efficient diagnosis assessment of the functionality of the treatment and/or mitigation strategies.

The assessment process involves:

• taking an appropriate history of symptoms and collecting relevant data;

• physical examination;

• generating a provisional and differential diagnosis;

• testing, if required (ordering, reviewing, and acting on test results); and

• reaching a final diagnosis and prognosis.

Health records help set targets and motivate farm staff to achieve the targets. Types of records kept are:

• veterinarian records;

• medication and treatment records;

• vaccinations;

• medicated feed mixing records;

• biosecurity checklists;

• visitor logs; and

• needle and drug storage inventories.

An element of health management that springs up right from the inception of the project is biosecurity. Biosecurity encompasses the procedures or measures designed to protect the pigs against harmful biological or biochemical substances.

The management of health issues regarding biosecurity can be classified into three fields:

First, there are strategies designed to live with endemic diseases. Generally, endemic diseases are instigated by pathogens that survive in the environment and are too difficult to eliminate, or they are ubiquitous organisms that generally cause few problems. Endemic diseases can be mitigated by maximising immunity and minimising the challenge, whereas ubiquitous organisms may be managed by solving environmental-management deficiencies which usually cause them.

The second field is the elimination of pathogens. Their elimination usually involves the administering of chemical substances such as antibiotics, or quarantine to create herd immunity.

The third and last part of biosecurity are actions to prevent pathogens from entering the herd, such as foot baths, spraying of vehicles, and limitation of human movement in the sties.

Poor health management can lead to a population of pigs with underdeveloped immune systems, stress leading to a weakened immune system, overwhelming pathogen challenges, or the entry of new pathogens into a population of pigs without specific immunity.

Health conditions affecting pigs include parasitic diseases, which may be internal or external. Parasitic diseases are roundworm and tapeworm that can

be controlled with medicine in the food, and the provision of clean and dry pens, periodic disinfection of sties, separation of young ones from adults, washing sows before farrowing, and preventing the pigs from wandering about where they can feed on human faeces.

External parasites such as mange, lice, myiasis can be solved by scrubbing sows with Gamma BHC insecticides four days before farrowing, cleaning and scrubbing the farrowing pens before use, maintaining proper animal nutrition and health programmes to reduce severity and spread. Recommended control products for this are: Ivermectin (1% injectable), or Malathion (1% spray).

Reproductive disorders and diseases include anaphrodisia, leptospirosis, brucellosis, uterus prolapse, mastitis and endometritis (bacteria). Preventative measures include improved feeding of mineral-rich feeds, regular deworming, vaccination, and hygienic measures.

Diseases and disorders of the digestive tract are scouring, birth diarrhoea, red diarrhoea or clostridial enteritis, transmissible gastroenteritis, salmonellosis, and swine dysentery. Measures to mitigate this include but are not limited to keeping pens, feed, and watering troughs clean, separation of affected animals from healthy animals, and keeping the pigs warm.

18 ProAgri Zambia 83

by Tapuwa Mashangwa

One of the first steps towards creating a health management system is the use of production records that keep track of your pigs’ health.

(Source: pexels.com)

Some of the diseases of the respiratory are influenza, pseudorabies, pneumonia, atrophic rhinitis and pasteurellosis. Preventative measures are good ventilation, vaccination, hygiene, and the use of antibiotics.

Under nutritional disorders is anaemia which can be treated by providing iron injections or oral iron-paste containing iron, feeding compost of good quality and supplied daily, as compost of poor quality may contain bacteria, and wood ash can also be put into the pen.

Other diseases are foot and mouth disease (FMD), swine fever/hog cholera and anthrax. Mitigation includes vaccination, quarantine, use of antibiotics and sometimes thorough disinfection of the farm and burning of carcasses.

The existence of a health anomaly for a pig may present itself by:

• the pig not eating or not showing an interest in feed and or water;

• rapid breathing which is usually indicative of a fever;

• white pigs may become reddish;

• diarrhoea which may be bloody or blood-stained;

• droopy ears or ears pointing downwards;

• dull eyes;

• dull skin and hair;

• a limp tail;

• and the pig may separate itself from the herd.

Generally, as elaborated, it is paramount for farmers to constantly monitor and assess the state (behavioural and physical) of their herd for the early detection of any health issues.

ProAgri Zambia 83

NoseRing® Wean with ease | No stress | Next to the mother NoseRing • Wean with ease • No stress • Next to the mother PO Box 1806, Vryburg,8600, South Africa Tel: +27 (0)53 927 4999 Cell: +27 (0)82 459 9451 E-mail: judy@nosering.co.za www.nosering.co.za ® Tel: +27 (0)53 927 4999 Cell: +27 (0)82 459 9451 judy@nosering.co.za NoseRing® is available at Livestock Services, Lusaka –Pamodzi Highway, o Nangwenya Road, Showgrounds; Tel: 0211-254497 / 254024; E-mail: admin@livestock.co.zm www.nosering.co.za

(Source: pexels.com)

Beekeeping Part 5: Challenges that beekeepers face

A beekeeper faces many challenges, but persistence is usually met with success.

The biggest challenges are finding a suitable terrain for his apiary and sufficient and diverse forage, the provision of fresh water, poisoning of bees, natural enemies of the bees, theft and vandalism by humans, climate change hazards like flooding and droughts, and veld fires.

Suitable terrain

The most important consideration for a beekeeper is to find a suitable terrain where he can place his bees. This was discussed in Part 4.

is not always suitable as honey – some Euphorbia species, like honey euphorbia, and bitter almond (Brabeium stellatifolium), provide bitter-tasting honey.

It is advisable to have different sources of forage available so bees will have access to feed throughout the year. If there is not enough forage during the winter months or a drought, it may be necessary to provide supplementary feed, but more about that in Part 6.

Water

Bees must have access to clean water for breeding as well as regulating the temperature inside the hive. It seems

Forage

It is important that the apiary is placed in an area where the bees will have access to a variety of flowering plants. These may include wild flowers, cultivated vegetable plots, grain or oil-producing plants, or orchards. Research has found that bees need nectar and pollen from a wide variety of flowering plants to keep them healthy so they can build a strong swarm and produce an abundance of honey.

The plants in the area must provide enough nectar that provides the bees with carbohydrates, and which can be developed into honey, as well as pollen, which provides the bees with protein. Some plants provide lots of nectar that

bees prefer water that is slightly heated by the sun. If a tank or drum is used to store water, a piece of wood that floats on top will provide a safe place for the bees to sit while they drink. Dripping water through a pipe from the drum into a sand filter pan or trough will also provide safe drinking water and prevent the bees from falling in and drowning.

Climate

Honeybees are the main pollinators of more than seventy percent of the world’s cultivated crops. As bees depend on the temperature of the environment, climate change that may bring about higher temperatures and longer

periods of drought may have a direct influence on their biology, behaviour and distribution. Indirectly, climate change can lead to fewer flowers, which will provide less food for the bees.

Bees work optimally between 16 and 32 °C, and the temperature inside the hive is kept at a constant 35 °C. To survive the cold of winter and the heat of summer, the bees employ heating and cooling strategies, mostly by positioning themselves and fanning their wings to thermoregulate their hives.

The general flight activities of bees are influenced by the weather, and they will not forage during rain and thunderstorms. Under these circumstances plants do not usually release pollen, but if they do, it will probably be washed away.

Poisoning of bees

Most insecticides used on agricultural crops are poisonous for bees. Insecticides are divided in three classes according to their toxicity to bees. Some insecticides are less toxic, while others can continue to kill the bees even days after it had been sprayed.

20 ProAgri Zambia 83

The yellow jacket wasp is an alien species that preys on bees. (Source: Pixabay)

A paper wasp, here seen on its typical nest, is another enemy of the honeybee. (Source: Pixabay)

The carmine bee-eater is one of several bird species that feed on bees. (Source: Pixabay)

Signs of poisoning and the effect thereof can be seen inside the hive. Bees may appear to be paralyzed, shaky and crawl about. The guardian bees at the entrance may be more active than usual because they will be throwing out the dead and dying bees. After a while, a heap of dead bees may be found in front of the entrance. Toxic pollen and nectar brought into the hive can cause the nursing bees feeding the larvae to die, and therefore the brood may be neglected, and the swarm will suffer.

Fieldworker bees are usually killed first, either directly by the insecticide, or by just walking over an area that had been sprayed. The swarm’s water source may also be poisoned.

Farmers can help to minimise the effect by informing the beekeeper in advance when spraying will take place.

Bees must be moved away – about eight kilometres from the area that will be sprayed is deemed safe. In the case of some insecticides, the bees can only be brought back to the area after three days.

It helps to cover the hives, but provision must be made to allow sufficient ventilation, additional space for bees to group together, and access to uncontaminated water.

The hives should be covered the evening before spraying will take place

ProAgri Zambia 83 21

Baboons sometimes break open hives to feed on the honey. (Source: Pixabay)

A troop of baboons can wreak havoc in an apiary. (Source: Pixabay)

Additional feed, such as sugary water, must be provided for the bees in lean times. (Source: Pixabay)

Putting the hives on stands and weighing down the lids may keep some predators at bay.(Source: Pixabay)

Swarming is a natural occurrence, but some beekeepers may regard it as a challenge. (Source: Pixabay)

Finding suitable forage is one of the biggest challenges in beekeeping. (Source: Pixabay)

and opened the morning after spraying, but only after the dew has evaporated. The wet poison is deadly, but the toxicity diminishes once the poison is dry. Care must be taken to prevent drift of the poison to adjacent fields or orchards due to wind.

Enemies

Bees have lots of natural enemies that feed on them.

Pirate wasps

These include predators such as the banded bee pirate (Palarus latifrons) This predatory wasp is mostly found at nest entrances while the female watches from her nearby nest. She catches bees returning from foraging in flight and carries them to her nest, usually in sandy soil, in which she buries up to three bees.

Sometimes the female wasp falls to the ground with the bee she has caught, and as soon as the bee stops struggling, she forces her mouth into that of the bee and by pressing her curved backside, she forces the contents out of the bee’s honey stomach. Once done, she leaves to find another meal.

Sometimes, when there are hundreds of wasps around, the bees stop working altogether and remain inside the hive. The wasps can completely decimate a bee colony.

The best solution to this problem is to move the bees away, or to lure the bee pirates into water traps with a mirror in it. A dish is filled with water and a small quantity of kerosene, and when the wasps dive into the water they are killed by the kerosene.

The yellow bee pirate or bee wolf (Philanthus triangulum) is a less destructive wasp that mostly prey on foraging bees.

European wasps

The yellow jacket (Vespula germanica) has been present in the Western Cape for almost forty years and appears to

These hives miraculously remained intact during a fire. Note the metal stands on which the hives are mounted to keep badgers at bay. (Source: Provided)

be spreading. They build huge nests and predate on bees that move in and out of the hive, but do not seem to do real damage. The European paper wasp (Polistes dominulus) was found in the Cape in 2009 and seems to be spreading rapidly. No record of predation on bees exists.

Birds also prey on bees. They may stop bees from foraging, but the interruption is usually temporary. These birds include some bee-eaters (Merops apiaster), Alpine swifts (Apus melba) and the fork-tailed drongo (Dicrurus adsimilis.) There is no real solution to the problem, except maybe putting the colonies in bushes to limit the birds’ effect.

Mice and toads sometimes get into the hives, but they cause only a minor nuisance. They eat the honey and pollen and make a mess, but small entrances should keep them out.

Baboons cause problems in some areas. To limit the damage, the hives can be strapped to keep the baboons out.

Honey badgers can cause havoc

when other food is scarce, especially near natural vegetation. Male badgers can destroy apiaries. This led farmers to set gin traps and use other unethical ways of capturing the badgers, but consumer pressure advocating badgerfriendly honey, has mostly put an end to the remorseless killing. Hives placed on stands of 1,2 meters above ground, straps or fastening the hives to the ground, or hanging bee colonies in trees, will keep the badgers at away.

Ants, including the Argentine ant (Linepithema humile), brown house ant (Phedole megacephala), pugnacious ant (Anoplolepis custodiens) and driver ant Dorylus (Anomma), can be a real problem. Poison is not a good solution – it is best to keep the ants out of the hives. Raise the hives on pedestals and use ant barriers like Plantex around the pillars. Termites can devour a wooden hive, but the same treatment should work for them – keep the hives out of their reach.

22 ProAgri Zambia 83

Swallows catch bees in flight. (Source: Tisha Steyn)

The fork-tailed drongo feeds on bees. (Source: Pixabay)

Theft and vandalism

Theft and vandalism are problems caused by humans who break into even enclosure apiaries, break open the hives and steal the honey. There is not much you can do about it, apart from keeping defensive bees!

Climate change and the associated prolonged droughts may cause more wildfires in dry areas. These are also often caused by humans who intentionally or by accident set the veld alight. The best way to prevent fires from destroying your apiary is to keep

A

the area around it free of vegetation. Disease is another challenge, but the different diseases will be discussed in future issues.

References

Allsopp, M. (2000) Predators of bees in Southern Africa. Agriculture Research Council (ARC) https:// rr-africa.woah.org/wp-content/uploads/2000/11/34_allsopp.pdf

Anderson, R.H., Buys, B., Johannsmeier, M.F (2014). Byeboerdery in Suid-Afrika Hersiene uitgawe. Departement van Landbou-tegniese Dienste. Bulletin no. 394, 1978

Jarimi, H., Tapia-Brito, E. and Riffat, S. (2020). A Review on Thermoregulation Techniques in Honey Bees’ (Apis Mellifera) Beehive Microclimate and Its Similarities to the Heating and Cooling Management in Buildings. Future Cities and Environment, 6(1), p.7. DOI: http:// doi.org/10.5334/fce.81

https://futurecitiesandenvironment.com/articles/10.5334/fce.81/

Reddy, P.V. R., Verghese, A., Rajan, V.V. (2012) Potential impact of climate change on honeybees (Apis spp.) and their pollination services. Division of Entomology and Nematology Indian Institute of Horticultural Research, India. Pest Management in Horticultural Ecosystems, Vol. 18, No. 2 pp 121-127. http://www.nicra-icar.in/nicrarevised/images/publications/Research_art/HRT20_Potential%20 impact%20of%20climate%20 change.pdf

ProAgri Zambia 83 23

Veldfires are a big challenge as they destroy the plants that bees need for nectar and pollen. Source: Tisha Steyn

bottling facility was destroyed by a fire. (Source: Provided)

Processing of condiments Part 24: Sweet potato sugar syrup

S

weet potato sugar syrups are made from sweet potato starch, which is converted into a range of different types of sugars by means of special enzymes. The manufactured syrups can be used to replace more expensive cane or beet sugar in the confectionery industry.

Sweet potato sugar syrup is not only a very economic option but offers a wide variety of products with different properties, which can be manufactured to suit specific needs.

Process description

1. Raw material for sweet potato sugar syrups: Different types of sugar syrups can be manufactured from sweet potato starch as shown in the process flow diagram. The specific properties of the enzyme used determines the type of sugar to be formed. The processing technique for each type of sugar is different and therefore only a basic processing procedure will be discussed here.

2. Enzyme conversion of starch to syrup: Specific enzymes are added to the starch slurry at an optimum temperature and left for a certain period during which the starch is converted into sugars. Different types of sugars such as glucose,

24 ProAgri Zambia 83

fructose, maltose et cetera may be formed depending on the type of enzyme used and processing parameters such as time and temperature. These enzymes are specially prepared and commercially available. The extent of saccharification may be tested with tincture of iodine. A second enzyme treatment with a different type of enzyme may be necessary for the production of certain types of sugar syrups. This is usually done after inactivation of the first enzyme.

3. Enzyme inactivation: The enzyme activity is stopped as soon as optimum saccharification has taken place. This is usually accomplished by means of a heat treatment.

4. Filtration: The syrup is filtered through activated carbon, using an ion exchange method to remove impurities.

5. Concentration: The liquid syrup is concentrated by vacuum evaporation or ordinary boiling until it is concentrated to the specified requirements. The syrups may also be dried into a powder form.

6. Packaging of sweet potato sugar syrups: Packaging is defined as the containment of a food product in a protective barrier that prepares goods for transport, distribution, storage, retailing and end-use.

requirements for sugar

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www. arc.agric.za for more information

ProAgri Zambia 83 25

Packaging

Sweet potato starch Enzyme treatment Enzyme inactivation Packaging Dextrose Glucose Malto-oligo saccharides Cyclo dextrins Maltose Hydrogenation Maltitol Hydrogenation Sorbitol High Fructose Filtration & purification Concentration or drying a = glucoamylase b = alpha-amylase c = glucose isomerase d = cyclodeztrin glucotransgerase e = beta-amylase f = malto-oligosaccharide forming amylase a b c f d e

are basically protective containment with easy dispensing features. Powdered syrups are highly hygroscopic and require moisture proof packaging.

syrups

Preventing early IBV variant 2 infections in pullets

flock, unless the cysts are so large that the abdomen is distended and the bird needs to stand upright to be able to breathe (penguin posture). Affected birds are usually called false layers, since they look sexually mature, eat their daily ration, but do not produce eggs. If there are a significant number of false layers, it will manifest as a healthy flock with sustained poor production levels.

Flocks that suffer early infection can also be reinfected later if proper preventative measures (including appropriate vaccination) are not implemented. It is opportune to mention that when Variant 2 infections occur during the late rearing and laying stages, the disease profile will be more severe and may result in higher mortalities, significant drops in egg production, as well as problems of eggshell quality (discolouration, brittle shells, shell-less eggs, etc.).

How to prevent early infections in pullets?

The most effective strategy to prevent IBV variant 2 infections in pullets and their associated production losses consists of implementing a vaccination

I

nfectious Bronchitis virus (IBV) variant 2 has been detected in Zambia by PCR and genetic sequencing. Although the number of cases is on the rise and the number of flocks sampled is increasing, we believe the disease is still underdiagnosed.

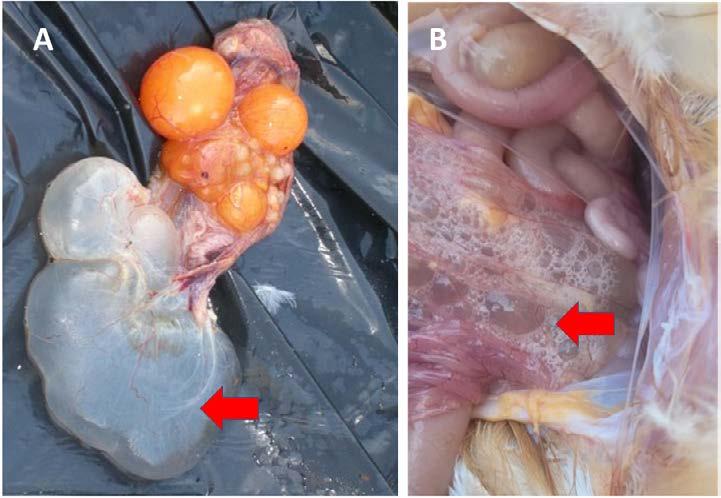

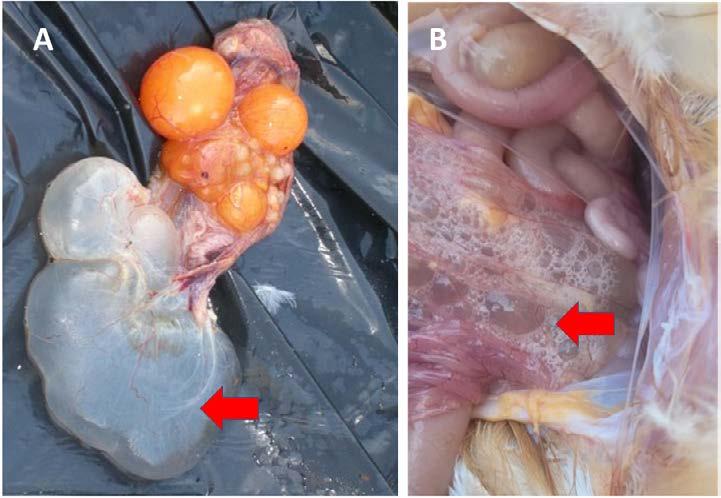

During post-mortem examinations, we observed the occurrence of cystic oviducts. They can often be linked to IB variant 2 infections that could have occurred during the first weeks in the life of the pullet. Although such early infections are normally not accompanied by high mortality rates, the multiplication of the IB variant 2 virus in the oviduct results in abnormal development of this organ, with subsequent thinning of the wall, accumulation of fluid, and formation of cysts (Figure 1). When birds with cysts reach sexual maturity, the progression of the yolk through the oviduct towards the uterus becomes impossible and the egg cannot be formed.

Oviductal cysts are an incidental finding during post-mortem examinations. It is impossible to detect birds with cysts by visually inspecting the

Figure 1. Two examples of oviductal cysts in layers (red arrows). In both, the oviduct presents very thin walls (atrophied) and it is filled with fluid. Picture B was taken in Lusaka (September 2022) in a 42 weeks-old bird from a layer flock positive to IBV variant 2.

26 ProAgri Zambia 83

Article supplied by Phibro

program with TAbic IB VAR206. This vaccine (developed from the IBV Variant 2 field strain) has shown to be highly effective in controlling field challenges by Variant 2 (as well as some other commonly circulating field strains), provided it is applied correctly.

It is necessary to remark that the inclusion of TAbic IB VAR206 at the hatchery is essential to minimise the chances of early infections in pullets, which are not unusual in Zambia. Hatcheries may be concerned about the possible spreading of IB vaccines (included TAbic IB VAR206) between chick boxes after hatchery vaccination, which could result in rolling reactions among chicks. However, studies have determined that such post-vaccination spreading does not occur, even if the boxes are very close to each other.

Tables 1 and 2 show two recommended vaccination plans to prevent infections by IB variant 2. The choice between them should be based on the

risk of infection at the farm.

As usual, inactivated (injectable) vaccines should be also included in the rearing vaccination program, according to local epidemiological situation. Whilst spray vaccination stimulates immunity mainly at the points of entry of the virus (eyes, nostrils, trachea), inactivated vaccines are essential for the generation of circulating immunity.

TAbic IBVar 206 can be combined in the same vaccination procedure with other IB vaccines (e.g. TAbic IB VAR) and with VH (against Newcastle disease), provided that no more than three vaccines are mixed at one time.

Some extra tips to improve vaccine effectiveness

Remember that, in order to maximise the vaccination effectiveness: 1. The water used for preparing the vaccine should be clean, free of chlorine and have a pH between 6-7.5. To achieve this, you can add

a commercially available chlorine neutralizing product to the water before adding the vaccine. Furthermore, the addition of some colourant will help you to evaluate the success of the vaccine application.

2. It is very important to ensure that the temperature of the water used in the vaccination process is kept between 6°C and 10° C as far as possible. For every degree above 10° C, the vaccine losses 3.3% effectiveness. Therefore, if the vaccine water is at 25° C, the vaccine will be (in the best of cases) 50% less effective.

3. Apply IB vaccine only in spray. The effectiveness of IB vaccines in drinking water is low and unpredictable.

As always, please consult your veterinarian before making any changes in your vaccination program.

Age Vaccine

Day 1 (Hatchery)

Day 12 to 14

Week 10 to 12

Just before transfer

Every 6 to 8 weeks post peak

TAbic IB VAR206

TAbic IB VAR206

TAbic IB VAR206

TAbic IB VAR206

TAbic IB VAR206

Age Vaccine

Day 1 (Hatchery)

Day 12 to 14

Week 10 to 12

Just before transfer

Every 6 to 8 weeks post peak

TAbic IB VAR206

TAbic IB VAR206

TAbic IB VAR

TAbic IB VAR206

TAbic IB VAR206 alternated with TAbic IBVAR.

Note: Research has shown that TAbic IBVAR can give good protection when used in combination with TAbic IB VAR206 in low-challenge areas – but not in high-risk areas.

Table 1. Vaccination program against IB variant 2 for farms under high infectious challenge conditions (when your farm and neighbouring farms have or already had the disease)

Table 2. Vaccination program against IB variant 2 for farms under low to medium challenge conditions (when the disease is in your region, but it has not yet been detected at your farm or neighbouring farms)

ProAgri Zambia 83 Extensive range of water storage tanks . Available in various colours. sales@rototankzambia.co.zm 0960 567 058 / 0971 926 953 Each tank is: • Built to withstand the demands of daily use and endure the elements. • Strong, reliable, durable and safe. • Manufactured from food-grade materials. • UV-resistant & non-toxic plastic Avoid low-quality tanks that let you down. Buy Roto Tanks for quality and longevity. ROTO AQUATANK www.facebook.com/RototankZambia • Easy to install • Fits all pipe sizes • Height adjustable • No rust • Durable • Easy access to pipe intersections and valves Plastic manholes and covers for sewerage and communication

Sheep raised for mutton Sheep breeds part 1:

by Natasha Kruger

Dorper sheep

I n South Africa, the Persian sheep, the Dorset sheep, and the Van Rooy sheep were used to create the Dorper breed. This process produced a robust, quick-growing meat breed well suited to areas with insufficient precipitation.

Dorper sheep have white bodies and black heads, and they are very strong and sturdy. The White Dorper has a white head. Lambs of this rapidly maturing, fertile breed are ready for the slaughter at only four months of age. The breed's skin, which has a smooth grain and no creasing, can be used for leather without the need for shearing. Mature Dorper rams weigh between 90 and 120 kg, and ewes between 50 and 80 kg.

In addition to being hornless, this breed of sheep is also quite long and has a relatively light coat of hair. Both black and white heads are present in the breed, but the black head is the most common. The ewes are also great mothers because of their strong maternal instincts, ability to adapt, hardiness, rate of reproduction, growth (reaching 36 kg at 3,5 to 4 months), and feed conversion rate.

The Dorper has a year-round breeding season. A good manager can schedule lambing throughout the year. The breed is fertile, and the percentage of pregnant ewes is high. Eightmonth lambing periods are possible with good forage and management. In optimal conditions, lambing percentages of 150% and 180% are possible. Under extensive conditions, lambing rates of 100% are expected. In a flock with many maiden ewes, the lambing

percentage is around 120% because they only have one lamb. If the lambing percentage is 150% and ewes can lamb three times in two years, a Dorper ewe will produce 1,5 lambs per year.

The Dorper adapts well to different climates and grazing conditions. This breed was originally developed for arid areas, but it is now widespread.

The Dorper is hardy and can thrive in conditions where other breeds cannot, and the ewe can raise a quality lamb in harsh conditions. As a strong and nonselective grazer, the Dorper is easy to manage.

Blackhead Persian

It is believed that Somalia or the Middle East were the original homes of the Blackheaded Persian sheep, an ancient meat breed. The Persian sheep has a hairy, fat tail and thrives in hot, dry climates. Long, floppy ears are another goat-like trait shared by hornless sheep. Blackheaded Persians make up the vast majority (90%) of the breed, with redheaded Persians (4%), and speckled Persians (6%). Persians are excellent mothers with an even temperament. There is a high rate of twin births and an eight month breeding period. Mature

rams and ewes weigh approximately 50 and 30 kg, respectively.

Although the Blackhead Persian variety is raised solely for its meat, the skin can be used to create thin, highquality leather goods. The disease resistance of the Persian sheep breed has made it a favourite for crossbreeding with other types of sheep in an effort to increase their overall productivity as mutton sheep. The mature weights of Blackhead Persian rams are between 68 and 75 kg, and those of ewes are between 52 and 60 kg.

ProAgri Zambia 83 29

Dorper ram. (Source: alibaba.com)

Blackhead Persian ewe and lamb. (Source: persiansheep.com)

Blackhead Persian ram. (Source: persiansheep.com)

Dorper ewes (Source: rhyniepastoral.com.au)

Modular design and easy clean nozzles that make maintenance easier and more efficient. Advanced brake technology ensures a smooth and consistent movement, offering optimum control for a wide and uniform application.

AGRICULTURAL IRRIGATION | A Hunter Industries Company Learn More. senninger.com

30 ProAgri Zambia 83

NEW!

DRIVE

EXPANDING THE REACH OF THE LDN®

DYNAMIC

-

Pressure

High Pressure

| 60

of

and Growing Together

EXPERIENCE INNOVATION RELIABILITY Low

0.69 bar (10 psi)

1.03 – 2.07 bar (15 – 30 psi) Part-Circle 0.69 – 2.07 bar (10 – 30 psi)

years

Gratitude

Ile de France

The Ile de France sheep is a French mutton breed. Commercial farming with this breed only started in the 1970s in South Africa. The animals of this breed tend to be large and stocky. The face and lower legs are not covered in wool. The nose and lips are pink, and the rest of the face is white. Both rams and ewes are hornless (polled).

The Ile de France is a large, smoothbodied mutton breed, producing strong white wool of 23 to 27 microns. Wool can contribute up to 20% of this breed’s income. An average fleece weighs between 4 and 6 kilogrammes, and its staple length is between 7 and 8 centimetres.

However, most consider the Ile de France a meat breed only due to the rams’ use in crossbreeding to produce heavy, early maturing slaughter-ready lambs. The first lambing is at twentythree months, with few birthing problems. The Ile de France can be used for

Van Rooy ewe and lamb. (Source: learnnaturalfarming.com)

Meatmaster ewe and lamb. (Source: lasarusgamefarm.co.za)

Ile de France ram. (Source: chiledefrance.co.za)

Van Rooy rams. (Source: vanrooysa. co.za)

The Van Rooy is a large, hornless sheep, covered in white hair, and has a thin wool undercoat across its chest and shoulders. Its hefty tail and broad, rounded chest set it apart. Most of the body fat is concentrated in the back and tail.

The Van Rooy has a thick skin and is therefore less likely to be infected by parasites. The mature weights of Van Rooy rams are between 70 and 80 kg, and those of ewes between 50 and 60 kg.

The fertile Van Rooy is able to produce and raise lambs, even in harsh environments.

Due to their distinct genetic makeup, they are frequently used in hybridisation. The average age for a first birth is sixteen months.

Meatmaster

their milk and is classified as a dairy sheep in the USA. The mature weights of Ile de France rams are between 100 and 150 kg, and those of ewes between 70 and 90 kg.

Van Rooy

The fertile Van Rooy sheep is a type of meat sheep that was "developed" in South Africa and bred to perform well in the drier conditions typical of fat-tail breeds, such as those found in Southern Africa.

Another South African mutton sheep breed, the Meatmaster, is a cross between the Damara, Dorper, Van Rooy, and Ile de France. The objective was to create a meat sheep that could thrive in veld grazing systems and require minimal care and feeding. In 2007, the Meatmaster was recognised as a separate breed, and in 2008, the Meatmaster Breed Society was established to promote and protect the breed.

The Meatmaster is a medium-sized, non-fat-tailed sheep with a short, shiny outer coat and a short, woolly undercoat. Weaning weight for a Meatmaster

Meatmaster ram. (Source: swartmodder.com)

is 27 kg at 100 days of age. At five months old, a Meatmaster lamb weighs about 38 kg, which means it can be slaughtered for a 17,5 kg carcass. A mature Meatmaster ram weighs between 85 and 105 kg, and an ewe between 60 and 70 kg.

References

Breeds of Livestock - Booroola Merino Sheep — Breeds of Livestock, Department of Animal Science. (1996). Available at: http://afs.okstate.edu/breeds/sheep/booroolamerino/index.html

Ngcobo, J.N.; Nedambale, T.L.; Nephawe, K.A.; Mpofu, T.J.; Chokoe, T.C.; Ramukhithi, F.V. An Update on South African Indigenous Sheep Breeds’ Extinction Status and Difficulties during Conservation Attempts: A Review. Diversity 2022, 14, 516. Available at: https://doi. org/10.3390/d14070516

Sheep breeds. (2008). Department of Agriculture. Available at: https:// www.nda.agric.za/docs/Infopaks/ Sheep_breeds.pdf

Sheep Farming in South Africa. 2022. Available at: https://southafrica.co.za/sheep-farming-southafrica.html

ProAgri Zambia 83 31

Ile de France ewe and lambs. (Source: hasbargenlandcattle.com)

Facebook: @nutrifeedszambia (+260) 966 321 310 Facebook: @nutrifeedszambia

Ancient African food Part 5.5:

Yam bean and horned melon

by Tisha Steyn

African yam bean (Sphenostylis stenocarpa)

The African yam bean belongs to the family Leguminosae. The annual climbing or prostrate vine is mainly grown for its fleshy roots that looks like a sweet potato.

It flourishes throughout tropical Africa, where both seed and tuber are important components of the diet.

It is not well known as a food source outside Africa, although it is used as an ornamental plant in Europe and elsewhere. It is different from Mexican yam or yam bean that grows in Central and South America, and especially in Mexico and Brazil. There, this tuberous vine is grown mainly for the tuber because the seeds are toxic.

In nutritional terms, the African yam bean contains more than twice the protein of sweet potatoes, yams, or potatoes, and more than ten times that of cassava.

The protein is of exceptional nutritional quality, which complements the proteins of maize, sorghum, and the other staples.

Cultivation

The abundance of seeds and leaves are edible, and the plant seems capable of delivering record quantities of protein from soils normally considered marginal. In the traditional farm setting it is usually interplanted with yams and other vegetables in the traditional village farm setting.

The vine produces linear pods of between twenty and thirty centimetres long, each bearing twenty to thirty oval seeds that are usually cream, orangebrown, brown, or mottled brown.

Flowering occurs 80 to 130 days after planting, while the seeds reach maturity after 150 to 300 days.

In poor soil, the seed yield is about 300 to 500 kg/ha, but higher yields of between 2 000 and 3 000 kg/ha have been reported for fertile soils.

The plant yields tubers of 100 to 300 g/plant, with hectare yields estimated at about 2 000 kg in fertile soils.

The African yam bean grows best in areas where annual daytime temperatures are within the range of 23 to 29 ° Celsius, but it can tolerate 15 to 35 ° Celsius. It prefers a mean annual rainfall in the range 1 000 to 1 200 mm, but tolerates 800 to 1 400 mm.

The plant requires a dry period when it is flowering. It prefers a position in full sun. It grows best in a fertile,

sandy soil and prefers a pH in the range 5,5 to 6, but tolerates 4,5 to 7.

Although perennial, the plant is usually treated as an annual in cultivation. Plants are probably day length sensitive.