1 minute read

MODULAR PANELS

from INTEGRATED PROJECT DELIVERY SYSTEM (IPD) utilizing DESIGN for MANUFACTURING & ASSEMBLY (DfMA) -2

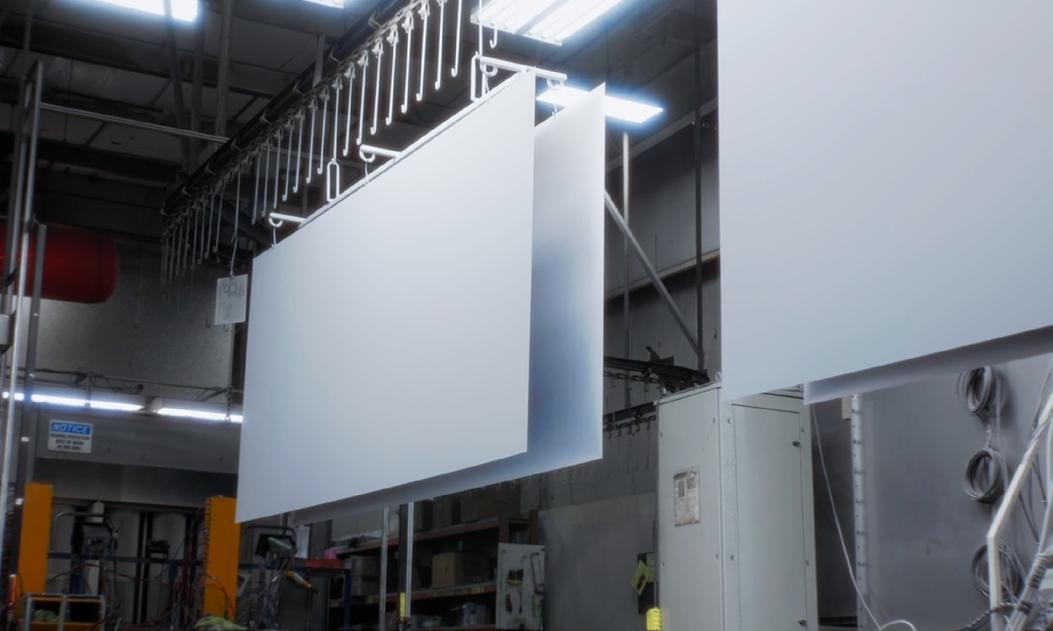

Our walls are prefinished 22 Gauge steel walls with sound attenuation and all required blocking.

Our pre-built walls are fully unitized, with all utilities (plumbing, electrical, etc.) in place

Easy to assemble and disassemble.

95% cut to fit in the factory, only posts and trim are cut on site, reducing mess, noise, and disruption.

Custom color matching available to incorporate client branding.

Dedicated Installation manager/ project management. Factory certified install network internationally.

Installation cost are “turnkey” and all-inclusive. To code fire suppression integration.

Our collective team includes a door company and a furniture company.

Furniture Vs Construction

Our premanufactured, demountable walls are considered furniture which limits permitting requirements and allows for acceleration depreciation, resulting in immediate savings to a corporation year one.

MANUFACTURING CAPABILITIES & CAPACITIES

We currently have the capacity to manufacture 1,600 panels a week. Our modular company is an Employee-owned company (2,500 employees worldwide) inclusive of the factory technicians. The average tenure of the manufacturing technicians is 15-years.

Our Modular Manitowoc, WI manufacturing facility is 225,000 square feet and has full fabrication, paint, and assembly capabilities to build wall product. The factory uses cellular manufacturing so it can easily scale up based on demand. The Manitowoc manufacturing facility also leases an 80,000 square foot warehouse to store raw materials and finished goods.