Hello and welcome to the latest edition of The Brewers Journal. In the blink of an eye 2025 hasn’t just started - it’s nearly a quarter complete.

But let’s get straight to the point. The hospitality sector has been under fire for a very long time. It is already in need of help and upcoming tax changes are going to make a tough situation for many even harder.

A recent joint survey from leading hospitality trade associations helped convey the sector’s fears of new employment costs and a reduction in rates relief will impact their businesses.

In short, 70% of hospitality businesses could be forced to cut employment when the new cost increases come into effect this April.

The figures from the British Beer and Pub Association, the British Institute of Innkeeping, Hospitality Ulster and UKHospitality also reveal that 60% of firms would put a stop to planned investment while 29% of respondents said they would reduce trading hours.

Hospitality was one of the major contributors to GDP growth in the last two months of 2024 so seeing 15% of those surveying say they will have to close at least one site makes for grim reading.

The trade bodies said that a delay to the changes to the employer NICs threshold would at least avoid the immediate impact on jobs and planned investment.

“These figures should serve as a clear warning that pubs, brewers and hospitality venues will be forced to make painful decisions to weather these new costs, which will have damaging impacts on

businesses, jobs and communities,” they said in a statement.

“At a time when hospitality has been one of the top contributors to economic growth, the last thing the Government should be doing is piling on costs that will impact employment and cut off our ability to grow.”

If it doesn’t act then businesses are clear that the impact on communities, employees and supply chains will be significant.

“Our message to Government is to delay its changes to the employer NICs threshold and allow hospitality to continue to deliver economic growth, regenerate our high streets and support local communities,” they conclude. And I, for one, fully agree. It needs help, and it needs it now.

Looking ahead in 2025, I’m thrilled to announce that our Brewers Congress and Brewers Choice Awards return once again this year and we have a new home - The Big Penny Social in London. Located just off Blackhorse Lane, Walthamstow, the two-day event will feature everything you’ve come to expect from The Brewers Congress and much, much more.

For up-to-date information on all of our events, including our Brewers Lectures, please visit www.brewersjournal.info

Until next time,

Tim Sheahan Editor

Comment | Waste

The UK’s SME manufacturing sector is under constant pressure to improve efficiency, reduce waste, and remain competitive in an increasingly challenging marketplace. Made Smarter outline some of the ways breweries can help achieve this.

Comment | Training

There is an increasing need for staff to be educated on the broad range of beer styles available. There are many benefits that come with it, too, explains WSET’s Natalya Watson.

Dear John

Different beers suit different dispense methods. And everyone tends to have a preference. But where do you stand? One thing is for certain, John Keeling knows his favourite.

Brewers Intelligence | Spring

The latest insights and expertise from across the field of ingredients and sales.

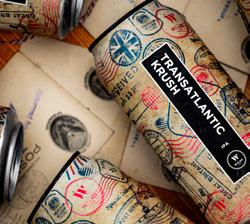

Labelling and Packaging

In today’s competitive craft beer market, standing out on the shelf is just as important as what’s inside the bottle or can.

Business Transformation

To meet changing demands brewers can build flexibility into their existing spaces and introduce modular approaches. Chris Sparrow, director of architecture at Niras a consultancy, engineering and delivery partner in the Food & Beverage sector, explains when and how.

Events

The upcoming beer and brewing industry events you can’t miss throughtout 2025

30

The story of Wye Valley Brewery A business historicaly known for its consistent and quality cask output, Wye Valley is thriving and growing as it celebrates its 40th anniversary.

48

Homebrew | Kevin Robinson

In starting Vibrant Forest, Kevin Robinson created a much-loved brewery. But before then he had a storied homebrewing background, one that still informs the ethos of the Hampshire business today.

Tim Sheahan Editor tim.sheahan@reby.media

+44 (0)1442 780 592

Tim O’Rourke Technical Editor

John Keeling Contributor

Josh Henderson Head of sales josh.henderson@reby.media +44 (0)1442 780 594

Jon Young Publisher jon.young@reby.media

Reby Media 42 Crouchfield, Hemel Hempstead, Herts, HP1 1PA

The Brewers Journal is a published four times a year and mailed every March, June, September & December. Subscriptions can be purchased for four issues. Prices for single issue subscriptions or back issues can be obtained by emailing: subscribe@ reby.media

UK & IRELAND £45 INTERNATIONAL £69

The content of The Brewers Journal is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service. The Brewers Journal is printed at Manson Group, St Albans, UK.

46

Technical | Quality

How rapid FT-IR technology enables brewers to test key parameters throughout the brewing process, gain full control of your fermentation process and save time, energy and money.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the publisher. The Brewers Journal ISSN 2059-6650 is published bimonthly by Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG. Subscription records are maintained at Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG.

The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom.

As of January 2025 there are 100 fewer breweries in the UK compared to the same month one year ago. While there are new businesses opening and an ongoing demand for quality, independent beer, this hasn’t stemmed an ongoing drop in the numbers of breweries trading.

According to the new figures, released by SIBA’s UK brewery tracker, there are now 1715 brewery businesses in operation. This is 100 down on the 1815 from last January and a greater drop when compared to year-on-year figures between 2023 and 2024.

Factors including legacy Covid debt, restricted access to market via pubs, and tight margins for small breweries have all attributed to this decline, explain Society of Independent Brewers and Associates (SIBA).

Andy Slee, SIBA chief executive, said: “The consumer appetite for independent beer is high and our indications suggest volumes for independent beer at the end of 2024 were up on 2023 – the issue for small independent breweries is lack of access to market and rising costs,

making it incredibly difficult to remain profitable. Speaking to many indie brewers who have closed their doors over the last twelve months it is a very similar story; they can’t sell into enough of their local pubs and make enough of a profit to remain viable.”

“Given the demand for independent beer isn’t being met locally you have to wonder whether more local beer in community pubs would help pub closure rates as well.”

While breweries have continued to close, the rate at which this is happening has slowed over the course of the year while Wales recorded a modest increase over 2024.

According to the figures, the average closure rate in percentage terms across the UK was around 5.5%.

Northern Ireland had a relatively small shift in their net number of six fewer breweries but in percentage terms this was by far the highest and accounted for more than a 20% reduction in the overall number of brewers.

And areas that have a higher density of breweries such as the South East recorded a bigger drop in overall brewery number terms but a percentage drop of around -7%, which is comparable to a similar sized region in like the Midlands.

Slee explained: “Brewery closures were at their highest in the first quarter of 2024 and steadily and encouragingly declined throughout the year, with the slowest rate of closures recorded in Q4 leading up until the end of December.

“As we begin 2025 our hope is that the dial continues to turn in the right direction and we see stable or even growing brewery numbers in the UK; however this will not happen without greater support from Government for the hugely valued indie brewers all across the UK.”

Dave Tugwell is the co-founder of Red Fin Cider and has a wealth of hospitality industry experience. He told us that while this figures are alarming, they should “come as no real surprise for anybody working at the coalface of our wonderful industry”.

He added: “Increases in costs now more than ever have put pressure on margins.

As an industry we need to embrace new, creative ideas and new technology to secure the future,”

Dave Tugwell, Red Fin Cider

It’s also proving harder for pubs to pass these on to the consumer which is completely understandable when they are trying to maintain a level of trade and margin that means they can survive.

“It’s now more important than ever to highlight to people outside of the ‘craft beer bubble’ that supporting our rich heritage and vital tapestry of breweries is so important but also comes at a premium.

“How we convey why consumers should put down the 4 pack of Madri and pick up some beer or cider from a local brewery is crucial. If the last 15 years are anything

to go by, we would have to assume that breweries will get little or no support from the government so we as an industry need to embrace new, creative ideas and new technology to secure the future.”

These brewery closures come at a time of consolidation in the industry, too.

Earlier this year, Keystone Brewing Group confirmed it had secured the future of beer brands Magic Rock and Fourpure, with both joining the group’s growing portfolio.

Since 2022, the holding company In Good Company Brewing has owned both brands, but in recent months, it had fallen into financial difficulties.

Keystone CEO Mark Williams commented: “Keystone Brewing Group has secured an exclusive license with the brand owners to take these fantastic brands forward in the UK and worldwide.

“We have managed to save two iconic beer brands for future generations of beer lovers, following Keystone’s strategy of building an impressive portfolio of

high-quality and distinctive beverages.” These brands join the growing beer brand and cider portfolio that include North, Black Sheep, Purity, Big Drop, Brick, Brew by Numbers, Wolf Pack, and premium cider brand Maison SASSY.

And last Autumn, Gipsy Hill Brewery was acquired by Sunrise Alliance Beverages, the UK brewing group, that owns St Peter’s Brewery, Wild Beer Co, Curious Brewing and Portobello Brewing.

Gipsy Hill will became part of the Sunrise Group, with Sunrise investing into Gipsy Hill, demonstrating a “strong commitment to support its long-term success, preserving its unique brand identity and sustainability ambitions, while ensuring continued quality and growth”.

Gipsy Hill said it will maintain its independence with day-to-day operations and brewing remaining in the hands of co-founder and Managing Director, Sam McMeekin, and his dedicated team.

Production stays at Gipsy Hill’s existing facilities, upholding the brand’s focus on

quality, sustainability, and community.

“This is an exciting time for us at Gipsy Hill. This strategic partnership allows us to keep doing what we do best: brewing exceptional beer for our loyal customers,” said Sam McMeekin, co-founder of Gipsy Hill.

“Sunrise Alliance Beverages shares our vision for quality, customer service, community, innovation and sustainability, and this partnership will empower us to continue to thrive and innovate.”

Richard Mather, Sunrise Alliance Beverages’ CEO, added, “We’re very excited to embark on this new partnership. Gipsy Hill is a fantastic business with excellent beers, strong brands and loyal consumers.

“Our union will enable Gipsy Hill to benefit from our group’s collective resources and operational efficiencies, while retaining its autonomy and character. We look forward to working with Sam and his team to enhance these strengths as a group of independent UK brewers.”

Jennings Brewery located in Cockermouth, Cumbria, has been acquired by two local business owners and entrepreneurs.

The acquisition of the brewery for an undisclosed sum will see two local business owners, Kurt Canfield (CEO of specialist engineering business Delkia) and Rebecca Canfield (Proprietor of wine and spirits company Wine and the Wood), take ownership of the brewery site, with the intention to resume brewing Jennings beer in Cockermouth following the brewery’s closure in 2022.

The deal also involves the transfer of rights to the Jennings brand, including all trademarks, intellectual property and recipes. Bottled beer under the Jennings brand will continue to be sold by Carlsberg Britvic until March 2025, following which beer production will transfer to the new company – Jennings Brewery Ltd.

Murphy and Son, which offers rewing supplies and consultancy, and the University of Nottingham’s International Centre for Brewing Science have launched a new partnership. As part of this expanded relationship, Murphy and Son’s laboratory and R&D team will be relocating to the Centre for Brewing Science.

This move will provide them with greater access to state-of-the-art facilities, enabling the company to offer more comprehensive product testing services to their customers and expand lab testing offerings to include a wider range of analysis for wine, cider, spirits as well as brewing.

“By relocating our lab and R&D team to the Centre for Brewing Science, we can leverage advanced facilities to better serve our customers and expand our testing services,” said Charles Nicholds, managing director of Murphy and Son.

A new “cutting-edge” seam analysis product line, designed to meet the quality and budgetary needs of craft beverage producers has been launched.

Manufactured by Innovus Engineering, the comprehensive system includes a lightweight beverage seam saw, a seam inspection camera, SeamVision software, a seam thickness gauge, and a countersink depth gauge.

Recognising the lack of affordable, high-quality seam inspection options for smaller beverage producers, Innovus Engineering has stepped in to provide a solution. The new product line delivers exceptional performance and functionality at a price point accessible to craft beverage producers without compromising on quality.

“Our goal was to empower smaller beverage producers with tools that rival those of large-scale manufacturers” said Michael McClue, commercial director at Innovus Engineering. “From the outset, we were determined to develop software that simplifies the inspection process for craft beverage producers,” McClue added. “SeamVision’s intuitive design and extensive features set it apart in the industry. It’s a game- changer, particularly for co-packers managing multiple client records.”

Gosport-based Powder Monkey Group has expanded following the acquisition of Goddards Brewery with Powder Monkey now “The Home of Goddards”.

Goddards, the oldest brewery on the Isle of Wight, was one of the first independent craft beer producers in the UK after starting out in 1993.

Originally based at Barnsley Farm near Ryde, in 2023 the brewery relocated to a bespoke built brewing centre near Arreton.

Following the acquisition, Powder Monkey “The Home of Goddards” will

both brew and sell the Goddards range completing it’s exisiting portfolio.

Andy Burdon, CEO of Powder Monkey Group, explained: “We opened our facilities in Priddy’s Hard, Gosport in 2021. Since then, Powder Monkey beer has been flowing in the Tap House, at events and our award-winning beers are available in can and keg for a wide range of stockists.

“We are delighted that Goddard’s is now part of the group, it adds cask and bottled beer to our portfolio as well as the Heritage associated with the brand.”

Anthony Goddard added: “We are delighted to join the family of coastal breweries in the Powder Monkey Group brand portfolio where we join strong brands with equally strong heritages. Since our modest start, we have brewed about 13.5 million pints of Goddards beer over 32 years.”

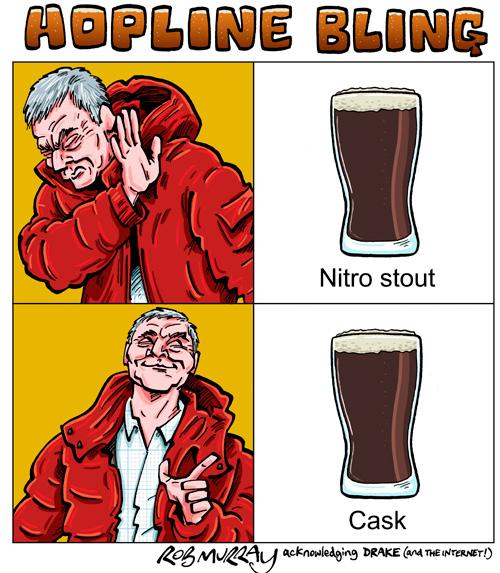

Lallemand Brewing has partnered with EvodiaBio, an award-winning Danish bioindustrial start-up, to launch Yops, a new yeast-derived aroma solution designed to enhance the flavour profile of low- and no-alcohol beers (NABLABs).

Lallemand said partnering with EvodiaBio allows them to take this one step further by providing brewers with a natural, highquality, and consistent aroma solution. Yops enables brewers to address the challenges of crafting NABLABs by restoring the hop aroma compounds often lost during production, resulting in full-bodied and aromatic beers, they said.

Through a patent-protected yeast fermentation process, EvodiaBio has developed an efficient method to produce some of these critical aroma molecules.

Leveraging yeast capabilities to produce flavours, Yops provides brewers with a new level of control over the aroma profile of their beer in a natural manner, allowing them to achieve the desired fullness of taste and consistency.

THE UK’S SME MANUFACTURING SECTOR IS UNDER CONSTANT PRESSURE TO IMPROVE EFFICIENCY, REDUCE WASTE, AND REMAIN COMPETITIVE IN AN INCREASINGLY CHALLENGING MARKETPLACE. HERE THE TEAM AT MADE SMARTER OUTLINE SOME OF THE WAYS BUSINESSES SUCH AS BREWERIES CAN HELP ACHIEVE THIS.

With rising costs and economic challenges, making the most of existing resources has never been more important.

In 2025 your business cannot afford to waste time or resources. Digital tools and automation can help businesses optimise operations, reduce downtime, and improve overall productivity.

Manufacturing inefficiencies stem from poor visibility over operations. Collecting, analysing, and integrating data from across the business – from stock levels to machine performance – allows for more informed decision-making.

Enterprise Resource Planning (ERP) systems help manufacturers consolidate business processes into a single, streamlined platform.

SMEs that implement ERP solutions benefit from enhanced order tracking,

reduced manual errors, and improved stock management.

Case studies show that UK manufacturers who implement digital tracking and automation see significant benefits.

For example, Ipac Packing Innovations were struggling to accurately keep track of stock across their two sites.

With Made Smarter’s help they implemented a WMS system into its existing ERP system, providing barcoded locations of every area across its two sites. This has created cost savings, particularly around stock levels and the increased productivity has opened up further business growth for iPac.

Unplanned downtime can cost manufacturers up to £24,000 per hour, yet 80% of companies struggle to

accurately quantify this impact. Beyond financial losses, downtime affects workforce morale and operational efficiency. Digital tools such as predictive maintenance systems and real-time data monitoring can help manufacturers preempt potential issues before they cause disruption.

Playdale, a UK play equipment manufacturer, used real-time performance data to optimise maintenance schedules, reducing downtime and improving productivity.

An area where manufacturers can also benefit is in minimising material waste. Digital tools, such as real-time quality control and automated tracking, help businesses reduce material losses, ensuring that only necessary resources are utilised in production.

Repetitive tasks can lead to inefficiencies and disengagement among employees. By automating routine processes, businesses can free up employees to

focus on higher-value tasks. Horsforth Brewery worked with Made Smarter after identifying the need for automation in its canning line.

This investment increased production capacity by 150%, rising from two hundred cans per hour to five hundred cans per hour. Importantly, the new system only requires one person to operate it, compared to the two staff members needed previously.

Before making costly investments in new equipment or facilities, manufacturers can use Digital Twin technology to create virtual simulations of their factories. This approach enables better decisionmaking by allowing businesses to evaluate and optimise layouts before implementation.

A UK aerospace manufacturer, MSM used this technology to design a state-of-the-art factory, maximising

productivity while minimising costs. Digital technology is revolutionising UK SME manufacturing by reducing costs, improving efficiency, and enhancing workforce engagement. Whether through predictive maintenance, ERP systems, or automation, businesses that embrace digital transformation will be better positioned for long-term success.

With programmes like Made Smarter, SME manufacturers can access the guidance and resources needed to future-proof their operations and remain competitive in a digital-first world.

FROM BREWERS AND BUYERS, TO BARTENDERS AND BOTTLE

WORKERS, THERE IS AN INCREASING NEED FOR STAFF TO BE EDUCATED ON THE BROAD RANGE OF BEER STYLES NOW AVAILABLE TO THEM. AND THERE

With the global drinks landscape continuing to develop and evolve, it’s never been more important for those of us working with beer to stay on top of trends and to sharpen our knowledge and skills to help contribute to the industry’s ongoing development and success. More premium products and a broader range of beer styles have become available on the bar over the last few years, leading to a greater interest from customers and therefore an increased need for staff – from brewers and buyers, to bartenders and bottle shop workers – to be educated on these products alongside the wider world of beer and brewing.

From accurately describing flavour profiles to making recommendations and serving drinks correctly, a well-rounded knowledge of beer is key.

Product knowledge isn’t the only benefit from beer training though. Staff that are equipped with the right know-how are more engaged with your brand, more confident with your products, and more likely to stay with your organisation. But given these benefits, why aren’t we seeing more businesses invest in beer education? There are of course a variety of factors at play here, but two key points to consider.

The first is that, for probably too long, drinks education has primarily been associated with the world of wine and spirits.

For whatever reason, many have considered beer to have played ‘second fiddle’ to other types of drinks when it comes to being able to learn about it in greater depth.

Secondly, while there have been training programmes and formal qualifications available to the beer industry, what’s on the market today isn’t meeting the industry’s needs. Why?

Much of the available training is brandled, meaning it focuses more on brand stories and tasting notes for a specific set of beers, not on general product knowledge and tasting skill development. Additionally, the formal qualifications out there have typically been targeted to specific job roles, are quite advanced, and often require candidates to prepare through self-study, without any educator support.

Fortunately, that’s all changed, as a new approach to beer education is now on offer and it’s already making a massive impact on the industry – the WSET Level 1 & Level 2 Awards in Beer.

The world’s leading provider of drinks education, WSET (Wine & Spirit Education Trust) has over 55 years of experience in the industry. You may not be familiar with WSET though, because until last year, we exclusively offered qualifications in wine, spirits and sake. Noticing the above trends, we decided to develop beer qualifications to fill the gap in what was currently available on the market.

We carried out in-depth consultancy with sensory and technical experts on the

content and applied our own teaching knowhow, before launching our new beer qualifications in February 2024.

As with all WSET qualifications, our beer courses are designed to improve a students’ product knowledge, tasting skills, and professional confidence. (They’re intended to be fun, too!)

WSET’s new beer qualifications cover topics like beer’s ingredients and the brewing process, the principles of storage, service and food pairing, and beer style characteristics.

Our Level 1 course is a beginner level qualification that focuses on the foundations of these topics and includes 20 key beer styles.

Level 2 is intermediate-level and covers these topics in greater detail, including over 60 different beer styles and specialty beers. In WSET structure, Level 1 is not a requirement for Level 2. In addition to the theory, WSET courses also focus on the development of tasting skills. We use our unique Systematic Approach to Tasting Beer to enable candidates to calibrate their palates and develop their ability to taste, describe and assess the quality of beer.

We then connect the flavours found in the glass with the ingredient or process choices that introduce them, in what we call linking theory to tasting.

Our mission is to empower people with inspiring learning experiences all over the world. By the end of the course, students will be able to make product recommendations, answer customer questions, and taste and describe any

beer on the bar with confidence. With decades of experience in the drinks education space, we’ve honed our expertise in delivering drinks training. Our courses are taught by rigorously trained expert educators. We provide course materials that cover all examinable content so students can feel confident that they’re exam-ready. We’ve designed our qualifications with multiple industry roles in mind – from service, sales and marketing, to production and finance – to deliver brand-neutral product knowledge and training for everyone on your team. Lastly, we meet your team where they are. Our courses are available both in-person or online, and you can start

with our beginner- or intermediate-level qualification, depending on your team’s current level of beer knowledge and confidence.

We’ve trained the sales team from Asahi UK, Heineken UK’s Marketing team, front of house staff at the Guinness Storehouse and Open Gate Brewery, alcohol-free beer brand Lucky Saint, and many more individual hospitality professionals and enthusiasts.

Of the candidates trained so far, the vast majority have agreed that WSET’s beer qualifications improved their product knowledge, tasting skills, and beer confidence, and strongly agreed that they had fun while learning.

Training benefits your team – and your business – with so much more than product knowledge. It’s been demonstrated to increase customer service, profitability, productivity, staff retention, and self-esteem.

And the perfect training solution for the beer industry is now available from WSET: courses and qualifications that deliver product knowledge and tasting skills, for those totally new to beer or who are looking to deepen their understanding, offered in-person or online, and for teams of any size.

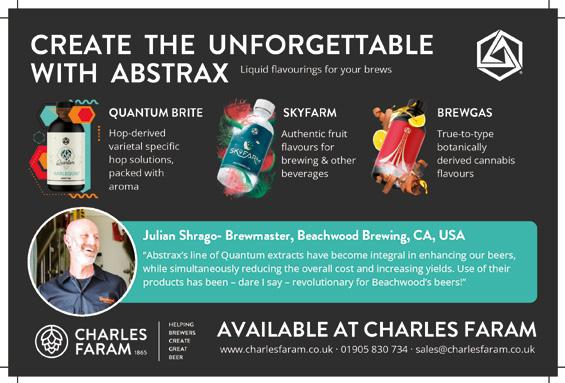

Cask of course is the best.

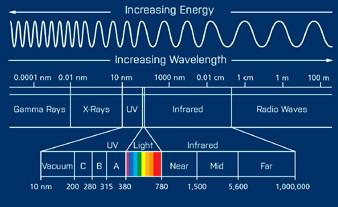

Well, that was a short column this month. Hope the cartoon is good! Cask is my favourite, it’s the beer I was brought up on. Lower alcohol ale (less than 5.5% ABV) has an ideal flavour profile for cask. Session ale is my favourite beer style although cask porter and stout are very good too. There are other reasons why cask is best other than my opinion and one of these is mouthfeel. The carbonation (at about 1.3-1.4 vols CO2) is perfect for the session ale flavour profile. It’s perfect for pub drinking too. Carbon dioxide does change the way we perceive flavour. Too little and the beer tastes dull and lifeless. Too little for cask is below 1.1 vols in my opinion. Too much carbon dioxide makes the flavour bland and one dimensional. That is why bottle versions of session ale are frequently disappointing. Over two volumes of CO2 are just too much. Let’s face it session ale does not work as well in bottle as in cask. The other main reason is temperature. Cask beer is served at between 11 and 13 degrees centigrade and again this is a perfect temperature for a session ale. Sure, it will warm after serving just like any other beer but unless you leave it for too long it is fine. If the temperature is too low again the flavour profile becomes blander but in addition to this because CO2 is more soluble at lower temperature it loses some of its sparkle. So, in short, good cask beer has a perfect

harmony of flavour, temperature and conditioning.

So, what about keg? I find it produces an inferior session ale being over carbonated and too cold. It completely ruins the balance of the beer. However, in order for keg to shine it needs a stronger flavoured beer to overcome the effects of higher carbonation and lower temperature.

Did someone say lager? I think keg is ideal for lagers above 5%ABV and below that, with some exceptions, they tend to be bland. I remember when (yes, I know it’s another anecdote but at my age what do you expect) in the seventies keg lager was around 3.1 % ABV. It’s no wonder CAMRA were formed.

But what about ale? Yes, certain styles suit keg too but again they have to be stronger. That is why generally where possible, and the cost is not too high, Fuller’s keg beers are stronger versions of the cask beer. An example of a beer suited to keg is American IPA for instance (I naturally prefer English IPAs but at my age what do you expect. Have I used that before? God I am getting old…) So, in short to overcome the higher CO2 content and the lower temperatures a different flavour profile is needed which usually means higher ABV.

Now for nitro pour and I must admit I have always had a problem with this. I find it is too heavy and it sits on my stomach. The mouthfeel is unnatural to me and this makes nitro beers virtually undrinkable for me.

Guinness invented the nitro pour as the closest approximation to the way Guinness was poured way back when. Even before I was drinking. It was supposed to replicate the creamy texture of the beer but easier to pour and dispense. This made Guinness the beer it is today. Very successful but not a beer I like.

Now I have met many Guinness people and a lovely bunch they are. I love the image of Guinness, and I wish I could drink their beer but unfortunately, I can’t.

I find nitro pours too heavy and they sit on my stomach,” John Keeling

My favourite Guinness by far was the old bottle conditioned beer which was superb. They stopped doing this beer and introduced nitro can. This too has been very successful so what do I know… You might know that Fuller’s produce a nitro stout called Black Cab and I admit that I can manage a pint of this. This is mainly due to its malty coffee flavour which provides a better balance although I greatly prefer the beer on cask. Anyway, I’m just off to the Post Office to get my pension. See you next time.

LALBREW POMONA IS THE NEWEST YEAST IN THE LALLEMAND LALBREW RANGE, SELECTED BY ESCARPMENT LABS IN CANADA. THE STRAIN WAS CHOSEN FOR ITS ABILITY TO PRODUCE DELICIOUS HOPFORWARD AND HAZY IPAS WITH A VARIETY OF STRENGTHS. HERE ALIX BLEASE, TECHNICAL SALES REPRESENTATIVE AT LALLEMAND BREWING, DELVES INTO THE ORIGIN STORY OF THIS YEAST AND LOOKS AT WHERE IT CAME FROM.

Yeast hybridisation can be used to improve a number of yeast characteristics, for example; sugar utilisation, temperature tolerance or, in this case, aroma production. Lalbrew Pomona actually started its life as two different yeasts. Sterling, a ScottishBritish yeast with great fermentation characteristics but low aroma; and Cerberus, an STA1 positive saison strain, which has excellent aromatic qualities but is a diastatic yeast, meaning it would break down unfermentable sugars. These yeasts were selected as the two parent strains from which a variety of hybrid yeasts were created using the “rare mating” technique.

There are two methods for creating hybrids from mating yeast, spore-tospore and rare mating. In spore-to-spore the parent yeast cells create spores which are then selected and combined. The equipment required for this is very expensive, however this method is incredibly efficient.

The second method, and the one used to create LalBrew Pomona, is rare mating; in this case thousands of cells from each parent yeast are mixed together and then the mixture is “screened” for the occurrence of hybridisation events. To make sure that the hybrids are identifiable, the parent cells are modified

so that the synthesis of one compound is inhibited in each. In the case of Lalbrew Pomona one parent cell was unable to synthesise uracil and the other lysine (this might sound familiar because it’s how they “contained” the dinosaurs in Jurassic Park). Hybrid cells can be identified because they will be able to produce both compounds, lysine and uracil, proving that genetic material has been exchanged and a hybrid has formed. This method is more labour intensive, but it can be achieved with relatively basic equipment.

Once all the hybrid cells have been identified their genetics need to be evaluated as well as their fermentation characteristics. In the case of LalBrew Pomona, one of the parents was a vigorous fermenter, while the other had great aroma. The resulting hybrid needed to have broad attenuation and good aromatic qualities; as well as not being diastatic (containing the STA1 gene).

Once the desired hybrids were selected, it became apparent that these hybrids didn’t have the required attenuation range or haze formation. The hybrids were further transformed using Adaptive Laboratory Evolution, coincidentally, ALE for short. ALE can be used to expose yeast to specific environmental conditions or to enhance certain metabolic capabilities.

Yeast is grown and then repitched in controlled stressful environments, for example extreme temperatures or high alcohol concentrations.

This promotes mutations in the yeast to become resistant to these conditions. It is essentially survival of the fittest but on fast forward.

Throughout this process the yeast population are regularly screened to identify any beneficial genetic mutations which may have occurred.

The hybrid selected from the rare mating of Stirling and Cerberus parent strains went through ALE in high gravity and heavily dry-hopped worts. This happened over 107 days and 48 successive transfers or re-pitches. The resulting yeast was screened for attenuation, haze formation and biotransformation ability.

The LalBrew Pomona strain pushes peach and stone fruit aromatics and is also compatible with a wide range of ABVs from session pale ales to triple IPAs. Research from Oregon

State University and Niagara College compared LalBrew Pomona and LalBrew Verdant IPA fermentations.

LalBrew Pomona showed a slightly higher affinity for fermenting maltotriose than LalBrew Verdant IPA resulting in a slightly higher ABV beer.

LalBrew Pomona also showed excellent liberation of (the very trendy) thiols, as well as a lesser known group of compounds called lactones.

Lactones are very well studied in winemaking, however there is very little research on their aromatic impact in beer. Lactone compounds are generally described as oily, coconut and peachy. In wine (and beer) they have been shown to have a compounding effect on the aromatic thresholds of terpenes and thiols.

This means that the presence of lactones in concentrations lower than threshold amounts will increase the perceived aroma and flavour imparted by terpenes and thiols. An analogy which can be made in beer is adding a handful of

Sabro (coconut) hops when brewing a tropical IPA. Although the beer won’t taste like coconut, the presence of this flavour increases the perception of tropical fruit in the beer.

The feedback on LalBrew Pomona wfrom our commercial trials was overwhelmingly positive; the beers created were described as citrus, tropical and peach!

WITH BARLEY THE PRIMARY RAW MATERIAL USED IN MALTING ACROSS THE WORLD, ANY FLUCTUATION IN THE PRICE OF BARLEY HAVE A DIRECT IMPACT ON MALT PRICES. AND MOVING FORWARD, AS THE GLOBAL DEMAND FOR CEREALS CONTINUES TO GROW, AND CLIMATE AND TRADE UNCERTAINTIES PERSIST, BARLEY PRICES AND MALT COSTS WILL REMAIN SUBJECT TO FREQUENT CHANGES, EXPLAIN THE TEAM AT SIMPSONS MALT.

Barley is a crucial commodity in a range of industries, including food production, animal feed and, of course, brewing and distilling.

However, the price of barley doesn’t operate in isolation and is deeply influenced by broader global cereal markets, which includes other commodities such as wheat and corn. In this article, we provide some insight into how these markets function and highlight how, ultimately, barley prices and malt costs are very closely linked. Cereal markets are highly interconnected because barley competes for the same

agricultural resources as the likes of wheat and corn. Any shift in dynamics or fluctuations can directly impact the price of barley, setting off a chain reaction through the malting industry and beyond. There are several factors that affect the pricing of barley and the wider global cereal markets and here, we take a deeper dive into four of these.

Barley competes with wheat and corn, especially in the animal feed market. When the prices of these cereals rise, buyers may turn to barley as a cheaper alternative. For example, a drought in a major wheat-producing region may drive wheat prices up, leading to increased demand for barley. On the other hand, when wheat or corn prices drop due to oversupply, barley becomes less competitive, so its price goes down.

Understandably, farmers take into consideration the allocation of their land for cropping based on the profitability of each crop. So, if wheat or corn prices soar due to global demand, farmers may choose to sow those crops instead. This leads to a scarcity of barley which will drive prices higher, especially in regions where barley is already in limited production.

In England, the expansion of Sustainable Farming Incentives (SFIs) – a government scheme that pays farmers and land managers to adopt and maintain sustainable farming practices – may also affect farmers’ cropping decisions moving forward.

Major barley-exporting countries like Canada and Australia also produce other cereals. Global trade policies, tariffs, and

geopolitical events that affect the export of the other cereal crops can influence barley prices.

For instance, if a country restricts wheat exports, it might increase its barley exports to fill the gap. This alters global barley supply and prices.

From a geopolitical point of view, prior to the war between Russia and Ukraine, the latter accounted for around 10% of the world’s wheat exports.

In the early months of the war, concerns rose about whether, firstly, Ukrainian farmers would be able to harvest their crops at all and, secondly, whether the harvested crops would be able to be exported.

As a result, wheat prices – and consequently prices of other commodities, including barley – rose to, in most cases, record highs.

Extreme weather conditions, such as droughts, floods, or unseasonal frosts, can drastically reduce crop yields, including barley. When production is hit in key regions, global prices spike, impacting barley and other grains simultaneously. Climate volatility in major barley-producing regions can therefore drive-up barley costs and disrupt supply chains.

So how does barley pricing affect malt costs? Barley is the primary raw material used in malting across the world and is chosen due to favourable characteristics such as its high enzyme and starch content. Because of this, it means that any fluctuations in the price of barley have a direct impact on malt prices.

Moving forward, as the global demand for cereals continues to grow, and climate and trade uncertainties persist, barley prices and malt costs will remain subject to frequent changes.

IN AN EVOLVING INGREDIENTS LANDSCAPE, FLOWABLE HOP EXTRACTS CAN CAPTURE HOP AROMA ATTRIBUTES WHILE DELIVERING THEM TO YOUR BEER IN EASYTO-POUR BOTTLES. AND HERE, THE TEAM AT YAKIMA CHIEF HOPS HELP OUTLINE HOW STRATA IS THE LATEST ADDITION TO THAT BREWING FABRIC.

Previously known as formerly YCH 701, HyperBoost is described as a concentrated hop oil extract produced via a novel supercritical extraction technique. Intended to amplify hop aromatics and increase yield, HyperBoost excels at adding beautiful hop aroma anywhere pellets are normally used, including cold-side applications. It is made from single-hop varieties to deliver variety-specific aroma boosts to your finished beer.

The product is designed to easily pour in your fermenter as a cold side addition, adding an intense saturation of hop flavour to your finished beer.

Most brewers choose to use HyperBoost as a fermenter addition, but it can also be added to the whirlpool. Using HyperBoost in place of traditional pellets can increase finished beer yield.

And at the beginning of this year Yakima Chief Hops (YCH) joined forces with Oregon-based Indie Hops to introduce a new offering to brewers: Strata HyperBoost. This marks the first collaboration between the two hop suppliers, combining Indie’s well-known and much-loved Strata variety with YCH’s HyperBoost formula.

“Indie Hops has always approached customers with a mutual interest in making great beer, so it’s natural that Indie Hops and Yakima Chief Hops have entered into a product collaboration to bring brewers the first Strata HyperBoost,” explains Ryan Hopkins, CEO of Yakima Chief Hops.

“Indie has been a great partner to the brewing industry in developing hop varieties that bring new and unique flavours to brewers, and they’ve always been a strong advocate for family-owned and operated farms.”

Indie Hops CEO Jim Solberg added that collaboration is a big deal between craft brewers and can be “a good thing between hop suppliers as well”. Strata, celebrated for its unique aroma profile of passion fruit, grapefruit, strawberry, and wafting cannabis, has become a favourite among modern brewers. Now, with HyperBoost’s concentrated oil formula, brewers can effortlessly incorporate Strata’s flavour profile into beer.

The HyperBoost product was created in response to brewers’ demand to have a highly flowable, concentrated hop product, that would enhance beer flavour and aroma with true-to-style hop attributes. Brewers using HyperBoost have reported significant gains in beer yield, with some achieving increases of up to 10%. HyperBoost can be used to replace a portion of the hop bill or as an addition to amplify the beer’s overall sensory impact.

“There is a dizzying number of hop oil extracts in the market now. One key factor that attracted us to YCH HyperBoost for our variety Strata is that HyperBoost is derived solely from hops,” adds Solberg. “Real hops grown by real people for brewers to excite customers who really like hoppy beer.”

On the process front, HyperBoost is not intended for kettle additions. For early kettle and bittering additions, they recommend pellets or CO2 extract. DynaBoost carries variety-specific oil and alpha acid content to the kettle and can be used as a late kettle addition.

For whirlpool use, brewers can replace up to 100% of pellets with HyperBoost. They suggest replacing T-90 pellet additions in the whirlpool at a rate of 50:1 by weight (20 g of HyperBoost to replace 1 kg T-90). Your brewery might choose to use more or less depending on beer style or overall goal.

In fermentation, the company adds that HyperBoost can be used as an active or post-fermentation hop addition. Incorporate HyperBoost anywhere in the process you would typically use pellets. While for dry hop additions, YCH recommends using HyperBoost for 25-50% of the addition and adding T-90 or Cryo pellets for the remainder of the hop charge. As a dry hop, They suggest starting with a replacement rate of 100:1 HyperBoost to T-90 pellets by weight (10 g HyperBoost in place of 1 kg T-90) to 125:1 (8 g HyperBoost in place of 1 kg T-90).

87kg CO2e / tn*

We can help you map your carbon impact for raw materials and tell your sustainability story. Get in touch to nd out more about lowering your carbon footprint.

WITH 2025 WELL UNDERWAY, WHAT BEER STYLES ARE PROVING A HIT, AND WHAT STYLES ARE PROVING LESS SO, WITH BOTTLESHOP OWNERS. AND WHAT BEERS WOULD THESE BUSINESSES LIKE TO SEE MORE OF, TOO.

Recent figures from UHY Hacker Young revealed that turnover of the UK’s top 25 independent breweries hit a record

£1.72bn in 2024, an increase of 9% on the £1.57bn recorded in the previous year.

Turnover has jumped 44% since COVID, up from £1.08bn in 2021/22, to £1.57bn in 2022/23.

But what beers are fuelling these figures?

With 2025 well underway, what style are proving popular with consumers?

At Ghost Whale, which has branches in Brixton and Putney, Ray Hadnett says IPA still rules the roost.

“Here at Ghost Whale, the question I’ve been continuously asked more than any other, is for directions to our juiciest New England IPAs, particularly at the notso-sessionable strengths of 6.5-8%,” he explains.

“The seemingly never-ending haze craze has been chugging along for years now, courtesy of some of our best-selling breweries Track, Pressure Drop, and Beak, as well as younger but equally exciting outfits like Two Flints, Azvex, and Floc, who all persist in pushing the boundaries of hop saturation.

“Despite this constant push for lusciously fruity hoppy ales, a spike in West Coast

IPA production over the last couple of months has been a welcome sight to our staff.”

Hadnett adds: “We’ve been treated to some excellent Westies from the likes of Pomona Island, Burnt Mill, and Baron, and have seen more and more breweries getting involved in turning out what had seemingly become a style pushed to the wayside due to the popularity of the Hazy IPA.

“A style I personally am enjoying at the moment, which seems to have been born off the effects of the in-demand New England IPA, is the New Zealand Pilsner, with iterations from Gravity Well, Pretty Decent, and Phantom all really impressing over the last couple months.”

He highlights the citrus, stone fruit, and white wine notes imparted by New Zealand grown hops that add a lovely complexity to an already hopforward Pilsner, appeasing the palates of Hazy IPA drinkers who have become accustomed to that level of fruitiness in their beer.

“I wouldn’t be surprised if we see more breweries embracing styles like this going forward, on account of the fact that it allows them to purchase hops in larger quantities, to satisfy the stable market for IPAs while maintaining a diverse offering,” he explains.

Across London, Marius Andrici is the founder of Acton-based A Pint of Hops, a business that celebrates its sixth anniversary in 2025 and one that has become a hit selling beers for takeaway and on-premise consumption in both small-pack and beers poured on-tap.

“For our customers, the darker German styles have been gathering popularity. Styles like the Schwarzbiers, Dunkels, Altbier, Bockbier & Winter Festbier have been a hit both in bottle and on tap with both drinkers that enjoy their lagers and ales with us,” he notes. “Sometimes that

complex depth really resonates with the consumer and they go on a journey across those styles.”

Elsewhere, the sour and hoppy styles sold at A Pint of Hops remain popular and especially in canned format. “Customers prefer this package and most times the labels stand out with the colourful artworks on the cans,” he says.

“We find it hard to sell the bottle format at the same rate as cans for these styles and many times they do reach their expiry date and at times we need to discontinue the lines.”

On a personal front, A London Porter from The Kernel has been a go-to for Andrici and he has also enjoyed the growing availability of high-quality UK lagers.

“There are too many breweries to list here, but it’s great to see that more UK breweries working hard at perfecting their own version of German & Czechstyle lagers.”

I wouldn’t be surprised if we see more breweries embracing styles like New Zealand Pilsners going forward,” Ray Hadnett, Ghost Whale.

WITH A PASSION FOR BIG, BOLD FLAVOURS COUPLED WITH A FLAIR FOR PRODUCING EXCELLENT SESSIONSTRENGTH BEERS, ALEX KERR AND HIS TEAM AT TWO FLINTS ARE HELPING BRING MODERN BEER STYLES TO THE GREAT AND THE GOOD OF WINDSOR, BERKSHIRE. AND THEY’RE JUST GETTING STARTED.

It takes two flints to make a fire.” Where did the inspiration for your brewery name come from? For Alex Kerr, founder of Windsor, Berkshire-based Two Flints, he has his own story to tell. And drawing influence from the famous quote from Louisa May Alcott’s coming-of-age novel Little Women was just the place to start.

“When we were planning this brewery the initial idea was to be more focused on mixed-fermentation and barrel-ageing than we probably currently are. Instead, these first two years has seen us really concentrate on hop-forward hazy pale ales and IPAs,” he explains. “And when it comes to these beers, we are extremely scientific in our approach. No stone is left unturned.”

Kerr adds: “For us, across the spectrum of lagers, IPAs and barrel-aged beers there is an art but there is also a science

to the brewing process. When these are combined they produce something greater than the sum of their parts.

“And in opening this business my wife Sophie and I found out we were expecting twins so that was that - the brewery had to be called Two Flints!” Opening at the end of 2022, Two Flints recently marked its second anniversary brewing in Berkshire.

A town that has been the home of Windsor and Eton Brewery for more than 10 years, Alex Kerr and his team would soon be joined by neighbours Indie Rabble, founded by Alex Rowlands, Alison Steele, and Naomi and Dave Hayward, in 2023. But before Berkshire came calling, there was Singapore and Kerr’s career in insurance.

“I’ll be brutally honest, I wasn’t really into cask beer growing up. And when I was studying at university craft beer wasn’t really a thing. But shortly after leaving I discovered the Bermondsey Beer Mile and The Kernel. They, like many others, would be my gateway to great beer,” he recalls.

“I was hooked. Their famous brownlabel bottles and the beautiful beer they made wasn’t like anything I had tasted before. Those experiences got me into the drinking side of craft beer and it snowballed, as it always does.”

Years would pass and Kerr’s work would take him into the field of insurance and that role would in turn take him to Singapore. “While you had a few beer bars and breweries such as Brewerkz, the beer scene was pretty poor on the whole. I missed the beers from home so naturally, I decided to give home brewing a shot,” he says.

“I had always loved cooking and the creativity involved in that, so it felt like something of a natural progression. It’s

quite amusing, I suppose. I bought what proved to be a pricey bit of kit from the US and the elements immediately blew after I plugged it in.

“Coming from the US, the system was obviously wired different and I didn’t realise. But it didn’t stop me and I was fortunate to find a second-hand one on the local market. Sophie thought I was crazy but there I was, trying my hand at clones of Sierra Nevada Pale Ale and getting a kick from witnessing fermentation take place.”

This early foray would lead Kerr down the well-travelled path to consuming all he could from magazines to podcasts and everything in-between, all in the confines of his basement bomb shelter, a common site in Singaporean residences.

“Hoppy beer was my passion but it became quite clear early on that to improve the quality of the hop-forward output I needed to improve the quality of my fermentation equipment,” he says. “Sophie was fine with it as long as the bomb shelter was where it stayed. But before long the whole spot was taken up.”

During his homebrewing journey in Southeast Asia, Kerr also saw the challenges that many brewers would encounter, too. “It’s probably one of the hardest places to brew, possibly in the world. Everything is imported so ingredients can become cost-prohibitive and you’re brewing in 30C heat at 100% humidity which isn’t ideal. But while I was there, it was great to see companies like Brewerkz making the beers that they did.”

For several years Kerr would continue working in insurance while also exploring the wonderful world of beer and brewing. But then the global pandemic hit. An event that changed his personal and professional trajectory, like countless others across the world.

“Singapore is a strict country at the best of times and they had very stringent measures in place during COVID. You were only allowed out at certain times so it left me more time to focus on brewing at home. I completed my General Certificate in Brewing and all I wanted to do was create recipes. It became an insane passion that I couldn’t

stop thinking about,” he says. “It got to the point where Sophie and I decided to move back to the UK. We ended up leaving Singapore when they were easing lockdown rules and we arrived back days before Boris Johnson put us into a two-month lockdown.”

In searching for commercial brewing experience, Kerr would be given the opportunity by Drop Project of Mitcham and Brixton Brewery to help hone his craft while also securing a Diploma in Brewing from Brewlab. It was during this time that the idea of starting his own operation would crystallise.

“We were living in North London at the time but that was going to prove prohibitive for what we wanted to do. In writing a business plan I knew I wanted a taproom to be a major part of our brewery,” he explains.

“Cambridge was somewhere we looked at originally and we probably visited close to 10 times looking at various properties. But for whatever reason it was never right. We then stumbled across Windsor and this classic railway arch. It had bags of potential, and great connections to London which were important both for us and the business. We took a gamble and went for it.”

Kerr would raise funding with help from family and friends and the lease for 25-26 The Arches, Windsor, was signed in September 2022. Although the taproom would open that December, they wouldn’t commence brewing on their 20HL semi-automatic brewhouse from 6ix Process Design (and installed by Gravity Systems) until February 2023, with contract brewing partners helping with the first batches until then.

And now, some two years into that journey, a constant at Two Flints is Kerr and the team’s passion for producing and drinking hop-forward, often hazy beers. Current offerings, as of February 2025, include 5.5% hazy pale Half Life, 6% hazy IPA Tunnel Vision, 4.8% hazy pale ale Never End and 8% DIPA Big Bash. These are complemented by 4.5% hoppy pils

Small Talk, 5% German-style pilsner Pils and the brewery’s flagship 3.8% hoppy session pale Santiago.

“That’s what we love to brew and drink. I’m absolutely fascinated by hops and a visit to Nelson and Yakima are on my bucket list. Early on, even before we started brewing, we were meticulous about sourcing raw materials and we set up direct relationships with suppliers such as hop growers in New Zealand,” he says. “I felt that by having an element of control in what we were using in the brewery we could ultimately positively impact the end product. I’m fixated on the best and freshest hops.”

While he has a passion for punchy, stronger ABVs, Kerr and the team knew that they also needed a session-strength beer in their portfolio and since day one that beer has been Santiago. Brewed with extra pale Maris Otter, torrified wheat, malted oats and a touch of Vienna, the beer features whirlpool and dry hop additions of Citra, Mosaic and Idaho 7.

“We love big, bold flavours but as any of our contemporaries have shown you also need a flagship beer that is approachable and drinkable. For us, that is Santiago.

At 3.8% it’s a beer that is designed for drinking in the pub. It has a prominent hop character but one that’s not too saturated either so you can enjoy a few if you like,” says Kerr.

“It’s a beer that we are always looking at, too. That desire to constantly tweak probably stems from the home brewing days. Because I feel that if you let a beer stand still for too long then it’ll probably get left behind. The beer world is constantly moving, constantly changing and constantly innovating so you need to as well.”

Santiago, as with Two Flints’ other beers, have proved a hit with patrons at its popular taproom. Open from Thursday until Sunday each week, Kerr has enjoyed seeing visitors become converts of modern beer styles that breweries such as his produce. And under the guidance of general manager Sophie, it goes from strength-to-strength as a social hub with live music, events and a growing run club with more besides.

Working with the excellent Sophie is a fantastic team that includes head of sales Nick Swallow who joined with a raft of experience from Siren Craft Brew, his sales colleague George Barrow, assistant brewer Dillon Cook and also drayman Paul Andrews. There is also head brewer Brett Moore who, along with Nick, was the first member of the team to join Two Flints.

“Brett and Nick have been amazing and we are very fortunate to have them,” says Kerr. “While I love modern hoppy flavours I also really enjoy Saisons and mixed-fermentation beers. So when it came to hiring a head brewer I wanted someone from that field. And with Brett he had proven that time-and-time again in handling the barrel programme at London Beer Factory. “He also had experience of clean beers at Beavertown so it really was the perfect fit. In addition he has an engineering background so as well as being our head brewer he is our electrician and everything in-between. Combined with Nick’s sales expertise, they were great to have on board since the start.”

Looking ahead to the rest of 2025 and beyond, Kerr is excited about the future. A cask release of Santiago, which marked the brewery’s second birthday, was a hit in the on-trade and three other cask beers will follow this year. But to produce more beer requires space and that has recently become a hurdle for the business. “We’re looking to get an additional unit and ideally in 2025 we’d love another retail venue, too. London is somewhere we’d love to have a presence and it’s already our largest market with trade sales so it makes sense.”

That extra capacity and new retail opportunities will also allow Kerr and the team to produce more beers like Never End, their 4.8% hazy pale. “We call it Never End because we have a neverending goal of continuous improvement,” he concludes. “It talks to who we are as a brewery, and that collective constant need to do better. That’s something that will never change.”

• Want to take control?

• Want short production runs at your convenience?

• Want to reduce product losses at contract packers?

• Want to save transport costs and double handling?

• Want to reduce your carbon footprint?

• Want to control your own hygiene and QA procedures?

• Want improve your packaging?

• Want to save money on labour costs?

• Want to reduce your dissolved oxygen?

You can with an Enterprise Tondelli craft beer Canning, Bottling or Kegging line!

✓ 1,300 cans per hour upwards to 80,000 cph

✓ 1,200 bottles per hour upwards to 60,000 bph

✓ 16 kegs per hour upwards to 1,000 kegs per hour

AN IMPORTANT MILESTONE IN ANY BUSINESS

IS A

Since starting out in 1985, Herefordshire-based Wye Valley Brewery has been producing a wealth of excellent cask, keg and small pack beers.

IT’S THE

REAL ACHIEVEMENT.

CULMINATION

OF HARD

WORK, COMMITMENT

AND THE RESULT OF PROVIDING A QUALITY

PRODUCT

OR SERVICE. PROBABLY BOTH. AND IN 2025, WYE VALLEY BREWERY TOAST THEIR 40TH YEAR IN THE WORLD OF BEER. AND AS WE ALL KNOW, THAT SIMPLY DOESN’T HAPPEN BY ACCIDENT.

They’ve earned a reputation for consistency and product quality, seeing their beers served in more than 1,200 pubs and bars throughout the West Midlands and South Wales.

As a result, they’ve gone from a humble beginning of producing approximately 10 brewers’ barrels a week to an average of 1000 barrels per week, with further growth to come. And the brewery’s story started nearly 40 years ago. After brewing for years at Guinness, Wye Valley Brewery founder, Peter Amor decided to branch out on his own.

He began brewing from the back of a pub in Canon Pyon in Herefordshire but soon moved to the old stable block of The Barrels in Hereford - Wye Valley Brewery’s very first pub.

After studying at Young’s brewery in London, Peter’s son, Vernon Amor joined the brewery to help with the demands of the growing business. And nearly 20 years later, the business would signal its latest growth by moving into a 9-acre former cider mill in Stoke Lacy.

But the journey doesn’t stop there - far from it. Ongoing expansion has included the installation of an impressive bottling and canning setup from Bedfordbased Enterprise Tondelli, as well as investment in its warehousing and solar PV infrastructure, with a new brewhouse part of the brewery’s future, too. And on the beer front, it’s super successful Nightjar, a kegged stout

based on an original Wye Valley Brewery cask recipe, has helped put the brewery in front of eager new audiences. Here we speak with head of sales and marketing Abbie Gadd and head brewer Gareth Batemen, to discover the secret of the brewery’s longevity, the importance of moving with the times and why its 40th year will be the start of a new period of growth for the much-loved business.

“When it comes to business, consistency has been the one of our biggest traits throughout,” says Gadd. “When I joined the business some 10 years ago, landlords would always recognize our reputation for consistency. With two flagship cask beers in HPA and Butty Bach people knew what they looked like, what they smelled like, and what they tasted like. And when they go in the pub, day-in, day-out, week-in, week-out, they know how their pint should taste. And they will also be the first to say if something isn’t right.

“So when you think about the ingredients that go into making those beers, and the fact that every year these ingredients can be affected by growing conditions, then maintaining that level of consistency becomes more a challenge. It continues to blow my mind that our brewers can maintain the levels people have come to expect from us.”

And for the last 12 years, brewing has taken place under the stewardship of a team that includes storied head brewer Gareth Bateman.

“My first job in a brewery was in Magor, South Wales with Interbrew or AB InBev as it is known now. Starting in microbiology, I would hold similar roles in

Australia when travelling,” he recalls.

“Upon returning to the UK, I’d work at Brains in Cardiff, Young’s in London and also Wells and Young in Bedford. I then moved here to Wye Valley and it hasn’t stopped since!”

He adds: “As soon as I got here I did my Master Brewer qualification, which was something I always wanted to do. It was interesting, especially after working for bigger businesses, to see what it was like being part of a family firm that has always been in growth. There’s always something happening. Despite the

growth taking place we are all looking to the future, too. We probably have the next five or so years planned out, which is enough to keep anyone entertained.”

While Bateman has proven to be a superb guardian of production at Wye Valley, Abbie Gadd has also helped steer the brewery into exciting new waters and secure its place in the changing, modern beer landscape.

and wasn’t as qualified when it came to the hospitality trade,” she says. “So it was refreshing to have our managing director Vernon see that I was coming at things from a different perspective. It was positive for both of us.

When it comes to business consistency has been the one of our biggest traits throughout,” Abbie Gadd

“I feel that we’ve always had a fantastic reputation for great beer, long before I joined! But before I started, the business had undertaken a research project by a third-party agency that opened our eyes a little,” she explains. “The feedback was that the company was great but the range was limited and a little stayed. It was at the time where lots of newer breweries were coming onto the scene and it was clear we needed to step up and inject more of our personality into this business.”

Thankfully Gadd had a wealth of marketing experience from her time in London. “I’ve worked with cars and coffee to chewing gum and nappies. You name it I’ve probably worked with it. But I hadn’t worked with a brewery until then

“We wanted to acknowledge and retain our traditional values as without them we would alienate our existing audience. But we wanted to reach a new consumer, too. So a way to do that was to introduce new, regular beers and showcase modern styles and modern flavours. By doing this, and by embracing keg beers we have found ourselves in markets and venues we traditionally weren’t reaching.”

And one beer that has helped consolidate the brewery’s position in the modern keg market is Nightjar. It’s a stout based on the original Wye Valley Dorothy Goodbody’s Wholesome Stout cask recipe dating back to 1985 when exGuinness alumni, Peter Amor, first began brewing his own beers at the back of the well-known watering hole, The Barrels in Hereford. As a kegged stout, Nightjar is chilled to 4°C and is nitrogenated.

“It’s no surprise that one of Peter’s early recipes was a stout,” says Gadd. “That early stout has won many awards over the years. But cask stout is more of a niche product these days and sadly it doesn’t appeal to everyone’s tastes. So when we started kegging, Gareth argued that we needed to see how that recipe worked on keg dispense. And it worked extremely well!”

She adds: “It’s a beer that has really resonated with the consumer and one that has grown organically so back in 2022 we made the conscious decision to rebrand it as ‘Nightjar’ and it has flown ever since. So much so that late last year I had a called from Diageo referencing that one venue had taken off Guinness to keep our beer on tap!

“To be on their radar, and to see consumers and licensees really take to the beer is really rewarding.”

Nightjar complements a range of beers that incude Butty Bach. Butty Bach is a Welsh term meaning ‘little friend’ – and

this charmingly smooth premium ale has certainly made more than a few friendships in its time. It’s brewed using Maris Otter and Crystal malts together with locally grown Fuggles, Goldings and Bramling Cross hops.

Also at 4.5% is 1985, described as a deliciously refreshing premium lager that boasts a moreish malty base, flecked with delicate floral notes. Pale straw in colour, 1985 is brewed using the best of British hops together with European lager hops to give this unique lager a cool, crisp taste. Elsewhere, Wye Valley Bitter is a cornerstone of the brewery’s range of real ales, this chestnut-coloured wonder is a mouthwatering example of a caskconditioned bitter.

At 3.7% it’s brewed using Maris Otter and Crystal malts together with locally grown Target and Goldings hops, Wye Valley Bitter has a delicate hoppy aroma leading on to a full malty flavour and ending in a crisp, clean bitter finish.

These beers are produced at a brewery that has sustainability as its beating heart from both buying local ingredients to a raft of technological measures across the brewery site. On the solar front alone there has been some four phases of solar panel array installs, accounting for just shy of 40% of the brewery’s electricity usage. “There’s no roof space without them!” Bateman smiles.

operators and good functionality. This line was supplied and installed by the business who also supplied the new bottling line too.

Twin lanes on the system ensure easy change over between 330 ml and 440 ml that the brewery run on the line just by switching a gate at the top. Cans can be either pre-printed or for some smaller runs they are labelled on an empty labeller supplied by Enterprise Tondelli.

While the packaging operation is in good hands, it’ll soon be time for the business to turn its attention to even more investment.

There’s always something happening at Wye Valley,” Gareth Bateman

Ongoing investment has become a calling card at the Bromyard-based outfit. While there is much on the horizon, a significant install in recent years came when the business was planning their new packaging hall with Enterprise Tondelli. A key consideration, Enterprise Tondelli managing director Craig Wilson outlines, was to maximise the flexibility of the packaging hall to allow both bottling and canning on the same line. Whilst the space was a challenge the final layout ensured good access, rationalisation of

“We have got some big plans that we’re looking at signing off. Plans that will signal more massive growth for the brewery,” says Gadd. “So that means a new brewhouse, new visitor centre, new taproom, the lot! When I look at the road map for the next three, four five years I think ‘wow’ it really is huge.”

yeast

Ideal to make beers with less than 0,5% ABV

Develops a subtle aroma profile

Assimilates simple sugars only (glucose, fructose, sucrose)

Exhibits medium sedimentation, with no clumps

STANDING OUT ON THE

IS JUST AS IMPORTANT AS WHAT’S INSIDE THE BOTTLE OR CAN. INVESTING IN HIGH-QUALITY

AND PACKAGING IS NOT JUST ABOUT AESTHETICS—IT IS A STRATEGIC MOVE THAT ENHANCES BRAND

First impressions matter. That much we know. Consumers often make split-second decisions when browsing the beer aisle. An eye-catching label can be the difference between a sale and being overlooked.

A well-designed, high-quality label conveys professionalism, craftsmanship, and brand personality, all of which influence purchasing behaviour. Studies have shown that packaging directly impacts consumer perception of product quality. A premium-looking label suggests a premium beer, enticing new customers to give it a try.

Consistent, high-quality packaging strengthens brand identity. Whether it’s a signature colour scheme, unique typography, or an iconic logo, wellexecuted packaging ensures that customers instantly recognise your beer. Strong branding fosters customer loyalty, as drinkers will seek out and recommend brands they trust and remember. With the proliferation of craft breweries, distinct, cohesive packaging helps build a recognisable and reliable brand that consumers return to time and again. Investing in quality labels and packaging materials is also a practical consideration. Labels need to withstand refrigeration, moisture, and handling without peeling, smudging, or fading. Inferior materials can lead to an unprofessional appearance and a poor customer experience.

Likewise, packaging should be sturdy enough to protect the beer during shipping and storage. Weak, flimsy packaging increases the risk of damage, which can hurt both sales and reputation.

For Hans Huyghe, part of the team at Rembrandt Labels, the company is seeing demand for vibrant “flashy” labels, especially on alcohol-free beers. “Brewers want to convince the younger public that (non-alcoholic) beers are not old fashioned but actually trendy. Hence, printing with an increased colour gamut is a hot topic,” he explains.

Labelling isn’t just about design; it must also comply with local and federal regulations. Accurate ingredient lists, alcohol content, government warnings, and barcode placement are all crucial details that must be properly displayed. Investing in professional labelling services or high-quality printing ensures compliance, avoiding costly recalls.

Additionally, sustainability is increasingly important to consumers and retailers. Eco-friendly packaging, such as recyclable materials or biodegradable inks, not only helps the environment but also appeals to the growing segment of environmentally conscious buyers.

Breweries that prioritise sustainable packaging can market this as a selling point, setting themselves apart from competitors.

This is something echoed by Huyghe. “Brands are ask for a recycled paper look, and there is an increase in demand of wraparound labels on cans, meaning the fraction of label residuals in the shredded aluminium is very low, compared to self adhesive labels on cans,” he says.

“In markets with a good reverse logistics, as re-use of bottles is ecologically better than recycling, the demand for flawless wash-off of the labels, ie. wet-glue labels, is increasing for smoothless wash cycles.

“The market is also starting to realise

that the siliconized liner of self-adhesive labels creates a high level of waste, pushing the demand towards wetglue labels.”

Given the increasing speed of industrial bottling/labelling lines, the market does not want to make compromises on runability of the labels. Increasing label paper grammage, which is viewed as heightening quality, is no issue when it also improves runabilty.

Quality packaging does more than attract buyers—it supports broader marketing efforts. Limited edition designs, seasonal variations, or collaborations can generate buzz and drive sales. Breweries can leverage high-quality, visually appealing packaging in social media campaigns, influencer partnerships, and other marketing strategies to expand their reach and engage consumers.

The ability to tell a compelling brand story through packaging gives breweries an additional edge in the marketplace. In the crowded craft beer market, the importance of premium labelling and packaging cannot be overstated. From making a strong first impression to ensuring durability, regulatory compliance, and sustainability, highquality packaging is an investment that pays off.

Brewery owners who prioritise this aspect of their business will see increased brand recognition, customer loyalty, and, ultimately, higher sales. In a market where differentiation is key, investing in superior packaging is not just a choice— it’s a necessity for long-term success.

IMPACTFUL LABELLING AND PACKAGING CAN ELEVATE YOUR BREWERY, MOVING A BEER FROM SHOP SHELF TO CONSUMER HAND. HERE ARE SOME COMPANIES THAT CAN HELP YOU ACHIEVE JUST THAT.

Bevcraft Group is a leading name in the ‘craft can’ packaging sector in Europe and providing can decoration, filling, distribution and related solutions to craft beverage producers. They believe cans are key to a sustainable beverage sector as they are light, robust, economic and infinitely recyclable. The company provides a professional, cost effective and commitment free canning solution. No need to tie up your valuable capital, staff time or floor space with a canning line that demands constant usage to pay its way or which might prove to be too small or too big for your future needs. They also operate specialised digital can printing plants as well as providing traditional decoration options such as labelling, sleeving and higher run, dry offset print.

Graphius Group, the Belgian printing company, which is also active in the UK with Park Communications (London) and Geoff Neal Printworks (London), has recently invested in their “Rembrandt Labels” wetglue labelling plant in Brussels with additional cutting and diecutting equipment. This investment quadruples their label production capacity.

Already well equiped with 3 AI controlled Heidelberg printing presses, Rembrandt Labels is a highly industrialised label printer, now ready to offer their labels to the UK market.

Rembrandt Labels’ recent investment in finishing equipment compliments their current services that include offset print quality with a very wide colour gammut (Multicolor), gloss/matt effects, metallic inks and hotfoil. Its labels printed on the reverse help to increase brand awareness (on transparent bottles), with for example, the company logo.

All labels can be square or form diecut into any desired shape. Compared to self adhesive labels, the wetglue label price per unit is far lower, and such labels are much more sustainable, as wetglue labels do not need a siliconised liner (which are difficult or impossible to recycle).

A wetglue label is mostly around 68grams/m², compared to the average 140grams/m² for a self adhesive label with backing paper.

At Berlin Packaging, they consider themselves true masters of packaging, designing and supplying full packaging solutions for the beer market. They excel by specializing in the combination of various materials, meticulously managing every aspect of the production and logistics chain. They explain that can offer the right packaging solution for your product, ranging across all beer varieties. Studio One Eleven is the design and innovation division of Berlin Packaging, which stands out as a distinctive offering within the industry, boasting world-class expertise and deep market insight. As the innovation engine of Berlin Packaging, Studio One Eleven seamlessly fuses the attributes of a design agency with the precision of a manufacturer to breathe life into groundbreaking products and design bespoke full packaging solution taking care about product and graphic design at the same time.