It’s no secret of late that much of the brewing industry across the globe has had to navigate various hurdles and overcome numerous challenges.

But when it comes to what we do with the magazine, the podcasts and events like, we want to continue to champion the industry, confront the challenges and to come out better on the other side. We’re not interested in talking the brewing sector down.

So I recently read, with great interest, the latest comments from Christine Comeau, the executive director at the Canadian Craft Brewers Association (CCBA). In referencing such headwinds such as the potential for U.S. tariffs and a prorogued federal government, the importance of the association’s “Pour Love Into Local” campaign is clear.

“These resources are designed to help you, and breweries nationwide, encourage communities to rally behind local craft beer. Together, we can amplify this message and reinforce the value of supporting local businesses during turbulent times, she explains.

In highlighting the ongoing 50% excise rate reduction which began April 1, 2024 and runs to March 31, 2025, she adds: “As we navigate these challenges together, I encourage everyone to stay connected and supportive.

“Share ideas, resources, and strategies to strengthen our community. Together, we can weather these uncertainties and emerge stronger than ever. Stay warm and remember—working together is our greatest strength.”

And that sense of togetherness and that celebration of the quality, talent and success that underpins this industry can be found through the brilliant breweries, brewers and beer professionals that will be recognised in our latest awards.

The team from Brewers Journal Canada is proud to announce the latest Canadian Brewers Choice Awards (CBCAs). With the shortlist featured in this issue, Get ready to embark on a national journey that celebrates excellence and innovation in the Canadian brewing industry.

Best of luck to all involved and until next time.

Tim Sheahan Editor

Keg distribution comes with its fair share of challenges, but Courtney Fromm, national manager at Kegshare, explores how a collaborative, communitydriven approach could offer much-needed solutions.

email: Courtney.fromm@kegshare.ca

phone: 705-737-7687

In Part 2 of a four part series, Derek Davy, CEO of Econse, shares tips for standing out as a sustainability leader.

Founded in 2013 by the Mills family, Four Winds Brewing Co. based in Delta, BC, is the result of years of passion, hard work, and a dedication to craft beer, inspired by a homebrewing journey that began in 2007 and continues to push boundaries with quality, innovation, and a love for the process.

Breweries have long been the heart of communities, and in Northern Ontario, the potential for a microbrewery to revitalize Espanola is undeniable, offering local jobs, unique flavours, and a new gathering place for residents and visitors alike, writes award-winning Blake Priddle.

Adding a tasting area to a craft brewery can boost revenue and attract new customers, but navigating space planning and regulatory approvals can be challenging—here, Adam Gillies of LRI Engineering Inc. shares key considerations for a smooth process.

email: agillies@lrifire.com

phone: 416-515-9331 ext. 351

CO₂ recovery can significantly impact beer quality, and brewing consultant Lenzie Kinyon breaks down the key factors to consider for a successful and efficient system.

As the American craft beer scene evolves, so do its festivals—Lotte Peplow, Brewers Association’s American Craft Beer Ambassador for Europe, explores the latest trends from the reimagined Great American Beer Festival.

Commentary | High Gravity

Fermenting high-gravity beer comes with unique challenges, from stuck fermentations to off-flavours, but the experts at White Labs share key tips and tricks to ensure a smooth, complete fermentation.

Tim Sheahan Editor tim@brewersjournal.ca

+44 (0)1442 780 592

Jakub Mulik Staff photographer

Johnny Leung Canada Partnerships johnny@brewersjournal.ca

Richard Piotrowski Publisher Richard@brewersjournal.ca

Magdalena Lesiuk Graphic Design GraphMad@gmail.com

Nicholas Hendrickson Contributor

Jason Murray Contributor

CFJ Media

Meet the Brewer | Tatamagouche Brewing Co.

From humble beginnings in a renovated butcher shop to an award-winning craft brewery, Tatamagouche Brewing Co. has spent the past decade mastering the art of brewing, embracing experimentation, and bringing the flavours of Nova Scotia’s North Shore to locals and visitors alike.

48 30

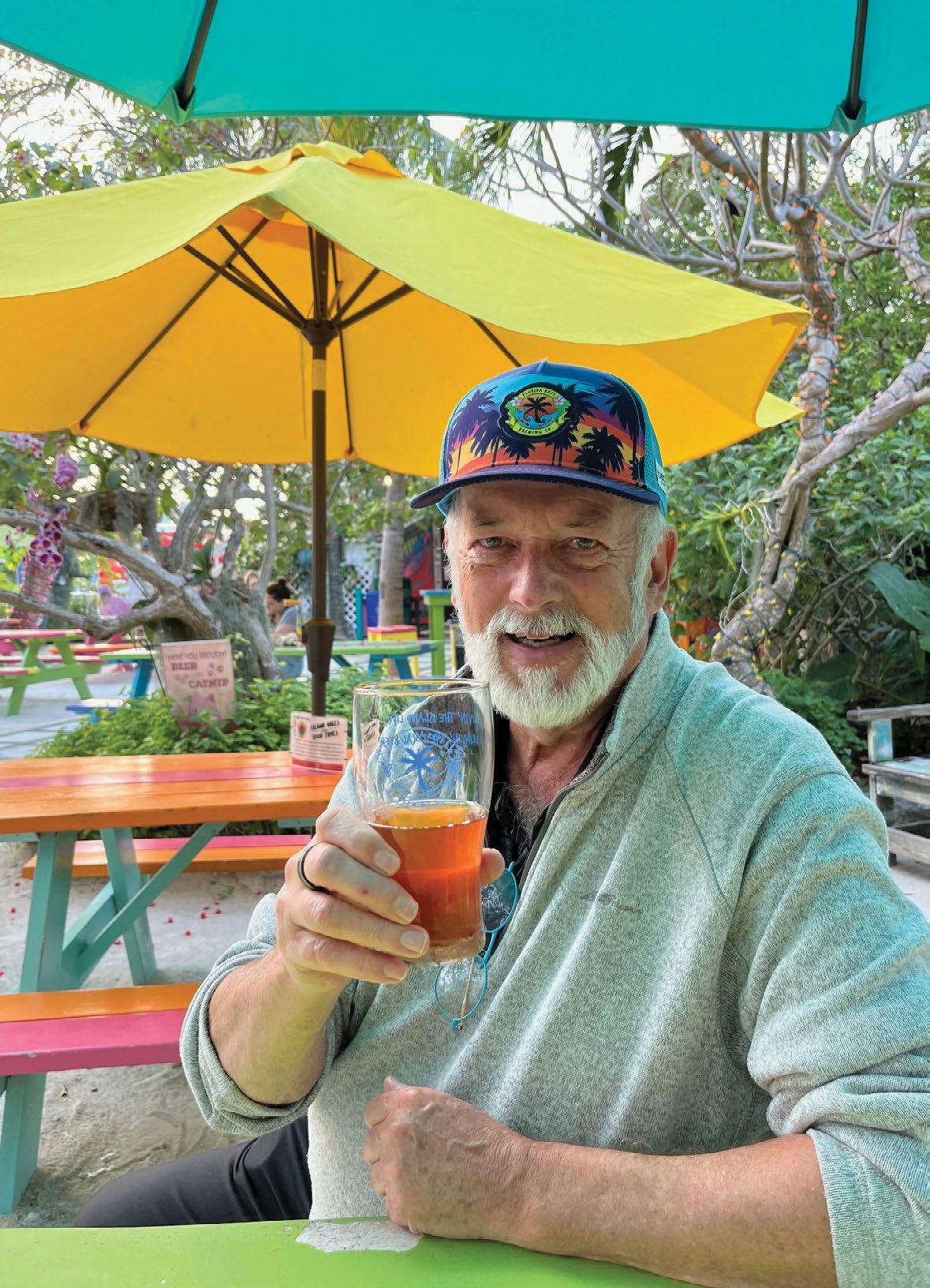

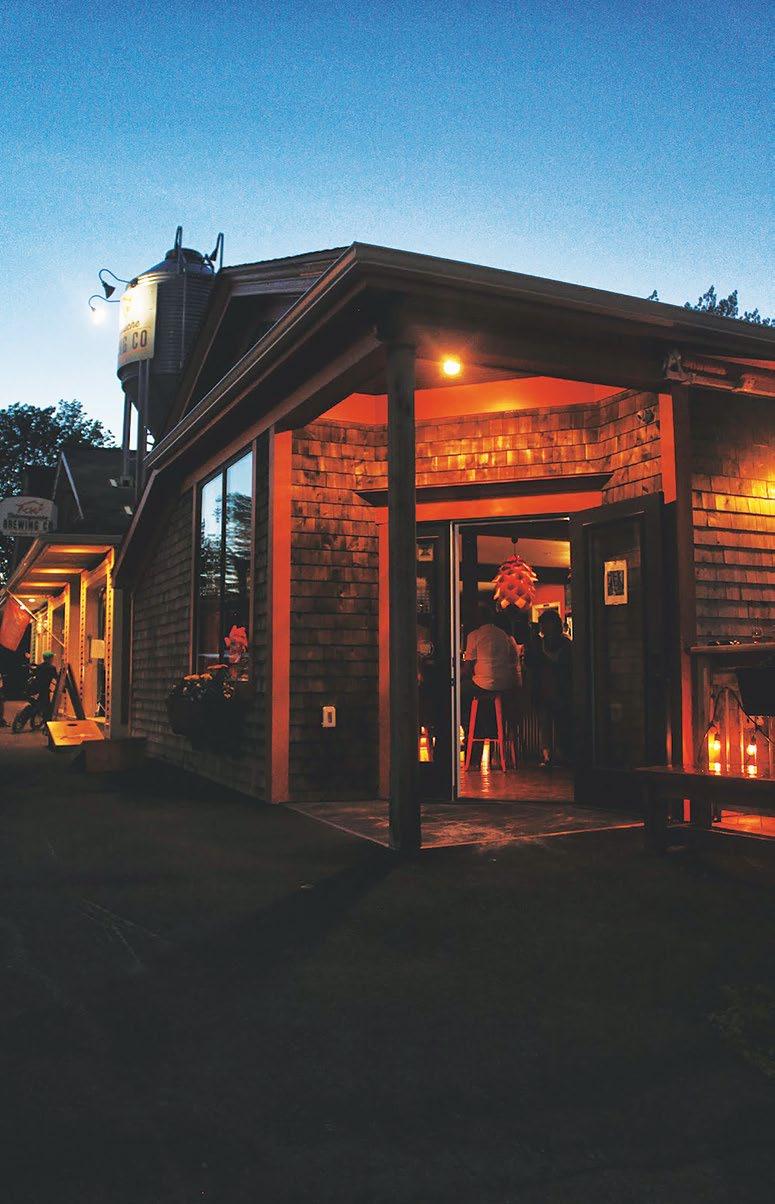

Crossing Continents | Florida Keys Brewery

Breweries have a unique ability to foster community—Paul Knowles shares how Florida Keys Brewery, with Canadian brewing expertise, is doing just that.

2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3

The Brewers Journal Canada is a quarterly magazine. Subscriptions can be purchased for four or eight issues. Prices for single issue subscriptions or back issues can be obtained by emailing: johnny@brewersjournal.ca

CANADA One year: $39

INTERNATIONAL One year: $49

The content of The Brewers Journal Canada is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service.

The Brewers Journal Canada is printed at Manson Group, St. Albany’s, UK.

All rights reserved. No part of this publication may be: reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the publisher. The Brewers Journal Canada ISSN 2398-6948 is part of Reby Media, 42 Crouchfield, Hemel Hempstead, Herts HP1 1PA. It is published quarterly in Canada by CFJ Media, 2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3, Canada. Subscription records are maintained at CFJ Media, 2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3, Canada. The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom.

Coupled with high storage costs and logistics expenses, many breweries are feeling the pinch. It’s a classic case of too many kegs in the wrong places, and the cost of storing those kegs can be a significant drain on resources.

Moreover, turnover rates are soaring, whether you’re working with your own distribution team or relying on third-party providers.

This inconsistency can leave gaps in communication and accountability, further complicating the process. And let’s not forget about visibility. Tracking where kegs are in the distribution cycle can feel like looking for a needle in a haystack, leaving breweries in the dark about their own inventory.

COULD PROVIDE THE SOLUTIONSWE DESPERATELY NEED.

In today’s craft beer landscape, many breweries are grappling with a series of keg distribution headaches that can feel insurmountable.

Slow keg returns and infrequent pickups from licensees, rising costs associated with storage and logistics, high staff turnover—whether self-distributing or working with third-party services—and a frustrating lack of visibility into the entire process.

These issues not only impact operational efficiency but can also strain relationships within our brewing community. However, a collaborative, community-driven approach could provide the solutions we desperately need.

First, let’s address the elephant in the room: keg returns are often painfully slow. Licensees might hold onto kegs longer than expected, leading to inventory shortages for breweries.

But what if we approached these challenges differently? Instead of viewing each other as competitors, we could work together as a community. A shared pooled model for keg distribution could revolutionize the way we handle kegs. By implementing a keg ID system and a shared dashboard, we can create a more streamlined process that benefits everyone involved.

Imagine a scenario where multiple companies come together to manage keg pickups. The more that participate, the quicker we can get kegs back into circulation. Faster returns mean fewer kegs are needed to service the same number of taps, ultimately reducing the burden on each individual brewery.

With a pooled system, storage becomes a community effort. Instead of each brewery bearing the brunt of storage fees, we can share resources and sometimes eliminate storage costs altogether. This not

only frees up capital but also ensures that kegs are kept in optimal conditions while waiting for their next journey.

By combining logistics across multiple breweries, we can negotiate lower rates and create a more efficient distribution network. Imagine a shared delivery system that maximizes vehicle capacity and minimizes the number of trips required. This not only reduces costs but also lessens our environmental impact.

When we centralize keg management within our community, accessing kegs becomes a breeze. Breweries can easily see what’s available nearby, facilitating smoother collaborations and making it easier for bars and restaurants to get the products they need without delay.

5. Support Through Challenges

In a pooled distribution model, when one partner faces an issue—be it a staffing shortage or a logistical hiccup—there

are plenty of other community members ready to step in and help. This support network means that we can overcome challenges collectively, ensuring that no brewery has to bear the weight alone.

A keg ID system paired with a community dashboard can provide real-time updates on the status of kegs. Breweries can track when they start using a keg, when it has been picked up, and when it is returned to storage. This transparency is crucial for maintaining accurate inventory and managing production schedules effectively.

The craft beer industry thrives on community and collaboration. By working together to solve keg distribution challenges, we can not only improve our operations but also strengthen our relationships with one another.

Embracing a shared pooled model is more than just a logistical strategy; it’s a way to reinforce the bonds that make our craft beer community so vibrant. Let’s raise a glass to a future where we all benefit from working together—cheers to community-driven solutions!

Kegshare would like to thank our KAPs, Kegshare Access Partners for making our Kegshare community across Canada the best in the keg industry

Accelerate 360

Backcountry Brewing

Blackburn Brewhouse

Broadhead Brewing

Connect Logistics

Container World

Driftwood Brewing

Drink Distribution

Elk Packaging and Logistics

FIL Delivery

Fourwinds Brewing

Good Hustle

John’s Delivery

Kingsville Brewing

Lake of Bays Brewing

Parallel 49 Brewing

Ravens Brewing

Set the Bar

Sleeping Giant Brewery

Superflux

Timax

Tofino Brewing

UBC Group

WETT Sales

YD Bev Co

Beaux Prés Microbasserie - Quebec

Beva Brewing & Blending - British Columbia

Pile O’ Bones Brewing - Saskatchewan

Great Lakes Brewery - Ontario

Kichesippi Beer Company - Ontario

Kemptville Brewing Co. - Ontario

Bad Bones Brewery - Quebec

Obsolete Brewing Co. - Manitoba

Endswell Beer - Ontario

Connector Brewing- British Columbia

Denny Vervaet - Red Barn Brewing Co.

Brad Tomlinson - Jackknife Brewing

Julio Duque - Orleans Brewing Co.

Tessa Gabiniewicz- Land & Sea Brewing Co.

Colin VanderMeulen - Dune Hopper Brewing Co.

Sangdon Lee - Mascot Brewery

Melissa Donaldson - Calabogie Brewing Co.

Joel Windich - Ridge Rock Brewing Co

Kerry Dyson - BREWHALL Beer Co.

Frédéric Pelletier - Herman Brasserie Artisanale

Harmon’s Craft Brewing- Ontario

Polyrhythm Brewing - Alberta

948 Brewing Co. - Alberta

Dune Hopper Brewing Co. - Ontario

Ale Architect Brewery- Alberta

Tofino Brewing - British Columbia

Unfiltered Brewing - Nova Scotia

Tailout Brewing - British Columbia

Nine Locks Brewing Co. - Nova Scotia

Bridge Brewing Co. - British Columbia

GoodLot Farmstead Brewing - Ontario

Blindman Brewing - Alberta

Yellow Dog Brewing - British Columbia

Silversmith Brewing Company - Ontario

Rewind Brewing- British Columbia

Kensington Brewing Co. - Spruce Up Red IPA

Corsaire Microbrasserie - Dark Mild

Blindman Brewing - Dwarf Sour Cherry

Tooth & Nail Brewing Co. - Valor Classic Saison

Obsolete Brewing Co.- Cavalry Soldier - Jobsolete

Main Street Brewing - Daytripper Hazy IPA

Microbrasserie Ateepic - Camp Malin

The Growlerly Brewery - Blueliner Lager

You’ve got a great line-up of delicious craft beers. Your hard-working staff is dedicated to consistently producing the highest quality product. Your entire team is engaged in your community. And, because you always want to attract more customers and grow your business, you’re still looking for even more ways to stand out from the crowd.

Sustainability presents itself as an opportunity to further elevate and distinguish your brewery. There are a number of great reasons to embrace this value— beyond its benefits for our environment. However, to maximize the impact, you need to be careful about how you introduce, implement, and communicate your sustainability value.

In this article, we’ll take a look at sustainability through the lens of your brewery, showing its positive impacts, the potential pitfalls, and actionable steps you can take to become a sustainability leader.

You know that sustainable efforts, from recycling and reuse to wastewater treatment and energy efficiency, support the

health of your community and planet. But you may be surprised at how those same initiatives can support your business.

Implementing sustainable practices can enhance your brand image and credibility. Studies reveal that 84 percent of consumers consider the causes a brand supports when making a purchase decision. Overlay that with a recent NeilsonIQ study that found 78 percent of US consumers say that a sustainable lifestyle is important to them, and you can quickly see how important your eco-friendly efforts become.

When consumers see that you’re actively supporting a cause that’s already important to them, they feel an instant connection. Now, your brewery isn’t simply providing them with great beer, you’re also providing good feelings about the choice they’ve made.

Cost is obviously a concern when updating or changing operations in any way. And while sustainable solutions do have an upfront expense, they often come with long-term savings. By optimizing your use of resources, minimizing your waste, and maximizing efficiencies, you start seeing reduced costs across your operation.

Some cost savings are obvious, like lower electricity bills and reduced material costs. However, there are other opportunities that positively impact the bottom line. For instance, an on-site wastewater treatment solution separates solids that could be sold to local farms as fertilizer, and treated water can be re-used on site for cleaning or landscaping.

Less tangible, but possibly more important, is minimizing risk. Environmental regulations continue to be implemented and strengthened. Starting eco-friendly business practices now enables you to stay ahead of the curve, reducing costly fines or excessive expenses created by a rushed project to meet new guidelines.

Finally, you establish your brewery as a proactive, innovative, forward-thinking business. This image does more than create a positive perception for your customers and community. When your brewery is seen as an environment that fosters creativity, inspires action, and encourages advocacy, you strengthen your internal team. This in turn can have e a cyclical effect, attracting new employees with the same proactive, forward-thinking values—helping keep your brewery ahead of the curve and in-front of the competition.

Bench Brewing Company, located in Beamsville, Ontario is a great example of a sustainability leader. Matt Giffen, Founder, says, “Our culture has been rooted in sustainability since the very beginning, with a focus on minimizing our environmental footprint in both big and small ways.” As a rural business, they don’t have access to a municipal sewer system, so they built their brewery with onsite wastewater purification.

“Out here, we have to be mindful of our impact at every step of the process. From our wastewater system to employees carpooling, we strive to be good stewards of our resources and a healthy addition to our community.”

As the Bench has grown, they’ve stayed true to their core sustainability values, becoming a certified B Corporation in 2020. Today they are carbon neutral and process up to 50 cubic meters of water per day, enabling them to maintain their goal of being a zero-wastewater facility.

It should go without saying that, to realize all of these benefits, sustainability has to be an authentic value of your business. Today’s green-minded consumers will immediately see through any insincere efforts. And if people believe that your business is greenwashing, the negative impact can be swift, monumental, and long-lasting.

Some examples are extreme. Volkswagen was found to be Implementing software that falsified data that helped evade emissions tests on its vehicles. Not only were they handed a $34.69 billion fine, the brand lost creditability and the consumer trust that had taken them decades to build. Since the scandal, Volkswagen has doubled-down on their environmentally friendly initiatives and engagement to build back their reputation.

Shell committed another form of greenwashing when they asked their consumers what they were willing to change to reduce emissions, while the company itself was doing little to curb their own carbon footprint. Asking your customers to care about sustainability when your brand isn’t doing the same is an invitation for backlash.

You also must remember that today’s consumers are savvier than ever. Starbucks found that out when they introduced a “more sustainable strawless lid” for their coffee cups. The brand announced that these recyclable, strawless lids were another step on their journey to reduce environmental impact. Except that consumers were quick to point out that the new lid contained more plastic than the old lid and straw combination. This blunder made the company look deceitful at worst and clueless at best.

When you’re ready to step into the role of a sustainability leader, there are a few guidelines and best practices you can follow. Start by examining your brand, your culture, and your operations to determine what area of sustainability makes the most sense for your business, your employees, and your community. When you find the right initiative that truly aligns with your values, it’s much easier to implement changes that are not only authentic, but also embraced by your team.

Second, make sure you do your homework. The sustainability landscape is constantly shifting as new areas of concern are identified and research discovers innovative solutions. Critically thinking through all angles will help you avoid missteps, so you can be confident that the initiative you choose is doing what you say it does—and making a meaningful positive impact without creating a negative impact elsewhere.

With your sustainability efforts in place, the next step is letting the world know about it. If you’ve properly analyzed your initiative, then authenticity and honesty should be easy. As you communicate, avoid being self-serving. Instead, focus on how the choices you’ve made will benefit your con-

Don’t be afraid to start small. As long as what you’re doing is helping create a healthier planet your consumers will notice and respond, Econse

CEO Derek Davy

sumers, your community, and your region. It’s great to “save the planet,” but it’s much more meaningful when your clean wastewater helps restore a favorite local lake or your recycled materials are used in the construction of a new playground.

Once you’ve built some credibility as a sustainable brand, it’s time to build more! If you remain stagnant, you lose goodwill you’ve established and miss the opportunity to build momentum. As you explore ways to expand your sustainability (remember to follow the guidelines each time), continue looking for those initiatives that match your values. Your ongoing efforts will further reinforce your position as a leader, an innovator, and a brand consumers want to support.

Craft breweries have always been at the forefront of sustainable innovations, and as our natural resources become contaminated and diminished, that’s never been more important. If you haven’t yet started any environmentally focused efforts, now is the time to begin. If you’re already on your sustainability journey, now is the time to accelerate. This is your opportunity to become a sustainability leader and establish your brewery as cornerstone of your community.

Derek Davy is the CEO of Econse. In this guide to water management he is investigating topics designed to give brewery owners and staff the information they need to know regarding: sustainability, leadership, pollution urban myths, and best available technology. And more importantly, brewers will come away with actionable insights that craft breweries can implement to grow sustainably.

“WE PRIDE OURSELVES ON HARD WORK. THAT’S THE STANDARD WE SET. WE WORK HARD, BUT WE PLAY HARD. WE LIKE TO HAVE FUN, AND HOPEFULLY MAKE SOMETHING THAT PEOPLE ENJOY. I HOPE WE’RE DOING THAT.”

Brent Mills and the team at Four Winds joined the burgeoning BC craft beer scene and opened their doors to a public thirsty for new local offerings in June 2013. Their vision was born out of passion for craft beer, community and entrepreneurial independence.

Owned, operated and built from the ground up by the Mills family and friends, they take great pride in their continued effort to improve, innovate and refine their craft. Simply put, they make the beers that they want to drink, and try to enjoy the process as much as the result. And it’s safe to say they’re doing just that.

While Four Winds is now a cherished and established part of the Delta fabric, Brent and his brothers have their father to thank for leading them into the wonderful world of brewing. And to get to where we are today, we first must head back to 2007.

“I had just spent a year abroad in Asia and I came back as a 23 year old, moving in with my parents,” he recalls. “The beer overseas, to be honest, was pretty bland and boring so as soon as I was home my dad said ‘let’s go to and get some beers with real flavour’. While there were only a few craft breweries in Vancouver at the time we were getting a lot of Belgian beers imported that we were really hyped on.”

He adds: “We enjoyed drinking these beers but one day he turned to me and said ‘You know, we could make beer at home’. I was like ‘What are you talking about, beer at home?’ But before we knew it we were at the local home brew shop, Dan’s Homebrewing Supplies, like most would-be brewers in Vancouver.

“So there we were, brewing on my parents’ stove stop and transferring the wort to a carboy with my dad in my ear telling me that we should open a brewery one day. I would end up working in restaurants for years and was very familiar with the back of house side of things as a result. The whole time I’d be asking myself how I can get into beer properly…”

While pursuing his passion on a homebrew basis Brent would make beer. A lot of beer.

“I mean, we’re talking way too much. I’d be giving beer to friends and family, whoever. I would end up quitting the restaurant business and then applied to work at the five breweries that existed in Vancouver at the time but unfortunately, there were just no jobs.

“Fortunately, though, my dad was semi-retired and was working on trying to open his own boat-building business and he hired me while I was trying to find my feet in beer more professionally.”

Several years prior to his new venture, in 2006, Brent’s dad Greg Mills and his family had just sold Mills Paint, which had been the Mills family business since 1930. Along with his brothers Sean and Adam, Brent would help their father set up shop in Steveston.

“I pretty much went from working in a kitchen one day to fiberglass boat building the next,” he says. “That was life until the 2010 Winter Olympics came to Vancouver and R&B Brewing, a brewery in East Vancouver contacted me to see if I was interested in working for them. They knew they were going to be busy with so much of their annual production taking place around that time.

“For those few months I was filling kegs, washing kegs and helping out around the place. When the Olympics were done I returned to the boat-building business but one day I got a call from them again saying there’s an opening for a brewer. Of course I said yes. Those three years with them, along with a stint at the Siebel Institute, really helped me solidify my knowledge.”

While dad Greg would eventually leave the world of boat-building, he found a new calling - “poking” Brent to open a brewery of his own.

Brent explains: “He was itching to jump back into something and I now had the experience I needed in brewing, so we thought

let’s do it! We brought in my two brothers Adam and Sean and just went for it.”

“Our dad was the driving force to get this brewery up and running, we would all be in a different place if he didn’t have the conviction he did to start this brewery. Through seven years of growth and all the challenges that come with opening and new business he was our rock and kept the ship steady until his sudden passing in early 2020.

“It was a tough time for us as he was not only our president he was the financial controller and the GM of the business. After Adam and I fumbled through managing the financial side of the business for a few months we convinced our sister Brooke to come on board and take on some of this responsibility.

“Our mom passed away in 2015 so the whole family that was once six now four work together operating the business. We brewed a commemorative beer for Greg for Father’s Day the year after he passed away and it became a full time SKU for us right away - Greg West Coast IPA.

“I get to work with my family everyday doing something that I never knew you could make a living at, we have had our challenges but I couldn’t be luckier to do what we do with the people we do it with.”

In starting out, Brent was excited about the challenge ahead: “I was the only one with industry experience, and we had very little money. But being outside of the city meant our rents were lower than a lot of other businesses. We’d go onto build most of the brewery ourselves, hiring out the really essential roles.

“And by June 2013, we found ourselves ready to open. Based in the middle of the an industrial estate some 15 kilometres from the closest community we thought that if 50 people come through the doors then we’ve done well.”

500 turned up that day…

“We were very lucky that people of Delta came out for us. There was a real appetite for craft beer but there was a real lack of beer made locally so the demand was there for all to see. It felt like the whole town was with us!”

Starting out, the brewery’s beers range was influenced by a number of different geographies. Four, if you will. “Four Winds is a classic sailor’s term. So we were scattered to the four winds, going in a number of directions. And early on it was very clear to us we would use that term to describe our influences,” says Brent. “Germany, Belgium, American and even British played their part.”

Rather than opting for a somewhat traditional six-pack beer offering, Four Winds opted for a four-pack bottle offering comprising a Pale, Pilsner, IPA and a Saison. “Saison is a style dear to me and we were probably the first to brew one full-time. Sadly that’s no longer the case because for the life of us, we just can’t sell them anymore,” he laments.

Early influences behind Four Winds’ initial beers came from Brasserie Dupont’s Saison Dupont, Mirror Pond Pale Ale from Deschutes and Green Flash West Coast IPA. Though the market availability of the required hops to match this profiles would lead them in different directions.

“In 2013 we couldn’t get Centennial so we had to settle for a blend of Cascade and Chinook, and also found ourselves, for a good while, using Falconer’s Flight as an aroma hop for our IPA,” he says. “And when it came to our Pilsner it was something of a Frankenstein beer! Inspired by Pivo Pils from Firestone Walker if was a Czech-style number dry-hopped with Motueka. I’m pretty proud of those beers. I feel like that had a uniqueness about them, backed up by a sense of character.”

And a sense of character is a trait that runs from the Mills family. In the near 12 years that have passed since that successful

opening, the day-to-day ethos of the business and those behind it is hard work. “It can be a grind but we pride ourselves on hard work. It’s the standard we’ve always set,” says Brent.

In 2025 the original River Road location is still going strong. With a trusted 25HL brewhouse, Brent admits that maintenance is becoming more of a regular part of life. But it’s a production setup that is still pro-

ducing a wealth of superb beers like Hazy IPA Flüff, Four Winds Light Lager, and Dryhopped Sour Nectarous.

He explains: “It’s a four vessel brew house. Originally it was two but then we added third and a fourth so we can turn a couple brews a day. With an initial focus on Belgian styles we needed to have a mash tun, or a mash kettle that we can do step infusion.

“We decided to add a mash kettle that doubled as a kettle whirlpool. So we’d mash into the mash kettle, send the mash over to the lauter, lauter back into the kettle whirlpool, boil whirlpool in there and send to the fermenter. So to do two turns in a day was was nearly impossible, because you had to wait make sure that you’re fully in the fermenter before you can start the second turn.

“So about a year later, we added a third and fourth vessel. They’re actually one vessel stacked, so up top is a brew kettle and below is a whirlpool. We just didn’t have the square footage for two vessels, but it works….”

Cellar capacity was added year-on-year, doubling and sometimes tripling in volume. The current output now is around 13,000HL per annum and this is made possible under the stewardship of head Brewer Jules Dubus who hails from France but also spent 10 years brewing in Quebec mastering the art of big stouts and mixed culture beers.

“Through the last couple years as Adam and I have had our heads down designing, planning and building the new Beach House location Jules has been the driving force of creativity, quality and execution in our beers alongside Jared Whalen our Production manager. These two dudes held it down while we built the new location,” says Brent.

And while the River Road location is responsible for production volumes, that’s

only part of the story. Because as of 2024, Four Winds added that exciting new location to their bow.

Southlands is Tsawwassen’s new agriculturally-focused beachside community development. But step back some 10 years, shortly after Four Winds started out the team were approached by Southlands to discuss the prospect of building a new brewing facility coupled with an attached onsite restaurant.

“They were redeveloping around 600 acres of land with most going back to organic farming while 100 of those were to be used for commercial and residential,” he recalls. “Initially we considered moving our whole operation there. You know what it’s like. We were enjoying extreme growth so why not shoot for the moon?

“But after spending a lot of time and money putting together an application, it failed at the final hurdle during a city council meeting. It was a tough loss. We went away and refocused on the original business but some time later the developer returned to us and asked: ‘How about if we forget about a 35,000sqft brewery and instead look at a 9,000sqft restaurant with brewpub attached?’

They got on board with the idea and thankfully, so did the local council. Opening last year, the Four Winds Beach House & Brewery offers a West

Coast take on the classic beer hall where they celebrate both traditional and modern brewing methods, paired with exceptional hospitality and memorable dining experiences.

“Tsawwassen, where the team grew up and now raise our families, is dear to us. Joining the Southlands development—a unique “agri-hood” with 530 acres of farmland, green spaces, a growing neighbourhood and a bustling market square, is a dream come true,” says Brent.

The fantastic new venture was made possible by assistance from Century Group that provided the superb building, The building was designed by Motiv architects while the interior design was Ste. Marie, Finally, Gillian Gonzalez-Risso, of Feast Strategy Partners was integral in handling the administrative side of the team’s goals and dreams.

Open six months in February 2025, the Beach House boasts a 15HL, semi automatic, decoction-capable brewery with two 15HL open-top FVs. Here they brew their traditional Czech beers and then blend the two 15 HL batches into 30 HL horizontals. You heard that right, Czechstyle beers such as the 4.4% Archetype Czech Pale Lager, 4.8% Czech Dark Lager Antithesis sit side-by-side a Hefeweizen, Dunkelweizen and Kölsch. While there’s also no shortage of hop-forward Pale, IPAs and Dry-hopped Sours, too.

I get to work with my family every day doing something that I never knew you could make a living at. We’ve had our challenges, but I couldn’t be luckier to do what we do with the people we do it with.” — Brent Mills, Four Winds Brewing

“We need to do a bit of everything here. Tsawwassen is a small community of around 25,000 people so if we made only the beer I wanted to drink we’d probably only have a very small group of die-hard fans,” he laughs. “So instead, while the focus is on beer there really is something for everyone.”

But it’s the ability to brew a range of Czechstyle beers, and educate the local consumer base on the beer’s appearance and form, that really excites Brent. And a timely visit to the Czech Republic as a guest on a ‘Beer Mission’, which featured Canadian diplomats, importers and brewers opened his eyes further.

“It was an amazing opportunity. I got there a few days earlier than everyone else so I could do a training session with a local pub chain and learn more about how to pour beer from Lukr taps. Something I’ve gone onto do here in Canada for our staff, too,” he explains. “Initially our visitors questioned the abundance of foam in some beers and whether we were short-changing them,” he smiles. “It takes time but after a while they could see the qualities foam offers.”

The manufacture Lukr follows the longstanding Bohemian tradition of brassmade beer towers with side-pour faucets. And during his visit to the Czech Republic Brent was able to visit their factory.

“I found myself speaking to our rep that I had ordered our kit from. We were on

a tour and I heard the guide explain how the tower in front of us was bound for a customer in Canada. I knew that had to be us! I went to check the clipboard and there was our name - Four Winds. But before I had to chance to look further I was being told off in case I left some fingerprints on our brand new tower!”

In addition to fantastic Czech-style beers, Brent and the team are also dabbling in such creations as a 5% Concord Grape Spritz to complement a superb list of other BC wines and ciders. “We really want to explore that world a little more,” says Brent. “I’m still not fully sure where we place these drinks on the menu but we’ll get there eventually.

And it’s that organic, considered approach to growth and evolution that has served Four Winds so well on its journey to-date. A small family business has grown to one that now employs 130 across both of its locations. Something that any business owner should be proud of.

“It can be hard. This industry has its challenges. And when things are hard, you don’t get a chance to really enjoy it. And then when things are good, you’re so busy, they don’t really get the moment to reflect.

“So to see these breweries that we’ve help build, breweries that didn’t exist years ago, employing people and contributing to our communities keeps me feeling invigorated and excited. It feels good.”

Igrew up in a small town in Northern Ontario called Espanola. Not many people know where it is. It’s a small town located between Sudbury and Sault Ste. Marie. For years, the community was a famous pulp and paper town until the mill became dormant.

It was upsetting to hear that my hometown’s main source of employment, a place where my father was once in charge of safety, would be no more. Around 400 employees were laid off.

That’s when I started brainstorming ideas on how Espanola could rebuild and create new jobs.

The first idea that came to mind was a microbrewery. Lots of communities have microbreweries that have created jobs and given visitors and residents alike the opportunity to try a unique beer that you might not be able to get anywhere else.

The idea popped into my head after learning about all the communities that have

microbrewys in Nova Scotia, where I am currently living.

Before I explain exactly why I think Espanola would be a great place to open a brewery, here are some fun facts about this little town, as there is more to the town than the old paper industry. It is also considered to be the birthplace of the game ringette.

The game was co-invented by a former Espanola resident and recreation director, “Red Mcarthy,” who also oversaw the first-ever ringette game played in the community in the early 1960s. It is also the childhood home of NHL enforcer Al Secord, who spent most of his career with the Chicago Blackhawks.

When I lived in Espanola, I found that drinking beer was and still is a very common thing to do at social events such as community suppers and the curling club. Because Espanola is a very community-minded place, I know that they would support local businesses like microbreweries and not hesitate to wet their whistles with some locally-made beer.

The Split Rail Brewing Company in Gore Bay and the Manitoulin Brewing Company on Manitoulin Island have been successful, and both of their beers are quite popular in the Espanola area. That is why I think Espanola would be a great place for aspiring craft brewery owners to set up shop.

I did reach out to Susan Snelling, a consultant who worked with The Split Rail Brewing Company, and she informed me that the brewery got some of the support it needed through a crowdfunding campaign, highlighting the fact that community support really can go a long way towards supporting a business.

Snelling wants to make it clear to people new in the brewing industry that if you want your brand of beer to be a success, it needs to have a unique taste that stands

out from other beers on the market; that way, people will come back for more.

Northern Ontario cities like Sault Ste Marie and Sudbury also have successful breweries. Keep in mind that independent microbrewers may not create hundreds of jobs, but it will certainly give community members hope that there is potential employment. There are quite a few restaurants in the Espanola area, and since it is a close-knit community, I could easily picture these restaurants serving locally-made beer.

The Pinewood Motor Inn dining room, for example, already serves Split Rail Brewing Company Beer along with other bars and restaurants on Manitoulin Island and Sudbury. Espanola does get a lot of visitors during the summer months, people

Keep in mind that independent microbrewers may not create hundreds of jobs, but it will certainly give community members hope that there is potential employment

who drive through the town on their way to the island and snowmobilers who ride through the trails in the winter. Tourists and visitors love trying beers that are unique to certain regions. I should take this time to remind snowmobilers and drivers not to drink and drive.

As part of my research, I went to a Facebook group called “What’s Happening Espanola,” and I asked the group members if Espanola had a microbrewery, what it should be called and if they had any ideas for beer names. Well, I got all kinds of ideas showing that there is real interest in having a microbrewery.

Some of the ideas for the breweries’ names that I liked included Boogie Mountain Brewery (Boogie Mountain is the name of the town Ski Hill), Paper Town Brewery, and Old Mill Town Brewery. The beer names were creative, too: Spanish River Lager, Ringette Red Ale, Lacloche

Foothills Lager, and my personal favourite, Stinktown Ale, a reference to the unpleasant odour often emitted from the mill. The names I came up with are Faraway Lager, named after the Road where my childhood home was; Secord Stout, named after Al Secord; and Ehrhardt Ale, named after Caroline Ehrhardt, one of Canada’s best triple jumpers that once called Espanola home.

The last time I looked in the real estate listings for the Espanola area, some commercial buildings for sale cost less than one million dollars. One such place was a warehouse at the edge of town that could be turned into a brewery easily.

If commercial real estate is outside your budget, there are all kinds of rural properties where you could either build a brewery from scratch or, if you ask around, you might find someone who might rent out a barn or a shed for you to brew your beer.

You might even find an affordable location in one of the surrounding communities like Massey, Baldwin Township, Webbwood, or Narin Centre.

There are a number of business success stories from Espanola, like Espanola Coffee Roasters and Farquhar’s Dairy, proving that Espanola is more than just a pulp and paper town. Suppose this article inspired you to start a brewery in this awesome community.

You can learn more about it by visiting the municipal website espanola.ca. While you are there, be sure to check out the economic development section, where you will find funding resources for small businesses.

If you know of a community that doesn’t have a microbrewery and you think it has the potential to support one, don’t hesitate to let me know. Visit my website: blakecrashpriddle.com

NESTLED AT THE MOUTH OF THE BAY, ALONG THE BEAUTIFUL AND SCENIC NORTH SHORE OF NOVA SCOTIA IS TATAMAGOUCHE BREWING CO. LONG SANDY BEACHES, QUAINT SHOPS AND LOCAL MARKETS AND RESTAURANTS ROUND OUT THIS UNIQUE PART OF THE WORLD.

Follow the world famous Sunrise Trail and you’ll run right through Tatamagouche (or Tatta as locals call it). The meeting of the waters is one way to describe the village on the edge of the ocean. Just a short drive from vineyards, year round ski and biking trails, provincial parks and some of the best seafood on the planet.

Celebrating 10 years in the game, Tatamagouche Brewing Co. is fresh off a silver medal at the Canada Beer Cup. Owners Matt Kenny and Christiane Jost opened the renovated butcher shop in 2014, after finishing university. They’d travelled and visited small craft brew shops in the US and Europe before deciding to take a chance in Nova Scotia.

“It took a little bit of awareness and education,” Kenny said. “People were used to big brands.”

The couple started small, brewing a couple of batches to feel out the mar-

ket. They offered a Hippie Dippy Pale Ale and a Butcher Block Red Ale and they sold really well. Tatamagouche is like a lot of small coastal towns in Nova Scotia, with a big population boost starting in the spring. Cottagers from around the area stopped in to try the new brew and started taking a few home to enjoy.

The crowds got bigger as the shoulder seasons expanded through the summer and into the fall. More locals were taking the scenic drive to see what Tatta Brewing was up to, so they expanded their beer offerings.

Next came an IPA, a lager, a strong porter and eventually sours. They learned by doing and hired some of the area’s best staff to compliment their tasty and popular beers. The shop expanded, so too did their clientele and now they offer up to 42 different beers at any given time during the year.

This includes non-alcoholic options, cider and wine drinks to allow for vari -

ety. Always experimenting, their master brewers are always looking forward with new ideas, trying new things that may or may not end up on the menu.

“Hiring great people made it easier for us to focus on the fundamentals,” Kenny said. “We were able to work on growing the business and not just working at the business.”

From a small packaging kit and a few cans they’re now looking to expand again. They need more space to store product and to lessen their supply chain issues from the pandemic. They’re trying to focus on buying as much local products as possible, not only to save money on freight but also to stimulate their local economies. They want to see more products available in Nova Scotia so they can keep their money in the province.

“We’re starting to get more locally produced products,” Kenny said. “The ones we can’t, we try to buy in bulk, so space is becoming an issue.”

We were able to adapt, learn and reset. Nothing has really been the same since,” Matt Kenny, Tatamagouche Brewing Co

Covid put a lot of things on hold in tourist centres like Tatta but sales at the Brewing Co remained steady. With local pick up and delivery Kenny and his staff saw a growing interest in shopping at home and that included local beer, produce, meat and handcrafted products.

This was enough to sustain the shop and help them keep the momentum they had been building on for the first six years of business.

“Sales stayed pretty consistent during Covid,” Kenny said. “We were able to adapt, learn and reset. Nothing has really been the same since.”

The plan is to expand their patio in the spring and keep up with the growing competition of craft breweries opening

all across the province. They have strong name recognition and a reputation to back it up.

The future looks bright for craft beer in Tatamagouche and all across the province. A new focus on local tourism and projects encouraged by the province will help make the area a go-to destination in the future.

With the new patio and over 42 beers readily available in house and at the local NSLC, Kenny is betting on another ten years.

“We’re super fortunate to be in an amazing area,” Kenny said. “With golf, the ski hill moving to year round, the beaches and more interest in growing tourism, we’re ready for what comes next.”

If you’re looking for a great day trip, long weekend adventure or need a couple of weeks to frolic along the North Shore of Nova Scotia, be sure to check out Tatamagouche Brewing Co. They work extremely hard to foster an inclusive atmosphere with exceptional product quality and attention to detail.

Their down to earth approach and comfortable environment will have you coming back after a swim, walk, round of golf or bike ride. You might even find yourself falling in love with a side of Nova Scotia you might not have experienced. Next thing you know, you’ll be a regular coming back every season to enjoy the beer, the people and the culture.

he building code classifies different spaces according to their use, or occupancy, such as residential, office, assembly, industrial and retail. Each occupancy typically has unique fire and life safety requirements associated with it.

There are also requirements related to how occupancies can be combined within a building. For example, certain occupancies are not even permitted to be located in the same building

Under the building code, breweries are typically considered industrial occupancies, while tasting areas are typically considered assembly occupancies (i.e. like bar or a restaurant). The code requires a fire separation between the two if they are each considered a major occupancy.

A fire separation is a barrier that is designed to resist the spread of fire and smoke from one space to another. Creating one between a brewery and a tasting area can present some challenges.

It necessitates constructing a wall that extends from the floor all the way up to either the slab or roof above, which can be expensive. The wall would mean that all your beautiful brewing equipment would no longer be visible from within the tasting area, which arguably takes away from the experience for patrons and could make both spaces feel cramped.

Windows in the wall could help make the spaces feel less cramped and allow patrons to see the brewery, but any window in a fire separation requires a fire-protection rating. This means it either needs to be wired glass in a steel frame, provided with a fire shutter, or it needs to be sprinkler-protected.

A major occupancy is defined as “the principal occupancy for which a building or part of a building is used or intended to be used, and is deemed to include the subsidiary occupancies that are an integral part of the principal occupancy.”

Wired glass windows are not especially aesthetically appealing, fire shutters are costly, and sprinkler protection can be expensive or difficult to install, especially in a building that is not already provided with sprinklers.

Similar to windows, any door in a fire separation is also required to be fire-rated, which adds to the cost and can make the two spaces feel disconnected. Fire-rated doors are typically constructed of steel, with very small windows if any, and provided with steel frames.

Rated doors are required to be provided with self-closing hardware and are generally required to be kept closed at all times unless they are provided with specialized hold-open hardware connected to the building’s fire alarm system.

Like the windows and doors, openings in the fire separation for things like plumbing or HVAC would also need to be protected. Openings for services like pipes would need to be provided with firestopping, which is a product/system that is specially designed to maintain the integrity of the fire separation.

Openings for ductwork would need to be protected with combination fire/smoke dampers, which are also designed to maintain the integrity of the fire separation.

Finally, subdividing your space with a fire separation could introduce some operational challenges. The floor area on the tasting area side of your operation is space that could be used for storage, moving equipment or receiving deliveries when the tasting area is not open.

With a fire separation dividing the two spaces, moving large equipment or product between the two spaces would be difficult unless the wall is provided with a rolling door, which again, would need to be fire-rated.

With some foresight and planning regarding the operation and design of the tasting area, the building code can be applied in a way that may not require a fire separation between the brewery and tasting area.

In some cases, the tasting area can be considered a retail occupancy rather than an assembly occupancy. The code does not require a fire separation between medium- or low-hazard industrial major occupancies, such as breweries, and retail major occupancies.

This is a relatively straightforward way to apply the building code but it does limit the maximum number of occupants, or occupant load, and therefore also limits the revenue that can be generated from the tasting area.

Another option is to examine whether or not the tasting area can be considered subsidiary to the industrial major occupancy. Subsidiary occupancies are generally not required to be fire separated from

the major occupancy they serve. The main advantage of this approach is that it can allow for more occupants than the retail approach discussed above.

“Subsidiary occupancy” is not defined in the building code, which leaves it open to interpretation and means you need to make a strong case as to why the tasting area should be considered subsidiary to the brewing operations.

This generally involves evaluating the scale of both the brewing operation and tasting area based on floor area and occupant load, reviewing how the two spaces will operate in terms of business hours and control, demonstrating that the two spaces are co-dependent, and evaluating how access is or isn’t provided between the two spaces.

Some building departments will be receptive to this approach and approve it after receiving a letter or report explaining how the Building Code is being applied to the project. Other building departments may require an Alternative Solution to be submitted.

An Alternative Solution is a formal process where you need to demonstrate to the building department’s satisfaction that your design achieves a level of performance that is equivalent to what is intended by the requirements contained in the building code.

Alternative Solutions are submitted with the building permit application and typically include a report prepared by an engineer that describes the design in terms of fire and life safety, and explains how the required level of performance is achieved.

Sometimes building departments require the design to include mitigating measures

There are costeffective ways to add a tasting area to your brewery while providing the level of safety intended by the building code,” Adam Gillies, LRI Engineering

in order to accept the Alternative Solution. Examples of mitigating measures include additional exit/egress doors, shorter travel distances to exits, and limiting occupant loads to a particular number.

However you approach it, there are cost-effective ways to add a tasting area to your brewery while providing the level of safety intended by the building code, but without compromising on the experience for your patrons or practicality for your operations.

LRI Engineering Inc is Canada’s most relied upon engineering firm specializing in fire protection, building and fire codes, emergency planning services.

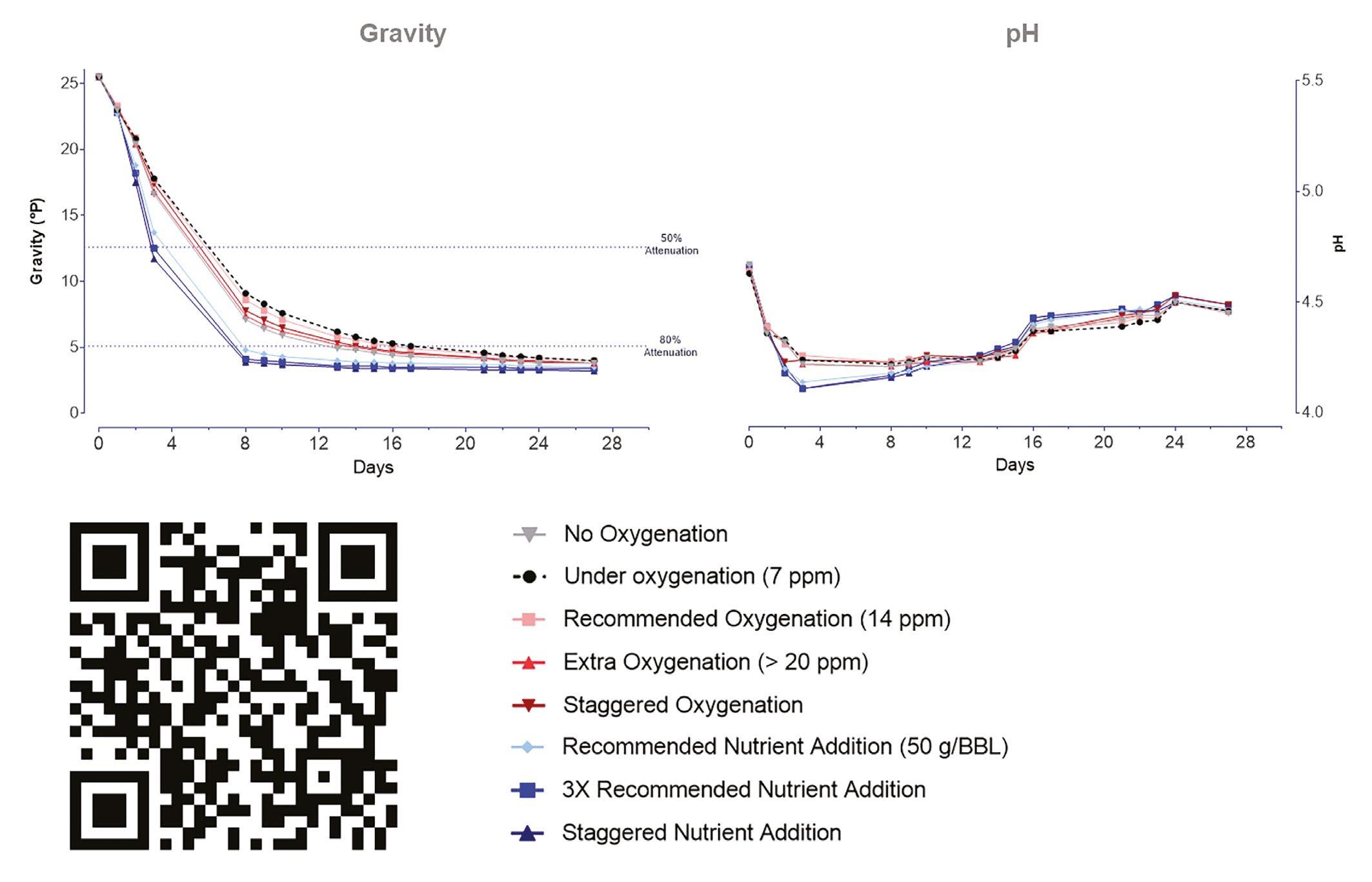

FERMENTING A HIGH-GRAVITY BEER IS ALWAYS CHALLENGING DUE TO HIGH LEVELS OF ALCOHOL, WHICH ARE TOXIC TO YEAST CELLS, AND MONSTROUS AMOUNTS OF SUGARS FOR THE YEAST TO CONSUME. THIS CAN LEAD TO STUCK FERMENTATIONS, FUSEL ALCOHOL OFF-FLAVORS, AND OTHER PROBLEMS. IN THIS ARTICLE, THE TEAM AT WHITE LABS SHARE SOME QUICK TIPS AND TRICKS TO HELP YOU HAVE A FULL, COMPLETE FERMENTATION.

Pitching the right amount is crucial for all the fermentables to be eaten and converted into ethanol. Similar to not inviting enough guests over to a Thanksgiving party. If the ratio of guests to food is off, there will be leftover food. In the context of brewing, not pitching enough yeast can lead to stuck fermentations, leftover fermentables, and overly sweet beers. Common pitch rates for high-gravity brews can range from 1 -1.5 million cells/P/mL.

Brewers inevitably want to minimize oxygen in their process, with one exception: wort. In other aspects of beer production, oxygen has detrimental effects on flavor and stability, but the opposite is true in the early phases of fermentation.

Yeast depends on oxygen to provide the building blocks needed to synthesize fatty acids and sterols, essential components in the yeast cell membrane. It helps the transportation of sugars, pH, and metabolic byproducts in and out of the cell. By having proper cell membranes, the reabsorption of acetaldehyde and diacetyl can be aided to convert into ethanol and acetoin.

From our previous research, fermentations with an added dosage (50g/ BBL) of a Nitrogen-rich Nutrient (FANMax Bio) led to quickening fermentation timelines by reducing the time to final gravity by around 50% in both 22 and 25 Plato wort. It reached terminal gravity in record time meaning faster high ABV beer with a clean fermentation profile.

Common pitch rates for high-gravity brews can range from 1 -1.5 million cells/P/mL.

With these three simple tips, the risks of a stuck fermentation and an acetaldehyde stout are less likely to occur. Healthy yeast is still needed, and we recommend a later generation, 3-5, as they are more accustomed to the requirements of fermenting a big beer.

Most texts will recommend a standard dissolved oxygen rate of 8-10ppm (mg/L) in a moderate gravity wort (up to 12° Plato). For a high-gravity brew, 1 ppm per Plato is a great place to start for oxygenation.

Nutrients give yeast the necessary boost needed to complete fermentation. Like our daily vitamins, nutrients such as zinc, magnesium, and nitrogen.

Be diligent and monitor your pH drops and gravity timelines, where a rousing of yeast or other brewing techniques might be needed. Big beers don’t need to be intimidating, in no time, a big brewed beer can be on its way.

For a high-gravity brew, 1 ppm per Plato is a great place to start for oxygenation.

THANKFULLY LENZIE KINYON, PROFESSIONAL BREWING CONSULTANT AND DALUM

CONSULTANT IS ON HAND TO EXPLAIN MORE.

An increasing number of breweries are investing in CO2 recovery technology, both in North America and around the world. Rising costs for liquid CO2, along with recent availability issues, have drawn serious attention to the importance of collecting and using CO2 from their own fermentation process.

Much of the success in the craft brewing industry is related to producing artisan products that stand out from the many products brewed by the major breweries, which often have similar characteristics.

By combining exceptional ingredients and their unique brewing processes, craft brewers offer beers and ales with flavours and aromas that please customers who are looking for something special. With this hands-on experience and knowledge, craft brewers are highly skilled at sourcing ingredients.

While this depth of knowledge applies to ingredients like malt and hops, this is not always true for CO2. Craft brewers certainly know how to manage carbonation levels in their products to compliment the aromas and flavours they want but have not had to concern themselves with quality of CO2 until they start researching recovering their own CO2 – and it might come as a bit of surprise but not all CO2 supply is created equal.

It is imperative that craft brewers understand that when recovering CO2, they need ensure the system or technology they are considering can achieve beverage-grade CO2 so that their new recovered supply doesn’t contaminate the beer being produced and impact their ability to deliver a desired product to their patrons,

By moving away from purchased CO2, brewers are giving up the purification that is part of the commercial CO2 manufacturing process. Purification must now be done by the new recovery system being purchased. Liquid CO2 from that system must be pure enough to carbonate without adding unwanted flavours and aromas.

The purity claims made by various recovery system suppliers should be compared to the purity recommendations for food and beverage use gases that are published by one or more industrial gas groups. These include the:

ISBT – International Society of Beverage Technologists

EIGA – European Industrial Gas Association

CGA – Compressed Gas Association

Brewery raw CO2 contains many organic compounds naturally formed during fermentation. These compounds include mercaptans, esters, aldehydes, sulfides, alcohols, and other fermentation prod-

ucts, including oxygen that is in the headspace of each fermenter.

Unless these compounds are removed by the recovery system, they may pass through and become defects in the flavour and aroma of the brewery products they come in contact with.

The chart provided here demonstrates the profile of the gas from fermentation at a brewery that has installed a Dalum CO2 Recovery Unit. On the left is the raw gas from fermentation coming into the CO2 recovery plant – as you move right you can see the non-CO2 components being eliminated as the purification and condensation process progresses. The stages include a water scrubber, compressor, dehydrator, and condenser.

The result is CO2 purity of 99.98599.995% pure. Higher than ISBT benchmark meaning it’s high enough purity to use in beer, sodas etc. Dalum had a customer who tested both their CO2 from a commercial source and the CO2 from their recovery unit and the recovered CO2 actually tested at a higher purity which is reassuring for brewers exploring this technology.

It’s difficult to appreciate the purity without understanding the risks associated with unwanted “contaminants “from CO2. Risks of “contaminated” CO2 include;

Contaminants and Off-Flavours

The introduction of contaminants that can spoil the taste and aroma of the beer. CO2 can contain impurities like sulfur compounds, hydrocarbons, or even small amounts of other gases that, if present in the brewing process, can lead to off-flavoUrs. Sulfur compounds, for example, can impart an unpleasant rotten-egg aroma, while hydrocarbons can give the beer a plastic-like taste. Even small levels of contamination can have a noticeable impact, leading to flavour defects that diminish the overall quality of the beer.

Preserving Freshness and Shelf Life

The quality of CO2 also affects the beer’s shelf life. Contaminated CO2 can interact with compounds in the beer, leading to chemical reactions that accelerate spoilage. For example, oxygen contamination in CO2 can cause oxidation, which gives beer stale or cardboard-like flavours.

Inconsistent Carbonation Levels

If CO2 levels fluctuate due to poor quality or impurities, it can result in over-carbonated or under-carbonated beer, both of which negatively affect the drinking experience. High-quality CO2 allows brewers to achieve precise carbonation levels across all batches.

Change in Mouthfeel and Drinkability

Using high-quality CO2 ensures that the carbonation process goes as intended, allowing brewers to achieve the perfect mouthfeel for each style. Poor-quality CO2 can create overly sharp or flat sensations that detract from the drinkability of the beer.

Once craft brewers start recovering their own high-quality CO2 they are usually quite proud to tell their customers that the CO2 used is derived from their local natural fermentation process and not trucked in from industrial sources such as a byproduct from a fertilizer factory, ammonia production and ethanol.

Recovery equipment requires special engineering and complex systems to remove most or all of these unwanted compounds and until recently there were no solutions for craft breweries like this patented system from Dalum Beverage Equipment.

Large industrial manufacturing companies such as Pentair support the industrial breweries, but these units are scaled much too large for your average craft brewery and not financially feasible.

CO2 recovery system suppliers should supply potential customers with sample analyses from actual installations they have installed at craft breweries. They should also perform start-up testing to demonstrate that the recovery system is producing high-quality CO2. Without these assurances, the reputation of the craft brewery is on the line.

As the American craft beer landscape continues to evolve and change so too must the festivals and events associated with it.

Nowhere is this more evident than at the latest iteration of the Great American Beer Festival (GABF), the largest public tasting event in America.

Organised by the Brewers Association, the not-for-profit trade association for small and independent American craft brewers, the 42nd GABF took place last week in Denver, Colorado and drew approximately 40,000 people who eagerly descended on the state capital to sample the 2,500 beverages from 600+ breweries, cideries, distillers and other beverage producers.

The GABF competition took place in the lead-up to the Festival, with results announced on the Saturday and providing a good barometer of American craft beer trends.

In total, 8,836 beers and 233 cider entries were judged across 102 beer categories and five new cider categories, all evaluated by 285 beer experts. The competition was made possible thanks to more than 250 volunteers who facilitated the multi-step judging process over seven days in three phases.

In total, 326 medals were awarded to 273 breweries. The top five most-entered style category winners included:

Juicy/Hazy IPA (349 entries)

West Coast IPA (292 entries)

American-style IPA (217 entries)

Dortmunder or German-style Oktoberfest (210 entries)

German Style Marzen (195 entries)

There are two trends within craft beer styles that are growing the fastest right now. IPA in its many iterations continues to lead the American craft brewing landscape, now accounting for 46% of the $29 billion craft beer industry, up from 30% in 2017.

Hop forward beers like American IPA, juicy/hazy IPA, and Imperial IPA saw the strongest market share gains in 2023.

Lighter styles, like American lager, wheat ale, and pilsner are also gaining traction, showing growth at both ends of the ABV spectrum.

Overall, growth is coming from both high and low ABV styles while mid-range ABV beers face more challenges.

There was a myriad of IPAs at the Festival but a good rule of thumb was to focus on award-winning breweries that produce world-class examples of the style such as Breakside Brewery, Reuben’s Brews or Sierra Nevada Brewing Co.

While most certainly not an IPA, Allagash White, the classic Belgian Witbier, won

gold again and is available in many export markets.

Topping the bill for extreme offerings was Sam Adams Utopias, boasting an impressive 28% ABV. This rare, bi-annual, boundary blending, barrel aged masterpiece drew the longest lines at the Festival.

Other popular examples included Revolution Brewing’s DBVSOD (Double Barrel Very Special Old Deth) at 17%, a double barrel aged imperial oatmeal stout; Fremont Brewing Company’s Rusty Nail, a Bourbon barrel aged imperial stout infused with liquorice and cinnamon bark, coming in at 14.5%; and Firestone Walker’s Bendy Foldies, a 14% double oaked ale with red foxy vanilla beans and toasted pistachios.

Lager and lighter styles are having their moment in the spotlight and there were plenty of excellent examples at the Festival.

Deschutes Brewery’s Fresh Hop King Crispy is a German-style pilsner which medalled in the latest competition, while Uinta Brewing Co’s Was Angeles, a 5% cream ale proudly took home a gold medal!

After indulging in a plethora of hop-forward IPAs and/or high-strength barrel-aged beers, it was refreshing to cleanse the

palate and explore something new with an easy-drinking non-beer beverage such as a hard tea from Upslope Brewing Co or a hard lemonade from Denver Beer Co.

Both beverages made their debut at the Festival this year, demonstrating the innovation and creativity that American craft breweries are embracing to remain competitive in an ever-evolving market.

Another strategy for navigating GABF was to seek out unique alcohol-free options. Athletic Brewing Co., a high-profile brand available in many international markets, picked up two medals at the GABF competition, making it an excellent choice, and Fremont Brewing won gold in the amber to dark non-alcohol category.

The low and no-alcohol beer segment is still small but rapidly expanding within the American craft brewing market.

For the adventurist, the Festival presented a cornucopia of experimental concoctions, notably, 903 Brewers’ Zesty Ranch Taco, a 6% cream ale, that delivered the savoury umami experience of eating a taco in liquid form!

A festival favourite overseas, Destihl Brewery’s Dill Pickle Sour offered a distinctive flavour experience, while Denver Beer Co.’s intriguing Fennel Rye ale took home a gold medal at the competition.

A COMMUNITY IS ONE OF THE GREAT QUALITIES BREWERIES CAN BOAST. FLORIDA KEYS BREWERY IS DOING JUST THAT, AND IT HAS SOME CANADIAN BREWING EXPERTISE BEHIND IT, TOO, HERE PAUL KNOWLES EXPLAINS ALL.

Craig McBay is from Burlington, Ontario. And yes, he fits the stereotype of beer-loving Canadians. Cheryl McBay is from the Florida Keys. And yes, she fits the stereotype of “Conchs” born in the Keys – fun-loving, sun-loving folk who enjoy having a good time, and providing the same to guests.

Craig credits his first experience with making beer to Cheryl’s mother, who, knowing his affection for brew, gave him a beer-making kit. At that time, Craig and Cheryl were living in an apartment in West Palm Beach, and Craig ended up with 400 bottles of home-brewed beer stored in sundry locations in his apartment.

Cheryl was not a fan of mainland Florida. And Craig happily moved with her, back to her home territory – the unique and very special region called the Florida Keys. It was an appropriate decision – they had met in a bar in the Keys while Craig was on a one-year job assignment in Floridas. The couple admits that “Hog Heaven” hook-ups don’t usually result in long-term

relationships, but in their case, something clicked in a big way.

When Cheryl and Craig moved back to the Keys, they soon noticed something that was an immediate challenge for beer lovers – the bars and restaurants they frequented (and there is no lack of bars in the Florida Keys) did not serve local beers.

They overheard patrons asking about local brew, only to be told the establishments only served the well-known national brands.

Craig admits that Cheryl had the idea first: why not turn his love of beer-making and her interest in design and event management into a craft brewery? Why not give beer-lovers some more interesting options?

Craig knew that his 400-bottle experiences in an apartment did not prepare him adequately for work as a professional brewmaster, so he contacted craft breweries and asked if he could “hang out” with them to learn the trade. Every brewmaster

agreed. “Craft brewers help each other,” explains Craig.

So, ten years ago, Cheryl and Craig made the leap. They opened the Florida Keys Brewery in the “Morada Way Arts and Culture District” in Islamorada. And the rest is history – albeit, hard-fought, patience-challenging history. Success was definitely not immediate. Craig smiles, today, admitting that “our bartenders were sleeping on the counter” because there were no customers.

And let’s be honest: maintaining a business started in 2015 meant surviving the wrath of Hurricane Irma, which slammed Islamorada in 2017, and then the horrendous impact of Covid, starting in 2020. Although the couple point out that Covid actually provided an opportunity, because of a plan already in place – they had acquired a nearby building with a big back yard, which they converted into an open-air beer garden.

So during the pandemic, people could still gather, drink beer, and enjoy live entertainment in a safe environment.

And it turns out that the McBays have a real gift for creating, not only great beer, but great experiences. Cheryl’s retro design sense means that guests at the Florida Keys Brewery can kick back in an ambience that is reminiscent of a Grateful Dead concert.

When they check out the extensive list of beers on tap, they are choosing between “Stoned Iguana”, “Alligator House Light Lager,” “Hurricane Hole Red,” “Death by Mermaid,” “Honey Bottomed Blonde”, or any other of twenty available quaffs – a frequently changing list.

Craig continues to hold the role of brewmaster, and he supervises production of 40 different beers each year. A few of those beers will probably be one-offs, never to be replicated, the result of Craig’s continual exploration of his craft. Or, he admits, the result of an accident that produces something unique and very drinkable, one time only! Customers can order from a range that includes Kolsch, IPA, lager, ale, red, blonde, wheat beer, sours and more.

The beer is brewed in the McBay’s original, rented, quarters, which today is full of tanks and kettles and storage space for 270 barrels. It’s only a few steps away from the tap room and beer garden that is now action central for the brewery.

The tap room is also the swag shop, and the McBays have discovered that their love for psychedelic colour and design is

contagious – their guests eagerly snap almost anything with the Florida Keys Brewery logo and wild colour combinations. That logo, by the way, is very special.

A small but crucial detail is found near the bottom – a symbol that is half red maple leaf and half conch shell. Canadian Craig and Conch Cheryl, with their love story pictured right there on their business’s logo.

Their business is a brewery, but much more than a brewery. Their beer garden has been honoured as the best music venue in the middle Keys. There is almost always live music happening in the beer garden, featuring many of the truly talented, local Keys musicians like Leah Sutter, The Barstool Sailers, Micah, The Sunshine Band, and David Feder.

Feder, self-described “hillbilly flamenco guitarist,” is acknowledged to be the unofficial godfather of Keys music. He organizes a huge charity festival that funds scholarships and provides hundreds of instruments to budding musicians. Although they are designated as fundraisers, the concerts at the festival are free of charge.

Most of the money is raised through beer sales. And Feder told me that all that beer is all donated by the Florida Keys Brewery, just

one of many acts of community charity and commitment carried out by Craig and Cheryl.

The McBays have come a long way from Craig’s high school days in Burlington, Ontario, and from an apartment where he home-brewed hundreds of bottles of beer. They have created a truly magical place in

Islamorada, where they welcome thousands of visitors, where they provide work for two dozen Brewery employees and many local musicians, where they raise their family (they are parents of twins), and where they have seen their international love story turn into a unique, thriving, highly entertaining brewery.