The brewing industry has

emissions, breweries must acknowledge their ethical responsibility to mitigate their

demanding sustainability from their favourite brands. A growing number of beer drinkers seek out breweries that demonstrate responsible sourcing, energy efficiency, and waste reduction.

Regulatory pressure is also mounting, with governments instituting stricter guidelines on water usage, emissions, and waste management. For breweries, adapting to these trends is key to maintaining consumer trust, reducing operational costs, and ensuring longterm viability.

We also shine the spotlight on leading technology available to breweries and how it’s being implemented across the globe.

Sustainability is no longer optional in the brewing industry—it’s a necessity for the future of business and the planet. By focusing on water conservation, energy efficiency, responsible sourcing, waste reduction, carbon emission management, and community involvement, breweries can make a significant impact.

duce just one barrel of beer. Additionally, brewing requires vast amounts of energy

Ethical business practices go beyond profitability; they involve making choices that positively impact society and the planet. Given the growing global climate crisis, breweries must recognise their role in protecting the environment and consider the ethical implications of their operations. Ignoring sustainability is no longer just bad business—it’s a violation of the duty to future generations.

As the craft beer movement continues to thrive, integrating sustainable practices will ensure breweries remain competitive, profitable, and environmentally responsible.

The time to act is now—because a greener brewing industry means a healthier planet and a more sustainable future for beer lovers everywhere.

Tim Sheahan Editor

Carbon dioxide (CO2) emissions, wastewater runoff, and spent grain disposal also contribute to the industry’s environmental footprint. Beyond the environmental toll, consumers are increasingly

In this latest supplement, we feature the insight and expertise from a wealth of forward-thinking individuals that are aiming to make the brewing industry better for all.

Carbon Literacy Training

Deepening an understanding of the science of climate change and its impact on brewing,

Heat Pumps

Why heat pumps are likely to be an essential feature in the modern brewery.

Biomass Boilers

What is biomass technology and just how feasible is it for your brewery?

How product carbon footprints give breweries the tools to cut emissions, cut costs, and more.

Advanced Thermal Solutions

Low viscosity heat transfer fluids and how they support sustainable brewing practices.

CO2 Reliance

How breweries can cut their reliance on CO2 via the adoption of sustainable solutions.

Hollistic Production

and

the industry can continue to thrive.

St Austell’s efforts to have a positive impact on people and the planet.

The Grower Relationship

Every hop has a story, and so does its grower. Charles Faram are keen to connect the two.

Brewing Greener

Fell Brewery’s goals to cut carbon emissions 50% by 2027.

CARBON LITERACY TRAINING IS ABOUT DEEPENING AN UNDERSTANDING OF THE SCIENCE OF CLIMATE CHANGE AND THE IMPACTS ON THE BREWING INDUSTRY, RECOGNISING WHAT NEEDS TO BE DONE AND HOW TO DO IT. IN THIS ARTICLE CHRIS TERRY, THE FOUNDER OF 86-CARBON, EXPLAINS HOW BREWERS CAN PLAY THEIR PART.

Carbon Literacy is a movement to empower citizens to understand the causes and impacts of climate change and the power they have to take meaningful action to change the course of climate change.

In 2024, the planet breached 1.5oC of warming above pre-industrial levels, a target put in place by nations in 2015 and now left in the dust.

We are seeing widespread impacts of this across the planet, from wildfires in California made worse by warmer air and an abundance of kindling to rising sea levels making the 100 years flood a more regular occurrence.

The climate change ocean liner has well and truly set sail, but there are still those on the dock arguing about its very existence.

It’s common to feel very small and powerless in the face of the climate emergency: how does one individual make a difference, and how do we mobilise a whole sector?

And for leaders, how do we bring the whole team along on the journey to

add sustainability to the brewery’s list of priorities. What’s that old analogy about trying to single handedly change the course of a cruise ship?

Carbon Literacy Training is about deepening an understanding of the science of climate change and the impacts on the brewing industry, recognising what needs to be done and how to do it.

In the workshops I run, I see learners come together and tackle problems head on, signpost one another to resources near and far and find optimism in the face of the climate crisis.

Brewing in the 21st century is about incorporating ingredients and materials from every corner of the globe, producing beer on a colossal scale with greater efficiency, less wastage and more automation than those that came before, but this growth and scaling has required a reliance on fossil fuels, every step of the way.

Human activity since the industrial revolution has released an unprecedented quantity of greenhouse gasses that are choking our atmosphere and causing global temperatures to rise.

Our wonderful ingredients are now being threatened by extreme and unpredictable weather conditions, energy and fuel costs fluctuate with significant knock on effects to the whole supply chain and our staff, customers and stakeholders are asking for action. A zero carbon society will arrive - either by careful management of our resources or by necessity when the wells run dry. A low carbon future is not just solar panels and electric vehicles, it’s also about adapting to a changed climate with new risks: Can we say with certainty what brewing will look like in 10, 20, 100 years’ time? With careful balance of the risks, there are opportunities to be gained in taking action on sustainability. Carbon Literacy Training draws down global trends to the individual and provides a manageable starting point for addressing a complex situation. It also inspires group action and collaboration across teams. By the end of the course, individuals are part of a 100,000 strong network of ‘Carbon Literate Citizens’ taking on climate change together.

It’s common to feel very small and powerless in the face of the climate emergency: how does one individual make a difference, and how do we mobilise a whole sector?” Chris Terry

During the workshop, we take a wide angle lens to the international picture and highlight the importance of just transitions and climate justice before zooming into the individual level and helping every learner identify a significant action they are able to take forward and encourage others to follow.

Workshops take place online or in person, and incorporate science, discussion and hands-on group activities. An online module rounds out a full day of learning and in order to become certified, learners pledge an individual and group commitment to an action that will reduce their carbon footprint. Learners go on to reduce their footprint by as much as 15%, with many pledging to go even further. 86-Carbon offers open workshops with learners from multiple breweries. We also deliver a course that will be specific to your brewery. We have supported breweries to develop their own course with materials and content they have helped devise. For more information, please visit 86-Carbon website.

Ludlow Brewing Co. commissioned their first solar PV system in 2021. A year later they doubled the size of it. And then they doubled it again.

At CleanEarth we’ve been working with them since their first foray into solar generation, and have brought their installed capacity up to 120 kW.

They are now generating their own clean electricity at less than 4p per kWh. That’s a small fraction of what they were paying for power from the grid.

With cost savings like that – and with more than 20 tonnes of carbon kept out of the atmosphere every year – it’s no surprise they keep coming back for more.

“Solar power is the cornerstone of our sustainability strategy. CleanEarth have been instrumental in future-proofing the brewery’s energy infrastructure, to help us create long-term operational e iciency and reduce emissions and costs.”

Here are some of the other breweries we’ve worked with:

• Goodh Brewing Co.

• Le Handed Giant

• Moor Beer Co.

• Keltek Brewery

• Verdant Brewing Co.

• Wiper & True

AS OUR INDUSTRY MOVES TOWARDS DECARBONISATION, THERE IS A COMPELLING ARGUMENT FOR ADOPTING THE HEAT PUMP AS A MEANS OF GENERATING HEAT. HERE JAMES FAWCETT, A BREWING SUSTAINABILITY CONSULTANT AND FOUNDER OF JAMES FAWCETT SUSTAINABILITY INVESTIGATES WHY HEAT PUMPS COULD BE AN ESSENTIAL FEATURE IN THE MODERN BREWERY.

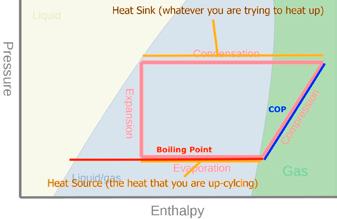

Before we start, we must ensure that we understand some basic principles. Heat Pumps utilise a phase change and compression of a fluid called a refrigerant in order to move and upcycle heat energy. This is the same OVC cycle (Evaporation, Compression, Condensation and Expansion) that is carried out within our chillers, only this time we are moving heat towards rather than away.

A heat source boils or evaporates the refrigerant. This phase change or latent heat transfer is how we transfer heat energy to the refrigerant so it is essential that we match the temperature of our heat source with the boiling point of the refrigerant.

A now vaporised refrigerant is then compressed increasing its potential heat energy. This is the work-horse of the heat pump as it is how we are able to upcycle low grade heat.

This compressed and vaporised refrigerant is then usually condensed on a heat sink imparting the heat energy via another phase change, exactly the same as steam is used for heat transfer.

The liquid refrigerant is then expanded to

reduce its boiling point to below the heat source so that we can start the cycle all over again. Practically speaking we could think of this more as releasing the compression rather than expansion, as this helps us understand how to increase efficiency.

When discussing the efficiency of heat pumps (or chillers) we often use the term COP (coefficient of performance).

This explains how efficiently electrical energy is converted to heat energy moved. A COP of 3 means for every 1kW of electrical energy used, 3kWs of heat energy are moved.

The COP is determined by how much work the compressor is having to do, since that is where most of the electrical energy in the heat pump is used. So if we reduce the amount of work needed by the compressor, or the extent that the compressor needs to be used to up-cycle the heat to what we require, we can improve the efficiency of our heat pumps.

This is the feature of air-sourced heat pumps that has made them disappointing for a lot of domestic users. If the ambient air outside is at a low temperature, then the pressure of the refrigerant also needs to be low to allow the refrigerant to boil/ evaporate (because fluids boil at lower temperatures when at lower pressures). The house still requires 60°C heat (and the pressure needed to achieve this), but now the compressor has to perform a much greater lift.

Domestic heat pumps suffer this because it is hard to find a heat source that is warm enough and that doesn’t fluctuate. This is why bore holes are being installed to allow for ground-sourced heat, which is warmer and much more stable. However, most brewhouses have an abundance of waste heat. Some of it is low grade but fairly consistent coming

from our fermentors. Some is high grade but sporadic coming from exhaust and effluent discharges.

Either way, the key to making our heat pump efficient is currently being vented on the floor or into to the atmosphere. If we can utilise this waste heat, we can have direct control over how efficiently we can generate heat.

Generally speaking, to get the operating cost competitive with gas, we need our heat pumps to operate with a COP of at least 2.5-3.

This COP decreases the higher the processing temperature required which is why it has been difficult directly swapping out a steam generating boiler. Having said that, there are some remarkable high temperature heat pumps (HTHPs) that can achieve this, even boasting steam producing heat pumps with of a COP of 4 and above (heat source dependent).

This increased performance currently comes with high CapEx, which will likely alienate many small and medium sized businesses.

But what is really interesting about this technology is that it allows us to

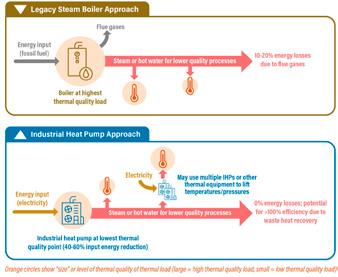

completely rethink our thermal design. A legacy thermal design bases the heating infrastructure on primarily identifying the maximum heat requirement. This is why we have steam boilers when most of our thermal load is under 80°C.

But with a heat pump, we can flip this on its head as it is much more efficient to instead create only the heat that we require.

Not only does this massively open up the availability and affordability of the technology to us now, but it allows us to compartmentalise our requirements and gives us the opportunity to decarbonise our heat systematically, enabling us to spread the CapEx.

Installing a heat pump to manage CIP requirements for example, would be a fantastic place to start, as by utilising high temperature effluent it may possible to achieve a COP of as high as 7.

Finally it is important to acknowledge the versatility of electricity. Renewable energy generation is for the most part a continuous process, and so in order to meet the electricity requirements of the grid during peak hours, there is an ever increasing surplus of green energy off peak.

In the absence of the grid being able to

battery store this surplus, there is huge potential to reduce the utility costs by taking advantage of Low Rate Off Peak Tariffs.

Switching the work load during this time by utilising thermal batteries to store the energy until we need it elegantly align with batch processing requirements. In addition, we must also appreciate the fact that fossils fuels such as gas and oil as well a natural gas can only ever generate heat, whilst obviously electricity can also be used for refrigeration. Load shift as cold storage will be easier for most of us and requires less space than heat storage.

Cooling cheaply is just as useful as heating cheaply to a heat pump, as the rejected heat from cooling will play a significant role in making hot side heat generation in the brewhouse affordable. We should all be at the very least be considering options to decarbonise our heat. As one of the most carbon intensive aspects of many of our Scope 1, it is essential that we start if we are to reach our NetZero goals.

Granted, this is not low hanging fruit, but there is huge potential for Heat Pumps to both save the planet, as well as pounds in your pockets. Good luck!

Doughty, K., 2024. Topic Brief - Stop the Waste: Using Industrial Heat Pumps to Rethink Thermal Loads, American Council for an Energy Efficient Economy. United States of America.

Iwrote an article in the last edition of the Brewers Journal on how we can decarbonise heat energy for small and medium-sized craft breweries.

It detailed why this is arguably the biggest challenge in decarbonising our industry. That came from personal experience, as I had literally just finished a mammoth project with the incredible Vault City Brewery on road mapping decarbonising their new brewery build in Penicuik, Scotland.

Without doubt, decarbonising heat was the single biggest headache I had. I conducted over six bespoke heat decarbonising feasibility studies including an electric steam generator, heat pump, creating biogas, purchasing biogas and a biomass boiler.

In this article, I want to share with you the findings of my feasibility study on biomass. Why this technology? Because I had the most fun doing it and many people have told me (and continue

to do so) that it’s not feasible. I believe differently.

If you read my opening call-to-arms piece in this edition you will know how invested I am in sustainability not meaning environmentalism, but people, planet, and profit in equal measures.

So we will investigate both the economic, environmental and process implications. I do not promise this is the silver bullet in decarbonising heat energy, but I promise that this is fun.

In an incredibly well-funded world of complex thermodynamics, fluid mechanics and electrical engineering, discussing combusting fuel in a furnace feels wrong.

A biomass boiler burns organic matter such as wood, agricultural waste or brewers spent grains to generate heat, which then undergoes a process called gasification and this hot gas is passed through a heat exchanger with water which in turn creates steam.

Flue gasses and ash are controlled and disposed of/reused, importantly flue gasses have specific regulatory consent limits.

Intrinsic to biomass boilers is the choice of biomass you burn. There are a lot of options available, some are quite frankly, horrendous and others extremely promising.

Your choice of fuel directly affects your return on investment, both economically and environmentally. The most common biomass used is wood.

For me personally, this is a challenging concept, how can burning wood for

heat possibly be economically or environmentally viable? As with just about everything in life, it depends on where you source it and how it was processed.

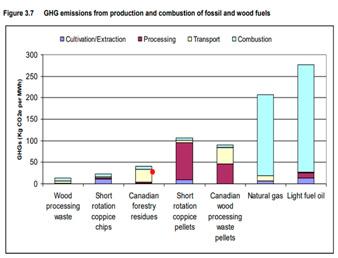

First let’s assess the environmental impact, Rory at Treco (Biomass Boiler Manufacturer) sent me this great chart from GOV.UK, a nice visualisation of the environmental cost of burning various types of wood compared to burning gas.

I like this chart a lot, you can clearly see where and why natural gas contributes so much damage to the environment. The combustion aspect of gas is the most significant environmental factor, but when you look at wood, it’s processing and transport.

As you can see from the chart, (aside from natural gas and light fuel oil) your choice of wood type, origin and amount of processing is intrinsic to the environmental impact.

It’s no surprise that non-UK wood types have significant transport costs associated, but more importantly, wood processing quickly starts to close the gap between wood and natural gas. A sustainability hack for you, generally

speaking, don’t just focus on the amount of miles your goods travel, focus on the way they are manufactured.

By far the best option (environmentally) is wood processing waste, there’s very minimal processing required (often just chipping) and you only need to account for the combustion and minor transport costs (depending on the location of the waste wood, usually it’s local).

Unfortunately, there just isn’t the data to compare brewers spent grain. Presumably, the processing and transport costs are close to zero, however there is good reason to believe it releases more NO2 when burnt compared to wood, so I would guess that it averages out the same kgCO2 per kWh as waste wood, potentially marginally higher.

One incredibly important metric of fuel choice is its net calorific value, i.e. how much energy will you get by burning 1 kg of the specific fuel type?

The lower the value, the more fuel you need to burn in order to get the same amount of heat energy, the higher the less fuel you will use.

This impacts the environmental, economic and practicality of a biomass boiler. Let’s check out some Net Calorific Values (NCV) of popular fuel choices and of course our friend, brewer’s spent grain (BSG)

You can see why we have been burning natural gas for so long, it’s NCV is far greater than any organic material, meaning we need far less of it. However, as our judgement of fuels has broadened beyond simple economic calculations, we now have to look at the rest of the organic material.

Wood pellets offer the best NCV followed by waste wood and then our friend BSG. Excitingly, the NCV of BSG here is looking very comparable.

The reason for this excitement is because if we update this table, with the cost per tonne you will see the cost is not comparable.

When conducting this for Vault City, I attributed a small £20 p/tonne cost of waste wood as there were transport costs and a modest incentive for the farmer.

Economically speaking there are two standouts: BSG and waste wood. Excitingly, this is the same as the environmental standouts.

Now we have two standouts (waste wood and BSG) let’s assess their practicality. Waste wood is fairly straightforward, you need to be able to secure X amount of tonnes per year, at regular intervals, store it and purchase at a stable price. It requires you to rely on either one or multiple sources which does create an additional workload for whoever is in charge of procurement.

BSG alleviates most of these concerns, however, comes with plenty of its own. First, let’s look at availability.

The key to BSG’s self-sufficiency is that you can provide enough per day in order to fuel your biomass boiler.

Ultimately, this varies heavily brewery-tobrewery as it depends on factors such as: Average plato of wort (per month/week/ day/brew), Brewhouse efficiency (% and standard deviation), Number of brews per day/week and Grain composition.

If you brew a lot of low/no beers now or in the future, then BSG being your fuel of choice will likely end here.

If, like Vault City, you’re famed for your higher abv styles, you can continue down the path of feasibility. I prepared this chart for Vault City (some data has been changed when replicating this chart for this article) which you can see, estimates a deficit of BSG created vs required. Exciting.

You also must factor in the efficiency of the biomass boiler, as that will determine the quantity needed. For this I used a recommended efficiency of 85%.

In the NCV charts above I did omit a very important aspect of the NCV for BSG, that the moisture content needs to be at 30%.

For most brewers, spent grain leaves the mash/lauter tun at ~80% moisture content (varies brewery-to-brewery).

And at this exact point, most will tell you that BSG becomes unfeasible as a fuel type. Because options to dry from 80% to 30% are compression screws, electric/ gas driers or a combination of them both.

All of these require significant energy which erodes the economic saving to a point of redundancy. I calculated for Vault City, there would be 104 kWh of heat energy a day required to dry the amount of BSG required a day. If you choose gas for this heat energy, you ruin the environmental return, if you choose electricity you ruin the economic return.

However, there is a silver bullet. A company called Stronga has invented a drying system specifically for spent grain that uses waste thermal energy from the biomass to dry the incoming BSG to the biomass boiler.

This now overcomes the former roadblock of drying as it uses little electricity to operate and can handle the quantities required.

They have an informative website, check it out here for more details (https:// stronga.com/en/drying-spent-grainwith-stronga-sustainable-uses-ofbrewers-grains/)

When burning organic fuel flue gasses are released and subject to regulation. Flue gasses of both waste wood and BSG contain CO2, water vapour, particulate matter and small amounts of Nitrogen Oxides (NOx) as well as volatile organic compounds (VOCs).

A benefit of waste wood as a fuel type is its commonly used as fuel for biomass, therefore managing flue gasses is well researched and managed. Wood produces large but manageable amounts of ash which does increase the need for routine maintenance and filter checking.

Publicly available research into BSG as 100% fuel type is extremely limited, leaning toward non-existent. The main concern is the residue left after combustion along with the heavy particulate (ash) created when burning BSG.

This is confirmed by Alaskan Brewery in the US, who operate a biomass plant that runs on BSG, they had to shut the plant down every 25 hours of operation to remove ash accumulation in the system. Their answer was to input a ‘sonic horn’, effectively a device that uses centrifugal force to pull ash out of the flue gas, not allowing it to settle in the boiler. They reported this increased time between maintenance from 25 to 96 hours, a huge improvement but still concerning.

I have had some experienced biomass boiler experts tell me that 100% BSG is simply not feasible due to the quantity of ash and poor burn quality, and others say it’s manageable with the right equipment. I’m sure this would make for a good debate in the Biomassers Journal or at the Biomassers Congress…

I am currently working on research with Treco, using Vault City’s BSG to evaluate the flue profile of burning this, once the research is obtained I will be sharing it to my Brew Resourceful subscriber list and potentially down the line, The Brewers Journal.

Payback (Years) 5.7

Environmental 10yr Savings (TCO2e) -1662

Another consideration is the type of biomass boiler you would require. There are two options, a Medium Temperature Hot Water (MTHW) or High Temperature Hot Water (HTHW) biomass boiler. The crucial difference is MTHW biomass boilers are capable of max 120c steam whereas HTHW can achieve 157c and above.

Generally, breweries use 157c for distribution which is then reduced when it reaches its destination.

The path of least resistance is, of course, to emulate what you would normally experience and opt for the HTHW biomass boiler, however, the investment cost is over double. Which for most medium-sized craft breweries will roadblock this project.

Operationally, 120c steam is usable, and it’s reasonable to implement this in a new brewery build, but it’s very difficult to retrofit into an existing steam distribution system that was designed for 157c steam.

So let’s push those rather large potential road blocks to one side, and focus on why I am so keen to pursue BSG as a fuel source.

Here are the results of the ROI calculator I created for Vault City. I must stress at this point that this return on investment calculation is NOT representative of your brewery.

These are based on multiple factors that are extremely bespoke to Vault City as well as an estimation of CAPEX cost

(to be fair to the supplier I did not share specific quote value).

The two major highlights from the ROI calculator are the 10-year ROIs. After the initial investment, Vault City would be £961k in the green from gas cost savings. And that over 10 years they would prevent 1,662 tonnes of CO2e from entering the atmosphere.

For context, I investigated over 30+ sustainability technologies, and in terms of return on investment both economically and environmentally, this was one of the top 3 technologies available right now that deliver that kind of ROI.

On top of that, Vault City would be entirely self-sufficient for heat energy, meaning they would be secure against any future shocks to the energy market like we saw in 2022.

And the story behind turning a waste stream into 100% of your heat demand is exceptional, which for me personally, is extremely exciting.

I’m sure you might be wondering if Vault City is going ahead with this technology, the answer is, potentially but not today. Ultimately, there were better (economic, environmental and process) options available that had less risk, and cumulatively better ROIs.

In my opinion, Vault City is in a unique position to implement this technology due to the availability of BSG, building a greenfield brewery and they genuinely care about sustainability. Which is exciting, and it does lead onto an important question.

What are the current alternatives? You could wait for heat pump technology to fall in price and increase in longevity, combine on-site electricity generation with an electric steam boiler (not viable in medium sized breweries) or simply wait for another alternative.

Or you could purchase a proven technology now, that will save you close to £1m and 1,666 tonnes CO2e over 10 years, by which time you can ‘upgrade’ to the latest modern, proven and affordable technology.

However, as you can see from this feasibility exploration, there are still major challenges to overcome, all of which will

take time to investigate.

On top of this Angus Morison (Head Brewer) and Steve Smith-Hay (CoFounder) rightfully pointed out that during a new brewery build, would you want to introduce this level of potential chaos? Absolutely not.

If you made it this far, you will know that there are some very important hurdles to overcome before I could actually recommend this technology.

These include investigations into the burn profile of Vault City’s BSG and how that will affect the operation and maintenance of the biomass boiler as well as the legal consenting limits for flue gasses.

Waste wood is still a good fuel source, it lacks the self-sufficiency angle but does alleviate a lot of the BSG concerns. You can also blend the two and burn simultaneously. A local reliable source of this is intrinsic to its feasibility.

I can’t stress enough how fun this was as a feasibility study and that it is far from complete. There is a chance, this time next year I can write the final article on this, with a picture of me next to an operational biomass boiler, but there’s an equal chance we have found a better route to decarbonise Vault City’s heat energy, all I know for sure is that we will do it.

I would love to hear your thoughts and feedback, please contact me via LinkedIn or email chris@brewresourceful.com and finally a huge thank you to Vault City for allowing me to share their data, this is the exact action of collaboration I expressed in my intro piece at the start of the journal is essential for us to progress our industry.

If you believe you’re brewery could house a biomass boiler, let’s work on feasibility and grant funding together!

Sustainability in brewing has come a long way from just slapping a “locally sourced” label on a bottle and calling it a day.

The conversation has moved past feelgood marketing—buyers, regulators, and even your own customers now expect more than vague promises.

But let’s be real: measuring carbon emissions isn’t exactly the most exciting part of running a brewery.

You didn’t get into this industry to crunch numbers, you got into it to make great beer. And yet, understanding the carbon footprint of each brew you produce could be the difference between leading the industry forward and getting left behind.

You’ve likely heard of a corporate carbon footprint, which measures the total greenhouse gas (GHG) emissions from your brewery’s operations, including brewing processes, transportation, and packaging.

A Product Carbon Footprint (PCF) takes it a step further, measuring emissions at an individual product level throughout its entire lifecycle. Think of it like brewing a recipe.

Raw materials & packaging: The emissions from growing barley, hops, and yeast, plus water usage and the production of packaging materials like bottles, cans, or kegs.

Brewery production: The energy used for mashing, fermenting, cooling, and other brewing processes.

Distribution & beyond: The emissions from transporting your beer to retailers or consumers, refrigeration during storage, and the disposal or recycling of packaging after consumption.

Depending on how far down the supply chain you want to go, PCFs are measured in two main ways. The first is Cradle-toGate, which covers everything up until the beer leaves your brewery.

The other is Cradle-to-Grave, which extends beyond your brewery, covering distribution, retail, consumption, and disposal. While this might sound technical, it boils down to understanding your beer’s full environmental impact so you can make smarter, more sustainable business decisions.

Several leaders in the brewing industry are already using PCFs to their

advantage, reducing emissions while gaining a competitive edge.

Deya Brewing has taken a data-driven approach to sustainability, measuring emissions across Scopes 1, 2, and 3 to pinpoint where reductions could have the biggest impact.

By doing so, they’ve lowered their emissions intensity year over year and even introduced carbon footprint labels on their cans to keep sustainability front and center for their customers.

Jubel Beer turned PCF insights into real action, cutting emissions by 67%—a shift largely driven by moving from glass bottles to aluminium cans.

They’ve also fine-tuned their brewing process, leading to a 7% reduction in carbon intensity per litre brewed in just one year.

Yakima Chief Hops, a 100% growerowned global hop supplier, has embraced carbon footprinting across its supply chain, helping brewers make more informed ingredient choices.

By moving their emissions tracking from spreadsheets to a centralised system, they’re improving accuracy and setting the stage for product-level carbon footprinting, which will allow brewers to make sustainability-driven decisions at the ingredient level.

Let’s cut to the chase: why should your brewery bother with PCFs?

Firstly, you can win over buyers and stay ahead of regulations. Supermarkets, distributors, and even bars are increasingly requiring suppliers to provide detailed carbon footprint data. If a buyer has to choose between two similar beers, one with clear sustainability data and one without, they’ll likely go for the one that meets their targets. And it’s not just buyers—regulations are tightening.The Corporate Sustainability Reporting Directive (CSRD) in the EU has introduced stringent requirements for companies to disclose carbon footprints in detail.

The UK is increasing carbon reporting standards, making it essential for breweries to measure and disclose emissions. Even in the US, proposed SEC climate disclosure rules could mean stricter reporting for breweries selling in major retail chains.

Adopting PCFs early means staying ahead of regulations rather than scrambling to comply later and risking potential penalties.

You can make smarter brewing decisions. Product carbon footprints help take the guesswork out of sustainability and serve as a strategic decision-making tool. With precise emissions data, you can: Refine your recipes before brewing, adjusting ingredients to lower emissions without affecting taste, evaluate packaging options like glass bottles vs.

aluminium cans, considering factors like recyclability and production emissions, and choose suppliers based on actual sustainability metrics rather than vague marketing claims.

Imagine being able to predict the carbon footprint of a new beer before you even brew it. That’s the level of control PCFs give you.

Also consider how you can track your progress and future-proof your brewery. One of the biggest challenges in sustainability is proving that you’re actually making progress. It’s one thing to set goals, but how do you show real, measurable improvements?

PCFs provide a clear benchmark for tracking reductions over time, allowing breweries to pinpoint where emissions are coming from—whether it’s highimpact ingredients, inefficient brewing methods, or packaging choices. Instead of guessing where to make changes, you’re making informed, strategic decisions that have real impact. At the same time, sustainability is becoming a bigger part of brand identity. Zevero’s 2023 research found that consumers are paying more attention to the environmental impact of the brands they support.

By transparently sharing your PCF data and outlining the steps you’re taking to lower emissions, you’re not just meeting regulations–you’re building credibility, trust, and brand loyalty with a growing base of conscious customers.

Product carbon footprints aren’t just about measurement; they’re the foundation of a smarter, more sustainable brewing strategy.

proactive one (“Let’s design lower-carbon beers from the start.”).

Instead of treating emissions as an afterthought, breweries that embed footprinting into their decision-making can lead the charge in shaping a more sustainable industry while staying profitable in the process.

Here’s the good news: you don’t have to be a sustainability expert to make this work. With the right approach, you can integrate carbon footprinting into your existing operations without adding unnecessary complexity.

Today, there are platforms designed to streamline emissions measurement, helping breweries collect, analyse, and act on footprint data without getting lost in spreadsheets or technical jargon. These tools take the heavy lifting out of carbon accounting, making it easier to understand the impact of ingredients, packaging, and brewing processes—and more importantly, identify practical ways to reduce emissions.

For breweries looking to take a datadriven approach to sustainability, investing in a carbon management platform is a logical next step.

The Bottom Line? Sustainability, when done right, isn’t just good for the planet— it’s good for business.

Product carbon footprints give breweries the tools to cut emissions, cut costs, and stay ahead of both customers and regulators.

Product carbon footprints help take the guesswork out of sustainability,” George Wade

With clear emissions data, breweries can find efficiencies, cut costs, and reduce waste, whether that’s optimising brewing processes, sourcing lower-carbon ingredients, or improving energy use. Over time, small changes add up, turning sustainability into a business advantage rather than an obligation.

Most importantly, PCFs help shift sustainability from a reactive process (“We should probably measure this…”) to a

And in an industry built on craft, quality, and constant innovation, that’s an opportunity worth raising a glass to.

Sustainability is no longer just a buzzword in the brewing industry - it’s a priority. From cutting carbon emissions to improving energy efficiency, breweries are finding new ways to make their operations greener while still producing top-quality beer.

One area that often gets overlooked is thermal energy management, but it’s central to almost every stage of the brewing process.

From chilling wort and fermenting beer to packaging and storage, controlling temperatures is crucial to ensuring consistency in taste profile and overall quality.

But these processes can be energyintensive, and outdated thermal systems can hold breweries back from reaching their sustainability goals.

Advanced thermal solutions, including cutting-edge heat transfer fluids (HTFs) in secondary coolant systems, are stepping up to make a difference.

Brewing beer relies on precise temperature control. However, traditional heating and cooling systems often use older heat transfer fluids that are less efficient and can have a detrimental environmental impact. That’s where new-generation fluids come in. They’re designed to improve performance, cut energy use, and reduce environmental harm.

For breweries that want to operate more sustainably without compromising on quality, rethinking thermal energy systems is an important step.

Switching to modern, eco-friendly LV HTFs brings several advantages: Low

viscosity fluids are easier to pump, especially at low temperatures, so your cooling systems don’t have to work as hard. This means lower energy consumption and reduced running costs. Many LV HTFs are biodegradable and derived from organic materials, so they’re less harmful if there’s a spill. Choosing a greener option helps breweries meet sustainability goals while reducing risk.

Many new LV HTFs are designed with more effective and less aggressive corrosion inhibitors to protect pipes, pumps, tanks, and chillers from damage with a reduced risk profile.

This keeps equipment in better condition for longer, reducing waste and saving money on replacements.

Through testing and regular fluid care advanced HTFs can last longer before needing replacement. This reduces chemical waste and saves on operating costs.

Brewing can be energy-intensive, particularly when it comes to heating and cooling. LV HTFs can make a big difference here. Their improved thermal properties allow for faster and more efficient heat transfer, meaning less energy is needed to achieve the right temperatures.

Lower energy use doesn’t just cut costs, it also lowers carbon emissions, which is a win for both breweries and the planet.

Green thermal solutions are already making an impact in breweries around the world. For example: Wort chilling: LV HTFs reduce the time needed to cool wort to fermentation temperature, increasing efficiency and throughput.

Brewing green isn’t just the way forward, it’s already here,” Jerry Lewis, Kilfrost

Fermentation: Temperature control during fermentation is key to a consistent flavour profile. High-performance HTFs make this process more energy-efficient and reliable.

Storage and packaging: Maintaining stable temperatures in storage tanks and during packaging is easier with advanced fluids, helping reduce energy waste and mitigate the risk of stock losses.

Breweries adopting these solutions are seeing improvements not just in sustainability but also in their bottom line.

Making your brewery greener isn’t just good for the environment, it’s good for business. Today’s consumers care about sustainability, and they’re more likely to support brands that share their values. Breweries that embrace greener practices, such as using advanced thermal solutions, can build stronger relationships with eco-conscious drinkers.

There’s also a knock-on effect throughout the supply chain. Distributors and retailers are increasingly prioritising products with strong sustainability credentials, so adopting greener practices can open up new opportunities. Despite the benefits, some breweries might hesitate to invest in advanced thermal solutions because of the perceived cost or disruption. But these challenges are often smaller than they seem.

Upgrading to modern LV HTFs might require an initial investment, but the longterm savings in energy and maintenance often outweigh the upfront costs. Plus, many suppliers offer support to help breweries make the switch smoothly.

Sustainability in brewing isn’t just about hitting targets or staying ahead of regulations, it’s about shaping the future of the industry. Advanced thermal solutions are helping breweries do their part for the planet while continuing to craft great beer.

For breweries just starting their green journey, upgrading thermal systems is a practical and impactful first step. Whether it’s switching to greener HTFs, improving energy efficiency, or protecting equipment, these solutions bring real benefits to both operations and the environment.

Brewing green isn’t just the way forward, it’s already here.

By making the move to advanced thermal solutions, breweries can show they’re serious about sustainability while staying competitive in an ever-changing market.

THROUGH THE ADOPTION OF SUSTAINABLE INDUSTRIAL GAS SOLUTIONS BREWERIES CAN REDUCE THEIR RELIANCE ON CARBON DIOXIDE (CO2). ANDREW BUTLER, BUSINESS DEVELOPMENT MANAGER FOR INDUSTRIAL GASES AT ATLAS COPCO UK, OUTLINES HOW ON-SITE NITROGEN GENERATORS AND ADVANCED PROCESS FILTRATION SYSTEMS, BREWERIES CAN ADDRESS RISING COSTS, SUPPLY DISRUPTIONS AND NET ZERO GOALS WHILE MAINTAINING QUALITY AND OPERATIONAL EFFICIENCY.

In recent years, CO2 supply chain disruption has posed significant challenges for breweries, Forcing some to reduce or stop production, and in certain cases, even driving smaller microbreweries out of business.

With rising CO2 costs and ongoing supply issues, many brewers are turning to nitrogen as a viable alternative for a variety of applications, including purging tanks and kegs, canning, kegging, and vessel transfer.

Unlike CO2, nitrogen is abundant and cost-effective, providing a stable, inert atmosphere that prevents oxidation, preserves beer quality, and maintains the freshness and flavour of the brew. By making the switch to nitrogen, brewers can enhance both efficiency and sustainability, while ensuring a consistent, high-quality product.

Embracing on-site nitrogen generation can mitigate CO2 supply challenges, helping to reduce reliance on external suppliers, streamline operations, and

contribute to long-term sustainability goals.

ENHANCING NITROGEN EFFICIENCY FOR BREWING OPERATIONS

As brewers continue to look for ways to optimise their operations, upgrading to a more efficient nitrogen generation system can offer valuable benefits.

Newer models, such as the Atlas Copco NGP+ and NGPs generators, incorporate

innovative features like the Variable Cycle Saver (VCS) algorithm, which adjusts to reduce energy consumption during lower demand periods, helping to lower overall operating costs.

These advanced systems also provide more precise control over nitrogen purity levels, ensuring the highest quality for brewing processes.

In modern breweries, effective filtration is key to maintaining consistency, hygiene, and efficiency throughout the production process.

Atlas Copco provides various types of filtration systems, such as pre-filtration, depth filtration, and sterile filtration, to be strategically employed at different stages of the brewing process, from clarification to final packaging.

By removing suspended solids, yeast, proteins, and other unwanted particles, filtration helps brewers achieve the desired taste, appearance, and shelf life of their beer, as well as meeting

regulatory standards. Our technology is helping both multinational brewers like Birra Peroni, which uses oil-free ZR air compressor technology, and independent craft brewers such as Whitewater Brewery in Northern Ireland. For Whitewater Brewery, the switch to on-site nitrogen generation has reduced its dependence on CO2, helping the company save approximately £35,000 annually.

The company’s expertise extends beyond nitrogen generation.

The company also provides compressed air systems that meet stringent air quality standards for every step of the brewing process, from fermentation to bottling. Meanwhile, energy-efficient process chillers can help brewers maintain stable temperatures, preserving the flavour and quality of the beer.

Whether you operate a microbrewery or a large brewing operation, Atlas Copco’s solutions offer a significant reduction in operational expenditure while boosting productivity and sustainability.

In modern breweries, effective filtration is key to maintaining consistency, hygiene, and efficiency throughout the production process,” Andrew Butler.

Our class-leading range of fuel-fired, electrically-powered and hybrid steam boilers and portfolio of aftercare solutions can help with your decarbonisation strategies and put your brewery on the Road to Net Zero.

As a complete solutions provider, Fulton can provide your processing facility with:

· fuel-fired, electric and hybrid steam boilers

· off-grid and point-of-use solutions

· ancillary plant / engineered systems

· steam surveys

· project management

· water treatment contracts

· accredited / certified training

· installation / commissioning / upgrades

· repair / service / maintenance programmes

For further information scan the QR code, visit www.fulton.co.uk, email sales@fulton.co.uk or call the office on +44 (0)117 972 3322.

HOSPITALITY, IT’S POSSIBLE TO UNEARTH UNEXPECTED OPPORTUNITIES THAT CAN BOOST EFFICIENCY, SAFETY AND SUSTAINABILITY. THIS CASE STUDY FROM YOUNG AND CO’S BREWERY PLC AND AIR PRODUCTS EXPLAINS MORE.

Young and Co’s Brewery Plc is a British pub group with more than 280 pub and hotel establishments operating at the heart of its communities across London and the South of England.

Despite the challenges facing the leisure sector and difficult economic conditions, Young’s has continued to thrive, with revenue and sales up on previous years. Part of its success can be attributed to the way in which it continues to scrutinise not just the efficiency and sustainability of its own operations, but the ways in which it can work smarter with its supply chain. World-leading industrial gas manufacturer, Air Products, has been working with Young’s for over 20 years, supplying food grade carbon dioxide, mixed gases, and dispense gas equipment.

The supply of these gases and equipment, which are used to carbonate fizzy drinks and dispense a range of beers and beverages, is key to Young’s successful operations. Without regular and reliable gas supply, Young’s simply cannot operate.

Traditionally, pub and hotel groups requiring gases such as carbon dioxide for their operations, tend to store gas cylinders within their premises. This presents challenges both in terms of safety and productivity as Bill Epsley, commercial manager at Young’s, explains: “The best possible place for our

teams is front of house, looking after our customers.

“The reality, however, is that if a gas cylinder needs connecting, or disconnecting and changing, so we can –for example – continue to carbonate our drinks, then we rely on our staff for that.

“Not only does this take them away from front of house duties, it also comes with all the health and safety risks associated with the manual handling of heavy equipment.”

In the spirit of collaboration and in seeking opportunities to improve productivity and efficiency at all levels of its business, Young’s has worked together with Air Products to tackle this challenge head on.

The majority of Young’s estate benefits from an Air Products’ CarboStore CO2 supply system comprising a liquid gas tank, and remote fill point to an external wall, as well as on site nitrogen generator.

This means that gas can be delivered at any time, without interruption to service and without the need to manually handle, transport and store high pressure gas cylinders.

There have been immediate safety wins from this approach – something that both Young’s and Air Products take very seriously as Jim Alexander, leisure business manager from Air Products explains: “Businesses in the leisure sector – and further afield – have to comply with stringent Manual Handling Operations Regulations, and are required to avoid, assess and reduce any associated risk of injury.

“Given that an average gas cylinder can range in weight from 20.35kg to 104kg,

and the pressurised nature of the gas, any opportunity to reduce the need for staff to move or handle cylinders is worth exploring.”

For added peace of mind, Air Products has also installed CO2 monitors across the Young’s estate – something that is not yet legally required in the UK but advised and recommended by the British Compressed Gases Association.

But while safety is a central consideration, this new solution delivers on other important fronts too. In a challenging economic climate, efficiency of operations is key, and leisure businesses are increasingly leaning on their supply chains for support.

For Young’s and Air Products this has been an area of focus, and the CO2 tank is fitted with an advanced telemetry system.

This introduces a new ‘fit and forget’ aspect to the pub’s gas supply, with gas delivered and the tank refilled on a ‘just in time’ basis.

Automated and autonomous gas replenishment means there is no interruption to Young’s service, ensuring staff can remain behind the bar, increasing sales and profit.

Epsley explains: “This fit and forget approach is unique to Air Products and really beneficial for our business – it removes the headache of co-ordinating deliveries, and it ensures we always have a steady and consistent supply of the gas we need to operate.

“As well as being efficient, the telemetry on the tanks also supports Young’s sustainability efforts – something that is very important to our business and future strategy.

It allows us – and Air Products, remotely - to know exactly when the tank needs refilling. This avoids unnecessary deliveries, in turn reducing our carbon footprint.”

It’s this holistic approach that is key as Jim Alexander from Air Products explains, “For a business of the scale of Young & Co, it would be easy to assume that the mode of gas supply and the way it is managed is pretty inconsequential to their overall operations. In fact, the opposite is true – every detail matters.

“By working together with us to explore and introduce this fit and forget system, they have been able to avoid timeconsuming change overs, and all but eliminate the time and administration

required to manage gas orders. It also facilitates real safety and sustainability benefits – something that is central to Young’s ethos and approach.”

The last four years have been challenging for all leisure businesses. Covid-19 lockdowns have been followed by surging inflation, a cost-of-living crisis and growing labour shortages and costs.

But for Young’s, the future looks bright and it’s at least in part due to the way it is collaborating with its supply chain to find new ways to work smarter, more safely and more sustainably.

For both organisations, this is much more than a demand-supply relationship, but rather a long-term partnership in which they are heavily invested, and the knowledge and expertise of the supply chain partner is put to good use.

Epsley concludes “We’ve found this spirit of collaboration with Air Products really

refreshing. Our point of contact is easy to work with and proactive in making suggestions.

“It takes a lot to successfully run a pub and hotel group – but there can be no doubt that the supply chain is integral.

Air Products’ gas products and equipment are critical to our operations, and we will continue to work together with them to improve and enhance the way we operate.”

THE BREWING INDUSTRY IS UNDERGOING A PARADIGM SHIFT TOWARDS SUSTAINABILITY, DRIVEN BY THE GROWING AWARENESS OF ENVIRONMENTAL ISSUES AND THE NEED FOR RESPONSIBLE BUSINESS PRACTICES. WITH COLLECTIVE EFFORTS AND INNOVATIVE SOLUTIONS, THE BREWING INDUSTRY CAN CONTINUE TO THRIVE WHILE MINIMISING ITS IMPACT ON THE PLANET, EXPLAINS THE TEAM AT FIRST KEY CONSULTING.

In an era where environmental consciousness is paramount, industries across the board are reevaluating their practices to minimise their ecological footprint. The brewing industry, with its significant consumption of resources and production of waste, is no exception. To address this, breweries worldwide are increasingly adopting sustainable practices throughout their production processes.

From minimising resource consumption to investing in renewable energy and optimising packaging and distribution, breweries are revolutionising their operations for a greener future.

Efficient resource management lies at the core of sustainable brewing. Breweries are focusing on minimising energy and water consumption throughout their operations.

By optimising raw material usage and production processes, breweries can significantly reduce their environmental impact.

As an example, breweries are investing in innovative wort boiling and brewhouse systems, that feature heat recovery mechanisms. These optimise energy efficiency while maintaining or improving the quality of the final product. These systems not only reduce energy consumption but also contribute to cost savings in the long run. Examples are Exergon (Banke),

Equitherm (Steinecker), Schoko (Schulz), Shark (Ziemann), Jetstar / IWM (GEA) and SmartBoil (Braukon).

Rod Waite, director of engineering at First Key Consulting, explains: “Breweries are in a position these days to leverage the many sustainability innovations being put forth by reputable vendors. “They just need to be careful to make educated decisions when implementing new technologies and process concepts to ensure the desired outcomes are achieved.”

The adoption of sustainable technologies is a key strategy for breweries looking to minimise their environmental footprint.

Changing to hot water as heat medium combined with heat pumps, for instance, are being increasingly used to harness renewable energy sources such as geothermal or solar energy for heating and cooling processes.

By utilising these technologies, breweries can significantly reduce their reliance on fossil fuels and lower their carbon emissions.

Another example is that of reducing water consumption and optimal wastewater treatment and disposal. Beer is approximately 95% water, and the amount of water needed in the brewing process is such that the volume of water used is multiple times greater than the volume of beer produced.

The water-to-beer ratio varies widely (e.g., close to a ratio of 2 for those highly efficient, vs a ratio of 8 or greater for others).

The major usage areas are packaging, brewhouse, utilities and cellars. A detailed survey of water usage in the brewery can help reveal points in the process where water is wasted, whether due to leaks or to unnecessary use of this precious resource.

The survey can also help point to areas where recycling may become a viable option.

Measuring usage and tracking water usage as a KPI, along with setting goals, has helped breweries drive improvement.

These improvements will not only help sustainability, but they will also help lower production costs, as the cost of water is not just the price of the incoming water, but it also includes the sewer service charge.

The Brewers Association has published the “Water and Wastewater: Treatment/ Volume Reduction Manual” which provides a very good collection of tools, best practices, and case studies to help brewers in the journey of lowering water usage, and provides options for wastewater treatment and disposal.

Transitioning to renewable energy sources is a crucial step towards sustainable brewing. Breweries are increasingly sourcing electricity from renewable sources such as wind, solar, and hydroelectric power.

By investing in renewable energy infrastructure, breweries not only reduce their environmental impact but also contribute to the growth of the green energy sector.

Another approach is that breweries are actively engaging in collaborative partnerships with other local industries to source clean energy more efficiently and effectively.

One promising avenue for renewable energy sourcing is through joint ventures with other local industries, such as the establishment of joint geothermal plants. Geothermal energy, where available, offers a reliable and sustainable source of power. By partnering with neighbouring industries, breweries can leverage shared

resources and infrastructure to access geothermal energy at a larger scale and lower cost.

Additionally, breweries are exploring the use of district heating systems, which distribute heat generated from renewable sources, such as biomass or solar thermal energy, to multiple buildings within a local area.

By tapping into district heating networks, breweries can significantly reduce their reliance on fossil fuels for heating and hot water needs.

Collaborating with other businesses and municipalities to expand and optimise district heating infrastructure can further enhance the sustainability and resilience of these systems.

Through strategic partnerships with local industries and communities, breweries can not only access renewable energy more affordably but also contribute to the development of integrated, decentralised energy systems.

By working together towards shared sustainability goals, breweries can strengthen their connections with the local community and foster a more resilient and environmentally friendly energy landscape.

When making investment decisions, breweries are increasingly considering the total cost of ownership (TCO) rather than solely focusing on upfront costs. TCO calculations take into account not only the initial investment but also the operational and maintenance costs over the entire lifespan of the equipment.

By adopting this approach, breweries can make informed decisions that maximise sustainability and long-term cost savings. Tim Wolf, senior advisor, engineering from First Key Consulting says: “Breweries must embrace innovation and experimentation to enhance efficiency without compromising quality and their own unique core values.”

An example of this would be when a brewery considers replacing its boiler system. Using TCO analysis, the brewer compares the costs of different boiler

“Breweries are in a position these days to leverage the many sustainability innovations being put forth by reputable vendors. “They just need to be careful to make educated decisions when implementing new technologies and process concepts to ensure the desired outcomes are achieved,” Rod Waite, First Key Consulting.

options, considering factors such as the initial purchase price, its energy efficiency, the expected maintenance requirements, the fuel costs, and the expected lifespan.

In this way, the brewery is able to identify the most cost-effective solution that minimises energy usage and long-term expenses, rather than simply going for the option that has the lowest initial investment.

Reliability-centered maintenance (RCM) is a proactive approach to equipment maintenance that focuses on optimising reliability, safety, and environmental performance.

By implementing RCM practices, breweries can minimise downtime, reduce energy consumption, and prolong the lifespan of their production equipment.

Regular maintenance and equipment upgrade also ensure optimal efficiency, further contributing to sustainability goals.

Reducing carbon emissions associated with packaging and logistics is another area of focus for sustainable breweries. Breweries in some parts of the world are opting for returnable containers over single-use packaging to minimise waste and energy consumption.

Lightweight primary and secondary packaging materials are being used to reduce transportation-related emissions and minimise environmental impact. These lightweighting efforts also result in lower packaging costs. Careful engineering and testing of these design changes can help ensure a good quality of the packaged beer when the consumer experiences the product. Moreover, breweries are increasingly sourcing raw materials locally to reduce transportation distances and support local economies.

By embracing green logistics practices, such as optimising delivery routes and utilising eco-friendly transportation modes, breweries can further lower their carbon footprint throughout the supply chain.

By implementing RCM practices, breweries can minimise downtime, reduce energy consumption, and prolong the lifespan of their production equipment,” Rod Waite, First Key Consulting.”

Engaging in international benchmark surveys is a crucial strategy for breweries committed to sustainability, providing them with valuable insights and comparative data on key performance indicators such as water and energy consumption per hectoliter of beer produced.

These surveys offer breweries the opportunity to assess their operations against global standards and identify areas for improvement, driving progress towards more sustainable practices.

Participating in international benchmark surveys offers breweries several benefits such as comparative analysis.

Benchmark surveys allow breweries to compare their performance metrics with industry peers on a global scale. By analysing data from other breweries of similar size, production layout, or geographic location, breweries can gain valuable insights into their relative efficiency and identify opportunities for optimisation.

They promote the identification of best practices.Through benchmark surveys, breweries can access information on best practices and innovative solutions for resource management. By learning from leading performers in the industry, breweries can adopt strategies to improve efficiency, reduce waste, and minimise environmental impact. Also consider stakeholder communication. Engagement in benchmark surveys enhances breweries’ ability to communicate their sustainability efforts to stakeholders effectively. By providing transparent and credible data on their environmental performance, breweries can build trust with consumers, investors, and regulatory authorities, demonstrating their commitment to sustainability. The brewing industry is undergoing a paradigm shift towards sustainability, driven by the growing awareness of environmental issues and the need for responsible business practices. By focusing on minimising resource consumption, investing in sustainable technologies, sourcing renewable energy, considering TCO calculations, implementing reliability-centered maintenance, and adopting eco-friendly packaging and logistics practices, breweries can pave the way for a more sustainable future.

With collective efforts and innovative solutions, the brewing industry can continue to thrive while minimising its impact on the planet.

This article was authored by Dr. Hugo Patiño, director of Technical Services, Rod Waite, director of Engineering Services and Tim Wolf, senior advisor of Engineering Services at First Key Consulting.

Our service team is always on hand to help

Be it the economical use of resources, consistent process sequences or maximum flexibility and performance: Krones Lifecycle Service offers you tailormade solutions that meet your specific needs – over the entire lifetime of your line.

ST AUSTELL BREWERY HAS RELEASED ITS FIRST IMPACT REPORT DEMONSTRATING THE FAMILYOWNED BUSINESS’ COMMITMENT TO SUSTAINABILITY AND ITS EFFORTS TO HAVE A POSITIVE IMPACT ON PEOPLE AND THE PLANET. HERE THEY SHARE SOME OF THE KEY DETAILS FROM THESE INAUGURAL

At the end of 2024, St Austell Brewery released its maiden impact report. A publication that would demonstrate the company’s commitment to sustainability and its efforts to have a positive impact on people and the planet.The report includes some ambitious targets, including the goal to reach net zero by 2040.

With more than 160 pubs across the South West, two breweries, a drinks wholesale business and six distribution centres, St Austell Brewery is one of the region’s largest businesses.

Sustainability has long been at the heart of St Austell Brewery’s mission. Since 2002, the company has partnered with Cornish farmers to source local barley, continuing to reduce food miles by

building a strong South West supply chain and supporting local businesses, as well as backing good causes through its Charitable Trust.

The impact report, which highlights the company’s sustainability efforts over the past three years, details initiatives aimed at tackling its carbon footprint.

These include reducing emissions from the drays which transport beer across the country by updating the lorries to Euro 6 engines, and its partnership with a food waste platform to redistribute leftover food from managed pubs to local communities.

St Austell Brewery’s Chief Executive, Kevin Georgel, explains: “Our priority is to build a company that will continue thriving for generations to come.

“This means investing in resilient, regenerative practices that not only support our operations, but also create lasting, positive impacts for our people, the places we cherish and operate in, and through our important local communities.

“We are a very proud regional employer and, as one of the largest private-sector companies in the South West, we recognise the significant role our people have in our ambition, but also the scale of our responsibility.

“From equality, diversity and inclusion to leadership and development training, we are continuing to invest in a number of people initiatives across the business to establish ourselves as a leading employer in the South West.”

He adds: “Whilst we are making progress in many areas, from investing in renewable energy and advanced water treatment technologies to reducing waste, we outline future focus areas in the impact report.

“Our ambitious roadmap will help us

eliminate the largest sources of carbon emissions and reach our net zero goal by 2040.

“We are also strengthening our supply chains, working closely with food suppliers and barley farmers to promote nature-first farming.”

A focus for St Austell Brewery going forward is investing in regeneration projects. In 2023, the company’s iconic Pier House pub in Charlestown reopened after a devastating fire the previous year. The refurbishment marked the business’s first circular economy pub refurbishment project.

Working with the University of Exeter, the company reused, recycled, and donated materials to minimise waste and restore the building with as little environmental impact as possible. This model will serve as the blueprint for future St Austell Brewery pub refurbishments.

In recent years, St Austell Brewery has made other sustainable changes, including switching to a 100% renewable CO2 supply at both of its production sites. The business also continues to reduce water consumption in its brewing process.

Since 2022, both breweries – St Austell and Hare – have sent 3,433 tonnes of spent grain from brewing back to local farmers for use as high-protein, high-fibre animal feed. Yeast produced during the beer fermentation process is also reused by local farmers as natural fertiliser.

In addition, the business has invested in a new state-of-the-art canning line at Hare Brewery, its second brewing site in Warmley, near Bristol, helping to reduce plastic packaging and overall production waste.

In late 2023, the business partnered with the local sharing app Olio, which helps reduce food waste by redistributing

surplus food from a selection of its pubs to nearby residents. As of October 2024, 1,504 food items had been diverted from waste and shared with the community.

To further its renewable energy focus, the company has already installed solar panels at Hare Brewery in Bath, St Austell Brewery, and its Central Distribution Centre (CDC) in St Columb.

As a result of these ongoing efforts, the business was shortlisted for Best Sustainability Pub Company at the 2024 Publican Awards.

Other key focus areas for the company going forward include rolling out EV charging points across its entire pub estate by 2028, with plans to install at least 400 additional chargers to improve EV accessibility across the rural South West.

The company also plans to expand its solar energy initiatives by adding more solar panels at its St Austell and Hare Brewery sites.

Our ambitious roadmap will help us eliminate the largest sources of carbon emissions and reach our net zero goal by 2040,”

Kevin Georgel, St Austell Brewery

Emily Coon, St Austell Brewery’s sustainability manager, explains:

“Sustainability has always been a core part of our business.

“We work closely with the natural world and prioritise locality and seasonality in everything we do, from sourcing barley from local farmers for our beers to curating a menu that showcases South West produce and suppliers.

“Now, we are formalising our sustainability strategy to provide a solid foundation for it to thrive. This includes focusing more on reporting and improving our data collection.

“We’re committed to expanding the data we capture and improving transparency in our decision-making.”

To further enhance its sustainability efforts, the business will soon be installing steam and electricity submeters, which will help identify energy-saving opportunities across the business.

THE BREWING PROCESS GENERATES SIGNIFICANT AMOUNTS OF BREWERY WASTE AND BY-PRODUCTS. BUT WHAT IF THESE MATERIALS WEREN’T WASTE AT ALL? MOORGATE FINANCE IS ON HAND TO EXPLAIN MORE.

Brewing is responsible for the generation of large amounts of by-products and waste. But what if we looked at these materials not as waste but, instead, something that that could be transformed into valuable income streams for your brewery? By adopting sustainable practices and thinking innovatively, breweries can not only reduce their environmental impact but also create new revenue opportunities.

Here we’ll explore five new effective ways to turn brewery waste into profitable ventures.

SPENT GRAIN: TURNING BREWERY WASTE INTO RESOURCE

Animal Feed: Spent grain is rich in protein and fibre, making it a perfect livestock feed. You can sell or donate this to local

farmers and in doing so, not only support local agriculture, but reduce your own wastage too.

Baked Goods: Spent grain can be processed and used to create highprotein flour, which is ideal for making bread, granola bars, cookies, and other home baked treats. Partnering with local bakeries to provide a steady stream of grain, or even creating your own line of baked products to compliment your beer, is another great revenue stream.

Pet Treats: Don’t forget the pets! Spent grain can also be used to safely produce healthy, natural treats for man’s best friend too.

Nutritional Supplements: Brewer’s yeast is a valuable source of B vitamins and protein. It can be dried and sold as a nutritional supplement for both humans and animals.

Skincare Products: Yeast extract is known for its skin-conditioning properties and can be used in the production of cosmetics and skincare products. Collaborating with beauty brands or creating a proprietary skincare line can provide a profitable revenue stream from the ever-growing wellness market.

Biogas Production: Wastewater from the brewing process contains organic material that can be converted into biogas through anaerobic digestion. This biogas can then be used to generate electricity or heat, reducing energy costs and potentially providing a surplus that can be sold back to the grid.

Fertilizers: Treated wastewater can be used to produce organic fertilizers, which are in high demand for sustainable agriculture. Partnering with local farms or gardening centres can provide a steady market with a constant demand for these products.

The fermentation process produces carbon dioxide (CO2) as a by-product. By capturing and purifying this CO2, breweries can reuse it for carbonation in their own beverages or sell it to others. Hop Residues: Extracting Value from Waste. Hop residues can be processed to extract essential oils and other valuable compounds used in the production of perfumes, cosmetics, and even pharmaceuticals. From tasty beer, to delicious scents!

Turning brewery waste into income streams often requires initial investment to fund new equipment and processes. Choosing to fund these with someone like Moorgate Finance means you have time to earn the money back on these investments, without a detrimental impact on cash flow in the meantime.

Financing Options include asset finance: Acquire the necessary machinery and equipment for processing spent grain or capturing CO2 through flexible asset finance solutions.

Business Loans: Secure funding for larger projects, such as biogas production facilities or wastewater treatment systems, with our competitive business loans tailored to your brewery.

Equipment Leasing: Stay up to date with the latest technology and equipment by opting for leasing options that allow you to upgrade assets, without the upfront costs.

Turning brewery waste into valuable income streams is not only a smart business move but also a step towards greater sustainability and a reduced environmental footprint. Moorgate Brewery Finance is here to support your journey towards a greener, more profitable brewery!

EVERY HOP HAS A STORY, AND SO DOES ITS GROWER, AND AS PART OF THE COMMUNITY AND INNOVATIVE VALUES, CHARLES FARAM ARE KEEN TO CONNECT THE TWO. HERE PATRICK WHITTLE OUTLINES HOW THEY’RE DOING JUST THAT WITH SUSTAINABILITY AT ITS HEART.

We all know hops are key to every brew, but have you ever thought about where they

come from? Not just the country, but the farm itself?

While many of us recognise varieties like Citra from the USA or Fuggle from the UK, there’s more to the story than just that, with loads to explore.

Let’s get to know our British hop growers British hop growers are key to the nations brewing heritage and one of the driving forces within the industry.

Their sense of tradition and dedication to quality, innovation, and sustainability ensures that every hop cone you touch

as brewers, or we touch as merchants contributes to beers of brilliant character and flavour.

Every hop has a story, and so does its grower, and as part of our community and innovative values we are keen to connect the two.

Hop growing is no easy feat and takes years to master, some say it even takes a lifetime of generations.

From the outside, farming seems like a simple occupation, you grow it, you sell it, but the truth is far from it.

Beyond planting and harvesting, each growing year is different. Weather, disease, and ever- changing regulations are a small part of the ongoing difficulties these farmers must face.

However, they aren’t just farmers, they are mechanics fixing their 60-year-old hop-picking machines, servicing their tractors and trailers.

They are agronomy experts, overcoming every disease and pest Mother Nature throws at them, and they are meticulous quality controllers ensuring every hop is dried perfectly to preserve those powerful flavours and aromas.

The British hop growing acreage is decreasing, year on year and without British hops, beer and our traditional landscapes will never be the same.

By supporting local hop growers and learning their stories, you help sustain a crucial part of Britain’s farming heritage. Don’t just get to know them, share their stories and use them to your advantage, storytelling is a powerful yet underutilised marketing tool.

Every hop and every hop grower has a story, use this story to educate your beer

drinker about the process, provenance, peculiarities and quality of these local ingredients