HEAT PUMP

Artic Heat Pump

HEAT PUMP

AIR SOURCE

HOW TO SERVICE MINI-SPLITS PROPERLY

Mini-split heat pumps are low maintenance, not maintenance-free, as some people tend to believe.

Dale Comeau

VERTICAL STACK EFFECTIVE HEATING AND COOLING IN MULTI-FAMILY BUILDINGS

For about half, if not more of the season, the VSHP operates as a self-sufficient water source heat pump that feeds and pulls from its own source. What makes it perform so well?

Matthew Reid

TO

Absorption heat pump technology, which has been available globally to end users for the past two decades, was introduced in Europe much earlier than in North America.

OTHER FEATURES

38PRODUCT DEVELOPMENT

DOE updates residential heat pump challenge, launches commercial challenge.

Carolyn Cooper

42AIR TO WATER

While it is true of any hydronic system, HP systems require a bit more attention to achieve the best results.

Bob (“Hot Rod”) Rohr

46,48,50PRODUCTS

A showcase of heat pump technology.

58JOBSITE JARGON

Match the correct definition or meaning to the terminology you hear in the field and enter for your chance to win a Yeti cooler from NIBCO.

Cover Photo: Jo-Ann Richards, Works Photography

AIR SOURCE

HOW TO SERVICE MINI-SPLITS PROPERLY

Mini-split heat pumps are low maintenance, not maintenance-free, as some people tend to believe.

Comeau Refrigeration has been in business in Bridgetown, NS since 2008, and it has always focused on heat pump technology.

In their service area of 140 km., heat pump systems are most often installed in a retrofit application to reduce or eliminate the need for fuel oil during the heating season. The added value of air conditioning is a secondary benefit. However, this is changing with summer highs seemingly increasing every year.

Nova Scotia is a Maritime province, meaning it typically has high humidity for much of the year. There are unique operational challenges when compared to similar systems in other parts of North America.

In an average year, Comeau Refrigeration will install 150 heat pump systems. The company has been installing Fujitsu heat pumps since 2008 and became an Elite dealer in 2015 to better serve its customer base.

MAINTENANCE IS CRITICAL

Like any piece of equipment, mini-splits operate most efficiently and effectively when properly maintained. We know that scheduled annual maintenance provides the greatest benefits for the customer, in the form of comfort, energy savings, and system longevity.

Comeau Refrigeration has one fulltime service technician on staff. Other technicians conduct service work regularly as well. From an accounting standpoint, service work is treated the same as installation work, meaning the profit margin for maintenance is similar to the company’s other work. Failing to be profitable on maintenance work is why many HVAC contractors don’t take it as seriously as they should.

Over the years, Comeau Refrigeration has developed a recipe for servicing heat pumps that’s kept clients happy, with word-of-mouth referrals as a steady benefit.

Technician removes the filter from a wall-mounted mini-split unit.

PRESSURE WASH INDOOR UNIT

As good as most mini-split indoor filters are, very fine dust can accumulate on the indoor coil and fan wheel over time. Accumulation occurs largely because the fan wheel is on the cool side of the system, so dust more readily adheres to the fan wheel. We’ve witnessed a reduction in airflow as a result of dirty components. Moisture on the fan can also initiate mould growth. The primary air filters are washed, and

the secondary electrostatic filters are also removed and washed with tap water. Some units have disposable carbon filters that can be replaced. With the covers off, a mini split bib kit is hung below the unit. The coil and fan are sprayed with a portable coil cleaning system to remove accumulated dirt. The bib kit catches all dirt and fluid, eliminating the need to remove the unit from the wall.

Dale Comeau (R) walks a customer through the maintenance process.

Spraying through the evaporator fins, technicians use a water and coil cleaner solution in the pressure washer to clean the coil and fan wheel. It’s not uncommon to flush the fan wheel two or three times, rinsing it until the solution runs out of the unit clean. When the solution entering the bib is clear, a final rinse is conducted with pure water.

Once rinsed, the unit is dried by running the system. Then a visual inspection is conducted to ensure all the small nooks and crannies have been reached.

TREAT INDOOR UNIT FOR MOULD AND MICROBIAL GROWTH

Once the indoor unit is clean and dry, apply an anti-microbial solution to the coil and fan wheel with a hand sprayer (we typically use Foster 4080 disinfectant). It is recommended to keep all surfaces of the fan and coil wet with the disinfectant for 10 minutes, after which the filters and covers can be re-installed.

ELECTRONIC REFRIGERANT LEAK TESTING

While the indoor unit is drying, technicians begin testing the indoor and outdoor units with a refrigerant sniffer. In the unlikely event a leak is discovered the customer is informed. If the unit is still under warranty, we confirm the warranty status and proceed with organizing a repair. If a leak exists refrigerant can’t be added until the leak is repaired.

If the unit isn’t working properly and we suspect a leak, we may ask permission to recover the refrigerant and conduct a high-pressure leak test to determine the source of the leak. As most units in the field are still using R410, it’s extremely important to avoid any refrigerant loss, considering its GWP (Global Warming Potential) number of 2,088.

Insect infestations can be more harmful to outdoor units than many realize.

HPJ

CARING FOR ELECTRICAL AND ELECTRONICS

Next, we move to the electrical system. All terminal screws are checked indoors and out. Outdoor unit electronic components are quite susceptible to water intrusion, insects (ladybugs/mud wasps), and the impact of freeze-thaw cycles in heating mode.

We’ve seen an infestation of ladybugs so severe that the main PCB, outdoor fan motor, four-way valve solenoid coil, and EEV solenoid coil needed to be replaced. This is an extreme example, but it illustrates the damage insects can cause if left unchecked.

FULL MECHANICAL INSPECTION

A full mechanical inspection is going on throughout the entire service process. Here, we’re actively looking for problems. A keenly observant technician can often find issues before they become a service call.

Is everything tight and straight? Is the insulation in good condition? Is the outdoor unit still sitting level?

We ensure the outdoor fan motor and blades are clean. While the outdoor fan and coil are less susceptible to dirt buildup, we still use the portable coil cleaning system as it was used inside. Sterilization is not necessary for outdoor components. The motor bearings are also checked for noise or wear.

By Dale Comeau

CHECKING REFRIGERANT PRESSURES AND TEMPERATURES

Now that the indoor and outdoor units are clean and a leak test has been done, we run the system. Depending on the time of the year, it could be in cooling or heating mode for this step.

Generally, we do not put gauges on the refrigerant piping because mini-splits are a critically charged system; we want to avoid losing any refrigerant by using testing gauges. Obtain the refrigerant pipe temperatures as well as the indoor supply and return air temperatures. The amperage draw is also checked. This data is compared to a pressure-temperature chart for the system refrigerant. Some quick calculations can help to confirm the system charge is good and the unit is working efficiently.

ON THE WAY OUT THE DOOR

If no issues arise, everything outlined above should take an experienced service technician about 90 minutes. The process can take less time if the unit is new and quite clean. If it’s filthy, the process could take up to three hours. The application and service interval will dictate how long the process takes.

For example, indoor units installed at convenience stores are notorious for being dirty because the door is constantly swinging, introducing dirt and humid air.

On our way out, we remind owners to wash their primary and secondary filters with water every three months. We also inform them that if they want to replace the optional apple-catechin filters on their indoor unit, it should be done on the same quarterly interval.

Like any airside HVAC system, mini-split systems need to be maintained regularly for optimal performance, comfort and indoor air quality.

Dale Comeau is general manager of Comeau Refrigeration Ltd. in Bridgetown, NS. The company’s five technicians focus heavily on heat pump applications. His company is pursuing Net-Zero certification. With the assistance of Nova Scotia Community College and the Energy Sustainability Engineering Technology program, the company has completed Scope 1 direct and Scope 2 indirect analysis.

VERTICAL STACK

Vertical stack heat pumps come with an energy recovery ventilator to meet building codes all over this country.

How it works

By Matthew Reid

Matthew Reid is technical director – heating division at Enviroair’s Richmond Hill, ON office. He can be reached at mreid@enviroair.ca

Effective heating and cooling in multi-family buildings

The world of heat pumps is rapidly growing and expanding every day. I see new products coming into the mix with huge outputs capable of providing hundreds of thousands of BTUs to buildings. We are seeing geothermal fields that can be used in different ways to both heat and cool buildings becoming a common talking point at engineering firms. We also see an increasing demand for VRF systems.

Air source heat pumps are at the mercy of outdoor ambient conditions for the COP. Water source heat pumps perform better, but that is also dependent on what temperature we can keep water on the source side and how we do that.

With the surge of interest in heat pumps there is a need to understand these systems and their nuances, and we need to do that fast. That’s a massive undertaking we all must now dive into if we want to remain current and competitive in this “new market.”

A product I have been spending time on lately is the vertical stack heat pump (VSHP) for multi-family applications. The VSHP has been around since the 1970s so it is by no means a new technology. No heat pump really is when you look through the history. The vertical stack has been going into our condo towers and other multi-family buildings for decades and it remains an incredibly effective way of heating and cooling buildings for a few reasons. The VSHP is basically a single loop hydronic system but it has multiple checks and balances to ensure it always works to meet demand.

What makes the VSHP perform so well is for about half, if not more of the season, it operates as a selfsufficient water source heat pump that feeds and pulls from its own source. Let me explain.

In a good vertical stack design, you will always have a main loop temperature of around 80⁰F. This water temperature is not cool enough for cooling nor is it hot enough for heating and that’s where the heat pump comes in and does its thing of lifting the refrigerant temperature to approximately 120⁰F for heating and approximately 45⁰F for cooling. These are not absolute numbers, but it helps paint the picture of what’s happening. Deviations from the main loop temperature will affect COP. Higher temp will give higher COP for heating but lower for cooling. Lower loop temperature will have the reverse outcome.

A VSHP system is a culmination of dozens or hundreds of water-to-air heat pumps inside a building. There are usually one or two per suite. The main loop is always designed to stay at a relatively steady temperature and then it lets the heat pump do the work to get either the necessary heating refrigerant temperature or cooling refrigerant temperature, depending on the load.

When in a shoulder season it’s very common to find some units doing heating and some doing cooling.

The main loop is designed to stay at a relatively steady temperature.

During a cooling call, the VSHP will send water back into the loop at 100⁰F. During a heating call, the VSHP will send water back to the loop at 65⁰F. If it’s a 50/50 split of heating and cooling in the building the main stack temp is now 82⁰F. This is a fine temperature to feed into a heat pump both for heating or cooling to get the desired results so no additional mechanical supplements are required.

Elevate your space with energy-e cient comfort.

Explore three Daikin single zone, wall-mounted inverter heat pumps equipped with low-GWP (global warming potential) R-32 refrigerant.

DAIKIN ENTRA

The Daikin ENTRA single zone inverter wall-mounted systems provide energy ef cient a ordable comfort.

Up to 18 SEER2

Up to 9 HSPF2

Up to 11 EER2

ADDITIONAL INFORMATION

DAIKIN OTERRA

Our e cient yet discreet wall-mounted unit — the Daikin OTERRA — provides high e ciency comfort control.

Up to 21 SEER2

Up to 10.2 HSPF2

Up to 12.5 EER2

DAIKIN ATMOSPHERA

Daikin ATMOSPHERA was the first single zone R-32 ductless system in North America, providing modern styling with ultra-high e ciency for extreme temperatures.

Up to 27.4 SEER2

Up to 11.2 HSPF2

Up to 16.3 EER 2

Before purchasing this appliance, read important information about its estimated annual energy consumption, yearly operating cost, or energy e ciency rating that is available from your retailer.

Daikin

VERTICAL STACK

However, let’s say that all units are in heating mode. This means that all of the units are sending that 65°F or less back into the loop. If we want that main loop to stay at 80°F as stated previously we need to inject some heat. This is where the “trim equipment” comes in. A boiler for example or any heat source, at the start of a system will remain off until it sees the loop temp drop somewhere below that 80°F standard the engineer has designed for. Once the boiler sees the low temperature it will kick on and buff the main loop temp back to setpoint. Alternatively, during a hot summer day and all units have a cooling call, the temperature of the loop will climb to 100+°F. This will activate the cooling tower to turn on and bring the temperature back down to design setpoint.

The long and short of it is, the heat pumps will do the heavy lifting of moving heat around the building to those that need it for a good portion of the year and only activate the heat injection or rejection when required to bring down the loop temperature into design setpoint.

VSHPs are also getting better and smarter every day. Most of them come ready to attach to any standard smart thermostat you would like, they also come with an energy recovery ventilator to meet building codes all over this country.

Where’s the catch?

So, you have a single unit in a suite doing the heating, cooling and ventilation. As is the case with all equipment, something must give. For VSHPs it’s usually related to noise. They are not excessively loud by any means. Most top tier manufacturers have sound test labs to ensure the dB levels of these units stay as minimal as possible, but consider that these units house a compressor and a fan, both operating inside the suite.

It is common to find some units doing heating and some doing cooling in the shoulder season.

Unit in cooling mode.

Noise is unfortunately subjective and can’t really be quantified when speaking in terms of comfort. Some folks like the ambient white noise such as that of a refrigerator. It may annoy others to no end. Still, these units are effective, highly efficient and can save a ton of space and piping in comparison to other methods.

I’m not trying to infer this or any heat pump is a perfect source for heating and cooling. There isn’t a magic bullet, especially in the heat pump world. What there is, is a multitude of options and variations allowing you to prescribe the best fit possible for your client when you understand them all.

PRODUCT DEVELOPMENT

By Carolyn Cooper

DOE updates residential heat pump challenge, launches commercial challenge

The U.S. Department of Energy (DOE) has announced an update to its Residential Cold Climate Heat Pump Challenge, which is now in its final phase, and launched a similar commercial challenge. As of October 23, 2024, all eight HVAC manufacturers involved in the residential challenge – Bosch, Carrier, Daikin, Johnson Controls, Lennox International, Midea, Trane Technologies and Rheem – have successfully completed rigorous field testing of equipment to demonstrate the energy efficiency and performance in cold weather. According to the DOE, manufacturers which developed cold climate heat pumps (CCHP) for the challenge will begin production on the units as soon as this fall. The DOE has also developed a residential CCHP decision tool to help contractors select and properly install the appropriate heat pumps for homes. Now the DOE is working with nine manufacturers – AAON, Addison, Carrier, Daikin, Johnson Controls, Lennox, LG, Rheem,

and Trane Technologies – to advance rooftop units (RTUs) for commercial buildings, as part of its Commercial Building Heat Pump Accelerator. The goal of the challenge is to produce cost and energy efficient heat pump RTUs that will help organizations meet decarbonization goals. The companies will create prototypes and test product performance and durability at partner businesses such as Amazon, General Motors, IKEA, and others. These units are expected to be available by 2027.

The accelerator also provides building owners and operators with resources and guidance on heat pump technology as part of a campaign to encourage heat pump adoption. The accelerator is scheduled to run until December 2027.

betterbuildingssolutioncenter.energy.gov/ accelerators/commercial-building-heat-pump

A new heat pump that will not only keep your home warm and comfortable this winter… but can also purify the air…

Suitable for cold climate

• -26°C (-15°F) cold climate heating operation

• Room Freeze Protection: Automatically turns on the compressor to help prevent plumbing damage if the room temperature falls below 7.8°C (46°F).

• Base Pan Heater: Helps prevent freezing condensate and allows very low ambient operation.

R32 Refrigerant

• Reduce energy cost

• Eco friendly

Improved nanoe™ X air purification effectiveness

• 10x more hydroxyl radicals/ second compared to previous ClimaPure™ XE model

5 effects nanoe™ X air purification technology

Inhibits 3 types of pollutants

ROAD WARRIOR

Name: Jae Van Hierden

Company: Green Coast Heat Pumps

Job title: Lead technician

Born in: Vancouver, BC

Live in: Victoria, BC

Age: 35

Pet: Joey, a mini Australian Shepherd

Jae Van Hierden: Committed to learning on and off the job

When Jae Van Hierden graduated high school, his father, a chef, suggested he try his hand at becoming a refrigeration technician. Almost 18 years and several careers later, Van Hierden decided to take that advice, and today works as lead technician for Victoria, BC-based Green Coast Heat Pumps.

“When I was 18 I did a couple ride alongs with refrigeration technicians, and though I liked the work I thought this isn’t really what I’m choosing,” he recalls, noting that he has always enjoyed learning new skills and working with his hands. Instead, Van Hierden went to university to study psychology, and eventually began working in a research lab.

After deciding that wasn’t for him, Van Hierden trained as a sommelier, and happily worked at the Fairmont Empress hotel in Victoria until COVID shut down the prestigious property in 2020. “I thought, what am I going to do for the foreseeable future?” he says. “So I started live streaming video games, and I was a content creator for about four and a half years. It’s been a roller coaster. But everything I put my mind to I’ve been able to figure out and do well at.”

Remembering his father’s advice, and hoping for a career with more job security, Van Hierden began researching the HVAC industry, and was initially hired by Green Coast Heat Pumps owner Darcy Cross to provide social media support.

“He told me, could you do social media work for me and then maybe I’ll pull you in on a job or two when I need extra hands,” he says. “And then he started bringing me out on all the jobs, and I just started learning on my own. I found lots of professional resources online, because that’s kind of how I’ve always gone about things, and I’m very self-motivated. I try and study about an hour every day, whether it’s listening to a podcast or reading a chapter of a book.”

In January Van Hierden will begin the refrigeration and air conditioning mechanic level one program at Thompson Rivers University in Kamloops, BC.

Green Coast Heat Pumps does mainly residential installations and servicing throughout the Southern Vancouver Island region, and is now looking into working with stratas.

“I would say 95 per cent of our work is heat pumps,”

says Van Hierden, who adds that educating consumers is a key part of installations. “At the end of our installs, we do a full walk through of how to use your heat pump, how to operate the thermostat, and the best ways to get your efficiency. Typically people turn their heat pump on and off and they think that’s the best for energy savings. But when your house is completely cold and you’re just turning your heat pump on it’s going to be operating at a very fast speed and working really hard to get your house up to temperature. And that’s going to take years off of your heat pump’s lifespan, as well as increasing your energy bill.”

The company is currently working on a luxury home new build featuring a heat pump and HRV system that Van Hierden says is “a really cool job. I’m really enjoying my time on the tools, and the biggest thing is that every single job is different, a new challenge, and we’re never installing the same system. And then everyone’s house is different, whether we’re retrofitting the house and needing to find a way to make it work, or going into a brand new build.”

In the mechanical industry since: February 2024

By Carolyn Cooper

The most useful tool in your toolbox: My Milwaukee M18 brushless drill and impact

Schools and programs: Refrigeration and air conditioning mechanic level one at Thompson Rivers University in Kamloops, BC beginning January 2025

Favourite teacher: Craig Migliaccio, owner of AC Service Tech LLC, YouTube host and author of the book Refrigerant Charging and Service Procedures for Air Conditioning

Best advice you’ve ever received: You’re never too old to learn something new

Advice for young people considering entering the trades: Look for quality professional resources and start studying now. There are so many great resources to learn from that will help you get a leg up in the field and prepare you for school. If you haven’t worked in the trade start calling every company in town and start working. All the information you learn will sink in quicker if you are studying and getting hands-on experience to reference to. Ask as many questions as you can to make sure you understand what you are doing and why you are doing it!

Favourite part of the job: Learning every single day. Every job is familiar but has its own unique challenges to overcome so I am constantly learning and my days fly by

Hobbies: Hockey, golf, skiing, hiking, video games

Your favourite tool in your toolbox: My Klein reversible nut drivers. I have them clipped on the side of my bag

Tool you wish you had: Navac electronic flaring tool

If you were granted one wish: Generational wealth

Favourite band/performer: Odesza

Best concert you ever attended: Arcade Fire

Favourite book: Lord of the Flies

Favourite TV show: One Piece

Favourite movie: Fight Club

Favourite sport: Hockey

Favourite car of all time: Porsche 911

Favourite video game and preferred gaming system:

Favourite season:

Favourite restaurant or local lunch hang out? Brasserie L’Ecole

Favourite outdoor activity: Golfing

Favourite place to be: In the woods

3 albums that you’d take with you to your desert island:

1.Odesza – A Moment Apart

2.Jamie XX – In Colour

3.Big Wild – Superdream

Biggest pet peeves: Stupidity

One place in the world you would like to visit: Japan

One thing most people don’t know about you: That I love anime

TO WATER SYSTEMS

Bob Rohr is a trainer with Caleffi, and was the recipient of the 2020-2022 Carlson-Holohan Industry Award of Excellence. He has 40+ years of experience as a plumbing, radiant heat and renewable energy contractor.

Piping hydronic heat pumps

Asair to water heat pumps (A2WHP) become more available and accepted, proper piping assures optimum results. While it is true of any hydronic system, HP systems require a bit more attention to achieve the best results.

For optimal operating results, I suggest you design to the highest Coefficient of Performance (COP) for the best efficiency. COP is simply defined as ratio of beneficial heat output divided by electrical power input. It is no secret that as we drive the HP to higher operating temperatures two things become noticeable. The COP drops. Also, the actual BTU output drops (see Figures 1 and 2).

So, a designer/installer should take the time to optimize the entire system with some quick design calculations. The bottom line is the lower the required supply water temperature (SWT), the better the performance and efficiency numbers will be.

The addition of some thermal storage will prevent short cycling.

Retrofitting an existing distribution system with a HP powered system? Find more design tips in Idronics 25 (idronics.caleffi.com).

CHOOSING A HEAT EMITTER

Those familiar with hydronic heat emitter choices generally agree radiant panels are the winner in the race to low temperature distribution. It is certainly possible to design a comfortable radiant slab system with a SWT of 90°F. That SWT puts us in a sweet spot to run an A2WHP system under the best conditions.

Other options in ascending temperature requirements may be radiant ceilings and walls, panel radiators, and light mass radiant over-pours. High output fin tube is another option to consider. Manufacturers are providing output data at lower SWT these days. This makes the number crunching fairly easy.

Another goal that may be worth chasing is the addition of some thermal storage. Some manufacturers insist on a percentage of storage volume to prevent short cycling of the components in the HP. More and more HP manufacturers are including a buffer tank in a packaged system. In some cases, the buffer and indirect tanks are stacked, and provide DHW in space saving packages.

Figure 1 BTU output at higher operating temperatures

Figure 2 Relationship between COP and SWT

By Bob (“Hot Rod”) Rohr

Photo:

Like a champion braving the cold, Fujitsu AIRSTAGE heat pumps deliver unwavering performance that won't quit, no matter what the temperature.

When facing off against extreme temps, our heat pumps deliver a power-play of innovation, performance and reliability. Thanks to advanced engineering, our systems consistently deliver best-in-class heating performance in subzero temperatures. Plus, no matter how cold it gets, they won't shut off. Unlike other heat pumps, our proprietary refrigerant system has no lockout temperature in heating mode, so your customers get all-star performance, year-round. For performance and reliability in subzero temps… the edge goes to AIRSTAGE.

Fujitsu

BUILT CANADA TOUGH

AIR TO WATER SYSTEMS

TAKE ADVANTAGE OF LOWER RATES

There are other reasons to consider larger thermal storage capacity. One reason is to allow the HP to operate at low or off-peak rates to decrease electric costs (see Figure 3). It is possible to size and design a buffer tank that allows you to run the HP only during these lowest rate times. It is all in the number crunching phase of the design.

You will need data from your utility to determine your options. There is a win in all of this for the utility also, as they look to optimize their power plant output. They prefer to sell power at reduced rates as opposed to stopping and starting the generation plants.

For those savvy in the ways of piping and pumping, adding a “vessel” to store the BTUs is not a big reach. Space and dollars will also be part of the tank size and type decision.

The next step in the process is piping all of these pieces into an efficient distribution package. While there are several ways to actually pipe a thermal storage/buffer tank, one method covers all the bases. The piping should cover the task of providing long run cycles for the HP, most importantly.

We can also add benefits like run or drawdown time and “direct to load” function. The drawdown time period is once again a simple formula based on the load or loads pulled from the tank. If you want to coast through those high energy cost periods, the tank should be sized to cover the full building load, under design conditions.

Figure 3 Time of use rates

the heat call is satisfied. When the load is satisfied, it will send all the HP output into the tank. The tank is a thermal battery, able to accept and store energy for the next heat call.

On the next heat call, energy from the tank goes directly to the load, and the HP does not need to fire until the tank’s energy is depleted.

Maximize this drawn capacity by pulling the tank down to the lowest possible, usable temperature. This again is leveraged by the lowest possible SWT. Heat emitters that can use a wide temperature difference (∆T) are a benefit, also. Consider that panel radiators are often designed around a wide 30 to 35° ∆T.

THE CHALLENGE OF RETROFITS

Certainly, all of these steps are easy if you are starting a project from scratch, and you have unlimited options for heat emitters and piping space. Retrofitting existing systems will put some limitations on what can be done to attain the most optimized system. Another option being implemented is a hybrid system where a HP has a backup such as a fuel or electric fired boiler for the high temperature needs. This also provides redundancy in the system should a repair take one of the heat sources offline.

“Direct to load” is basically messaging the piping to allow the HP output to go directly to the system without interfacing with the tank’s volume. Simply stated, if the HP output matches the system load, you may as well bypass the tank.

The tank will be charged as either the loads start dropping off, or

Several HP manufacturers are offering equipment capable of 175°F operating temperatures. This will open more doors for retrofitting the older boilerbased systems.

If the home or building has an operating boiler in good condition, let it stay as part of the hybrid option. Energy costs will always be somewhat unpredictable. It is wise to have options ready to go.

As the HP market continues to heat up, watch the industry provide more and more options for components and piping and control.

Watch the pages of Mechanical Business as it continues to lead with HP news and product options.

These are exciting days to be in the industry – stay up to date on the methods and trainings available to allow you to be an expert in the A2WHP field. It will not take too much additional effort to be outstanding in your field.

EDEN ENERGY

HEAT PUMP PRODUCTS

Adaptable heat pump

GeoSmart NetZero variable capacity water-to-water inverter heat pumps are now available with low GWP R454B refrigerant. The series is available in a wide range of power that covers from 1 kW to 22 kW. With a COP of over 5.0, these inverter-driven heat pumps are versatile and intelligent water-to water units for ground source, air source, or hybrid application. The GeoSmart NetZero adapts to the needs of the installation.

geosmartnetzero.com

High-efficiency heat pump

Available in 2 to 5 tons, Daikin’s DZ20VC heat pump offers up to 8.2 HSPF2 heating and 22.5 SEER2 cooling performance. The heat pumps are powered by Daikin’s proprietary inverter technology and highefficiency, variable-speed swing and scroll compressors. Daikin Inside Intelligence monitors performance, while a high-efficiency ECM indoor condenser fan motor moves air quickly and quietly. Highlights include coil and ambient temperature sensors; diagnostic indicator lights, seven-segment LED display, and fault code storage; and a heavy-gauge, galvanized steel cabinet with a removable sound-control top. www.

northamerica-daikin.com

Air to water system

Cold climate heat pumps

Arctic EVI air-to-water heat pumps are specifically designed for North American weather, with the ability to operate in as low as -22⁰F (-30⁰C) temperatures for hydronic heating and cooling. With a mono-block design and multi-heat pump staging, the Arctic EVI has a COP of 3.1/3.2, and is available in three models offering 29,000 BTU, 48,000 BTU and 60,000 BTU respectively. The unit is Wi-Fi enabled for full remote control, and offers ultra-quiet DC motor fans, intelligent defrost based on ambient temperature, and Blue Fin technology on evaporator and condenser fins for high corrosion resistance. www.

arcticheatpumps.com

Viessmann’s Vitocal 100-AW is a residential air-to-water heat pump system for heating, cooling, and domestic hot water that includes an outdoor unit, indoor unit and a 20-gal steel buffer tank. The kit is delivered on a single pallet. The heat pump is available in 1.5, 3, and 4.3 tons for cooling/20.5, 34, and 58 MBH for heating (nominal capacities), which allows for flexible application types. The buffer tank can be physically mounted on top of the domestic tank for additional space savings. www.

viessmann.ca

Universal heat pumps

Compatible with most existing HVAC systems, or as a universal replacement, the Sure Comfort Vantix Line RD17AZ heat pump features a compact footprint, and sound as low as 50dBA. The unit is Cold Climate Energy Star certified, with efficiency up to 9.5 HSPF2, 19 SEER2 and beyond. It offers premium performance even at -15⁰C, with Vantix Gas Furnace back-up performance listings. www.

surecomfort.ca

the Amana brand S-series and the smart thermostat is smart thinking inside and out.

The Amana brand S-series system wouldn’t be complete without a smart thermostat to support control and comfort. The new Amana brand smart thermostat does just that! The range of intuitive functions o ers homeowners control from almost anywhere via the Amana home app or voice control with compatible Amazon and Google smart devices (with Wi-Fi).

Amana

HEAT PUMP PRODUCTS

Monobloc design

Hitachi’s Yutaki M monobloc heat pumps for residential applications offer space heating, cooling and domestic hot water. The air-to-water heat pumps can maintain an output of up to 140⁰F by -4⁰F outdoors. An embedded electrical back-up automatically ensures heating continues on colder days. Units are available in 3 and 4 tons, and can be controlled through Hitachi’s Advanced Color Wired Remote Controller, with Wi-Fi capability.

www.

hitachiaircon.com

Inverter technology

The Conforto Maximum Heat Pump Series provides year-round comfort through heat pump inverter technology. Designed for single and multi-zone applications, the ductless mini split systems do not need ductwork. With top-tier energy efficiency ratings, these units are ENERGY STAR certified. Features include Auto Restart − if the system shuts down due to power failure, it will restart with previous function settings when power is restored. www.

confortohvac.com

Split system heat pumps

Amana’s S-series E ASZS6-E is an ENERGY STAR Certified Residential CCHP. With up to 8.6 HSPF2 and 17.5 SEER2 performance, the splitsystem heat pumps are engineered for traditional ducted applications with heat pump, gas furnace or dual fuel connectivity. Inverter-driven, they need just 4 in. of clearance. The units can use existing line sets, connecting up to 100 ft. of pipe for typical installations.

www.

amana-hac.com

-30°C

UNIX SERIES

HIGH-EFFICIENCY CENTRAL HEAT PUMPS WITH CASED COILS

Heat pump combination AHRI Certified for installation with ANY 3rd party furnace.

ROOFTOP

COLD CLIMATE DC INVERTER HEAT PUMP

Two-stage, two-cylinder compression and hot gas injection for unparalleled heating efficiency.

Eligible to financial incentives in certain provinces, contact us for more detail.

Gree

SPARE PARTS

TO FULLY SUPPORT OUR DEALER NETWORK

OFFICIAL DISTRIBUTOR IN CANADA

*GREE Canada is not responsible for warranty on units sold outside GREE Canada’s sales channel. For more detail, contact our team at proservice@gree.ca

HEAT PUMP PRODUCTS

Wastewater energy recovery

The Piranha self-contained wastewater heat pump from Sharc Energy uses a specifically designed direct expansion heat exchanger to recover thermal energy from a building’s wastewater to heat domestic hot water. Models have a heat output of 60, 120 and 180 MBH, and a cooling capacity of 48, 96 and 144 MBH respectively, and an average combined COP up to 7.0. The units are NSF-372 rated BPHE, with double-wall leak detection.

www.

sharcenergy.com

CONFORTO MAXIMUM HEAT PUMP

The perfect blend of comfort & convenience with heat pump inverter technology.

• Ductless systems use our sleek wall or ceiling mounted indoor air handlers, with a single or multi-zone R410A outdoor condenser to deliver precise temperature control of one or more rooms.

• Advanced heat pump variable speed technology provides year-round cooling and heating solutions in extreme weather conditions.

• Maximum energy efficiency ratings qualify for utility rebates. ENERGY STAR® Certified.

• Auto Restart - if system shuts down due to power failure, system will restart with previous function settings when power is restored.

Granby/Conforto

Smart heat pump

The Ultranixx Eco heat pump is priced similarly to an AC unit. It offers both heating and cooling for ducted homes and low-rise units up to 4,000 sq. ft., with efficient operation at a balance point of 0°C. Paired with the Kinghome Smart Thermostat, the Ultranixx Eco maximizes efficiency and savings. Leveraging cloud-based intelligence, it optimizes switching between the heat pump and gas furnace based on weather forecasts, equipment efficiency, and real-time energy prices. Users can control the thermostat remotely via the Kinghome+ App. www.

kinghomecanada.com

Rooftop system

Rebel Applied Air Source Heat Pump (ASHP) is a 30- to 68-ton packaged rooftop system that provides up to 75 per cent more heating capacity at 0°F compared to current technologies with R-410A refrigerant. The ASHP has a heating-only boost compressor to enhance refrigerant mass flow at low-ambient temperatures, to increase heating capacity while maintaining energy efficiency. Supplemental heating options, including dual fuel, are also available if needed. The heat pump uses an alternating circuit defrost cycle. www. daikinapplied.com

Cintas

An introduction to GAHP technology

Heatpumps have been around for decades and are proven to support heating operations with very high efficiencies. Most common heat pump applications are powered by electricity. In contrast, thermally driven heat pumps can run on natural gas, hydrogen, or renewable and low-carbon fuels, such as Renewable Natural Gas (RNG) to make complex heating systems more efficient by replacing legacy boiler systems for space heating and hot water applications.

In particular, facilities located in electric grid-constrained areas that are dealing with electrical capacity issues and have access to gas supply networks may consider thermal heat pumps to lower operating costs and reduce emissions over conventional natural gas equipment.

Background and history

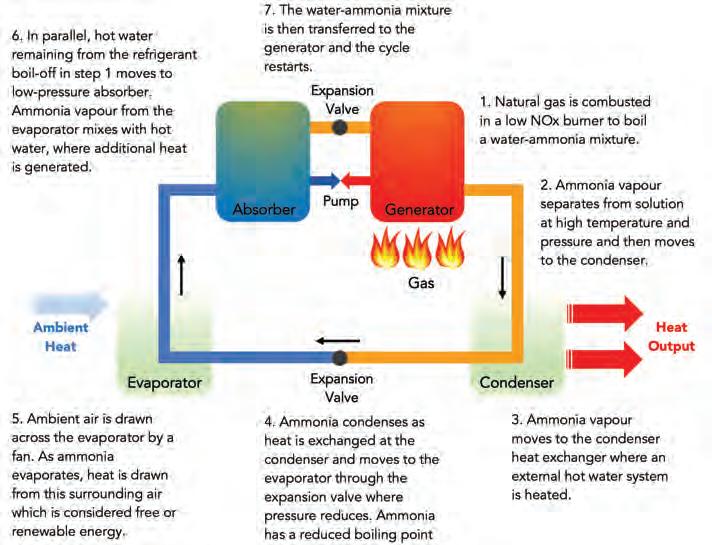

The absorption heat pump technology has been available globally to end users for the past two decades. It was introduced in Europe much earlier than in North America. The Asian market has also seen rapid growth of the technology in the last five years. Unlike traditional heat pumps that operate on a vapour compression cycle, gas absorption heat pump (GAHP) units work on an absorption cycle.

The working principle of ammonia-water based absorption was originally patented in 1859 and has since been widely used in refrigeration systems. One of the earliest pilot projects for GAHPs was run in Germany during the mid-1980s for residential applications.

More recently, California’s Energy Commission Natural Gas Research & Development Program also funded the demonstration and assessment of GAHP technologies between 2017 and 2021. GAHP units were installed at two full-service restaurants and residential sites in Los Angeles. This pilot confirmed the possibility of quick paybacks in less complicated retrofits, with gas savings up to 45 per cent.

In Canada, Toronto Metropolitan University (formerly Ryerson) has run a technology review project in the last five years. The university collaborated with The Atmospheric Fund, Toronto and Region Conservation Authority (TRCA) and Enbridge Gas. The project tested Robur’s

GAHP units being commissioned at a facility for a FortisBC pilot project in Vancouver, BC.

Did you know?

Renewable Natural Gas is produced in a different manner than conventional natural gas. It is derived from biogas, which is produced from decomposing organic waste from landfills, agricultural waste, and wastewater from treatment facilities. The biogas is captured and cleaned to create carbon-neutral RNG (also called biomethane).

36 kW GAHP units across different water and space heating configurations in cold ambient conditions and confirmed its viability in decarbonizing the conventional boiler-based systems. This project identified the best applications and locations for GAHP technology, which can be deployed in engineering design.

The study concluded that domestic hot water (DHW) applications have strong potential for notable operational cost and carbon reductions. Annual cost savings of $1,500 for residential DHW preheating were estimated.

In 2019, FortisBC started a pilot program to test Robur’s 36 kW GAHP-A units in MURBs and school facilities under live conditions in the Lower Mainland (Climate Zone 4). These projects helped FortisBC verify the manufacturer’s published performance data for GAHP units and apply it at a system level. The project has since expanded to test the GAHP application with different end-uses.

Other groups that have either successfully tested the technology or are contemplating the launch of GAHP pilots include National Energy Action (NEA) UK, Northwest Energy Efficiency Alliance (NEEA), Gas Technology Institute (GTI Energy), Energy Solutions Center, Southern California Gas and SEMCO Energy Gas in Michigan.

Photo:

Designed for fresh air.

AAON Delta Class is breathing life into our indoor environments.

AAON is always innovating. Learn more about our dedicated outdoor air systems (DOAS).

AAON

GAS ABSORPTION

Working principle of the technology

GAHPs operate on a heat-activated absorption cycle. The cycle relies on the absorption of refrigerant (ammonia) by a transport medium (water). GAHPs need three energy inputs to run the absorption cycle and transfer heat from the heat source to the heat sink.

1. Renewable heat source in the environment: All heat pumps require a source of heat to operate. This heat can be extracted from the surrounding air, a water source, or the ground.

2. Combustion heat: The generator carries the ammonia-water solution that is separated into water and ammonia by introducing thermal energy. Today, this energy is mainly provided through the combustion of natural gas or renewable and low-carbon gases, such as RNG.

A simplified schematic of a GAHP operating in heating mode

A complete heat pump solution for residential applications

The Vitocal 100-AW air to water heat pump is designed for heating, cooling and domestic hot water. Featuring an outdoor unit, an indoor unit and a steel buffer tank (20 gal). The optional domestic indirect tanks come in three sizes (53, 66 or 79 gal), and the buffer tank can be physically mounted on top of the domestic tank to save space.

Viessmann

According to some manufacturers, the units can also operate on a blend of natural gas with 20 per cent hydrogen. In addition to the available heat in the environment, GAHPs can capture supplemental heat from the combustion process. This improves the overall system efficiency and makes GAHPs operation effective in colder climates.

3. Electricity: The absorption cycle does not require work input of compressors like most vapour-compression refrigeration cycles. Instead of a compressor, the refrigerant is cycled between the evaporator and condenser using an absorber, a pump, and a generator. Since liquid is pumped instead of vapour, the electrical work required for pumping in the absorption systems is minimal. A condenser fan on the external unit also consumes electricity.

Application end uses

GAHP units perform at their peak when supporting systems that require continuous heating loads. GAHPs are best suited to support any hydronic hot water heating systems that are alternatively served by conventional or condensing boilers. Preferably, closed loop hydronic systems (non-potable water) with an operating set point between 40 to 60°C (104 to 140°F) are more compatible with GAHP technology. GAHPs have also demonstrated promising results when hot water coils are connected with make-up air units.

Moreover, GAHPs have also been deployed in hybrid configurations for high temperature (> 60°C/140°F) applications where GAHP units pre-heat the water and high-efficiency boilers provide the additional heating. Some manufacturers also offer hybrid systems where GAHPs and condensing boilers are built into a single package. Another example of hybrid configuration involves connecting GAHP units with solar water heaters.

Some GAHP manufacturers also offer units with dual capability of heating and cooling. In those cases, chilled water can also be used for space cooling applications.

Adapted with permission from the Gas Absorption Heat Pump Best Practices Guide developed by CLEAResult Canada Inc. in collaboration with Building Energy Solutions Inc. for FortisBC.

JOBSITE JARGON

Match the terminology you hear in the field to the correct definition or function by January 3, 2025 and enter for your chance to win a Yeti cooler from NIBCO. This contest is open to Mechanical Business subscribers in Canada. Send your answers to kerry.turner@mechanicalbusiness.com or enter online at mechanicalbusiness.com.

JOBSITE JARGON

EXAMPLE: 5) Seasonal performance J) Depends on the climate in which the heat pump is working Answer 5,J

A) Configuration that keeps all components within a single outdoor enclosure

B) Equals mean daily temperature minus 65°F

C) Fan and motor are under the top panel

D) Enable the quick connection of pressure and temperature measuring instruments

E) Uses an outside unit to extract low-temperature heat from the outside air. The heat generated is delivered to a hydronic distribution system in the building

F) Used to check the glycol percentage and freeze protection in a system

G) COP for a heat pump operating in cooling mode

H) Programmed with four data points

I) Decreases as water temperature leaving AWHP’s condenser increases

J) Depends on the climate in which the heat pump is working

K) Heat pumps use a closed system of underground pipes filled with

TIGHT SPACES. QUIET PLACES.

ENDLESS POSSIBILITIES.

KEY FEATURES AT A GLANCE

• Optimal Performance, compact design

• WIFI enabled, Cold Climate Energy Star certified

• Boasting efficiency up to 9.5 HSPF2, 19SEER2 & beyond

• Premium performance even at -15C, with Vantix Gas Furnace back-up performance listings.

• Eligible for the NRCan Greener Home Interest Free loan

• Sound as low as 50dBA

• 10 Year Conditional Parts Warranty (Registration Required)

UNLIKE BLENDS, R-32 IS A PURE, SINGLE-COMPONENT REFRIGERANT, MAKING IT EASY TO REUSE, RECYCLE, RECLAIM, AND SERVICE!

Daikin