17 minute read

HIGH PERFORMANCE HVAC Gord Cooke Tune up your approach to match the heightened expectations and needs of clients

SO, YOU WANT TO BE IN THE IEQ BUSINESS?

There is so much going on to raise the public’s awareness of the challenges and opportunities in providing safer, healthier, more comfortable indoor environments. CBC’s Marketplace recently aired an episode where they measured the air quality in several homes and evaluated five commonly available portable air “purifying” devices. There have also been multiple stories in national newspapers and on national network news broadcasts on the efficacy of air cleaning devices in schools and workplaces. Even my community newspaper ran a story about air cleaners being used in local schools.

With consumer awareness and angst regarding indoor air quality (IAQ) at all-time highs, let’s explore the opportunities for HVAC professionals.

There are at least four business opportunities in helping your residential and commercial clients breathe the healthiest possible air: testing and diagnostic services; remediation and restoration; installation of HVAC products targeting indoor environmental quality (IEQ); and maintenance programs specific to air quality control.

While most HVAC professionals are undoubtedly offering elements of each of these opportunities now, I would advocate tuning up your approach to match the heightened expectations and needs of clients. Those expectations include relevant credentials or, at the very least, demonstration of training and experience in the specific field of indoor environmental quality IEQ.

In workplace environments, the expertise and services of a Certified Industrial Hygienist (CIH) are usually expected to create remediation plans for hazards such as mould, asbestos, lead and soil gases (radon). Creating a protocol for reducing viral infection spread in a workplace may also best be handled by a CIH. A CIH designation involves a college or university level education in a science or engineering related field, in addition to a field mentoring experience.

There are other recognized designations such as those offered by The Institute of Inspection, Cleaning, Restoration Certification (IICRC), or the Building Biology Institute. While some readers may wish to pursue these designations, in the short term I would advocate developing a relationship with accredited professionals who you can refer clients to as needed. Use their knowledge to guide you in finding the most effective resolutions to indoor air challenges.

In most residential applications and even in many general commercial applications, such as offices or small retail stores, HVAC contractors with commonly available industry training and appropriate tools can provide a thorough and comprehensive diagnosis and air quality remediation or enhancement plan to clients. Start with information from Canada M Mortgage and Housing Corporation and the Environmental Protection Agency (U.S.). Information from these sources represents the findings and opinions of consensus documents and independent research.

For training, a great start would be the two-day Indoor Air Quality course offered by the Heating, Refrigeration and Air Conditioning Institute (HRAI) through its SkillTech Academy. The course covers a range of building issues that can lead to air quality problems. It

edly es

enh

Gord Cooke Gord is a professional engineer who has spent 20 years helping builders and HVAC contractors implement innovative technologies into high-performance homes. He has particular expertise in IAQ and airflow management in houses, and can be contacted at gordc@buildingknowledge.ca.

discusses tools, techniques and protocols for investigating IAQ issues and identifies the range of solutions available. Contractors who take this workshop will immediately want to get some field experience to apply and reinforce the information they have learned.

For remediation or cleanup of specific events such as floods, fire, mould or other insurable events, you would be advised to align yourself with a “disaster or restoration company” or take the training yourself through organizations such as the Institute of Inspection, Cleaning, Restoration Certification (IICRC) or the Center for Disaster Recovery. They have day-long modules for specific restoration projects and they all include provisions for mechanical systems assessments and remediation you should be aware of.

When it comes to providing equipment and maintenance solutions, it is important to broaden and deepen your offerings to be true to the needs of clients’ environmental quality. Seldom will one piece of equipment be sufficient to make claims that air quality concerns have been addressed. Be ready to confidently offer proper temperature and humidity control. That is, humidification and whole house dehumidification equipment to maintain the optimal 40 per cent to 60 per cent RH level year-round. Then, offer appropriate ventilation options that include source control devices such as bathroom fans, kitchen range hoods and garage exhaust fans, as well as whole building ventilation systems.

Next, would be appropriate filter systems, to include both filtration of central air handling systems, as well as in-room filtration systems for vulnerable occupants. Offering appropriate filtration includes the responsibility to measure and assess pressure drops and make fan or duct work adjustments accordingly so that you can offer MERV 8 to 13 filters in air handling systems.

Effective maintenance requires verification of cleanliness of coil and drain pans and adjustments to allow for thorough inspection. Adjustment of dampers and fans to ensure appropriate pressure differences across different sections of a building are another item to add to your seasonal or annual duties. Finally, some specialized situations may benefit from application of deactivation strategies such as ultraviolet light. Verify the efficacy and safety of such technologies for each application using the design services offered by the manufacturer, as there are few industry wide standards for their use.

If you are offering both diagnostic testing and equipment solutions based on those tests, clients will expect a “before and after” test to validate the performance of your solution. This can be problematic in that there are so many possible daily variations and site conditions that will affect results. Be careful to set proper expectations. For example, a particle counter can be very effective in showing the percentage reduction in particles across the new filter you installed. However, you may not be able to effectively demonstrate a reduction in particle counts in their office or bedroom since ambient levels of particles are highly dependent on occupant activities and outdoor air concentrations that can change by an order of magnitude in a matter of hours. Therefore, tell your clients how you will be demonstrating success before you install the equipment.

Indoor environmental quality will be top of mind for at least the next three to four years as both homeowners and business owners re-evaluate the best opportunity for safe spaces for work, schooling, relaxation and rest. All professional HVAC contractors should enhance their level of knowledge and the services and products they offer. It provides great opportunities, but more importantly, provides clients with effective and efficient solutions.

ng and equipment expect a “before e of your solution. so many possible ill affect results. Be ample, a particle the percentage r you installed. ely demonstrate a or bedroom since endent on occupant hat can change by rs. Therefore, tell ng success before you op of mind for at least eowners and business

Photo courtesy Cameron Instruments

EQUIPMENT AND SERVICE OFFERING CHECKLIST

• Air handlers with ECM fan motors • Bathroom fans, range hoods • ERVs – ECM motors • Humidity control – humidifiers, dehumidifiers • Make-up air • Filtration – MERV 8 to 13, HEPA • Sealed duct work • IAQ monitors and controls • Commissioning • Planned maintenance to include coil and drain pan inspection, pressure control • Radon testing and control

TOOLS YOU WILL NEED

From my experience, if you are offering diagnostic services, your client’s expectations will lead you to needing at least the following testing equipment or capabilities: • Thermometer (both a probe type for inserting into ducts and a surface sensor) • Hygrometer for humidity measurement and material moisture meter

• Gas leak detection

• Carbon monoxide measurement

• Carbon dioxide (ideally a device you could leave for logging over time) • Volatile Organic Compound (VOC) meter/logger • Particle counter/logger to measure particulate down to at least 2.5 Microns

• Manometer to measure pressures in cavities and spaces • Air velocity and volume measurement devices to confirm ventilation rates

• Radon monitors (or access to a facility that tests for radon) • Access to a material testing laboratory to send samples of dust, mould, etc. for analysis Be sure you have appropriate calibration certificates for each piece of equipment. An investment of approximately $7,000 to $8,000 can be expected, with the particle counter being the single largest investment. These industry tools are a great complement to the primary value your eyes and nose, and your experience bring to clients. Use the industry tools to confirm and demonstrate your diagnosis to your client.

Carbon dio logging ov • Volatile Or • Particle co to at least • Manomete spaces • Air velocity confirm ve • Radon mo radon) • Access to samples o Be sure you for each pie approximate the particle c

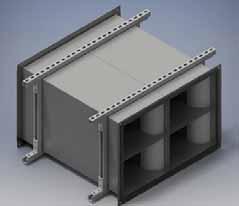

Installation of acoustic plenum silencers at Toronto Western Hospital called for design accuracy and pre-fabrication time.

Matt Downey is president of Parklane in Oakville, ON. The company designs, manufactures and installs custom noise-mitigation systems for commercial and industrial applications.

MITIGATION OPTIONS

Some of the most common noise abatement solutions include:

an operational change, such as running equipment at a lower capacity (often by installing a variable frequency drive to operate equipment on demand rather than at a constant output) to reduce noise emissions relocating equipment to avoid impacting sensitive receptors, such as neighbouring structures replacing or decommissioning a piece of equipment and replacing it with a quieter unit installing OEM supplied solutions such as insulated casings, compressor blankets or low-noise fan blades to reduce operating sound levels on noisy componentry installing customized noise attenuation components around the noise source, such as silencers, noise barriers or acoustic louvres

A STRATEGIC APPROACH TO MITIGATING NOISE ISSUES IN HVAC SYSTEMS

When noise from mechanical equipment becomes a problem for facility owners or managers, they often turn to mechanical service partners for assistance. Whether it’s a noisy chiller on the roof or a recent equipment change that exceeds regulatory noise ordinance levels, mechanical service firms are often the first line of defence.

As a trusted partner, you’ll go above and beyond to support your clients when they face a mechanical challenge. But when it comes to noise abatement, you may lack the specialized acoustic expertise to handle the task. Cue the inevitable project uncertainty, stress and frustration.

Mechanical noise issues are typically complex, challenging to mitigate and nearly always involve significant bottom-line risk. Rudimentary solutions often focus on the physical components that can be used to address the issue such as sound barriers or silencers, but they frequently overlook the potential consequences. Installing and integrating those solutions as part of a complete building system can give rise to a series of unintended, long-term issues. At times, simply informing the client an acoustic problem will need to be immediately addressed is difficult enough, let alone making it understood that inaction could result in far more serious consequences: fines, a legal challenge or even a facility shutdown imposed by a regulatory agency in extreme cases. That is why it’s essential to tackle a noise problem strategically by developing a comprehensive plan and executing it.

So, your client has a noise problem. Now what?

Gather as much information about the problem as possible by asking basic questions: Is the noisy equipment operating at full capacity? Has it been serviced lately? Are there any external factors that could be impacting its performance, such as impeded airflow or malfunctioning parts? In some cases, a simple mechanical fix will address the issue.

Once those potential problem sources have been ruled out, be prepared to engage a reputable acoustical consultant. The consultant will conduct an analysis using in-field sound monitoring and/or

Understanding the source of a noise challenge and developing process of navigating often complex logistical site constraints important to note almost all noise mitigation solutions require some form of on-site construction during the installation installation of acoustic plenum silencers across each of the Though the project posed challenging acoustic requirements design accuracy to avoid interference and time-consuming

computer-aided acoustical modelling, and will use that data to assess mechanical noise levels against regulatory ordinances to determine the extent of the problem.

The consultant will produce an acoustic assessment report identifying the source of the noise and its potential impact on surrounding receptors, including reduction requirements for the noise source based on eight-octave band frequency strata. This information is critical in assuring the mitigation strategy selected is designed to quantitatively fix the problem.

At this point your client may ask a very reasonable question: How much will this problem cost to fix? The answer depends on several factors, two of the most important being the structure of the existing facility and equipment specifications.

If noise control solutions such as rooftop sound barriers or silencers are required, the building may need to be reinforced to support the added weight. Gaining access to the facility’s original structural drawings will be crucial to understanding its structural constraints and to better understand the full range of mitigation options. In the absence of drawings, it may be necessary to hire an engineering firm to evaluate the building’s structural integrity and capacity.

It’s important to determine the operating capacity and design conditions for the equipment. Reference technical data sheets to understand the component’s key performance parameters. Everything from system air flow and pressure drop allowances, to clearance requirements and maintenance accessibility considerations is pertinent. With this information in hand, you can better advise the facility owner/manager on next steps.

INTRODUCING THE ALL NEW MULTI-POSITION AIR HANDLER

Putting the spotlight on Performance.

BTU/h WIFI compatible

www.airsolutions.ca

The takeaway: Facility owners/managers need noise abatement can be a challenging and methodical process. Solution design by installation constraints.

Duct and chiller silencers are among the noise attenuation components that can be installed around the noise source. WHAT IS AN ACOUSTIC ASSESSMENT?

An acoustic assessment measures sound emissions from facilities or mechanical components, and determines whether the acoustic output falls within acceptable limits under local regulatory noise guidelines. Acoustical consultants will measure noise emanating from each piece of equipment, as well as background levels surrounding the facility. From there, the consultant will build a model that predicts the acoustic impact on sensitive receptors neighbouring the facility and create a final assessment summarizing three key details: an inventory of noise sources on-site, identification of sources deemed out of compliance, and the amount of sound reduction required at each problem source to bring the facility into compliance.

Design Enhancement

16% % %166% S SLIMMER!LIMMER SLIMMER! 16% 16% SLIMMER! SLIMMER!

SLIMMER

C-RHEX® 1/4 in. and 5/16 in.

CLEANABLE, REVERSIBLE, MAGNETIC HEX DRIVERS

U.S. Patent No. 10,328,554

MSHC 2 in. MSHMLC 4 in.

MSHLC HLC 2-5/8 in. /8 in. MSHXLC MSHX XLC 6 in. 6 in.

New Slimmer Design Enhancement reduces the 1/4 in. size by 16%, to gain easier access in tight spaces for ultimate flexibility and productivity!

Malco Products, SBC • Annandale, MN. U.S.A. • www.malcotools.com • ©2021

HVAC/R Products

Humidity and temperature probe

Vaisala’s Humicap humidity and temperature probe HMP1 provides performance measurements in critical production, storage centres and data centre applications or other high demand facilities. The probe is compatible with any Vaisala Indigo series transmitter and forms a single wall-mounted unit. www. vaisala.com

Dual-mode air scrubber

The Carrier OptiClean dual-mode air scrubber for schools, dental offices, office spaces and clinics, uses 99.97 per cent efficient long-life (~40,000 hour) HEPA filters to remove particles as small as 0.3 microns. The negative air machine mode converts normal hospital rooms into negative-pressure airborne infectious isolation rooms to meet ASHRAE Standard 170 for Ventilation of Health Care Facilities. www. carrier.ca

Series differential commercial pressure switch

Winters WPS Series is a low-pressure differential switch for monitoring and controlling air and non-aggressive gases. Designed to monitor pressure, vacuum and differential pressure, it is suited for HVAC applications and can be integrated into BAS systems. www. winters.com

The clear choice is Neutra-Safe® for Condensate Neutralizers, Neutralizing Condensate Pumps and Model Specific Recharge Kits

Neutra-Safe’s innovative product designs set us apart from the competition. Visit www.neutrasafe.com for more information. Find a rep near you: • Servicing BC and Alberta:

Altatech Agencies Ltd. www.altatech.ca • Servicing Saskatchewan and Manitoba:

Westcan Mechanical Sales www.westcansales.ca • Servicing Ontario:

Jess-Don Dunford Ltd. www.jessdondunford.ca Neutrasafe Corporation • Servicing The Maritimes: 421 Page Street, Suite 1 Stoughton, MA 02072 USA

Thomas Industrial Sales Ltd. www.thomasindustrial.ca www.neutrasafe.com

HVAC/R Products

Direct drive mixed flow fans

S&P Canada’s SMXD direct drive mixed flow fans are rated to 17,800 CFM. Available in six sizes, the SMXD has an epoxy coated steel housing. It is designed for indoor or outdoor use and is suited for ventilating commercial or institutional buildings. Units are compatible with Ecowatt-Drive VFDs and are AMCA air and sound licensed. www. solerpalaucanada.com Portable HEPA air cleaning system

The KOCH Filter ENVIRCO IsoClean CM portable air cleaning system from Johnson Controls comes equipped with a MERV-8 and a 99.97 per cent high-capacity HEPA filter. A variable speed centrifugal blower with adjustable fan speeds controls the number of air changes per hour to support a variety of room sizes from 400 to 1,700 CFM. www. johnsoncontrols.com

Danfoss’ Smart Refrigeration Solution has been added to its Alsense IoT digital service portfolio for managing food retail operations. It enables managers to benchmark and prioritize efforts across stores to save time and maintenance costs. Technicians can be provided with a prioritized action plan to assess system prioritized action plan to assess s performance and concerns prior rformance and concern to arrival. arrival.

danfoss.com nfossco

HE-Z Series Zoning Fan Coil

1, 2, 3 or 4 Small Diameter Sm Flexible Duct F

3-Stage HEPS In-Duct

CUBE Series

Fan Coils

HE-P Series Fan Coils

HVAC/R Products

Supervisory control platform

Emerson’s Lumity supervisory control platform for refrigeration and facility management enables top-down visibility and control of all systems within a network including refrigeration, HVAC and lighting. It provides users with two management control device options: the E3 with integrated touchscreen display, and SS with optimal mounted display. www. emerson.com

Duct insulation

Reflectix duct insulation consists of two layers of highly reflective film (96 per cent reflectivity) bonded to two tough layers of polyethylene. Two inner layers of insulating bubbles resist conductive heat flow while a centre layer of polyethylene adds strength. A tape running the length of gth of the roll identifies the manufacturer and ASTM d ASTM testing. www. reflectixinc.com

Refrigeration motor

The Packard EC Max RM refrigerator Th motor from Ontor is available in four to mo 25 watts and features IP67 protection 25 against dust and water. The back features ag five drilled and tapped holes for mounting fiv on various OEM applications. Four on threaded holes on the front are designed thr to adapt to top-mount applications. to www. ww packardonline.com ontor.com pa

Combustion analyzer

The Testo 300 combustion analyzer, available from Ontor, simplifies measurement of flue gas, draft, pressure, ambient CLO and differential temperature. Features include intuitive measurement menus and fast-response touch display, O2 and CO sensor up to 4,000 ppm, 5 in.-HD display, and documentation creation and email capabilities. www. testo.com ontor.com

THE CHOICE IS CLEAR

Rising prices and unstable supply. That’s the future of R-22. But it doesn’t have to be your future.

RS-70 is readily available, stably sourced and has the lowest GWP of all R-22 drop-ins. It is suitable for low, medium and high temperature applications in refrigeration and AC systems, and requires no oil change or system modifications.

Talk to us today. 1-866-999-COLD

www.rscool.com Refrigerant Services Inc. nc