MARITIMEJOURNAL

COMMERCIAL MARINE BUSINESS

VESSEL BUILDING & LAUNCHES

Future fuels

Tugs, Towing & Salvage

Industry News | Marine Civils | Offshore Renewables

Issue No 428 APRIL/MAY 2024

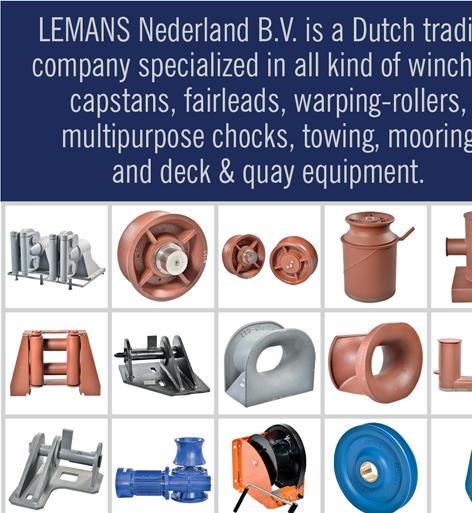

UZMAR was founded in 1984 by senior Pilot Captain Altay Altuğ (1925-2021) as the first privately established pilotage and towage company in Turkey to serve at various private ports and harbors on the Aegean Sea, Turkey.

Today, UZMAR serves public safety at four different ports in Turkey; pilotage at Nemrut Port, Izmir, pilotage and towage at Akcansa Port, Canakkale, towage at AmbarliPort Istanbul, and Iskenderun Port, Hatay.

In 1996 UZMAR started to build tugboats and workboats for its own fleet requirements and later for international markets using compact tugboats and offshore vessel designs. Through the achievement of building numerous tugs and workboats, in 2005,

UZMAR established a modern shipbuilding facility at Kocaeli Free Zone, near Istanbul Turkey.

UZMAR Shipyard is invested in new technologies as autonomous vessels, methanol-powered tugboats, and electric-powered tugboats to extend its product line with highly competitive in-house design and to conduct its know-how to the future.

Having built more than 200 vessels and delivered them to more than 25 countries on 6 continents, today, UZMAR Shipyard has grown into a world-class pioneer shipbuilder. The Shipyard has become the first choice of the leading tug owner and operator companies of the world for their significant new-built projects.

8 For further enquiries

https://uzmar.com/

For the latest news and analysis go to www.maritimejournal.com/news APRIL/MAY 2024 | 3 COVER SHOT www.maritimejournal.com CONTENTS NEWS FEATURES FEATURES 44 US offshore wind More projects are being given the green light 45 Port building £750 million of bids invited for UK-wide programme Industry News Marine Civils Offshore Renewables MARITIMEJOURNAL COMMERCIAL MARINE BUSINESS Issue No 428 APRIL/MAY 2024 VESSEL BUILDING & LAUNCHES Tugs, Towing & Salvage Future fuels 46 New SWATH design Adhoc unveils a new crew transfer vessel 48 3rd Dutch renewal Royal Netherlands Institute for Sea Research names research vessel 12 Tunnel to France? Subsea Channel Islands link under discussiion 16 London 'Super Sewer' complete Works end on Victorian sewer upgrade 18 Dali salvage Baltimore bridge collapse aftermath 24 Alarm & optimism at WindEurope Delegates voice fears over Asian competition 30 All-electric tugs SAAM Towage brings in two 100% E tugs 44 Biomethane workboat Estonia's chooses its first alternative fuel 50 First E-ROV sold to Jan De Nul SMD makes its first sale to ewngineering giant 62 Oil & chemical spills up in 2023 An ISU report shows leaks were worse

6 62 18

16

BRIEFS

Salvors on call in early 2024

Europe’s marine salvors have reported a busy start to 2024, dealing with ship groundings, fires and engine breakdowns along with minimising pollution from plastic pellets washing ashore in Spain. Greek salvage contractor Tsavliris has been on the frontline, with engine room fires and failures to deal with, along with recorded incidents from Multraship Salvage and URS Nederland, Smit Salvage, Ardentia Marine and Five Oceans Salvage.

8 Full report here

Hefring partners SAFE Boats

A formal partnership has been struck between Hefring Marine and SAFE Boats International with a focus on crew welfare and vessel lifecycle management, the new partners say. Hefring is bringing its IMAS (Intelligent Marine Assistance System) to the table, which will be rolled out to SAFE Boats customers. The SAFE 35 Interceptor is equipped with the Hefring IMAS to ensure optimized safety, fuel efficiency, and vessel lifecycle management.

Vard appoints new CEO

Former Ulstein CEO Cathrine Marti has been appointed CEO of shipbuilder Vard Group as ’part of a long-term strategy to strengthen Vard as the leading world player in offshore and specialised vessels and a key business pillar’. Mathri is believed to have a strong link to Norwegian business and solid international shipbuilding experience ‘to ensure continuity of performance and at the same time provide a boost for further growth’.

NY OFFSHORE WIND FARM GIVEN GREEN LIGHT

Potentially the largest offshore wind farm in the US has been given the go-ahead by the BOEM (Bureau of Ocean Energy Management), clearing one of the obstacles to development.

Developers Ørsted and Eversource also said they had taken a Final Investment Decision on the Sunrise Wind project, which is designed to deliver 924MW to the state of New York.

They will now begin onshore construction activities, they said, as agreements to finalise the project with NYSERDA (New York State Energy Research and Development Authority) are negotiated.

“Offshore wind continues to soar in New York,” said US Senator Charles E. Schumer. “Today’s announcement that Sunrise Wind has flown through another critical milestone, combined with the recent announcement that South Fork Wind is officially online,

shows that the sky is the limit for offshore wind.

“Sunrise Wind -- built by the men and women in union labour -- will change the energy landscape in New York. Supporting projects like Sunrise is exactly why I fought so hard to pass the Inflation Reduction Act last Congress, and I remain committed to working closely with New York and the Biden Administration to uplift offshore wind.”

The wind farm will be situated

30 miles east of Montauk, New York State, and Is projected as having the capacity to power 900,000 homes.

“These milestones achieved by Ørsted and Eversource on the heels of South Fork Wind entering full operation demonstrate New York’s leadership in building the US offshore wind industry with Sunrise Wind and future projects on their way to generating clean wind energy to power the grid,” said Doreen M. Harris, president and CEO at NYSERDA.

Ørsted has agreed to buy Eversource’s 50% ownership share in Sunrise Wind, becoming the project’s sole owner, subject to signing of an OREC contract with NYSERDA, finalization of acquisition agreements, COP approval, and other relevant regulatory approvals.

Eversource will remain contracted to lead the project’s onshore construction.

SOV LAUNCHED FOR FRENCH OSW FARM

Norway-based Edda Wind has taken delivery of a new service operation vessel (SOV) to operate at the St Brieuc offshore wind farm being operated by Siemens Gamesa Renewable Energy.

The C416. which will be named Edda Goelo, has been prepared for operations using hydrogen as energy carrier in a concept adopted by Edda Wind called its ’Liquid Organic Hydrogen Carrier’ concept.

She is a Salt 0358 design and the sister vessel of Edda Brint, which was delivered from Astilleros Balenciaga shipyard in Spain in October 2022. Sixty persons can be accommodated in separate cabins.

“C416 represents the future of offshore wind service vessels, being the second SOV worldwide prepared for a hydrogen-based energy system capable of up to four weeks of endurance”, says Kenneth Walland, CEO of Edda

Wind. “This milestone positions the vessel to support the construction and commissioning of wind farms without generating carbon emissions, aligning with our commitment to sustainability.”

In addition to Edda Goelo and seven vessels (all CSOVs) currently under construction, Edda Wind owns and operates the SOVs Edda Mistral and Edda Brint and three CSOVs, Edda Breeze, Edda Boreas and Edda Nordri.

GO-AHEAD FOR THE LARGEST OFFSHORE WIND PROJECT IN THE US

The U.S. Environmental Protection Agency (EPA) has issued the final air quality permit for Dominion Energy’s 2.6 GW Coastal Virginia Offshore Wind (CVOW) project located off the coast of Virginia Beach, USA.

Issued on April 9 following a 30-day public comment period, the permit authorises the construction and operation of the project, which will feature up to 176 wind turbines located 26 to 38 nautical miles from the coast.

“To have the largest offshore

wind project right here in the Mid-Atlantic is both a privilege and a responsibility and we take our role in enabling clean energy initiatives very seriously,” said Adam Ortiz, EPA Mid-Atlantic Regional Administrator.

“This project will generate enough renewable energy to power nearly five times as many homes as there are in Richmond – all done with the environment and communities front of mind."

The permit is the 11th and final federal permit required to begin

offshore construction, which is set to start in May 2024 with the installation of monopiles for the project, according to Dominion Energy.

This permit includes requirements such as the prevention of significant deterioration (PSD) permitting program and applicable Virginia Department of Environmental Quality requirements that regulate air pollutants from the construction and operation of the windfarm, including those from the vessels used to construct and support the project.

NEWS

4 | APRIL/MAY 2024 For the latest news and analysis go to www.maritimejournal.com

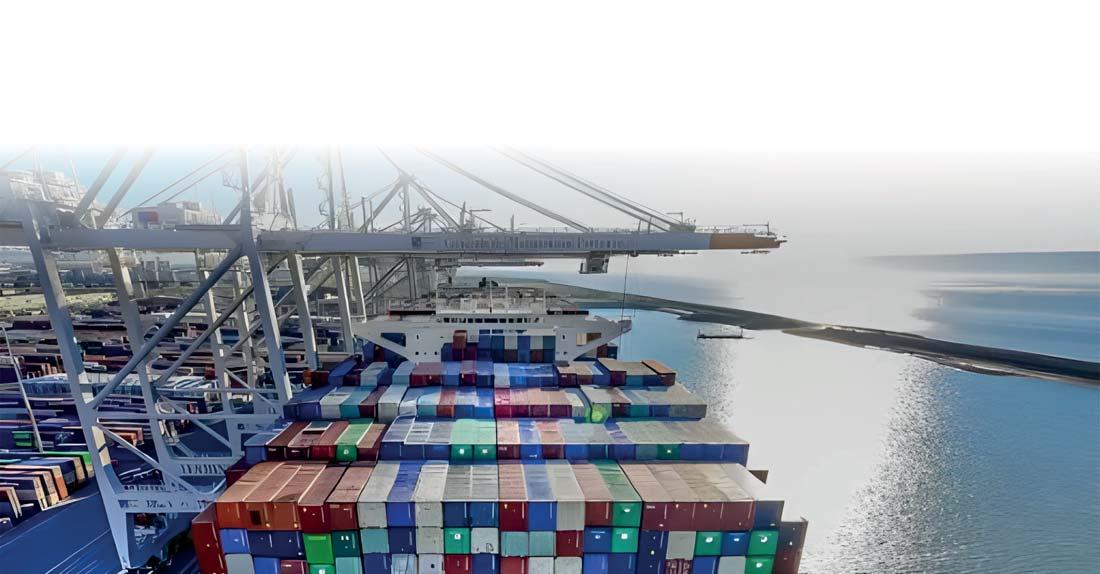

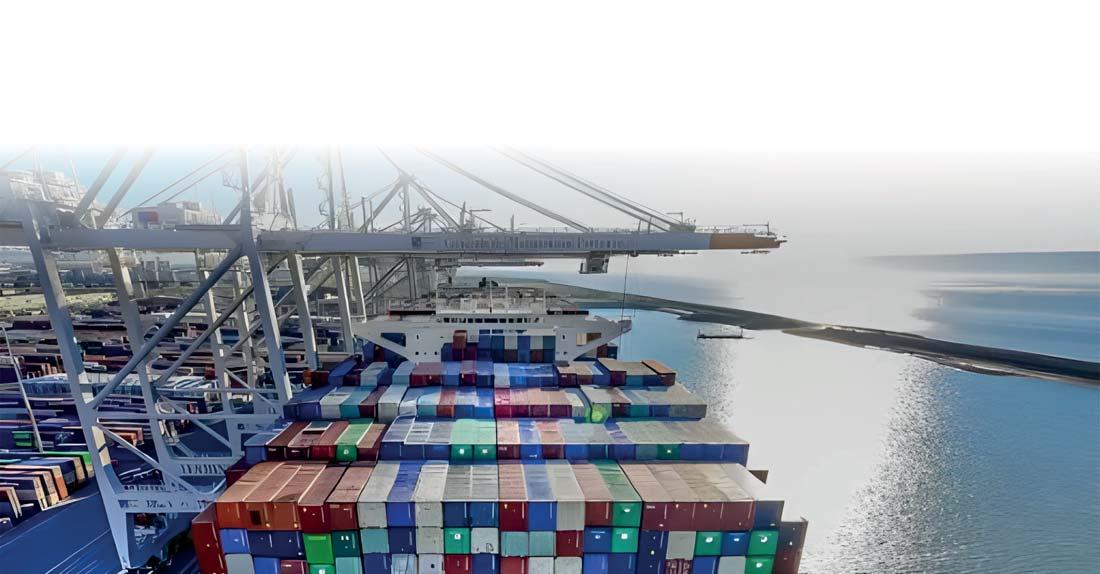

One of the UK’s largest port operators is inviting bids for a multi-million pound long-term programme of building works across the UK and Ireland.

One of the UK’s largest port operators is inviting bids for a multi-million pound long-term programme of building works across the UK and Ireland.

The Peel Ports programme has been split into two frameworks – one for general construction, the other for marine construction – and together they will be worth £750 million (€874 million) over eight years.

The first framework’s scope covers general construction works including drainage; the construction and maintenance of new and existing roads and car parks; earthworks and ground remediation; foundations and piling; the construction, maintenance and refurbishment of new and existing warehouses; paving, surfacing and concrete works; rail construction; bridge

BIDS INVITED FOR £750m UK PORTS PROGRAMME

construction and refurbishment; and demolition. The second framework covers specialist marine construction works including piling; asset renewal and refurbishment; berthing furniture and bollards; quay walls; Lock and Sluice gate maintenance and replacement; and RoRo.

“Our ports form a network of busy logistics hubs servicing

local, national and global supply chains, and this move represents a huge step in our efforts to future proof that network, so we can keep responding and adapting to our port users’ needs in an agile way,” said Lewis McIntyre, managing directorPort Services at Peel Ports Group.

AGREEMENT SIGNED TO BUILD A -CLASS WTIV

Two of the best-known firms in offshore installation have signed a long-term agreement to build a much-needed new vessel.

The agreement between Ørsted and Cadeler means that Ørsted will have access to a new-build A-Class vessel from early 2027 to the end of 2030, it says.

The A-Class can transport up to six XXL monopile foundations at one time, or up to seven complete 15MW turbine sets per load.

It is even capable of

transporting the next size coming in turbines – a 20MW giant turbine, five of which could be transported at a time.

“We have ambitiously invested and poured our unique knowhow into our new-build wind turbine installation vessels to create security in our part of the value chain,” said Cadeler CEO Mikkel Gleerup.

“And we’re ready to handle the largest and most complex next-generation offshore wind

installation projects. Our ambition is to help our partners install and realize the offshore wind farms needed for the world’s energy transition.”

“Securing long-term capacity with strategic suppliers is key for Ørsted to build collaboration and together manage risks and execution of our offshore wind construction program towards 2030 and beyond,” said Patrick Harnett, chief operating officer at Ørsted.

LATVIA EMBARKS ON OFFSHORE WIND VOYAGE

The Baltic nation of Latvia has signed a contract with Dutch engineering giant Van Oord to build one of the first offshore wind farms in the country.

The E-Pusher is a modular and scalable. Over the next two years, Van Oord will carry out works including developing a business plan and helping with the technical design of the site.

Construction of the offshore wind support base will begin in the Outer Harbour of the Port of Liepaja in 2026, with plans to get it operating for the middle of 2027.

“The new terminal will address the lack of the port infrastructure

capacity needed for the construction of wind farms in the Baltic Sea,” said a statement from the port. “Moreover, it is expected that the developed site will be used for handling other oversized cargoes as well as for industrial manufacturing purposes. The

55-hectare area will be created by reclaiming the dry land areas, thus establishing a new multifunctional cargo-handling infrastructure and also giving the opportunity to place new production and/or assembly facilities.”

The Outer Harbour, says the statement, is surrounded by breakwaters and equipped with three port gates, thus offering vast opportunities for the development of offshore wind and other energy projects.

The Baltic Sea is home to a growing number of offshore wind farms, but this is the first one under the flag of Latvia.

BRIEFS

Latvia kicks

off OSW

The Baltic nation of Latvia has signed up marine engineering giant Van Oord to start construction on its first offshore wind farm in the Baltic Sea. An offshore wind hub will be created at the Port of Liepaja, where 55 hectares at the Outer Harbour, which is surrounded by breakwaters, will be reclaimed as dry land to handle cargo and accommodate new assembly or production facilities.

MHO-Co unveils

E-CTVs

CTV designer, owner and operator MHO-Co has unveiled two electric CTVs that do not use diesel engines for propulsion.

MHO Boreas and MHO Balder have fully integrated designs that combine Danfoss Drives with IPS drivelines by Volvo Penta, fed by a battery bank for full electric mode. Eight Volvo Penta D8 variable-speed gensets are also included to increase the vessel range.

Claus Larsen, with MHO-Co, said the electric drivelines would allow a future-proof design to be created and the possibility of using future fuels.

All-Energy

Glasgow 2024

Glasgow’s SEC will host the exhibition and conference on May 15-16, this year co-locating it with ‘DCarbonise’ to encompass a range of topics from offshore wind and renewable energy to building cities and transport networks in a low-carbon way. More than 10,000 visitors and exhibitors from all over Europe are expected to attend, as well as Scottish first minister Humza Yousaf, organisers said.

For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 5 NEWS

8 Peel Ports’ Liverpool2

8 Port of Liepafa on the Baltic Sea, Latvia

NEW SWATH DESIGN OF CTV FROM AD HOC

A new SWATH design has been announced for a vessel order that will be built in Finland.

Ad Hoc Marine Designs (AHMD) has announced a new design of Small Waterplane Area Twin Hull (SWATH) crew transfer vessels (CTVs) for Maritime Craft Services (MCS).

Three vessels to the new design will be initially be built at Työvene yard in Finland.

The SWATH design concentrates a large proportion of its floatation volume into bulb-like hull sections deep beneath the waterline.

These torpedo-submarine shaped flotation bulbs support the weight of the vessel through narrow, hydrodynamically efficient hull struts and in the case of the AHMD design have additional motion stabilisation with zero speed heave mode controllable fins .

The vessel’s engines, fuel and other heavy equipment are contained within the upper haunch region for easy access and maintenance from the main deck, allowing the struts to only require minimal wiring and plumbing to pass through them - thus enabling them to be made very narrow and hydrodynamically efficient.

The main advantages of a SWATH hull form over a more traditional monohull or catamaran are twofold - the efficiencies derived from a low waterplane area; and decreased vertical accelerations in rough sea conditions, which allow a wider window of operation with more comfort for passengers and crew.

Reduced waterplane area

The waterplane area is the part of a vessel’s hull that would be seen if it was sliced horizontally along the waterline. It is a major contributor to wave-making drag and hence a vessel’s overall drag, as well as the vessel’s natural period of motion.

A SWATH vessel design largely reduces the waterplane area by having only the two foil-shaped, knife-like support struts intersecting the waterline. A correctly designed SWATH hull offers significant CO2 reductions over a comparable catamaran or monohull, particularly at slow speeds.

At much higher speeds, monohulls and catamarans are able to use their hull shape to minimise resistance, whereas the efficiency advantages of the SWATH hull form begin to reduce with increasing speed.

It is also the reduced waterplane area that brings the improved seakeeping of a SWATH hull.

A vessel’s volume distribution and waterplane area are what causes it to heave and pitch as it passes through waves.

Reduce the waterplane area and the designer reduces the heaving and pitching forces that waves can exert on the vessel.

Adding motion control fins to the SWATH hulls as in this design reduces these vertical accelerations even further, making for a supremely seakindly ride, at any speed and sea state.

Ad Hoc’s designs

While SWATH designs have been around for many decades, and even more on paper alone, the number of naval architects and shipyards worldwide that can routinely produce SWATHs that can deliver all the promised advantages can be counted on the fingers of one hand.

“For more niche designs such as SWATH hulls there is nowhere near as much prior art as there is for more conventional hull forms,” said John Kecsmar, naval architect at AHMD. “Ad Hoc Marine Designs has been involved in highly successful and proven SWATH designs for more than 30 years, and these range from 13m in size up to current SOV designs of 71m.

“Our back catalogue of designs spans from our first SWATH MV Patria in the late 1980s as well as the naval architecture design of the Lockheed Martin SLICE© SWATH, to our latest range of Typhoon Class of CTV SWATHs that are extending the North Sea operational window by more than three months per year.”

The vessels will carry 30 tonnes of deadweight along with 24 technicians in business-class seating with low risk of seasickness thanks to the extremely low motions of a SWATH hull form.

This new design is a larger version of the Typhoon Class of SWATHs currently operated by MCS, thereby pushing the safe operational envelope from their existing Hs(significant wave height capability) of 2.5m to 3m.

“The major advantage of the SWATH design is its superior response to high seas, allowing operation up to an extra 100 days a year over a conventional catamaran,” said Menno Kuyt, commercial director at MCS and operator of two AHMD SWATH CTVs.

The hull form also exhibits low resistance at low/loitering speeds and requires less than 50% of the power required by an equivalent size and displacement conventional vessel when operating at slow speed.

6 | APRIL/MAY 2024 For the latest news and analysis go to www.maritimejournal.com

VESSEL BUILDING & LAUNCHES

Diverse Marine’s second stock build is now under way - The Typhoon Class CTV, which is equipped with zero-emission power management and resistance-reducing technology.

The 25m Diverse Marine Typhoon Class CTV has been developed in combination with designer, builder, multiple CTV operators, windfarm developers and prime contractors to meet O&M project requirements.

Honed expertise

Extensive CFD has been carried out to develop the hull form of the vessel that incorporates an ultra-fine entry for excellent head sea performance and tower access.

During the design process, the team assessed many options to reduce hull resistance and as a result the hull form dismisses a conventional chine construction in favour or a rounded bilge type design.

This resulted in a 11% reduction in resistance at transition speed, commonly referred to as‘hump speed’ and a 7% reduction in resistance at operational speed.

A further 21% reduction in resistance at service speed is also gained through the transom foils, also reducing the running trim. Less resistance results in a reduction of fuel

DIVERSE BEGINS ITS SECOND TYPHOON CLASS CTV BUILD

burn and CO2 emissions speed for speed.

The Typhoon Class is offered as standard with Zero Emissions (Power Management) class notation, recognising its reduction in fuel consumption and CO2 emissions. Available

For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 7

as

Quad Hybrid IPS, Twin IPS Professional Hybrid, Twin CPP, Twin CPP Hybrid and in the future alternative fuels, leading to full electric to cater for different end user

and budgets. VESSEL BUILDING & LAUNCHES

Quad IPS,

requirements

Marine 8 The Typhoon Class CTV is equipped with zero-emission power management and resistance-reducing technology MARINE PLANT SPECIALISTS WESERVICE WORLDWIDE! Fastnet ShippingLtd • Vessels with International Load Line for sea bed mapping and sampling • Tugs & Pontoons • Jack up Barges • Windfarm Support Vessels • Dive Support Vessels • Multicats Tel: +353 (0)51 832946 Email: info@fastnetshipping.com www.fastnetshipping.com Fastnet Shipping Qtr Page Ad indd 1 14/02/2024 12:24

Source: Diverse

LATEST OF THREE DUTCH

VESSEL RENEWALS CHRISTENED

The Royal Netherlands Institute for Sea Research (NIOZ) has celebrated the christening of the research vessel Wim Wolff from Netherlands-based Thecla Bodewes Shipyards, marking the entry of the latest component in the institute’s three-vessel renewal programme.

The contract was awarded by the Dutch government’s NWO-I Foundation Board and a green sustainable approach to the vessel’s operation was a principle that the builder said “suited us well”. But with alternative marine fuel very much going through an evolving process and the vessel’s expected lifespan of 30 plus years, at the time of the order the builder considered Wim Wolff’s power plants could be outdated multiple times within the vessel’s life-cycle.

A diesel-electric modular power management system including a lithium-free battery pack from Dutch electric solutions provider D&A Electric was selected, including provision for the vessel to be easily adapted to new technologies and energy sources without major renovations.

The vessel will operate on HVO in combination with the battery pack, and the design includes provision for the future use of hydrogen or methanol

The vessel will operate on HVO (Hydrotreated Vegetable Oils) in combination with the battery pack, and the design includes provision for the future use of hydrogen or methanol.

NWO-I had earlier said that Wim Wolff approaches its “high green ambition level of zero-emissions” as much as was currently possible and with its area of operations including

Dutch coastal waters, Wadden Sea and Zeeland Delta, less disturbance of the marine environment will result from operating at the equilibrium of optimal propeller and engine rpm, whereby noise and vibration are “notably reduced”. It will be capable going aground for extended periods of time with batteries providing the necessary energy to run the vessel’s equipment.

The 36.9m LOA craft has a draught of just one metre and power is supplied by twin Scania main engines driving fixedpitch propellers providing a speed of 10kn. Wim Wulff will replace the research vessel Navicula, which was delivered in 1981 by Dutch shipyard Visscher & Zoon – Zwartsluis.

Fleet replacement

The realisation that the Dutch marine research community’s three-vessel fleet needed to be replaced originates from 2015. In 2021, Next Generation Shipyards in Lauwersoog was contracted to build the second replacement vessel, the 19m LOA, 20kn Adriaen Coenen to replace the “seriously outdated” 50-year-old Wadden Sea research vessel Stern. The new vessel was christened in July 2022.

Also in 2022, Spanish shipbuilder Astilleros Armon Vigo SA was contracted to build the 79.9m long, 3,481gt research vessel Anna Weber – van Bosse to replace the 35-year-old research vessel Pelagia. The new vessel is capable of operating close to the edge of sea ice in the Arctic and Antarctic and with its keel laid in December 2023 and launching scheduled for October 2024, delivery is expected at the end of 2025.

8 Wim Wolff will be capable of spending long periods aground during its research activities

8 | APRIL/MAY 2024 For the latest news and analysis go to www.maritimejournal.com

VESSEL BUILDING & LAUNCHES

Source: Thecla Bodewes

Seawork exhibiting shipbuilder Strategic Marine has delivered a StratCat 27 hybridready wind farm support vessel for the offshore wind farm Yunlin as the country tries to achieve 5.7GW by 2025.

Taiwan has set itself high goals for offshore wind, but will not hit these targets without help from the rest of the world, says global law firm Norton Rose Fulbright.

The crew and cargo transfer vessel contract was worth $3 million to Strategic Marine and will be owned and operated by Prosperous Wind Shipping, which will use it for construction, maintenance and operations from this April.

Taiwan’s offshore wind industry is in its infancy, with the first few steps just being taken but an ambitious goal set of installing 5.7GW by 2025.

The first project was installed in 2019, according to Norton Rose Fulbright, with a generating capacity of just 128MW.

The lawyers say that to hit its goal of installing more than 700 turbines by 2025, Taiwan will need to throw $20 billion at the industry.

“Taiwan’s ambitious program to promote offshore wind power as a major energy source – installing over 700 turbines in the Taiwan

TAIWAN’S WIND FARM SECTOR SETS 5.7GW GOAL BY 2025

Strait by 2025 - will require an estimated investment of US$20 billion, the firm said in its Focus on Taiwan commentary. “Lacking experience in the industry, Taiwan is relying heavily on the participation of global players by making firm policy commitments, offering attractive subsidized rates, and adopting new financing models.”

Strategic Marine, which is based in

Singapore, has customers all over the world, with the government of Bermuda selecting the yard to build two 550-passenger catamarans last month.

In January, the company was selected to build a fast crew boat for Bruneian oil and gas company Amarco.

8 StratCat 27 For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 9

BUILDING & LAUNCHES

VESSEL

--Pilot Vessel - ORC 121-Project Support Vessel---MARKET-LEADING MARINE EXPERTISE NEW VESSELS AVAILABLE FOR CHARTER IN 2024: To Enquire: T: +44 (0)1592 872939 | E: enquiries@briggsmarine.com | W: briggsmarine.com

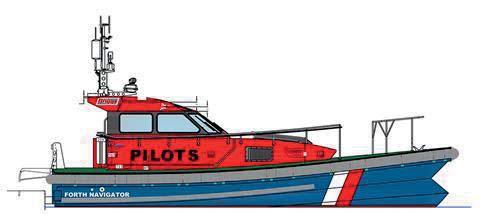

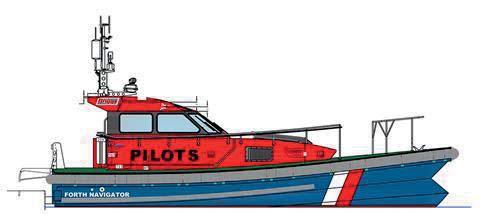

NEW PILOT VESSEL FOR BRIGGS MARINE

Maritime services provider Briggs Marine has added another pilot launch to its varied fleet of vessels following delivery of the ORC-121 Forth Navigator from UK-based, family-owned boatbuilder Goodchild Marine.

In 2022 when Briggs Marine took delivery of another ORC121 pilot launch, bringing the number of ORC-design vessels in its fleet to six, the Burntisland-based company said demand for such vessels was outstripping supply. That provision is now enhanced following the arrival of Forth Navigator, which adds another of the class to its portfolio with the total number of assets in its diverse fleet standing at 30 vessels.

Port support services are part of Briggs Marine’s activities, the company reporting the transfer of 6,984 pilots and the carrying out of 7,719 ship mooring operations in 2023.

This latest addition is road transportable, offering rapid mobilisation to anywhere in the country, and will be available for short or long-term charter for a range of activities including pilot boat or harbour patrol duties.

This latest addition is road transportable, offering rapid mobilisation to anywhere in the country, and will be available for short or long-term charter for a range of activities including pilot boat or harbour patrol duties

Goodchild Marine is now well established with production of ORC series pilot vessels, a design from naval architect Pantocarene Limited. The Burgh Castle, Great Yarmouthbased boatbuilder has four ORC variants in its catalogue ranging from 12m to 17m in length, the ORC-121 the smallest in the range.

Steven Pierce, of boatbuilder Goodchild Marine, said: “One of the main benefits to this vessel is that the semi displacement hull design of the ORC is about 40% more fuel efficient than counterparts of similar size, helping to reduce emissions. In addition, the road transportability of the 12m pilot vessel adds another dimension of flexibility, allowing it to reach various locations swiftly.”

Looking in detail at Forth Navigator’s specification, the vessel meets MCA Category 3 (30 miles from a safe haven) certification and has a length overall of 12.056m and beam overall 4.73m with a draught (98% conditions) of 1.379m dependant of loadings. Constructed of GRP, it has an approximate maximum displacement of 14.3t and is subdivided by four watertight bulkheads with a maximum capacity of six persons.

Power is provided by two Volvo Penta D8, Tier III compliant main engines, each developing 450hp at 2,700rpm and connected to Twin Disc MGX-5126A 2.5:1 reduction gearboxes with propulsion in turn via ISO 8845 NAB 27x37 five-bladed, fixed-pitch propellers.

Fuel capacity is 1,436 litres and total power is stated as 882kW, delivering a service speed of approximately 21kn and maximum speed 26kn.

Goodchild Marine was founded in 1978, the company designing, building, repairing and refitting vessels in the commercial and leisure sectors. As well as the ORC series (which are in operation as far afield as Australia), which includes hybrid versions, Goodchild offers Halmatic Nelson pilot boats and boats from the AquaBell series, which meet MCA Category 2 Workboat Code rules for operation up to 60 miles offshore. These are popular as angling boats and workboats as well as harbour, pilot and police launches.

Goodchild’s refit and repair activities include work for the Royal National Lifeboat Institution, for whom it has been a nominated refit and repair yard since the mid-1990s.

10 | APRIL/MAY 2024 For the latest news and analysis go to www.maritimejournal.com

8 Forth Navigator is built to the distinctive ORC design

VESSEL BUILDING & LAUNCHES

Source: Briggs Marine

8 Goodchild Marine is based near Great Yarmouth on the UK east coast

The best things come in small packages.

Damen’s compact ASD Tug 1810 represents the latest in multi-purpose harbour towage. With 30 tonnes of bollard pull it has the power to confidently handle ships of all sizes, and the combination of Damen’s patented twin fin skeg and twin Azimuth thrusters ensures excellent manoeuvrability. The double drum winch is positioned inside the deck house, allowing the single winch to operate over both the bow and stern. As the latest in tug technology, the ASD Tug 1810 comes prepared for full compliance with IMO Tier III regulation.

Find out more on Damen.com

Pictured here: ASD Tug 1810

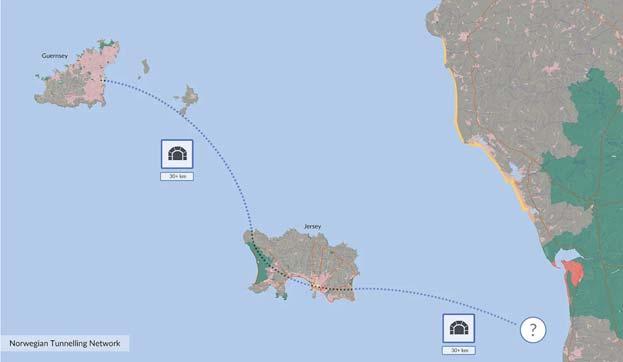

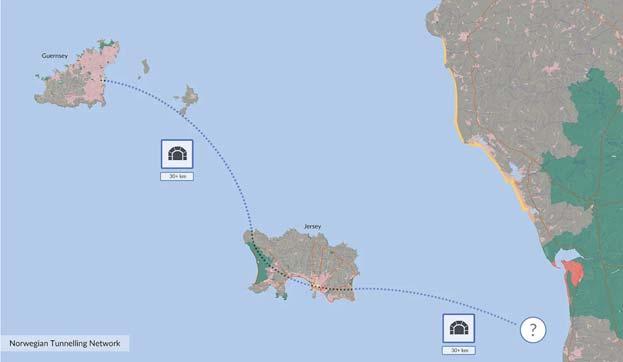

CHANNEL ISLANDS TUNNEL TO FRANCE - DREAM OR REALITY?

Subsea tunnels connecting the Channel Islands to France have become a very real possibility, says Martyn Dorey, a Guernsey local who founded an impact group to assess the potential of such a scheme.

High-speed trains would take French residents between Normandy and the Channel Islands on a daily, commuter friendly basis.

A 44km tunnel would be dug between Guernsey and Jersey, and a second from Jersey to Normandy – possibly Granville.

The idea has been spawned largely because of Jersey and Guernsey’s need for workers across all sectors, says Dorey. Shortage of housing means they would have to commute, which would be convenient and quick by train.

The cost of shipping goods on and off the islands has also boomed, and a tunnel would open a vital freight route, he says.

Dorey, who runs his own finance company, is a former president of the Guernsey Chamber of Commerce. Having explored the different engineering successes of subsea tunnels around the world, such as an 11km one in the Faroe Islands and at least 40 in and around Norway, he decided to pursue the idea with the Norwegian Tunnelling Association, which agrees that the idea is not lunacy.

“There were suggestions for a cable car, airship, seaplane – and we looked at all these things,” he said. ”We ruled out cable cars because you do actually need mountains for that, and neither island has one.

What could once have seemed impossible because of the engineering costs and time-scale is now looking like a real possibility, with initial theories about what kind of rock lies underneath the water where the tunnels would be dug

“Airships have vertical take-off and landing, they’re a tenth of the cost of an aircraft to run – what’s not to like? So we spoke to a technology firm in Munich and they said you’d only be able to use it for two months a year and you can’t fly it at night.

“So then we moved on to a seaplane – there was a brilliant wave-piercing seaplane design, but you’d need at least £500 million just for the R&D. And it’s about 20 years down the line.

“The tunnel was literally the last thing left on the board.”

Meeting at a Chamber of Commerce event earlier this month, presentations were given by Arild. P. Sovik, network director at the Norwegian Tunnelling Society; and Teitur Samuelsen, CEO of Eystur- og Sandoyartunlar, the Faroe Islands government-owned tunnel corporation.

Rock quality

What could once have seemed impossible because of the engineering costs and time-scale is now looking like a real

possibility, with initial theories about what kind of rock lies underneath the water where the tunnels would be dug.

If the rock along the route is of the granite variety, as the Norwegians believe, the tunnels could be mined as opposed to dug out with a boring machine and not require concrete supports, as was the case with the Channel Tunnel, which Dorey calls ’a physical success and a financial failure’.

“We would also be able to sell the spoil, which would be far more valuable than the more sifted, silty material produced with a boring machine,” he says.

“Holes would be blasted and large chunks of rubble excavated possibly by sinking shafts into the route of the tunnel, into the seabed, then working in stages.”

Even if the rock did have clay or chalky areas, there are methods whereby rock can be frozen, sealed or cut out, depending on what is there.

“Realising the rock was probably hard was a light-bulb moment,” says Dorey. “The harder the granite the better, you drill and blast it and it supports itself. The experts say it looks like it’s hard rock but even if there’s a sandstone section, we can work with it.”

The scheme is in its embryo stages, but if Forey is right it could completely transform the economies of the Channel Islands and northern France.

12 | APRIL/MAY 2024For the latest news and analysis go to www.maritimejournal.com

8 Proposed tunnel route between the Channel Islands and France

MARINE CIVILS

8 Martyn Dorey

More than 60,000 solar panels will be installed on Port of Liverpool roofs in what energy firm Eon is calling the largest solar project in the UK.

The panels will be placed on the roofs of 26 buildings in the first stage of a target to cut emissions to zero at the port.

The second phase will be to ‘re-power’ wind turbines along the River Mersey, in other words, replace the existing five machines with four larger ones.

The new ones will increase the power generation capacity of the turbines to 20MW to complement the solar panels’ capacity of 31MW, which is estimated to be 25% of the port’s needs.

Port of Liverpool owner Peel Ports has signed a 25-year agreement with Eon in a bid to achieve net zero emissions throughout its operations by 2040.

All equipment and machinery needed for the installation work will be delivered to the port by sea to avoid snarling up the road network, the developers say.

“Ports of the future need to become more sustainable environments and we must play our part in a greener supply chain,” said Claudio Veritiero, Peel Ports CEO. “There is still work to do, but this project is a huge step for

PORT LAYS OUT AMBITIOUS SOLAR AND WIND PLANS

Planning applications have been made to

Improve your working days

Install Humphree ACTIVE Stabilisation and working days on the sea will be steadier than ever. Our ACTIVE interceptor system lowers roll and slamming by up to 50%. And it feels like even more. It also reduces resistance. That means lower fuel consumption and less CO² emissions. Easy to install, easy to operate. Premium technology at aff ordable pricing. Help our planet and ensure a successful mission

8 Port of Liverpool For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 13

MARINE CIVILS

Peel Ports Group in cutting emissions and driving our ambition to become a net zero port operator by 2040.”

FOR ALL BOATS, FAST FERRY, PILOT, POLICE , RESCUE , COAST GUARD, NAVY, MONOHULLS AND CATAMARANS. www.humphree.com

Humphree international dealer network - visit humphree.com

the authorities for the solar panels to be installed by the middle of 2026 and the turbines re-powered from 2027.

Steady at sea

For

you

crew

for

and your

at humphree.com

EMERGENCY DAM INSTALLED WITH DUTCH EXPERTISE

An emergency temporary dam has had to be built in the Netherlands’ city of Maastricht after a spillway dam on the River Meuse was damaged earlier this year.

Part of the lining of the spillway had been loosened and washed away by the force of the water, and strong currents made it impossible to repair the dam within a short time scale.

The Public Works and Water Management Office (Rijkswaterstaat) commissioned contractor Mourik to organise the repairs, many of which were carried out by Van Oord.

“Due to the high water discharge and associated flow velocities, this was a complex operation,” said Van Oord. “After the hole in the spillway dam was caused, a first emergency dam was constructed within a week to reduce the strong current.

A second emergency dam has now been installed to secure the river water level with the use of fascine mattresses – the use of which is particularly common in the Netherlands

“To construct this first quarry stone emergency dam, Van Oord deployed crane vessel Leendert Sr and two excavators. To build the emergency dam from both banks, Rijkwaterstaat engaged the Ministry of Defence to build a ferry connection between the east and west banks of the River Meuse for moving equipment across.

“Simultaneously, Chinook helicopters flew back and forth with nets full of quarry stone to partially close the hole in the spillway dam.”

Dutch speciality

A second emergency dam has now been installed to secure the river water level with the use of fascine mattresses – the use of which is particularly common in the Netherlands.

These are essentially large woven mats made of brushwood or twigs, and are placed in rivers to strengthen banks and coastal structures such as groynes. They can also be used to protect river and sea beds from scour. Because these mattresses are used so widely in the Netherlands, the materials required to make them are harvested in specially created plantations.

In the Meuse River, Van Oord towed them to where they were needed then weighted them down with rocks. More than 150,000 tonnes of quarry rock was installed to raise the emergency dam to the correct height and now the water is at a level that can allow permanent restoration of the spillway dam to be undertaken.

‘Titanic’ builder selected for Falklands contract

Harland & Wolff is the preferred bidder to build a port facility on the Falklands Islands, the famous shipbuilder has announced.

The Falklands Islands Government (FIG) has selected the Belfast-based shipbuilder to replace its FIPASS (Falklands Intermediate Port and Storage System) at Port Stanley.

FIPASS is a floating structure consisting of six linked pontoon open deck or warehouse barge units and one ro-ro pontoon unit, which also connects the barge units with a steel modular causeway to the shore.

The original facility was built and installed by Harland & Wolff though the UK Ministry of Defence in 1984, two years after the Falklands War, and the FIG bought it in 1988.

The FIPASS project involves the build, transport and installation of four floating pontoons, each measuring around 90 metres each in length, says Harland & Wolff,

8 A total of 150,000 tonnes of quarry stone was installed as part of a spillage dam repair

which says it will build the structure across its four sites of Belfast, Appledore, Arnish and Methil.

“We are proud to have been chosen as the preferred bidder for the FIPASS replacement, marking another significant achievement in our expanding non-defence portfolio,” said CEO John Wood.

“This project not only highlights our enduring partnership with the Falkland

Islands Government but also reinforces our reputation as a trusted provider for large and complex marine engineering projects.

“With our history of delivering the original FIPASS, we bring a wealth of experience combined with the latest in manufacturing innovation to deliver a modern, efficient, and sustainable port system.”

14 | APRIL/MAY 2024For the latest news and analysis go to www.maritimejournal.com

MARINE CIVILS

Source: Van Oord

8 Port Stanley

A multi-million euro project to transform the Italian Port of Genoa with a 6.2km breakwater built on a base 50 metres deep has had a million tonnes of gravel laid along the seabed, amounting to 40% of the laying activities.

The Italian engineering firm Webuild Group says it has submerged 1,320 gravel columns with material supplied from quarries in Liguria, Piombino and Cartagena in Spain and transported to Genoa on three bulk carriers.

A large barge equipped with four 40m tall cranes, each with 22m needle-shaped vibrating probes, is moored at the port, ready to build the caissons that will be at the heart of the breakwater. The building of the caissons is scheduled to begin next month.

“These huge cellular reinforced concrete blocks, when built, at a maximum depth of 50 metres, one next to the other, will complete the 6.2 kilometres foreseen for the breakwater project,” says the Webuild Group.

“Phase A of the project foresees the construction of 97 caissons, of which the largest will be each as tall as a 10-storey building, therefore reaching 33 metres in height, 35 metres in width, 67 metres in length.”

It has also been necessary to carry out UXO searches, 70% of which are now complete, the firm says, with the remainder

COLUMNS SUBMERGED FOR 6.2km GENOA BREAKWATER

due to be completed this summer.

Costs have risen in the project, from a projected €930 million when the contract was signed to €1.3 billion at the stone-laying ceremony last May.

International Media Relations spokesman Gilles Castonguay said the project was ‘unique in the world’ for scale and complexity.

The breakwater will provide safe access for today’s 450m long ships, which cannot use the Port of Genoa in its current form. A new 800m turning basin will give the port, Webuild says, the ability to compete with Europe’s biggest ports.

8 Port of Genoa For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 15

MARINE CIVILS

EngineeringInnovationAboveandBelowthe WaterlineSince1976 www.kaymacmarine.co.uk EngineeringInnovation Above&Belowthe Waterline Kaymacisamulti-award-winningspecialistMarineandCivilEngineering Contractorwithatrackrecordofexcellence,innovationandsafetyinthe utilityandtransportsectors. Wespecialisein: ThedesignandinstallationofbespokeInnovativein-watertemporaryworks Restoringandmaintainingthe nation'sriversandwaterwaystransportassets ScourProtection FloodProtection WasteandWaterSolutions

LONDON 25km ‘SUPER SEWER’ FINALLY COMPLETED

The largest infrastructure project ever undertaken by the UK water industry has finally been completed, some 12 years after initial investigations were carried out.

After eight years of intensive building works London’s new ‘Super Sewer’, formally known as the Thames Tideway Tunnel, is now complete, resulting in a 25km long, 7.2m wide main tunnel with a 4.5km connection tunnel in southeast London and a 1.1km tunnel in southwest London.

The critical milestone was achieved by engineering firm Tideway in March, with the fitting of a 1,200-tonne concrete ‘lid’ on the top of a 70m-deep shaft.

Twenty-four metres in diameter, the lid had to be placed using a purpose-built gantry crane and other manoeuvring equipment in a procedure that took five hours.

It was the heaviest lift in the entire project, which has been done by Tideway, a consortium of investors including more than two million pensioners.

The cost of the tunnel is estimated to be £4.5 billion (€5.3 billion), and will be paid for by Thames Water customers through their water bills, which Tideway promises will rise by no more than £25 (€30) a year.

Engineering works

The project, extending from Acton to Beckton, involved 70 work sites, including 11 riverside construction sites.

The main reason for the project was to reduce by almost 100% the millions of tons of storm sewage that spills into the River Thames every year, thanks to an outdated Victorian sewer system that has never been updated despite the population more than doubling since then.

The main reason for the project was to reduce by almost 100% the millions of tons of storm sewage that spills into the River Thames every year, thanks to an outdated Victorian sewer system that has never been updated despite the population more than doubling since then

The storm sewage will be diverted into the new infrastructure to change the famous river into a cleaner waterway than it has been since London was a city.

Jack-up rigs were deployed along the river in 2011 to carry out ground investigations to analyse the material that tunnel boring machines would have to deal with.

Red7Marine’s Seajack rigs were hired for the job, and it used its own tug to move them around the river.

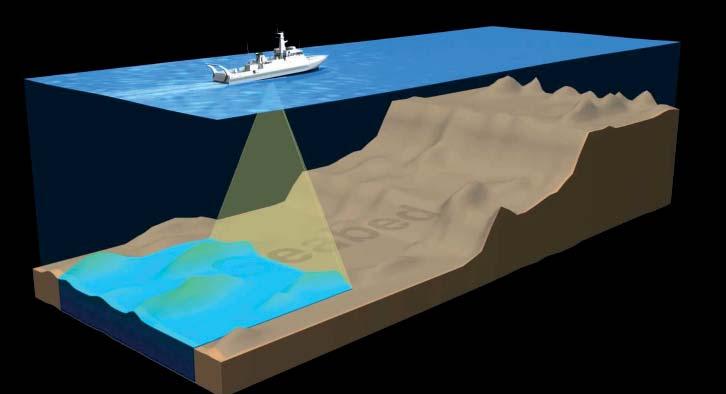

Other investigations were carried out by Fugro, which over a seven-month period undertook drilling, downhole geophysics and testing down to 80 metres along a 10km stretch of the river.

The company designed and installed adaptations to the

Skate 2D jack-up barge so that leg handling and storage could be done with a single vessel, as well as completing the grilling and testing.

As the tunnels were excavated, millions of tons of underground material were removed by waterway from central London and are now being used to create new parcels of land.

A range of barges from 500t to 1,800t has been used to remove the spoil.

“This is the moment we’ve all been waiting for,” said Tideway CEO Andy Mitchell. “The underground civil engineering on the Tideway project is now complete following eight years of dedicated hard work from all our teams working in the capital.

“There is still work to do – we need to finish some aboveground structures and, crucially, test the system – but this nonetheless marks an absolutely critical milestone for the Tideway project and for London.”

8 It

8 Seajack by Red7Marine

concrete

1,200

16 | APRIL/MAY 2024For the latest news and analysis go to www.maritimejournal.com

took five hours to fit a 24m diameter

‘lid’, weighing

tonnes,

on to a 70m deep shaft

MARINE CIVILS

SALVAGING THE ‘DALI’ AFTER FATAL BRIDGE COLLAPSE

As the authorities in Baltimore prepare to untangle the container ship Dali from the collapsed Francis Scott Key Bridge, the local community along with the wider shipping industry are starting to untangle the circumstances surrounding the accident and extract any ‘lessons learned’ for the future.

Ships coming into contact with other objects generally attract little attention beyond the maritime community, usually restricted to webcam clips doing the social media rounds.

When the outbound container ship Dali lost power and struck one of the bridge’s support towers the result was little short of catastrophic, with virtually the entire bridge collapsing in seconds. A warning by the ship of its dilemma allowed the bridge to be closed to road traffic, but a team of eight persons working on the bridge plunged into the water following its collapse.

The immediate consequences were widespread, affecting not only the port but also local communities, for whom the bridge was a major artery.

The access channel was blocked, the ships within effectively trapped and while there are tunnels and bridges upstream, vehicles carrying hazardous materials are prohibited from using them, adding to the ensuing congestion, which is unlikely to ease potentially for years until the bridge is rebuilt.

Response

The immediate priority was search and rescue.

Two of the bridge workers were rescued, two bodies were recovered and the remaining four are now assumed not to have survived. No serious injuries were reported to the 21 crew and two pilots on the container vessel.

A Unified Command was established ashore, including the USCG; US Army Corps of Engineers (USACE); Maryland Department of the Environment; Maryland Transportation Authority; Maryland State Police; and Witt O’Brien’s, representing Synergy Marine.

The next priority was to remove wreckage from the seabed to allow access to the port, along with freeing the Dali, reportedly pinned to the seabed by bridge sections lying on its forepart.

Progress was made with clearing the seabed, allowing a pusher tug and fuel barge to transit a temporary alternate channel with a depth of just 3.35m and vertical clearance 28.9m just a week later, with a second deeper temporary alternate channel opened the following day.

The two elements of the recovery operation involves both marine salvage expertise and similar skills from federal, state and local players for the shoreside elements, including removing the bridge debris. Seven cranes, 10 tugs and nine barges along with more than 1,000 specialist workers are reported to be involved in the recovery operations.

Subsequent global speculation has been widespread but it is reliably reported that USACE is leading the efforts to clear the channel.

It is also reported that Dali’s charterer, Maersk, has appointed Fort Lauderdale-based Resolve Marine to salvage the vessel, while New Jersey-based Donjon Marine is among the other non-government organisations mobilising equipment, including a crane barge.

Lessons learned

The National Transportation Safety Board (NTSB) will investigate and eventually report on the accident in the wake of wild speculation on every aspect of the accident, from the design of the bridge to Port of Baltimore’s operational procedures.

One aspect that soon gained traction was the tug arrangement for vessels using the port.

Two shiphandling tugs assisted Dali from its berth, including turning it to leave via the Key Bridge before being released as per standard practice. The question has been asked whether the ship could have been brought back under control if tugs were still in attendance.

Other ports where escort tugs accompany ships, including under bridges, have been mentioned and it is important to consider the term ‘escort towing’ in this context.

Escort towing generally involves a powerful tug tethered to the ship’s stern to influence its heading (for example if the ship loses steering) from forces generated by the hydrodynamic effect of the tug’s underwater hull profile.

Referred to as ‘indirect towing’, it is carried out when the ship’s rudder still influences its heading and at speeds greater than during ‘direct towing’ operations. NTSB reports that Dali’s speed was approximately seven to eight knots when it lost power, around the limits of when tugs operate in direct mode.

There is still much to emerge from the event that claimed six lives, and the eventual NTSB investigation and recommendations will provide the ultimate verdict.

For the communities around Baltimore, however, the consequences of the loss of their bridge will linger far beyond when the Dali is repaired and likely back in service.

18 | APRIL/MAY 2024 For the latest news and analysis go to www.maritimejournal.com

8 Wreckage from the bridge fell on the fore part of the container ship

TUGS, TOWING & SALVAGE

Source: Uni fi ed Command

Kotug International and Dutch shipbuilder

Padmos have signed a framework agreement where the Stellendam-based shipyard will complete the entire Kotug E-Pusher range of inland pusher tugs.

The E-Pusher is a modular and scalable electric pusher tug featuring swappable energy containers with Stage V diesel, biogas, hydrogen and battery power provisions.

The E-Pusher moved from being purely a concept in 2023, when Padmos built an M-Model, fully-electric example named E-Pusher 1 to move barges loaded with cocoa beans between Amsterdam and Zaandam for global food corporation Cargill.

Kotug says the operation reduces CO2 emissions by 190,000kg per year, the equivalent of 15,000 single truck trips covering the same distance.

The E-Pusher’s zero-emission energy containers can switch energy sources depending on the circumstances and client’s preferences, and Kotug says the modular approach to construction and “circular building” principle implies the vessel has an eternal lifespan as every single part can be replaced, adjusted or removed, including the energy source.

Construction time is claimed to be reduced

PADMOS SIGNS UP TO BUILD KOTUG E-PUSHER TUGS

by more than half compared with traditional vessels.

The series has three models: S, M and L, ranging from 9m to 22m in length. The smallest ‘S’ model, also known as the Kotug CityBarge, is also in operation where with partner Circle Line Logistics, a CityBarge is deployed for various projects in the

Netherlands, including at Amsterdam, Leiden, Rotterdam and Utrecht.

The vessel can navigate shallow waters and low bridges, making them suitable for water transport in historic city centres and a “natural alternative to road transport”.

For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 19

8 Padmos previously built E-Pusher 1 for Cargill

TUGS, TOWING & SALVAGE

CARLIER CHAINES SAS FRANCE 37-41 rue Salengro - B.P. 10145 - 59733 Saint-Amand-Les-Eaux cedex Tél. +33 (0)3 27 48 12 00 • Fax : +33 (0)3 27 48 95 27 info@carlier-chain.com • www.carlier-chain.com Chain manufacturer

/ LIFTINGMARINE / MOORINGINDUSTRIE / INDUSTRY Fabricant certifié ISO 9001

LEVAGE

BARGES TRANSPORT HEAT IN BATTERIES ALONG RIVER

UK-based Cory Group along with low carbon infrastructure project arranger Sheen Parkside has announced a partnership to decarbonise heating by moving waste heat in thermal batteries on barges towed by tugs on London’s River Thames

Cory’s extensive fleet of tugs and barges have for many years been a part of the Thames river scene, moving around 900,000 tonnes of non-recyclable black bag waste a year between riverside waste transfer stations and its energy from waste (EfW) facility downstream at Belvedere.

The Thames Mobile Heat Consortium includes thermal storage technology company Sunamp, and plans to use the capital’s main infrastructure artery to take heat from along the river, initially from the Belvedere EfW facility and transported by barge to major heat consumers, such as district heat networks.

The project will use “world-leading” phase change thermal storage developed by Sunamp and the University of Edinburgh in batteries which use a salt-based, non-toxic, long duration phase change material (PCM) housed in specially designed shipping containers, making them easy to transport by barge.

The thermal batteries remain on the barge at all times, towed by tugs throughout the passage. At the discharge location a water pipe is run out along a jetty and draws heat from the batteries via an internal heat exchanger.

Cory will draw on its long experience with its lighterage waste transfer operation on the Thames and oversee the marine logistics of the project, which would be run as an independent logistics operation from the waste transfer side of its business.

Using the heat District heating, where high-grade industrial heat is used to provide heat for homes, is expanding across London and other European cities where industry sits alongside urban areas.

Sheen Parkside says the heat is often wasted ‘simply because it is in the wrong place’. One potential customer is the Pimlico District Heating Undertaking (PDHU), owned and operated by Westminster City Council. PDHU is the UK’s oldest district heating scheme, supplying more then 3,000 homes and 50 commercial and community buildings, originally taking heat from Battersea Power Station.

Cory says the Thames Mobile Heat Consortium has the scope to provide around 50GWh of heat per year, transported on two barges, each carrying up to 120MWh in 40 batteries, travelling 28km each way along the river.

Heat supplied on this basis has been modelled at 12gCO2/ kWh or lower, a substantial reduction compared to gas, which is modelled at around 216 gCO2/kWh. From completion of planning and approvals and final commercial agreement it could be operational in less than a year.

Westminster City Council is exploring options for decarbonisation and district heat schemes are considered to have the potential to provide lower-carbon heat, rapidly and at scale, without dependence on electricity grid upgrades. Not coming from an electrical source, it can also help when demand is placed on the UK’s national grid.

Fleet upgrades

Cory’s fleet of Thames tugs and barges are currently being upgraded.

Early in 2023, two additional Shoalbuster 2208S tugs were ordered from Dutch shipbuilder Damen on the back of plans for a second EfW plant adjacent to the existing facility at Belvedere. Both vessels are scheduled for delivery prior to the new plant becoming operational, scheduled for 2026.

In parallel to the new tug programme, Cory is currently taking delivery of new barges.

In 2019 it reported that Belgian shipyard Meuse and Sombre had signed a contract for 14 new barges, the deal followed in the next year by a reported multi-million pound contract for delivery of 21 barges over a seven-year period from Newcastle-based A&P Tyne.

Belfast’s Harland & Wolff shipyard also benefited from Cory’s ambitious barge replacement plans with two contracts signed in 2022, valued at £18.1 million (€21.1 million), for 23 new barges.

“At Cory, we are proud to provide a vital public service which diverts non-recyclable waste from landfill,” said Development director Chris Girdham. “The EfW process produces huge amounts of heat, and rather than seeing this valuable resource go to waste we want to use it to benefit communities in the UK that are seeking to cut carbon emissions and keep energy bills down.

“By moving heat to where it’s most needed, we can help to reduce our reliance on fossil fuels and maintain the UK’s role as a clean energy innovator.”

20 | APRIL/MAY 2024For the latest news and analysis go to www.maritimejournal.com

8 The River Thames is an artery already well utilised by Cory’s fleet of tugs and waste barges

TUGS, TOWING & SALVAGE

Source: Cory

Boluda Towage will expand its global operations with the purchase of French towage operator Les Abeilles.

Les Abeilles owner Econocom Group has confirmed entering into exclusive negotiations with Boluda to sell 100% of its shares in the French towage operator.

Les Abeilles and Boluda Corporación Marítima have long histories dating back to 1864 and 1837 respectively, with Boluda’s towage division making recent acquisitions including Resolve Salvage and Fire (Gibraltar) Ltd and an agreement to acquire Smit Lamnalco.

This latest development, planned for completion in Q2 2024, will expand Boluda’s presence in France, including the operation of Abeilles’ fleet of Emergency Towing Vessels (ETVs) in operation with the French government.

Econocom describes itself as “Europe’s first digital general contractor”, acquiring Les Abeilles in 2020 before reclassifying it as an ‘asset held for sale’ in 2023. The usual procedures surrounding such acquisitions are now under way, including consultation with the bodies representing staff. The transaction also remains subject to the agreements being finalised and the condition precedents that usually apply to this type of transaction, including approval from the French authorities.

For Econocom the sale is part of its longer term strategy.

“We are delighted with this transaction with the Boluda Group, a global leader in towage,” said chairman and managing director Jean-Louis Bouchard. “Through this sale, Les Abeilles will enjoy support from a major player to develop in the future. The sale will take place as part of our plan to sell certain assets that are not strategic for our core business, which we announced in mid-November as part of our strategic plan for the 2024–2028 period.”

Les Abeilles has been keen to strengthen and develop its French maritime activities, including in 2022 introducing two new powerful additions to its fleet of ETVs, Abeille Normandie and Abeille Méditerranée, stationed in Boulogne to cover the Dover Strait and Toulon in the Mediterranean.

BOLUDA EXPANDS WITH ANOTHER ACQUISITION

Boluda is a family group that is over a hundred years old. Today, the group has reached a key moment in its history by becoming an undisputed global leader in towage. The arrival of Les Abeilles, with its operational expertise, in our group is a new stage in this growth ‘‘

Boluda chairman Vicente Boluda Fos said: “Our group has been present in France since 2007 and is deeply rooted there. Our commitment to French employment and growth has always been a prominent characteristic of our identity.

“Boluda is a family group that is over a hundred years old. Today, the group has reached a key moment in its history by becoming an undisputed global leader in towage. The arrival of Les Abeilles, with its operational expertise, in our group is a new stage in this growth.”

For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 21 TUGS, TOWING & SALVAGE

Source: Marine Nationale

years as the World’s #1 Keel Cooler, Boxcooler & Pillow Plate.

OUR COMPETITION, WE DON’T CUT CORNERS. fernstrum.com • 906.863.5553 See you at Seawork Stand E3.

8 Emergency intervention with marine casualties is all part of Les Abeilles’ services

75

UNLIKE

FLEET RENEWAL FOR DUTCH PUSHER TUGS

Dutch logistics operator Thyssenkrupp Veerhaven has commissioned two companies to produce designs for climate-friendly replacements of its existing pusher tug operation transporting raw materials to Thyssenkrupp’s iron and steel plant in Germany.

C-Job Naval Architects and Kooiman Marine Group have been commissioned to design this “next generation” of pusher tugs.

The colourful seven Thyssenkrupp Veerhaven pusher tugs are regular sights on Dutch and German inland waterways, pushing barges loaded with raw materials between Europoort in Rotterdam and parent company Thyssenkrupp Steel Europe’s iron and steel plant at Duisburg, at the junction of the Rhine and Ruhr rivers.

In what is a 24/7, 365 days-a-year operation, a typical combination of four barges is 193m long, carrying around 11,000 tons of raw material, while a six-barge combination is 269m long.

Transporting 16,000 tons on the 240km journey takes 26 hours at a speed of 9km/hr.

After de-coupling, which takes around three hours, the tug picks up empty barges for the 12-hour return journey to Europoort, where they are loaded again with raw material including coal and iron ore unloaded from bulk carriers that arrive from as far away as Brazil and Australia. Around 18 million mt of raw material are transported to Duisburg via this route every year.

Decarbonising the supply chain

The plan to replace the tug fleet is part of the steelmaker’s programme of decarbonising its entire supply chain, Thyssenkrupp Veerhaven saying it is “venturing into uncharted waters with these plans”.

“In this challenging area of inland waterway shipping, there are currently no vessels that run on environmentally friendly fuels such as methanol,” said CEO Frank Tazelaar. “We intend to play a pioneering role and, with our planned fleet modernisation, we are laying the foundation for innovative technologies that will significantly reduce our carbon footprint.”

In the past, Thyssenkrupp Veerhaven has commissioned a

shipyard to build a new vessel but with this project it is taking an innovative approach in its planning process, the owner arranging for specialist design offices to prepare offers for three separate designs.

Thyssenkrupp Veerhaven says its plans to use methanol as a fuel could save around 80% of current CO2 emissions, compared to diesel.

The water level of the River Rhine has tended to dip below critical levels more and more frequently during the summer months in recent years, with implications including restricting the draught (and cargo volumes) of the tug and barges. In response to this, the planned new fleet of tugs are having to be optimised for lower water levels.

The process will involve reference vessels as well as lowwater push tugs with Stage V propulsion and dual-fuel/ methanol-capable variants. Following the selection process, C-Job Naval Architects and Kooiman Marine Group were commissioned to design this “next generation” of pusher tugs.

After receiving the plans, Thyssenkrupp Veerhaven will evaluate their technological and economic feasibility and as the oldest existing tug in its fleet will soon reach the end of its technical service life, it is planned to order the first “pusher tug of the future” in the near term, assuming the investment decision is positive.

Svitzer readies itself for Maersk demerger

Svitzer is strengthening its financial organisation in preparation for the intended demerger from A.P. Møller – Mærsk.

Christian Lintner has been appointed as head of treasury, effective 1 May 2024 and Michael Nass Nielsen as head of investor relations and financial planning and analysis, commencing 1 June 2024.

“We are pleased to welcome Christian and Michael to Svitzer. I am convinced that their experience and drive will further strengthen our value creation and future dialogue with investors and financial analysts as we

continue to deliver on our strategy,” said Knud Winkler, CFO of Svitzer.

Financial expertise

Mr Lintner currently serves as the head of international treasury at Nets and has previously held a similar position at Torm. Mr Nielsen currently holds the position of head of investor relations at NKT and has previously worked for GN and SEB.

Svitzer has been part of APMM for almost 45 years. On 8 February 2024, APMM announced its decision to initiate a

8 The existing pusher tugs are to be replaced by a climate-friendly fleet of vessels

separation of Svitzer through a demerger, subject to approval at an APMM extraordinary general meeting expected to be held on 26 April 2024.

There will be a subsequent listing of the new parent company, Svitzer Group A/S, on Nasdaq Copenhagen and an anticipated first day of trading on 30 April 2024.

Further details on the demerger and separate listing of Svitzer will be made available on www.maersk.com when the statutory demerger documents have been published, reportedly on 22 March 2024.

22 | APRIL/MAY 2024 For the latest news and analysis go to www.maritimejournal.com

TUGS, TOWING & SALVAGE

Source: Peter Barker

ITS 2024 DUBAI

The 27th International Tug & Salvage Convention, Exhibition & Awards

In association with premier biennial gathering of the tug, towage and salvage community, held every two years in a different leading maritime hub since 1969.

tugandosv.com/ITS2024

21-23 May 2024

Dubai

SCAN HERE FOR DETAILS AND EVENT PASSES

The ITS 2024 conference programme will be shaped by leading industry experts from across the international tug and salvage industry.

BOOK YOUR EXHIBITION STAND:

Showcase your latest products and services

Social Events Awards Conference Exhibition ENQUIRIES For further information, please contact: Indrit Kruja, Brand Manager t: +44 20 8370 7792 • e: indrit.kruja@rivieramm.com

Strategic

Event partners

Destination partner

partner

ALARM AND OPTIMISM AT WINDEUROPE 2024

Thousands of players in the rapidly emerging on and offshore wind industry gathered this week at WindEurope’s annual event, but while the number of delegates was healthy, a prominent theme running through the entire event was the threat to the European sector coming from Asia – particularly China.

There were many signs of confidence in the offshore wind market and deals signed, to name just two: Norway’s announcement of its first large-scale offshore wind auction, and a new ‘Wind Energy Initiative’ launched by WindEurope and other organisations including Siemens Gamesa and Vestas to foster more collaboration in the sector.

With more than 12,000 delegates, 520 exhibiting companies and more than 400 conference speakers, the event was ‘in line’ with expectations, said WindEurope Press and Communications manager Christoph Zipf.

“The event is not the biggest WindEurope Annual Event so far but it was in line with our expectations,” he said. “There has been a strong focus on international competitiveness but also new sectors and companies participating – digitalisation, floating wind, grid operators, system integration providers.”

But fears about supply chains and price competitiveness were aired by many exhibitors that spoke to Maritime Journal, and a conference focusing on the issue – Can we reduce our dependency on Asia? – broached the subject but ultimately did not provide answers to the question.

Chairing the discussion, WindEurope’s Laura Casuscelli, senior advisor - Wind Energy Trade and Competitiveness, said that with a 2050 target for Europe of 425GW and a current capacity of just over half that, the challenge would be a tough one yet in view of recent geopolitical events, an even more necessary one.

“It’s a critical issue for everyone, using more and more elements and materials. We can’t avoid it, no matter what we do,” said Evdokia Tapoglou, project officer in the Joint Research Centre with the European Commission. “In Europe we don’t have all the materials we need, nor in the quantities we need them.”

The processing capacity was also not here, she said, adding that China had 25% of the global resources and 90% of the processing capacity.

Demand will only increase

With the rapid growth in ‘green’ and digital technologies, raw material demand would become more intensive, said Petra Inghelbrecht, Sustainability Leader EU Composites at Owens Corning Fibreglass – supplier of material for turbine manufacturers.

“A recent study shows that demand will grow by four and a half times more by 2030 and by five to six times by 2050,” she said, urging a ramp-up of recycling and a circularity within Europe, improving efficiency to reduce reliance on Asia.

Steel is of course a major component in vessel and turbine building and it was also infinitely recyclable, said Stéphane Tondo, technical head of Governmental Affairs/Decarbonization with steel manufacturer ArcelorMittal.

“We have to keep it in Europe and recycle it here,” he told the panel. “We know how to do it for vessels and turbines but it’s missing in European policy. If other countries do not do it

in the green way they will have a huge advantage.”

“We can’t compete in costs,” said Inghelbrecht. “We still have production in Europe but a big part of the raw materials are not coming out of Europe any more.”

“We have to keep what manufacturing we have here, make more effort strengthening the supply chain and finding partners, getting more information out there and improving trade policies,” said Evdokia Tapoglou.

Supply chain neglect

“Europe is about to kill its own supply chain with high prices,” said David Rapidel, CEO of the French firm O5 Marine, which assists foreign vessels and operators to work in French waters, where offshore wind is on the brink of a major launch. We need to regulate.

“The US has forbidden competition from China with solar panels, for instance, and they have started to rebuild them in the US. In Europe, we are absorbing the overflow from China that used to go to the US. This will happen in every sector.

“We are taking a risk and it will shut down our future. In Europe, they don’t understand what’s behind the high price of energy. It’s about the sovereignty of Europe.”

“It used to be 100% supply production from Europe. Today it looks totally different. Nearly all the raw materials are coming out of Asia,” said Andreas Evertz, CEO of the Flender Group, which makes gearboxes for turbines. “At least, for the first time, we are seeing Europe working together to find solutions. But Europe is not competitive any more. For 10 to 20 years, global supply chains have neglected local capability.

“No matter what we talk about here, everybody is talking about sourcing from Asia.”

Maximillian Schnippering, head of Sustainability with Siemens Gamesa Renewable Energy, summed up: “It’s really about survival now in our industry.”

8 Discussing the Asian threat to Europe’s wind industry: from left, WindEurope chair Casuscelli; Evdokia Tapoglou at the EC; Petra Inghelbrecht, Owens Corning Fibreglass; and Stéphane Tondo with ArcelorMittal

24 | APRIL/MAY 2024 For the latest news and analysis go to www.maritimejournal.com

OFFSHORE RENEWABLES

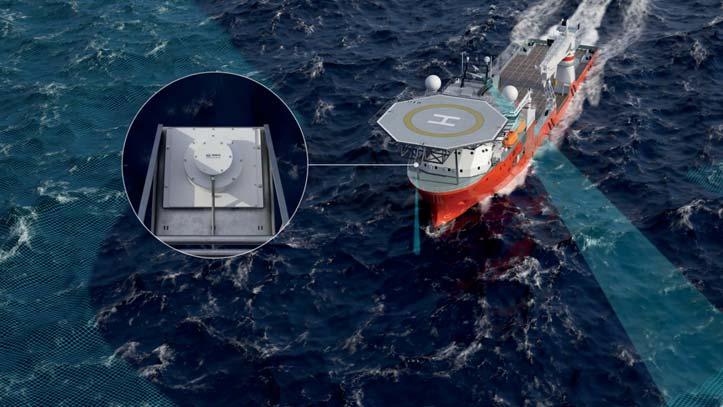

Seatrium Limited is commencing work on its third two gigawatt (GW) High Voltage Direct Current (HVDC) electrical transmission for The Netherlands.

It’s Seatrium’s third system as per its five-year Framework Cooperation Agreement with the companies to supply three HVDC electrical transmission systems for the country’s offshore windfarm projects.

“This project underscores our commitment to helping our customers achieve their renewable energy goals by providing innovative and cost-effective solutions that help accelerate the energy transition,” said Samuel Wong, executive vice president, fixed platforms, Seatrium.

With this latest project, Seatrium is currently working on five HDVC offshore Converter Platforms, creating a franchise for series-built opportunities in HVDCs to achieve greater synergies from project repeatability.”

Offshore grid acceleration

Each HVDC system is valued at €2 billion, with a total combined capacity of 6GW as part of TenneT’s offshore grid acceleration programme. Seatrium’s work will include the engineering, procurement, construction, transport, installation and commissioning of

SEATRIUM HELPS DELIVER DUTCH OFFSHORE WIND GOALS OFFSHORE

the HVDC Offshore Converter Platform.

The platform will contribute to TenneT’s ambition of installing 40GW of offshore wind in the German and Dutch North Seas. It will serve the NWBE (formerly named as Nederwiek 2) offshore wind farm. Like the HVDC projects

awarded to Seatrium in

For the latest news and analysis go to www.maritimejournal.com APRIL/MAY 2024 | 25

8 Seatrium is supplying three HVDC electrical transmission systems for the country’s offshore windfarm projects

RENEWABLES

Atlas Winch and Hoist Services have almost 60 years experience of hiring and selling to industry. So if you need expertise

advice on heavy lifting or pulling,

can help. You’ll also find one of the largest plant hire fleets of its kind in the UK. Atlas specialise in equipment for renewables, marine and offshore applications. Serving the UK, European and International markets. Providing cable pulling equipment, mooring systems, deck and rigging equipment, air, electric, diesel and hydraulic winches to the renewables, oil and gas, marine and offshore industries. If you need a winch, talk to the experts. Talk to Atlas. TRUST ATLAS FOR YOUR MARINE AND OFFSHORE SOLUTIONS RENEWABLES • UTILITIES • CONSTRUCTION • MARINE • ENGINEERING • OIL & GAS HEAVY LIFTING OR PULLING? Head Office: Atlas Winch & Hoist Services Ltd, Old Station Yard, Station Road, Biggar, Scotland ML12 6DQ. Southern Office: Atlas Atlas Winch & Hoist Services (Southern) Ltd, Drakeswell Yard, Duck End, Great Dunmow, Essex CM6 3RY. +44 (0)1899 221577 (Head Office) info@winchhire.com +44 (0)1371 859555 (Southern Office) winchhire.co.uk

March, the Group will work with consortium partner GE Vernova’s Grid Solutions. Source: Seatrium

and

we

US IN COMMERCIAL OFFSHORE WIND FIRST

The completion of America’s first commercial offshore wind farm is expected imminently.

Once final tests are completed in the coming weeks, South Fork Wind in New York state will be providing 132 MW of green electricity to the grid, enough to power more than 70,000 homes and businesses.

“The US offshore wind industry now enters a new phase with its first operational commercial-scale wind farm,” said Liz Burdock, founder and chief executive of Oceantic Network, the member-network dedicated to promoting offshore wind in the US.

“Now the question is no longer if we can, but how fast we can.”