From ploughing through angry seas to reach people in distress to simply patrolling the coastline, Scania Power Solutions deliver engines designed to perform in any situation. Each one has been developed to deliver impressive power and immediate response when they’re needed most. When it has to work, it has to be Scania.

SPEAK TO OUR SCANIA POWER SOLUTIONS

TEAM TODAY – CALL 0845 034 3034

scania.co.uk/powersolutions

44 Ørsted struggles Energy giant cuts OSW targets

46 Scottish build-out Ports will need massive change to cope with new vessels

8 Seawork Preview

Looking ahead to our 25th event

20 Thames upgrade London's artery seeks engineering partner

21 Flood defence Vital works go ahead t0 protect Welsh coast

Sanmar’s electric tugs are leading way to a sustainable future

Sanmar Shipyards’ new generation of groundbreaking ElectRA Series of electric battery powered harbour tugs offer power and performance and unrivalled protection for the environment.

Already operating in some of the most ecosensitive regions on the planet, the emissions-free tugboats are available in a range of sizes (19-28m) and power outputs (30-80 TBP).

The ElectRAs are the result of Sanmar’s ongoing collaboration with Robert Allan Ltd and Corvus Energy to utilise alternative fuels and innovative technological advances to build a sustainable tug and towing industry.

Our picture shows HaiSea Wamis, an exclusive-to-

30 US reaches out Europe exports its expertise

32 Flying focus

The latest in foiling technology

36 Svitzer dropped Maersk de-lists towage division

40 Tug heroes

How three men saved 21 lives and a tanker

46 IKEA offshore Swedish furniture giant applies to build offshore wind farm

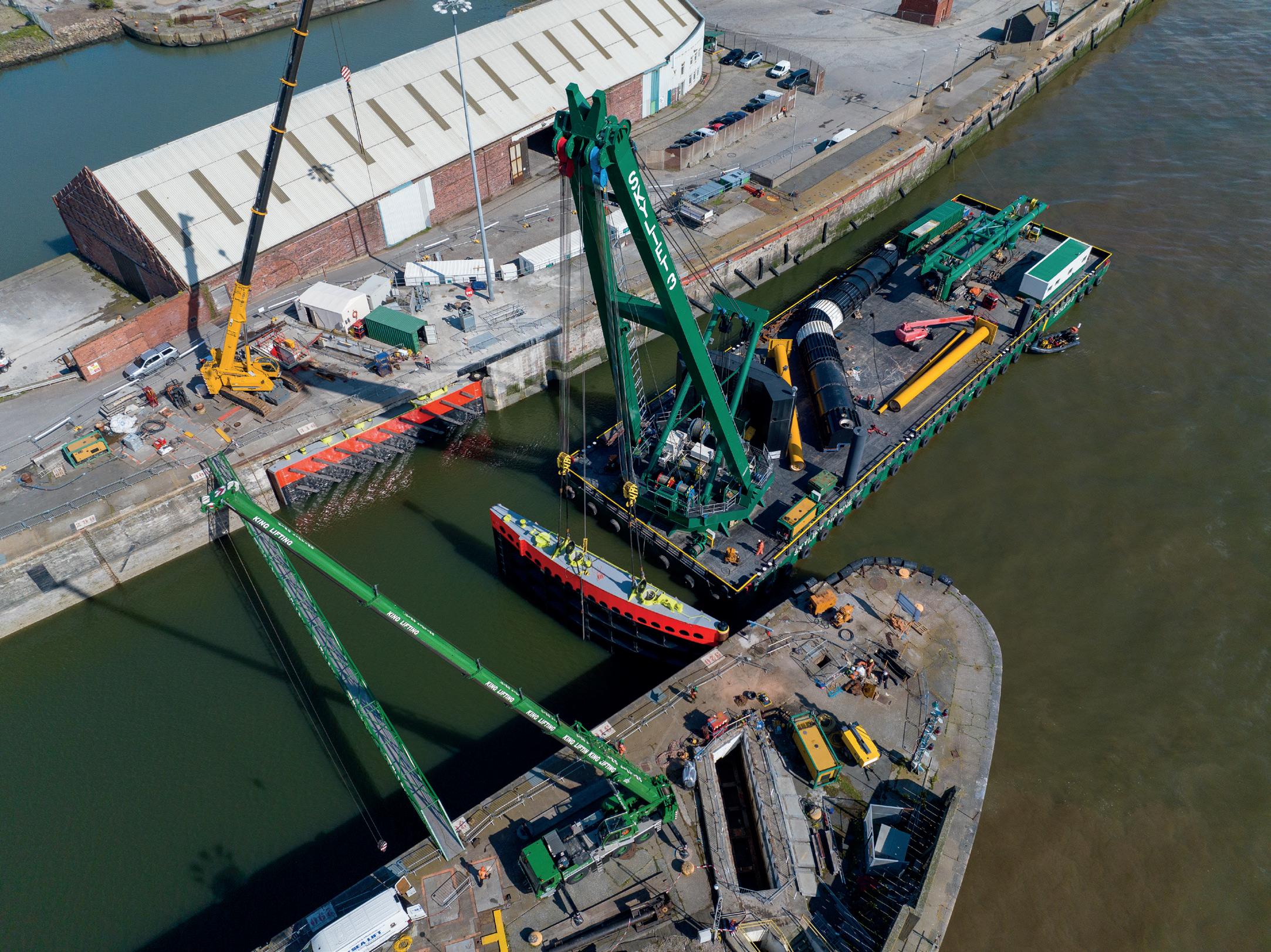

48 JV targets obsolete wind farms

Joint venture prepares for decommissioning

66 EU subsea grid

A major network will connect countries

72 Oceanology 2024

A glimpse of Oi in London in March

Sanmar ElectRA 2800SX design tugboat, which measures 28.4m LOA, with a 13m beam and 5.9m draft. It has 6,000 kWh of battery capacity and can achieve an impressive 70 tonnes of bollard pull; performing all ship-berthing and unberthing missions on battery power alone.

HaiSea Wamis is also exceptionally quiet, both onboard and in terms of underwater radiated noise, further enhancing its green credentials through the protection of both marine and wildlife.

Sanmar Vice Chairman Cem Seven said: “We are delighted with the impact that our ElectRA tugs have made, and extremely proud to be leading our industry to a sustainable future where protecting the planet is central to everything we do.”

n For further enquiries: www.sanmar.com/tr/

Scotland based OEG has bought the Dutch offshore services firm Marine Coordination Services, its 12th acquisition since it embarked on its offshore renewables voyage in 2000. MSC will be part of the group's renewables division, expanding OEG’s marine capabilities and opening new market opportunities to the European offshore wind sector, says OEG, which can now provide topside, subsea and marine services to the offshore renewables sector.

Rockabill Marine Design will draw up a 14m crew transfer vessel for Irish Commercial Charter Boats.The custommade vessel will be able to carry 12 passengers and one tonne of deck cargo to fulfil contracts in Irish and UK waters. “This new vessel not only enhances our fleet but also enables ICCB to excel in the competitive market of commercial charter services,” said Eoin Grimes, owner of ICCB.

Plans to build a tunnel at the Port of Helsinki could cost another €130 million and take 10 more years because of a flying squirrel population in a park where the tunnel entrance would be in a cheaper, shorter route. Oil caverns would need to be decommissioned, which is currently prohibited, for route D, so that the animals were not affected. The port dealt with 15.2 million tonnes of goods in 2022, a record, the ports said.

Scottish ports are in line for massive infrastructure changes to cater for the amount of offshore wind farms in the pipeline for the North Sea.

In total, 38 projects with a potential capital value of £6.5 billion (€7.5 billion) have completed Stage One of a so-called Strategic Investment Model (SIM) process, which the SIM Working Group is supporting by facilitating discussions between project developers and the ports that need to be upgraded.

SIM is a group of offshore wind developers, the Scottish government, enterprise agencies

and Crown Estate Scotland.

“It takes 10 years to build an offshore wind farm,” said Maf Smith, of Lumen Energy & Environment, one of the companies providing support.

“So far the focus has been on

the east of England. Coming down the pipeline is going to be Scotland, particularly in floating wind. We’ve seen ports being built out but not at the scale we need for this. It’s a quantum challenge to keep up.”

The Icelandic Association for Search and Rescue (ICE-SAR) has formed a commercial partnership with Hefring Marine to increase its fleet safety and operational efficiency.

This collaboration aims to equip all new vessels in the ICE-SAR fleet with Hefring Marine’s Intelligent Marine Assistance System (IMAS), promising significant advancements in safety and operational efficiency.

“This partnership with Hefring Marine marks a pivotal moment in our continuous effort to advance the capabilities of our crew and fleet,” said Björn Jóhann Gunnarsson, Maritime SAR Project Manager at ICE-SAR.

The integration of Hefring Marine’s innovative technology aligns with our commitment to safety and efficiency, ensuring our crews are supported by the best tools available as they perform their critical missions in the tough conditions they are often forced to encounter.”

Real-time testing

The decision to integrate Hefring Marine’s IMAS systems across the fleet follows a successful pilot project on the rescue vessel Þór in Vestmannaeyjar.

Hefring Marine’s IMAS focuses on optimising vessel performance, reducing fuel consumption, enhancing vessel life cycle and minimising environmental impact, thereby aligning with global sustainability goals.

”This partnership embodies our dedication to leveraging our data-driven technology to improve operational efficiency and more importantly, to significantly elevate safety standards at sea,” said Hefring CEO Karl Birgir Björnsson.

Three firms have formed an alliance to look at fuel options – in particular methanol – for offshore vessels.

US-based Caterpillar Marine has signed a Memorandum of Understanding with Norwaybased Solstad Offshore, one of the biggest offshore support operators in the world, and Pon Power, the Norway-based distributor of Caterpillar products

The MoU sets out plans to ‘identify and evaluate solutions

that will increase the fuel efficiency of Solstad’s offshore vessels and reduce their greenhouse gas emissions'.

The three have close working partnerships, with 50% of Solstad’s fleet powered by Cat engines.

Pon Power has worked closely with Solstad for 35 years.

“We’re committed to supporting our customers’ climate-related objectives through methanol-powered solutions,” said Brad Johnson,

vice president and general manager of Caterpillar Marine. “These solutions are fuelefficient, cost-effective and meet our fuel standards."

Becoming the most sustainable shipbuilder means promoting environmental responsibility in all that we do. It means improving the processes by which we build our vessels; making them cleaner, more efficient. It means addressing the performance of our ships; reducing their noise and emissions and lowering their fuel consumption. It also means providing you with solutions to support the responsible, renewable production of our energy - safely, sustainably, reliably and with optimal efficiency.

Schottel MD takes on Elkon

Schottel sister company Elkon has appointed a new managing director –the same MD as Schottel Turkey. Seçkin Uz will use various synergies between propulsion specialist Schottel and Elkon, an electrical system integrator of electrical propulsion technology, electrical systems and automation for the maritime industry for more than 40 years. He aims to strengthen Elkon’s international growth and business development in the global industry, the company says.

Dutch shipbuilder Royal Bodewas is the latest firm to join the Maritime Battery Forum, an organisation comprising more than 75 members in three continents that facilitates discussions about battery technology and solutions in the shipping sector. Royal Bodewas is working on a range of vessels from hybridpowered ships to selfdischarging methanol-ready cement carriers at its three shipyards in the northern Netherlands, the forum says.

The Ports of Jersey’s expanding vessel fleet has welcomed its first workboat, the Eurocarrier 2611 Viking Energy. The largest of the Channel Islands, Jersey is dependent on its connections to the outside world by air and sea. Maintaining the port and outlying harbours requires multi-purpose tug/workboat type vessels and its fleet has grown to satisfy these demands, now numbering four also put to profitable use in markets beyond the confines of the Channel Islands.

Danish energy giant Ørsted has slashed its 2030 offshore wind target of 50GW by around a quarter to 35-38GW.

Chairman Thomas Thune Andersen will step down at the AGM on March 5, and ‘to become a leaner and more efficient organisation’, the company will cut 600-800 jobs around the world.

It has announced plans to exit other offshore markets, including Norway, Spain and Portugal, and will be ‘de-prioritising development activities in Japan’ and ‘planning for a leaner development within floating offshore wind and P2X’ (electricity conversion, energy storage and reconversion pathways from

Port authorities and emergency services have responded to minimise damage to the environment following the sinking of an inland barge in the Port of Hamburg, media outlets have reported.

The inland barge Alster was moored alongside the Kalikai terminal in Hamburg overnight. Two crew members on the 80m vessel managed to get on to the quay before the barge sank while still alongside around an hour after it started listing.

Alster was moored at a busy terminal that handles potash fertiliser and salt products, and was carrying around 3,500 litres of diesel.

surplus renewable energy).

As a result of the review, Ørsted now believes that it has a more robust portfolio of projects, and it has refocused its offshore strategy for the US. The portfolio

changes will result in approx. DKK3 billion (€402 million) of development expenditure reductions in 2024-2026 compared to the numbers presented at the Capital Markets Day in June 2023.”

“In order to improve our competitiveness, ensure value creation, and ensure our ability to attract capital to the renewable build-out, we will make Ørsted a leaner and more efficient company,” said Mads Nipper, group president and CEO. “This will include reducing the number of positions across the company. We are committed to carrying this through in a fair and respectful manner.”

Local media reported around 40 shore-based firefighters responded to the incident along with emergency response vessels from Hamburg Port Authority, and while initially the risk of damage to the environment from the vessel’s cargo was unclear, the fuel oil on board obviously presented an environmental risk.

A containment boom was deployed around the vessel with a spokeswoman for the environmental authority reported as saying: “Diesel spilled into the

water. Around 5,000 square metres of water were contaminated, there are now 350m of solid barriers designed to prevent further expansion of the contamination.”

Pollution prevention measures also included absorbent ‘sponges’ to contain pollution, although it was also reported that an oil film had formed outside the containment boom.

Attention later turned to salvaging the vessel with the port authority, the vessel’s owner and specialist salvage contractors.

Multimarine Services Ltd and the Columbia Group have sign a Memorandum of Agreement to explore and identify collaborative projects they can work on in the maritime and energy sectors.

The companies will work together to explore specialised engineering and technical support services, ship repair and shipyard services, opportunities and collaboration in the superyacht industry, decarbonisation initiatives and ship/yacht newbuilding and conversion projects.

“At Multimarine we strongly

believe in joining forces with like-minded organisations and we see that cooperation with Columbia will create several added value opportunities,” said Pavlos Phokas, commercial director of Multimarine Services.

Multimarine Services is a diverse group of companies that includes leaders in providing shipyard, engineering, fabrication, construction, heavy lifting and integrated logistics services in the Mediterranean.

n Mr Phokas said that both companies will combine their extensive expertise from the maritime and energy industries

As Seawork prepares to host its 25th show on June 11-13, its 25th edition, the show organisers are emphasising its growing international flavour.

One of the most popular events in the diary at Seawork is the awards evening (Tuesday 11 June), which recognises the innovators and most outstanding movers shaping our industry.

More than a quarter of last year’s exhibitors to the show, which runs alongside the Marine Civils event, were from overseas, with 20% from Europe and the rest from other corners of the globe. To reflect the growing number of overseas friends and competitors booking stands or registering attendance, Seawork will be welcoming National Pavilions this year.

One of these is a 25m2 stand booked by Netherlands Marine Technology, which has already confirmed a number of companies who will exhibit in its Dutch pavilion. So far they include EST-Floattech, VDL Klima, Bachmann, Bayards Marine Structures, Rotterdam Ship Repair, VABO Composites, Next Generation Shipyards and Royal Roos.

Netherlands Marine Technology ‘ensures facilitated participation, extra publicity and additional networking opportunities’, it says.

Another is the 36m2 Italian Pavilion organised by Confindustria Nautica, the Italian Marine Industry Association, a national non-profit institution that has been representing the Italian yachting supply chain on a national and international level since 1967. The Italian pavilion will host the following exhibitors: ABI Trailers (heavy transport equipment - trailers); F.Lli Razeto & Casareto (boat door accessories, handles, locks and on-board hardware); Gianneschi (marine pumps and blowers); Veleria San Giorgio (lifejackets and safety equipment).

Meet the UK Government Seawork provides the ideal opportunity to talk to the influencers and policy-makers at the heart of national government.

Multiple departments, such as the National Shipbuilding Office (NSO), Ministry of Defence (MOD) and Department for Business and Trade (DBT), will be out in force, as well as taking part in a full programme of sessions.

The UK government will have its own Government Zone for anyone to drop by at any time, and for exhibitors it’s even better, as they have access to the online exhibitor manual and can arrange one-to-one meetings with any of these departments.

Talk to them about supply chain issues; how to drive international competitiveness; how they encourage innovation; improve productivity; and all sorts of other topics at the top of the commercial marine agenda.

Also on tap will be UK Export Finance, the government’s Export Credit Agency, which works with more than 100 private credit insurers and lenders to help UK companies access export finance, such as the recently launched Shipbuilding Credit Guarantee Scheme.

Split into two main categories – the European Commercial Marine Awards (ECMAs) and Innovations Showcase – judges will shortlist the main contenders and present prizes at the ceremony on the first evening, with bubbles to go with them.

Last year’s ECMA winners were:

n Maritime Sustainability: Windcat, for a retrofittable hydrogen system

n Marine Civils: Teignmouth Maritime Services, for complicated deepening work

n Young Person’s Development: Seren Nix, for showing ‘enormous commitment’

n Maritime Professional: Jason Parker, of Farra Marine, ‘championing his crew’

n Lifetime Achievement: UK Harbour Masters’ Association

2023 Innovation Award winners:

n Frog Environmental - Bubble tubing for coastal sound attenuation

n HST Marine - HST Frances

n ePropulsion - I-series electrical inboard

n Dacoma – AirKeel

n Searchmaster - SL680 searchlight

*Overall winners of the Spirit of Innovation Award were Searchmaster, for their life-saving SL680 search light.

in partnership with

Held on the Isle of Wight on June 10, the day before the exhibition opens in Southampton, fast boat owners and designers get the chance to put their vessels on the water and provide delegates with a sea trial operating at optimum speeds.

As well as the boats, guests will enjoy breakfast on the ferry from Southampton to the Royal Ocean Racing Club at Cowes, with presentations and networking opportunities. There are also exhibiting opportunities available at the club.

It’s a full day of fast workboat demonstrations and sea trials, lunch is provided at the club and the return journey is laid on back to Southampton with the usual refreshments and more chances to see the exhibiting vessels in action.

A few slots are still available for owners wanting to enter their vessel in the trials, and all booking information is on the website www.seawork.com/aboutspeed. Get in touch with the sales team on +44 1329 825 335, sales@seawork.com.

2024 is the 200th anniversary of the Royal National Lifeboat Institution, and the occasion will be marked with a service of thanksgiving at London’s Westminster Abbey in March.

Since its founding in 1824, the RNLI has saved at least 144,000 lives – whether in the wooden, oar-propelled boats of two centuries ago, or in today’s motor-powered all-weather vessels of today.

The first purpose-built lifeboat was built in 1790 by Henry Greathead from South Shields. The oldest surviving vessel of this original type, the Zetland, is still in a museum and is reckoned to have saved about 500 lives.

But it was Sir William Hillary, a British militia officer and author, who founded the RNLI on the Isle of Man in 1824 after witnessing many shipwrecks, including the wreck of HMS Racehorse two years earlier.

He eventually won enough support to found the institution, backed by King George IV and then prime minister Robert Jenkinson.

The RNLI awarded its first gold medal in 1824 to Charles Fremantle, who swam to reach crew on a stranded ship off the coast of Dorset.

Gold, silver and bronze medals are still awarded for particular acts of bravery.

In 1838, a silver one was awarded to the

famous Grace Darling and her father, who used their fishing boat to save nine survivors of the shipwrecked steamship Forfarshire on the rocks that grounded their vessel.

It wasn’t for another 30 years that life jackets appeared and were handed to RNLI

volunteers. The first ones were cork, invented by RNLI inspector Captain Ward.

The first motorised lifeboat, the McConnell Hussey, was launched at Tynemouth Lifeboat Station in 1905, opening the service to many more volunteers.

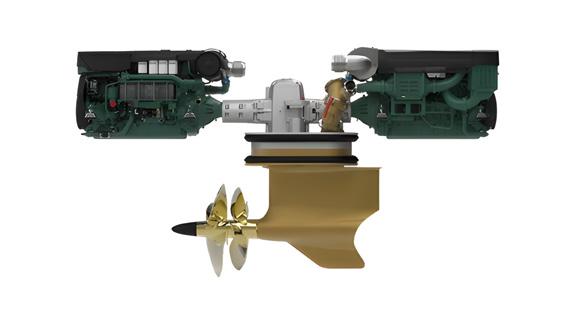

When the first of Northern Offshore Services’ new 34m CTVs hits the water later this year, it will also be demonstrating Volvo Penta’s latest technology.

“Both I-Class vessels that we currently have in production are being fitted with the Volvo Penta IPS Professional Platform,” says N-O-S CEO David Kristensson.

The reason is straightforward but noteworthy: while ‘integration’ has long been Volvo Penta’s buzzword, the new platform promises to tie together a range of energy sources. This in turn has the potential to lift Volvo Penta’s offering into the larger commercial sphere.

Put simply, it works by enabling and managing multiple power inputs to cover everything from clean running combustion engines to hybrid and battery solutions.

In fact, the I-Class design is Swedish fleet owner N-O-S’ first fully electric-ready CTV – which means Volvo Penta’s platform allows the vessels the ability to operate in part or fully electrical mode during transit and docking manoeuvres.

“The N-O-S vessels have two propulsion units - IPS 40 drives - and four combustion engines; two per drive,” says Jan-Willem Vissers, Volvo Penta’s commercial marine director. These CTVs will initially aim at operating on lowemission fuel, but changing the mix is fairly straightforward.

“The engines can be upgraded or replaced by electric motors in the future,” he says.

According to Volvo Penta, the technology should also yield fuel savings of up to 30%.

This is largely supported by the platform’s Eco Mode, which bases the ship’s energy use on real-time requirements, raising efficiency by reducing fuel consumption across a large swathe of the drive cycle.

Altogether, it makes a very appealing choice for CTVs with their typically broad operating profile.

“It’s a flexible engine configuration that only draws the power it needs and adapts to whatever situation it’s in,” says Kristensson.

Cockpit features

Although the onboard management is capable of automatically starting and stopping individual engines or energy feeds, the helm is still able to keep an eye on it through the company’s ‘Glass Cockpit’, which provides a full overview and control of engine data, navigation and so on.

Smart features such as Assisted Docking and Dynamic Positioning are also tied into the display, while beyond the bridge, predictive maintenance, remote diagnostics and remote software downloads all contribute to increased uptime.

The IPS Professional Platform is far from a leap in the dark.

Rather, each element has a solid precedent behind it: for example, integration originally stems from the company’s Electronic Vessel Control technology; the Glass Cockpit and ancillary features emerged a while ago; and the IPS 40 drives come from Volvo Penta’s established line of quiet, lowvibration propulsion systems.

The new dual-input on these new IPS units have allowed the company to push the power up into the useful range for the commercial workboat market. It’s also worth noting that the platform, suitable for vessels 55m and over, can also

handle triple or even quad drivelines, potentially yielding up to 8,000hp/5,880kW.

It may be less dramatic, but the IPS 40 drive has another useful characteristic: like its forbears it’s rather more compact than traditional inboard shaft installations.

Taking advantage of a position far to the rear of the vessel can also mean freeing up much needed internal volume further forward, while dropping vibration and noise levels where it matters.

It’s a package that seems especially suited to N-O-S’ bigger, longer endurance CTVs: the 34m, 11.20m beam I-Class allows a large 131m2 forward deck with an extra 40m2 at the rear, and there’s also room for 32 seats onboard.

The service company has kept innovation central: Kristensson believes it’s key to meeting the evolving energy requirements as well as improving the onboard experience.

These two elements go hand in hand.

“CTVs benefit from new technologies that make the work more efficient and more precise, which in turn could make operations easier, safer and more comfortable for crew and technicians,” he says. “They also hold the potential for more sustainable operations, which is a priority.”

There’s little doubt that giving CTVs the ability to make use of new energy sources will be crucial for the industry’s growth and sustainability in the potentially demanding years ahead.

Seawork exhibitor and engine builder Barrus has formed a new company with Hybrid Marine to focus on hybrid engines for marine.

Hybrid Marine International will be headed up by Graham Knox, CEO of Barrus, who was only appointed in September 2023, working closely with Graeme Hawksley, engineer at Hybrid Marine.

The two firms have been working together for nearly 14 years, said Karen Clarke, in the marketing department at Barrus, so the joint venture was a natural step.

“We created a new company because we have been bursting at the seams with enquiries,” she said. “This was the natural step in being able to cope with the increased demand, which is coming from all over ther place.

“Boat builders were initially a bit sceptical about all of this but now they are being asked themselves about hybrid systems so they can see the potential. We are trying to position ourselves as being able to offer all types of propulsion, whether it be the conventional ones or new low emissions types.

“We have had a relationship with Graeme for nearly 14 years and with our own brand we’ve also been exploring electric versions as well.”

The two firms have been developing propulsion systems based on Yanmar diesel engines, which they consider ‘a global standard’ in sailboat and small craft propulsion.

“Hybrid Marine International has been

established to design, manufacture and sell hybrid propulsion systems for applications including inland canal boats, commercial barges and sailing boats,” said Graham Knox, “The joint venture cements our successful collaboration thus far, and we look forward to working together to unlock the potential of our combined expertise.”

“When we first started investigating marine hybrids, the market for these systems did not exist,” said Graeme Hawksley. “Apart from a few early adopters, hybrids were viewed as blue sky products, something for the future rather than now. Finally, in 2024, ‘the future is now’.

“Our next stage on the journey is to scale up to meet the demand we have helped to generate.

Hybrid Marine International will continue to provide custom packages to OEM boat builders in the UK and across the world who wish to offer hybrid technology to their customers requiring new boat builds in the leisure and commercial markets.”

Seawork exhibitor Brunvoll has signed a number of contracts with Vard for its ducted azimuth propulsion thrusters, retractable azimuth thrusters, and tunnel thrusters.

All contracts are for vessels in the offshore wind sector and include new customer Toyo Construction, for whom Vard is building a cable-laying vessel that will be propelled by the thrusters and use Brunvoll’s control system for propulsion and manoeuvring, its BruCon PTC (Propulsion & Thruster Control). This was launched last year, with new hardware and software to make the system more modular and modern and improve its cyver security,” said Sivert Olsvik Sæther, technical marketing engineer and naval architect with Brunvoll.

Toyo Construction is a Japanese general construction company that has a focus on offshore work, including container terminals and marine airports.

“This is important to us because it is for a new customer, it is a large delivery and Toyo is looking to expand its business in Japan,” said Sæther. By 2030, Japan aims to have 10GW installed.

The cable-laying vessel will be 150m long with a 28m beam and cable capacity of 9,000 tons. It is scheduled to be commissioned in the first half of 2026.

Other orders

Maritime Journal in November reported on the two CSOVs ordered by Windward Offshore, a consortium set up to expand offshore wind services, and for these designer Vard again selected Brunvioll’s propulsion systems.

A further two vessels could also be ordered in the coming years. Another two CSOVs were ordered by Purus Wind in May, with a similar theme – designed by Vard, who selected Brunvoll’s thrusters.

“Offshore wind is the theme here, as you can see,” said Sæther. CSOVs and SOVs work in close proximity to offshore structures and windmills. Brunvoll’s ducted azimuth propulsion thrusters have been improved to meet the increasingly stricter requirements for rapid, safe, and accurate DP operations for them.

“This includes significantly improved azimuth rotation speed, increased propeller acceleration/deceleration, and arrangements for increased thrust efficiency in terms of reduced thruster and hull interaction. These operations are rough on our equipment and there has been a lot of emphasis on limiting wear and tear and increasing the power efficiency.”

“We are humbled and proud of the cooperation we have had with Vard as their trusted partner for these newbuilds, and hopefully many more to come,” said Kåre Øyvind Vassdal, Group CEO at Brunvoll.

“The offshore wind market has become an important segment for Brunvoll, and these projects include state-ofthe-art propulsion systems developed in the last few years.

“In addition to the efforts in product development, we also put significant efforts into our integrated value chain to ensure efficient production of the systems from our factory in Norway. With a combination of these additional orders to our orderbook, we can already see a good use of our factories in 2024 and into 2025, which has led us to invest a large amount in new production technology to increase our capacity.”

Seawork exhibitor ePropulsion has launched what it is calling a ‘revolutionary, ground-breaking’ electric outboard.

The eLite has nominal power of 500W and 750W in boost mode.

Created for the smaller boating market, the direct drive motor and propeller operate in near silence, the company says.

It also has a new compact and lightweight design that weighs just 6.7kg and is just 297 x 75 x 890mm in size.

ePropulsion says the eLite has an easy-grip twist grab handle, controlling forward, reverse and power output.

It also has a full digital control and display with information on the battery and power output as well as system status and alerts.

“We are excited to start the year by introducing the eLite electric outboard motor, a game-changer in marine propulsion,” said co-founder and CEO Danny Tao. “We believe the eLite will redefine the eco boating experience for enthusiasts worldwide.”

The company says the motor is an entry-level product in ePropulsion’s electric outboard portfolio, and sells for just over €1000.

Small and smart, Starlink delivers super-fast broadband across the oceans. And now you can try it out for FREE on a month’s trial. Just call and register your interest.

Charity & Taylor provides the equipment free if you sign up for a month’s trial. All you have to pay is for the airtime you consume in the trial, such as 50GB at £247/mth.

Check out all the benefits your business will get by installing Starlink. It’s not just the important commercial activities of your business, there are significant benefits for crew welfare and retention.

We can provide smart management systems for usage, user costing, identification and billing.

Starlink Maritime equips your business communications with fast, reliable broadband.

It can also give your crew face-to-face connections to friends and families back home. Social media, film and TV streaming as well as much else that’s available ashore. Including, connections such as mobile phones, tablets, TV, laptops and almost anything using broadband.

Reliable,

Starlink’s Maritime services provide global coverage from a low orbit satellite network. Minimal signal latency means super-fast broadband speeds. The antenna has no moving parts. It is a small, square flat device, which faces skyward. It’s easy to install and connects to a router to feed your internet devices via your hardwire network and WiFi.

Will fast broadband enhance your ship’s business communications? And could it help with crew retention? It can do both.

Our Starlink offers start below £3000 and competitive lease purchase (APR 9.5%) is available over 36 months starting at just £152 a month, which includes our remote access support plan for remote diagnostics and support. You will own the product after 36 months. Try it and get the business benefits of super- fast broadband.

For business and pleasure we are sure your crews will not want go to sea without it.

To take advantage of Charity & Taylor’s 1-month FREE trial, call the C&T Team on: +44(0)1493 804731 or +44(0)7990 576734 or email: salesenquiries@charityandtaylor.com quoting FREE TRIAL

Seawork exhibitor Rotec Hydraulics has announced a new agreement to collaborate on marine repair services at A&P’s Cornish facility.

Rotec specialises in hydraulic, pneumatic and electrical mechanical components and systems for the marine sector and it will now base a service centre at the facility, which has three large graving docks and deep-water berthing.

Rotec’s new service centre will be dedicated to electro-mechanical repairs and servicing as well as supplying hose assemblies and hydraulic maintenance.

The new workshop can offer clients services including breakdown fault diagnostics, electrical installation, AC and DC motor repairs, pump, gearbox, generator and alternator repairs, laser alignment, dynamic balancing and hose assemblies, Rotec says.

“We are delighted to announce our new collaboration with A&P in Cornwall,” said Rotec managing director Paul Prouse. “Already a valued customer, we were keen to respond to their needs and to all those in the surrounding Cornish area.

“By adding a new electrical mechanical services workshop and hydraulics service centre to our company’s portfolio we will be strengthening the breadth of support we are

able to provide to the marine industry and provide customer service to our clients, and A&P’s customers in turn.”

A&P has three facilities, two in the northeast of England and the Cornish one, in Falmouth, which boasts one of the world’s deepest harbours.

Clever Marine Services Ltd

Gob-E-Volley Depot

Main Road, Sulby IM7 2HR Isle of Man

SCOPE OF SERVICES OFFERED:

Repair, Overhaul, Reconditioning & Supply of OEM Spares for Diesel Engines CAT (incl. diagnostic), MAN, Yanmar, Deutz, MAK and many more...

UK distributor for GreenOil Standard

Supply of Welders, Rope Access Personnel (multi-qualified) & NTD Services

It carries out repairs in the commercial marine, oil and gas, offshore renewables, nuclear, defence and fabrication sectors, as well as marine construction and port operations.

clevermarine@clevermarine.com

www.clvermarine.com

Ultrasonic Thickness Measurement Approved by DNV-GL, ABS, BV, NKK & RINA.

Overhaul & Maintenance of Marine Thruster Systems Brunvoll, Rolls-Royce, Wartsila, Kawasaki & ABB/Zamech

Distributor for Sound Steel Aquajet Blasters & Magnetic Hatch Cover Seals

365 days a year 24/7 same service rates charged Teams & Personnel dispatched from Poland

Workshop facilities available in Poland, Germany and the Isle of Man

Direct contact to Korean, Chinese and European OEM’s

The Cloud Towing Tank (CTT) team is bringing a service reserved for big ship companies to the workboat sector: a systematic approach to lowering a vessel’s water resistance.

“Normally, hull development is half science, half art,” says naval architect Inno Gatin. But in CTT’s case, its most recently developed service brings together CFD (computational fluid dynamics) and parametric shape optimisation. In short, it promises to take the initial hull design and tweak it for hydrodynamic efficiency.

“We find the best form in terms of fuel consumption,” says Gatin, so rather than taking iterative steps, CTT’s software will take the concept and develop a handful of practical variations.

This is not new.

“There are very good tools on the market serving ship design offices but it’s too expensive for smaller vessels and one-off projects,” he says. “If you’re designing for one or two boats, maybe crew transport, a tug, dredger or a fire-fighting vessel, then the budget doesn’t usually allow running a proper hydrodynamic optimisation study.”

‘‘

Our optimisation of the hull achieved a 4.5% resistance

reduction: it showed that the approach makes sense as you can get a meaningful improvement for relatively little effort

While not identical to these bigger software systems, CTT’s is a very-cost effective option: “We cannot explore as many variants as the full service, but we can get 80% of the effect for about a quarter of the typical market price,” says Gatin. It appears to be a worthwhile pursuit. In-house R&D studies on a 40-metre semi-displacement vessel, typical of fast patrol or search and rescue missions, has been convincing enough to be published in a white paper (available on CTT’s website).

“Our optimisation of the hull achieved a 4.5% resistance reduction: it showed that the approach makes sense as you can get a meaningful improvement for relatively little effort,” he says.

The company’s research also demonstrated that their work could turn up some surprising, non-intuitive outcomes. For example, variations on transom width for this particular hull form didn’t yield the expected efficiencies in the required speed range. Yet transom depth did make a substantial difference, demonstrating the value of an unforeseen departure from the predictable.

Bring these elements together and it appears CTT’s services could prove very useful for the workboat segment. It’s especially timely now that the drive for alternative fuels, hybrids and electric running means hull efficiency is inexorably rising up the agenda.

Zodiac Milpro, a global leader in the design and manufacture of military and professional craft, has received an order from the UK Ministry of Defence for twenty-four Intercept and Escort Craft (IEC) for the UK MoD Police.

The IEC design is based on Zodiac Milpro’s proven SRA range of aluminium Rigid Inflatable Boats (RIBs) designed by Vectis Marine Design, the group’s specialist naval architecture and design consultancy.

More than 200 of the Zodiac Milpro SRA RIBs are in service with professional organisations worldwide.

The standard SRA 800 design has been

adapted to meet the specific requirements of the MoD Police and will be used for patrol, escort, and security duties in UK naval bases.

David Bartholomew, managing director of Zodiac Milpro UK, said, “We are delighted to have been selected by the UK Ministry of Defence to deliver the Intercept and Escort Craft to the UK MoD Police. This important success follows other recent projects to supply Zodiac Milpro boats to the UK MoD and strengthens our position as a leading provider of military and professional boats within the UK.”

Zodiac Milpro designs and manufactures vessels to meet demanding operational requirements and has facilities in the UK, Europe, North America and Australia.

Shipbuilder Tor Group is preparing for the introduction of its hybrid utility vessel Tor Boreas, a compact yet feature-packed multi-purpose vessel where adaptability will make the design attractive for a wide variety of duties.

While closely associated with tugs, utility vessels and workboats take the idea of a ‘working vessel’ to a different level providing a wide range of capabilities to satisfy an equally wide range of requirements.

Workboats are typically represented by pontoon-shaped ‘multi cat’ type vessels, series-built mainly by a handful of European-based shipbuilders and designers. But UK-based Tor Group’s new utility vessel employs a more conventional hull form while still offering capabilities to provide a range of support services.

Tor Boreas is being built to a design from Aberdeenshirebased MacDuff Ship Design and is currently under construction for Tor Group in Turkey.

“The vessel is currently undergoing outfitting – pipework, blasting and painting – and we are still looking at a Q2 launch,” Stephen Talbot, head of Operations at Tor Group, told MJ. “The vessel is available for sale or for charter.”

Renderings of the vessel indicate a conventional profile similar to a tug with two high decks, forecastle and bridge deck above the main deck, providing notable protection for the main deck work area aft with space for various deck machinery provisions.

The forecastle deck also provides weather protection from high bulwarks apart from a lower section forward, where personnel access provision over the bow is indicated.

Basic functions for Tor Boreas include dive support and offshore services, lifting, utility, berthing and towing. The Bureau Veritas-class vessel carries the notation: BV1 HULL, MACH, Wind Farm Service Ship – M2 Tug standardised bollard pull 15 tons, Unrestricted Navigation, AUT-UMS, DYNAPOS AM/AT. Main particulars include a length overall of 26.95m on a breadth of 11m and maximum draught 2.9m.

Looking into the machinery space, the diesel/electric arrangement comprises three MAN D2676 main generators each developing 340ekW, 400V, 50Hz and supplying power to two Schottel SRP 210 FP azimuth thrusters, making the overall vessel configuration an ASD design.

A Baudouin 4W105 ES, 76ekW, 400V harbour generator is included and manoeuvrability is enhanced via a Veth VT-90, 99kW bow thruster. Duties could include supplying compressed air and two 1.5kW, 10bar air compressors are included along with a 25m3/hr emergency fire pump.

Deck machinery for such vessels is all-important and Tor Boreas is adequately equipped in this regard.

A four-point mooring system is included, comprising four 1,000kg Delta Flipper anchors each connected by 600m of 20mm diameter wire rope to four electrically driven, deck and bridge controlled winches.

Band brake holding load for each is 25 tons with tension, length and speed monitoring systems included.

Conventional towing duties are provided by an electrically driven, single-drum towing winch aft, again controlled from

the deck or bridge. It has capacity for 600m of 34mm steel wire with a nominal pull of 25 tons (first layer) and a monitoring system similar to the anchor/mooring winches.

A hydraulically driven, local and remotely controlled offshore crane is included in the deck machinery list with a maximum outreach of 12.7m and maximum lifting capacity of 13,000kg at 4m (sea state 3). A moonpool is also included and finally a hydraulic 5000kg at 3m maximum capacity A-frame and 30 ton SWL stern roller are provided.

The wheelhouse has conventional split consoles and a seating area together with an extensive communication and navigation fit including DP1 system. Accommodation on Tor Boreas comprises two single-berth and eight double-berth crew cabins, all en-suite with additional provision for 12 passengers.

Tor Group has an interesting history, its origins dating back to the 1880s when Mustafa “the carpenter” Torlak started manufacturing wooden boats in the Rize Province of the Eastern Black Sea region.

It became part of the newly established Republic of Türkiye in the 1920s and from these origins as a small family business, Tor Group is now headquartered in the UK, has a brand new shipbuilding facility in Istanbul and a global network of partner yards.

The current reference list dates from 1974 with nearly 100 vessels up to 23,000dwt listed as delivered, covering a wide spectrum including container vessels; bulk carriers, general cargo vessels; chemical and product tankers; oil recovery vessels; tugs and workboats; pilot and patrol boats; and finally, yachts. The main focus is now tugs and workboats.

New exhibitor to Seawork JEL Products, which specialises in industrial lighting, will showcase its fully stainless steel housing for LEDs that it says are a first for the market.

Lucas de Graaf and his father Jaap de Graaf co-own the company exactly 50/50, Lucas in the role of chief technical officer, Jaap as CEO. JEL Products is the European importer of products made by DCbright, which makes the world’s brightest and most efficient LED lighting products for industrial, offshore, construction, mining and automotive applications.

DCbright currently has set up distribution networks in Europe, Australia and Asia, while the designing offices are located in Europe and Australia and the production base is in China.

Speaking to Maritime Journal, de Graaf Jnr said a company that has now been sold used to exhibit at Seawork and recommended it to him.

“We need to get more exposure, so we decided to take a stand,” de Graaf said. “Our background was the heavy-lifting industry and we have sold our products to the big companies, like Boskalis and Damen, and now we are keen to move more into offshore wind. We started with crane ships and supply vessels, and now are moving into the wind farms themselves.

“What we discovered during the production process of our lighting was how to get the right heat distribution so that we could make the housing entirely from stainless steel, which is a first for the market.”

DCbright has two facilities: one in the Netherlands and one in Shanghai, where it is better placed to supply the Australian market.

De Graaf says the company is focusing on ‘solving the problems at hand’ in Europe, China and Australia rather than moving too fast into other areas of the globe, although they do plan a trip to North America later this year.

• JEL Products will be exhibiting at Seawork with DCbright on stand E36

Naval architects at Darley H2NA have been working to make inland waterways - and those who work on them - safe.

“We seem to have cornered the inland waterway market,” says Ian Darley of naval architects Darley H2NA, a longterm Seawork exhibitor.

However, this wasn’t a game plan: it’s come from an overarching concern for safety, especially around civil works.

“The issue is that there’s no regulation for working craft. So if you ask ‘what’s a good enough standard?’ there’s nothing you can apply,” says Darley’s colleague, Phil Henderson.

It’s a problem because there are a lot of people working on inland waterways with no consistent guidance – and there have been accidents.

“Some construction engineers assume they can do the same on water as on land,” says Darley. “While a crane might physically fit a barge we have to point out that stability demands a pontoon that’s an awful lot larger.”

Hopefully this loophole is about to close, but the transition isn’t happening merely because it’s a good idea.

“We’ve done a lot of work for the Environment Agency, the Canal and River Trust as well as other inland waterway operators,” says Henderson. “We’ve applied what we think are decent standards… and these seem to have taken root.”

In short, the team has made its presence felt: so much so that this year Henderson will join a British Standards working panel that should put these standards on a more formal

footing. “That will help us – and everyone else,” he says.

At the other end of the spectrum has been involvement with Seas Your Future, a charity that aims to get a tall ship up and running. The idea is to bring 49 cadets onboard the Fridtjof Nansen to help them develop their confidence and resilience.

Darley, the most senior of the venture, has now reached a half century as a naval architect. “Fifty years… but I can’t seem to put it down,” he says.

How did a Cornish fender manufacturer manage to help US tug builder and operator Signet Maritime take the ‘Most Significant Boat’ award at the 2023 International Workboat Show?

Winning the contract to design and build the fender system for the Robert Allandesigned tug was based on three points, says Jack Wickham, head of Marketing.

First, there’s the high-performance polyurethane fender system with its multiple cavity core. That offers a tailored approach for specific performance parameters.

“A combination of a low reaction force required when working with LNG carriers and an overall weight saving of 10 tonnes gave significant operational benefits,” he says.

Second, a modular approach meant the one-piece cylindrical bow and stern fenders could be replaced with smaller sections.

These are much easier to handle and if a section is damaged beyond repair, only a small section needs replacing at a much lower cost.

Finally, a wear-resistant and non-marking contact surface is beneficial for tug

operations.

To be clear, Jack Wickham underlines that tug fenders are not simply an afterthought. They play a significant role in performance.

“Robert Allan and Signet Maritime engaged with us very early in the design process,” he says. “Our fendering solutions contribute to the increased performance of the tug, generate fuel savings and offer long-term maintenance benefits.”

The FenderIT products achieve this by

incorporating a network of cavities in high-performance polyurethane, making them 20% to 50% lighter than equivalent rubber fenders.

Material properties are also tuned to requirements, including a low reaction force and high energy absorption generated by progressive resistance. This tailored approach allows varying the contact requirements across the fender.

Buoyant Works, a Seawork exhibitor, also saw another North American breakthrough with a project that involved a chartered fishing boat being converted to a Crew Transfer Vessel for the offshore wind industry.

The bow of the 18m Capt Les Eldridge was redesigned to accommodate the necessary bow fendering.

“It’s one of the most important requirements for a CTV,” says Wickham, adding that last year saw the company pass its 100th CTV installation.

Finally, increasing demand and reach into new markets is being met with product development, along with a second factory due to be completed in the summer.

Following demanding evaluation trials, KNRM (The Royal Dutch Lifeboat Association) has ordered 12 class 50 DuroWipers for the latest four hulls of its newbuild KNRM 18m RIBs.

Currently in build at the Habbeké Shipyard at Hoorn in The Netherlands, the Valentijn class of aluminium-hulled rigid inflatables are the latest purpose-designed and built coastal search and rescue vessels from a design family well known for its legendary seakeeping ability.

“As these are cabin RIBs, the performance and reliability of their wiper systems are fundamental to the success of their search and rescue duties,” says Noel Gould, CEO at DuroWipers. “Aside from major engine or safety equipment issues, the only other thing that would stop these boats going to sea would be a wiper problem. For search and rescue, it is that critical to be able to see out of the screens at all times and in all weathers.”

With this in mind KNRM undertook a multi-stage testing program with the DuroWipers. Hans van der Molen, technical department manager at KNRM, said the organisation evaluated the DuroWipers for use on its coastal lifeboats.

Search and rescue is a tight knit community internationally, hence it was no surprise to UK

SME manufacturer DuroWipers that KNRM discovered their products through the RNLI - the UK’s largest sea rescue institution.

For the past decade the RNLI has been using Class 50 DuroWipers on its Shannon class all-weather lifeboats, and has signed a nine-year contract to refit its older Severn class vessels with them.

Reygar provides robust and reliable remote monitoring solutions for CTV, ferry, tug and workboat vessels. Our team's solid understanding of the practical challenges faced by mariners and vessel operators, coupled with a hands-on approach to problem solving, has translated into award-winning, simple to use and cost-effective telematics technology.

BareFLEET, our industry-leading, fleet remote performance monitoring system, provides unparalleled, business-critical insight into fuel consumption, emissions, machinery health issues, VMMS motion and navigational activity based on continuous on-board sensor measurements. BareFLEET is fully compatible with a wide range of engines, navigation systems and third-party onboard equipment.

We strive to overcome difficult technical challenges and lead the charge towards decarbonisation and optimal fleet efficiency for our customers. Stop by stand B12 at Seawork for a demonstration of how BareFLEET enables the capture and consolidation of comprehensive, critical vessel data for sound fleet intelligence - direct from boat to boardroom.

”There are few more demanding roles for a marine windscreen wiper than aboard a high-speed, all-weather search and rescue boat, and at KNRM we are delighted to have a household name in sea rescue organisations give DuroWipers the nod of approval,” said Orm de Waart, owner and managing director of Habbeké Shipyard.

attachment on superyachts and navy vessels, providing a smart alternative to drilling and bolting. This approach significantly reduces the likelihood of structural cracks, ensuring the continued strength of the deck or bulkhead. Trust in Roxtec’s tested and certified seals to maintain the integrity of your vessel.

A total of 760 pre-cast concrete panels are being installed to protect part of the Welsh coastline in a project that is using satellite and drone technology to fit them within 1mm of accuracy.

In a key milestone for the River Thames Scheme (RTS), The Environment Agency and Surrey County Council have launched the next phase of their search for a construction partner to build the scheme.

The RTS aims to protect more than 11,000 homes and 1,600 businesses, as well as key elements of national infrastructure.

“This is a huge opportunity for firms in the civil engineering and construction sector and represents a vital step forward in progressing the RTS,” said Caroline Douglass, executive director for flood and coastal risk management at the Environment Agency.

”Our aim now is to build a shortlist of potential partners with the skills and vision to deliver this unique scheme.”

The RTS, announced in 2022, has a £300m package of works to include more than five miles (8km) of new flood channels to carry excess rainfall from the river, reducing the risk of the river overflowing and flooding.

It also aims to improve existing river structures downstream and deliver a new landscape so communities can benefit from quality green open space, active travel routes and richer in wildlife and biodiversity.

The RTS said the project will take a landscape-based approach to creating a more resilient and sustainable community.

The chosen partner will lead in the construction of the two sections of the flood alleviation channel. Other works include increasing the flow capacity of existing weirs, demolition of residential properties to make way for channel and landscaping works, including creation of areas for community

areas post-construction and areas of habitat to mitigate impacts during construction.

Because the RTS has been designated an infrastructure project of national significance, it means it must be granted a Development Consent Order (DCO) before construction can begin. As part of the process the RTS launched a six-week consultation on 22 January.

The RTS is calling for potential candidates to fill out a selection questionnaire designed to find out more about their skills, experience and suitability. It will then shortlist between four and six candidates for Invitation to Tender following the selection questionnaire process.

Following an evaluation of initial tender responses, up to three tenderers will then progress to the negotiation stage, with the contract due to be awarded in 2025.

To participate and access the procurement documents, candidates must register on the Atamis portal at https://defra-family.force. com/s/Welcome and then search for project ref. C22875. The Contract Notice Reference is 2024/S 000-002786.

Van Oord has been contracted by FSRU Wilhelmshaven to build a Floating Storage and Regasification Unit jetty at Wilhelmshaven in Germany.

FSRU Wilhelmshaven is a joint venture between ENGIE and TES, Tree Energy Solution.

The state-owned DET (Deutsche Energy Terminal) was set up to operate Germany’s FSRU vessels, of which there will be five. This is the second one at Wilhelmshaven, which is implementing – together with its partners TES and Engie –the FSRU and jetty as a priority project under Germany’s LNG Acceleration law, which was passed in May 2022.

This is the second FSRU in Wilhelmshaven and the fifth in Germany built according to this law, which aims to plug the energy supply gap and bolster Germany’s security of supply.

Van Oord is combining its marine services, using dredging

and construction engineering to install monopiles for the jetty foundations. In total, 10 monopiles will be put in place, complete with scour protection.

Trailing suction hopper dredger Vox Apolonia, which is currently in Liverpool, UK, will be deployed to dredge the berth pocket and turning basin.

“We are proud to be part of this project, leveraging our extensive portfolio of marine capabilities,” said August Runge, commercial director at Van Oord. “Through the synergy of our expertise, experience and equipment we were able to provide a tailor made integrated solution to our clients challenge.”

Associated British Ports (ABP) has launched a tender seeking a lead contractor or consortium to design and build a bulk liquid green energy terminal at the Port of Immingham on England’s east coast.

Immingham Green Energy Terminal will be a multi-user bulk liquid green energy terminal to support the import of green ammonia from NEOM in Saudi Arabia to be converted to green hydrogen.

A mega green hydrogen production facility is being developed at Oxagon in Saudi Arabia’s region of NEOM at a total investment value of US$8.4 billion. It will integrate up to 4GW of solar and wind

energy, producing up to 600 tonnes per day of carbon-free hydrogen by the end of 2026, in the form of green ammonia.

As well as importing ammonia, ABP expects the new terminal to help with decarbonising the UK’s transport sector and the import of carbon dioxide for carbon capture storage.

ABP is responsible for developing and operating the marine facilities to meet the infrastructure needs and is now looking to appoint a lead contractor or consortium to undertake a design and build contract.

The contract will be worth £140 million and has a duration of 30 months. The time limit for requests to participate is set for 12 January 2024.

Floating wind developer Gazelle Wind Power has signed an MOU with Tugdock to develop a new assembly system that it says will ‘to dramatically drive down costs and increase production of floating offshore wind farms’.

The two firms will work together to deploy the technology at Italy’s largest offshore wind farm, Molise, in the Adriatic Sea.

Gazelle’s platform, the company says, includes a dynamic mooring system that eliminates pitch and balance movement in response to the external forces of wind, waves, and tide.

“The platform’s modular design allows for scalable and adaptable configurations, making it a more affordable and accessible solution for deep water deployment,” Gazelle says. “The modularity of the components enables the wind platform to be fabricated cost-effectively in shipyards and then transported to an assembly port, adjacent to a wind farm, to be completed.

“The Tugdock Submersible Platform provides a build-and-launch platform that overcomes port constraints. The structure combines a steel frame and patented airlift bags to act as additional buoyancy or as a submersible platform for lifting or launching heavy marine structures.”

n Tugdock and Gazelle Wind Power will use floating technology to install Italy’s largest offshore wind farm

“This collaboration will unlock great opportunities for both partners as well as help to accelerate the floating offshore wind industry,” said Lucas Lowe-Houghton, chief revenue officer at Tugdock.

Tugdock, which introduced its roadtransportable floating dry dock known as the

Tugdock Submersible Platform at Seawork in 2020, is rolling its technology out apace, in September signing a deal with a joint venture comprised of Simply Blue Group, Ørsted and Subsea7 to install offshore wind in Scotland.

The project will see 70 wind turbines installed with a generation capacity of 1.05GW.

A large marine civil engineering project in the Netherlands is reaching completion, the leaders of the Terneuzen New Lock (Nieuwe Sluis) project have said.

The new lock, at the North Sea Port, which is in the south of the Netherlands about 40 miles to the west of the Port of Antwerp, had an initial delivery date of March 2023 but was delayed a number of times, partly by the Covid outbreak. Now it is expected to be finished by the end of this year.

Construction of the lock will entail a 427 x 55 metre inland waterway allowing Panamax seagoing vessels a draught of 14.5 metres and better access from the Western Scheldt to the Ghent-Terneuzen Canal and then on to France.

Panamax vessels are 100 metres longer and 16 metres wider than the vessels that currently pass through the lock, and need much deeper water, which will eventually be at least 15 metres at the sea canal.

“It is also useful to guarantee that the Ghent-Terneuzen Canal stays easily accessible in case the Westsluis (until now still the only lock for seagoing vessels) should fall out,” say the project leaders. “It also takes care of the increasingly busy navigation at the lock complex: both inland and seagoing navigation. This way, waiting times can be avoided as much as possible.”

In total, 10 million cubic metres of soil was dredged by marine contractors DEME, with disposal locations along the sides of the locks.

DEME also altered the western harbour entrance of the Westvoorhaven and removed existing spits of land around the Middle Lock, which was actually built in 1010 and is to be replaced.

As much as possible of the soil removed in dredging will be re-used, some at Knokke in Belgium.

‘‘

It is also useful to guarantee that the Ghent-Terneuzen Canal stays easily accessible in case the Westsluis (until now still the only lock for seagoing vessels) should fall out

“Bank and bottom protection will be applied around newly constructed keys, mooring arrangements and the new lock itself, said deem. This bank and bottom protection consists primarily of rip maps, representing approximately 400,000 tonnes.”

Team also said that some contaminated sites have had to be remediated before preparation for construction went ahead.

The full scope of works for DEME are as follows:

• Design & construction of a new sea lock of 427 m x 55 m and water depth of NAP-16.44 m.

• Installation of sea lock operating system, including preparatory works for future remote operation.

• Demolition works of the existing ‘Middle lock’, and existing surrounding buildings.

• Construction of the new operations building.

• Construction of a new service port and service building.

• Installation of guiding, standby and service facilities for the lock operation.

• Adaptation of existing road network and site layout, including execution of two bascule bridges.

• Dry excavation works and soil remediation works.

• Demolition and reinstallation of scour & shore protection.

• Adaptation to the primary and regional flood defence systems.

• Deepening of inner harbour (from –11 to –14 m) and outer harbour (from –12 to –16.44 m).

• Backfill of lock platforms at levels NAP +7.5 m and NAP +9.5 m.

• Dredging works.

• Lock maintenance for two years post completion. Dutch consultancy firm Svašek Hydraulics was hired to design the lock gates, which meant modelling water level variations depending on ship passage, which creates different forces on the gates.

The North Sea Port is rated by its operators as 10th in Europe in terms of goods volume; seventh in the HamburgLe Havre region and third for ‘added value’ at €12.6 billion. It actually extends across both the Netherlands and Belgium.

Netherlands-based Van Wijngaarden Marine Services (VWMS) has formerly welcomed the latest addition to its already sizeable Damen-built workboat and tug fleet following the naming ceremony for Waddenstroom, the largest Multi Cat in the Dutch shipbuilder’s portfolio.

The Multi Cat 3713 was named recently at VWMS’ premises in Hardinxveld-Giessendam by Mrs Cory van WijngaardenDekker together with her great-granddaughter, Leandra Biesheuvel. Waddenstroom now joins six other Damen vessels, the similar but smaller Multi Cat 3013 Kilstroom and five tugs comprising two Shoalbuster 3512s (61tbp), two Shoalbuster 3009s (45tbp) and a Shoalbuster 2609 (30tbp).

The vessel was ordered in May 2023 while under construction as part of Damen’s series build strategy allowing its early delivery. While based on the standard design and as normal with individual orders, Waddenstroom was modified to meet the client’s specific needs, in particular to ensure its suitability for supporting the offshore renewables energy sector for which it has DP2 capability.

Modifications included adaptation of the steel work and deck to accommodate the range of equipment VWMS requires to fulfil its diverse work scope. The vessel’s owner maintains “exacting” standards for crew comfort and 10 of the vessel’s 16 berths are above deck.

Waddenstroom details

Waddenstroom meets IMO Tier III requirements via Damen’s in-house developed Marine NOX Reduction System, the vessel ensuring optimal efficiency and reductions of both fuel consumption and emissions from a diesel-electric propulsion arrangement.

The vessel has four Caterpillar main engine/gensets: a type C32-TTA ACERT, two C32 ACERT models and a type C4.4 genset. Veth provides the thrusters comprising two VZ900 FP azimuth thrusters (two 825ekW E-motors) and two CJ1000V, 325ekW 360’ rotatable bow thrusters. Performance figures include 35tbp (approx) and speed 11kn.

Deck equipment for the BV-classed vessel includes two HS Marine AKC 410/18 HE3 deck cranes with a hydraulic

winch on the

Listed as “optional” by VWMS are a 50t A-frame (25t with plough), a water-injection dredging system, four-point mooring system, ROV - diving operations platform and a power supply up to 125A 50/60Hz.

Damen Shipyards Hardinxveld commercial manager Jeroen van Woerkum said: “We are very proud of what we have achieved with the Waddenstroom. This is an innovative vessel that meets all the current requirements for sustainable performance. We are also very proud that VWMS continues to place its trust in Damen. Our two companies have enjoyed an excellent relationship for a considerable time now and it’s a pleasure to see this continue into the next generation with VWMS.

Danish vessel builder ESVAGT has won a contract to service the Hollandse Kust West offshore wind farm in the Netherlands.

The company will build a new Service Operation Vessel (SOV) to fulfil the15-year contract with turbine manufacturer Vestas, which is supplying the turbines to wind farm developer Ecowende, a joint venture between Shell and Eneco.

The newbuild will be the sixth purposebuilt SOV for Vestas in a partnership that has been working together since 2010.

“Vestas has been one of our key partners in developing and refining our SOV concept,” said chief strategy and commercial officer

ESVAGT’s position as the largest owner of build-to-contract SOVs.”

The vessel will be a battery hybrid SOV in what ESVAGT says is a new compact design. ESVAGT has more than 40 vessels in its fleet.

The wind farm, which is due to be commissioned by 2026, will include a ‘bird corridor’ within its lay-out, “increasing the hub height to create more vertical space for birds as well as integrating bird and bat detection and deterrence systems into the turbine design”.

Vestas’ wind turbines across the globe amount to 173GW of power generated, the company says, in 88 countries.

forward model; a Kraaijeveld towing/anchorhandling winch of 100t and 150t load respectively for each application; two 12t tugger winches; one Tugpin GP2S1; and bow and stern rollers.BMT is breaking boundaries with the launch of its 48m Service Operation Vessel at the Annual Offshore Support Journal Conference.

Designed for a new era in offshore operations, the new methanol-ready SOV aims to deliver safety, comfort and efficiency, while minimising environmental impact.

“In an industry facing rapid change, the BMT 48m SOV is a testament to our commitment to leading innovation in offshore vessel design,” said senior naval architect Alex Blake.

”This vessel is a proactive step towards setting new standards in efficiency and environmental responsibility.”

Cost-effective

Mid-sized vessels that sit between CTVs and SOVs can provide a more cost-effective solution to achieving offshore operational requirements.

The BMT 48m SOV represents the latest evolution in BMT’s long history of designing cutting-edge vessels for offshore support.

With a legacy of 70 crew transfer vessels operating worldwide, the new SOV is addresses the extended O&M demands of modern offshore settings.

Its SWATH hull design enables operations in challenging sea conditions and significantly boosts seakeeping capabilities and uptime.

The SOV features an optimised hull form and machinery configuration, built on a dynamic diesel-electric platform. This innovative approach ensures not only enhanced operational efficiency, but also a significant reduction in environmental impact.

Aligned with BMT’s vision of innovation, the

48m SOV is equipped to facilitate autonomous technology, featuring an adaptable ROV bay, a control room and the flexibility to host up to 5m uncrewed surface vessels.

Offshore infrastructure service company North Star has announced its first contract with a company beyond the UK.

German utility EnBW has given North Star a contract to build a hybrid-electric Service Operations Vessel (SOV) on a decade-long minimum charter to service its He Dreiht wind farm off the coast of Germany.

North Star is treating the contract as a ‘milestone step’ in its European growth strategy to add 40 new SOVs to its fleet by 2040.

The newbuild is a Vard 407 design and includes Voith Schneider eVSP propulsion. It has been prepared to use methanol as a fuel.

The ship is also fully equipped with a height adjustable motion compensated gangway and 3D compensated crane.

This vessel will be the backbone of our service and logistics operations at our He Dreiht wind farm

“Penetrating the European offshore wind sector so promptly after establishing our presence in Hamburg last summer is testament to our service-led approach and passion to deliver SOVs that easily integrate into wind farm operations and O&M strategies,” said North Star European renewables lead Caspar Blum.

“With high operability a key component to providing fast, safe and efficient personnel transfers, we worked closely with EnBW and Vard to develop a robust and superior SOV to mitigate sea state and wave height challenges.”

Michael Splett, Global Head of O&M Wind Offshore at EnBW, said: “This vessel will be the backbone of our service and logistics operations at our He Dreiht wind farm.

“Working with North Star, we were able to specify its set-

up to ideally meet the requirements of our operations teams. Its methanol-based propulsion system helps us to further decarbonise our industry’s operations. This aligns with EnBW’s strategy of continually optimising the operation of its offshore wind farms through the deployment of new technologies in the field.”

Scheduled to commence long-term charter with EnBW from the end of next year, the walk-to-work vessel will provide in-field accommodation for up to 34 wind technicians as they maintain the 64 wind turbines, located around 90km northwest of the island of Borkum and 110km west of Helgoland. The SOV will also act as a logistics hub and warehouse.

This is the seventh newbuild SOV for North Star since entering the renewables market in 2021.

Two Ulstein-designed commissioning service operation vessel newbuilds under construction for Bernhard Schulte Offshore have reached important milestones.

The steel cutting and keel laying ceremonies for yard numbers 320 and 321 took place at the Crist hull yard, Poland, on 30 January.

“It’s great to be here at the yard and to witness the birth of our two newbuildings,” said Matthias Müller, managing director at Bernhard Schulte Offshore.

“We look forward to the further construction progress of these remarkable offshore vessels planned for delivery in 2025.”

The CSOVs have Ulstein’s TWIN X-STERN which features fore and aft main propeller units to help improve dynamic positioning.

The hulls will be prepared at Crist before being towed to Ulstein Verft in Norway for the final phases, which include outfitting, paint work, electrical installation, equipment integration, commissioning and sea trial.

“We are delighted to be here at Crist, together with Bernhard Schulte Offshore, to celebrate this important occasion for the two newbuilds,” said Lidvar Lillerovde, project manager at Ulstein Verft.

“We look forward to continuing the excellent cooperation between the shipowner, the hull yard and Ulstein Verft yard for these vessels.”

With Europe’s decades-long experience in offshore wind, it comes as no surprise that the fledgling US sector is reaching out for help.

European companies now have the skills and experience from the continent’s early adoption of offshore wind under their belt and are increasingly exporting their knowledge globally as the rest of the world plays catch-up.

The US, for example, aspires to add 30GW of offshore wind energy by 2030 with class society ABS estimating a requirement for more than 100 vessels to service the industry.

European companies have the knowledge while US operators, with extensive experience in the offshore oil and gas industry, hold the key to providing the all-important US content. Unsurprisingly, companies on both sides of the Atlantic are coming together to provide solutions.

For the US offshore wind industry, however, operators have to negotiate the Jones Act where federal law requires vessels to be US built and flagged.

In February 2023 Esvagt and US-owned Crowley established a joint venture, CREST Wind, to operate an SOV for long-term charter to Siemens Gamesa Renewable Energy for operation at Dominion Energy’s Coastal Virginia Offshore Wind project.

Esvagt says it has a “strong relationship” with key operators and OEMs moving to the US from many years of collaboration, while Crowley’s logistics experience stretches back over 130 years and translates into offshore wind farm project support.

Construction of the vessel is now under way at Fincantieri Bay Shipbuilding in Sturgeon Bay, Wisconsin, with HAV Design selected for the vessel based on its HAV 832 SOV design.

The Havyard 832s are well-proven offshore support vessels dating back more than a decade, originally built as PSVs for the oil and gas industry. More recently an SOV variant has been introduced, including Esvagt Njord, Esvagt Faraday and Esvagt Froude, which means CREST Wind will reap the benefits of a proven vessel design from a European company experienced with such vessels.

Notable features of the HAV 832 SOV in general include a compensated gangway providing walk-to-work access to turbines; 3D compensated crane options; various Safe Transfer Boat options; station-keeping capabilities from four azimuth thrusters (two forward two aft); options for additional services including ROV and drone operation; high-quality accommodation facilities with high-speed wifi; and optimised cargo loading, storage and transfer workflows to turbines including stepless elevators.

The battery-hybrid machinery arrangement involves Siemens Blue Drive systems, the vessel also capable of 100% battery operation from offshore charging, even offering power generation via its own wind turbines and solar panels. The 80m long, US-flagged vessel will provide accommodation for 20 crew and 60 technicians and is due in service in 2026.

While the demand for SOVs and CSOVs is seeing a number of conversions of existing Offshore Support Vessels there is also a healthy appetite for newbuild vessels designed from the keel up to satisfy the particular requirements of this emerging niche sector.

Basic requirements for an SOV include a DP-capable vessel able to remain on site, housing technicians servicing turbines for typically a month at a time with access via motion-compensated personnel transfer systems.

Credit: HAV Design

n The SOV for CREST is based on the well-proven HAV 832 design

Norwegian shipbuilder Ulstein Verft will build four construction service operation vessels for the offshore wind industry in a new contract with JP Morgan.

The contract is for an initial two CSOVs with an option for another two, and they will be equipped with hybrid battery propulsion systems as well as being prepared for green methanol as a future fuel, Ulstein says.

The ships have a large, centrally positioned walk-to-work motion-compensated gangway and elevator tower for personnel and cargo transfers along with a 3D compensated crane capable of 5 tonne cargo lifts.

They have a length of 89.6m and a beam of 19.2m and can accommodate 132 people.

“We are excited to add to our existing presence in the offshore wind maintenance sector,” commented Andrian Dacy, Global Head of J.P. Morgan Asset Management’s Global Transportation Group. He added, “These latest technology Construction Service Operation Vessels (CSOVs) will play a critical role in the development and delivery of renewable energy and global energy decarbonization.”

”The offshore wind industry is an important enabler to achieve the climate goals, and we believe that our fuel-efficient ships will be vital

assets in this mission,” states Ulstein Group CEO Gunvor Ulstein.

Banking giant JP Morgan also carries out ship management, crew management, education and training of seafarers, technical

services and commercial operations around the world.

Ulstein is headquartered in Ulsteinvik, Norway.