UN DELIVERS ‘HISTORIC’ PROTECTION TO HIGH SEAS

After two decades of talks, United Nations’ member countries have agreed a treaty to protect the high seas that will ensure the conservation and sustainable use of marine biological diversity in areas beyond national jurisdiction.

Calling the agreement a “breakthrough”, UN Secretary-General António Guterres said the action agreed at the body’s headquarters in New York was “a victory for multilateralism and for global efforts to counter the destructive trends facing ocean health, now and for generations to come”.

The agreement reached by delegates of the Intergovernmental Conference on Marine Biodiversity of Areas Beyond National Jurisdiction (BBNJ) is the culmination of UN-facilitated talks that began in 2004. Referred to as the “High Seas Treaty”, the legal framework will place 30% of the world’s oceans into marine protected areas (MPAs), put more money into marine conservation, and covers access to and use of marine genetic resources. The agreement will enter into force once 60 states have ratified it.

“It is also vital for achieving ocean-related goals and targets of the 2030 Agenda for Sustainable Development, and the KunmingMontreal Global Biodiversity Framework,” said Guterres, referring to the so-called “30x30” pledge

to protect a third of the world’s biodiversity – on land and sea – by 2030, which was made by a UN conference in Montreal in December.

EU Commissioner for the Environment, Ocean and Fisheries Virginijus Sinkevičius described the agreement as a “historic moment” for the ocean.

“With the agreement on the UN High Seas Treaty, we take a crucial step forward to preserve the marine life and biodiversity that are essential for us and the generations to come,” he said.

While two-thirds of the world’s oceans are currently considered international waters (or high seas), until now only about 1% of these waters have been protected, which has left the marine life in these areas at risk of exploitation from a variety of threats including overfishing.

FIRST SMART FARM SHIP CERTIFIED

NEW HORIZONS

High hopes as iFarm version 3 gets underway page 14

NEWBUILDS

Mekhanik Maslak joins RFC fleet page 17

SPECIAL REPORT

Smart, connected seafood processing page 21

AQUACULTURE

China-based aquaculture ship Conson No. 1 has become the first large yellow croaker (Larimichthys croceus) farm to achieve the Aquaculture Stewardship Council (ASC) certification.

Conson No. 1 is regarded as the world’s first full-scale “smart farming ship”. It produces 3,700

tonnes of large yellow croaker annually.

The vessel, which cruises in waters up to 100 nautical miles offshore, is owned by Qingdao Conson Blue Silicon Valley Development Co Ltd. It officially started operating in May 2022, and soon after started the improvement of its aquaculture system to meet the ASC standard.

Ukraine’s challenges intensify page 46

APRIL 2023 l VOL 72 ISSUE 4 worldfishing.net

Viewpoint 3 | Insight 12 | Fishing Technology 40

8 The new treaty will place 30% of the world’s oceans into MPAs

VIEWPOINT

JASON HOLLAND | Editor | jholland@worldfishing.net

DOING SEAFOOD BETTER

Welcome to the April issue of World Fishing & Aquaculture and also our latest Special Report starting on page 19, which looks at some of the companies and innovations that are changing the seafood processing landscape. In putting these articles together, it was heartening to learn about the advancements that key players in the seafood space are making to utilise more of the raw materials available in more costefficient, quality-boosting ways, while also generating more value from those products. I would once again like to offer my thanks to all those that took the time to discuss their strategies and experiences with us.

As these pages confirm, for some, strong progress is being achieved through investments in new technologies, while for others it’s coming from approaching opportunities and challenges in different ways and breaking away from what’s been standard practice. But while the approaches differ greatly, most ventures have a common end goal – to do seafood better.

Our very diverse, multi-faceted industry is a remarkable one. The determination that exists within seafood to do better by people and planet is something to celebrate. Equally so, is its inherent resolve to build better, more resilient and predictable businesses and all that entails. It’s further evidence that the seafood economy is on the right trajectory for a bright, sustainable future and more than equipped to overcome any challenges that it might face along the way in the wider world of food production.

WF is already looking forward to revisiting the topic of smarter, more connected seafood processing. Our hope is that a lot more of you in this crucial space will share your stories and visions with us and inspire others in the process.

The international fishing & aquaculture industry magazine

EDITORIAL & CONTENT

Editor: Jason Holland jholland@worldfishing.net

News Reporter: Rebecca Strong rstrong@mercatormedia.com

Regular Correspondents: Please contact our Correspondents at editor@worldfishing.net

Tim Oliver, Bonnie Waycott, Vladislav Vorotnikov Quentin Bates, Terje Engø Eduardo Campos Lima, Eugene Gerden

Production

David Blake, Paul Dunnington production@mercatormedia.com

SALES & MARKETING t +44 1329 825335 f +44 1329 550192

Media Sales Manager: Hannah Bolland hbolland@worldfishing.net

Marketing marketing@mercatormedia.com

EXECUTIVE Events Director:

Marianne Rasmussen-Coulling

Chief Executive: Andrew Webster awebster@mercatormedia.com

WF magazine is published monthly by Mercator Media Limited, Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD UK t +44 1329 825335 f +44 1329 550192 info@mercatormedia.com www.mercatormedia.com

Subscriptions

Subscriptions@mercatormedia.com Register and subscribe at www.worldfishing.net

1 year’s digital subscription with online access £204.50 For Memberships and Corporate/multi-user subscriptions: corporatesubs@mercatormedia.com ©Mercator

Launched in 1952, World Fishing & Aquaculture is published by Mercator Media, a B2B media and events company specialising in international maritime industries, including marine business and technology, ports and terminals, and environmental strategies.

Through its monthly publication and free access website (www. worldfishing.net), World Fishing & Aquaculture provides expert-written, in-depth coverage of the fisheries, aquaculture and processing sectors, with a strong focus on the emerging solutions, technologies and innovations that are shaping the broader seafood economy’s landscape.

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 3

Ltd. All rights reserved. No part of this magazine can be reproduced without the written consent of Mercator Media Ltd. Registered in England Company Number 2427909. Registered office: Mercator Media Limited, Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD UK.

Media Limited 2023. ISSN 2044-1908 (online). World Fishing is a trade mark of Mercator Media

‘‘

The determination that exists within seafood to do better by people and planet is something to celebrate

BRIEFS NEW EU PLAN LAUNCHED

85% of tuna at healthy levels

Some 85% of tuna sourced worldwide is from stocks at a healthy level, according to the latest figures from the International Seafood Sustainability Foundation. Its ‘Status of the Stocks’ analysis also reports that 11% is from overfished stocks and 4% from those at an intermediate level of abundance.

Faroes to raise salmon tax

The recently-elected Faroese government has issued a proposal to adjust the revenue tax for the salmon farming industry. Nine tax rates are proposed between 0.5% and 20%.

Cooke acquires US giant

Canadian seafood group Cooke Inc has entered into a binding purchase agreement to acquire Slade Gorton, one of the United States’ largest distributors, importers, and manufacturers of fresh and frozen seafood.

Seafish seeks levy changes

UK seafood public body Seafish has begun consulting with its levy payers and the wider seafood industry on its proposals for a new levy model. The Seafish levy hasn’t changed since 1999. Levy is due on the first sale of seafood, both domestically landed and imported.

A package of measures to improve the sustainability and resilience of the EU’s fisheries and aquaculture sectors has been launched by the European Commission.

Its main objectives are to promote the use of cleaner energy sources and reduce dependency on fossil fuels as well as reduce the sectors’ impact on marine ecosystems.

The package includes four elements: A Communication on the Energy Transition of the EU Fisheries and Aquaculture sector; an Action Plan to protect and restore marine ecosystems for sustainable and resilient fisheries; a Communication on the common fisheries policy today and tomorrow and a Report on the Common Market Organisation for fishery and aquaculture products. Its proposed actions will be carried out gradually to help the sectors adapt.

Additionally, a ‘Pact for Fisheries and Oceans’ will support the full implementation of the Common Fisheries Policy (CFP) in coordination with member states and fisheries

stakeholders. The proposals also want to make the sectors attractive for younger generations looking for employment.

“We want to establish a ‘Pact for Fisheries and Oceans’ to work together with everyone to ensure sustainable and resilient fisheries, protect and restore our marine ecosystems, make the sector profitable and strengthen our food security in the long-term,” EU Commissioner for Environment, Oceans and Fisheries Virginijus Sinkevičius said.

Sinkevičius added: “We are also promoting an energy transition to help the sector adapt its vessels and equipment, improve working conditions and move towards renewable, lowcarbon energy sources. We know this is a challenging task. For this reason, the transformation will be gradual and we will promote dialogue between all communities to lay the foundation for a resilient fisheries and aquaculture sector.”

SCOTTISH FISH FARMS BOOST ECONOMY BY BILLIONS

Scotland’s fish farms have delivered a £3.3 billion boost to the country’s economy over the last decade, with a new government report finding that farmers’ economic contributions soared by 76% from £206 million in 2011 to £362 million in 2020.

Farming staff numbers also increased by nearly a third over the same period.

Trade body Salmon Scotland said the research shows that farm-raised salmon “generates vital wealth” for the country.

“Farm-raised Scottish salmon is a global success story that everyone in Scotland can take pride in, putting the best-tasting and healthiest protein product on people’s plates and delivering the

highest environmental and welfare standards,” Salmon Scotland CEO Tavish Scott said.

“All this has been achieved despite the incredible challenges of Covid and Brexit, and with the right

government support –streamlined regulation, a more business-friendly approach to immigration in the post-Brexit environment, and action to tackle rural housing shortages – we can deliver further sustainable growth,” he said.

According to the findings, aquaculture was the third largest marine contributor in gross value added (GVA), only behind oil and gas, and construction and water transport services. Fish farming accounted for 9.4% of the Scottish marine economy in 2020, compared to 7.3% for sea fishing at £284 million.

Over the decade, farmers grew 1.9 million tonnes of fish worth £9 billion, with sustainable production rising on average by 2.9% year-on-year.

4 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net NEWS

8 In 2020, there were 124,630 people employed in EU commercial fisheries and 57,000 in aquaculture

8 Fresh Scottish salmon accounts for more than £500 million worth of fish sales across the UK retail market annually

EU backs blue projects

Twenty multinational projects will receive over €117 million to contribute to the objectives of the EU mission ‘Restore our Ocean and Waters’: protect and restore biodiversity, cut pollution and support a sustainable blue economy.

Sea Safe for Aussie fishers

A programme designed to improve the culture of safety in Australia’s commercial seafood industry has been launched by seafood industry body Seafood Industry Australia, in conjunction with the Australian Maritime Safety Authority and the Fisheries Research and Development Corporation.

Namibian salmon go-ahead

Benguela Blue Aqua Farming has secured permits to raise Atlantic salmon in net pens off the coast of Namibia. The farm will be located 8km offshore from the town of Lüderitz and will use submersible pens, submerged grid infrastructure and other open ocean technology to raise its fish

Skretting opens in India

Aquafeed company

Skretting has set up a new production facility for shrimp and fish feeds in Mangrol, Surat, explaining that the high-end facility is part of its commitment towards Indian aquaculture and its strategy to further develop in Asia.

ICELAND LAUNCHES NEW ECO-BUSINESS PARK

A property formerly destined to be a large aluminum smelter that was never completed has been given a new lease of life by being transformed into a new Eco-Business Park for Iceland and the largest coworking space in the country.

Co-founded by the Iceland Ocean Cluster, the 280,000-square-metre park is situated in a highly advantageous location – just two minutes from Helguvik harbour, 10 minutes from the International Airport in Keflavik and 45 minutes from Reykjavik city centre.

There is an option to double the existing 25,000-squaremetre floor space by installing an additional level.

The park will benefit from a close relationship with The Resource Park in the Reykjanes where companies are striving to make full use of the rich local resources, including geothermal hot water, cold water, steam, renewable electricity and carbon dioxide.

With over 60 companies under its roof in Reykjavik, the Iceland Ocean Cluster House has become a global showcase of Iceland’s aim to use 100% of the fish to create value and waste nothing. The aim of the Eco-Business Park is to extend this ideology to a whole array of other industries.

It will grow the existing

co-working space of the Iceland Ocean Cluster 10-fold, providing a platform for diverse industry players that have the ambition to move toward circular business models.

The long-term vision of the park is to build bridges between the water, energy and food sectors and create the opportunity for companies inhouse to re-imagine each other´s waste streams into new value.

Meanwhile, according to new figures from Statistics Iceland, the total volume of fish and shellfish landed by the country’s fishing fleet increased by 23% or almost 261,000 tonnes in 2022, with a total 1,414,598 tonnes. The year’s catch value climbed 20% to ISK 195 billion.

A substantial increase was confirmed in the volume of pelagic fish, while demersal, flatfish and shellfish landings all shrank. 2022’s total pelagic catch jumped 47% to 955,954

tonnes. This spike was mainly due to a 207% increase in the capelin volume, which amounted to 449,934 tonnes. The value of the pelagic catch reached ISK 48 billion, up 41%. Of this, capelin accounted for ISK 20 billion, which was an 80% rise on the previous year.

Within the demersal category, with a total catch of 433,385 tonnes – an 8% drop versus 2021 – cod landings decreased 10% to 243,483 tonnes, and the redfish catch slipped 21% to 39,658 tonnes. However, the 2022 volumes of haddock (57,026 tonnes) and saithe (62,039 tonnes) were up by 1% and 4% respectively. In value terms, the cod catch increased 13% to ISK 85 billion, haddock was up 30% to ISK 21 billion and saithe climbed 46% to ISK 14 billion. The redfish landings’ value decreased 10% to ISK 10 billion.

NEW POST-BREXIT DEAL AGREED

A new agreement aimed at fixing post-Brexit problems in Northern Ireland has been reached by UK Prime Minister Rishi Sunak and President of the European Commission Ursula von der Leyen.

The agreement, named the “Windsor Framework”, replaces the old Northern Ireland Protocol, providing a new legal and UK constitutional framework.

Confirming the change, Sunak said: “It means food retailers like supermarkets, restaurants and wholesalers will no longer need hundreds of certificates for

every lorry. And we will end the situation where food made to UK rules could not be sent to and sold in Northern Ireland.”

According to the UK government, the new agreement delivers free-flowing trade in goods between Great Britain and Northern Ireland by removing any sense of the border in the Irish Sea for goods staying within the UK. These goods will travel as normal through a new green lane without red tape or unnecessary checks, with the only checks remaining designed to prevent smuggling or crime.

All goods destined for the EU will use the red lane.

The agreement rewrites the treaty text with a new Stormont Brake that means the UK can veto new EU goods laws if they are not supported by both communities in Northern Ireland, which goes far beyond previous agreements or discussions on the old protocol.

All requirements have been scrapped for trade from Northern Ireland to Great Britain on a permanent basis, including the requirement for export declarations.

6 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net NEWS BRIEFS

8 Emphasis will be placed on establishing 100% circularity in the water, energy and food sectors

Ma x ilo n ensures lo nger P GARWARE TECHNICAL FIBRES LTD. Plot No 11, Block D -1, MIDC, Chinchwad, Pune, Maharashtra 411019. Tel.: +91-20-27990301, 27990306 | Toll Free (India): 1800 120 5165 Email : sales@gar warefibres.com | Website : www.gar warefibres.com Follow us on Long life Trawl shap e retention Easy to sho ot and haul Option available with HMPE in Core for lower drag Visit us at 3QQ203 25 - 27 April 2023 / Barcelona, Sp ain

BRIEFS

First salmon-kelp farm

Start-up seaweed producer

Folla Alger and salmon producer Cermaq have teamed up to test a new combined sea site for salmon and kelp in Steigen in Nordland, Norway. It will be the world’s first farm built for the combined production of both salmon and kelp, whereby the seaweed will be grown inside the farm.

Seafood certifiers team up

A collaboration memorandum of understanding has been agreed by the Responsible Fisheries Management certification programme and the Global Seafood Alliance, with the two groups looking to expand their global reach.

Tilapia parents for Colombia

Colombia has received its first tilapia from GenoMar Genetics Group’s SPF (Specific Pathogen Free) breeding centre in the Philippines. The fish will be grown to maturation and serve as the parent stock for commercial fingerling production.

Major upgrade for Peterhead

Work has begun on a major new £30 million processing facility and coldstore upgrade for Denholm Seafoods in Peterhead. The investment is one of the largest ever undertaken by a wild-catch fish processing company in Scotland.

IKEA INVESTS IN BLUE ECONOMY

The Ocean 14 Capital fund has received an investment of €30 million from Ingka Investments, the investment arm of Ingka Group which represents retailer IKEA, to support its mission of funding sustainable solutions to improve ocean health.

This is the first time Ingka Investments has invested in the blue economy, with Head of Financial Market Investments at Ingka Investments, Samuel Rundle explaining that the Ingka Group is guided by the IKEA vision to create a better everyday life for people.

“As a purpose-led company, our aim is to invest with impact, delivering positive returns for communities and the environment for generations to come. Ocean health is critical to a cleaner and more inclusive recovery. We were very impressed with the strategy of the Ocean 14 team and are excited to support the acceleration of sustainable solutions to improve our oceans,” he said.

Following the Principality of Monaco’s €10 million

commitment from the sovereign wealth fund in September 2022, Ocean 14 Capital has now raised €130 million since launching its growth-stage impact fund in November 2021.

With this backing, the purpose-led €150 million impact fund believes it is well on track

to grow its portfolio to between 20-25 businesses within three years, having invested in four companies to date.

Using the United Nations Sustainable Development Goal number 14: Life Below Water as a guiding principle, Ocean 14 Capital is searching for entrepreneurs and businesses with big ideas around aquaculture and alternative proteins, reducing plastic waste pollution, protecting ecosystems and marine flora, and ending overfishing.

The fund’s mission is to supercharge the blue economy, which is expected to be worth $3 trillion by 2030, according to the OECD. At the same time, it will provide jobs to 40 million people.

“It is a real testament to the quality of our fund and intention that Ingka Investments has come on board in such a significant capacity,” Ocean 14 Capital Founding Partner Chris Gorell Barnes said. “If there’s no ocean, there’s no us – it connects us all. It provides food security and plays a vital role in achieving the UN sustainability agenda.”

INDIA AIMS TO DOUBLE SEAFOOD TRADE

India is seeking to double its income from seafood exports to US$14 billion by 2025 amid a sustained annual growth of 3% in the sector, according to Union Minister of State for Commerce and Industry Smt Anupriya Patel.

The country exported 1.36 million tonnes of seafood during 2021-22, earning an alltime record of $7.76 billion.

“In two years from now, we plan to achieve a target of 14 billion dollars,” Patel said after inaugurating the 23rd edition of India International Seafood Show (IISS) in Kolkota.

Highlighting that India is already among the world’s top five seafood-exporting countries, the minister said 17% of the country’s agricultural exports comprises fish and allied products.

“We are the world’s thirdlargest fish producer, secondlargest aquaculture producer and fourth-largest seafood exporter,” she said.

While noting duty concessions on the import of vital shrimp/fish feed ingredients announced in the Union Budget 2023-24, she highlighted the government’s measures towards protection of the interest of the country’s aqua farmers and the sector as a whole.

“We slashed the import duty from 15% to 5% for fishmeal/ krill meal and vitamin premixes, whereas the duty has been halved to 15% for fish lipid oil and algal prime,” she said.

As for RoDTEP (Remission of Duties and Taxes on Exported Products), the minister said the flagship export promotion

scheme has effected a favourable revision in both its rate and cap for a majority of the exportable fishery products.

The government has enhanced the RoDTEP rate and cap for frozen shrimp, which is the country’s principal foreign exchange earner, to 3.1% from 2.5% and Rs 42 from Rs 16, respectively.

She also said the 2020introduced Pradhan Mantri Matsya Sampada Yojana (PMMSY) scheme plays a vital role in bringing about the socalled “blue revolution” through sustainable and responsible development of the fisheries sector in India, and that its investment of Rs 20,050 crore, will increase the country’s marine production capacity, productivity, intensification, diversification and exports.

8 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net NEWS

8 Ocean 14 Capital Fund 1 is an impact fund targeting €150 million that’s focused on driving a sustainable and regenerative blue economy

MORE NATIONS SIGN UP TO TACKLE IUU FISHING

Iceland, the Republic of Korea, Norway, New Zealand, Panama, the European Union and Chile have become the newest members of the Illegal, Unreported and Unregulated (IUU) Fishing Action Alliance, a coalition of governments and organisations committed to ending IUU fishing.

Tackling IUU fishing involves alliance members striving to be leaders in their respective countries by enacting and enforcing effective fisheries regulations, investing in monitoring and surveillance technologies, and promoting sustainable fishing practices. Members should also coordinate their efforts internationally to combat the

problem while also sharing information and best practices.

The alliance is working to identify and ensure competent authorities take action against those who engage in or profit from IUU fishing, including vessels, companies and individuals.

“For too many communities, the threat of IUU fishing looms year after year, as they bear the brunt of the instability and violence that accompanies this serious, organised, transboundary crime,” said Thérèse Coffey, UK Secretary of State for Environment, Food and Rural Affairs.

“For marine species, the impact can be devastating, and this has a catastrophic effect

on the lives of the hundreds of millions of people who depend on fisheries for their livelihoods. So, we need to accelerate our efforts and scale up.”

European Commissioner for the Environment, Oceans and Fisheries Virginijus Sinkevičius said the EU is pursuing a zerotolerance approach against IUU fishing as part of the European Green Deal and its international

ocean governance agenda.

“We are committed to strengthening our efforts by further promoting compliance with applicable rules and by strengthening monitoring, control and surveillance mechanisms. We also need to ensure a level playing field for legitimate operators and legal products on our markets,” he added.

FLOTTWEG CENTRIFUGES FOR MANUFACTURING AND PROCESSING OF FISH OIL, FISH MEAL, FISH BY-PRODUCTS AND SURIMI

Your advantages

More than 60 years of experience in separation technology

· Highest performance and separation efficiency

· Highest reliability and availability of machines and systems explicitly adapted to customers’ requirements

Highest possible cost efficiency due to continuous and automatic operation

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 9 NEWS

8 Annual losses attributable to IUU fishing are estimated to be at least €10 billion

RAINBOW TROUT – A FISH WITH HEALTHY POTENTIAL

The global market for the species is expected to surpass $7 billion by the end of 2033, writes Fact.MR

Associate Vice President Shambhu Nath Jha

Be it baked, grilled or steamed; rainbow trout is proving increasingly popular among millennial “foodies”. Some of this popularity is driven by the fish’s mild, nut-like flavour and tender texture, while other consumers are being drawn by its high nutritional value and its relative affordability compared with other species. Market research conducted by Fact.MR predicts the consumption of rainbow trout will surge at a compound annual growth rate (CAGR) of 5.2% over the coming decade. The study also estimates rainbow trout sales will climb from a current level of US$4.2 billion to $7 billion by the end of 2033.

Retailers are playing a prominent role in expanding this market through sampling, marketing and merchandising strategies, while the penetration of online delivery platforms and e-commerce has seen the availability of canned and frozen rainbow trout increase at an incredible pace. This trend will benefit rainbow trout suppliers immensely, especially those in the United States, Japan and Germany.

The global market for rainbow trout consists of both farmraised and wild variants, with the study, suggesting that farm-raised trout is likely to generate substantial demand in the coming years. This is largely due to advancements taking place in the fish farming sector, with the technology leveraged allowing round-the-clock monitoring of fish health.

Despite the species’ promising potential, there are some challenges for companies and fisheries to overcome – most prominently, the costs necessary for establishing, operating and maintaining farms. As such, emerging players are likely to find it hard competing with the bigger names in the market. At the same time, several environments where rainbow trout thrive are at an increasing risk of habitat destruction, which is likely to affect biodiversity in the long run and reduce wild rainbow trout populations.

Europe on top

Europe is expected to cement its position as the dominant regional market for rainbow trout in the 10 years through 2033, with the research suggesting the region has a 50% share of the global industry. This is largely due to Europe’s thriving fish farming sector.

North America is set to follow in Europe’s footsteps, with the United States also poised to register significant sales. This will be supported by efforts made by the US government and health agencies to promote fish consumption. Rainbow

trout farming is also on the rise in the States, with the sector governed by the United States Trout Farmers Association.

In Asia, Japan looks set to lead the way with fish imports in the country skyrocketing in recent years. This island nation’s proximity to the Pacific Ocean also allows its fish farmers to source wild trout.

Key players operating in the rainbow trout market are focusing on establishing bases across regions where the demand is significant. Fact.MR expects fish farming costs to rise in the years to come, and that’s why players should spring into action and capitalise on the opportunities available now. Market participants also need to be mindful of the regulations enforced by governments across different regions to protect biodiversity. Sourcing wild trout by going against stringent regulations is likely to lead to harsh sanctions.

All in all, there are lucrative opportunities for players to explore and risks to steer clear of. With growing demand for rainbow trout, key players are tapping into fish imports and aquaculture. For instance, in November 2021, Finnforel Oy, a leading ecological fish farm announced plans for breeding rainbow trout. The Finnish company’s production capacity will expand from 1 million to 3 million kg. It also intends to export to European countries such as Germany, the United Kingdom and the Netherlands.

8 Rainbow trout sales are being boosted by consumers’ growing attention to healthier foods

10 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net ANALYSIS

Headquartered in Dubai, UAE, with offices in the United States and India, Fact.MR is leading provider of syndicated and custom market research reports across several industries. Photo Credit:

Fact.MR

TWISTER SPIRAL THAWING, CHILLING AND BLEEDING TANK

Twister – new customized equipment from MEST for Thawing Chilling Bleeding Buffer tank

We supply a wide range of Twister tanks according to your needs.

Please contact us on sales@mest.fo or phone us +298 791100

Twister13 delivered to Bakkafrost at their processing plant, Faroe Islands Tel. (+298) 79 11 00 · sales@mest.fo · www.mest.fo/uk

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 11

INSIGHT

The future of fishing

SQUEEZED OUT

Industry is concerned the UK’s new fisheries strategy fails to factor in its biggest challenge, writes Jason

Holland

Published by UK government towards the end of last year, the post-Brexit Joint Fisheries Statement (JFS) is supposed to bring improved social, economic, and environmental benefits to the country’s seafood industry as an independent coastal state. But for many stakeholders, the strategy doesn’t go far enough in its support of industry, particularly in safeguarding access to fishing grounds.

Setting out high-level rules on how to deliver key fisheries objectives in the Fisheries Act 2020 and how to manage fisheries while restoring the marine environment, the JFS forms a key part of a new Fisheries Framework. It contains positive elements, including recognising the importance of the UK’s fishing, aquaculture and processing sectors and working with supply chains on key issues like access to labour.

However, the recent Westminster Food & Nutrition Forum policy conference: Next steps for fisheries policy in the UK heard that the JFS fails to bring clarity to the issue of spatial squeezing and the displacement of fishing activities by other marine industries and environmental protection initiatives, not least offshore energy production and marine protected areas (MPAs).

Scottish Fishermen’s Federation (SFF) Chief Executive Elspeth MacDonald told the conference that spatial pressure is among the biggest threats now facing UK fishers.

“I think it gets very scant reference in the fishery statement, yet it’s a really major issue, and one that many of us are going to have to grapple with,” MacDonald

said. “It’s a really big challenge for us as we look ahead, so it’s disappointing it only merits two paragraphs in the joint fishery statement in terms of what to do about displacement.

“It is worrying that governments are pressing ahead with policies that will likely increase the displacement of fishing with so little prior consideration of how to manage it,” she said.

MacDonald warned displacement could force more vessels inshore, which would in turn have consequences for the hard-pressed inshore grounds, and that some inshore vessels might then venture offshore where they could encounter safety challenges.

Safety could be further undermined by conflicts between static and mobile gears, she said, adding that in this scenario, sustainable fisheries plans could be jeopardised.

A seat at the table

Chief Executive of the Cornish Fish Producers Organisation Chris Ranford told the conference the “massive appetite for offshore renewable energy” and the growing number of MPAs are challenging the increasingly important role that fishing has as a source of food security.

“As an industry, we’re neither anti-renewable nor antimarine protection; we recognise the importance of both to achieve other policy aims. But what I really want to highlight is the importance of bringing fish to the table much earlier in the marine spatial planning process as a way to co-locate and minimise the unknowns that will

8 There’s growing industry concern that displacement will force more vessels inshore and cause increased gear conflict

12 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net

happen if we aren’t included,” he said.

“Probably the most worrying thing is that nobody’s really asked the industry what it will do as a result of the spatial challenges. Will it move to new grounds? Is there space to do that? Will big boats be sold to buy three smaller ones – putting a squeeze on the inshore fleet? Or will fishers simply go out of business? Either way, we face catastrophic displacement and many unintended consequences.”

Michel Kaiser, Professor of Fisheries Conservation at Heriot-Watt University, believes that moving forward, areas that are important seafood production areas need to be classified.

“At the moment, we’re quite happy identifying areas that are fit for purpose for wind farms, tidal power and so on, but nobody is talking about the necessity to identify key areas for fishing. At the end of the day, we’re talking about food production. And if we undermine our ability to produce food, it’ll be very difficult to wind that back once those areas have been blocked out. I think it’s an important area of discussion, and one that’s entirely justified to give the industry business certainty going forward,” he told the conference.

Progress through technology

Nevertheless, Kaiser believes the JFS remains a good opportunity for the UK to become world-leading in terms of sustainable fisheries.

While countries such as New Zealand, Iceland, Norway, the United States and Canada are ahead of the UK in terms of managing their fisheries in a sustainable manner, it has an opportunity to move things that would make it much better placed, he said.

“The JFS will allow us to take control of the situation and use technologies to our advantage – to make the industry much more sustainable.

“But there’s a lot of work to do. The elements that make this possible now are the advent of technologies and the fact that they’ve become miniaturised and far less expensive. We talk a lot about remote electronic monitoring, and we typically think about that in terms of enforcement, but that’s just one element of it. What we could be doing is turning our fishing vessels into smart fishing platforms where they’re capturing data that is useful to the industry – informing it how to fish better.”

Kaiser said the “ultimate ambition” of the JFS is for healthy seas, healthy stocks and healthy fishing communities, and that the more efficient the catching sector becomes at catching the same volume of fish, the less it interferes with the marine environment.

Professor Michel Kaiser, Heriot-Watt University

Another critical area that needs much greater focus is the supply chain and the improvements that can be made so that fish caught or farmed by UK businesses, and then processed by British processors can thrive, said Kaiser.

“Some of our key blue-chip fisheries have actually gone bust as a result of post-Brexit complexities that have occurred at borders and in [foreign] trade. Improvements need to be made if we’re truly going to realise the profitability of our fishing sector, which at the end of the day exports very high-quality luxury products overseas.”

“Not only will that improve profitability, it will also improve conservation outcomes. That will feed back into sustaining the health of the stocks that we’re exploiting. But we can only do that with data and information,” he said. “We keep talking about fishermen contributing data. This is entirely possible – every fishing vessel is an environmental sampling platform, we just need to capitalise on that.” MacDonald agreed that there’s a “tremendous capacity” for fishing vessels to be much more involved in terms of data data.

“We’ve got a modern, efficient fishing fleet in Scotland, with some very sophisticated vessels. There’s a great deal these vessels could do, and we would certainly be keen to have conversations with government about how we can how we can do that,” she said.

8 The rapid growth of offshore wind farming is increasingly displacing fishing vessels from traditional grounds

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 13 INSIGHT

At the end of the day, we’re talking about food production

‘‘

NEWHORIZONS

Focusing on Fisheries Development

HIGH HOPES AS IFARM VERSION 3 GETS UNDERWAY

Cermaq, BioSort and Scale AQ’s third version of iFarm has been installed in Norway. This small step could become a giant leap for salmon farming if the technology proves successful, writes

Bonnie Waycott

Bonnie Waycott

Facial recognition tools are used in criminal investigations or when tagging people on social media, but over the past few years, they have also been appearing in aquaculture. In January 2020, Norwegian fish farmer Cermaq and the technology firms BioSort with support from ScaleAQ formally launched the first version of iFarm, a system that uses artificial intelligence (AI) and machine learning in facial recognition software to improve the management and oversight of salmon farming.

Three years on, and iFarm’s third version has been installed in pens at Hellarvika, a Cermaq farm in Steigen. Version Three will mostly focus on sensors, data collection, machine learning, and further development of the fish sorting mechanism. Sensors will retrieve high-quality images and follow up key parameters such as fish ID, lice, growth and welfare.

Most salmon farms currently assess the health of their fish as a group. If some are found to have lice, diseases or parasites, the whole farm is treated. But the iFarm system aims to assess each individual fish for growth, sea lice, disease, lesions and other factors that affect health and welfare. This allows farmers to determine how fast each fish grows and check for any problems.

Each iFarm pen contains around 150,000 salmon. Around every four days, they come to the surface and take a gulp of air to regulate their swim bladders. When they do this, they are guided through a sensor arrangement where cameras can recognise and monitor them individually before recording data on them based on their unique

markings and structure. Any sick individual can then be treated, stopping or limiting the spread of disease and dramatically reducing the extent of treatment and associated costs as it no longer becomes necessary to treat an entire farm.

“Sea lice and mortality are two important challenges that iFarm has been aiming to address over the past few years, along with building a history or health record for each individual fish so that they can be monitored and sorted according to their conditions,” BioSort Managing Director Geir Stang Hauge told WF.

“Fish that have sea lice will be sent to a treatment unit, while those with skin lesions are handled according to their needs. The most unique feature of iFarm is the ability to remove individuals from a pen for a particular treatment. One of the core things with iFarm is helping farmers to be more targeted in their treatment approach and this emphasis on the individual plays a huge role.”

Step-by-step learning

The main focus of Versions One and Two were understanding how iFarm affects fish behaviour, perfecting system construction, ensuring that the fish are well and have good welfare, and testing two versions of the sensor housing and cameras. This offered insights into camera arrangement, lighting and data processing to create health records for each fish.

First and second-generation sensor arrangements and camera units were also tested to collect statistics for lice growth and get the best possible images. This involved

14 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net

8 iFarm Version 3 has been installed in pens at Hellarvika, a Cermaq farm in Steige

Photo Credit: BioSort AS

establishing specific illumination around the fish and photographing each one from multiple angles. Meanwhile, a lot of work was carried out on operational adaptations, such as sorting, cleaning cameras and maintaining equipment.

Version Three aims to make it easier to catch swimming fish individually by further developing a robotic mechanism that was established a year ago. Meanwhile, the sorting mechanism will be made more autonomous so that together with the iFarm sensor system, it can make its own decisions based on defined criteria such as the discovery of lice or wounds. The sorting mechanism will also be simpler than the previous versions of iFarm with less motors.

The process will require the development of precise machine vision, rapid processing of large amounts of data, and interaction with a mechanical sorting unit with its own control systems. An automated cleaning system has also been installed to enable the cleaning of lamps

when it comes to what we can do automatically. The other important aspect is the sorting and handling of the fish. Right now, we are working on the newly-installed sensor arrangement as well as feeding and fish behaviour, and we believe that with Version Three, we will have much more of a proof-of-concept. However, iFarm is very much a stepby-step process, where we learn new things from each version and improve upon those.”

Unique insights

iFarm aside, Hauge believes that AI and technology are proving their versatility in salmon farming, promising to deliver greater efficiencies and insights.

They can enable farmers to count sea lice quickly and easily or closely monitor the size of their fish, he said, while autonomous feeding is another area that is getting a lot of attention in terms of AI. Indeed, Hauge and his team have been investigating fish growth drivers in subsea feeding –feeding the fish at a deeper depth to offer better protection from sea lice.

As for iFarm, it can give farmers access to a technology that can offer considerable protection against sea lice and greatly reduce mortality. Shifting from stock-based aquaculture to individualised follow-up and care will greatly impact on fish health and welfare, enabling early disease detection and implementation of countermeasures to stop infections from spreading.

The iFarm system, which should be ready for commercial use in a few years, is likely to be in high demand.

and cameras, while a new fish transport system is being implemented to lead the fish through a pipe and bring them close to the surface in the same pen for treatment or removal.

“At Hellarvika, the key thing for us now is to gain momentum on the AI or computer vision part, in other words what we can see on each fish,” said Hauge. “We want to be able to see the different stages of sea lice or wounds as early as possible and have the data to be able to analyse a particular population. Perhaps the most important thing for us this year is to have plenty to show for

“There is a lot of interest in iFarm and increasing talk in aquaculture circles of the welfare of individual salmon as opposed to groups,” said Hauge. “With 150,000 to 200,000 fish in a pen, it’s difficult to see how sea lice attach to the fish, spread through a population, or whether some fish are impacted more than others. But the potential to monitor every single fish, coupled with big data analysis on the population, will provide farmers with unique insights and understandings of important elements that they don’t fully comprehend yet. We look forward to installing iFarm on customers’ farms when all the key features are fully up and running.”

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 15 NEW HORIZONS

8 The BioSort installation team

iFarm is very much a stepby-step process, where we learn new things from each version

‘‘

Geir Stang Hauge, BioSort

Photo Credit: BioSort AS

LATEST IN RFC SERIES HEADS FOR FAR EAST

The latest in a planned series of new trawlers for the Russian Fishery Company has been delivered by the Admiralty Shipyard in St Petersburg

Mekhanik Maslak sailed from the yard in February for the long delivery trip, taking the southern sea route via the Suez Canal and calling at Busan in Korea before its scheduled first call in Sakhalin in April.

This series of 108-metre long, 21-metre breadth ST192 factory trawlers is designed to operate in the Bering Sea and the Sea of Okhotsk, fishing with pelagic gear for pollock and herring – and replacing much of the Russian Fishery Company’s fleet of well-maintained by elderly Soviet-era tonnage.

A key reason for embarking on this very significant investment, part of the Russian government’s investment quotas initiative intended to boost both shipbuilding and fisheries, is the need to move into more sophisticated processing at sea, not least in producing surimi. The older fleet, dating back to the Soviet era, inevitably becomes increasingly high-cost in terms of maintenance, while having also reached the limits of what can be achieved by upgrading factory decks and facilities on board.

Increased capacity

Each of the new series of larger and higher capacity vessels is expected to replace several older vessels, and to be able to harvest around 60,000 tonnes each annually, with facilities for producing 60-80 tonnes of conventional frozen fillets per day, as well as having production capacity for surimi, fishmeal and fish oil onboard, with zero-waste as everything is processed at sea.

A pair of freight elevators and a freight conveyor take frozen production to the 4,250-cubic metre refrigerated fishroom. There are also 400 and 600 cubic metre holds for

fishmeal, packaging and other products, and a roughly 100 cubic metre fish oil capacity in two stainless steel tanks. Designed for extended operation, Mekhanik Maslak has gantries and cargo booms for transhipment at sea into reefers, plus there are 8t/17m and 8t/8m deck cranes. Accommodation is for 40 crew in single- and two-berth cabins, and there is accommodation space for up to 99 factory crew single- double-and four-berth cabins. Mekhanik Maslak has separate mess facilities for officers and crew, and it fitted out with its own cinema, gym and sauna.

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 17 NEWBUILDS

8 Mekhanik Maslak has been completed by the Admiralty Shipyard in St Petersburg for the Russian Fishery Company

8 Mekhanik Maslak has been completed by the Admiralty Shipyard in St Petersburg for the Russian Fishery Company

Russian optimism

Mekhanik Maslak follows the first vessel of its kind built at the Admiralty yard, Kapitan Vdovichenko, which was delivered in early 2022. This was preceded by Vladimir Limanov, built to the same ST-192 design, but constructed at the Tersan yard in Turkey as a forerunner to the Russianbuilt series.

Two more trawlers, Mekhanik Sizov and Kapitan Martynov, are under construction at the yard in St Petersburg, but there is some doubt about the remaining vessels planned for the series as there are indications that RFC and other fishing companies have put newbuilds on hold due to the sanctions that prevent access to the almost exclusively western systems that have been installed onboard newbuilds so far. This includes main and auxiliary engines, processing systems, deck equipment, electronic systems, fishing gear and more, and there is a real prospect that further newbuilds for the Russian fleet will have to be re-engineered practically from the keel up to accommodate alternative technologies.

Despite this, official sources in Russia remain upbeat about the rounds of new vessel on the way and during Mekhanik Maslak’s handover ceremony Deputy Minister of Industry and Trade Viktor Evtukhov announced that around 92 high-tech fishing vessels are currently being built at Russian shipyards, with 19 of these expected to be delivered this year.

“Our main concerns were related with the lead trawler of the series,” said the yard’s chief designer Ruslan Kasimov.

“We can safely say that Kapitan Vdovichenko has successfully confirmed its capabilities both during field trials and during operation. We also expect an excellent result from Mekhanic Maslak. I am confident that the trawler will cope with the trials just as efficiently, confirming the design specifications and once again demonstrating the high quality of the Admiralty construction.”

8 The press were given an opportunity to view the new trawler before it sailed for the Far East

KVITHOLMEN SCALES UP

It’s only a few years since the owners of Kvitholmen took delivery of a new seiner – and now that vessel has been replaced with a new one from the same builder

The new vessel has a 14.99-metre length and a 7-metre beam, and this makes a big difference, allowing for an 80-cubic-metre fishroom, compared to the previous Kvitholmen’s 50 cubic metres. There’s also more space for the crew and the deck layout, and everything is larger, including the high-capacity pump for transferring catches from the gear, Kvitholmen has a 750hp Volvo Penta main engine, designed to minimise consumption and emissions, and driving a larger propeller than the older vessel had. The deck equipment layout is also more powerful, and the new seiner has winches with a 12-tonne pull, providing more power than the old vessel’s 3-tonne winch system.

The previous 12.95-metre LOA, 5.9-metre breadth Kvitholmen was delivered to fishing company Kvitholmen AS in June 2018 and has fished successfully with seine net gear, but the owners soon became aware that carrying capacity in particular was limited.

They went back to the Skogsøy Båt yard in southern Norway and placed an order for a larger, aluminiumhulled seiner, which was delivered at the beginning of this year and headed north to fishing grounds off the north of Norway.

Rigged to fish with seine net for groundfish or purse seine gear for pelagic species, new Kvitholmen has been built with a new hull design, optimised for these fishing methods. Sea trials prior to delivery showed the same turn of speed fully loaded as empty.

18 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net NEWBUILDS

8 Kvitholmen on sea trails before heading for the north of Norway

8 Kvitholmen’s deck equipment and fishroom capacity are much greater than those of the boat it replaces

Promote your business to the right audience in the right place at the right time. Engage with our international audience of decision makers and buyers. The World Fishing & Aquaculture multi-media platforms offer our commercial partners a wide range of opportunities for campaign delivery. We deliver bespoke marketing packages with quantifiable ROI. Hannah Bolland, Brand Manager t: (+44) 1329 825 335 e: sales@worldfishing.net www.worldfishing.net Contact us today WORLDFISHING SINCE 1952 & AQUACULTURE Reach industry professionals with World Fishing & Aquaculture MAGAZINE RECIPIENTS 14,500 DECISION MAKERS 70% PAGEVIEWS PER MONTH 53,000 World Fishing & Aquaculture’s valued content focuses on all aspects of commercial fishing, relied upon by vessel operators, fleet managers, ship’s officers, and government departments.

Join us in 2024

How

• Keynote Address: Iceland’s Use of Captured Seafood By-Products

Jonas R. Vidarsson, Director of division of value creation, Matís

• Keynote Address: What role may byproducts play in the future of marine ingredients?

Petter Johannessen, Director General, IFFO

• Innovative Technology unleashing fish waste value potential

Wenche Uksnay, Cluster Manager, NCE Blue Legasea

• Co-Product Valorization – Towards an industrial Implementation of innovative Food Processing Concepts to achieve 100% Utilization

Dennis Lohmann, Head of Technology Management, BAADER & Dr Pia Meinlschmidt, Product Manager Fish, Food Science & Technology, BAADER

• The Journey to 100% Utilisation

Erla Ósk Pétursdóttir, Managing, Director, Marine Collagen ehf

• N-Atlantic pelagic fish oils originated from Herring and Mackerel - The new exciting Natural fish oil source in times shortage

Snorri Hreggvi Osson, CEO, Margildi

Please note: recordings of the sessions are also available

Innovation | Industry insight | Knowledge Sharing

To make your purchase, or download the papers visit: icefishconference.com contact: +44 1329 825335 or email: info@icefishconference.com #FishWasteForProfit

Operated by:

Media Partner:

5th 2024

WORLDFISHING SINCE 1952 & AQUACULTURE

2022 Downloads still available including:

to maximise return on investment from potentially discarded parts of the catch that can be turned into high value products for non-food sectors.

SPECIALREPORT

SMART, CONNECTED SEAFOOD PROCESSING

How automation is elevating end-product quality

Optimising at-sea processing through innovation

Getting Europe back on track and adding value

Canada looks to digitalisation

New tech for full-fish utilisation

World Fishing & Aquaculture

TRACEABILITY TECH TARGETS SEAFOOD PROCESSING

In Canada, work is underway to help seafood processors digitise their data in real time. Hopes are high that this will improve the profitability and sustainability of a critical player in the global seafood supply chain, writes Bonnie Waycott

Amidst unprecedented consumer demand, the need for the global seafood value chain to scale up productivity is becoming increasingly important. One way in which it can do this is by incorporating technology such as analytics software, robotics or artificial intelligence (AI) to boost performance in quality control and improve efficiency, traceability and transparency.

Canadian artificial intelligence firm ThisFish Inc. is working to digitise seafood processing with its new software Tally. According to CEO and Co-Founder Eric Enno Tamm, Tally was born as a result of gaps in the seafood supply chain, particularly among processors.

“I would describe seafood processors as a linchpin in the supply chain,” he said. “There are millions of farmers and fishermen on one side, and millions of retailers, restaurants and consumers on the other. In the middle, there are around 23,000 processing firms engaged in

global trade, but most are still analogue and not very digitised at all. If you are going to have a transformative effect on the global seafood supply chain, the best place to start is the seafood processor.”

Data collection improvements

Tamm and his family have been in the commercial fishing industry in Canada for years. Having grown up in a small fishing village on the west coast of Vancouver Island, Tamm himself worked as a buyer of fish and in seafood processing plants.

Over the years, he saw first-hand the challenges involved in providing high quality seafood to the end consumer. In 2017, Tally was developed to help seafood processors reduce the cost of data collection and management, strengthen process control and improve compliance through strong traceability.

8 Tally provides real-time control over the many processing steps

SPECIAL REPORT

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 23

Photo Credit: ThisFish

Customers can use it to digitise the unloading of fishing vessels, conduct quality control checks and digitise lab quality control and shipping logistics, Tamm said.

“One of Tally’s benefits is more efficient data collection,” he said. “A quality control manager may spend a couple of hours at the end of the day taking paper records, converting them into Excel and managing Excel records to produce reports. With Tally, everything is automated. Press a button and a record is generated.

“Also, if you don’t have strong traceability and can’t meet MSC or ASC requirements, you will lose opportunities to sell in particular markets, where often very strong

that can be embedded in Tally for automating processes, predictive analytics and computer vision.

TallyBot can be programmed with standard algorithms for cost accounting, data validation and other calculations, and analyses the large datasets created by Tally to help processors maximise yields, improve quality and reduce data errors and non-compliance.

ThisFish has also developed a machine-learning algorithm for yield prediction in a tuna cannery and salmon processor. Based on the raw materials that each processor purchases and their previous production, the algorithm can predict what their yields will be and help them understand how they are performing each day, whether they are above or below the predicted amount of yield and by how much.

While hoping that this type of algorithm will mitigate low yields and waste as a way to improve sustainability, Tamm and his team are looking forward to the launch of their next product, Tally-Vision, at the Boston Seafood Show in March 2023.

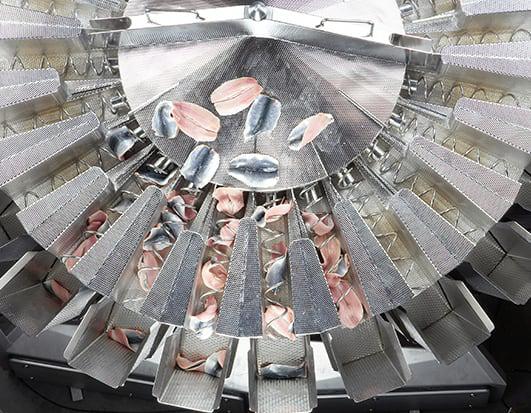

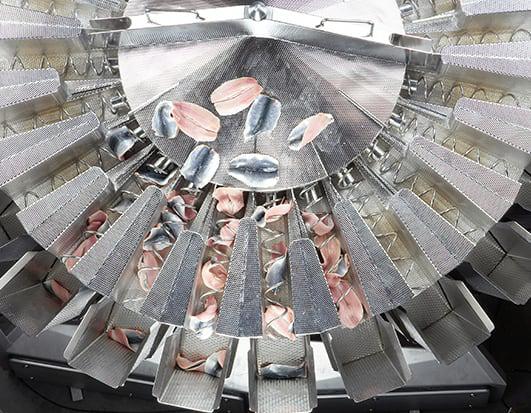

Tally-Vision is a video camera that is integrated into the Tally software and placed over a conveyor belt. The camera photographs every fillet before classifying them according to their size, colour distribution and five types of defects, such as gaping and bruising.

traceability and compliance are required. Tally brings much more transparency to processing.”

It also offers real-time control over the many steps involved in processing.

“In a tuna cannery, for example, if there is a production problem on a Monday morning, this may not be picked up until Tuesday afternoon because paper records are given to someone who works a graveyard shift, digitises the records and puts them into Excel,” said Tamm.

“On Tuesday morning, a manager collects, analyses and puts together the Excel spreadsheets before realising that mistakes were made the previous day. With Tally, digital data goes into the system in real time so that supervisors and workers can spot and flag mistakes as they happen. This real-time nature gives people a sense that their business is under control, that they can see what’s happening in their factories, when and why.”

Optimised, predictive yields

ThisFish has also introduced TallyBot, an AI-enabled app

The number of fillets that have been processed during a certain time period, and how many were defective during that period, can also be checked. The data is then collected and sent to TallyBI, the business intelligence or analytics dashboard.

If yields are shown to have been negatively impacted, data can be sent back to the processor to determine what practices and conditions might have caused this. Tamm hopes that one day, this can extend to aquaculture to improve control over fish feeding and grow-out.

“We would like to take large datasets on fillet quality and link them back to all the data around farm practices, such as feed, farm location, handling during grow-out and any genetic cohort,” he said. “Over time, a machine learning algorithm can tease out what might be causing certain defects and why. Feeding this back to farms will be extremely helpful.”

Top down, bottom up approach

With a growing market and regulatory demand for transparency in seafood products, an increasing number

8 Tally-Vision classifies every fillet according to their size, colour distribution and types of defects, such as gaping and bruising

24 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net SPECIAL REPORT

If you are going to have a transformative effect on the global seafood supply chain, the best place to start is the seafood processor

‘‘

Eric Enno Tamm, ThisFish Inc

Photo Credit: ThisFish

of consumers want to know more about the sustainability and social responsibility of the products that they buy. Tamm says that for more companies to get on board with software like Tally and improve their transparency, a topdown, bottom-up approach is key.

“If you’re a company president who wants to go digital, but your production manager and quality control manager are resisting, you must convince them of the benefits of the technology,” he said. “You need a common vision of where you want to go. Usability is also important. If workers find the software difficult to use, there will be more resistance, while poor user interfaces can slow things down.

“You also need at least six months to a year’s worth of digital data to get your system working effectively. Determine your core business objective as well. Are there problems with warehouses or cold storage? Does inventory control need to be tighter? Focus on these and keep the scope of initial digitisation narrow to begin with.”

With more companies also using automated machines and equipment, Tamm believes that in future, the demand for data on the uptime and downtime of such machines will rise, leading to potential opportunities in the realm of the Internet of Things (IoT) and the installation of sensors on

factory equipment to determine how efficiently equipment is being used. Going forward, Tamm and his team plan to focus on potential IoT opportunities while continuing to develop Tally with existing customers.

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 25 SPECIAL REPORT

Over time, a machine learning algorithm can tease out what might be causing certain defects and why Eric

‘‘

Eric Enno Tamm, ThisFish Inc

8 Tally offers easyto-use software

Photo Credit: ThisFish

‘GIVE US FISH’

Europe’s seafood processing sector craves access to more raw materials, writes Jason Holland

As well as being the world’s biggest seafood market, the European Union is also one of its leading processing regions, with a large proportion of an estimated 10.1 million tonnes of raw materials going into the industry ahead of consumption by the EU-27’s estimated 450 million residents.

According AIPCE-CEP, the EU Fish Processors and Traders Association, this volume comprises some 4.7 million tonnes of domestic fisheries and aquaculture production of 4.7 million tonnes (with 1.1 million tonnes going to non-food use) and 9 million tonnes of thirdcountry imports (with the EU exporting around 2.4 million tonnes of products to overseas markets).

135,000 direct employees across Europe,” AIPCE President Guus Pastoor told a recent AIPCE-CEP Webinar.

“We are talking about a lot of economic activities and a lot of participants,” he said.

For its part, AIPCE-CEP represents around 3,300 European processor and trader enterprises that have a combined annual turnover of €31 billion, and which directly employ 116,000 people, including many in rural areas. This makes upholding and growing European seafood processing a priority for the association, and an economic value driver for communities and regions.

“If we didn’t have these processing and logistics networks, then where would the seafood go that’s produced by Europe’s fishers and aquaculture businesses?” asked Pastoor. “There are many with a mutual interest in this business.”

Diminishing self-sufficiency

In maintaining a healthy trading and processing industry, EU’s reliance on third-country imports is increasing, explained Mike Turenhout, Fisheries and Trade Expert at CEP and the Dutch Fish Federation (Visfederatie).

“The economic value of seafood processing in Europe and the trade is large – larger than many people think –with a direct value of €25 billion based on present prices. And if we count the multipliers of services, logistics etc it increases to €35 billion. It’s also a big employer with

In 2019, this dependency stood at 59.3% but had climbed to 65.4% in 2021, he said. As for key species, the EU is sourcing 99% of its salmon – or more than 1.41 million tonnes – from third-countries, alongside 95% (891,000 tonnes) of its cod and 100% (808,000 tonnes) of its Alaska pollock.

The EU’s increased seafood import dependence has increased in part due to the Ukraine-Russian conflict, which has driven up fuel costs for the European fleet. Indeed, many vessels haven’t been going to sea, Turenhout

8 Europe’s seafood processing sector has an estimated direct value of €25 billion

26 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net SPECIAL REPORT

Our joint ambition is to keep and grow seafood processing in Europe. The main restricting factor to this is not the output to the market; it’s the input of raw materials

‘‘

Guus Pastoor, AIPCE

advised the webinar. Another major diver has been the consequences of the Covid-19 pandemic, with prices for species that feature prominently in the foodservice sectors dropping dramatically during lockdown measures.

Added to this, Brexit and the UK’s withdrawal from the EU on 31 January 2020 has unsettled the market, with the country becoming a third-country and its vessels having an important share of certain European quotas, and new tariff barriers being implemented, he said.

Specifically with regards to the Ukraine war, and in addition to the increased fuel and energy prices, the sanctions imposed on Russia have created large shift in the marketplace, said Turenhout. In the UK, for example, there is an additional import tariff of 35% on Russian seafood, while the US market has imposed a complete ban on imports.

“This has meant that those market’s whitefish products such as cod and pollock have had to be sourced from elsewhere. This has driven up the price of other products, such as Norwegian cod.”

Pre-conflict, Russia was the eighth-largest seafood supplier to the EU market, involving some 391,000 tonnes of seafood.

Supply utilisation opportunities

With regards to its outlook for 2023, AIPCE-CEP believes the current inflation level in the EU will decrease its purchasing power. In 2022, this stood at around 10%, resulting in increased costs for production and processing, while the purchasing power of the region’s consumers decreased.

The processing sector is therefore expecting a slight decrease in seafood consumption in the EU in the shortterm but that this will grow again over the longer-term, said Turnhout.

Looking ahead, he added that the EU’s focus should be on improving its own seafood production, said Turnhout. According to AIPCE-CEP’s own analysis, the region utilises just 75% of the EU’s total available fishing quota.

“We need to find a way to optimise this utilisation and to get more raw materials to the EU’s processing industry. Another thing is that we need to invest in EU aquaculture production.

“I believe the EU is really pushing to increase aquaculture growth. There’s a strong focus there.

“Alongside this, there’s a need to simulate favourable EU trade policies, including new trade agreements and ATQs (autonomous tariff quotas), where we can bring in more raw materials with zero import duties for EU processing. Furthermore, we need to look at ways to further optimise and reduce logistics and storage costs.”

Ensuring future-readiness

New technologies will also have an important role to play in Europe’s seafood processing future, Turnhout told the webinar.

“I think that smarter processing lines and new technologies will help the processing industry to produce more seafood, especially when it comes to adding more value to products and optimising the various parts of the products and by-products.”

The Secretary of the FAO Subcommittee on Fish Trade, Marcio Castro de Souza, agrees.

“An issue that’s important not just from a European perspective but globally is that Industry 4.0 can facilitate the traceability of products. This is still a very important and challenging aspect in many countries. So, as we incorporate more technical and logistical information in the value chain, we can trace back the products through the value chain. That can be a very important element in terms of the prize of reaching more markets because of sustainability.

“That’s something for the global scale this technological approach towards the sector can definitely bring more benefits, particularly in the approach of net-to-plate that is still missing in many countries around the world,” Castro de Souza said.

Turnhout also stressed the “high importance” of raw materials coming into Europe from third-countries.

“We have the ATQ systems, we have the free trade agreements, and we also have the IUU (illegal, unreported and unregulated fishing) system that prevents illegal fish from coming into the EU. These systems fit our processing industry, because we want to process as much seafood as we can in the EU and keep the focus on that. And not have a system or situation whereby it’s more beneficial to do the processing outside of the EU.”

Pastoor emphasised this point, adding, “Our joint ambition is to keep and grow seafood processing in Europe. The main restricting factor to this is not the output to the market; it’s the input of raw materials.

“With the EU’s low self-sufficiency, we need to provide the right circumstances for its production. Seafood imports are needed now and in the future.”

With the right platform – one that encompasses environmental and social sustainability, exploits the full potential of EU fisheries and aquaculture, and facilitates international trade – the long-term aspirations of the industry can be ensured, Pastoor insisted.

“If we can achieve all that, the market for seafood in Europe will surely grow and can provide more consumers with our nutritious, healthy and sustainable products now and in the future,” he said.

For the latest news and analysis go to www.worldfishing.net APRIL 2023 | 27 SPECIAL REPORT

8 The EU sources 99% of its salmon from third-countries

SIEMENS: AUTOMATION TO ENSURE FRESH FISH

Through new tech, seafood processors are able to meet the changing needs of consumer markets, writes Bonnie

Waycott

Quality control is key to ensuring fresh seafood. Historically, this has been done by processing staff who use their senses and experience to examine the condition of gills and eyes, the firmness and smell of flesh and the colour of skin to distinguish between a fresh product and one that is not of good quality. But now, machines are helping seafood processors to supply retailers and consumers with top quality products, quantifying the freshness of seafood to meet food quality and safety regulations.

Torill Østingsen of Digital Industries Siemens insists that this type of automation is key to guaranteeing consumers the best-quality seafood.

Processors are one part of the supply chain where automated processes are crucial

Torill Østingsen, Digital Industries Siemens

“For Siemens, the food and beverage industry is a very important one to do business with,” she told WF. “Fisheries and aquaculture obviously fall within this industry, and we are seeing that aquaculture is becoming increasingly important as the oceans are dramatically overfished and more than 100 million tonnes of fish are consumed worldwide. If we are to protect the oceans while also meeting the demand for seafood, we will need automated processes across the seafood supply chain.

“Processors are one part of the supply chain where automated processes are crucial, because they must guarantee that retailers and consumers only receive top quality seafood. At Siemens, our focus is to help our customers obtain good quality, profitable food that has been produced in a sustainable way.”

Hyperspectral analysis

Because of the natural variability of fish and other seafood, producers often find it difficult to conduct physical measurements to determine quality or predict production outcomes such as yields.

During seafood processing, ice-covered seafood is delivered in large crates, taken out manually by warehouse staff, weighed and repacked. But this can result in a higher possibility of human error, or differences in interpreting results. For example, on a scale of one to 10, one person may interpret a result as three, while another interprets it as two. As it turns out, however, this is a perfect problem for machines and AI, which can take over the roles that people with specific knowledge have been responsible for, and produce the same results based on the same assumption, helping seafood supply become more predictable and profitable.

Efforts by researchers at Siemens to automate seafood processing have resulted in a range of potential solutions such as hyperspectral analysis, an optical analysis method that uses AI to ensure fish quality, and robotic fingers that can grip and repackage slippery items, making handling procedures more efficient.

Hyperspectral analysis is currently being used to analyse the surface of fish skin. When fish are slaughtered, the skin goes through a biochemical ageing process,

8 Digitalisation being used to improve controls at a fish farm in Asia

28 | APRIL 2023 For the latest news and analysis go to www.worldfishing.net SPECIAL REPORT

‘‘

Photo Credit: Siemens

losing elasticity and forming a thin layer of mucus. Proteins on the skin also break down and new chemical substances form, which can be easily detected by the human nose. Hyperspectral analysis involves irradiating with electromagnetic waves with wavelengths between 900nm and 1,700nm in the infrared spectrum.

Researchers then observe how much of the different wavelengths is absorbed by surface molecules on the skin and infer which molecules are present in what quantity. Fresh and not-so-fresh fish have been used to train an AI algorithm, which can evaluate the absorption pattern of a specific fish and state whether it is freshly caught, edible or of substandard quality.

Flexibility in AI

“Siemens, together with several machine builders and system integrators, is involved in several aspects of seafood processing,” said Østingsen. “We have a huge portfolio of equipment and solutions that range from software, automation, monitoring, networks, cybersecurity and process instrumentation to control products. In general, AI is still in the early stages in all industries, even though we have been talking about digitalisation for a while. But there is a lot of flexibility with it, and it can be used in several areas of seafood processing to help the sector reduce maintenance, increase production and earn more money.”

With industries like aquaculture becoming more and more important for global food production, Østingsen said seafood producers will have to be open-minded and be able to share information, collaborate with technology suppliers and spend time and money on new technology in order to improve efficiency, product quality and overall productivity.

“Aquaculture, seafood processing and other industries are curious about technology such as AI, cutting-edge soft sensors, digital twins, and are focusing on it a lot,” she said. “These solutions can accurately detect the level of freshness and overall visual quality and reduce food waste. Our next steps are to understand our customers’ needs and help them grow, stay profitable and competitive. We aim to use our vast know-how and experience in various industries to share information and collaborate in order to accelerate digital transformation.”

The 24th edition of Europe’s largest commercial marine and workboat exhibition, is a proven platform to build business networks.

Seawork delivers an international audience of visitors supported by our trusted partners.

Seawork is the meeting place for the commercial marine and workboat sector.

12,000m2 of undercover halls feature 500 exhibitors with over 70 vessels, floating plant and equipment on the quayside and pontoons.

Speed@Seawork on Monday 12 June at the Royal Yacht Squadron in Cowes offers a sector specific event for fast vessels operating at high speed for security interventions and Search & Rescue.

The European Commercial Marine Awards (ECMAs) and Innovations Showcase.