8 minute read

Features

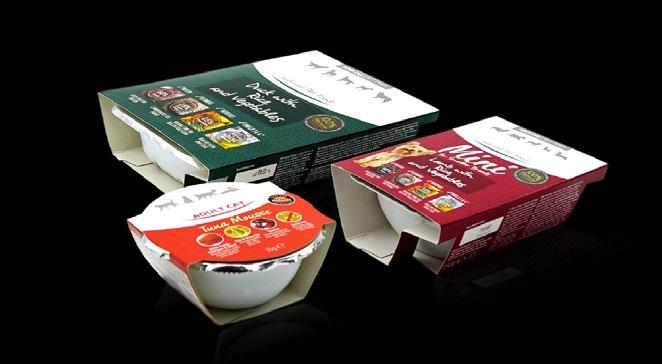

Proseal solutions meet quality pet food packing requirements

Proseal tray sealing technology is enabling pet food manufacturers to meet growing demand for high quality products and packaging, as well as providing mass customisation solutions that can help businesses in the sector to diversify and introduce online ordering for home delivery services.

A recent report from Transparency Market Research has predicted a CAGR of 6% in the global pet food market in the ten years from 2019, reaching an expected value of US$168.3 bn by autumn 2029. Increasing consumer demand for premium quality products has led manufacturers to use high quality materials and ingredients while streamlining their production techniques and processes, with the corresponding need for appropriate quality packaging to reflect this premium image.

The comprehensive Proseal tray sealer range has the flexibility to perform in a wide range of disciplines, including Gas Flush Modified Atmosphere Packaging (MAP), Vacuum MAP with lid control and Skin Packaging. In particular, the company’s advanced sealing systems ensure absolute control and integrity of the seal between the lid and the tray, a vital requirement for applications that incorporate a substantial controlledretortion-process or other High Pressure sterilisation processes after sealing. The tray sealers also include several Proseal-developed features that help to maximise performance, reliability and efficiency, such as the company’s pioneering Eseal® energy saving technology, ifilm™ intelligent film monitoring, and ProTect™ RFID access login system that provides full audit trail visibility and layered security.

In addition, Proseal’s AP60 linear conveyor tray sealing system is able to provide bespoke automated solutions for high speed applications and demanding production conditions, based around individual customer production processes and requirements.

Among the system’s many features, the length and width of the indexing conveyor can be customised to accommodate particular de-nesting and filling requirements. Full or partial vacuum systems can be incorporated to enable post seal processes such as retort or High Pressure Processing (HPP), and X-ray inspection systems and checkweighers can be included after sealing for enhanced quality control. The AP60 also offers seamless integration with third party process equipment including depositors, multihead weighing applications and CIP systems with sealing speeds of up to 240 packs per minute.

Furthermore, Proseal’s AP60 benefits from shared technology across the Proseal machinery range. Options can be specified and retro-engineered at the customer request, allowing a more flexible approach to each distinct application.

All Proseal machines offer a userfriendly interface and easy to maintain design, with a rugged and hygienic food industry approved construction geared to full washdown protection.

“As the pet food market continues to expand, we were keen to provide solutions for companies requiring a significant upscale in their production of core products in new packaging formats, which could be met on one machinery platform,” said Tony Burgess, Head of Sales and Control Systems, Proseal.

“The flexibility of our technology and the wide variety of machines available, including fully integrated conveyor systems, mean we can offer a full turnkey production line solution which is key for this particular market. We are delighted that our expertise can help companies to achieve a point of differentiation in the competitive pet food sector.”

Founded in 1998, Proseal designs and manufactures high quality tray sealing machines, conveyor systems and sealing tools for food industry markets worldwide. The company became part of the US-based JBT Corporation in 2019. JBT is a complete solutions provider to the growing pet food sector, committed to exceeding customer expectations.

www.proseal.com

The Delta Speed Air: A Game Changer, Inside & Out

ENERCO is pleased to launch the Delta Speed Air, an innovative high-speed door that pairs proven self-repairing technology with an adjustable air curtain which significantly enhances the doors efficiency.

Designed to intelligently separate areas where the traffic is high, the Delta Speed Air is a perfect match for internal and external applications. It makes easy work of confined spaces with different temperature and humidity levels, making it suitable for warehouses, factories, food processing facilities, car washes and many other industrial environments.

Made for minimum maintenance to maximise reliability and reduce the need for costly maintenance, the Delta Speed Air is simplistic in its design, and available in standard sizes up to 4.5m wide x 8.0m high. The galvanised side columns ensure high resistance and exceptional durability, whilst they are self-lubricated with directional air vanes for a smooth and fast action.

VISION PANELS ELEVATE SAFETY The 1300g curtain includes vision panels (available as standard), allowing workers to see the other side clearly, minimising potential dangers from approaching traffic. Multiple vision panels manufactured using clear PVC or mesh for air flow can be included if required.

Boost speed, manage traffic flows and prevent temperature fluctuations with a rapid operating speed and excellent seal, the Delta Speed Air facilitates efficient traffic flow while minimising temperature variations. This makes it ideal for a broad spectrum of applications, guaranteeing a strong, secure and robust barrier to maximise 6 FDPP - www.fdpp.co.uk

hygiene, improve safety and maintain optimum room temperatures. The vertical air curtain is fitted to both columns maximising the barrier effect across the full width of the door.

EXTREMELY EASY TO OPERATE The motors can be front or sidemounted and the standard 3PH inverter controls are simple to use. The door can be equipped with a single-phase 230V supply, available up to 9m2. The door is 100% fail safe with its light grid and soft edge bottom rail technology and will accept all forms of activations devices as well as traffic light and interlocks.

ENERGY SAVING The Delta Speed Air reflects the company’s commitment to helping businesses boost energy efficiency, improve goods flow and minimise energy costs in industrial and commercial environments.

HOW CAN THE DELTA SPEED AIR IMPROVE YOUR OPERATIONS? Whether you want to make it easier for your people (and equipment) to move efficiently around your premises, wish to increase privacy or need a quality door to deliver a superior seal around the full perimeter of your opening, ENERCO’s Delta Speed Air is a fine choice. It also comes with a 24-month warranty (subject to a service contract being taken out at the time of installation based on their intended operational usage). Whilst standard sizes will meet most operational requirements, ENERCO recognises that in certain situations a bespoke solution is best. Their team can provide a truly tailored service to ensure your Delta Speed Air exceeds your operational requirements, utilising proven highspeed and self-repairing technology.

With over 25 years of experience, ENERCO has developed longstanding partnerships across a diverse range of industries including construction, food, retail, manufacturing and logistics. The Delta Speed Air is an exciting addition to the collection because it delivers on speed, energy-efficiency and flexibility, whilst it’s also very versatile, being suited for internal and external applications. The door can help organisations reduce heat loss, save money, keep the temperature constant, control hygiene, enhance the work environment, reduce noise and maintain security.

If you’d like to learn more about its features or wish to discover ENERCO’s full range of high speed, self-repairing doors, other industrial doors and loading bay solutions, please visit WWW.ENERCO.co.uk.

Kecol Pumping Systems

Kecol Pumping Systems offers solutions to many product transfer problems – read on to find out more.

Kecol Pumping Systems Ltd are manufacturers of Air driven, Positive Displacement Piston Pumps and Priming Devices in polished stainless steel or carbon steel, for transferring high viscosity nonflowable products from drums and containers as used in the cosmetic, food, pharmaceutical, chemical and general industries.

Products in drums or similar sized vessels that normally need to be heated in order to reduce the viscosity - can be transferred cold. Products with a viscosity up to 10,000 Poise can be transferred (cold) using the Kecol Maxiprime Pump and follower plate system and is also used to transfer pastes and products that stick to the inside of an open top drum, wiping the inside of the drum or vessel, eliminating product waste.

Kecol Air Powered Drum Pumps and transfer systems are suitable for all standard size closed top or open top drums and can be adapted to suit open top containers with an internal diameter up to 1200mm. Non contact parts as well as contact parts are available in polished stainless steel, clamp - type construction is also available for hygienic applications.

Typical applications in the food industry include transferring tomato puree, concentrated fruit juice, honey, fruit pastes, biscuit creams, jams, butter, margarine, sweet mince meat, sausage meat and meat pie fillings with cooked vegetables. Applications in the pharmaceutical and cosmetic industries include transferring mascara, petroleum jelly, face creams, base creams, magnesium hydroxide, aluminium hydroxide, toothpaste, lip-gloss waxes and suntan lotions.

Kecol’s articulated pump systems

Kecol’s articulated pump systems

Applications in the chemical and general industries include the transfer of paints, resins, adhesives, polymers, latex, high viscosity grease, mastic’s and inks – all pumped cold without pre-heating the products.

As manufacturers, Kecol Pumping Systems can offer solutions to your particular product transfer problem, by offering a bespoke system designed to exceed your particular production requirements for single drum/vessel use or multi drum use.

The inside of a standard 200 litre Open Top Drum is wiped clean – as the drum is emptied – with minimal product waste

The Kecol Follower plate system will also work on 200 litre Open Top Drums fitted with an aseptic bag – wiping the bag clean